High-Temperature Performance of Polymer-Modified Asphalt Mixes: Preliminary Evaluation of the Usefulness of Standard Technical Index in Polymer-Modified Asphalt

Abstract

1. Introduction

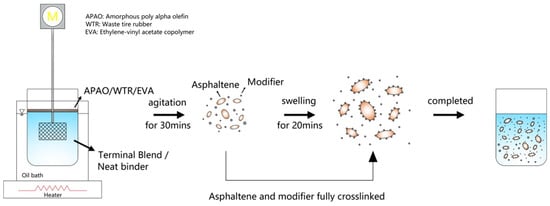

2. Materials and Asphalt Mixture Design

3. Testing Methods

4. Laboratory Results and Analysis

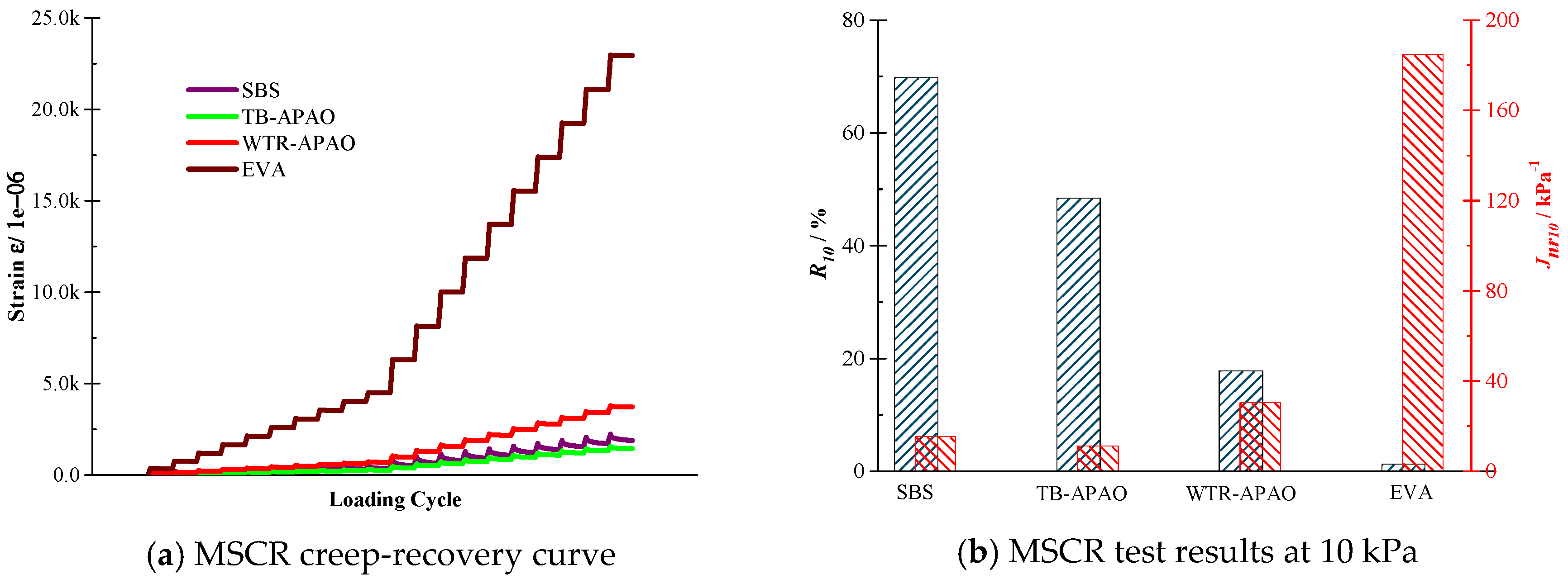

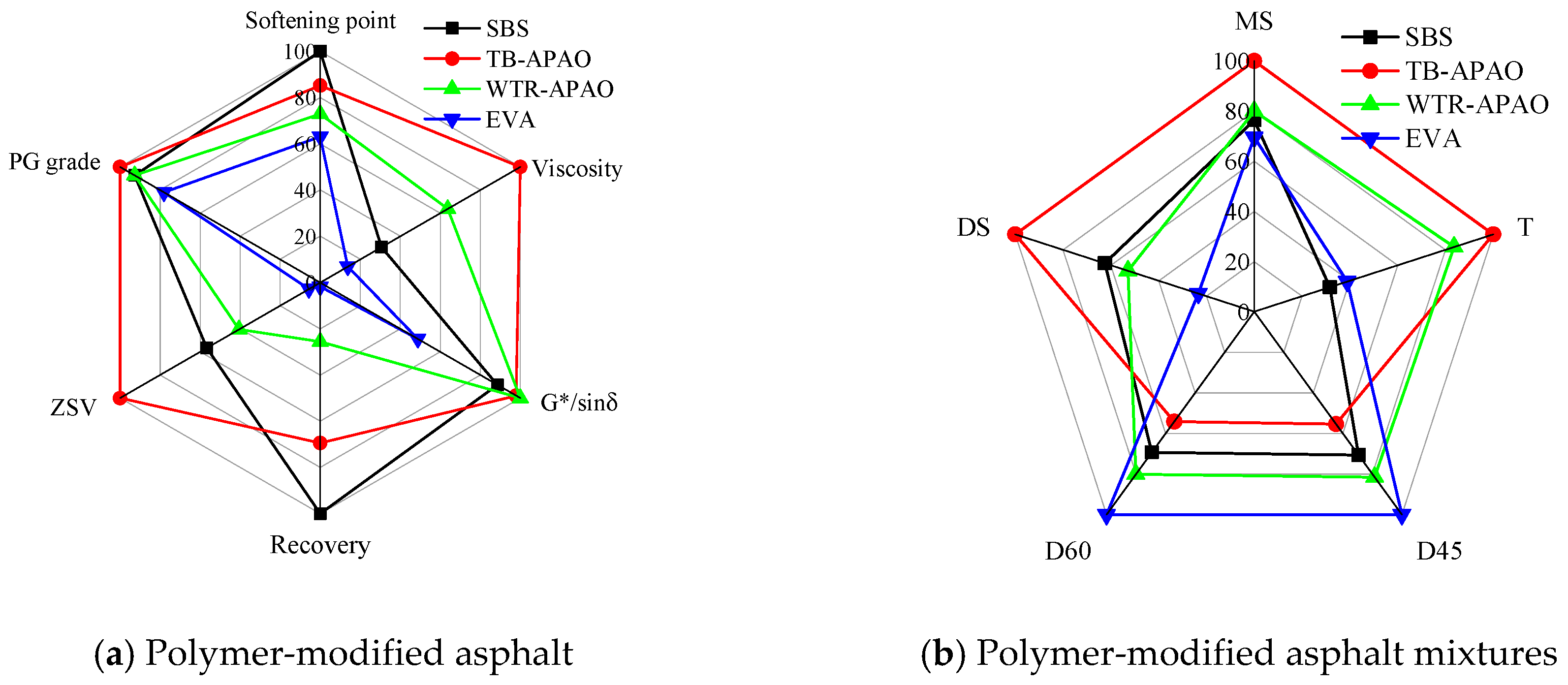

4.1. High-temperature Rheological Properties of Asphalt

4.2. High-Temperature Performance of Asphalt Mixtures

4.3. Comprehensive Analysis for the Technical Indexes

5. Summary, Conclusions, and Future Research Works

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kennedy, T.W. Superior Performing Asphalt Pavements (Superpave): The Product of the SHRP Asphalt Research Program; Strategic Highway Research Program; National Research Council: Washington, DC, USA, 1994. [Google Scholar]

- Harrigan, E.; Leahy, R.; Youtcheff, J. Superpave Manual of Specifications, Test Methods and Practices; SHRP-A-379. Strategic Highway Research Program; National Research Council: Washington, DC, USA, 1994. [Google Scholar]

- Yan, K.; Xu, H.; You, L. Rheological properties of asphalts modified by waste tire rubber and reclaimed low density polyethylene. Constr. Build. Mater. 2015, 83, 143–149. [Google Scholar] [CrossRef]

- You, L.; You, Z.; Dai, Q.; Zhang, L. Assessment of nanoparticles dispersion in asphalt during bubble escaping and bursting: Nano hydrated lime modified foamed asphalt. Constr. Build. Mater. 2018, 184, 391–399. [Google Scholar] [CrossRef]

- Lv, S.; Fan, X.; Yao, H.; You, L.; You, Z.; Fan, G. Analysis of performance and mechanism of Buton rock asphalt modified asphalt. J. Appl. Polym. Sci. 2019, 136, 46903. [Google Scholar] [CrossRef]

- Yildirim, Y. Polymer modified asphalt binders. Constr. Build. Mater. 2007, 21, 66–72. [Google Scholar] [CrossRef]

- Nicholls, J.C.; Carswell, I. The Behaviour of Asphalt in Adverse Hot Weather Conditions; Transport Research Laboratory: Wokingham, UK, 2001. [Google Scholar]

- King, G.; King, H.; Pavlovich, R.; Epps, A.L.; Kandhal, P. Additives in asphalt. J. Assoc. Asphalt Paving Technol. 1999, 68, 32–69. [Google Scholar]

- Ge, D.; Yan, K.; You, Z.; Xu, H. Modification mechanism of asphalt binder with waste tire rubber and recycled polyethylene. Constr. Build. Mater. 2016, 126, 66–76. [Google Scholar] [CrossRef]

- Yan, K.; He, W.; Chen, M.; Liu, W. Laboratory investigation of waste tire rubber and amorphous poly alpha olefin modified asphalt. Constr. Build. Mater. 2016, 129, 256–265. [Google Scholar] [CrossRef]

- Liu, N.; Yan, K.; You, L.; Chen, M. Laboratory testing on the anti-aging performance of amorphous poly alpha olefin (APAO) modified asphalt binders. Constr. Build. Mater. 2018, 189, 460–469. [Google Scholar] [CrossRef]

- Li, B.; Huang, W.; Tang, N.; Hu, J.; Lin, P.; Guan, W.; Xiao, F.; Shan, Z. Evolution of components distribution and its effect on low temperature properties of terminal blend rubberized asphalt binder. Constr. Build. Mater. 2017, 136, 598–608. [Google Scholar] [CrossRef]

- Presti, D.L.; Airey, G.; Partal, P. Manufacturing terminal and field bitumen-tyre rubber blends: the importance of processing conditions. Procedia Soc. Behav. Sci. 2012, 53, 485–494. [Google Scholar] [CrossRef]

- Huang, W.; Lin, P.; Tang, N.; Hu, J.; Xiao, F. Effect of crumb rubber degradation on components distribution and rheological properties of terminal blend rubberized asphalt binder. Constr. Build. Mater. 2017, 151, 897–906. [Google Scholar] [CrossRef]

- Lin, P.; Huang, W.; Tang, N.; Xiao, F. Performance characteristics of Terminal Blend rubberized asphalt with SBS and polyphosphoric acid. Constr. Build. Mater. 2017, 141, 171–182. [Google Scholar] [CrossRef]

- Sybilski, D. Non-Newtonian viscosity of polymer-modified bitumens. Mater. Struct. 1993, 26, 15–23. [Google Scholar] [CrossRef]

- Sybilski, D. Zero-shear viscosity of bituminous binder and its relation to bituminous mixture’s rutting resistance. Transp. Res. Rec. 1996, 1535, 15–21. [Google Scholar] [CrossRef]

- Hossain, Z.; Ghosh, D.; Zaman, M.; Hobson, K. Use of the multiple stress creep recovery (MSCR) test method to characterize polymer-modified asphalt binders. J. Test. Eval. 2015, 44, 507–520. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, W.; Chen, J. Investigating impacts of warm-mix asphalt technologies and high reclaimed asphalt pavement binder content on rutting and fatigue performance of asphalt binder through MSCR and LAS tests. J. Cleaner Prod. 2019, 219, 879–893. [Google Scholar] [CrossRef]

- AASHTO. Standard Method of Test for Multiple Stress Creep Recovery (MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer (DSR); American Association of State Highway and Transportation Officials: Washington, DC, USA, 2009. [Google Scholar]

- Zoorob, S.E.; Castro-Gomes, J.P.; Oliveira, L.A.P.; O’Connell, J. Investigating the Multiple Stress Creep Recovery bitumen characterisation test. Constr Build Mater 2012, 30, 734–745. [Google Scholar] [CrossRef]

- Wasage, T.L.J.; Stastna, J.; Zanzotto, L. Rheological analysis of multi-stress creep recovery (MSCR) test. Int. J. Pavement Eng. 2011, 12, 561–568. [Google Scholar] [CrossRef]

- Bahia, H.U.; Hanson, D.; Zeng, M.; Zhai, H.; Khatri, M.; Anderson, R. Characterization of Modified Asphalt Binders in Superpave Mix Design; Transportation Research Board: Washington, DC, USA, 2001. [Google Scholar]

- DuBois, E.; Mehta, Y.; Nolan, A. Correlation between multiple stress creep recovery (MSCR) results and polymer modification of binder. Constr Build Mater 2014, 65, 184–190. [Google Scholar] [CrossRef]

- Mehta, Y.; Nolan, A.; DuBois, E.; Zorn, S.; Batten, E.; Shirodkar, P. Correlation between Multiple Stress Creep Recovery (MSCR) Results and Polymer Modification of Binder; University Transportation Research Center: New York, NY, USA, 2013. [Google Scholar]

- D’Angelo, J.; Kluttz, R.; Dongre, R.N.; Stephens, K.; Zanzotto, L. Revision of the superpave high temperature binder specification: the multiple stress creep recovery test (with discussion). J. Assoc. Asph. Paving Technol. 2007, 76, 123–162. [Google Scholar]

- D’Angelo, R.; Dongre, R. Practical use of the MSCR test: Characterization of SBS dispersion and other additives in PMA binders. J. Transp. Res. Rec. 2009, 2126, 73–82. [Google Scholar] [CrossRef]

- Dreessen, S.; Planche, J.; Gardel, V. A new performance related test method for rutting prediction: MSCRT. Adv. Test. Charact. Bitum. Mater. 2009, 1, 971–980. [Google Scholar]

- Golalipour, A.; Bahia, H.U.; Tabatabaee, H.A. Critical Considerations toward Better Implementation of the Multiple Stress Creep and Recovery Test. J. Mater. Civ. Eng. 2017, 29. [Google Scholar] [CrossRef]

- Xiao, F.; Ma, D.; Wang, J.; Cai, D.; Lou, L.; Yuan, J. Impacts of high modulus agent and anti-rutting agent on performances of airfield asphalt pavement. Constr. Build. Mater. 2019, 204, 1–9. [Google Scholar] [CrossRef]

- Wang, J.; Yuan, J.; Xiao, F.; Li, Z.; Wang, J.; Xu, Z. Performance investigation and sustainability evaluation of multiple-polymer asphalt mixtures in airfield pavement. J. Cleaner Prod. 2018, 189, 67–77. [Google Scholar] [CrossRef]

- You, L.; Yan, K.; Hu, Y.; Ma, W. Impact of interlayer on the anisotropic multi-layered medium overlaying viscoelastic layer under axisymmetric loading. Appl. Math. Modell. 2018, 61, 726–743. [Google Scholar] [CrossRef]

- You, L.; You, Z.; Yan, K. Effect of anisotropic characteristics on the mechanical behavior of asphalt concrete overlay. Front. Struct. Civ. Eng. 2019, 13, 110–122. [Google Scholar] [CrossRef]

- Lv, S.T.; Liu, C.C.; Chen, D.; Zheng, J.L.; You, Z.P.; You, L.Y. Normalization of fatigue characteristics for asphalt mixtures under different stress states. Constr. Build. Mater. 2018, 177, 33–42. [Google Scholar] [CrossRef]

- You, L.; You, Z.; Dai, Q.; Guo, S.; Wang, J.; Schultz, M. Characteristics of water-foamed asphalt mixture under multiple freeze-thaw cycles: laboratory evaluation. J. Mater. Civ. Eng. 2018, 30, 04018270. [Google Scholar] [CrossRef]

- You, L.; Yan, K.; Shi, T.; Man, J.; Liu, N. Analytical solution for the effect of anisotropic layers/ interlayers on an elastic multi-layered medium subjected to moving load. Int. J. Solids Struct. 2019, 172–173, 10–20. [Google Scholar] [CrossRef]

- Liu, P.; Xu, H.; Wang, D.; Wang, C.; Schulze, C.; Oeser, M. Comparison of mechanical responses of asphalt mixtures manufactured by different compaction methods. Constr. Build. Mater. 2018, 162, 765–780. [Google Scholar] [CrossRef]

- Roberts, F.L.; Kandhal, P.S.; Brown, E.R.; Lee, D.-Y.; Kennedy, T.W. Hot Mix Asphalt Materials, Mixture Design and Construction; National Asphalt Pavement Association Research and Education Foundation: Lanham, MD, USA, 1991. [Google Scholar]

- Safaei, F.; Lee, J.-s.; Nascimento, L.A.H.d.; Hintz, C.; Kim, Y.R. Implications of warm-mix asphalt on long-term oxidative ageing and fatigue performance of asphalt binders and mixtures. Road Mater. Pavement Des. 2014, 15, 45–61. [Google Scholar] [CrossRef]

- Hamzah, M.O.; Valentová, T.; Valentin, J.; Benešová, L. Effect of a Poly-olefin Based Additive on Bitumen and Asphalt Mix Performance. Adv. Civ. Eng. Mater. 2018, 7, 489–508. [Google Scholar]

- Zhao, X.; Yan, K.; He, W.; Cai, C. Effects of Sasobit/Deurex on amorphous poly alpha olefin (APAO) modified asphalt binder. Constr. Build. Mater. 2017, 154, 323–330. [Google Scholar] [CrossRef]

- Liu, W.; Yan, K.; Ge, D.; Chen, M. Effect of APAO on the aging properties of waste tire rubber modified asphalt binder. Constr. Build. Mater. 2018, 175, 333–341. [Google Scholar] [CrossRef]

- China, M. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering: JTG E20-2011; China Communications Press: Beijing, China, 2011. [Google Scholar]

- China, M. Technical Specification for Construction of Highway Asphalt Pavements: JTG F40-2004; China Communications Press: Beijing, China, 2004. [Google Scholar]

- AASHTO. Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). 2010. [Google Scholar]

- AASHTO. Standard Method of Test for Effect of Heat and Air on a Moving Film of Asphalt Binder (Rolling THIN-film Oven Test). 2009. [Google Scholar]

- Yang, X.; You, Z. High temperature performance evaluation of bio-oil modified asphalt binders using the DSR and MSCR tests. Constr. Build. Mater. 2015, 76, 380–387. [Google Scholar] [CrossRef]

- AASHTO. Standard Specification for Performance-Graded Asphalt Binder: Washington, DC, USA. 1998. [Google Scholar]

- Zhang, J.; Walubita, L.F.; Faruk, A.N.; Karki, P.; Simate, G.S. Use of the MSCR test to characterize the asphalt binder properties relative to HMA rutting performance–A laboratory study. Constr. Build. Mater. 2015, 94, 218–227. [Google Scholar] [CrossRef]

- Yuan, J.; Wang, J.; Xiao, F.; Amirkhanian, S.; Wang, J.; Xu, Z. Impacts of multiple-polymer components on high temperature performance characteristics of airfield modified binders. Constr. Build. Mater. 2017, 134, 694–702. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, H.; Gao, J.; You, Z.; Yang, X. High temperature performance of SBS modified bio-asphalt. Constr. Build. Mater. 2017, 144, 99–105. [Google Scholar] [CrossRef]

- Wang, H.; Bu, Y.; Wang, Y.; Yang, X.; You, Z. The effect of morphological characteristic of coarse aggregates measured with fractal dimension on asphalt mixture’s high-temperature performance. Adv. Mater. Sci. Eng. 2016. [Google Scholar] [CrossRef]

| Items | Unit | Modified Asphalt Binders | Test Standard Code | ||||

|---|---|---|---|---|---|---|---|

| AH-90A | SBS | EVA | WTR-APAO | TB-APAO | |||

| Penetration at 25 °C | 0.1 mm | 92.0 | 71.1 | 61.2 | 46.2 | 46.4 | T0604 |

| Penetration index | n/a | −0.80 | 0.80 | 1.09 | 2.96 | 1.24 | T0604 |

| Ductility at 5 °C | cm | - | 44.7 | 12.6 | 10.5 | 34.6 | T0605 |

| Softening point | °C | 49.1 | 90.2 | 56.9 | 65.7 | 76.8 | T0606 |

| Viscosity at 135 °C | Pa*s | 0.52 | 2.05 | 0.93 | 4.28 | 6.71 | T0625 |

| Sieve Size (mm) | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

|---|---|---|---|---|---|---|---|---|---|---|

| Upper (%) | 100 | 100 | 75 | 34 | 26 | 24 | 20 | 16 | 15 | 12 |

| Lower (%) | 100 | 90 | 50 | 20 | 15 | 14 | 12 | 10 | 9 | 8 |

| Intermediate (%) | 100 | 95 | 62 | 27 | 20.5 | 19 | 16 | 13 | 12 | 10 |

| Asphalt Content (%) | 5.4 | 5.7 | 6.0 | 6.3 | 6.6 |

|---|---|---|---|---|---|

| Gmb | 2.448 | 2.450 | 2.454 | 2.450 | 2.440 |

| VV (%) | 4.968 | 4.461 | 3.820 | 3.538 | 3.479 |

| VMA (%) | 16.571 | 16.779 | 16.880 | 17.290 | 17.897 |

| VFA (%) | 70.020 | 73.414 | 77.373 | 79.540 | 80.562 |

| MS (kN) | 7.060 | 7.530 | 7.900 | 6.760 | 6.240 |

| FL (0.1 mm) | 44.000 | 44.800 | 35.400 | 33.200 | 32.350 |

| Mixture Types | Marshall Stability MS/ kN | Marshall Modulus T/ kN*mm−1 |

|---|---|---|

| SBS | 6.80 | 1.97 |

| TB-APAO | 8.90 | 6.22 |

| WTR-APAO | 7.12 | 5.20 |

| EVA | 6.19 | 2.42 |

| Mixture Types | D45/mm | D60/mm | DS/times·mm−1 |

|---|---|---|---|

| SBS | 4.02 | 4.11 | 7087 |

| TB-APAO | 3.15 | 3.21 | 11,340 |

| WTR-APAO | 4.64 | 4.75 | 5989 |

| EVA | 5.69 | 5.93 | 2655 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, K.; You, L.; Wang, D. High-Temperature Performance of Polymer-Modified Asphalt Mixes: Preliminary Evaluation of the Usefulness of Standard Technical Index in Polymer-Modified Asphalt. Polymers 2019, 11, 1404. https://doi.org/10.3390/polym11091404

Yan K, You L, Wang D. High-Temperature Performance of Polymer-Modified Asphalt Mixes: Preliminary Evaluation of the Usefulness of Standard Technical Index in Polymer-Modified Asphalt. Polymers. 2019; 11(9):1404. https://doi.org/10.3390/polym11091404

Chicago/Turabian StyleYan, Kezhen, Lingyun You, and Daocheng Wang. 2019. "High-Temperature Performance of Polymer-Modified Asphalt Mixes: Preliminary Evaluation of the Usefulness of Standard Technical Index in Polymer-Modified Asphalt" Polymers 11, no. 9: 1404. https://doi.org/10.3390/polym11091404

APA StyleYan, K., You, L., & Wang, D. (2019). High-Temperature Performance of Polymer-Modified Asphalt Mixes: Preliminary Evaluation of the Usefulness of Standard Technical Index in Polymer-Modified Asphalt. Polymers, 11(9), 1404. https://doi.org/10.3390/polym11091404