T-Shaped Microfluidic Junction Processing of Porous Alginate-Based Films and Their Characteristics

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Polymer Solutions

2.3. Characterization of Precursor Materials and Polymer Solutions

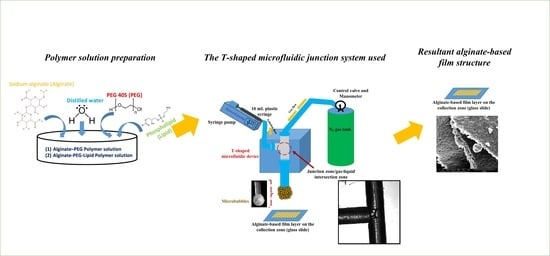

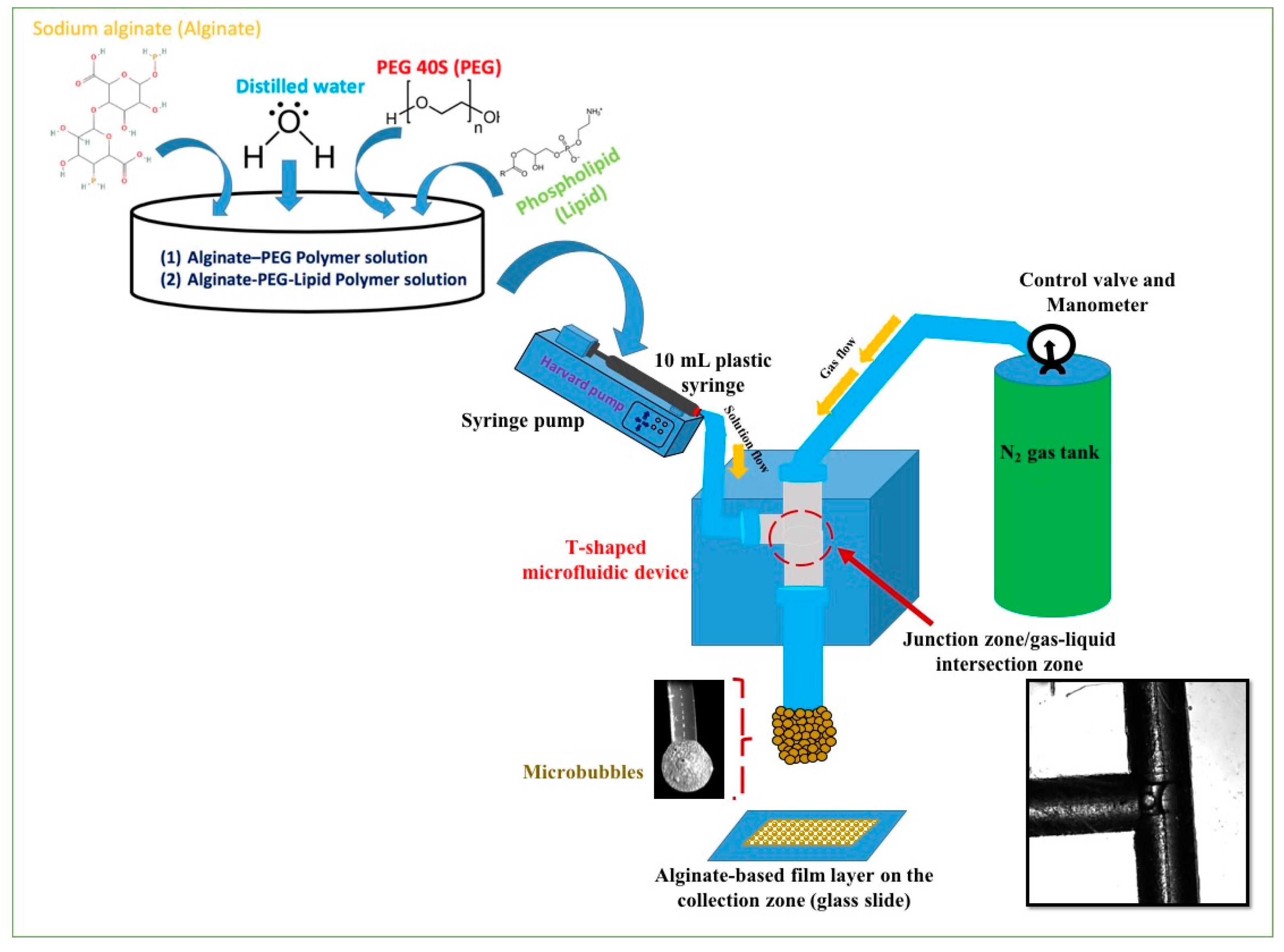

2.4. Preparation of Alginate-Based Polymeric Microbubbles

2.5. Microstructural Characterization

3. Results

3.1. Physical Properties of Alginate-Based Polymeric Solutions

3.2. Production of Alginate-Based Microbubbles by Using a T-Shaped Microfluidic Junction Device

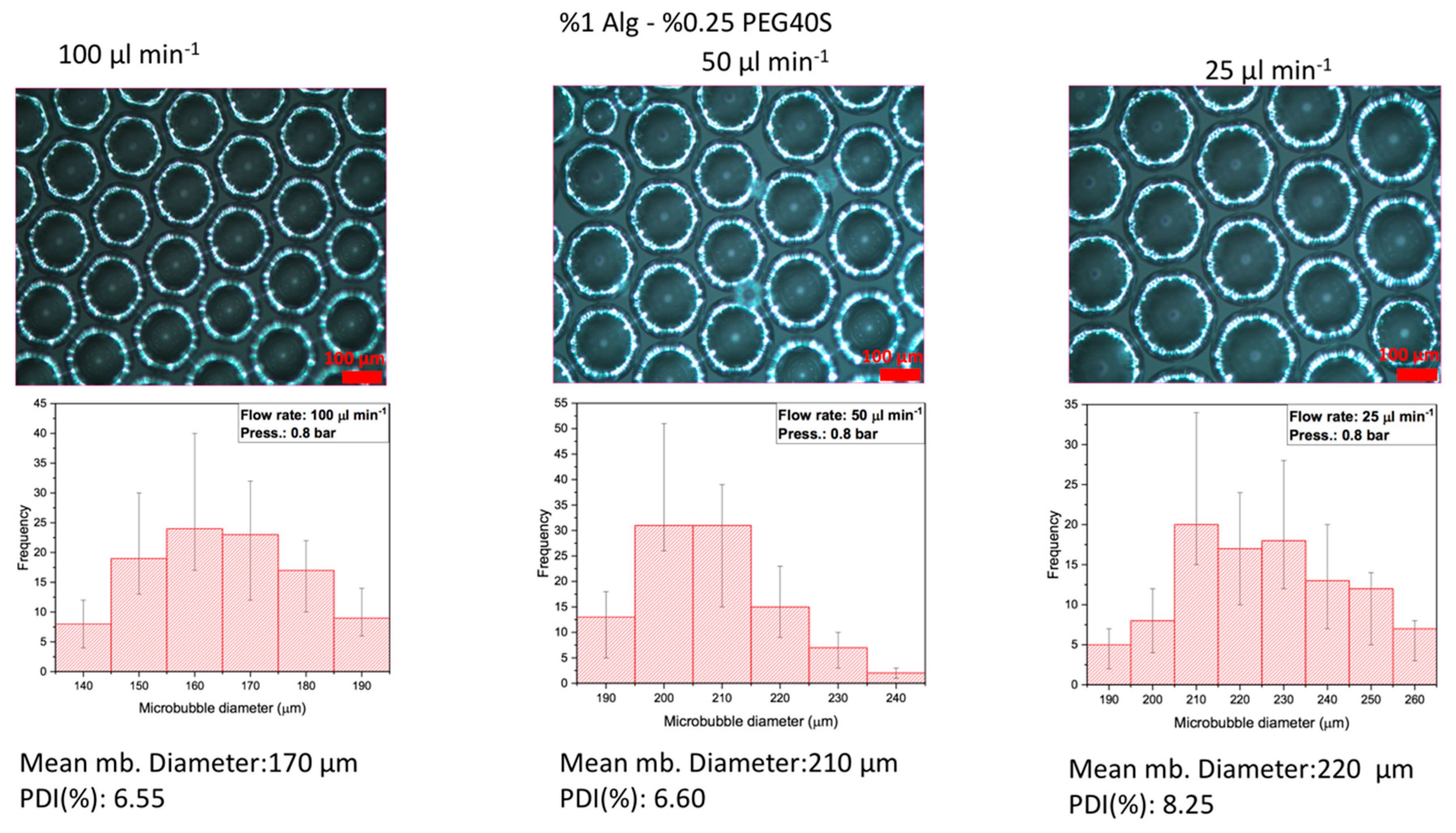

3.3. Effect of Polymer Solution Flow Rate on Alginate-Based Porous Film Structures

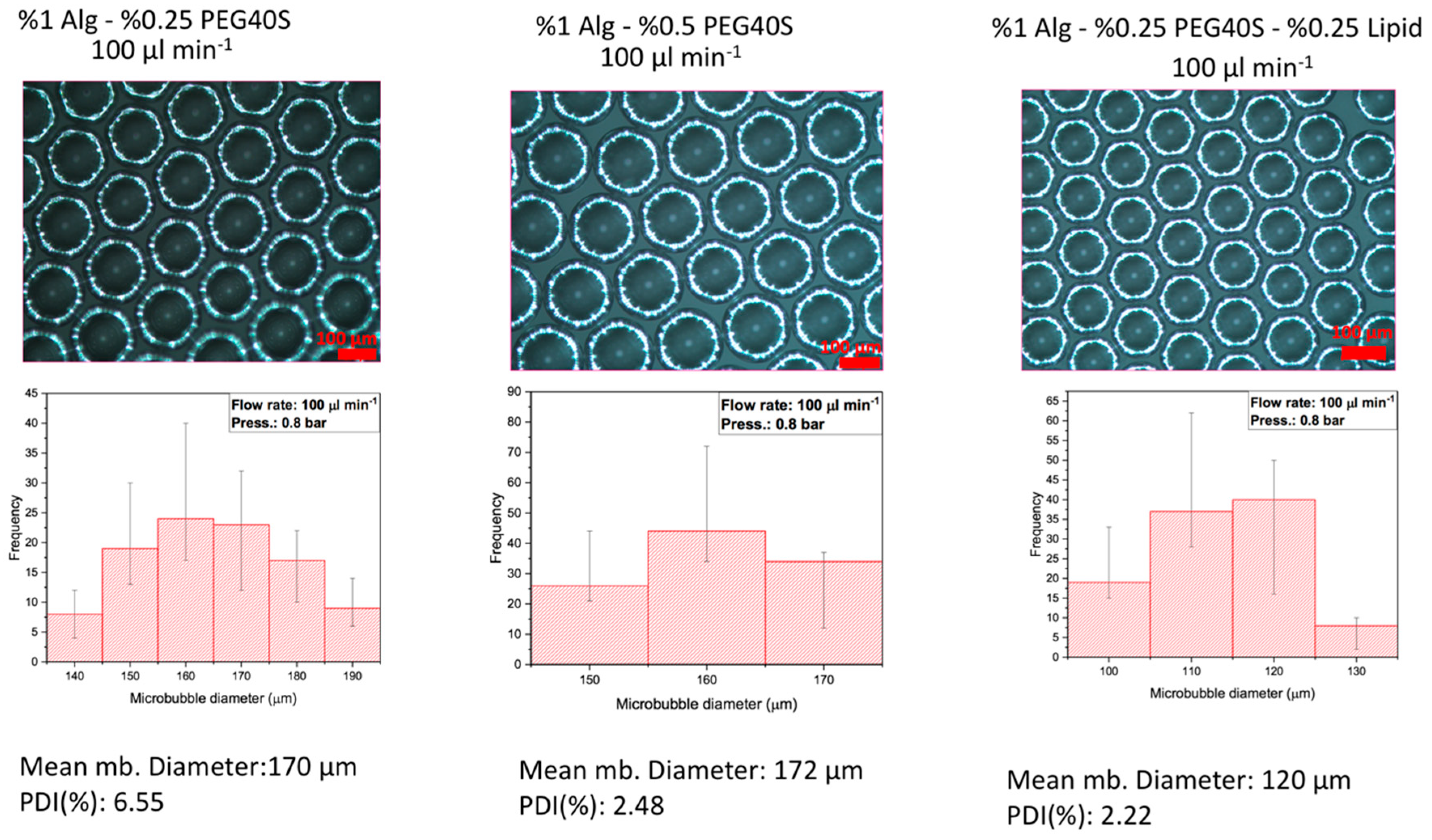

3.4. Effect of the PEG-40S on Alginate-Based Porous Films

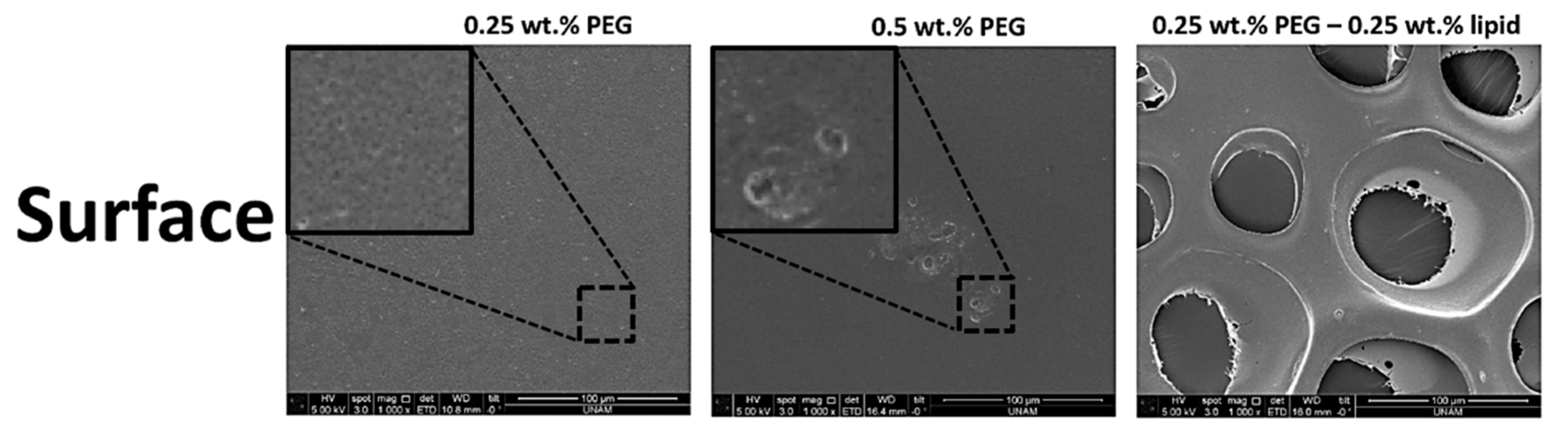

3.5. Scanning Electron Microscopy of the Resultant Film Structures

3.6. FTIR Results of the Precursors Used and the Alginate-Based Porous Film Structures

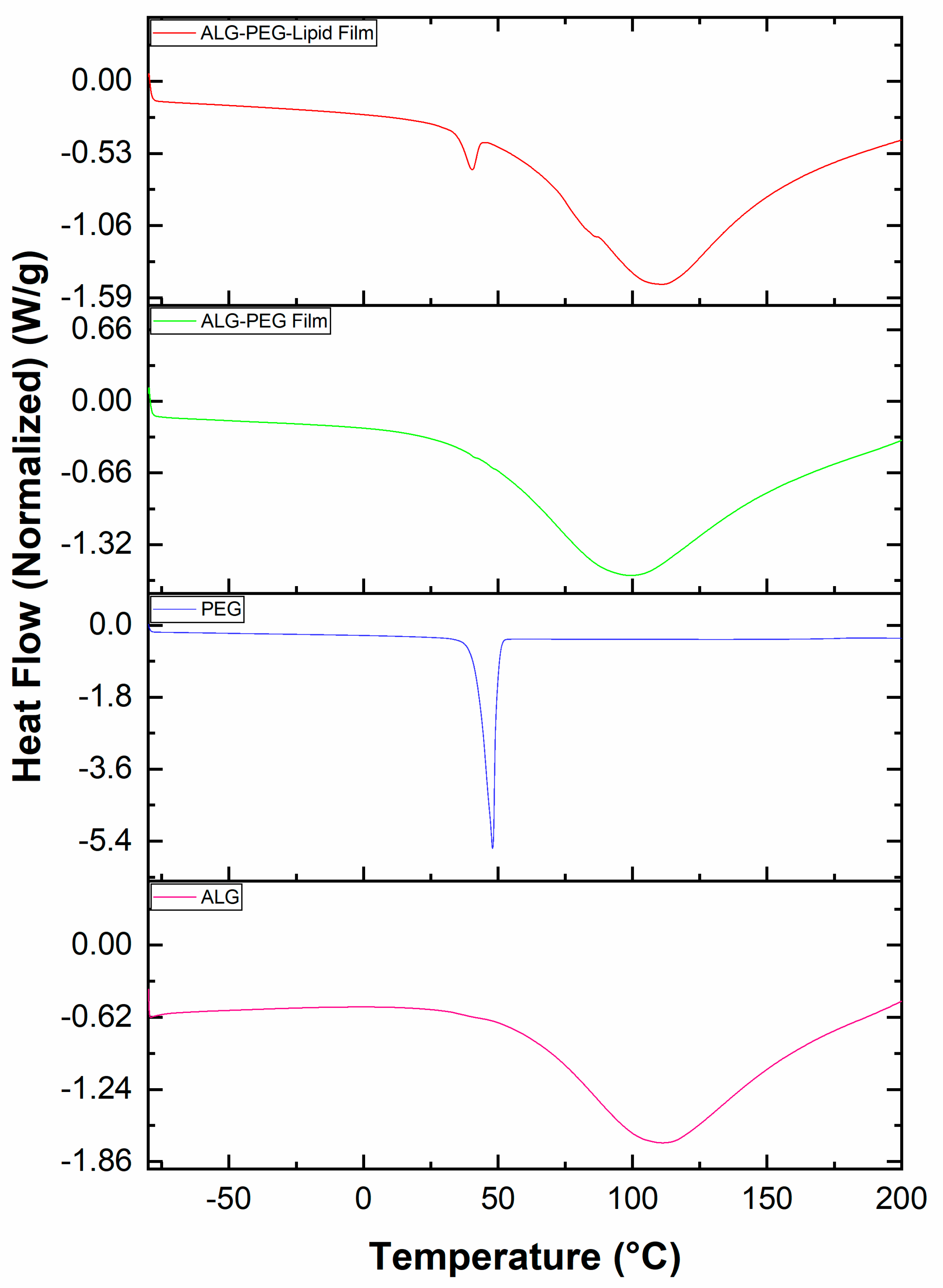

3.7. Differential Scanning Calorimetry Results of the Precursors Used and the Alginate-Based Porous Film Structures

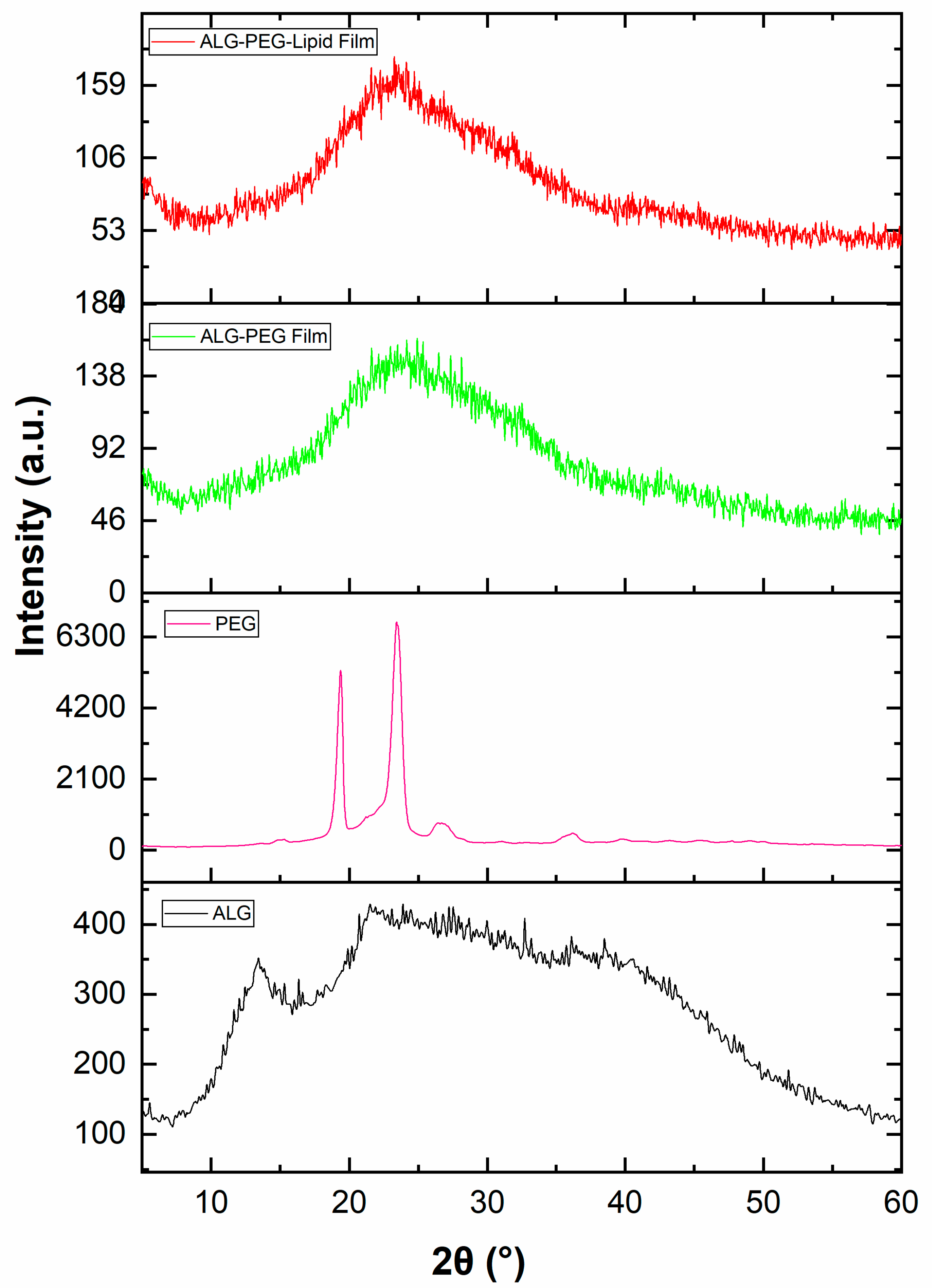

3.8. XRD Spectra of the Precursors Used and the Alginate-Based Porous Film Structures

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yuk, S.H.; Cho, S.H.; Lee, H.B. pH-sensitive drug delivery system using OW emulsion. J. Control. Release 1995, 37, 69–74. [Google Scholar] [CrossRef]

- Lin, S.Y.; Ayres, J.W. Calcium alginate beads as core carriers of 5-aminosalicylic acid. Pharm. Res. 1992, 9, 1128–1131. [Google Scholar] [CrossRef] [PubMed]

- Mjahed, H.; Porcel, C.; Senger, B.; Chassepot, A.; Netter, P.; Gillet, P.; Decher, G.; Voegel, J.-C.; Schaaf, P.; Benkirane-Jessel, N. Micro-stratified architectures based on successive stacking of alginate gel layers and poly (L-lysine)–hyaluronic acid multilayer films aimed at tissue engineering. Soft Matter 2008, 4, 1422–1429. [Google Scholar] [CrossRef]

- Tan, W.H.; Takeuchi, S. Monodisperse alginate hydrogel microbeads for cell encapsulation. Adv. Mater. 2007, 19, 2696–2701. [Google Scholar] [CrossRef]

- McMillan, J.R.; Akiyama, M.; Tanaka, M.; Yamamoto, S.; Goto, M.; Abe, R.; Sawamura, D.; Shimomura, M.; Shimizu, H. Small-diameter porous Poly (ϵ-Caprolactone) films enhance adhesion and growth of human cultured epidermal keratinocyte and dermal fibroblast cells. Tissue Eng. 2007, 13, 789–798. [Google Scholar] [CrossRef] [PubMed]

- Lawrence, B.J.; Madihally, S.V. Cell colonization in degradable 3D porous matrices. Cell Adhes. Migr. 2008, 2, 9–16. [Google Scholar] [CrossRef] [PubMed]

- Malafaya, P.B.; Silva, G.A.; Reis, R.L. Natural–origin polymers as carriers and scaffolds for biomolecules and cell delivery in tissue engineering applications. Adv. Drug Deliv. Rev. 2007, 59, 207–233. [Google Scholar] [CrossRef] [PubMed]

- Yao, Z.-C.; Yuan, Q.; Ahmad, Z.; Huang, J.; Li, J.-S.; Chang, M.-W. Controlled morphing of microbubbles to beaded nanofibers via electrically forced thin film stretching. Polymers 2017, 9, 265. [Google Scholar] [CrossRef]

- Mehta, P.; Al-Kinani, A.A.; Arshad, M.S.; Singh, N.; van der Merwe, S.M.; Chang, M.-W.; Alany, R.G.; Ahmad, Z. Engineering and development of chitosan-based Nanocoatings for Ocular Contact Lenses. J. Pharm. Sci. 2019, 108, 1540–1551. [Google Scholar] [CrossRef]

- Gao, G.; Cui, X. Three-dimensional bioprinting in tissue engineering and regenerative medicine. Biotechnol. Lett. 2016, 38, 203–211. [Google Scholar] [CrossRef]

- Yao, Z.-C.; Wang, J.-C.; Wang, B.; Ahmad, Z.; Li, J.-S.; Chang, M.-W. A novel approach for tailored medicines: Direct writing of Janus fibers. J. Drug Deliv. Sci. Technol. 2019, 50, 372–379. [Google Scholar] [CrossRef]

- Wang, B.; Prinsen, P.; Wang, H.; Bai, Z.; Wang, H.; Luque, R.; Xuan, J. Macroporous materials: Microfluidic fabrication, functionalization and applications. Chem. Soc. Rev. 2017, 46, 855–914. [Google Scholar] [CrossRef] [PubMed]

- Riche, C.T.; Zhang, C.; Gupta, M.; Malmstadt, N. Fluoropolymer surface coatings to control droplets in microfluidic devices. Lab Chip 2014, 14, 1834–1841. [Google Scholar] [CrossRef] [PubMed]

- Parhizkar, M.; Edirisinghe, M.; Stride, E. Effect of operating conditions and liquid physical properties on the size of monodisperse microbubbles produced in a capillary embedded T-junction device. Microfluid. Nanofluid. 2013, 14, 797–808. [Google Scholar] [CrossRef]

- Elsayed, M.; Huang, J.; Edirisinghe, M. Bioinspired preparation of alginate nanoparticles using microbubble bursting. Mater. Sci. Eng. C 2015, 46, 132–139. [Google Scholar] [CrossRef] [PubMed]

- Hauck, N.; Seixas, N.; Centeno, S.; Schlüßler, R.; Cojoc, G.; Müller, P.; Guck, J.; Wöll, D.; Wessjohann, L.; Thiele, J. Droplet-assisted microfluidic fabrication and characterization of multifunctional polysaccharide microgels formed by multicomponent reactions. Polymers 2018, 10, 1055. [Google Scholar] [CrossRef] [PubMed]

- Jameela, S.; Misra, A.; Jayakrishnan, A. Cross-linked chitosan microspheres as carriers for prolonged delivery of macromolecular drugs. J. Biomater. Sci. Polym. Ed. 1995, 6, 621–632. [Google Scholar] [CrossRef]

- Moe, S.; Skjåk-Bræk, G.; Smidsrød, O.; Ichijo, H. Calcium alginate gel fibers: Influence of alginate source and gel structure on fiber strength. J. Appl. Polym. Sci. 1994, 51, 1771–1775. [Google Scholar] [CrossRef]

- King, A. Brown seaweed extracts (alginates). Food Hydrocoll. 1983, 2, 115–188. [Google Scholar]

- Swamy, T.M.; Ramaraj, B. Siddaramaiah, sodium alginate and poly (ethylene glycol) blends: Thermal and morphological behaviors. J. Macromol. Sci. Part A Pure Appl. Chem. 2010, 47, 877–881. [Google Scholar] [CrossRef]

- Schuster, B.; Pum, D.; Braha, O.; Bayley, H.; Sleytr, U.B. Self-assembled α-hemolysin pores in an S-layer-supported lipid bilayer. Biochim. Biophys. Acta (BBA) Biomembr. 1998, 1370, 280–288. [Google Scholar] [CrossRef]

- Zhao, Y.-Z.; Luo, Y.-K.; Lu, C.-T.; Xu, J.-F.; Tang, J.; Zhang, M.; Zhang, Y.; Liang, H.-D. Phospholipids-based microbubbles sonoporation pore size and reseal of cell membrane cultured in vitro. J. Drug Target. 2008, 16, 18–25. [Google Scholar] [CrossRef] [PubMed]

- Amoyav, B.; Benny, O. Microfluidic based fabrication and characterization of highly porous polymeric microspheres. Polymers 2019, 11, 419. [Google Scholar] [CrossRef] [PubMed]

- Kočárková, H.; Rouyer, F.; Pigeonneau, F. Film drainage of viscous liquid on top of bare bubble: Influence of the Bond number. Phys. Fluids 2013, 25, 022105. [Google Scholar] [CrossRef]

- Del Gaudio, P.; Colombo, P.; Colombo, G.; Russo, P.; Sonvico, F. Mechanisms of form and disintegration of alginate beads obtained by prilling. Int. J. Pharm. 2005, 302, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Sun, F.; Guo, J.; Liu, Y.; Yu, Y. Preparation, characterizations and properties of sodium alginate grafted acrylonitrile/polyethylene glycol electrospun nanofibers. Int. J. Biol. Macromol. 2019, 137, 420–425. [Google Scholar] [CrossRef] [PubMed]

- Hallow, D.M.; Seeger, R.A.; Kamaev, P.P.; Prado, G.R.; LaPlaca, M.C.; Prausnitz, M.R. Shear-induced intracellular loading of cells with molecules by controlled microfluidics. Biotechnol. Bioeng. 2008, 99, 846–854. [Google Scholar] [CrossRef] [PubMed]

- Lhuissier, H.; Villermaux, E. Bursting bubble aerosols. J. Fluid Mech. 2012, 696, 5–44. [Google Scholar] [CrossRef]

- Li, D. Coalescence between small bubbles: Effects of surface tension gradient and surface viscosities. J. Colloid Interface Sci. 1996, 181, 34–44. [Google Scholar] [CrossRef]

- Filho, W.D.A.; Schneider, F.K.; Morales, R.E. Evaluation of stability and size distribution of sunflower oil-coated micro bubbles for localized drug delivery. Biomed. Eng. Online 2012, 11, 71. [Google Scholar] [CrossRef]

- Huerre, A.; Miralles, V.; Jullien, M.-C. Bubbles and foams in microfluidics. Soft Matter 2014, 10, 6888–6902. [Google Scholar] [CrossRef] [PubMed]

- Hahn, P.S.; Chen, J.D.; Slattery, J. Effects of London-van der Waals forces on the thinning and rupture of a dimpled liquid film as a small drop or bubble approaches a fluid-fluid interface. AIChE J. 1985, 31, 2026–2038. [Google Scholar] [CrossRef]

- Borden, M.A.; Longo, M.L. Dissolution behavior of lipid monolayer-coated, air-filled microbubbles: Effect of lipid hydrophobic chain length. Langmuir 2002, 18, 9225–9233. [Google Scholar] [CrossRef]

- Jang, Y.; Park, S.; Char, K. Functionalization of polymer multilayer thin films for novel biomedical applications. Korean J. Chem. Eng. 2011, 28, 1149–1160. [Google Scholar] [CrossRef]

- Qi, Y.; Jiang, M.; Cui, Y.-L.; Zhao, L.; Zhou, X. Synthesis of quercetin loaded nanoparticles based on alginate for Pb (II) adsorption in aqueous solution. Nanoscale Res. Lett. 2015, 10, 408. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Tao, W.; Chen, D.; Guo, X.; Chen, Y.; Jiang, Y. High performance shape-stabilized phase change material with nanoflower-like wrinkled mesoporous silica encapsulating polyethylene glycol: Preparation and thermal properties. Nanomaterials 2018, 8, 385. [Google Scholar] [CrossRef] [PubMed]

- Shen, Z.; Wang, J.; Lu, D.; Li, Q.; Zhou, C.; Zhu, Y.; Hu, X. Synthesis and properties of flexible polyurethane using ferric catalyst for hypopharyngeal tissue engineering. BioMed Res. Int. 2015, 2015, 798721. [Google Scholar] [CrossRef] [PubMed]

- Simpliciano, C.; Clark, L.; Asi, B.; Chu, N.; Mercado, M.; Diaz, S.; Goedert, M.; Mobed-Miremadi, M. Cross-linked alginate film pore size determination using atomic force microscopy and validation using diffusivity determinations. J. Surf. Eng. Mater. Adv. Technol. 2013, 3, 1. [Google Scholar] [CrossRef]

- Dudek, G.; Turczyn, R. New type of alginate/chitosan microparticle membranes for highly efficient pervaporative dehydration of ethanol. RSC Adv. 2018, 8, 39567–39578. [Google Scholar] [CrossRef]

- Guo, Y.; Ma, J.; Lv, Z.; Zhao, N.; Wang, L.; Li, Q. The effect of plasticizer on the shape memory properties of poly (lactide acid)/poly (ethylene glycol) blends. J. Mater. Res. 2018, 33, 4101–4112. [Google Scholar] [CrossRef]

- Chen, Y.; Zhu, Y.; Wang, J.; Lv, M.; Zhang, X.; Gao, J.; Zhang, Z.; Lei, H. Novel shape-stabilized phase change materials composed of polyethylene glycol/nonsurfactant-templated mesoporous silica: Preparation and thermal properties. JOM 2017, 69, 2774–2778. [Google Scholar] [CrossRef]

- Aprilliza, M. Characterization and Properties of Sodium Alginate from Brown Algae Used as an Ecofriendly Superabsorbent; IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; p. 012019. [Google Scholar]

- Qu, B.; Li, J.-R.; Xiao, H.-N.; He, B.-H.; Qian, L.-Y. Facile preparation and characterization of sodium alginate/graphite conductive composite hydrogel. Polym. Compos. 2016, 37, 3050–3056. [Google Scholar] [CrossRef]

| Solution ID | Alginate Concentration (% w/v) | PEG-40S Concentration (% w/v) | Phospholipid Concentration (% w/v) |

|---|---|---|---|

| 1 | 0.5 | - | - |

| 2 | 1 | - | - |

| 3 | 2 | - | - |

| 4 | 3 | - | - |

| 5 | 0.5 | 0.25 | - |

| 6 | 1 | 0.25 | - |

| 7 | 2 | 0.5 | - |

| 8 | 3 | 0.75 | - |

| 9 | 1 | 0.25 | 0.25 |

| Solution ID | Alginate (% w/v) | PEG-40S (% w/v) | Phospholipid (% w/v) | Contact Angle (θ) | Surface Tension (mN/m) | Viscosity (mPa·s) |

|---|---|---|---|---|---|---|

| 1 | 0.5 | - | - | 39.68 | 68.69 | 6.51 |

| 2 | 1 | - | - | 48.03 | 70.09 | 16.94 |

| 3 | 2 | - | - | 51.48 | 72.1 | 70.51 |

| 4 | 3 | - | - | 42.91 | 62.1 | 159.4 |

| 5 | 0.5 | 0.25 | - | 38.08 | 48.3 | 6.86 |

| 6 | 1 | 0.25 | - | 46.27 | 58.99 | 16.85 |

| 7 | 2 | 0.5 | - | 49.84 | 56.73 | 60.6 |

| 8 | 3 | 0.75 | - | 34.23 | 57.68 | 155.72 |

| 9 | 1 | 0.25 | 0.25 | 46.95 | 49.6 | 16.00 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mutlu, B.; Farhan, M.; Kucuk, I. T-Shaped Microfluidic Junction Processing of Porous Alginate-Based Films and Their Characteristics. Polymers 2019, 11, 1386. https://doi.org/10.3390/polym11091386

Mutlu B, Farhan M, Kucuk I. T-Shaped Microfluidic Junction Processing of Porous Alginate-Based Films and Their Characteristics. Polymers. 2019; 11(9):1386. https://doi.org/10.3390/polym11091386

Chicago/Turabian StyleMutlu, Betul, Muhammad Farhan, and Israfil Kucuk. 2019. "T-Shaped Microfluidic Junction Processing of Porous Alginate-Based Films and Their Characteristics" Polymers 11, no. 9: 1386. https://doi.org/10.3390/polym11091386

APA StyleMutlu, B., Farhan, M., & Kucuk, I. (2019). T-Shaped Microfluidic Junction Processing of Porous Alginate-Based Films and Their Characteristics. Polymers, 11(9), 1386. https://doi.org/10.3390/polym11091386