Preparation and Properties of Rubber Blends for High-Damping-Isolation Bearings

Abstract

1. Introduction

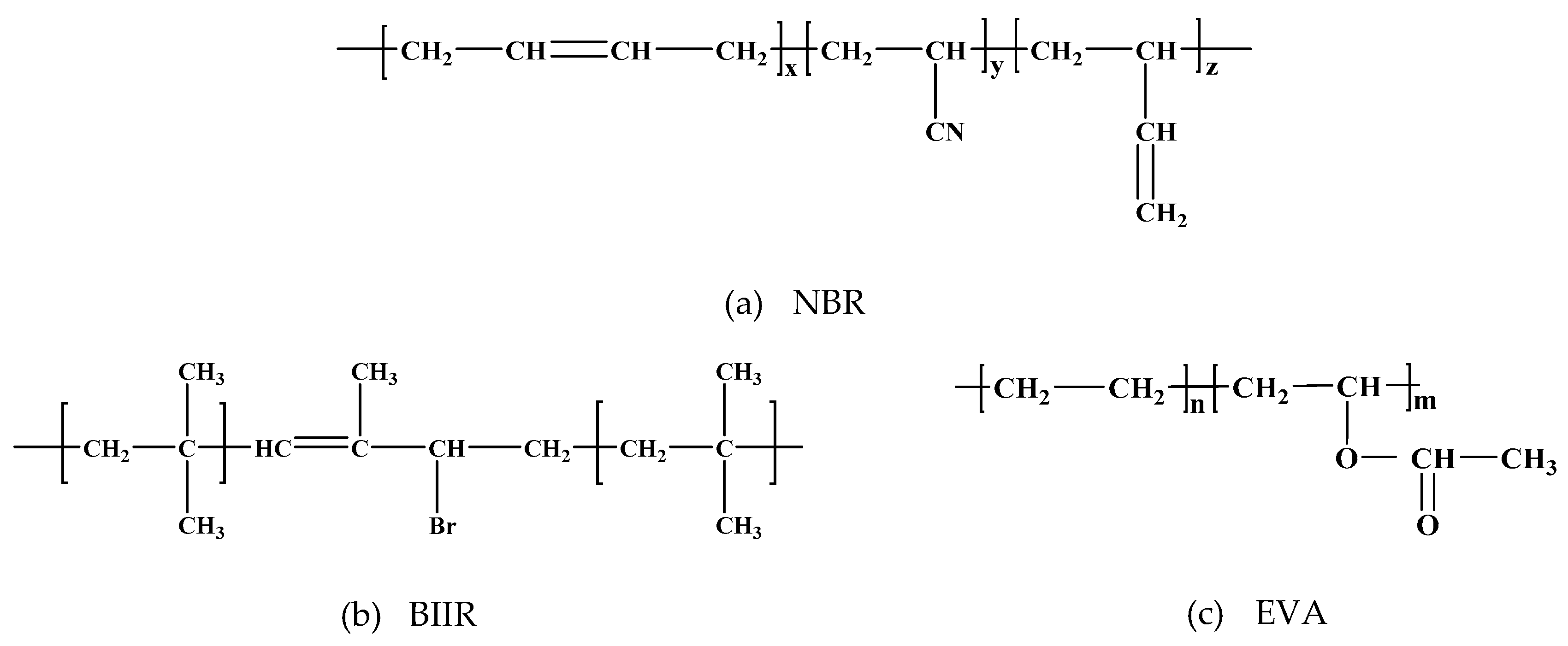

2. Experimental Research

2.1. Materials

2.2. Basic Formulation

2.3. Sample Preparation

- NBR, BIIR and EVA masterbatch: The as-received NBR, BIIR and EVA were kneaded on a two-roll mill at room temperature for 3 min and then blended with compounding and cross-linking additives (the basic formulas of the recipes are shown in Table 1), respectively. Each compound was then kneaded on the two-roll mill at room temperature for 5 min to form the NBR, BIIR and EVA masterbatch.

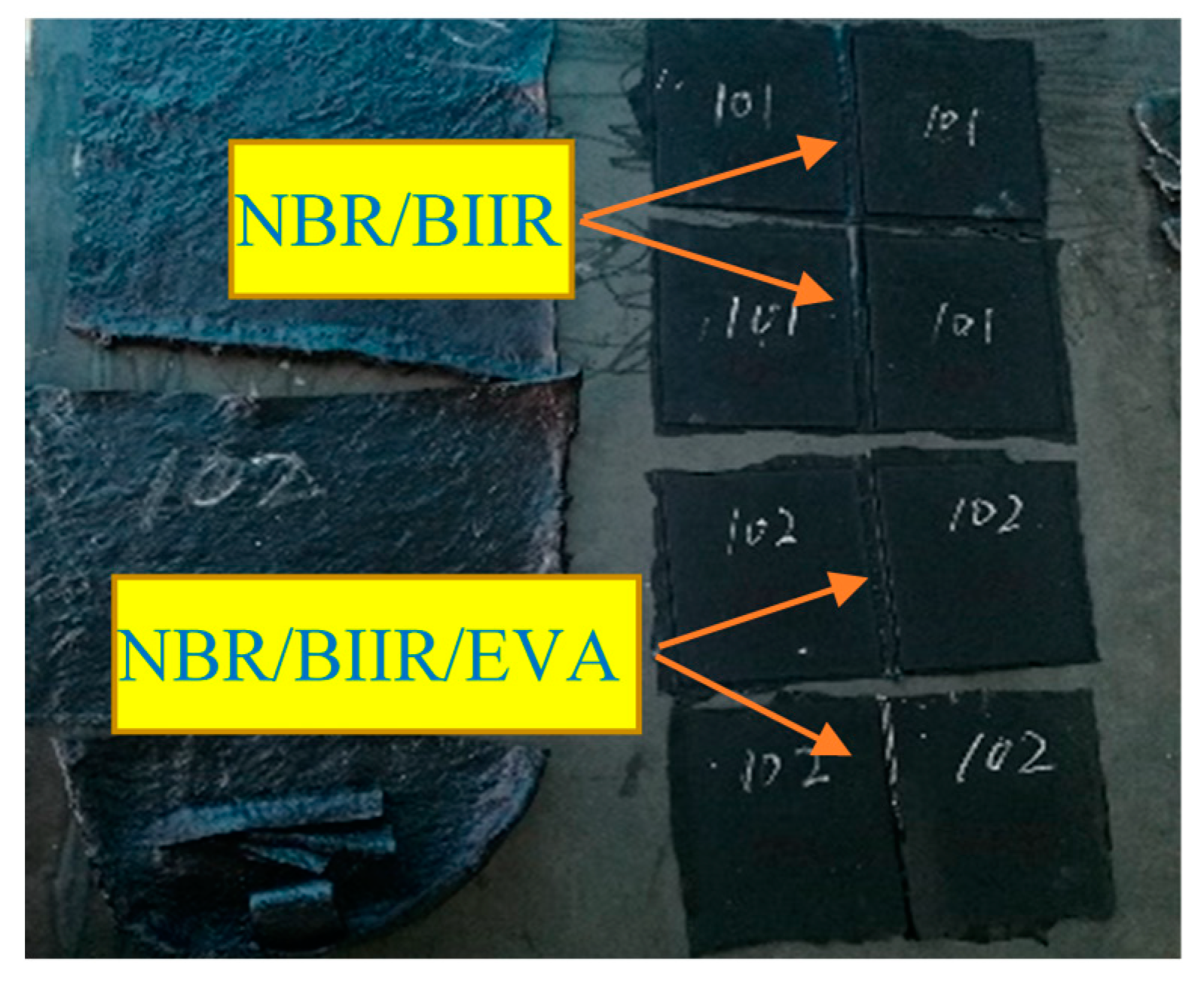

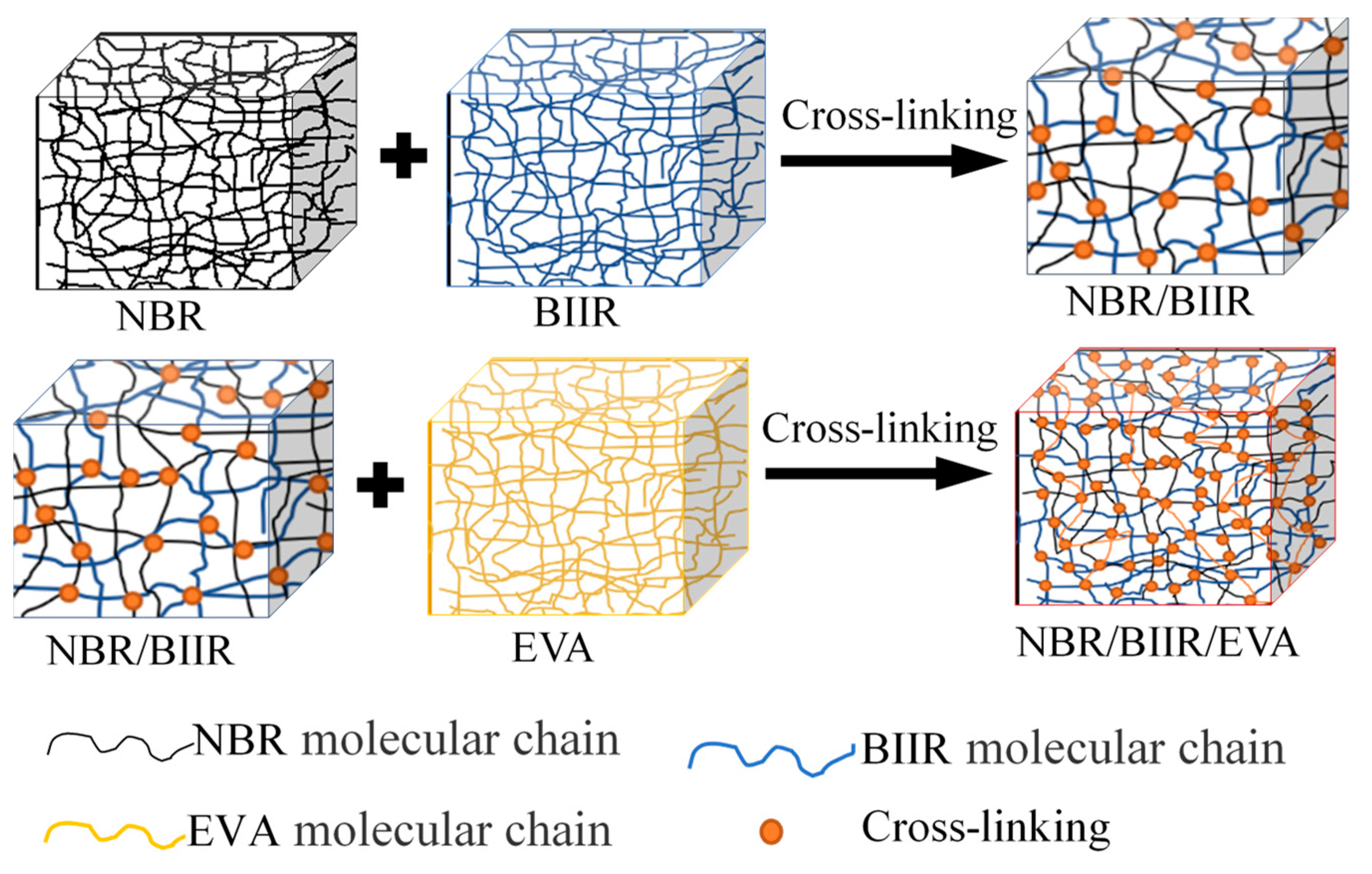

- NBR/BIIR and NBR/BIIR/EVA blends: The NBR, BIIR and EVA masterbatch was mixed in the corresponding proportions (the specific proportions of the blends are shown in Section 4.1 and Section 4.2) in a certain order (i.e., for NBR/BIIR, first BIIR, then NBR; for NBR/BIIR/EVA, first BIIR, then NBR, and finally EVA) on the two-roll mill at room temperature for 5 min. After 16 h, a rheometer analyzer was used to determine the scorch time T10 and the vulcanization time T90 of the mixture. These mixtures were then hot pressed and vulcanized at 150 °C under a pressure of 15 MPa for T90 to obtain cross-linked NBR/BIIR and NBR/BIIR/EVA samples (Figure 2).

2.4. Performance Test

2.4.1. Vulcanization Characteristics

2.4.2. Mechanical Property Test

2.4.3. Dynamic Mechanical Analysis (DMA)

2.4.4. Aging Characteristic Test

2.4.5. Shore Hardness Test

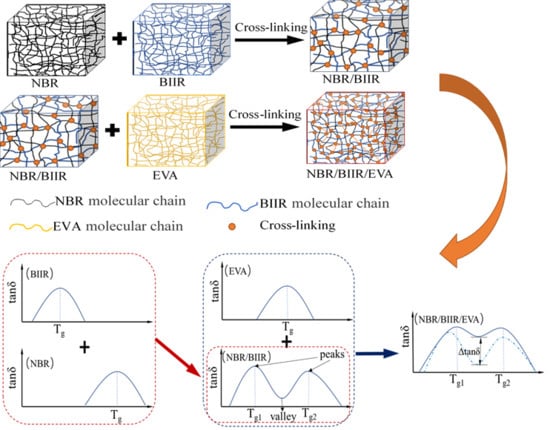

3. Polymer Blend Theory

3.1. Phase Structure Mechanism of Polymer

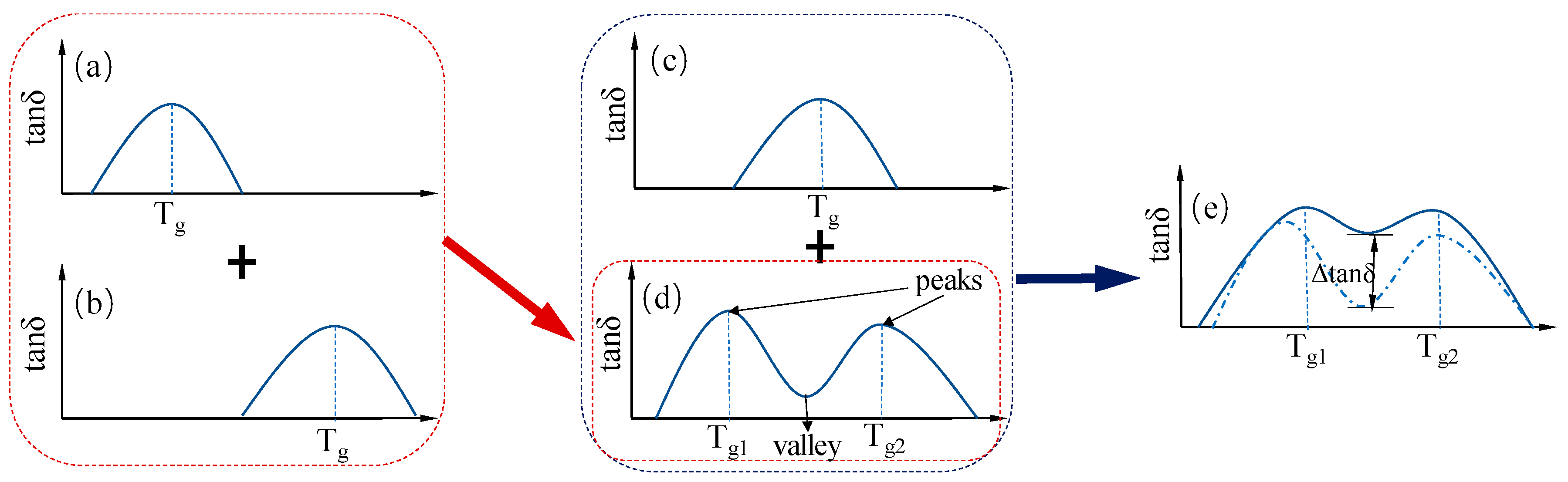

3.2. Polymer Wide Temperature Range Mechanism

3.3. Polymer Damping Mechanism

4. Results and Discussion

4.1. NBR/BIIR Results and Discussion

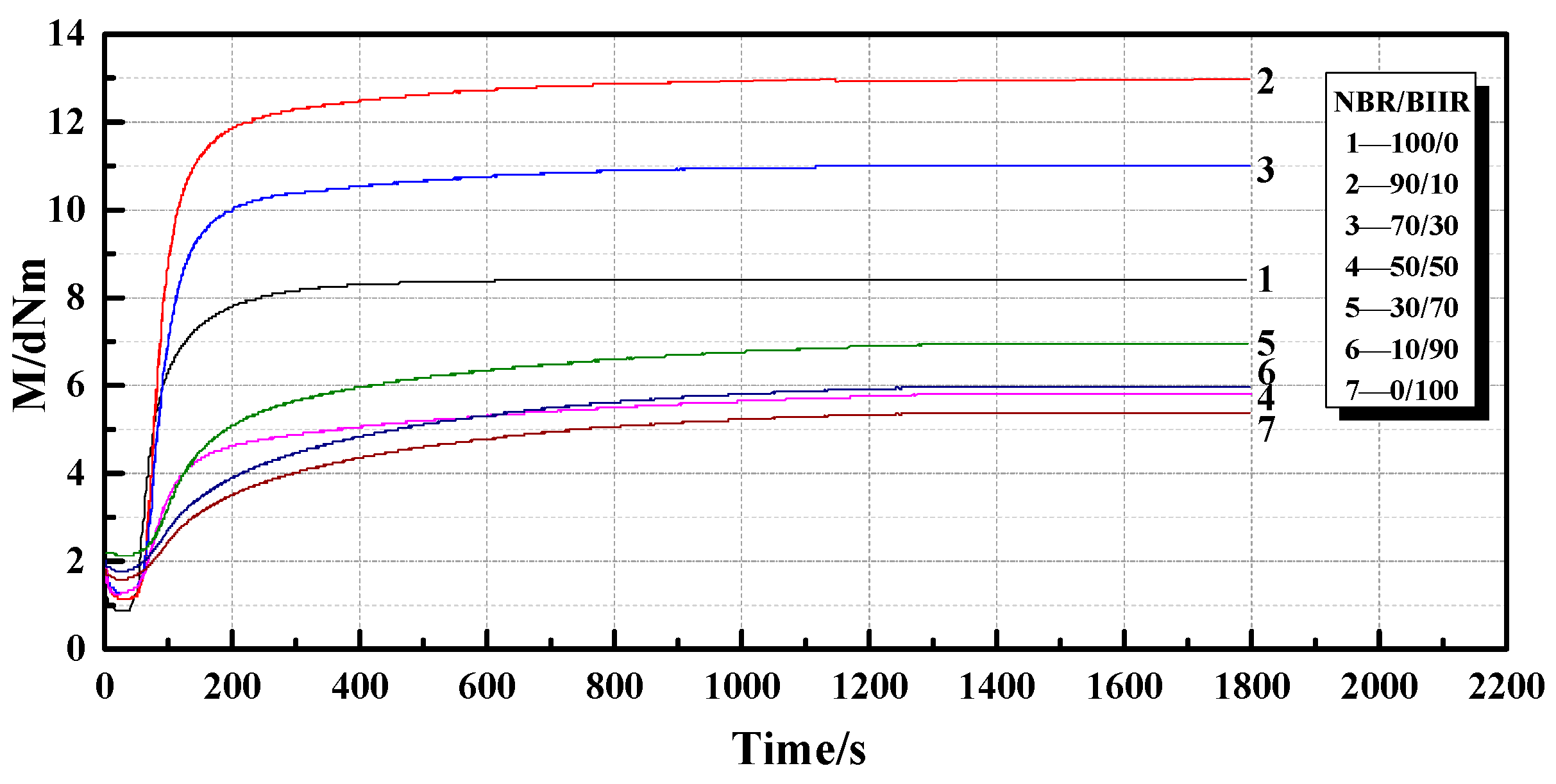

4.1.1. Fluidization Characteristics

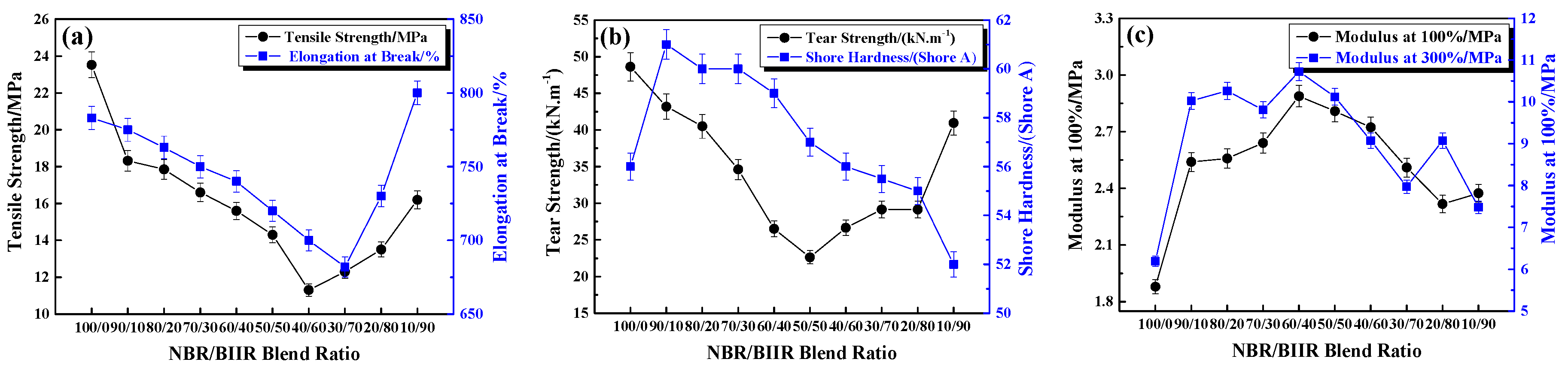

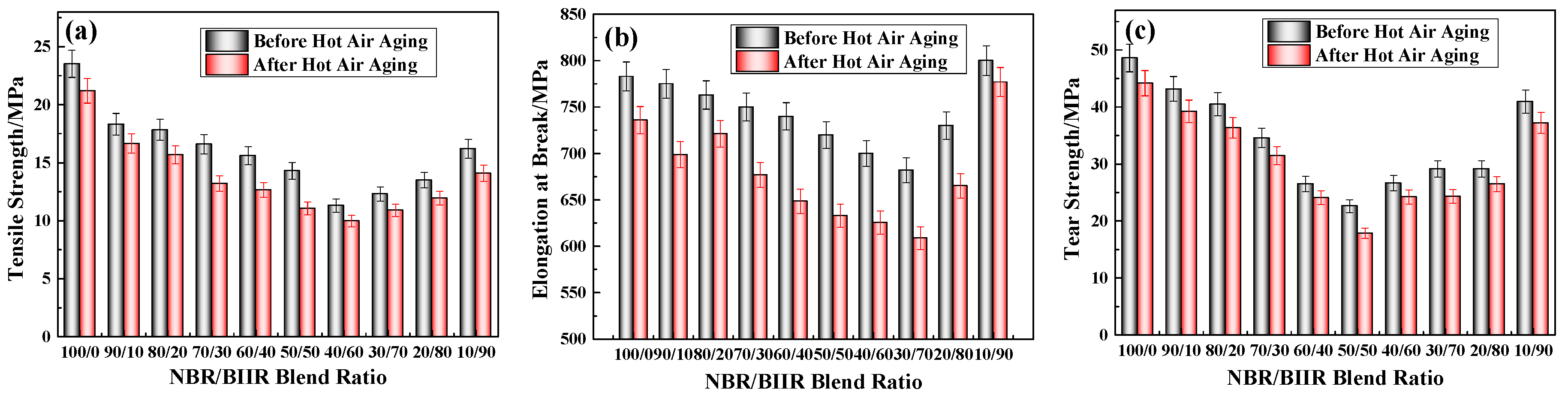

4.1.2. Mechanical Properties

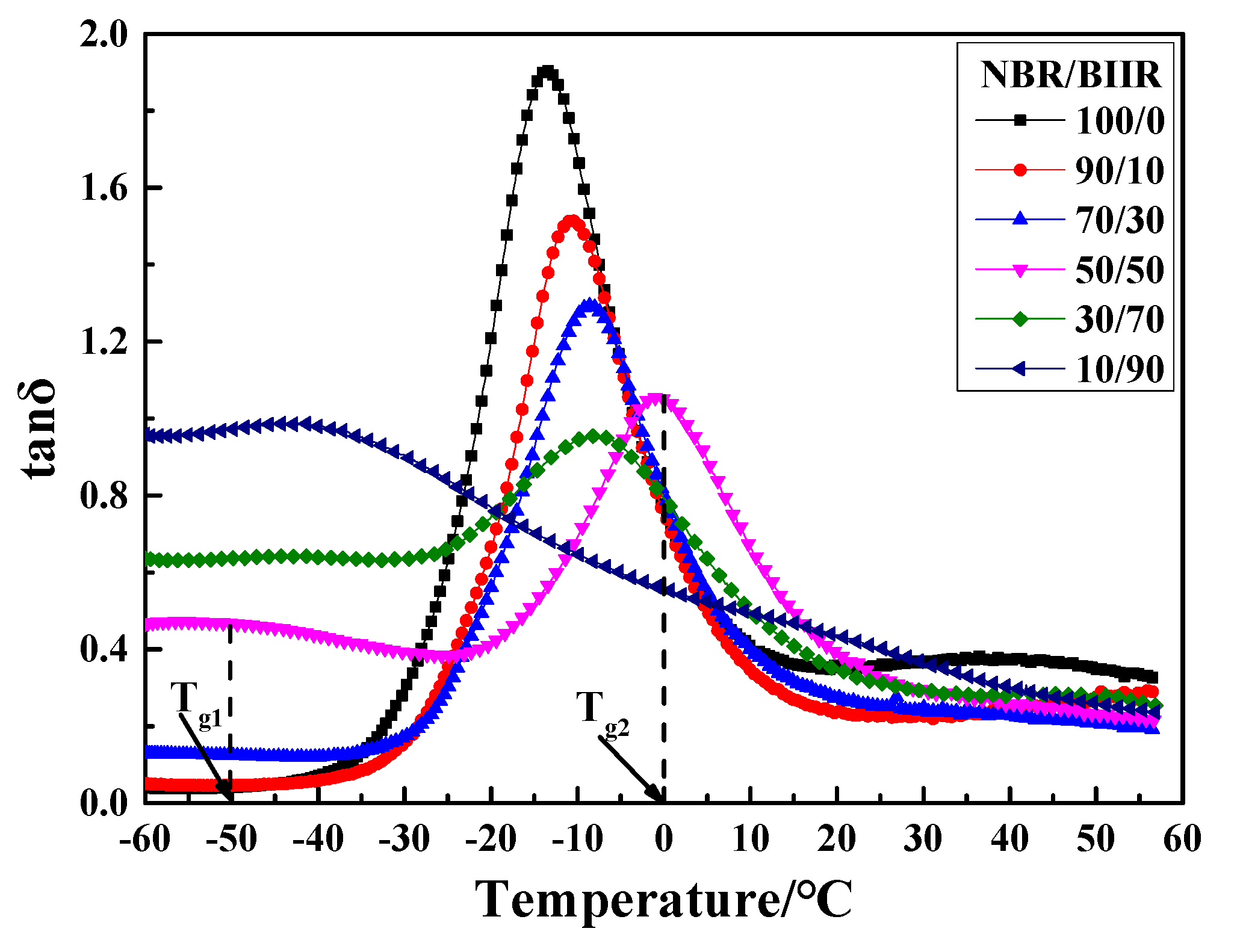

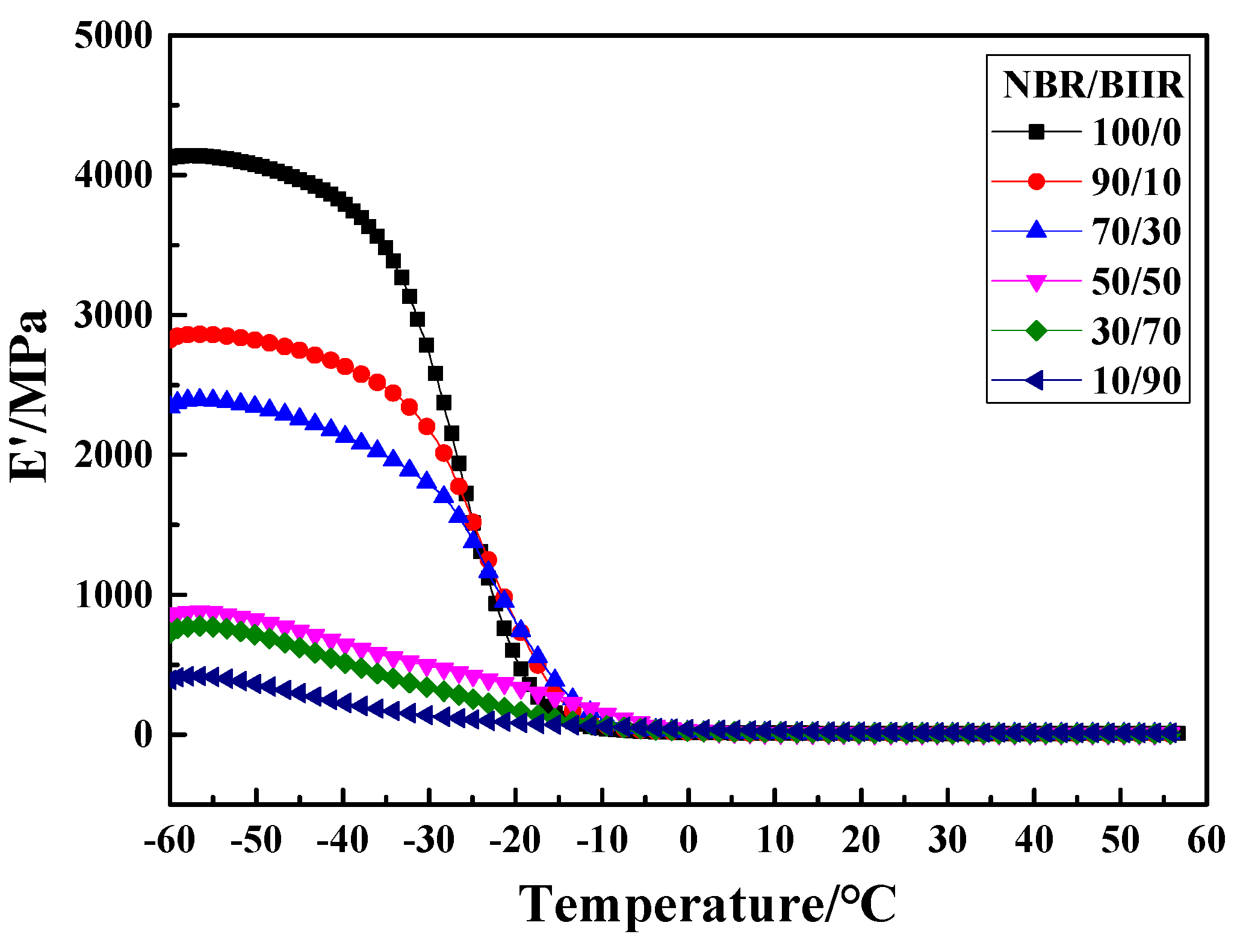

4.1.3. Damping Performance

4.1.4. Aging Performance

4.2. NBR/BIIR/EVA Results and Discussion

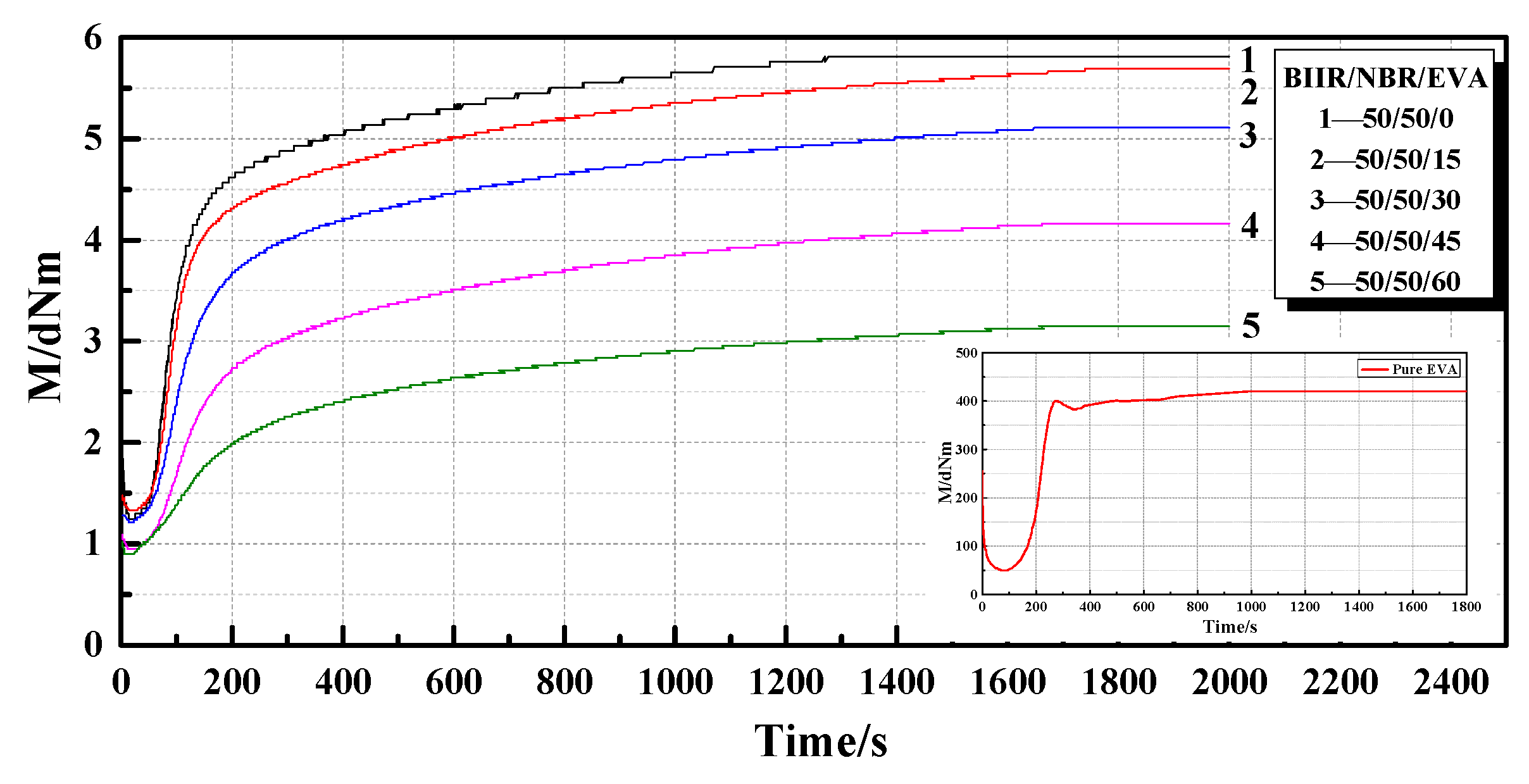

4.2.1. Fluidization Characteristics

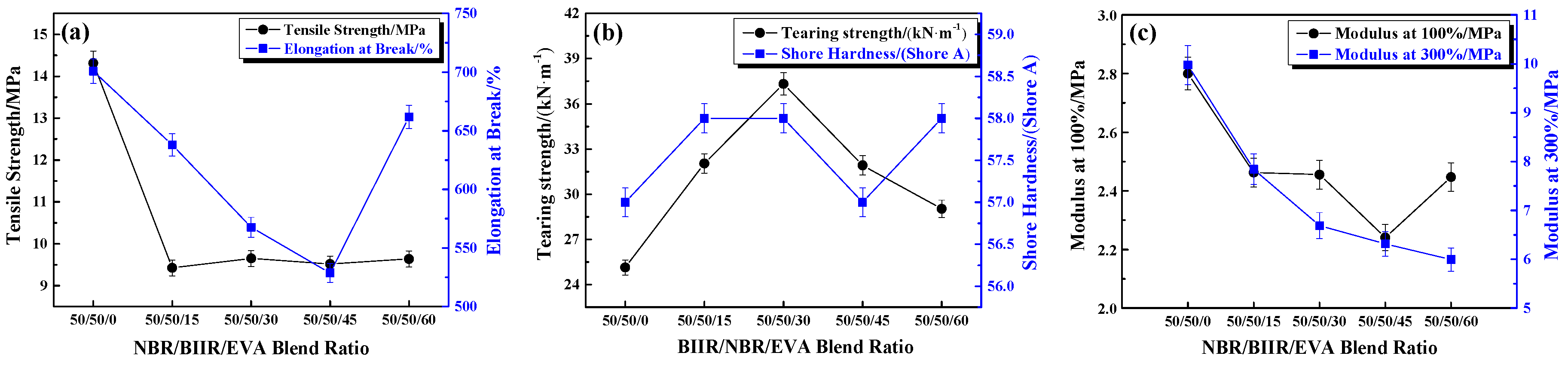

4.2.2. Mechanical Properties

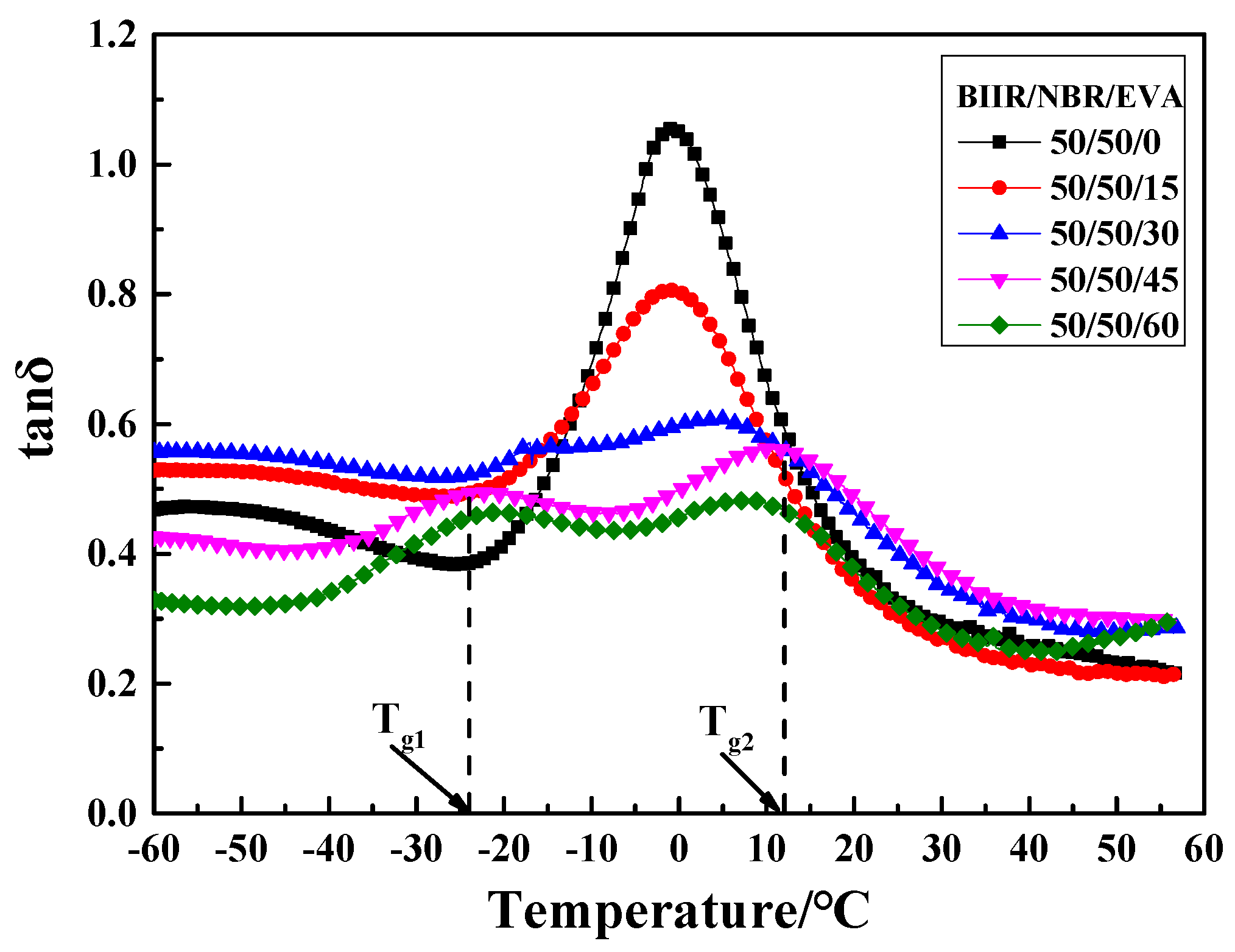

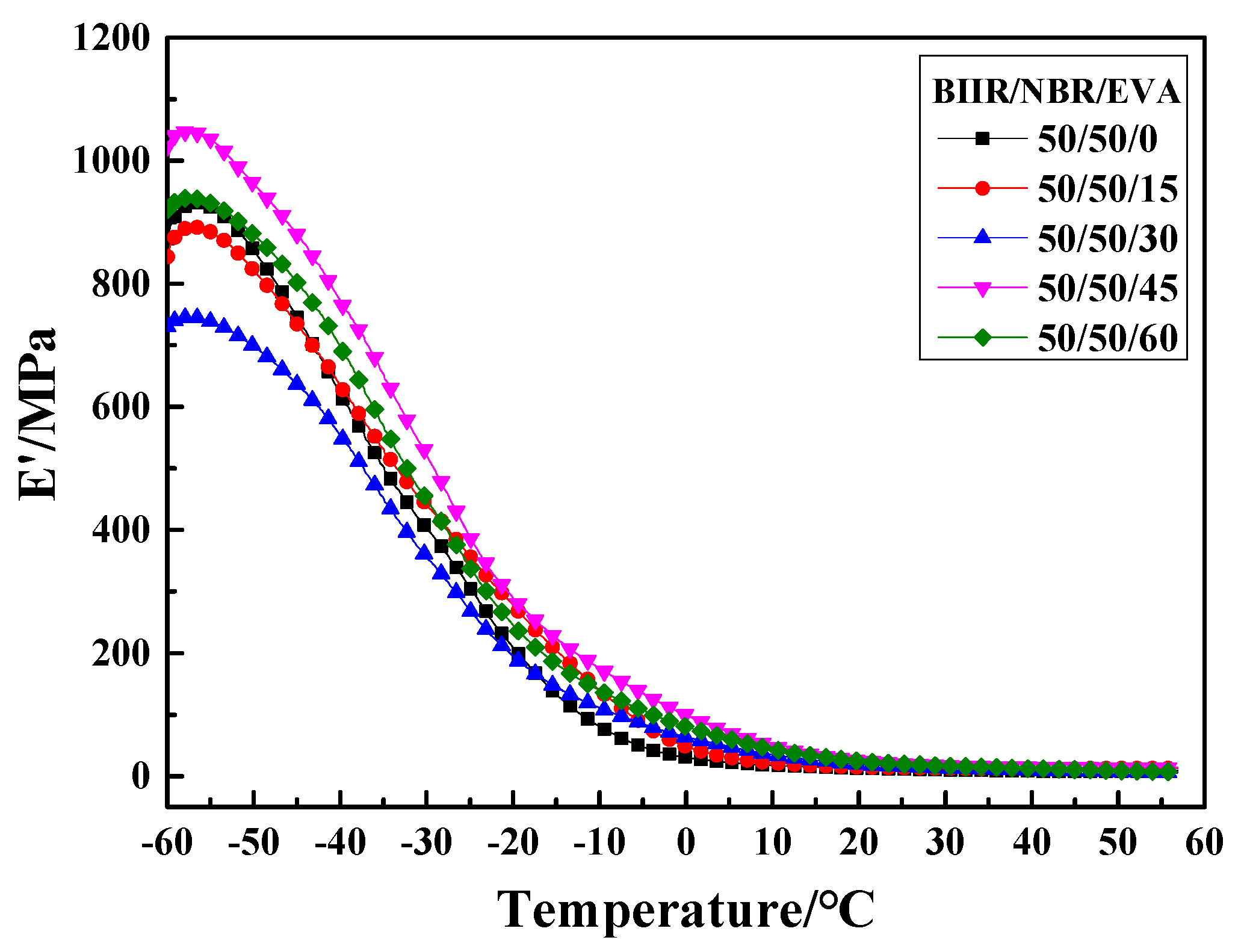

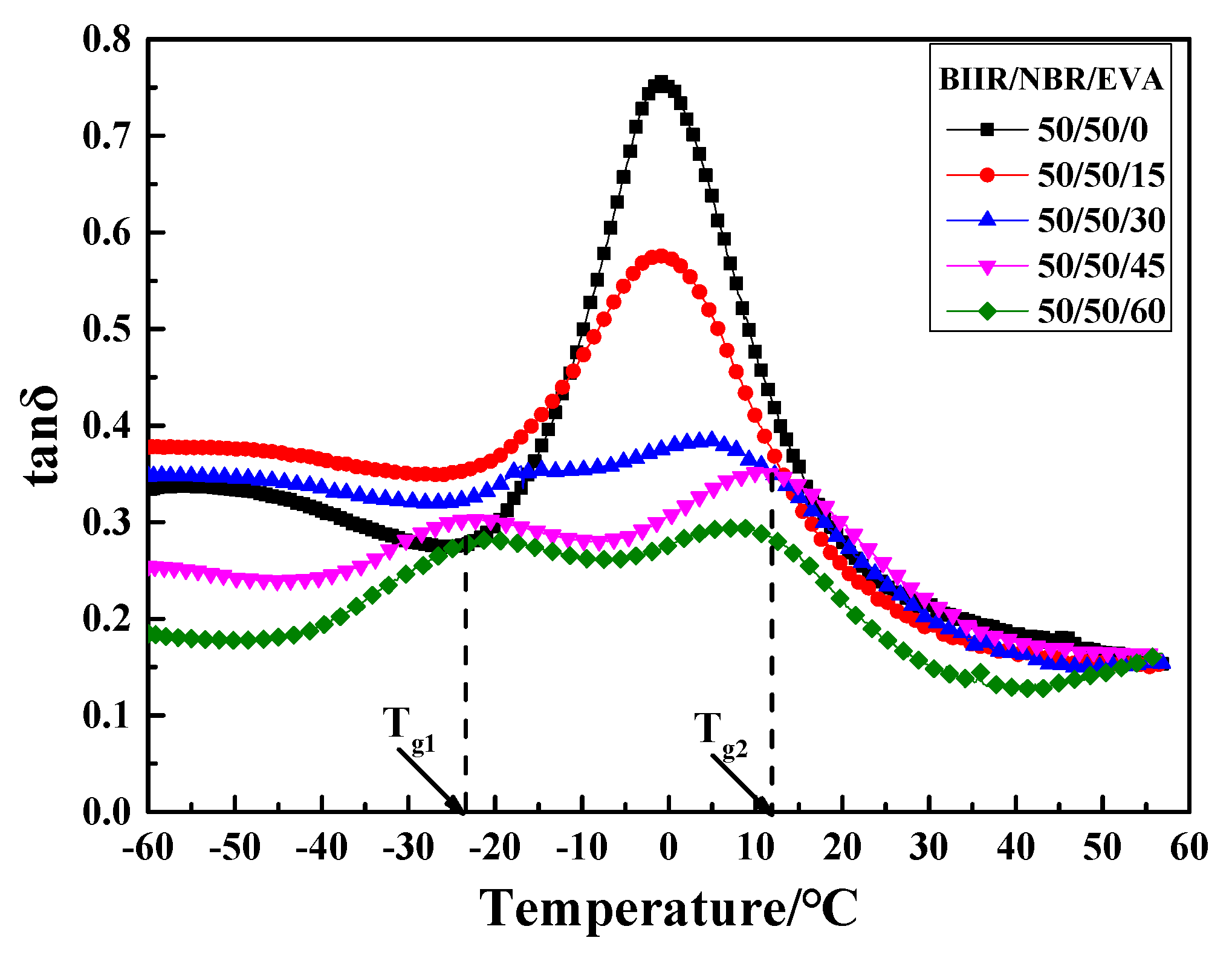

4.2.3. Damping Performance

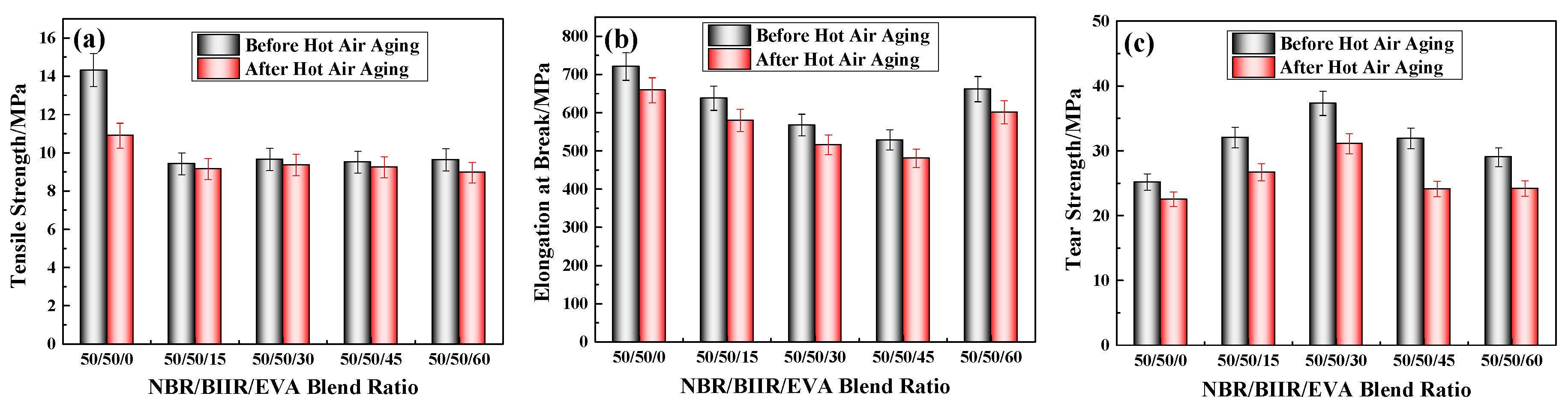

4.2.4. Aging Performance

5. Conclusions

- NBR/BIIR and NBR/BIIR/EVA possess good vulcanization and mechanical properties. The addition of EVA reduces the mechanical properties of NBR/BIIR. Nevertheless, the blends can still fulfill the standard requirements.

- The blending of NBR and BIIR is efficient in expanding the damping temperature range. When the NBR/BIIR ratio is 50/50, the effective temperature range is at least 87.0 °C. However, the damping in the valley is low.

- The addition of EVA to the NBR/BIIR effectively increases the damping in the valley of the tanδ-T curve (tanδ ≥ 0.3) and moves the effective temperature range toward high temperatures. Moreover, the NBR/BIIR/EVA with a 50/50/30 blend ratio is a comparatively ideal material.

- Hot air thermal aging tests of NBR/BIIR and NBR/BIIR/EVA show that the anti-aging stabilities of the two materials are not significantly altered.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Reggio, A.; De Angelis, M. Combined primary–secondary system approach to the design of an equipment isolation system with High-Damping Rubber Bearings. J. Sound Vib. 2014, 333, 2386–2403. [Google Scholar] [CrossRef]

- Steelman, J.S.; Fahnestock, L.A.; Filipov, E.T.; LaFave, J.M.; Hajjar, J.F.; Foutch, D.A. Shear and Friction Response of Nonseismic Laminated Elastomeric Bridge Bearings Subject to Seismic Demands. J. Bridg. Eng. 2013, 18, 612–623. [Google Scholar] [CrossRef]

- Zordan, T.; Liu, T.; Briseghella, B.; Zhang, Q. Improved equivalent viscous damping model for base-isolated structures with lead rubber bearings. Eng. Struct. 2014, 75, 340–352. [Google Scholar] [CrossRef]

- Zhou, F.L. Seismic isolation, energy dissipation, and structural control system-Inevitable technological options for ending urban and rural earthquake disasters in China. Cities Disaster Reduct. 2016, 5, 1–10. [Google Scholar]

- Japan Society of Architecture. Recommendation for the Design of Base Isolated Buildings, 3rd ed.; Japan Society of Architecture, Ed.; Earthquake Press: Beijing, China, 2006; pp. 35–64. [Google Scholar]

- Kim, H.-S.; Oh, J. A Study on Isolation Performance of High Damping Rubber Bearing Through Shaking Table Test and Analysis. J. Korea Acad. Coop. Soc. 2016, 17, 601–611. [Google Scholar]

- Shen, C.; Zhou, F.; Cui, J.; Huang, X.; Zhuang, X.; Ma, Y. Dependency test research of mechanical Performance of HDR and its parametric value analysis. J. Earthq. Eng. Eng. Vib. 2012, 32, 95–103. (In Chinese) [Google Scholar]

- Bakhshi, A.; Jafari, M.H.; Tabrizi, V.V. Study on dynamic and mechanical characteristics of carbon fiber-and polyamide fiber-reinforced seismic isolators. Mater. Struct. 2014, 47, 447–457. [Google Scholar] [CrossRef]

- Chen, Y.J.; Guo, K.M.; Li, Y.; Chen, F. Behavior of high damping seismic isolation rubber bearings for bridges. J. Vib. Shock 2015, 34, 136–141. (In Chinese) [Google Scholar]

- Gu, H.S.; Itoh, Y. Ageing behavior of Natural Rubber and High Damping Rubber Materials Used in Bridge Rubber Bearings. Adv. Struct. Eng. 2010, 13, 1105–1113. [Google Scholar] [CrossRef]

- Radhakrishnan, C.K. Dynamic mechanical properties of styrene butadiene rubber and poly (ethylene-co-vinyl acetate) blends. J. Polym. Res. 2008, 15, 161–171. [Google Scholar] [CrossRef]

- He, W.; Xing, T.; Liao, G.X.; Lin, W.; Deng, F.; Jian, X.G. Dynamic Mechanical Properties of PPESK/Silica Hybrid Materials. Polym. Technol. Eng. 2009, 48, 164–169. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, X.; Wang, W.; Geng, X.; Zhang, L.; Guo, B.; Nishi, T.; Hu, G.-H. Significantly Improving Strength and Damping Performance of Nitrile Rubber via Incorporating Sliding Graft Copolymer. Ind. Eng. Chem. Res. 2018, 57, 16692–16700. [Google Scholar] [CrossRef]

- Kaneko, H.; Inoue, K.; Tominaga, Y.; Asai, S.; Sumita, M. Damping performance of polymer blend/organic filler hybrid materials with selective compatibility. Mater. Lett. 2002, 52, 96–99. [Google Scholar] [CrossRef]

- Tao, G.; Lu, X.; Guo, J.; Tian, M. Preparation and Properties of High Damping Rubber with Wide Temperature Range and Frequency Range. Polym. Mater. Sci. Eng. 2013, 29, 114–118. (In Chinese) [Google Scholar]

- Li, J.-C.; Zhang, H.-S.; Zhao, X.-Y.; Jiang, J.-G.; Wu, Y.-X.; Lu, Y.-L.; Zhang, L.-Q.; Nishi, T. Development of high damping natural rubber/butyl rubber composites compatibilized by isobutylene-isoprene block copolymer for isolation bearing. Express Polym. Lett. 2019, 13, 686–696. [Google Scholar] [CrossRef]

- Cristea, M.; Ibanescu, S.; Cascaval, C.N.; Rosu, D. Dynamic Mechanical Analysis of Polyurethane-Epoxy Interpenetrating Polymer Networks. High Perform. Polym. 2009, 21, 608–623. [Google Scholar] [CrossRef]

- Qin, C.; Zhao, D.; Bai, X.; Zhang, X.; Zhang, B.; Jin, Z.; Niu, H.; Zhao, D. Vibration damping properties of gradient polyurethane/vinyl ester resin interpenetrating polymer network. Mater. Chem. Phys. 2006, 97, 517–524. [Google Scholar] [CrossRef]

- Babkina, N.V.; Lipatov, Y.S.; Alekseeva, T.T. Damping properties of composites based on interpenetrating polymer networks formed in the presence of compatibilizing additives. Mech. Compos. Mater. 2006, 42, 385–392. [Google Scholar] [CrossRef]

- Wang, Y.-B.; Huang, Z.-X.; Zhang, L.-M. Damping properties of silicone rubber/polyacrylate sequential interpenetrating networks. Trans. Nonferr. Met. Soc. China 2006, 16, s517–s520. [Google Scholar] [CrossRef]

- Huang, G.-S.; Li, Q.; Jiang, L.-X.; Huang, G.; Jiang, L. Structure and damping properties of polydimethylsiloxane and polymethacrylate sequential interpenetrating polymer networks. J. Appl. Polym. Sci. 2002, 85, 545–551. [Google Scholar] [CrossRef]

- Wang, T.M.; Chen, S.B.; Wang, Q.H.; Pei, X.Q. Damping analysis of polyurethane/epoxy graft interpenetrating polymer network composites filled with short carbon fiber and micro hollow glass bead. Mater. Des. 2010, 31, 3810–3815. [Google Scholar] [CrossRef]

- Chen, S.; Wang, Q.; Wang, T. Damping, thermal, and mechanical properties of carbon nanotubes modified castor oil-based polyurethane/epoxy interpenetrating polymer network composites. Mater. Des. 2012, 38, 47–52. [Google Scholar] [CrossRef]

- Chen, S.B.; Wang, Q.H.; Wang, T.M. Damping, thermal, and mechanical properties of montmorillonite modified castor oil-based polyurethane/epoxy graft IPN composites. Mater. Chem. Phys. 2011, 130, 680–684. [Google Scholar] [CrossRef]

- Chen, S.B.; Wang, Q.H.; Wang, T.M. Hydroxy-terminated liquid nitrile rubber modified castor oil based polyurethane/epoxy IPN composites: Damping, thermal and mechanical properties. Polym. Test. 2011, 30, 726–731. [Google Scholar] [CrossRef]

- Zhao, X.-Y.; Xiang, P.; Tian, M.; Fong, H.; Jin, R.; Zhang, L.-Q. Nitrile butadiene rubber/hindered phenol nanocomposites with improved strength and high damping performance. Polymer 2007, 48, 6056–6063. [Google Scholar] [CrossRef]

- Xu, K.; Zhang, F.; Guo, J.; Wu, H. Molecular insights into the damping mechanism of poly(vinyl acetate)/hindered phenol hybrids by a combination of experiment and molecular dynamics simulation. RSC Adv. 2015, 5, 4200–4209. [Google Scholar] [CrossRef]

- Wu, C.; Yamagishi, T.A.; Nakamoto, Y.; Ishida, S.; Nitta, K.H.; Kubota, S. Organic hybrid of chlorinated polyethylene and hindered phenol. I. Dynamic mechanical properties. J. Polym. Sci. Part B Polym. Phys. 2000, 38, 2285–2295. [Google Scholar] [CrossRef]

- Zhao, X.Y.; Guo, C.M.; Zhang, D.Y.; Tian, M.; Zhang, L.Q. Preparation and damping properties of hindered phenol AO-80/chlorinated butyl rubber/nitrile rubber composites. China. Synth. Rubber. Ind. 2014, 37, 42–46. (In Chinese) [Google Scholar]

- Qiao, B.; Zhao, X.; Yue, D.; Zhang, L.; Wu, S. A combined experiment and molecular dynamics simulation study of hydrogen bonds and free volume in nitrile-butadiene rubber/hindered phenol damping mixtures. J. Mater. Chem. 2012, 22, 12339. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, G.; Lu, F.; Zhang, L.; Wu, S. Molecular-level insight of hindered phenol AO-70/nitrile-butadiene rubber damping composites through a combination of a molecular dynamics simulation and experimental method. RSC Adv. 2016, 6, 85994–86005. [Google Scholar] [CrossRef]

- Zhang, J.H.; Wang, L.F.; Zhao, Y.F. Fabrication of novel hindered phenol/phenol resin/nitrile butadiene rubber hybrids and their long-period damping properties. Polym. Compos. 2012, 33, 2125–2133. [Google Scholar] [CrossRef]

- Song, M.; Zhao, X.; Li, Y.; Hu, S.; Zhang, L.; Wu, S. Molecular dynamics simulations and microscopic analysis of the damping performance of hindered phenol AO-60/nitrile-butadiene rubber composites. RSC Adv. 2014, 4, 6719. [Google Scholar] [CrossRef]

- Hu, W.; Ruxia; Zhang, Y.; Li, F.; He, X. Effects of sericite modified by macromolecular dispersant on the thermal, mechanical and electrical properties of the NR/SBR composites. J. Macromol. Sci. Part A-Pure Appl. Chem. 2011, 48, 962–968. [Google Scholar] [CrossRef]

- Hintze, C.; Boldt, R.; Wiessner, S.; Heinrich, G. Influence of processing on morphology in short aramid fiber reinforced elastomer compounds. J. Appl. Polym. Sci. 2013, 130, 1682–1690. [Google Scholar] [CrossRef]

- Zuo, K.C. Performance and Characterization of Nitrile Rubber Hybrid Damping. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2016. [Google Scholar]

- Lu, X.; Li, X.J.; Tian, M. Preparation of high damping elastomer with broad temperature and frequency ranges based on ternary rubber blends. Polym. Adv. Technol. 2014, 25, 21–28. (In Chinese) [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, Y.; Gong, J.; Li, C.; Xi, Z.; Cai, J.; Xie, H. Microstructures, thermal and mechanical properties of epoxy asphalt binder modified by SBS containing various styrene-butadiene structures. Mater. Struct. 2018, 51, 86. [Google Scholar] [CrossRef]

- Zhang, J.; Zao, W.; Wang, L.; Zhao, Y. Preparation and characterization of low-temperature hydrogenated nitrile butadiene rubber hybrid with hydrogen bonds for the sealing applications. Mater. Des. 2013, 52, 896–904. [Google Scholar] [CrossRef]

- Li, F.; Zhu, W.; Zhang, X.; Zhao, C.; Xu, M. Shape memory effect of ethylene–vinyl acetate copolymers. J. Appl. Polym. Sci. 1999, 71, 1063–1070. [Google Scholar] [CrossRef]

- Jia, L.Y.; Fu, G.J.; Shi, X.Y. Foaming and Damping Properties of Ethylene Vinyl-Acetate Copolymer/Polylactic Acid Blends. J. Macromol. Sci. Part B-Phys. 2015, 54, 190–202. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, H.; Song, Y.; Zheng, Q. Influence of crosslinking on crystallization, rheological, and mechanical behaviors of high density polyethylene/ethylene-vinyl acetate copolymer blends. Polym. Eng. Sci. 2014, 54, 2848–2858. [Google Scholar] [CrossRef]

- Lai, S.-M.; You, P.-Y. Preparation and Characterization of Ethylene Vinyl-Acetate Copolymer/Silicone Blends with Excellent Two-Way Shape Memory Properties. Macromol. Res. 2018, 26, 984–997. [Google Scholar] [CrossRef]

- Hou, J.; Bai, H.; Li, D. Damping capacity measurement of elastic porous wire-mesh material in wide temperature range. J. Mater. Process. Technol. 2008, 206, 412–418. [Google Scholar] [CrossRef]

- Wang, W.F.; Lin, X.Z.; Ma, Y.L. Viscoelastic Vibration Damping Materials for Application in a Temperature Range above 150 °C. Key Eng. Mater. 2017, 730, 569–573. [Google Scholar] [CrossRef]

- Kan, L.; Ouyang, X.; Gao, S.; Li, R.; Ma, N.; Han, S.-H.; Wei, H.; Liu, L.-H. High damping and mechanical properties of hydrogen-bonded polyethylene materials with variable contents of hydroxyls: Effect of hydrogen bonding density. Chin. J. Polym. Sci. 2017, 35, 649–658. [Google Scholar] [CrossRef]

| Name | ZnO | Stearic Acid | S | DCP | 2402 Resin | TMTD | CZ | DBP | N330 | PBAN | 4010NA |

|---|---|---|---|---|---|---|---|---|---|---|---|

| NBR | 5–10 | 2–6 | 1–4 | – | – | 0.2–0.6 | 1–3 | 8–10 | 20–50 | 1.5–3 | 1–3 |

| BIIR | 5–10 | 2–6 | – | – | 5–10 | 0.2–0.4 | 1–1.5 | 8–10 | 20–50 | 1.5–3 | 1–3 |

| EVA | 5–10 | 2–6 | – | 1–2 | – | 0.2–0.4 | 1–1.5 | 8–10 | 20–50 | 1.5–3 | 1–3 |

| Test Numbers | Rubber Name NBR/BIIR | MH dNm | ML dNm | T10 min | T90 min |

tanPA (min) |

|---|---|---|---|---|---|---|

| 1 | 100/0 | 8.5 | 0.9 | 0.6 | 3.2 | 0.08 |

| 2 | 90/10 | 13.0 | 1.2 | 1.1 | 3.1 | 0.03 |

| 3 | 70/30 | 11.1 | 1.4 | 1.1 | 3.4 | 0.04 |

| 4 | 50/50 | 6.0 | 1.3 | 1.0 | 13.2 | 0.07 |

| 5 | 30/70 | 7.1 | 2.0 | 1.1 | 12.5 | 0.08 |

| 6 | 10/90 | 6.1 | 1.8 | 1.2 | 13.2 | 0.05 |

| 7 | 0/100 | 5.4 | 1.6 | 1.2 | 13.5 | 0.05 |

| NBR/BIIR | Value | Tg ( = Tg2)/ °C | T1/ °C | T2/ °C | (T2 − T1)/ °C |

|---|---|---|---|---|---|

| 100/0 | — | −14.3 | −29.8 | 18.1 | 47.9 |

| 90/10 | — | −8.3 | −25.9 | 12.0 | 37.9 |

| 70/30 | — | −5.1 | −24.9 | 15.9 | 40.8 |

| 50/50 | 0.4 | 0.4 | ≤−60.0 | 27.0 | ≥87.0 |

| 30/70 | 0.6 | −5.8 | ≤−60.0 | 25.6 | ≥85.6 |

| 10/90 | 1.0 | −38.9 | ≤−60.0 | 38.5 | ≥98.5 |

| NBR/BIIR | Tensile Strength/MPa | Elongation at Break/% | Tear Strength/kN/m |

|---|---|---|---|

| Before and after Aging/% | Before and after Aging/% | Before and after Aging/% | |

| 100/0 | 9.9 ↓ | 6.0 ↓ | 9.1 ↓ |

| 90/10 | 9.1 ↓ | 9.9 ↓ | 9.1 ↓ |

| 80/20 | 12.2 ↓ | 5.5 ↓ | 10.2 ↓ |

| 70/30 | 20.4 ↓ | 9.8 ↓ | 9.1 ↓ |

| 60/40 | 18.8 ↓ | 12.4 ↓ | 9.2 ↓ |

| 50/50 | 22.7 ↓ | 12.1 ↓ | 16.3 ↓ |

| 40/60 | 11.8 ↓ | 10.7 ↓ | 9.6 ↓ |

| 30/70 | 11.4 ↓ | 10.7 ↓ | 15.4 ↓ |

| 20/80 | 11.5 ↓ | 8.9 ↓ | 10.7 ↓ |

| 10/90 | 13.6 ↓ | 2.9 ↓ | 9.0 ↓ |

| Test Number | Rubber Name NBR/BIIR/EVA | MH dNm | ML dNm | T10 min | T90 min | tanPA (min) |

|---|---|---|---|---|---|---|

| 1 | 50/50/0 | 6.0 | 1.3 | 1.0 | 13.2 | 0.07 |

| 2 | 50/50/15 | 5.7 | 1.3 | 1.1 | 14.3 | 0.07 |

| 3 | 50/50/30 | 5.3 | 1.2 | 1.1 | 15.2 | 0.07 |

| 4 | 50/50/45 | 4.3 | 1.0 | 1.1 | 17.0 | 0.07 |

| 5 | 50/50/60 | 3.3 | 0.9 | 1.0 | 17.6 | 0.10 |

| 6 | 0/0/100 | 421 | 49.5 | 1.3 | 2.3 | 0.03 |

| NBR/BIIR/EVA | Value | Tg( = Tg2)/ °C | T1/ °C | T2/ °C | (T2 − T1)/ °C |

|---|---|---|---|---|---|

| 50/50/0 | 0.4 | 0.4 | ≤−60.0 | 27.0 | ≥87.0 |

| 50/50/15 | 0.5 | 3.2 | ≤−60.0 | 25.1 | ≥85.1 |

| 50/50/30 | 0.5 | 8.9 | ≤−60.0 | 27.9 | ≥87.9 |

| 50/50/45 | 0.4 | 12.5 | ≤−60.0 | 29.5 | ≥89.5 |

| 50/50/60 | 0.3 | 11.5 | −48.6 | 21.7 | 69.4 |

| NBR/BIIR/EVA | Tensile Strength/MPa | Elongation at Break/% | Tear Strength/ kN/m |

|---|---|---|---|

| Before and after Aging/% | Before and after Aging/% | Before and after Aging/% | |

| 50/50/0 | 22.7↓ | 12.1↓ | 16.3↓ |

| 50/50/15 | 2.9↓ | 9.1↓ | 16.2↓ |

| 50/50/30 | 2.9↓ | 10.2↓ | 15.6↓ |

| 50/50/45 | 3.0↓ | 10.3↓ | 21.3↓ |

| 50/50/60 | 6.9↓ | 9.0↓ | 15.5↓ |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, T.; Zhang, Y.-W.; Kuang, D.-L.; Yang, Y.-R. Preparation and Properties of Rubber Blends for High-Damping-Isolation Bearings. Polymers 2019, 11, 1374. https://doi.org/10.3390/polym11081374

Lei T, Zhang Y-W, Kuang D-L, Yang Y-R. Preparation and Properties of Rubber Blends for High-Damping-Isolation Bearings. Polymers. 2019; 11(8):1374. https://doi.org/10.3390/polym11081374

Chicago/Turabian StyleLei, Tuo, Yong-Wang Zhang, Dong-Liang Kuang, and Yong-Rui Yang. 2019. "Preparation and Properties of Rubber Blends for High-Damping-Isolation Bearings" Polymers 11, no. 8: 1374. https://doi.org/10.3390/polym11081374

APA StyleLei, T., Zhang, Y.-W., Kuang, D.-L., & Yang, Y.-R. (2019). Preparation and Properties of Rubber Blends for High-Damping-Isolation Bearings. Polymers, 11(8), 1374. https://doi.org/10.3390/polym11081374