A Multilayer Emitter Close to Ideal Solar Reflectance for Efficient Daytime Radiative Cooling

Abstract

1. Introduction

2. Materials and Methods

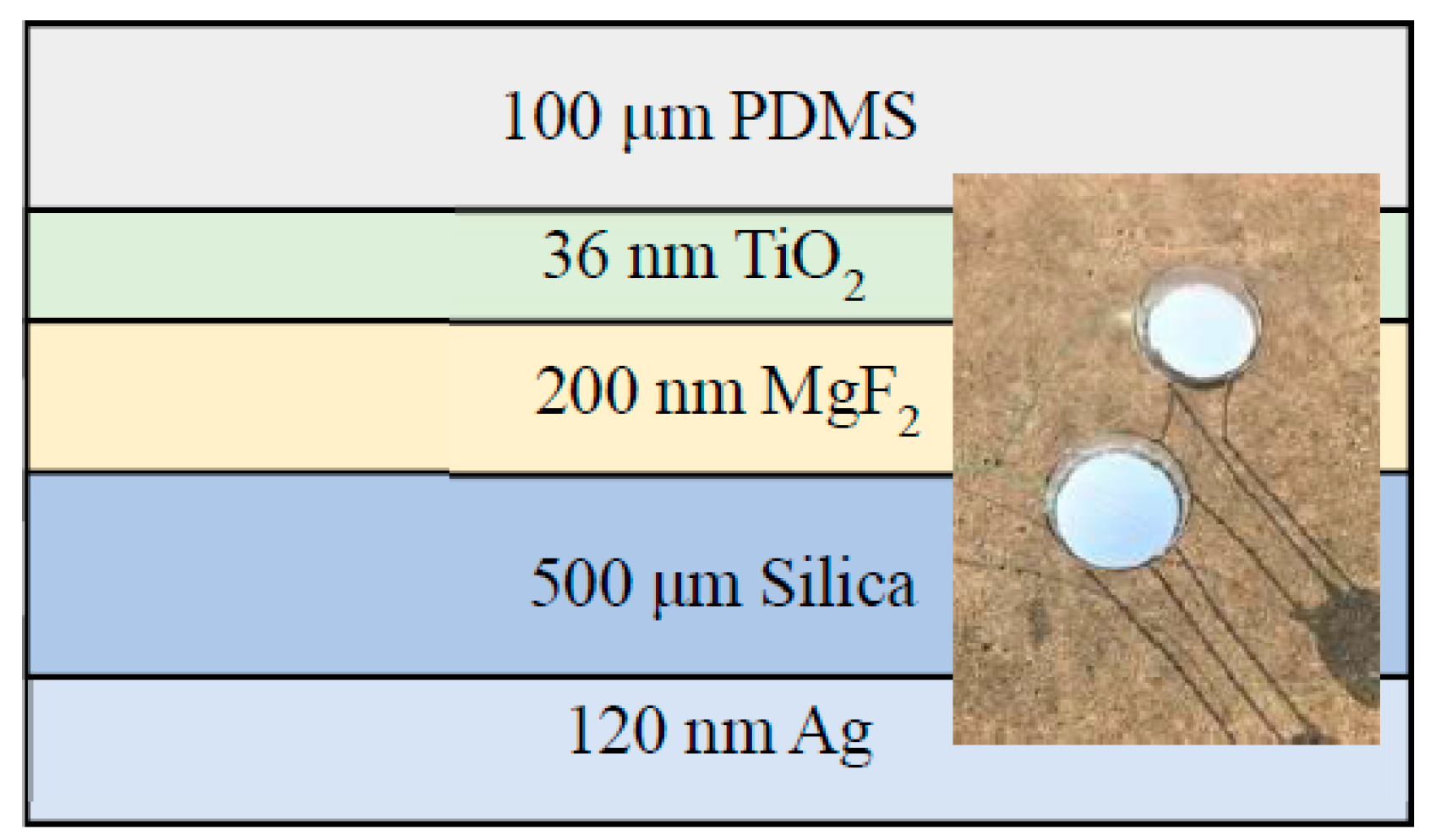

Sample Design and Preparation

3. Results and Discussion

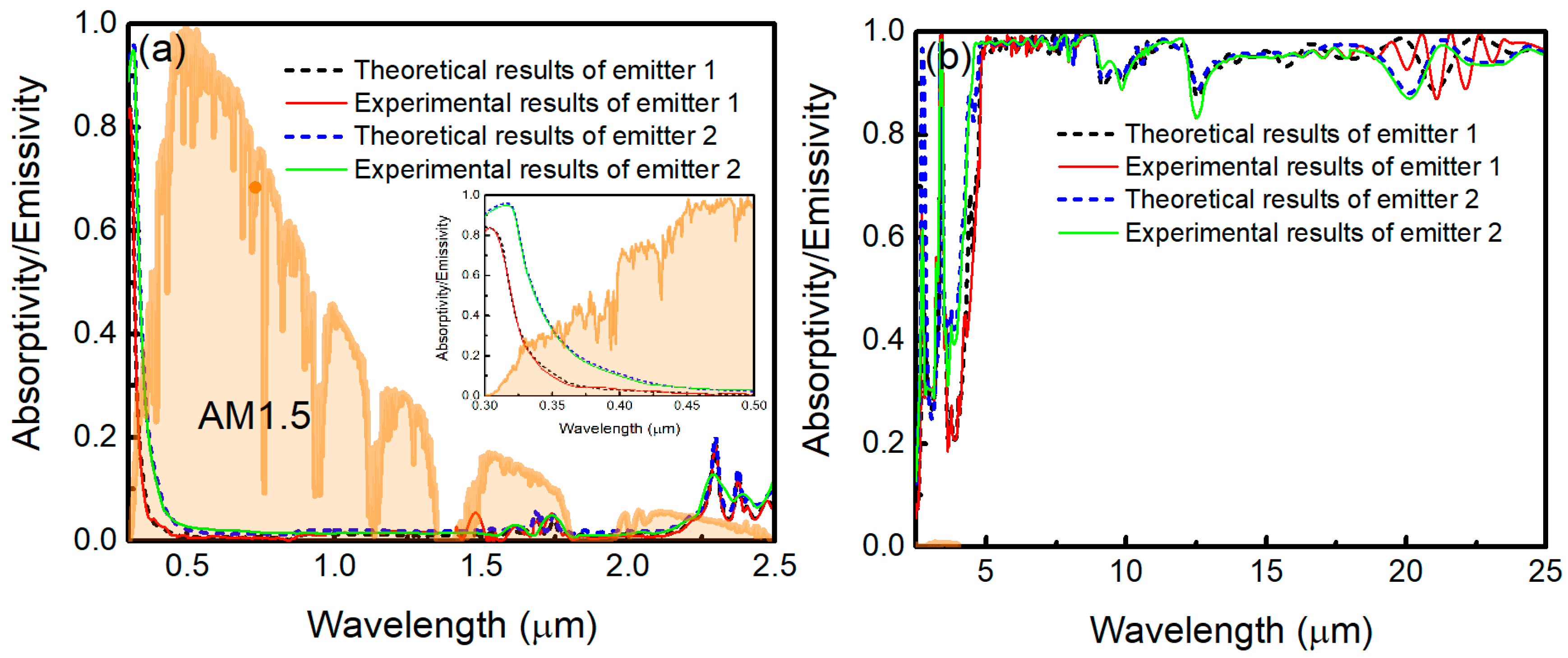

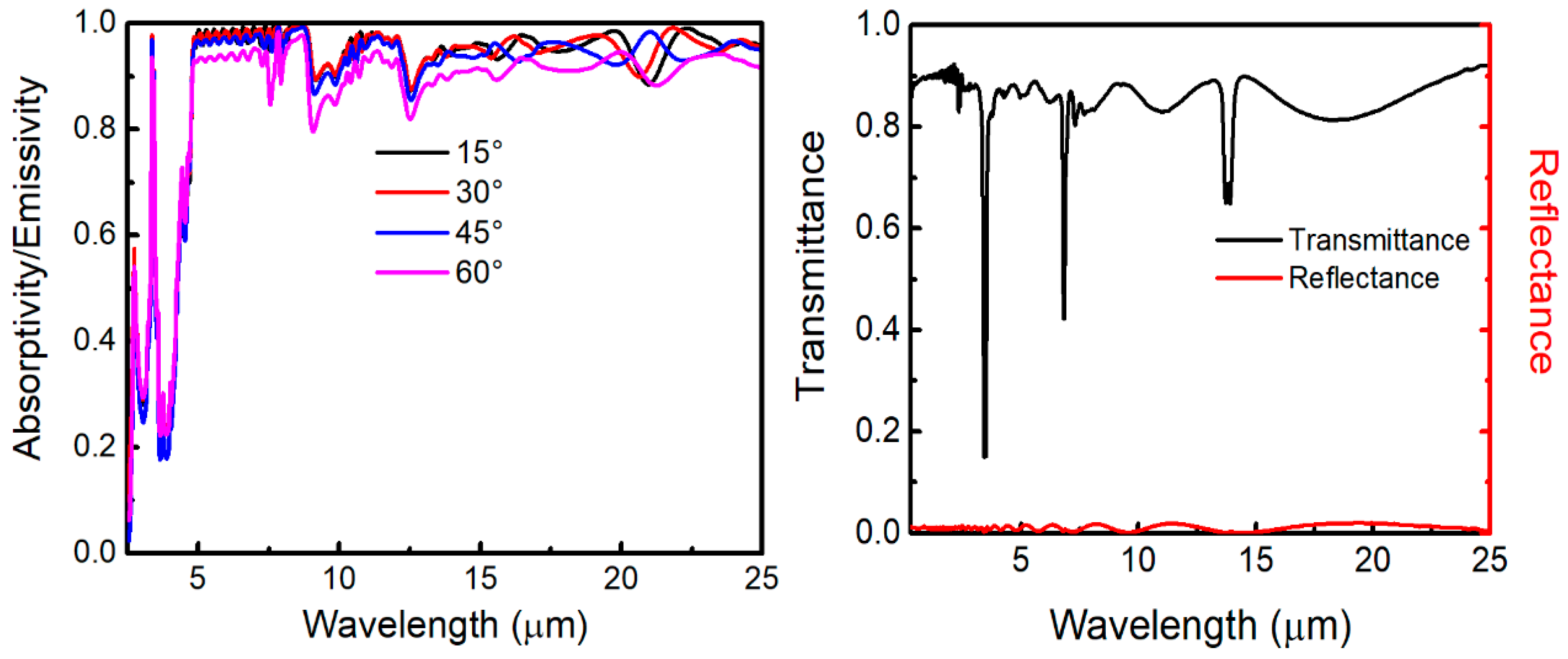

3.1. Spectroscopic Performance

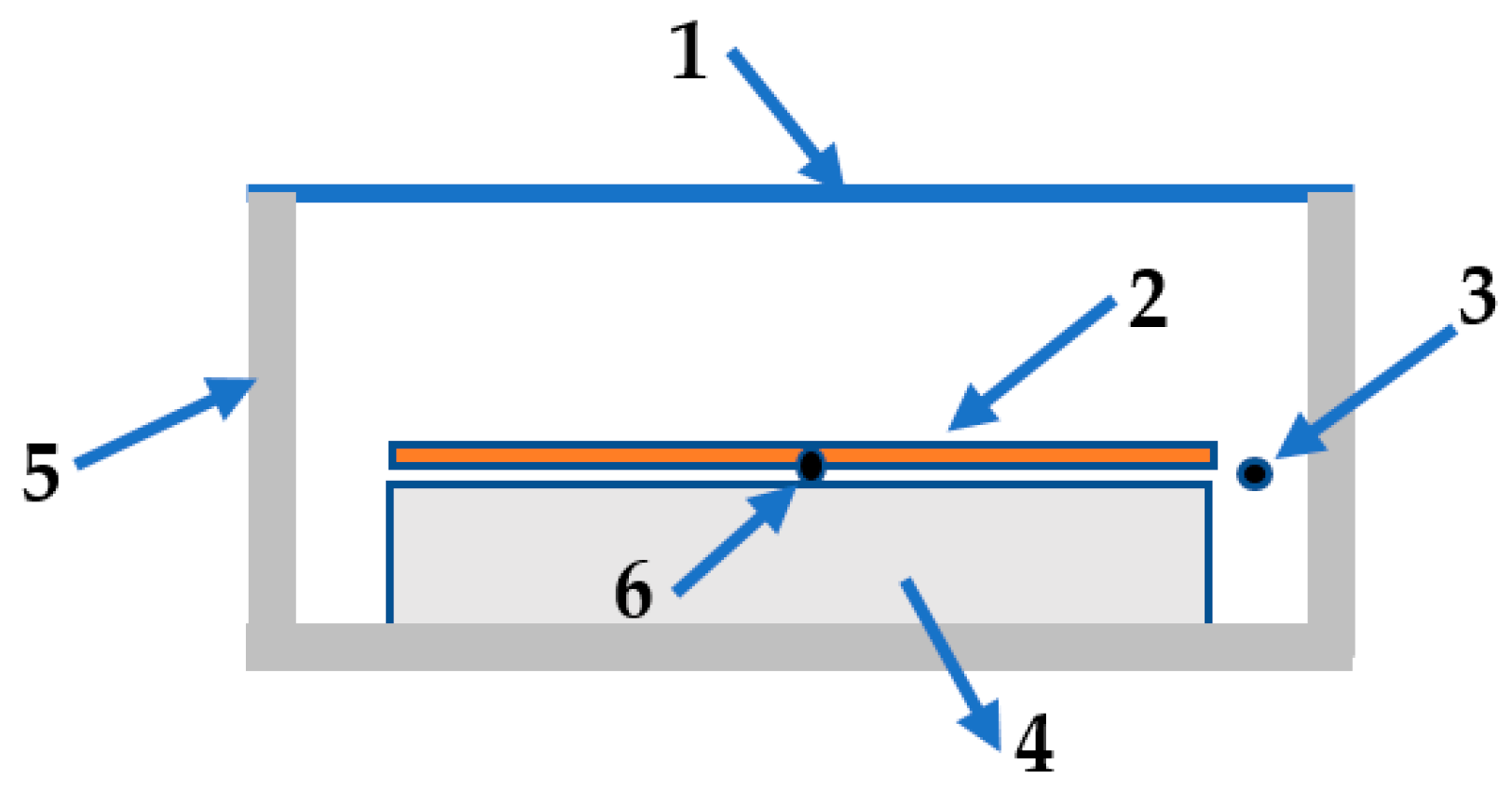

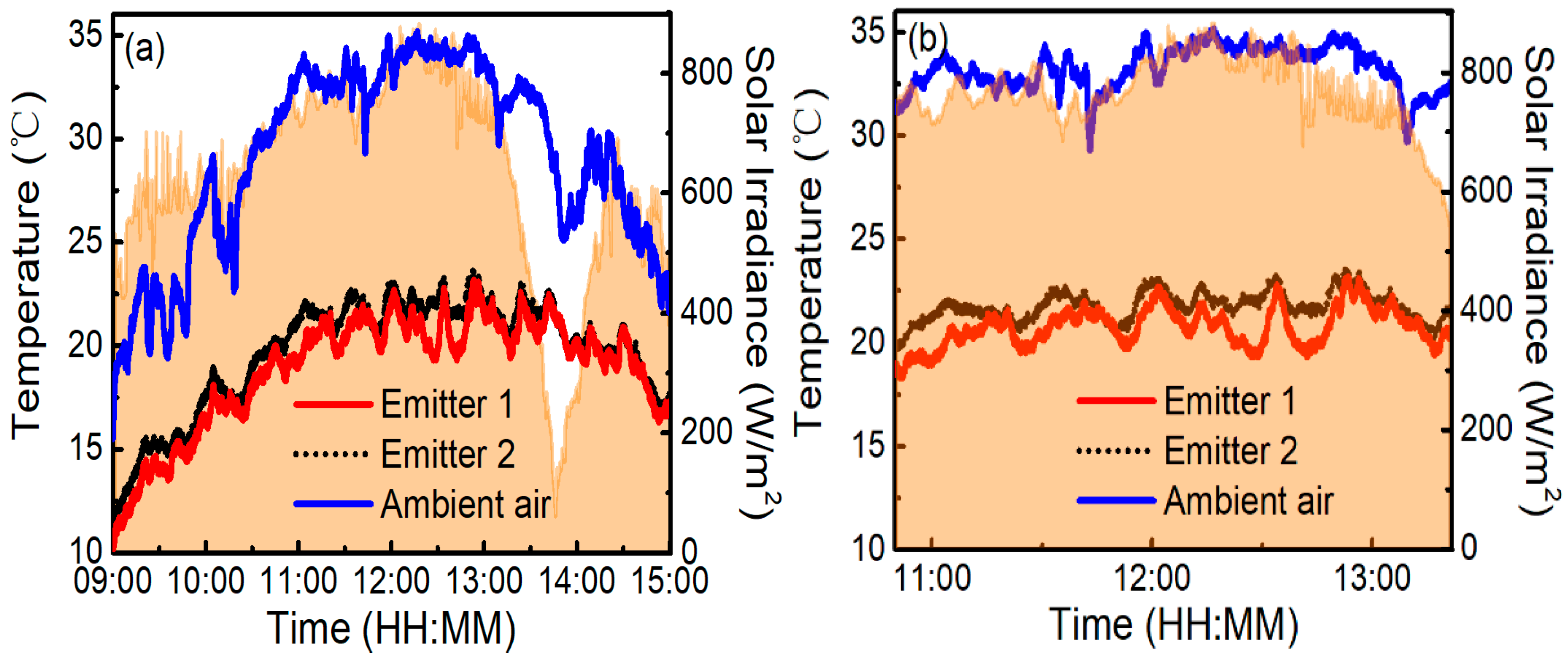

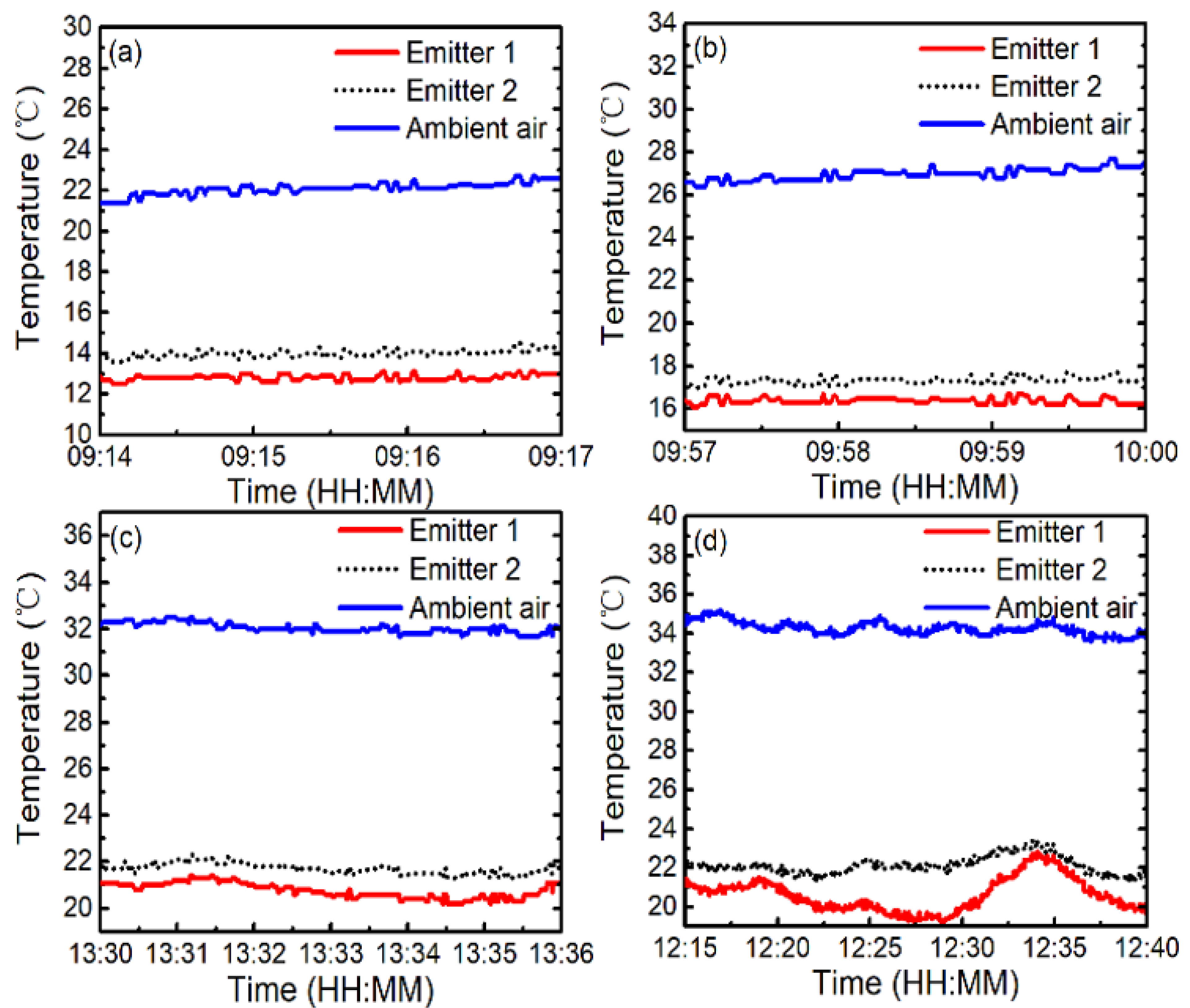

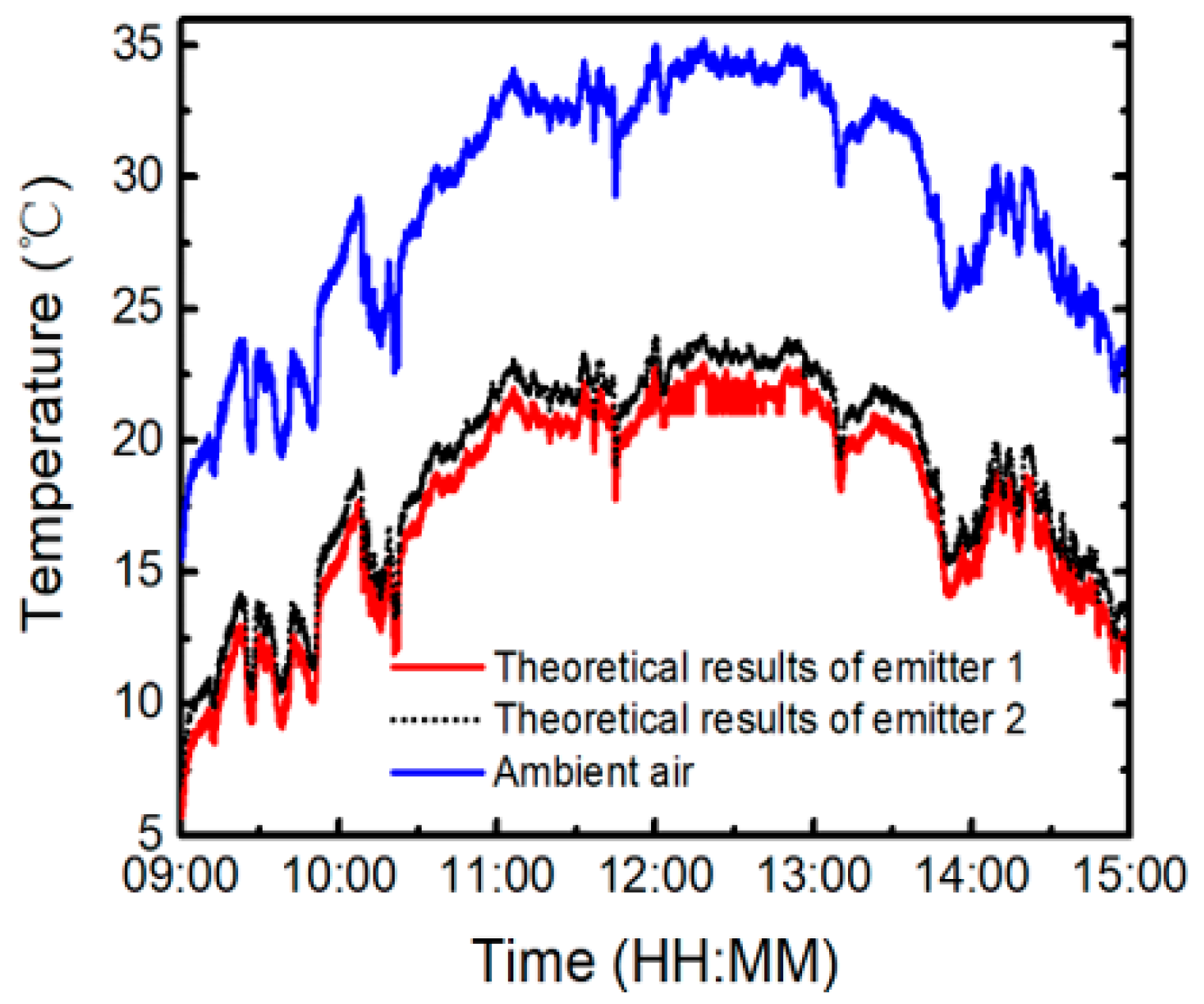

3.2. On-Site Measurements

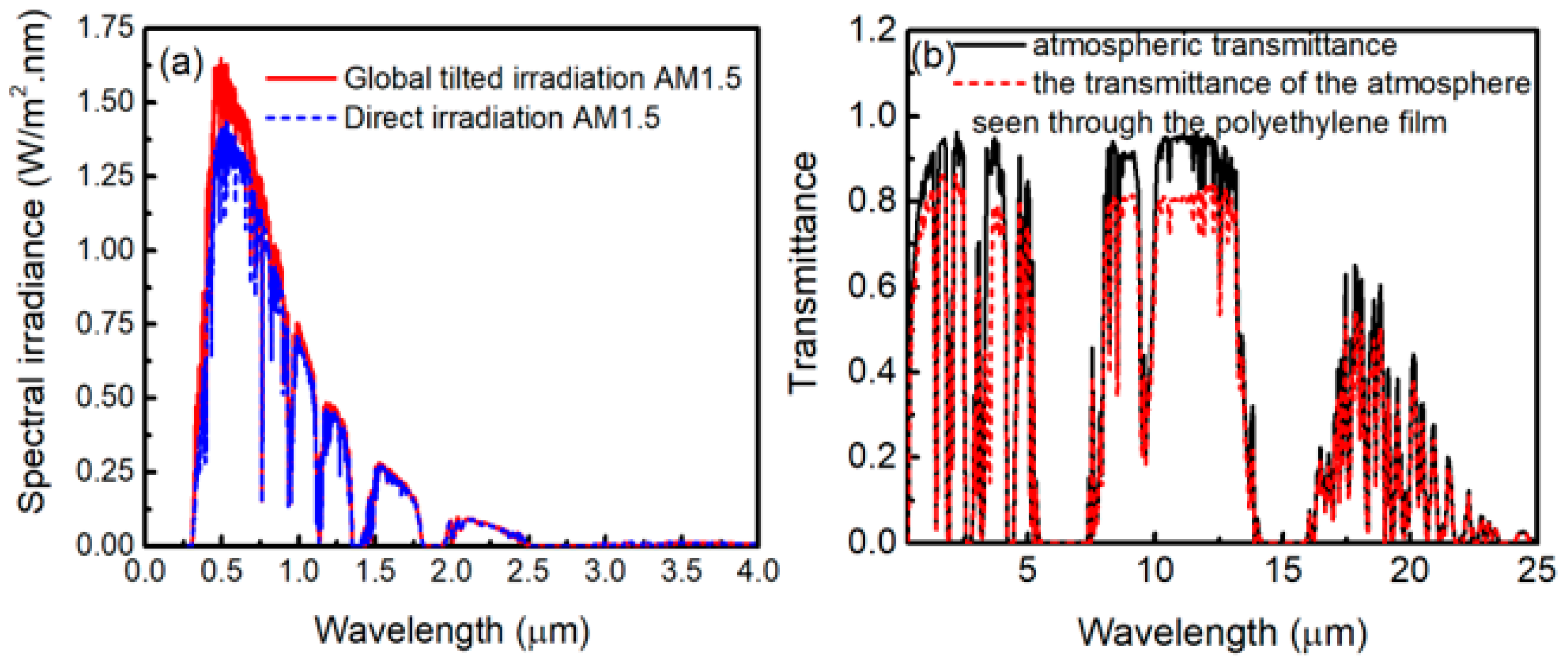

3.3. Solar Irradiation and Atmospheric Transmittance

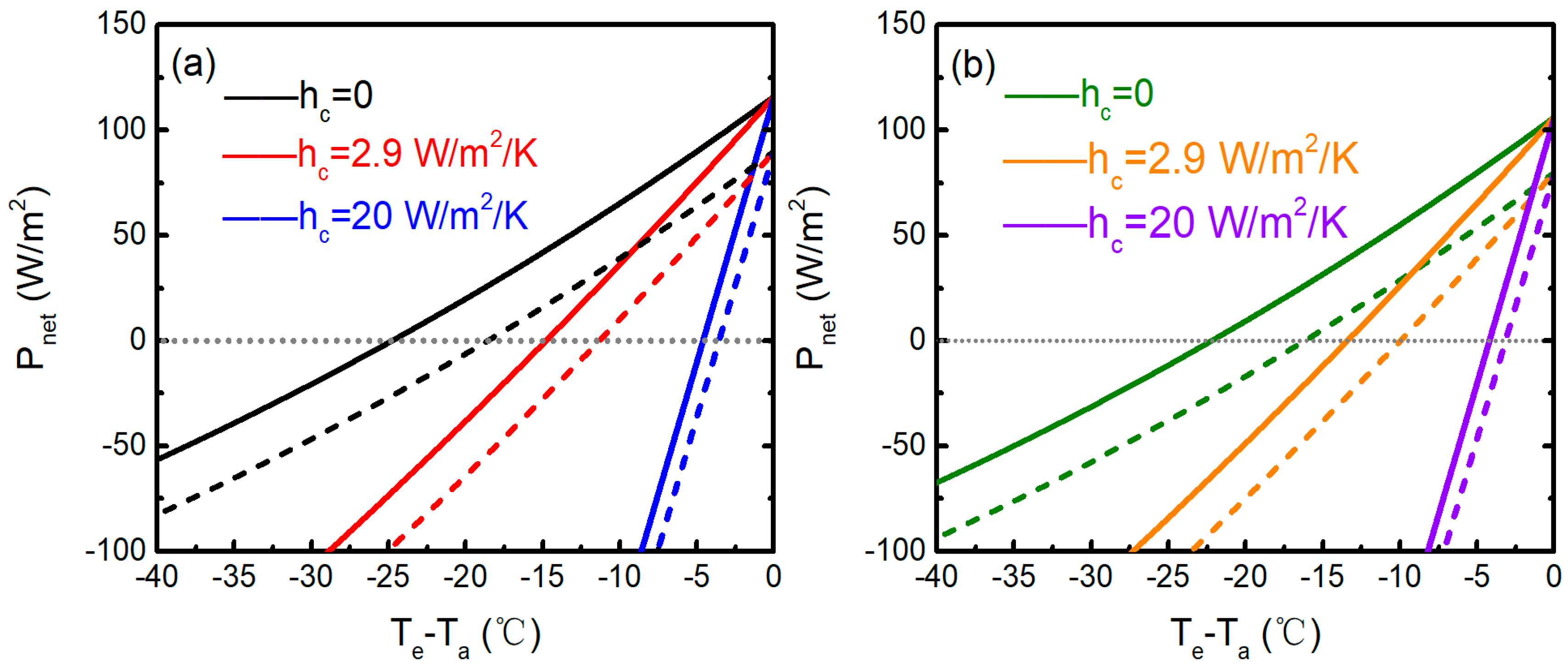

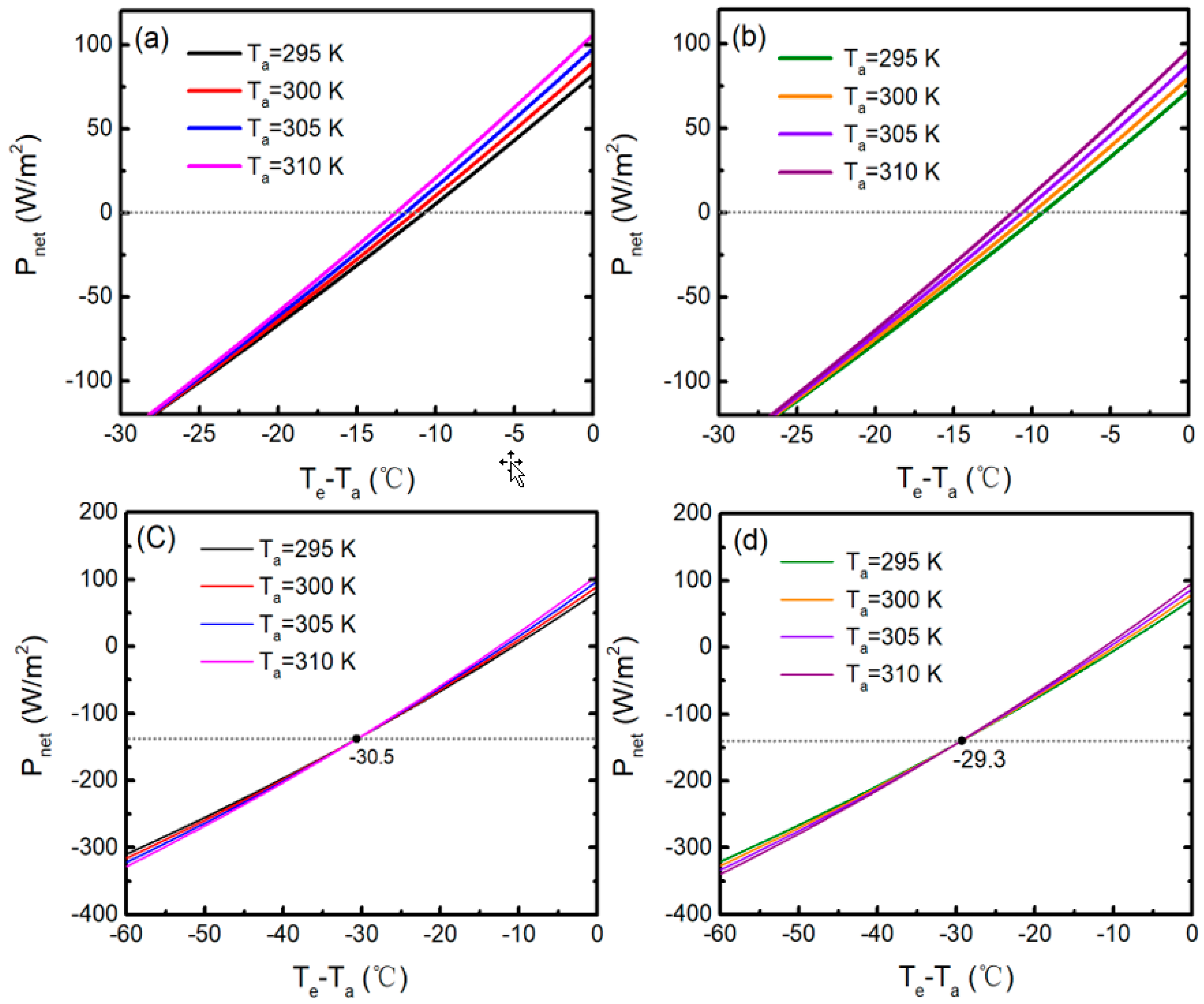

3.4. Theoretical Cooling Performance and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bahadori, M.N. Passive Cooling Systems in Iranian Architecture. Sci. Am. 1978, 238, 144–154. [Google Scholar] [CrossRef]

- Hossain, M.M.; Gu, M. Radiative Cooling: Principles, Progress, and Potentials. Adv. Sci. 2016, 3, 1500360. [Google Scholar] [CrossRef] [PubMed]

- Granqvist, C.; Hjortsberg, A. Radiative cooling to low temperatures: General considerations and application to selectively emitting SiO films. J. Appl. Phys. 1981, 52, 4205–4220. [Google Scholar] [CrossRef]

- Gentle, A.R.; Smith, G.B. A Subambient Open Roof Surface under the Mid-Summer Sun. Adv. Sci. 2015, 2, 1500119. [Google Scholar] [CrossRef] [PubMed]

- Zhai, Y.; Ma, Y.; David, S.N.; Zhao, D.; Lou, R.; Tan, G.; Yang, R.; Yin, X. Scalable-manufactured randomized glass-polymer hybrid metamaterial for daytime radiative cooling. Science 2017, 355, 1062–1066. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Ruan, X. Nanoparticle embedded double-layer coating for daytime radiative cooling. Int. J. Heat Mass Transf. 2017, 104, 890–896. [Google Scholar] [CrossRef]

- Gentle, A.R.; Smith, G.B. Radiative Heat Pumping from the Earth Using Surface Phonon Resonant Nanoparticles. Nano Lett. 2010, 10, 373–379. [Google Scholar] [CrossRef] [PubMed]

- Bao, H.; Yan, C.; Wang, B.; Fang, X.; Zhao, C.Y.; Ruan, X. Double-layer nanoparticle-based coatings for efficient terrestrial radiative cooling. Sol. Energy Mater. Sol. Cells 2017, 168, 78–84. [Google Scholar] [CrossRef]

- Atiganyanun, S.; Plumley, J.B.; Han, S.J.; Hsu, K.; Cytrynbaum, J.; Peng, T.L.; Han, S.M.; Han, S.E. Effective Radiative Cooling by Paint-Format Microsphere-Based Photonic Random Media. ACS Photonics 2018, 5, 1181–1187. [Google Scholar] [CrossRef]

- Lin, S.Y.; Fleming, J.G.; El-Kady, I. Three-dimensional photonic-crystal emission through thermal excitation. Opt. Lett. 2003, 28, 1909–1911. [Google Scholar] [CrossRef]

- Zhu, L.; Raman, A.; Fan, S. Color-preserving daytime radiative cooling. Appl. Phys. Lett. 2013, 103, 223902. [Google Scholar] [CrossRef]

- Rephaeli, E.; Raman, A.; Fan, S. Ultrabroadband Photonic Structures to Achieve High-Performance Daytime Radiative Cooling. Nano Lett. 2013, 13, 1457–1461. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Raman, A.; Wang, K.X.; Anoma, M.A.; Fan, S. Radiative cooling of solar cells. Optica 2014, 1, 32–38. [Google Scholar] [CrossRef]

- Hossain, M.M.; Jia, B.; Gu, M. A Metamaterial Emitter for Highly Efficient Radiative Cooling. Adv. Opt. Mater. 2015, 3, 1047–1051. [Google Scholar] [CrossRef]

- El-Kady, I.; Farfan, G.B.; Rammohan, R.; Taha, M.R. Photonic crystal high-efficiency multispectral thermal emitters. Appl. Phys. Lett. 2008, 93, 153501. [Google Scholar] [CrossRef]

- Li, W.; Fan, S. Nanophotonic control of thermal radiation for energy applications [Invited]. Opt. Express 2018, 26, 15995–16021. [Google Scholar] [CrossRef] [PubMed]

- Granqvist, C.G. Radiative heating and cooling with spectrally selective surfaces. Appl. Opt. 1981, 20, 2606–2615. [Google Scholar] [CrossRef]

- Zeyghami, M.; Goswami, D.Y.; Stefanakos, E. A review of clear sky radiative cooling developments and applications in renewable power systems and passive building cooling. Sol. Energy Mater. Sol. Cells 2018, 178, 115–128. [Google Scholar] [CrossRef]

- Vall, S.; Castell, A. Radiative cooling as low-grade energy source: A literature review. Renew. Sustain. Energy Rev. 2017, 77, 803–820. [Google Scholar] [CrossRef]

- Sun, X.; Sun, Y.; Zhou, Z.; Alam, M.A.; Bermel, P. Radiative sky cooling: Fundamental physics, materials, structures, and applications. Nanophotonics 2017, 6, 997–1015. [Google Scholar] [CrossRef]

- Zhao, D.; Aili, A.; Zhai, Y.; Xu, S.; Tan, G.; Yin, X.; Yang, R. Radiative sky cooling: Fundamental principles, materials, and applications. Appl. Phys. Rev. 2019, 6, 021306. [Google Scholar] [CrossRef]

- Raman, A.P.; Anoma, M.A.; Zhu, L.; Rephaeli, E.; Fan, S. Passive radiative cooling below ambient air temperature under direct sunlight. Nature 2014, 515, 540–544. [Google Scholar] [CrossRef]

- Kou, J.L.; Jurado, Z.; Chen, Z.; Fan, S.; Minnich, A.J. Daytime Radiative Cooling Using Near-Black Infrared Emitters. ACS Photonics 2017, 4, 626–630. [Google Scholar] [CrossRef]

- Chen, Z.; Zhu, L.; Raman, A.; Fan, S. Radiative cooling to deep sub-freezing temperatures through a 24-h day–night cycle. Nat. Commun. 2016, 7, 13729. [Google Scholar] [CrossRef]

- Mastai, Y.; Diamant, Y.; Aruna, S.T.; Zaban, A. TiO2 Nanocrystalline Pigmented Polyethylene Foils for Radiative Cooling Applications: Synthesis and Characterization. Langmuir 2001, 17, 7118–7123. [Google Scholar] [CrossRef]

- Diatezua, D.M.; Thiry, P.A.; Dereux, A.; Caudano, R. Silicon oxynitride multilayers as spectrally selective material for passive radiative cooling applications. Sol. Energy Mater. Sol. Cells 1996, 40, 253–259. [Google Scholar] [CrossRef]

- Granqvist, C.G.; Hjortsberg, A. Surfaces for radiative cooling: Silicon monoxide films on aluminum. Appl. Phys. Lett. 1980, 36, 139–141. [Google Scholar] [CrossRef]

- Tikhonravov, A.V.; Trubetskov, M.K.; DeBell, G.W. Application of the needle optimization technique to the design of optical coatings. Appl. Opt. 1996, 35, 5493–5508. [Google Scholar] [CrossRef]

- Schneider, F.; Draheim, J.; Kamberger, R.; Wallrabe, U. Process and material properties of polydimethylsiloxane (PDMS) for Optical MEMS. Sens. Actuators A Phys. 2009, 151, 95–99. [Google Scholar] [CrossRef]

- Srinivasan, A.; Czapla, B.; Mayo, J.; Narayanaswamy, A. Infrared dielectric function of polydimethylsilox-ane and selective emission behavior. Appl. Phys. Lett. 2016, 109, 061905. [Google Scholar] [CrossRef]

- Reference Solar Spectral Irradiance: Air Mass 1.5. Available online: http://rredc.nrel.gov/solar/spectra/am1.5 (accessed on 23 October 2018).

- Fu, Y.; Yang, J.; Su, Y.S.; Du, W.; Ma, Y.G. Daytime passive radiative cooler using porous alumina. Sol. Energy Mat. Sol. Cells Sol. Energy 2019, 191, 50–54. [Google Scholar] [CrossRef]

- Eriksson, T.S.; Granqvist, C.G. Radiative cooling computed for model atmospheres. Appl. Opt. 1982, 21, 4381–4388. [Google Scholar] [CrossRef]

- Berk, A.; Anderson, G.P.; Acharya, P.K.; Bernstein, L.S.; Muratov, L.; Lee, J.; Lockwood, R.B. Modtran5: 2006 update. Proc. SPIE 2006, 6233, 62331F. [Google Scholar]

- Catalanotti, S.; Cuomo, V.; Piro, G.; Ruggi, D.; Silvestrini, V.; Troise, G. The radiative cooling of selective surfaces. Sol. Energy 1975, 17, 83–89. [Google Scholar] [CrossRef]

| 280 | −8.9 | 62.0 | −7.4 | 51.7 |

| 285 | −9.5 | 68.4 | −8.0 | 58.2 |

| 290 | −10.1 | 75.2 | −8.7 | 65.1 |

| 295 | −10.7 | 82.3 | −9.3 | 72.3 |

| 300 | −11.3 | 89.9 | −10.0 | 79.9 |

| 305 | −11.9 | 97.8 | −10.6 | 87.9 |

| 310 | −12.7 | 106.1 | −11.3 | 96.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Wang, D.; Fang, C.; He, P.; Ye, Y.-H. A Multilayer Emitter Close to Ideal Solar Reflectance for Efficient Daytime Radiative Cooling. Polymers 2019, 11, 1203. https://doi.org/10.3390/polym11071203

Zhu Y, Wang D, Fang C, He P, Ye Y-H. A Multilayer Emitter Close to Ideal Solar Reflectance for Efficient Daytime Radiative Cooling. Polymers. 2019; 11(7):1203. https://doi.org/10.3390/polym11071203

Chicago/Turabian StyleZhu, Yeqing, Dong Wang, Cheng Fang, Ping He, and Yong-Hong Ye. 2019. "A Multilayer Emitter Close to Ideal Solar Reflectance for Efficient Daytime Radiative Cooling" Polymers 11, no. 7: 1203. https://doi.org/10.3390/polym11071203

APA StyleZhu, Y., Wang, D., Fang, C., He, P., & Ye, Y.-H. (2019). A Multilayer Emitter Close to Ideal Solar Reflectance for Efficient Daytime Radiative Cooling. Polymers, 11(7), 1203. https://doi.org/10.3390/polym11071203