Mechanical and Static Stab Resistant Properties of Hybrid-Fabric Fibrous Planks: Manufacturing Process of Nonwoven Fabrics Made of Recycled Fibers

Abstract

1. Introduction

2. Materials and Methods

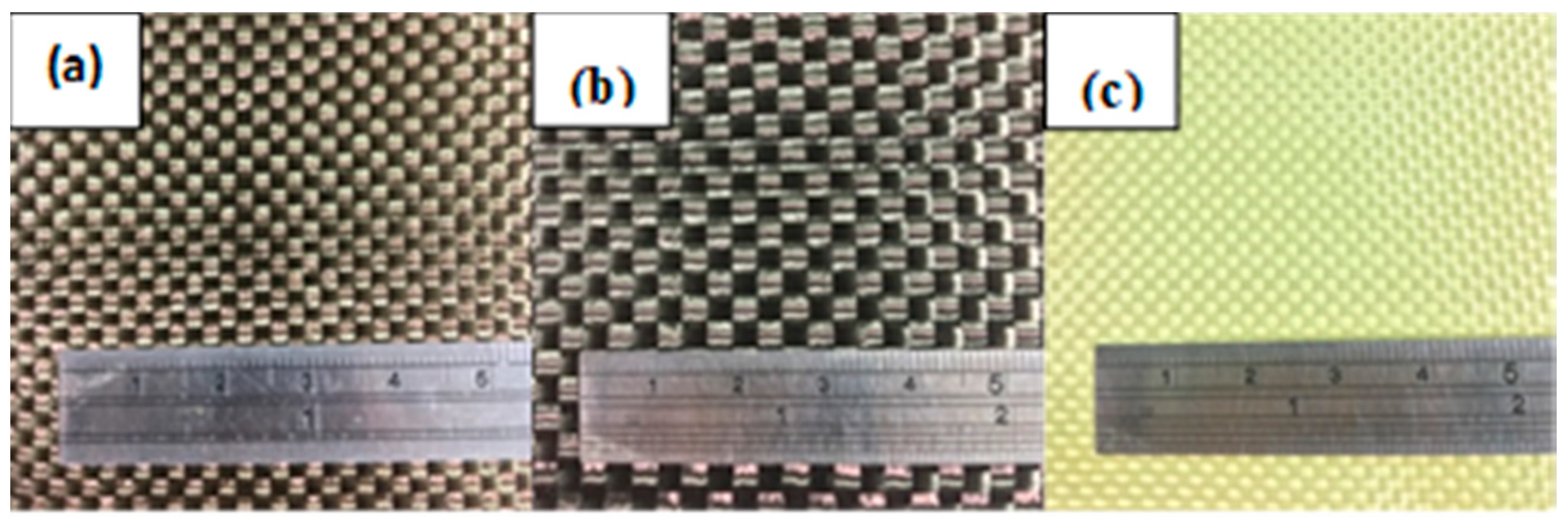

2.1. Materials

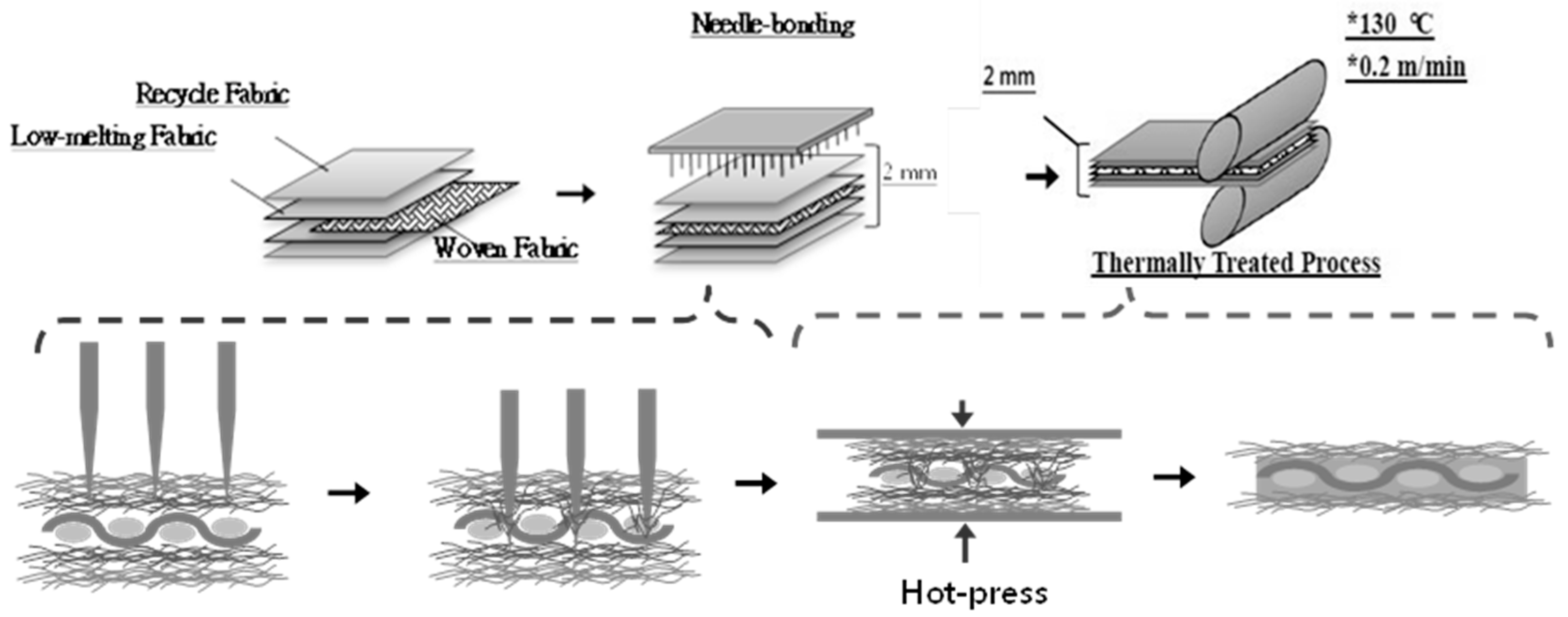

2.2. Method

2.3. Tests

2.3.1. Air Permeability

2.3.2. Tensile Strength

2.3.3. Tearing Strength

2.3.4. Bursting Strength

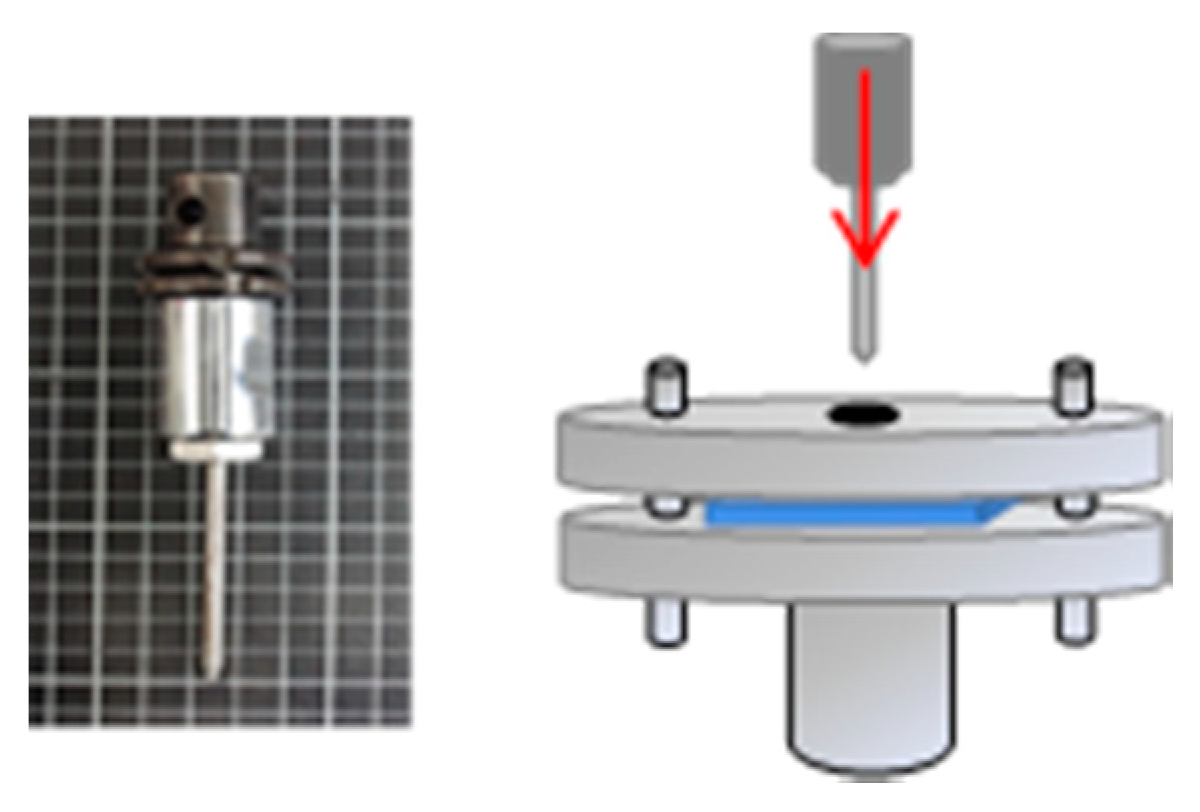

2.3.5. Static-Stab Resistance Test

3. Results

3.1. Mechanical Property of Recycle High Strength PET Matrices

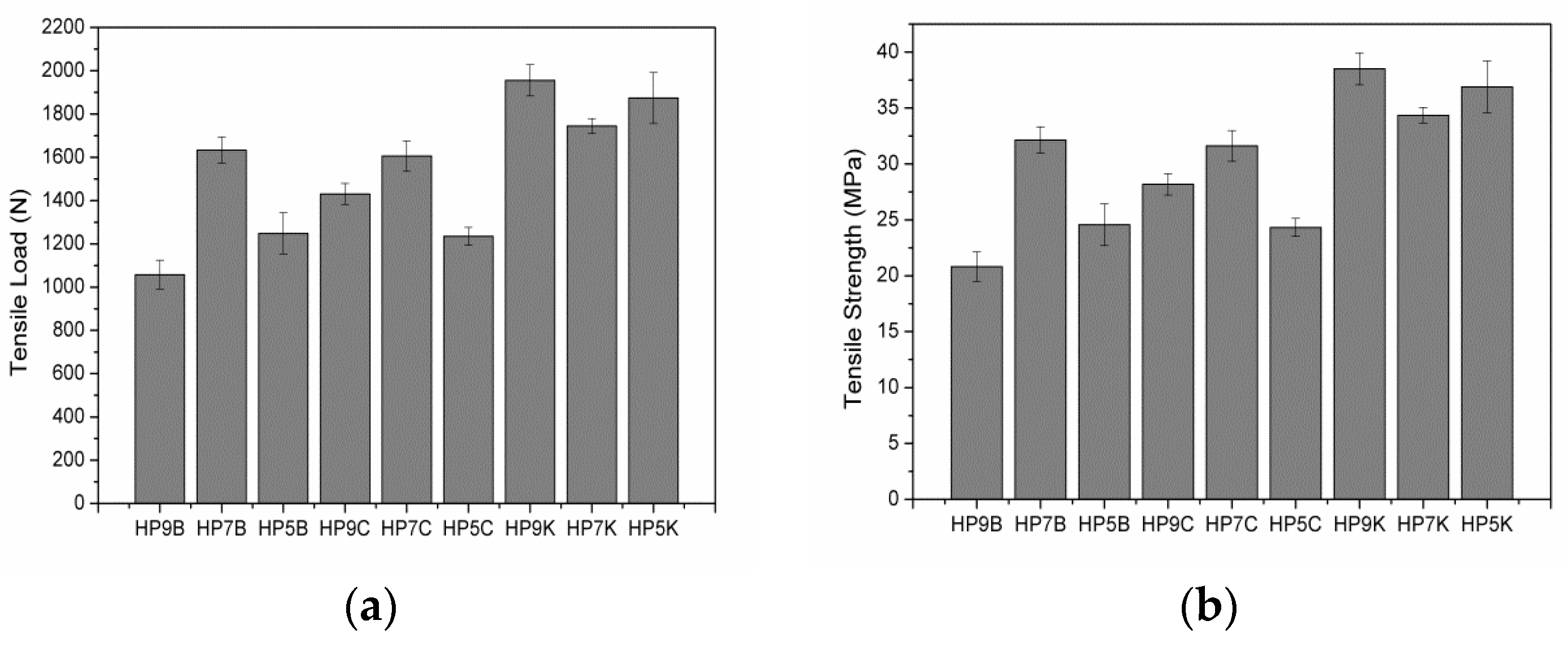

3.2. Tensile Strength of Hybrid-Fabric Fibrous Planks

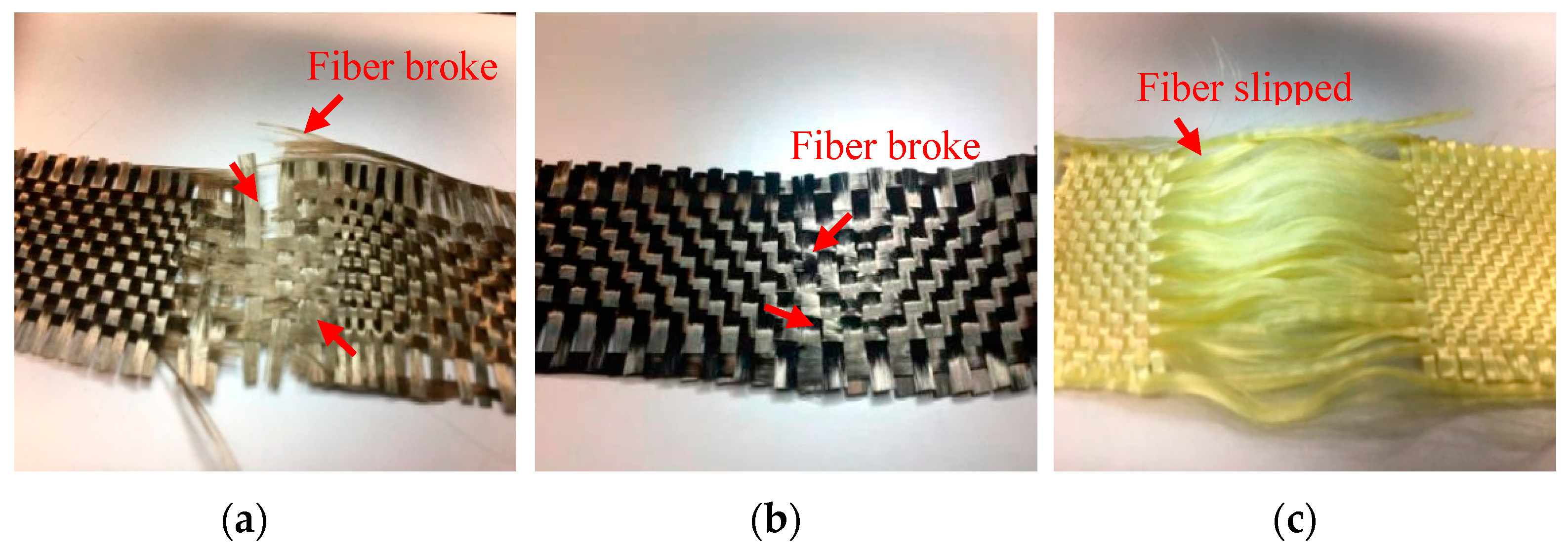

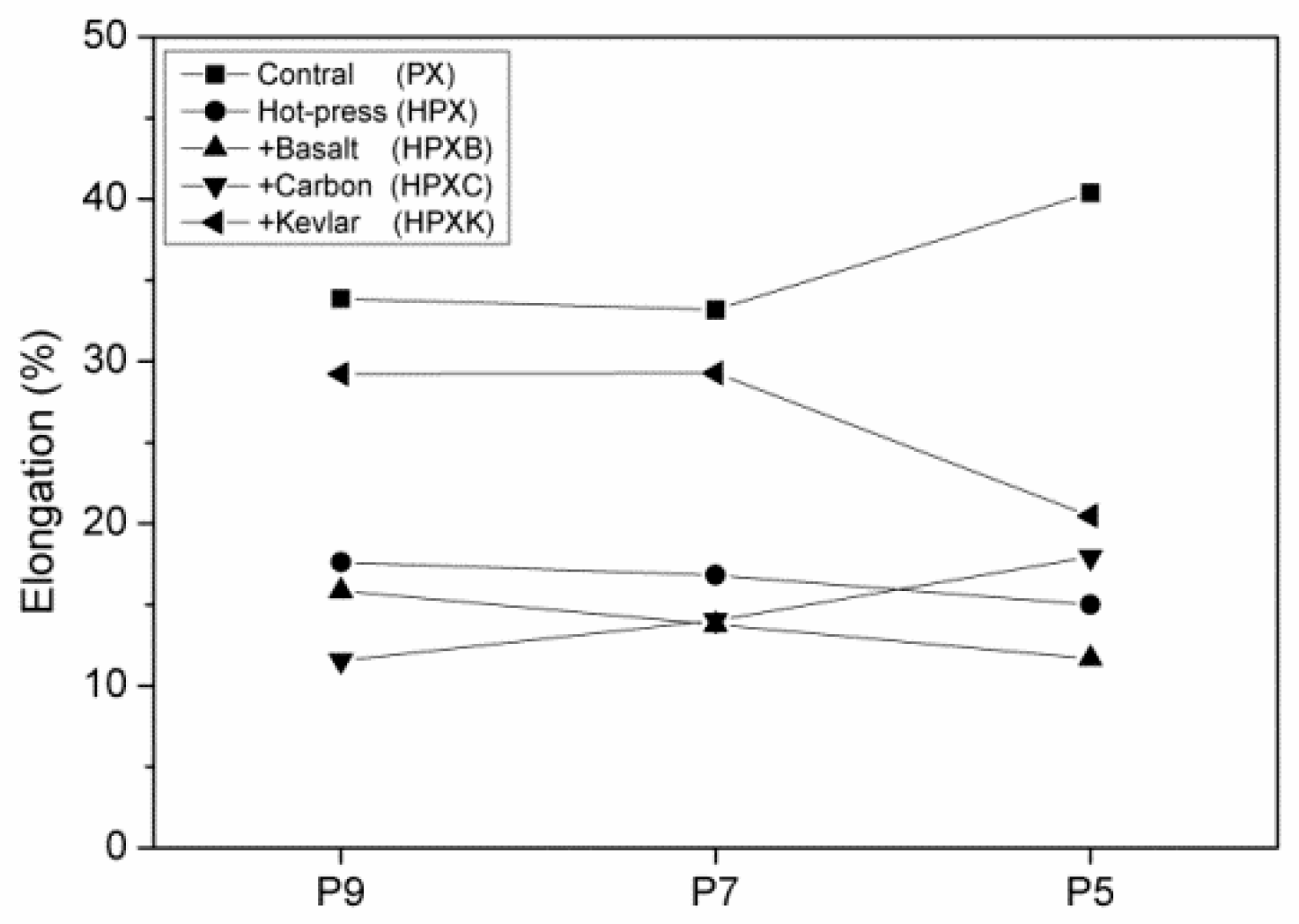

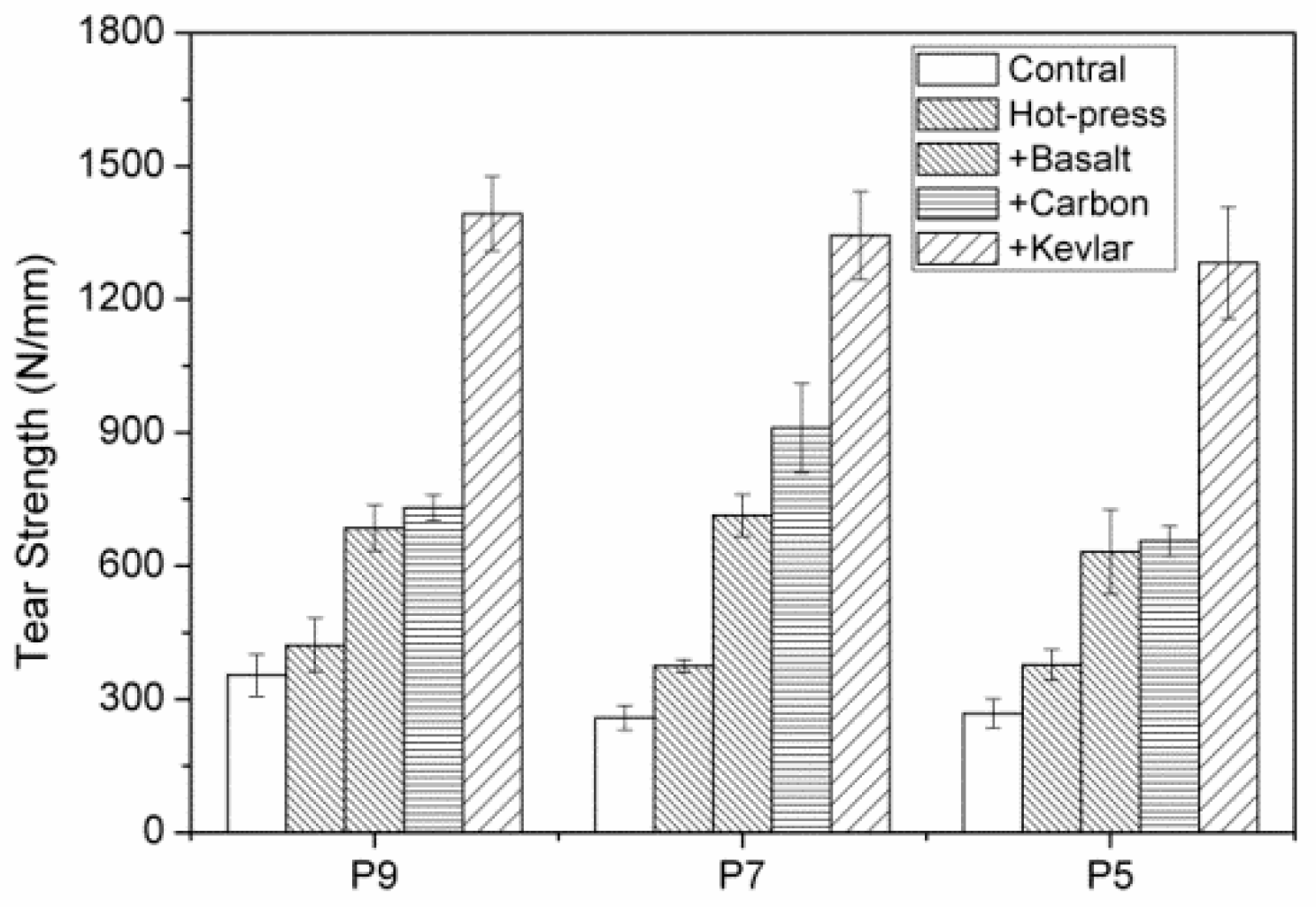

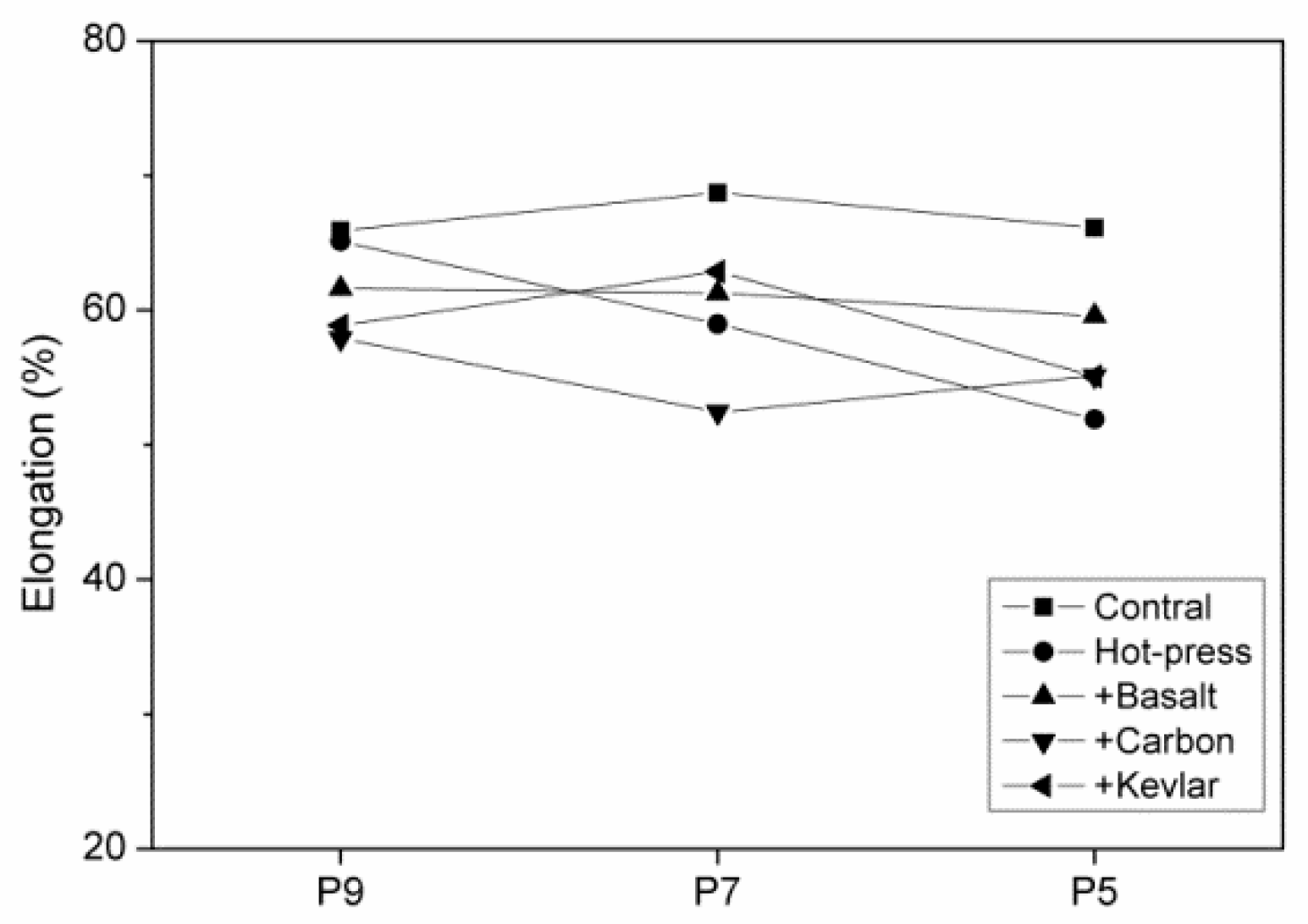

3.3. Tearing Strength of Hybrid-Fabric Fibrous Planks

3.4. Bursting Strength of Hybrid-Fabric Fibrous Planks

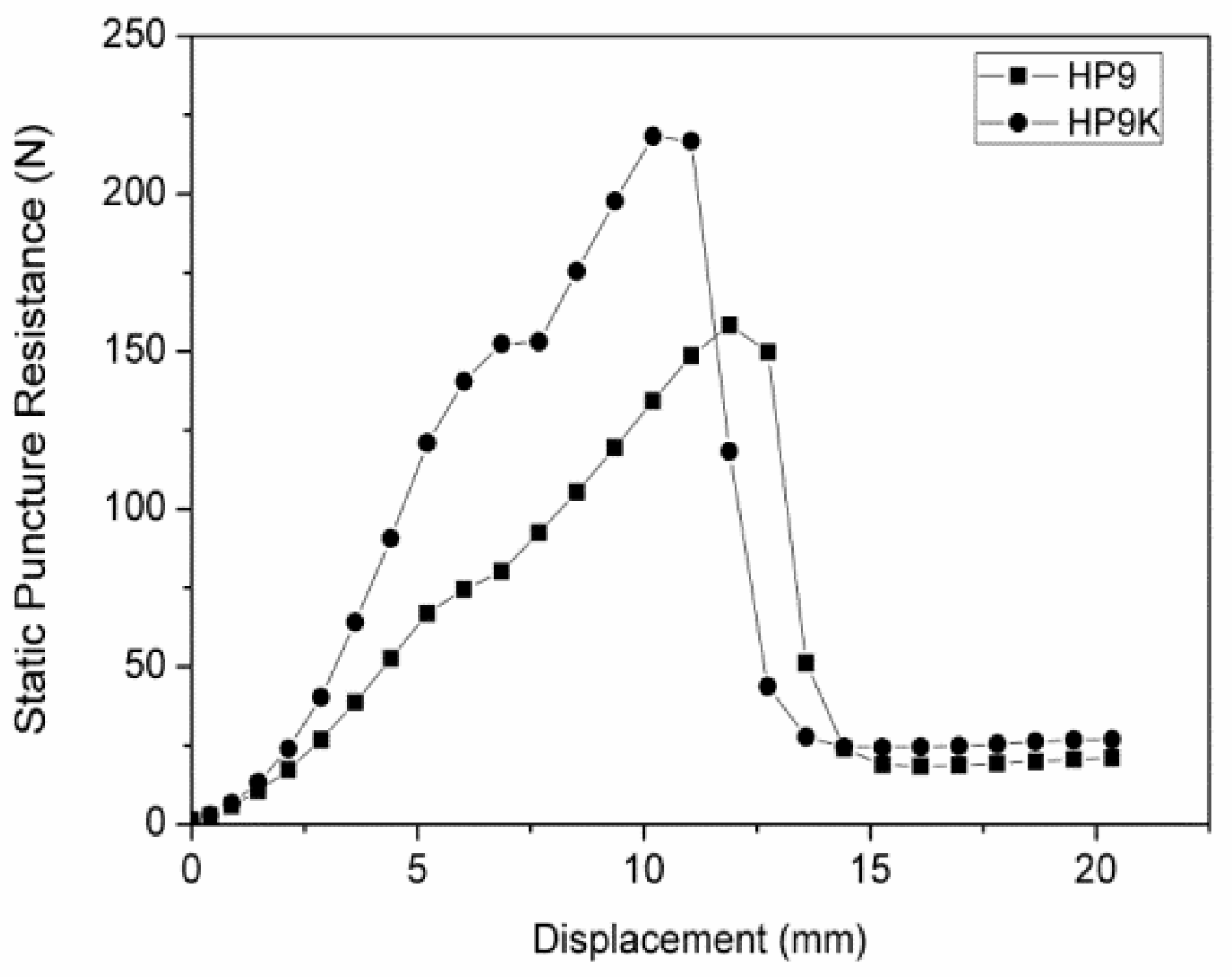

3.5. Static Stab-Resistance of Hybrid-Fabric Fibrous Planks

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yasin, S.; Behary, N.; Curti, M.; Rovero, G. Global consumption of flame retardants and related environmental concerns: A study on possible mechanical recycling of flame retardant textiles. Fibers 2016, 4, 16. [Google Scholar] [CrossRef]

- Mayo, J.B., Jr.; Wetzel, E.D.; Hosur, M.V.; Jeelani, S. Stab and puncture characterization of thermoplastic-impregnated aramid fabrics. Int. J. Impact Eng. 2009, 36, 1095–1105. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Kadivar, N.; Sajjadi, A. Analytical assessment of woven fabrics under vertical stabbing—The role of protective clothing. Forensic Sci. Int. 2016, 259, 224–233. [Google Scholar] [CrossRef] [PubMed]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Yang, Y.X.; Boom, R.; Irion, B.; Heerden, D.V.; Kuiper, P.; Wit, H.D. Recycling of composite materials. Chem. Eng. Process. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Sidhu, S.; Gullett, B.; Striebich, R.; Klosterman, J.; Contreras, J.; DeVito, M. Endocrine disrupting chemical emissions from combustion sources: Diesel particulate emissions and domestic waste open burn emissions. Atmos. Environ. 2005, 39, 801–811. [Google Scholar] [CrossRef]

- Kamal, A.; Ali, U.; Ramay, M.I.; Younis, S.M.Z.; Sumbal, S.; Malik, R.N.; Rashid, A. Principle component analysis of flue gas exhaust and health risk estimates for the population around a functional incinerator in the vicinity of Rawalpindi Pakistan. Arab. J. Chem. 2017, 10, S2302–S2306. [Google Scholar] [CrossRef]

- Pope, C.A., III; Dockery, D.W. Health effects of fine particulate air pollution: lines that connect. J. Air Waste Manag. Assoc. 2006, 56, 709–742. [Google Scholar] [CrossRef]

- Hu, Y.; Du, C.; Leu, S.Y.; Jing, H.; Li, X.; Lin, C.S.K. Valorisation of textile waste by fungal solid state fermentation: An example of circular waste-based biorefinery. Resour. Conserv. Recycl. 2018, 129, 27–35. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Godina, R.; Matias, J.C.O.; Catalão, J.P.S. Economic and environmental benefits of using textile waste for the production of thermal energy. J. Clean Prod. 2018, 171, 1353–1360. [Google Scholar] [CrossRef]

- Hadded, A.; Benltoufa, S.; Fayala, F.; Jemni, A. Thermo physical characterisation of recycled textile materials used for building insulating. J. Build. Eng. 2016, 5, 34–40. [Google Scholar] [CrossRef]

- Termonia, Y. Puncture resistance of fibrous structures. Int. J. Impact Eng. 2006, 32, 1512–1520. [Google Scholar] [CrossRef]

- Wang, Q.S.; Sun, R.J.; Tian, X.; Yao, M.; Feng, Y. Quasi-static puncture resistance behaviors of high-strength polyester fabric for soft body armor. Results Phys. 2016, 6, 554–560. [Google Scholar] [CrossRef]

- Bao, L.; Sato, S.; Morikawa, H. Improving stab-resistant textile materials with a non-woven fabric structure. J. Text. Eng. 2016, 62, 37–42. [Google Scholar] [CrossRef]

- Bao, L.; Wang, Y.L.; Baba, T.; Fukuda, Y.; Wakatsuki, K.; Morikawa, H. Development of a high-density nonwoven structure to improve the stab resistance of protective clothing material. Ind. Health 2017, 55, 1–8. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Barnes, H.A. Shear-thickening (“Dilatancy”) in suspensions of nonaggregating solid particles dispersed in Newtonian liquids. J. Rheol. 1989, 33, 329. [Google Scholar] [CrossRef]

- Egres, R.G., Jr.; Halbach, C.J.; Decker, M.J.; Wetzel, E.D.; Wagner, N.J. Stab performance of shear thickening fluid (STF)–fabric composites for body armor applications. In Proceedings of the SAMPE 2005: New Horizons for Materials and Processing Technologies, Long Beach, CA, USA, 1–5 May 2005. [Google Scholar]

- Decker, M.J.; Halbach, C.J.; Nam, C.H.; Wagner, N.J.; Wetzel, E.D. Stab resistance of shear thickening fluid (STF)-treated fabrics. Compos. Sci. Technol. 2007, 67, 565–578. [Google Scholar] [CrossRef]

- Bao, L.; Sato, S.; Wang, Y.L.; Wakatsuki, K.; Morikawa, H. Development of flexible stab-proof textiles impregnated with microscopic particles. J. Text. Eng. 2017, 63, 43–48. [Google Scholar] [CrossRef][Green Version]

- Park, H.; Branson, D.; Kim, S.; Warren, A.; Jacobson, B.; Petrova, A.; Peksoz, S.; Kamenidis, P. Effect of armor and carrying load on body balance and leg muscle function. Gait Posture 2014, 39, 430–435. [Google Scholar] [CrossRef]

- Dempsey, P.C.; Handcock, P.J.; Rehrer, N.J. Impact of police body armour and equipment on mobility. Appl. Ergon. 2013, 44, 957–961. [Google Scholar] [CrossRef]

- Yasin, S.; Sun, D.; Memon, H.; Zhu, F.; Jian, H.; Bin, Y.; Mingbo, M.; Hussain, M. Optimization of mechanical and thermal properties of iPP and LMPP blend fibres by surface response methodology. Polymers 2018, 10, 1135. [Google Scholar] [CrossRef] [PubMed]

- Hussain, M.; Zhu, F.; Yu, B.; Han, J.; Memon, H.; Yasin, S. LMPP effects on morphology, crystallization, thermal and mechanical properties of iPP/LMPP blend fibres. Fibres Text. East. Eur. 2018, 26, 26–31. [Google Scholar] [CrossRef]

- Correia, N.; Bueno, B. Effect of bituminous impregnation on nonwoven geotextiles tensile and permeability properties. Geotext. Geomembr. 2011, 29, 92–101. [Google Scholar] [CrossRef]

- Lin, M.C.; Lou, C.W.; Lin, J.Y.; Lin, T.A.; Lin, J.H. Mechanical property evaluations of flexible laminated composites reinforced by high-performance Kevlar filaments: Tensile strength, peel load, and static puncture resistance. Compos. Pt. B-Eng. 2019, 166, 139–147. [Google Scholar] [CrossRef]

- Zakriya, G.; Ramakrishnan, G. Insulation and mechanical properties of jute and hollow conjugatedpolyester reinforced nonwoven composite. Energy Build. 2018, 158, 1544–1552. [Google Scholar] [CrossRef]

- Rawal, A.; Saraswat, H. Stabilisation of soil using hybrid needlepunched nonwoven geotextiles. Geotext. Geomembr. 2011, 29, 197–200. [Google Scholar] [CrossRef]

| Reinforced Woven Fabric | Fineness | Base Weight (g/m2) | Thickness (mm) | Tensile Load (N) |

|---|---|---|---|---|

| Basalt | 2970 D | 328 | 0.31 | 118.45 |

| Carbon | 12 K | 390 | 0.60 | 164.63 |

| Kevlar | 1000 D | 180 | 0.31 | 512.23 |

| Sample | RPET Content (wt%) | LPET Content (wt%) | Reinforcing Layer | Employment of Hot Press |

|---|---|---|---|---|

| P9 | 90 | 10 | - | N |

| P7 | 70 | 30 | - | N |

| P5 | 50 | 50 | - | N |

| HP9 | 90 | 10 | - | Y |

| HP7 | 70 | 30 | - | Y |

| HP5 | 50 | 50 | - | Y |

| HP9C | 90 | 10 | Carbon | Y |

| HP7C | 70 | 30 | Carbon | Y |

| HP5C | 50 | 50 | Carbon | Y |

| HP9B | 90 | 10 | Basalt | Y |

| HP7B | 70 | 30 | Basalt | Y |

| HP5B | 50 | 50 | Basalt | Y |

| HP9K | 90 | 10 | Kevlar | Y |

| HP7K | 70 | 30 | Kevlar | Y |

| HP5K | 50 | 50 | Kevlar | Y |

| LMPET Bonding Layer | - | 100 | - | - |

| Experiment | RPET Content (wt%) | Tensile Strength, (MPa) | CV (%) | Elongation, (%) | Tearing Strength, (N/mm) | CV (%) | Elongation, (%) | Air Permeability, (cm3/cm2/s) |

|---|---|---|---|---|---|---|---|---|

| Without Hot-press | 50 (P5) | 13.3 ± 1.29 | 9.72 | 40.38 ± 1.36 | 267.9 ± 32.96 | 12.30 | 66.1 ± 7.13 | 49.3 ± 4.63 |

| 70 (P7) | 16.7 ± 1.92 | 11.48 | 33.17 ± 2.22 | 258.2 ± 27.63 | 10.70 | 68.7 ± 8.70 | 45.1 ± 3.75 | |

| 90 (P9) | 16.0 ± 1.32 | 8.26 | 33.85 ± 2.40 | 354.4 ± 47.32 | 13.35 | 65.9 ± 9.42 | 40.1 ± 2.71 | |

| Hot-press | 50 (P5) | 13.8 ± 0.67 | 4.3 | 15.02 ± 1.04 | 376.7 ± 34.75 | 9.22 | 51.9 ± 7.09 | 28.4 ± 2.98 |

| 70 (P7) | 15.6 ± 0.80 | 5.79 | 16.82 ± 2.03 | 375.1 ± 14.68 | 3.91 | 59.0 ± 5.84 | 20.5 ± 3.53 | |

| 90 (P9) | 17.0 ± 1.03 | 6.04 | 17.61 ± 1.79 | 422.0 ± 60.44 | 14.32 | 65.1 ± 2.58 | 15.8 ± 1.39 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chuang, Y.-C.; Bao, L.; Lin, M.-C.; Lou, C.-W.; Lin, T. Mechanical and Static Stab Resistant Properties of Hybrid-Fabric Fibrous Planks: Manufacturing Process of Nonwoven Fabrics Made of Recycled Fibers. Polymers 2019, 11, 1140. https://doi.org/10.3390/polym11071140

Chuang Y-C, Bao L, Lin M-C, Lou C-W, Lin T. Mechanical and Static Stab Resistant Properties of Hybrid-Fabric Fibrous Planks: Manufacturing Process of Nonwoven Fabrics Made of Recycled Fibers. Polymers. 2019; 11(7):1140. https://doi.org/10.3390/polym11071140

Chicago/Turabian StyleChuang, Yu-Chun, Limin Bao, Mei-Chen Lin, Ching-Wen Lou, and TingAn Lin. 2019. "Mechanical and Static Stab Resistant Properties of Hybrid-Fabric Fibrous Planks: Manufacturing Process of Nonwoven Fabrics Made of Recycled Fibers" Polymers 11, no. 7: 1140. https://doi.org/10.3390/polym11071140

APA StyleChuang, Y.-C., Bao, L., Lin, M.-C., Lou, C.-W., & Lin, T. (2019). Mechanical and Static Stab Resistant Properties of Hybrid-Fabric Fibrous Planks: Manufacturing Process of Nonwoven Fabrics Made of Recycled Fibers. Polymers, 11(7), 1140. https://doi.org/10.3390/polym11071140