FDM 3D Printing of Polymers Containing Natural Fillers: A Review of their Mechanical Properties

Abstract

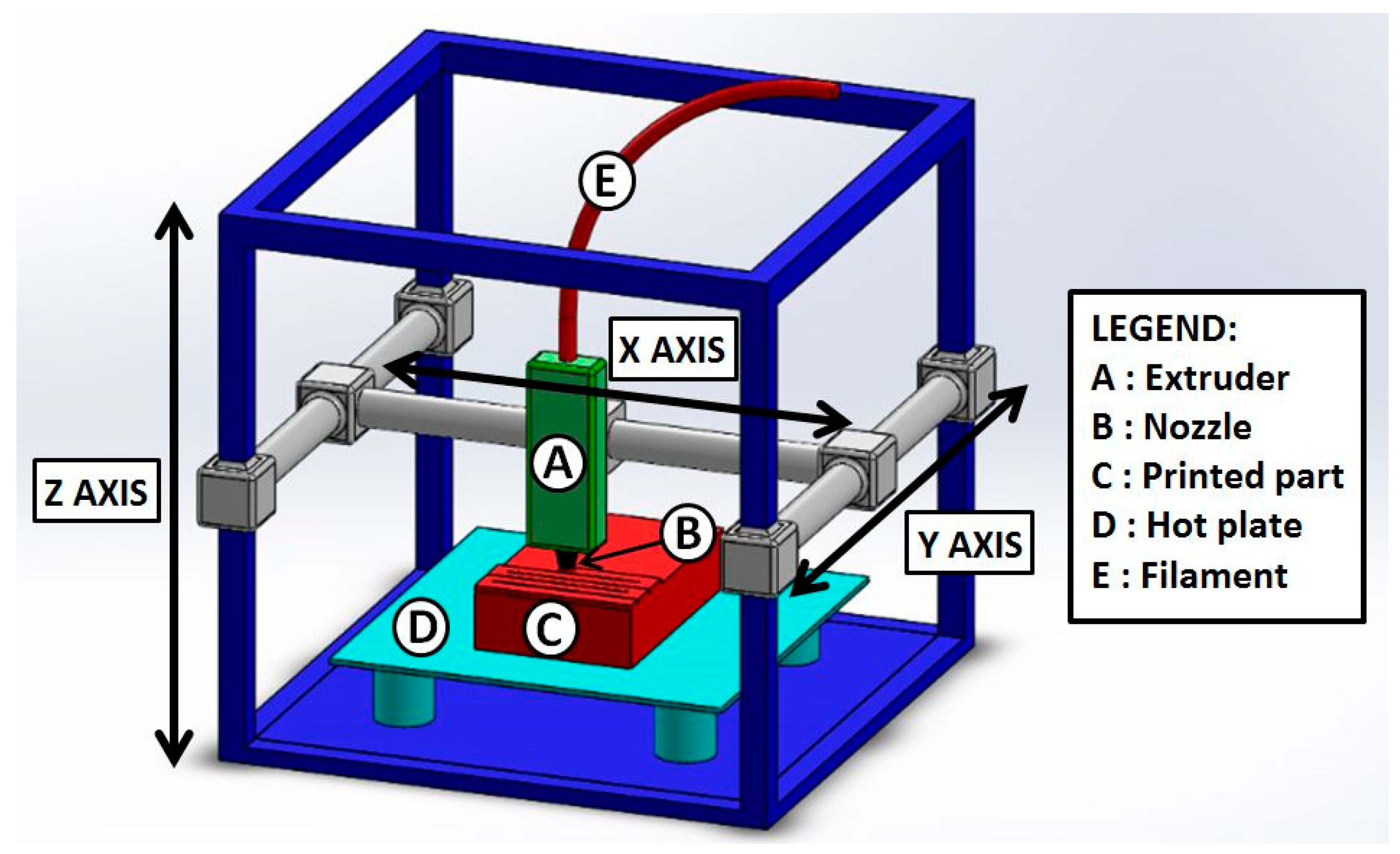

1. Introduction

2. Methods

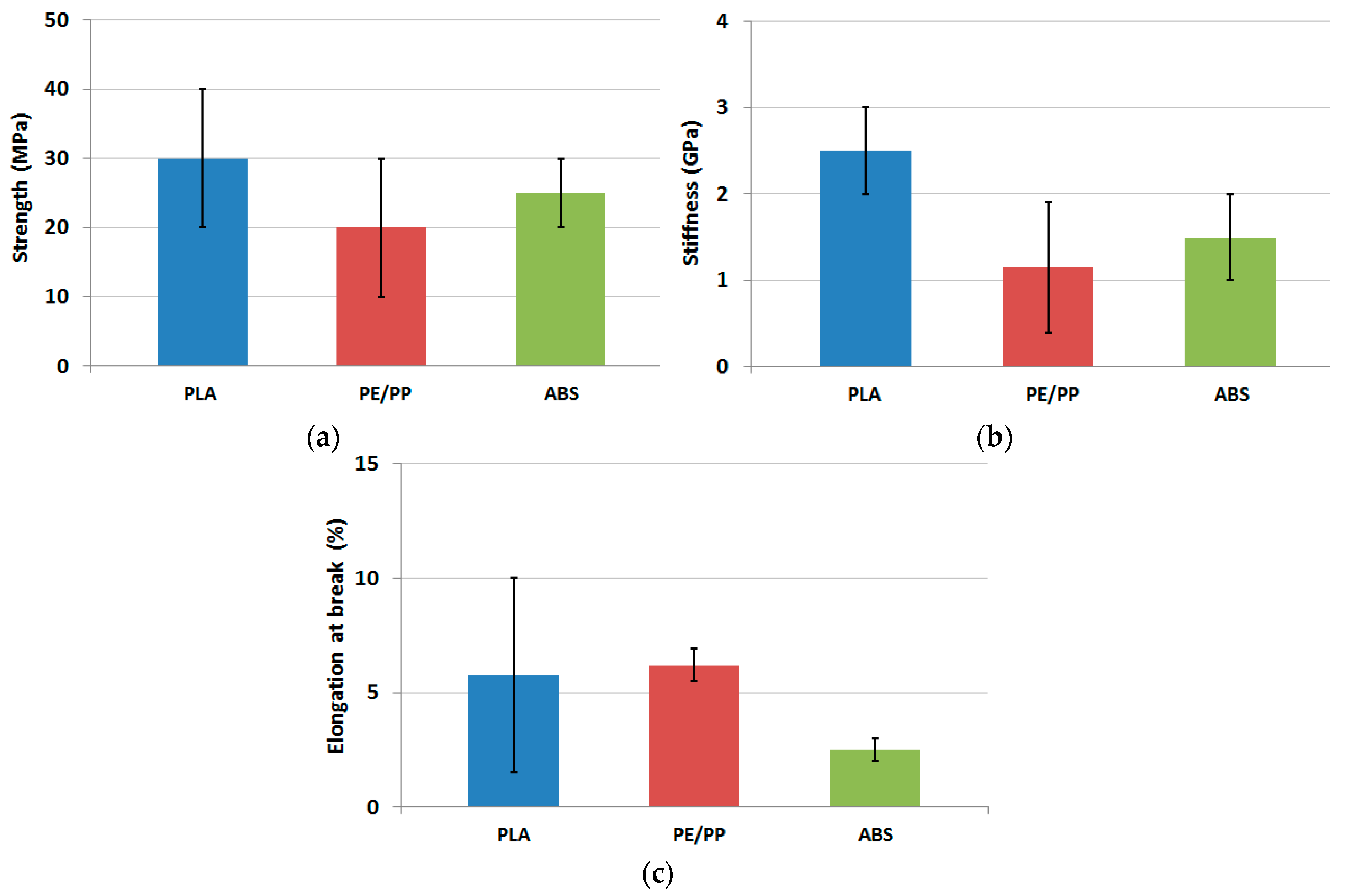

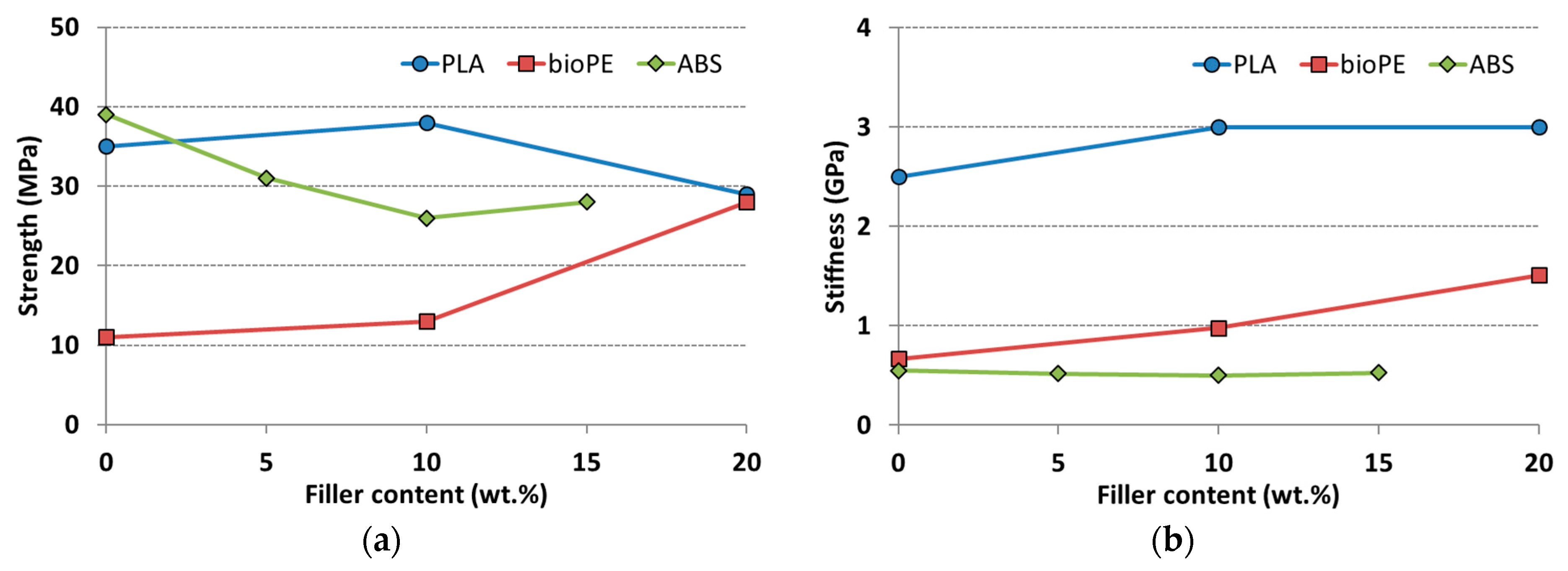

3. Materials

3.1. Non-Biodegradable Polymeric Matrices

3.2. Biodegradable Polymeric Matrices

4. Mechanical Properties

4.1. Filaments

4.2. 3D Printed Components

4.2.1. Tensile Properties

4.2.2. Compressive Properties

4.2.3. Flexural Properties

4.2.4. Impact Properties

5. Discussion and Conclusions

Funding

Conflicts of Interest

References

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Wahab, M.S.; Wagiman, A.; Ibrahim, M. Development of wood-based composites material for 3D printing process. App. Mech. Mat. 2013, 315, 987–991. [Google Scholar]

- Tisserat, B.; Liu, Z.; Finkenstadt, V.; Lewandowski, B.; Ott, S.; Reifschneider, L. 3D printing biocomposites. J. Plast. Res. Online (SPE) 2015, 1–3. [Google Scholar]

- Nguyen, N.A.; Bowland, C.C.; Naskar, A.K. A general method to improve 3D-printability and inter-layer adhesion in lignin-based composites. Appl. Mater. Today 2018, 12, 138–152. [Google Scholar] [CrossRef]

- Vaidya, A.A.; Collet, C.; Gaugler, M.; Lloyd-Jones, G. Integrating softwood biorefinery lignin into polyhydroxybutyrate composites and application in 3D printing. Mater. Today Commun. 2019, 19, 286–296. [Google Scholar] [CrossRef]

- Filgueira, D.; Holmen, S.; Melbø, J.K.; Moldes, D.; Echtermeyer, A.T.; Chinga-Carrasco, G. 3D Printable filaments made of biobased polyethylene biocomposites. Polymers 2018, 10, 314. [Google Scholar] [CrossRef] [PubMed]

- Kuo, C.C.; Liu, L.C.; Teng, W.F.; Chang, H.Y.; Chien, F.M.; Liao, S.J.; Kuo, W.F.; Chen, C.M. Preparation of starch/acrylonitrile-butadiene-styrene copolymers (ABS) biomass alloys and their feasible evaluation for 3D printing application. Compos. Part B 2016, 86, 36–39. [Google Scholar] [CrossRef]

- Milosevic, M.; Stoof, D.; Pickering, K.L. Characterizing the mechanical properties of fused deposition modelling natural fiber recycled polypropylene composites. J. Compos. Sci. 2017, 1, 7. [Google Scholar] [CrossRef]

- Tao, Y.; Wang, H.; Li, Z.; Li, P.; Shi, S.Q. Development and application of wood flour-filled polylactic acid composite filament for 3D printing. Materials 2017, 10, 339. [Google Scholar] [CrossRef] [PubMed]

- Kariz, M.; Sernek, M.; Kuzman, M.K. Use of wood powder and adhesive as a mixture for 3D printing. Eur. J. Wood Prod. 2016, 74, 123–126. [Google Scholar] [CrossRef]

- Pitt, K.; Lopez-Botello, O.; Lafferty, A.D.; Todd, I.; Mumtaz, K. Investigation into the material properties of wooden composite structures with in-situ fibre reinforcement using additive manufacturing. Compos. Sci. Technol. 2017, 138, 32–39. [Google Scholar] [CrossRef]

- Le Duigou, A.; Castro, M.; Bevan, R.; Martin, N. 3D printing of wood fibre biocomposites: From mechanical to actuation functionality. Mater. Des. 2016, 96, 106–114. [Google Scholar] [CrossRef]

- Tarrés, Q.; Melbø, J.K.; Delgado-Aguilar, M.; Espinach, F.X.; Mutjé, P.; Chinga-Carrasco, G. Bio-polyethylene reinforced with thermomechanical pulp fibers: Mechanical and micromechanical characterization and its application in 3D-printing by fused deposition modelling. Compos. Part B 2018, 153, 70–77. [Google Scholar] [CrossRef]

- Henke, K.; Treml, S. Wood based bulk material in 3D printing processes for applications in construction. Eur. J. Wood Prod. 2013, 71, 139–141. [Google Scholar] [CrossRef]

- D'Amora, U.; D'Este, M.; Eglin, D.; Safari, F.; Sprecher, M.C.; Gloria, A.; De Santis, R.; Alini, M.; Ambrosio, L. Collagen density gradient on three-dimensional printed poly(ε-caprolactone) scaffolds for interface tissue engineering. J. Tissue Eng. Regen. Med. 2018, 12, 321–329. [Google Scholar] [CrossRef] [PubMed]

- Tran, T.N.; Bayer, I.S.; Heredia-Guerrero, J.A.; Frugone, M.; Lagomarsino, M.; Maggio, F.; Athanassiou, A. Cocoa shell waste biofilaments for 3D printing applications. Macromol. Mater. Eng. 2017, 302, 1700219. [Google Scholar] [CrossRef]

- Zhao, D.; Cai, X.; Shou, G.; Gu, Y.; Wang, P. Study on the preparation of bamboo plastic composite intend for additive manufacturing. Key Eng. Mater. 2016, 667, 250–258. [Google Scholar] [CrossRef]

- Šafka, J.; Ackermann, M.; Bobek, J.; Seidl, M.; Habr, J.; Behalek, L. Use of composite materials for FDM 3D print technology. Mater. Sci. Forum 2016, 862, 174–181. [Google Scholar] [CrossRef]

- Osman, M.A.; Atia, M.R.A. Investigation of ABS-rice straw composite feedstock filament for FDM. Rapid Prototyp. J. 2018, 24, 1067–1075. [Google Scholar] [CrossRef]

- Pop, M.A.; Croitoru, C.; Bedő, T.; Geaman, V.; Radomir, I.; Cosnita, M.; Zaharia, S.M.; Chicos, L.A.; Milosan, I. Structural changes during 3D printing of bioderived and synthetic thermoplastic materials. J. Appl. Polym. Sci. 2019, 47382. [Google Scholar] [CrossRef]

- Xie, G.; Zhang, Y.; Lin, W. Plasticizer combinations and performance of wood flour—poly(lactic acid) 3D printing filaments. BioResource 2017, 12, 6736–6748. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.K.; Asahara, H.; Horiguchi, K.; Nakamura, T.; Todoroki, A.; Hirano, Y. Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation. Sci. Rep. 2016, 6, 23058. [Google Scholar] [CrossRef] [PubMed]

- Kariz, M.; Sernek, M.; Obućina, M.; Kuzman, M.K. Effect of wood content in FDM filament on properties of 3D printed parts. Mater. Today Commun. 2018, 14, 135–140. [Google Scholar] [CrossRef]

- Yang, T.C. Effect of extrusion temperature on the physico-mechanical properties of unidirectional wood fiber-reinforced polylactic acid composite (WFRPC) components using fused deposition modeling. Polymers 2018, 10, 976. [Google Scholar] [CrossRef] [PubMed]

- Mazzanti, V.; Mollica, F.; El Kissi, N. Rheological and mechanical characterization of polypropylene-based wood plastic composites. Polym. Compos. 2015, 37, 3460–3473. [Google Scholar] [CrossRef]

- Barczewski, M.; Mysiukiewicz, O.; Kloziński, A. Complex modification effect of linseed cake as an agricultural waste filler used in high density polyethylene composites. Iran Polym. J. 2018, 27, 677–688. [Google Scholar] [CrossRef]

- Mazzanti, V.; Pariante, R.; Bonanno, A.; Ruiz de Ballesteros, O.; Mollica, F.; Filippone, G. Reinforcing mechanisms of natural fibers in green composites: Role of fibers morphology in a PLA/hemp model system. Compos. Sci. Technol. 2019, 180, 51–59. [Google Scholar] [CrossRef]

- Le Troedec, M.; Sedan, D.; Peyratout, C.; Bonnet, J.P.; Smith, A.; Guinebretiere, R.; Gloaguen, V.; Krausz, P. Influence of various chemical treatments on the composition and structure of hemp fibres. Compos. Part A 2008, 39, 514–522. [Google Scholar] [CrossRef]

- Yi, S.; Xu, S.; Fang, Y.; Wang, H.; Wang, Q. Effects of matrix modification on the mechanical properties of wood–polypropylene composites. Polymers 2017, 9, 712. [Google Scholar] [CrossRef]

- Bledzki, A.; Faruk, O. Wood fibre reinforced polypropylene composites: Effect of fibre geometry and coupling agent on physico-mechanical properties. Appl. Compos. Mater. 2003, 10, 365–379. [Google Scholar] [CrossRef]

- Valente, M.; Tirillò, J.; Quitadamo, A.; Santulli, C. Paper fiber filled polymer. Mechanical evaluation and interfaces modification. Compos. Part B 2017, 110, 520–529. [Google Scholar] [CrossRef]

- Koronis, G.; Silva, A.; Fontul, M. Green composites: A review of adequate materials for automotive applications. Compos. Part B 2013, 44, 120–127. [Google Scholar] [CrossRef]

- Santoni, A.; Bonfiglio, P.; Fausti, P.; Marescotti, C.; Mazzanti, V.; Mollica, F.; Pompoli, F. Improving the sound absorption performance of sustainable thermal insulation materials: Natural hemp fibres. Appl. Acoust. 2019, 150, 279–289. [Google Scholar] [CrossRef]

- Bouafif, H.; Koubaa, A.; Perre´, P.; Cloutier, A.; Riedl, B. Wood particle/high-density polyethylene composites: thermal sensitivity and nucleating ability of wood particles. J. Appl. Polym. Sci. 2009, 113, 593–600. [Google Scholar] [CrossRef]

- Mazzanti, V.; Mollica, F. In-process measurements of flow characteristics of wood plastic composites. J. Polym. Environ. 2017, 25, 1044–1050. [Google Scholar] [CrossRef]

- Elsawy, M.A.; Kim, K.H.; Park, J.W.; Deep, A. Hydrolytic degradation of polylactic acid (PLA) and its composites. Renew. Sust. Energ. Rev. 2017, 79, 1346–1352. [Google Scholar] [CrossRef]

- van den Oever, M.J.A.; Beck, B.; Müssig, J. Agrofibre reinforced poly-(lactic acid) composites: Effect of moisture on degradation and mechanical properties. Compos. Part A 2010, 41, 1628–1635. [Google Scholar] [CrossRef]

- Gkartzou, E.; Koumoulos, E.P.; Charitidis, C.A. Production and 3D printing processing of bio-based thermoplastic filament. Manufacturing Rev. 2017, 4, 2016020. [Google Scholar] [CrossRef]

- Guo, R.; Ren, Z.; Bi, H.; Song, Y.; Xu, M. Effect of toughening agents on the properties of poplar wood flour/poly(lactic acid) composites fabricated with fused deposition modeling. Eur. Polym. J. 2018, 107, 34–45. [Google Scholar] [CrossRef]

- Gardan, J.; Roucoules, L. 3D printing device for numerical control machine and wood deposition. Julien Gardan Int. J. Eng. Res. App. 2014, 4, 123–131. [Google Scholar]

- Wimmer, R.; Steyrer, B.; Woess, J.; Koddenberg, T.; Mundigler, N. 3D Printing and wood. Pro Ligno 2015, 11, 144–149. [Google Scholar]

- Gardan, J.; Nguyen, D.C.; Roucoules, L.; Montay, G. Characterization of wood filament in additive deposition to study the mechanical behavior of reconstituted wood products. J. Eng. Fibers Fabr. 2016, 11, 56–63. [Google Scholar] [CrossRef]

- Rosenthal, M.; Henneberger, C.; Gutkes, A.; Bues, C.T. Liquid deposition modeling: a promising approach for 3D printing of wood. Eur. J. Wood Wood Prod. 2018, 76, 797–799. [Google Scholar] [CrossRef]

- Stoof, D.; Pickering, K. Sustainable composite fused deposition modelling filament using recycled pre-consumer polypropylene. Compos. Part B 2018, 135, 110–118. [Google Scholar] [CrossRef]

- Daver, F.; Lee, K.P.M.; Brandt, M.; Shanks, R. Cork–PLA composite filaments for fused deposition modelling. Compos. Sci. Technol. 2018, 168, 230–237. [Google Scholar] [CrossRef]

- Kariz, M.; Sernek, M.; Kuzman, M.K. Effect of humidity on 3D-printed specimens from wood-PLA filaments. Wood Res. 2018, 63, 917–922. [Google Scholar]

- Correa, D.; Papadopoulou, A.; Guberan, C.; Jhaveri, N.; Reichert, S.; Menges, A.; Tibbits, S. 3D-Printed wood: Programming hygroscopic material transformations. 3D Print. Addit. Manuf. 2015, 2, 106–118. [Google Scholar] [CrossRef]

- Depuydt, D.; Balthazar, M.; Hendrickx, K.; Six, W.; Ferraris, E.; Desplentere, F.; Ivens, J.; Van Vuure, A.W. Production and characterization of bamboo and flax fiber reinforced polylactic acid filaments for fused deposition modeling (FDM). Polym. Compos. 2019, 40, 1951–1963. [Google Scholar] [CrossRef]

- Filgueira, D.; Holmen, S.; Melbø, J.K.; Moldes, D.; Echtermeyer, A.T.; Chinga-Carrasco, G. Enzymatic-assisted modification of thermomechanical pulp fibers to improve the interfacial adhesion with poly-(lactic acid) for 3D printing. ACS Sustainable Chem. Eng. 2017, 5, 9338–9346. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Rauwendaal, C.J. Analysis and experimental evaluation of twin screw extruders. Polym. Eng. Sci. 1981, 21, 1092–1100. [Google Scholar] [CrossRef]

- Ayrilmis, N. Effect of layer thickness on surface properties of 3D printed materials produced from wood flour/PLA filament. Polym. Test. 2018, 71, 163–166. [Google Scholar] [CrossRef]

- Mohan, N.; Senthil, P.; Vinodh, S.; Jayanth, N. A review on composite materials and process parameters optimisation for the fused deposition modelling process. Virtual. Phys. Prototyp. 2017, 12, 47–59. [Google Scholar] [CrossRef]

- Dunne, R.; Desai, D.; Sadiku, R. Material characterization of blended sisal-kenaf composites with an ABS matrix. Appl. Acoust. 2017, 125, 184–193. [Google Scholar] [CrossRef]

- Girdis, J.; Gaudion, L.; Proust, G.; Loschke, S.; Dong, A. Rethinking timber: Investigation into the use of waste macadamia nut shells for additive manufacturing. JOM 2017, 69, 575–579. [Google Scholar] [CrossRef]

- Bi, H.; Ren, Z.; Guo, R.; Xu, M.; Song, Y. Fabrication of flexible wood flour/thermoplastic polyurethane elastomer composites using fused deposition molding. Ind. Crops Prod. 2018, 122, 76–84. [Google Scholar] [CrossRef]

- Bates, S.R.G.; Farrow, I.R.; Trask, R.S. 3D printed polyurethane honeycombs for repeated tailored energy absorption. Mater. Des. 2016, 112, 172–183. [Google Scholar] [CrossRef]

- Pakkanen, J.; Manfredi, D.; Minetola, P.; Iuliano, L. About the use of recycled or biodegradable filaments for sustainability of 3D printing. Sust. Des. Manuf. 2017, 68, 776–785. [Google Scholar]

- Mazzanti, V.; Mollica, F. Rheological behavior of wood flour filled poly-(lactic acid): Temperature and concentration dependence. Polym. Compos. 2019, 40, E169–E176. [Google Scholar] [CrossRef]

- Grossman, R.F.; Nwabunma, D. Poly(lactic acid): Synthesis, Structures, Properties, Processing, and Applications, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Hsu, S.H.; Yen, H.J.; Tseng, C.S.; Cheng, C.S.; Tsai, C.L. Evaluation of the growth of chondrocytes and osteoblasts seeded into precision scaffolds fabricated by fused deposition manufacturing. J. Biomed. Mat. Res. Part B 2007, 80, 519–527. [Google Scholar] [CrossRef]

- Ochi, S. Mechanical properties of kenaf fibers and kenaf/PLA composites. Mech. Mater. 2008, 40, 446–452. [Google Scholar] [CrossRef]

- Oksman, K.; Skrifvars, M.; Selin, J.F. Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Huber, T.; Müssig, J. Fibre matrix adhesion of natural fibres cotton, flax and hemp in polymeric matrices analyzed with the single fibre fragmentation test. Compos. Interfaces 2008, 15, 335–349. [Google Scholar] [CrossRef]

- Zhang, Q.; Cai, H.; Zhang, A.; Lin, X.; Yi, W.; Xhang, J. Effects of lubricant and toughening agent on the fluidity and toughness of poplar powder-reinforced polylactic acid 3D printing materials. Polymers 2018, 10, 932. [Google Scholar] [CrossRef] [PubMed]

- Mangat, A.S.; Singh, S.; Gupta, M.; Sharma, R. Experimental investigations on natural fiber embedded additive manufacturing-based biodegradable structures for biomedical applications. Rapid Prototyp. J. 2018, 24, 1221–1234. [Google Scholar] [CrossRef]

- Liu, H.; He, H.; Peng, X.; Huang, B.; Li, J. Three-dimensional printing of poly(lactic acid) bio-based composites with sugarcane bagasse fiber: Effect of printing orientation on tensile performance. Polym. Adv. Technol. 2019, 30, 910–922. [Google Scholar] [CrossRef]

- Stoof, D.; Pickering, K.; Zhang, Y. Fused Deposition Modelling of Natural Fibre/Polylactic Acid Composites. J. Compos. Sci. 2017, 1, 8. [Google Scholar] [CrossRef]

- Martikka, O.; Kärki, T.; Wu, Q. Mechanical properties of 3D-printed wood-plastic composites. Key Eng. Mater. 2018, 777, 499–507. [Google Scholar] [CrossRef]

- Ahn, S.H.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modelling ABS. Rapid Prototyp. 2002, 8, 248–257. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núñez, P.J. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Hinchcliffe, S.A.; Hess, K.M.; Srubar III, W.V. Experimental and theoretical investigation of prestressed natural fiber-reinforced polylactic acid (PLA) composite materials. Compos. Part B 2016, 95, 346–354. [Google Scholar] [CrossRef]

- Dong, Y.; Milentis, J.; Pramanik, A. Additive manufacturing of mechanical testing samples based on virgin poly(lactic acid) (PLA) and PLA/wood fibre composites. Adv. Manuf. 2018, 6, 71–82. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Kariz, M.; Kwon, J.H.; Kuzman, M.K. Effect of printing layer thickness on water absorption and mechanical properties of 3D-printed wood/PLA composite materials. Int. J. Adv. Manuf. Technol. 2019, in press. [Google Scholar] [CrossRef]

- Tao, Y.; Pan, L.; Liu, D.; Li, P. A case study: Mechanical modeling optimization of cellular structure fabricated using wood flour-filled polylactic acid composites with fused deposition modelling. Compos. Struct. 2019, 216, 360–365. [Google Scholar] [CrossRef]

- Fortini, A.; Mazzanti, V. Combined effect of water uptake and temperature on wood polymer composites. J. Appl. Polym. Sci. 2018, 46674. [Google Scholar] [CrossRef]

- Migneault, S.; Koubaa, A.; Erchiqui, F.; Chaala, A.; Englund, K.; Wolcott, M.P. Effects of processing methods and fiber size on the structure and properties of wood-plastic composites. Compos. Part A 2009, 40, 80–85. [Google Scholar] [CrossRef]

- Hung, K.C.; Yeh, H.; Yang, P.C.; Wu, T.L.; Xu, J.W.; Wu, J.H. Characterization of Wood-Plastic composites made with different lignocellulosic materials that vary in their morphology, chemical composition and thermal stability. Polymers 2017, 9, 726. [Google Scholar] [CrossRef] [PubMed]

- Mazzanti, V.; Mollica, F. Pressure dependent wall slip of wood flour filled polymer melts. J. Non-Newtonian Fluid Mech. 2017, 247, 178–187. [Google Scholar] [CrossRef]

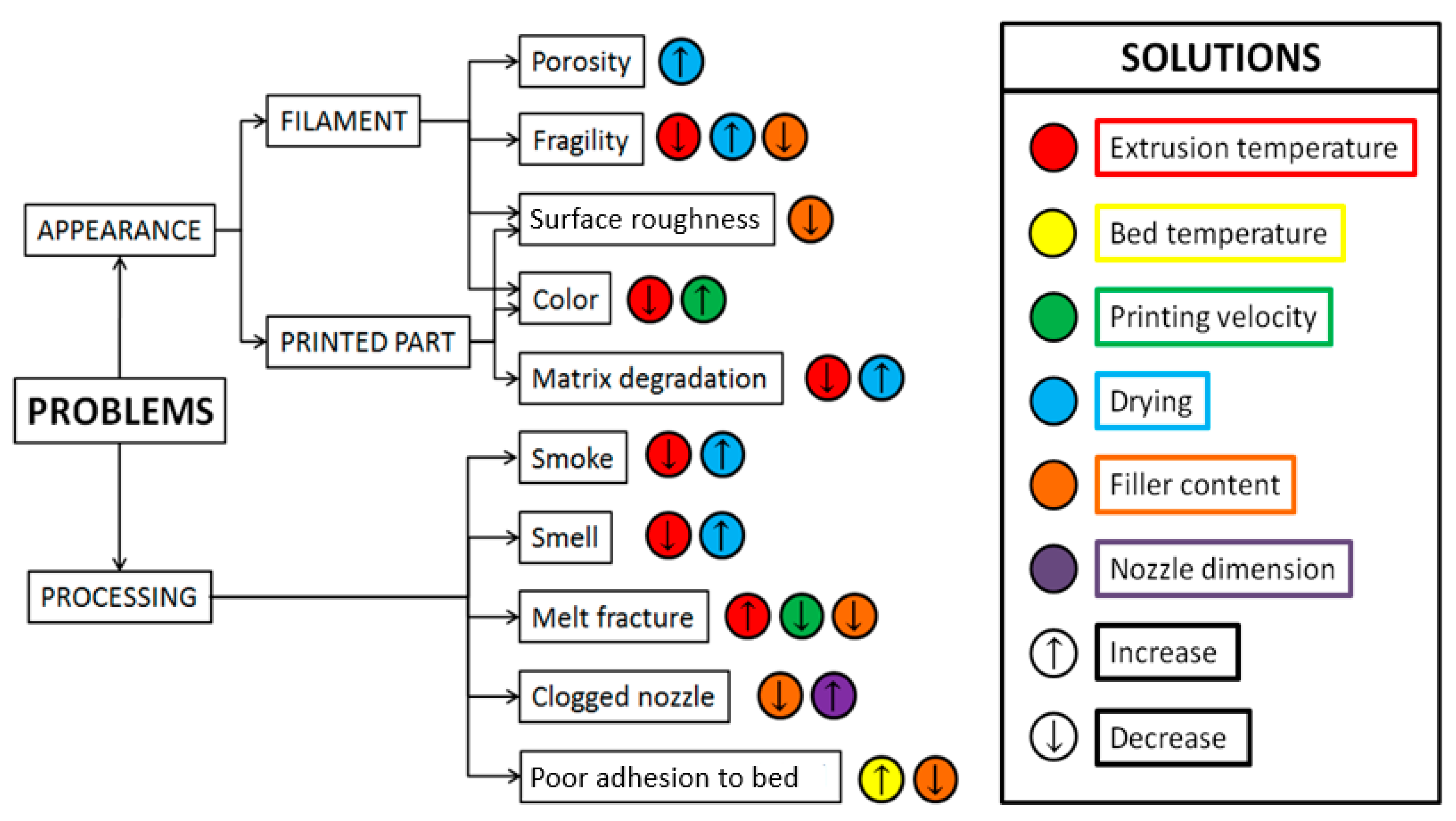

- Ahmed, I.; Shariff, M.S.; Zeeshan, M.S.I.; Prasanth, S. Troubleshooting for FDM technology. Int. J. Res. Appl. Sci. Engng. Tech. 2018, 6, 986–990. [Google Scholar]

| Parameters | Description | |

|---|---|---|

| Extruder Geometry | Nozzle diameter | Size of the exit orifice of the extruder |

| Filament diameter | Size of the filament required by the extruder | |

| Processing | Melt temperature | Temperature of the molten material exiting the extruder |

| Hot plate temperature | Surface temperature of the workspace plate | |

| Printing speed | The velocity of the material deposition | |

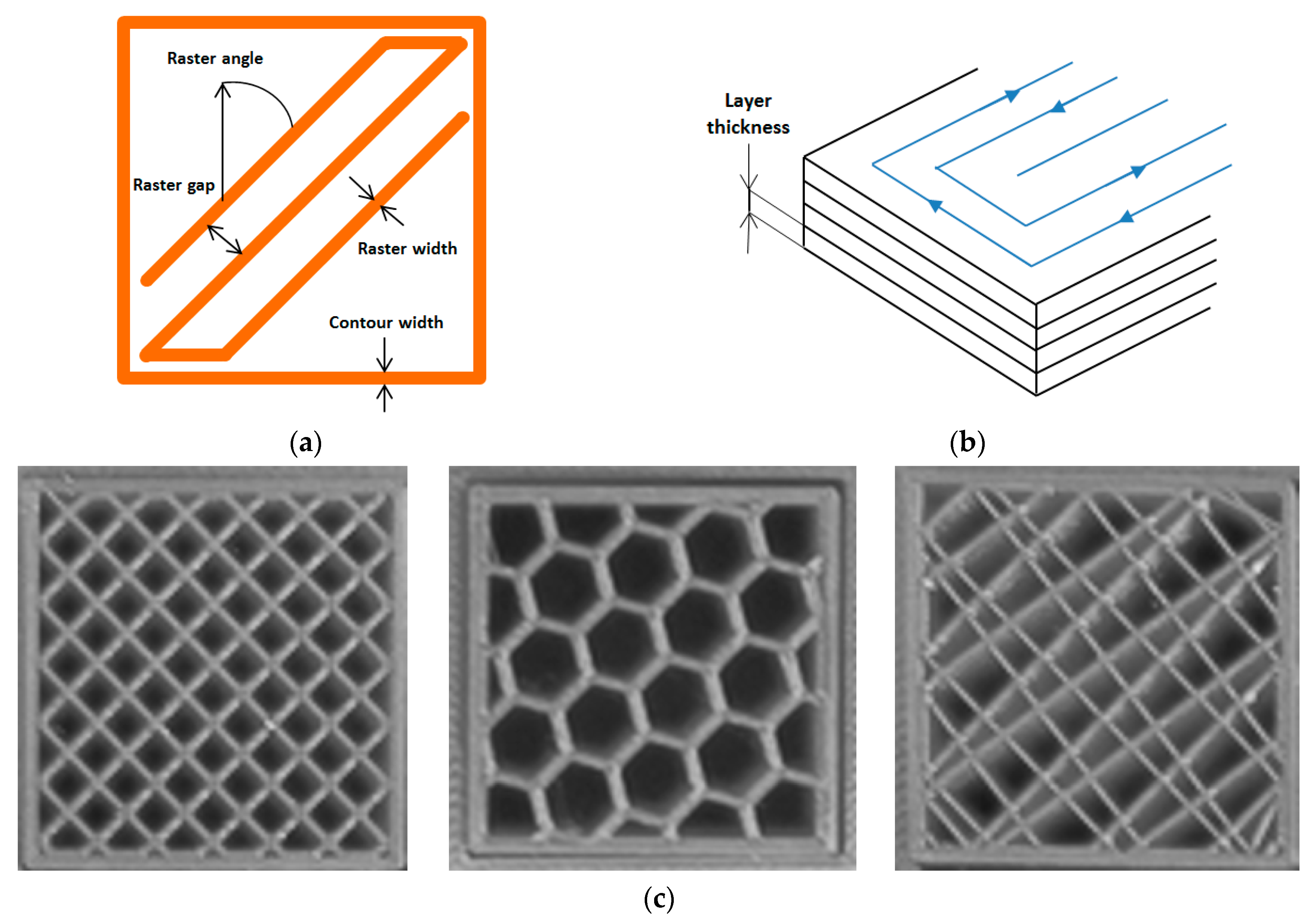

| Structural | Layer thickness | The thickness of the layer deposited by the nozzle |

| Infill geometry | The internal structure of the printed component | |

| Infill density | Material percentage filling the component apparent volume | |

| Number of layers | Number of shells deposed | |

| Raster angle | The angle between the deposed material and the x-axis | |

| Raster gap | The distance between two contiguous paths on the same layer | |

| Raster width | Width of the deposed material | |

| Patterning | Path followed to deposit the material on the workspace | |

| Matrix | Matrix Trade Name | Filler | Filler Trade Name | Filler Content (%) | Filler Chemical Treatment | Compatibilizer | Toughening Agent | Diameter (mm) | Test Type 1 | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| ABS | Scientific Sales, Inc. | hardwood lignin + carbon fibers | Lignol Innovations | 20–40 + (CF10) | / | / | Nitrile rubber | 2.5 | T | [4] |

| Magnum 3616 7 NAT HTP | coir fibers | / | 15 | / | / | / | 1.75 | T | [18] | |

| Taitalac 5000s | rice straw | Local farmlands | 0–15 | / | / | / | 1.75 | T-F | [19] | |

| Not Specified | macadamia nutshells | / | 19–29 | / | MAH 3 wt % | / | 1.75 | T-C | [55] | |

| PP | Astron Plastics | hemp | Hemp Farm NZ Ltd. | 10–30 | Alkaline | MAHg-PP 2 wt % | / | 2.4–3.1 | FT-T | [8] |

| Astron Plastics | harakake | Templeton Flax Mill | 10–30 | Alkaline | MAHg-PP 2 wt % | / | 2.4–3.1 | FT-T | [8] | |

| Astron Plastics | hemp | Hemp Farm NZ Ltd. | 0–30 | Alkaline | MAHg-PP 2 wt % | / | 3 | FT-T | [44] | |

| Astron Plastics | harakake | Templeton Flax Mill | 0–30 | Alkaline | MAHg-PP 2 wt % | / | 3 | FT-T | [44] | |

| Astron Plastics | gypsum | Gib Plasterboards | 0–30 | Alkaline | MAHg-PP 2 wt % | / | 3 | FT-T | [44] | |

| bioPE | Braskem | TMP | Norske Skog Saugbrugs | 10–20 | Lauryl Gallate Octyl Gallate | MAH-PE | / | 2 | / | [6] |

| Braskem | TMP | Norske Skog Saugbrugs | 10–20 | BioPE solubilisation | MAH-PE | / | / | T | [13] | |

| TPU | Deansheng Plastic Company | poplar wood flour | Lingshou County Mineral Plant | 10–40 | / | EPDM-g-MAH, POE-g-MAH, chitosan, MDI 5 wt % | / | 1.75 | T | [56] |

| Matrix | Matrix Trade Name | Filler | Filler Trade Name | Filler Content (%) | Filler Chemical Treatment | Compatibilizer | Toughneing Agent | Plasticizer | Diameter (mm) | Type of Test 1 | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PLA | / | Paulownia wood | / | 25 | / | / | / | / | 1.75 | T | [3] |

| / | Orange wood | / | 25 | / | / | / | / | 1.75 | T | [3] | |

| Ingeo 4032D | Aspen sawdust | Laboratory | 5 | / | / | / | / | 1.75 | T | [9] | |

| Ingeo 4032D | Bamboo | Faber-Castell | 20 | / | / | / | PEG600 Ester | 1.75 | / | [17] | |

| / | Poplar wood | / | 30 | / | / | / | Glycerol Tributyl citrate | 1.75 | T | [21] | |

| Ingeo 2003D | Wood powder | Laboratory | 0–50 | / | / | / | / | 1.75 | FT-F | [23,46] | |

| Ingeo 2003D | Pine lignin | MWV Chemicals | 5 | / | / | / | / | 1.75 | T | [38] | |

| Ingeo 4032D | Poplar wood | / | 10 | / | Graft copolymers Glycidyl methacrylate Dicumyl peroxide | TPU, POE 10 wt % | Aliphatic polyesters 10 wt % | / | T-F-I | [39] | |

| Ingeo 4032D | Cork powder | Amorim Revestimentos | 5 | / | / | / | Tributyl citrate 5 wt % | 1.75 | T | [45] | |

| / | Bamboo | Bambooder Fibers | 15 | / | / | / | cPLA1–cPLA2 | 2.85 | FT | [48] | |

| / | Flax | Lineo | 15 | / | / | / | cPLA1–cPLA2 | 2.85 | FT | [48] | |

| Ingeo 4043D | TMP | Norske Skog Saugbrugs | 10–20 | Lauryl Gallate Octyl Gallate | / | / | / | 2.2 | FT-T | [49] | |

| Ingeo 4032D | Poplar wood | / | 0–10 | / | / | POE | / | 1.75 | I | [65] | |

| Ingeo 4032D | Sugarcane | Guangzhou Inst. | 3–15 | Alkaline | / | / | / | 1.75 | T-F | [67] | |

| Ingeo 3052D | Harekeke | Templeton mill | 0–30 | Alkaline | / | / | / | / | T | [68] | |

| Ingeo 3052D | Hemp | Hemp Farm | 0–30 | Alkaline | / | / | / | / | T | [68] | |

| PHB | Biomer | Sawmill | Local | 20 | Enzymatic saccharification | / | / | / | 1.75 | / | [5] |

| PCL | Polysciences | Cocoa shell | Ferrero S.p.A. | 0–50 | / | / | / | / | 1.75 | FT | [16] |

| PLA + PHA | / | Cellulose pulp | / | / | / | / | / | / | 1.75–3 | / | [41] |

| Matrix | Filler | Filler Content (%) | Commercial Name | Diameter (mm) | Type of Test 1 | Ref. |

|---|---|---|---|---|---|---|

| PLA | / | / | Verbatim | 2.85 | / | [20] |

| Cedar fibers | 40 | EasyWood | 1.75 | T-C-F | [24] | |

| Cellulose | 40 | Laywood | / | / | [47] | |

| Wood | 30 | Not specified | 1.75 | / | [52] | |

| / | 0 | PLA PrintPlus | 1.75 | FT-T-I | [69] | |

| Recycled wood | 30 | WoodFill fine | 1.75 | FT-T-I | [69] | |

| Recycled wood | 40 | Laywoo-D3 | 1.75 | T-I | [69] | |

| Wood | 40 | Bilby 3D | 1.75 | T-F-I | [73] | |

| Wood | 30 | Not specified | 1.75 | T-F | [74] | |

| Wood | / | Not specified | 1.75 | C | [75] | |

| PLA + PHA | Recycled wood | 15 | ColorFabb | 2.85 | T | [12] |

| Bamboo | 20 | ColorFabb | 2.85 | / | [20] | |

| ABS | / | / | Verbatim | 2.85 | / | [20] |

| Nozzle Diameter (mm) | Extrusion Temperature (°C) | Bed Temperature (°C) | Extrusion Speed Rate (mm/s) | Layer Height (mm) | 3D-printer | Ref. |

|---|---|---|---|---|---|---|

| 0.4 | 220 | 70 | 90 | 0.34 | MakerBot-Replicator 2 | [3] |

| 0.5 | 230 | 110 | 50 | / | LulzBot TAZ | [4] |

| 0.75 | 190 | 40 | 25 | 0.3 | MakerGear™ V2 | [5] |

| 0.4 | 210 | / | 15 | / | Ultimaker Original | [6] |

| / | 210 | / | / | / | da Vinci 1.0 | [7] |

| 1.5 | 230 | / | / | 1 | Diamond Age | [8] |

| 0.4 | 210 | / | / | / | Self-assembled | [9] |

| 0.4 | 210 | 70 | 18 | / | Prusa i3-Rework | [12] |

| / | 180–200 | / | / | / | Prusa i3 | [13] |

| 0.6 | 120 | / | 50 | 0.3 | Prusa i3-Hephestos | [16] |

| / | 190–195 | / | 30–50 | / | / | [17] |

| / | 230-245 | 70 | 21 | 0.2 | Easy3DMaker | [18] |

| 1 | 250 | 100 | / | 0.2 | Printrbot Simple Metal | [19] |

| / | 220–275 | 60–90 | 30–40 | 0.4 | CreatBot DX-3D | [20] |

| / | 220 | / | / | / | MakerBot-Replicator 2 | [21] |

| / | 210 | 80 | 60–100 | / | Blade 1 | [22] |

| 0.4 | 230–275 | / | 30 | 0.19 | Zortrax M200 | [23] |

| 0.4 | 200–230 | 50 | 30 | / | Creator Pro-Flashforge | [24] |

| / | 205 | / | 20 | 0.1 | Zmorph 2.0 | [38] |

| / | / | / | / | / | MR300 | [39] |

| 1 | 230 | / | 50 | / | / | [44] |

| 0.8 | 230 | 60 | 30 | 0.4 | MakerBot-Replicator 2 | [45] |

| 0.4 | 230–275 | / | 30 | 0.19 | Zortrax M200 | [46] |

| / | / | / | / | 0.8 | / | [47] |

| 0.4 | 210 | / | 15 | / | Ultimaker Original | [49] |

| 0.4 | 200 | 80 | / | 0.05–0.3 | Zaxe | [52] |

| 0.5 | / | / | / | / | Leapfrog Creatr | [55] |

| / | 185 | / | / | / | MR300 | [56] |

| 0.5 | 180 | / | / | 0.1 | / | [65] |

| 0.4 | / | / | / | / | Accucraft | [66] |

| 0.6 | 200 | 50 | 40 | 0.1 | / | [67] |

| 1 | / | 110 | / | / | Diamond age | [68] |

| 0.5 | 188 | 50 | 60 | 0.4 | Profi3Dmaker | [69] |

| / | 215 | / | 60 | 0.2 | MakerBot-Replicator 5 | [72] |

| / | 230 | 70 | 90 | / | MakerBot-Replicator 2 | [73] |

| 0.4 | 200 | 80 | / | / | Zaxe | [74] |

| 0.4 | 200 | 60 | 30 | 0.3 | Open source, 605 S model | [75] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D Printing of Polymers Containing Natural Fillers: A Review of their Mechanical Properties. Polymers 2019, 11, 1094. https://doi.org/10.3390/polym11071094

Mazzanti V, Malagutti L, Mollica F. FDM 3D Printing of Polymers Containing Natural Fillers: A Review of their Mechanical Properties. Polymers. 2019; 11(7):1094. https://doi.org/10.3390/polym11071094

Chicago/Turabian StyleMazzanti, Valentina, Lorenzo Malagutti, and Francesco Mollica. 2019. "FDM 3D Printing of Polymers Containing Natural Fillers: A Review of their Mechanical Properties" Polymers 11, no. 7: 1094. https://doi.org/10.3390/polym11071094

APA StyleMazzanti, V., Malagutti, L., & Mollica, F. (2019). FDM 3D Printing of Polymers Containing Natural Fillers: A Review of their Mechanical Properties. Polymers, 11(7), 1094. https://doi.org/10.3390/polym11071094