Synthesis of a Novel Phosphorous-Nitrogen Based Charring Agent and Its Application in Flame-retardant HDPE/IFR Composites

Abstract

:1. Introduction

2. Experiments

2.1. Materials

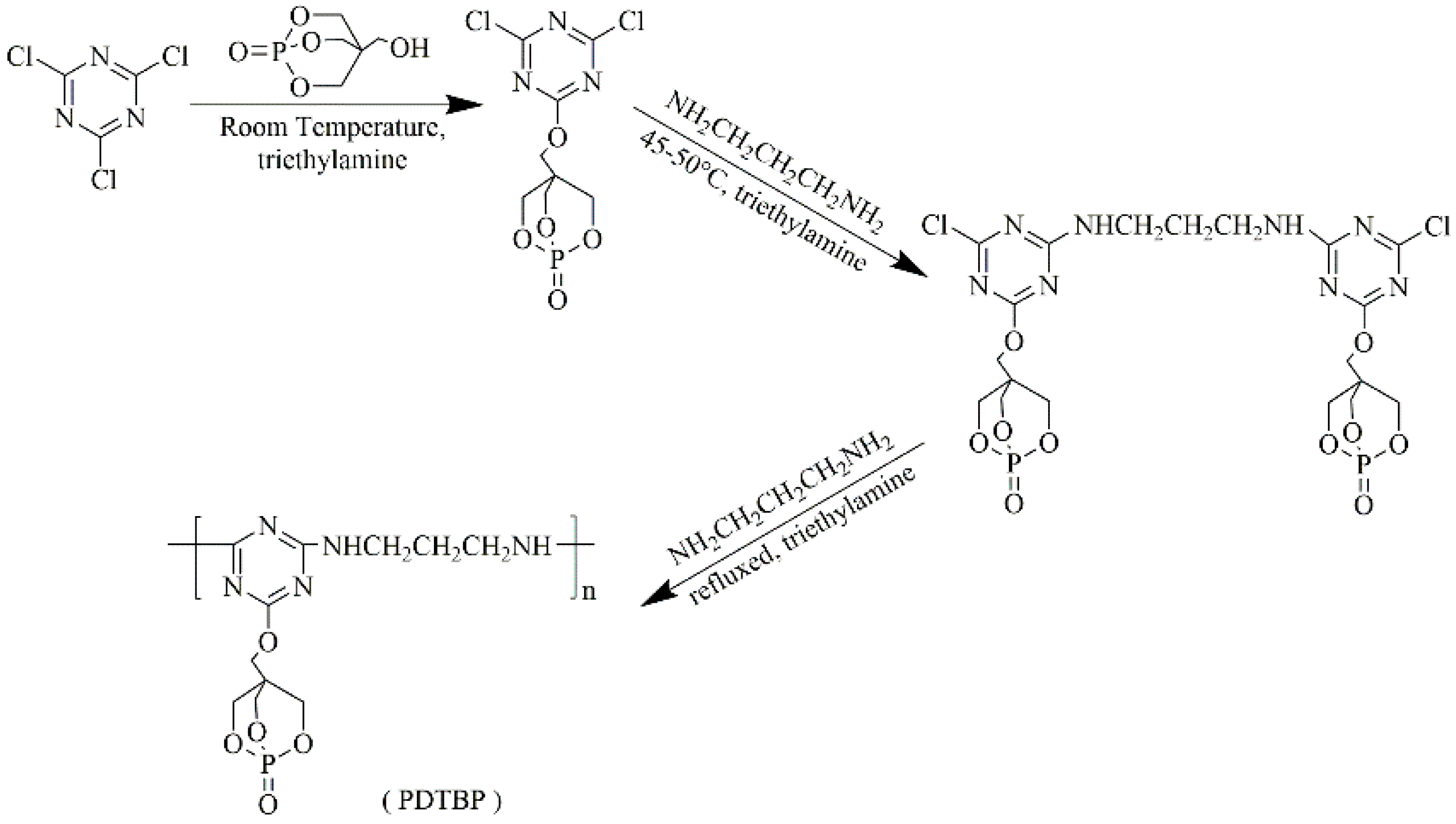

2.2. Synthesis of PDTBP

2.3. Preparation of Flame-Retardant HDPE/IFR Composites

2.4. Characterization

3. Results and Discussion

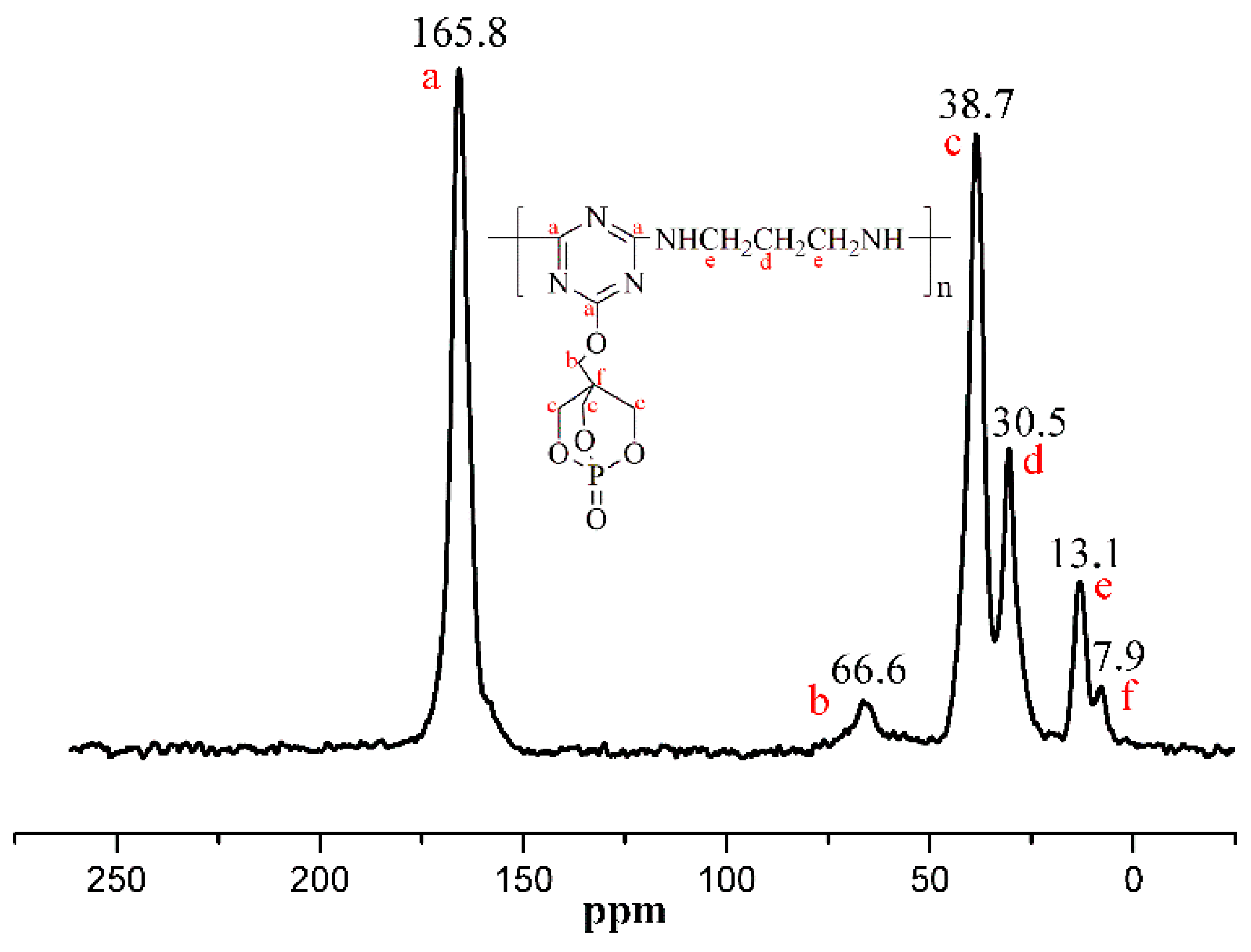

3.1. Characterization of PDTBP

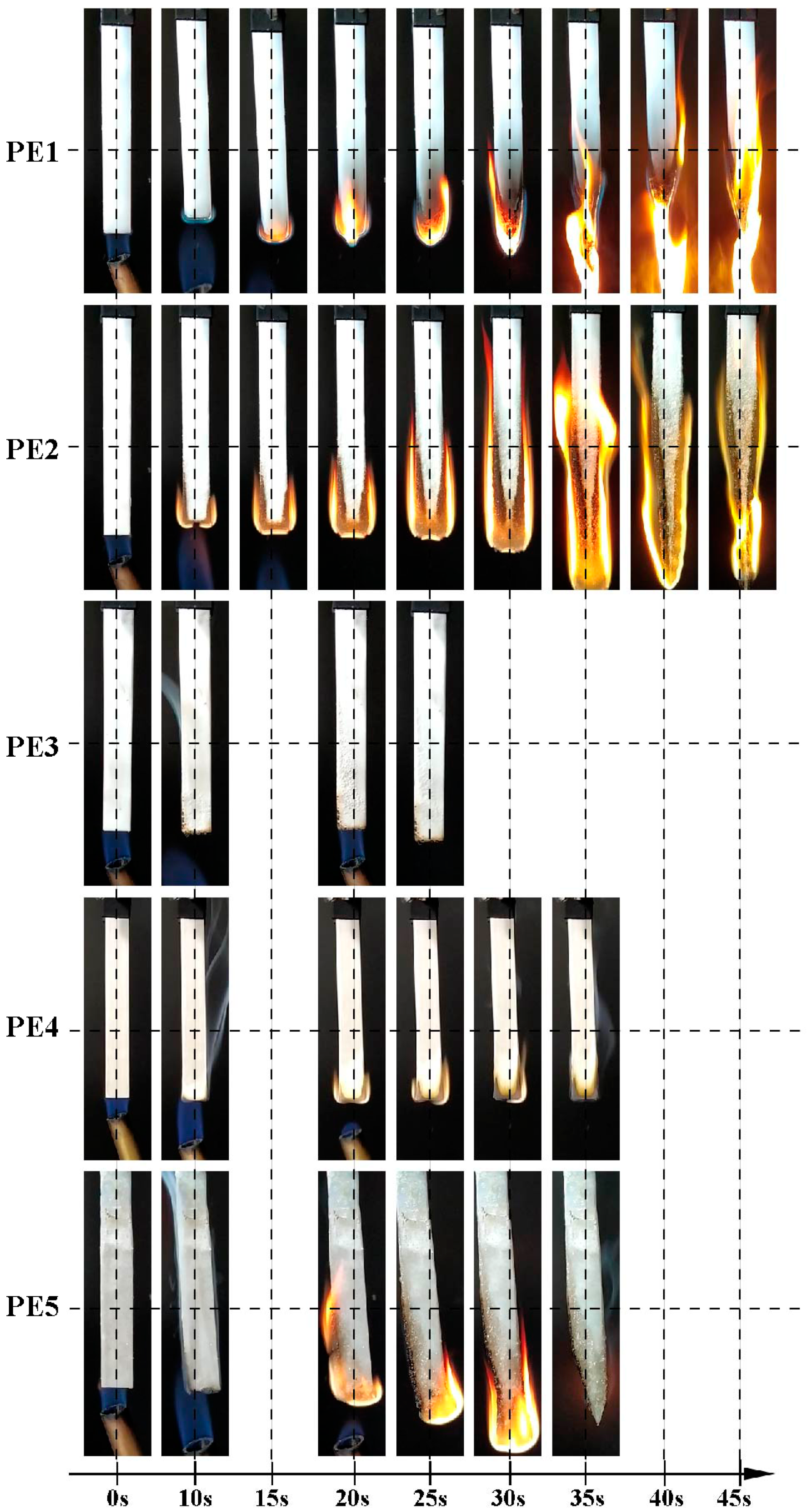

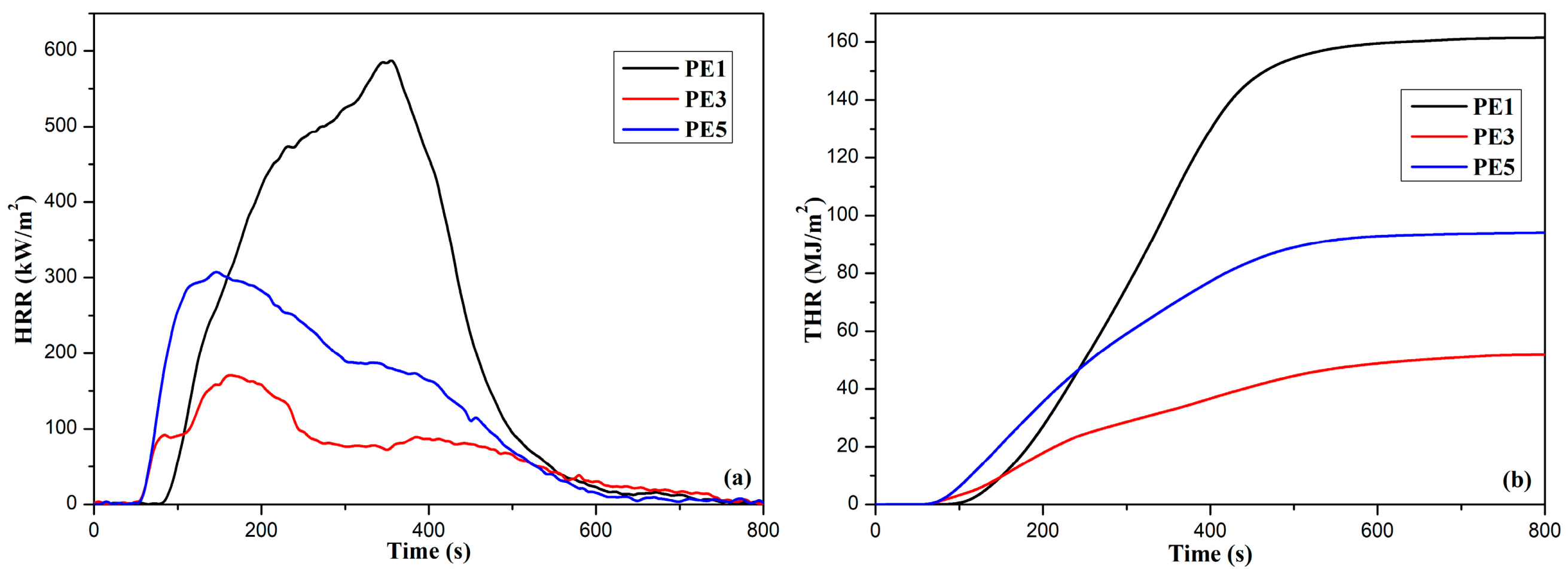

3.2. Flame Retardancy and Water Resistance of Flame-Retardant HDPE/IFR Composites

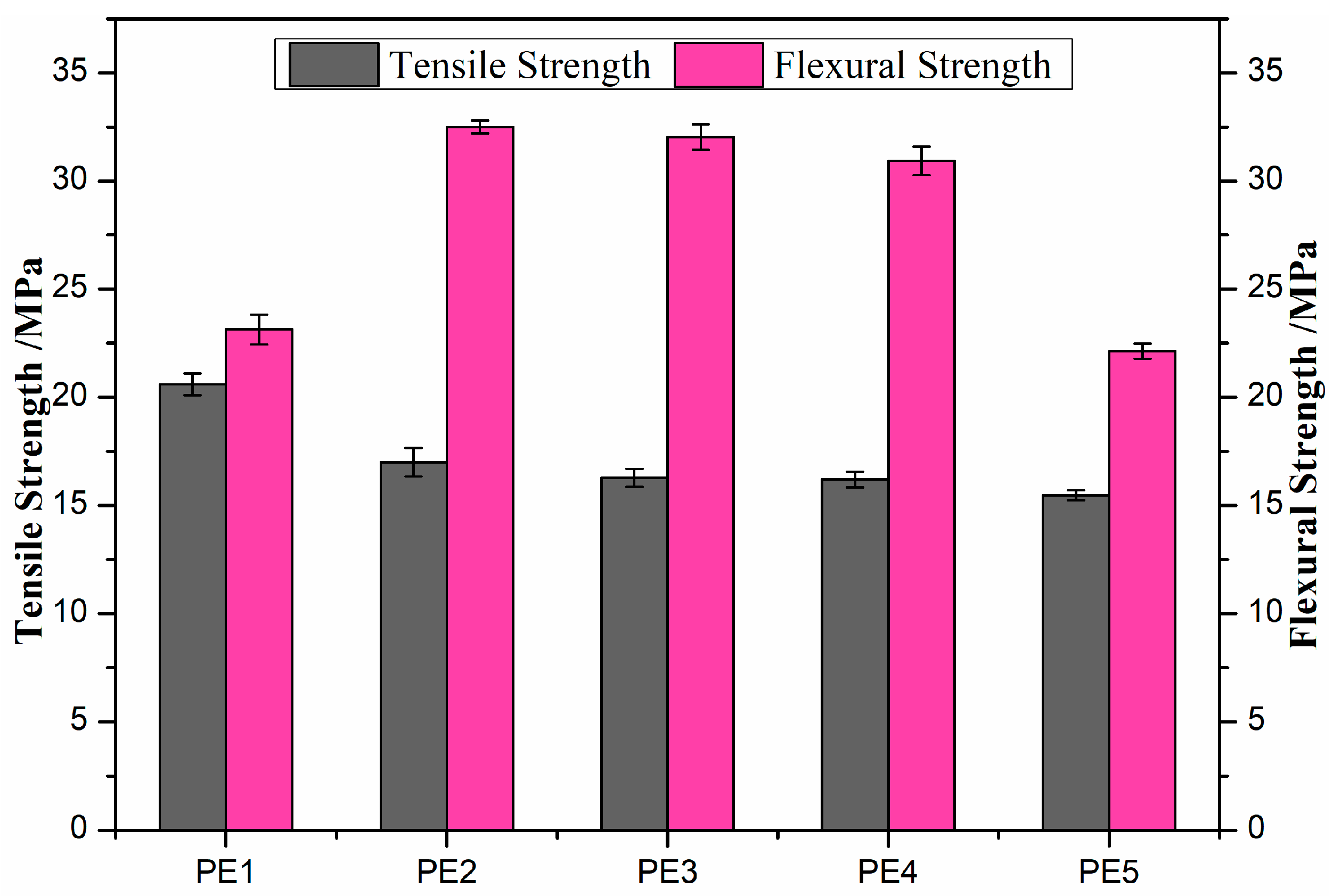

3.3. Mechanical Properties of Flame-Retardant HDPE/IFR Composites

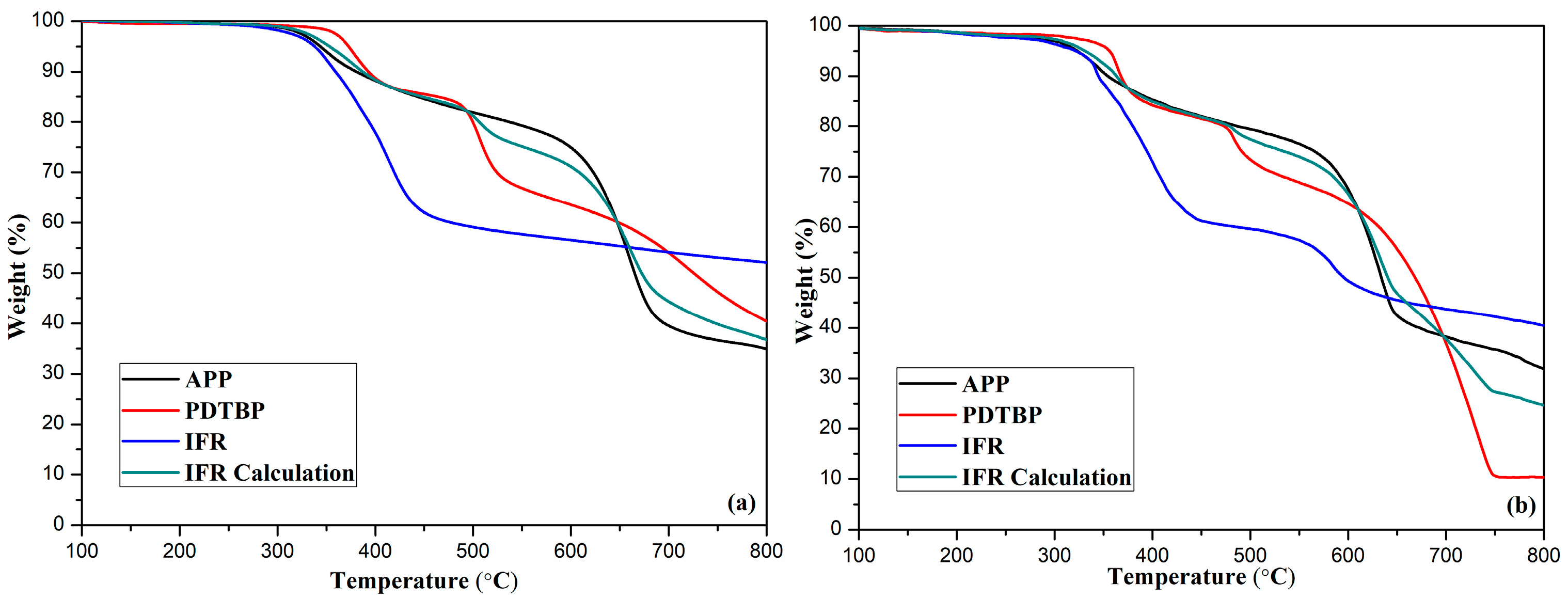

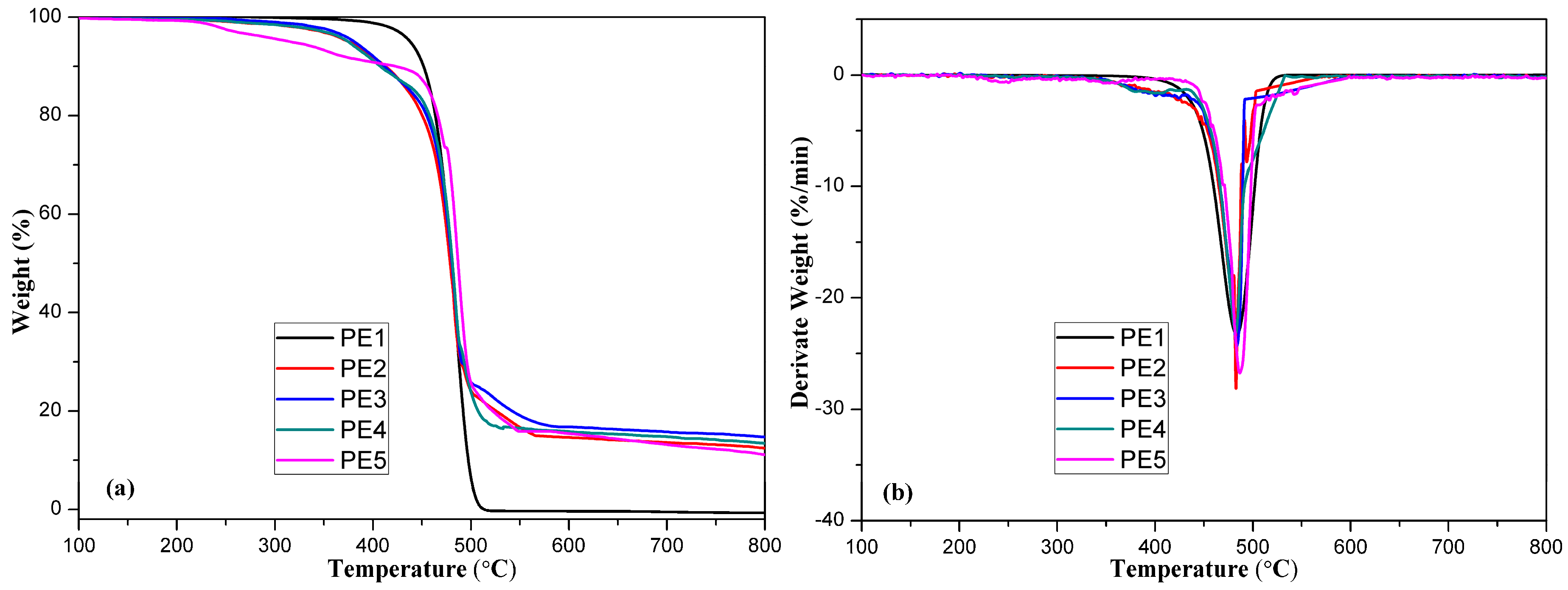

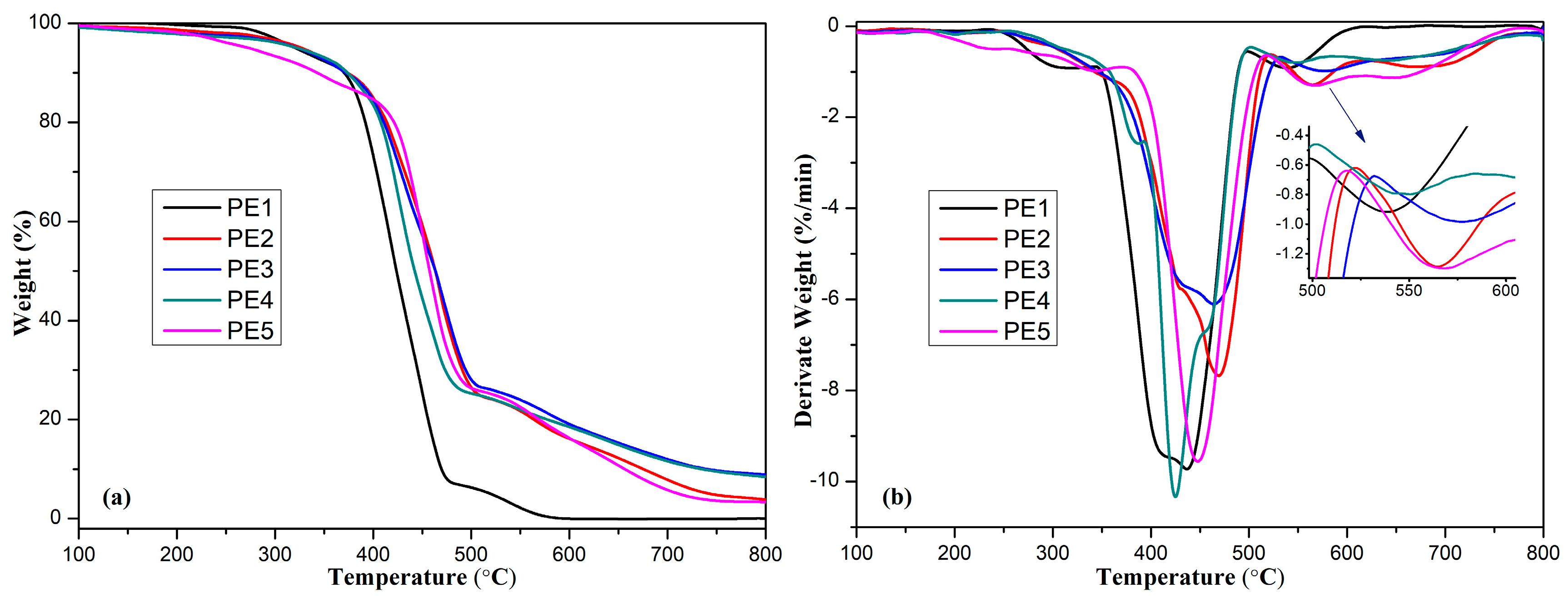

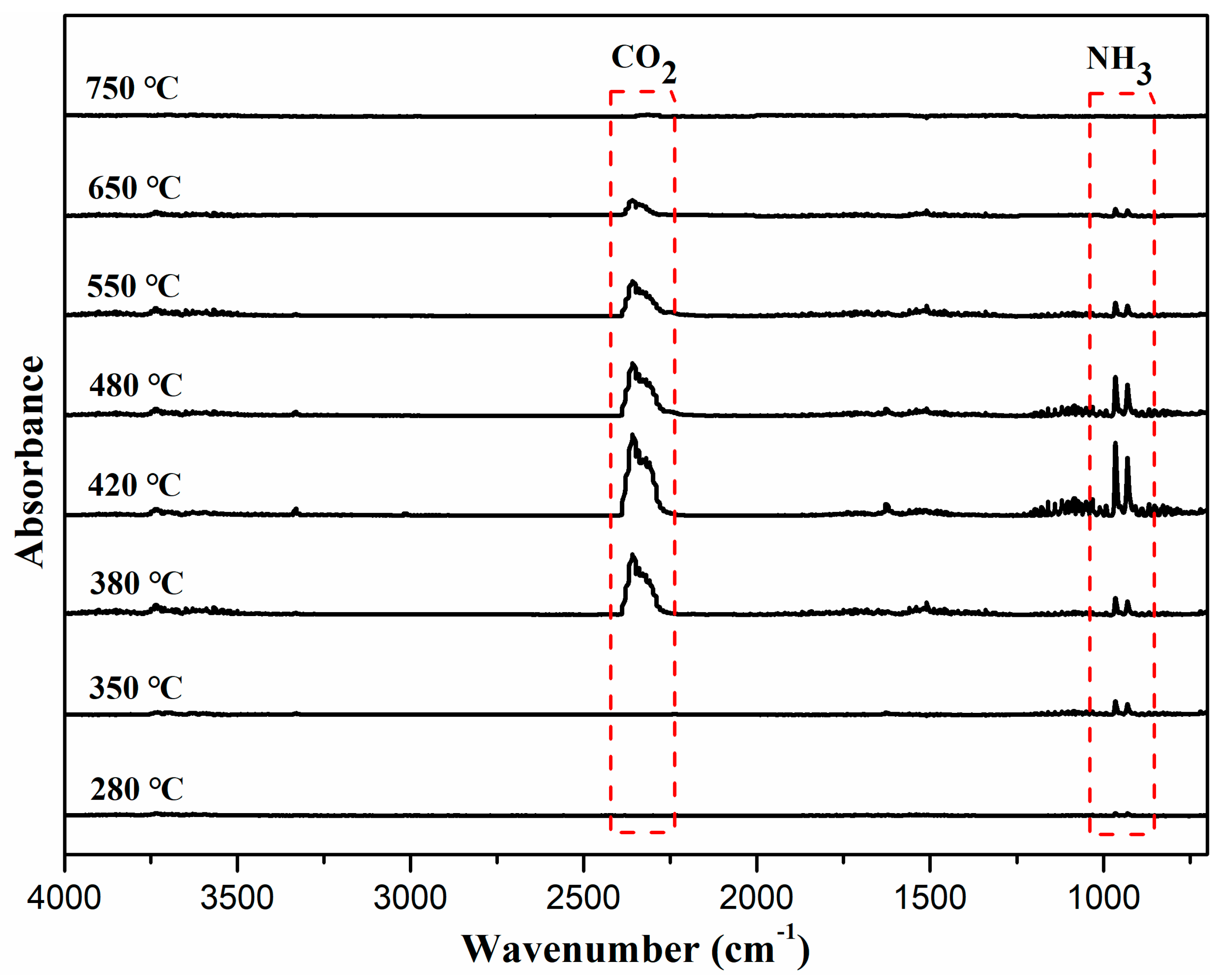

3.4. Thermal Properties and TG-FTIR Analysis

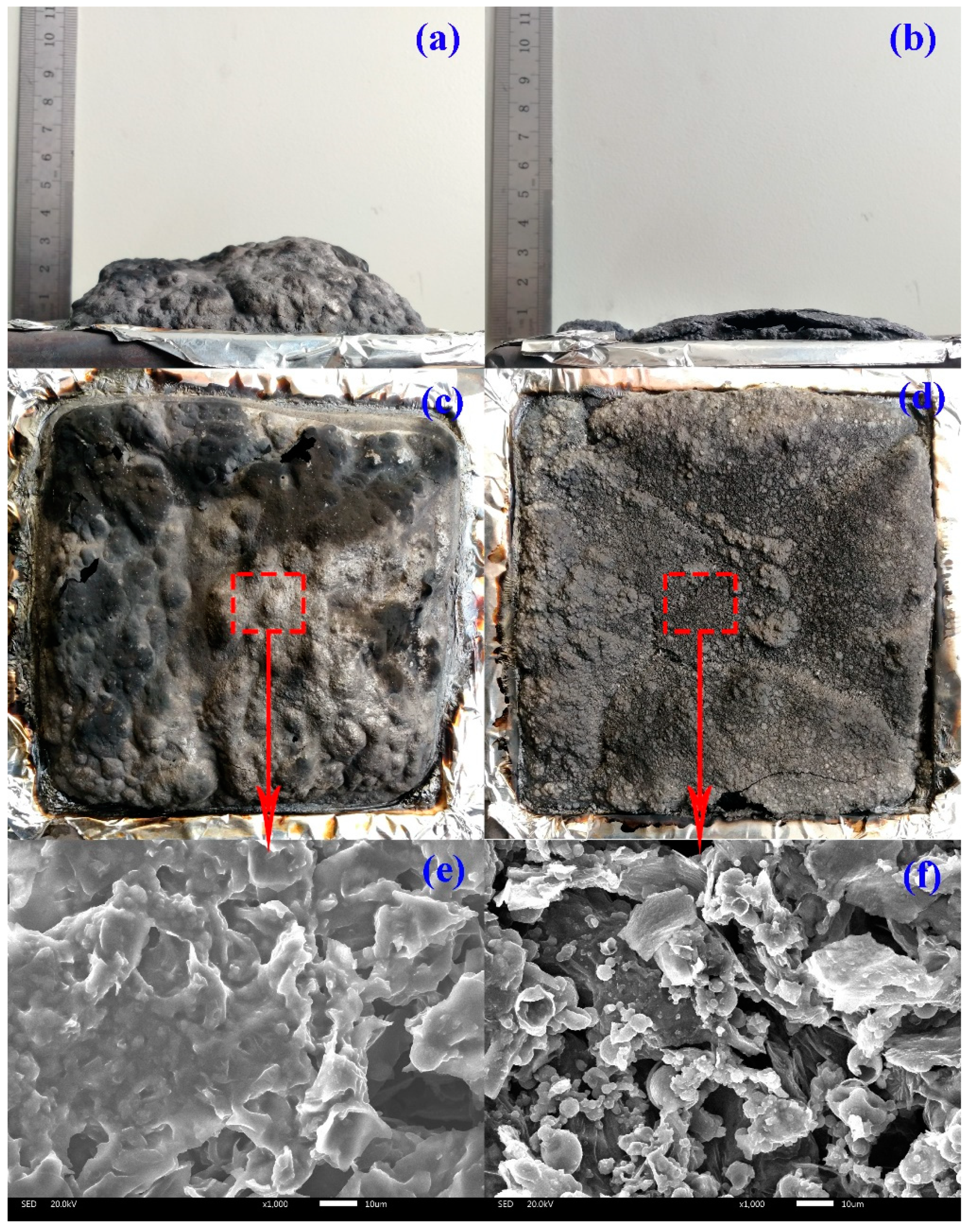

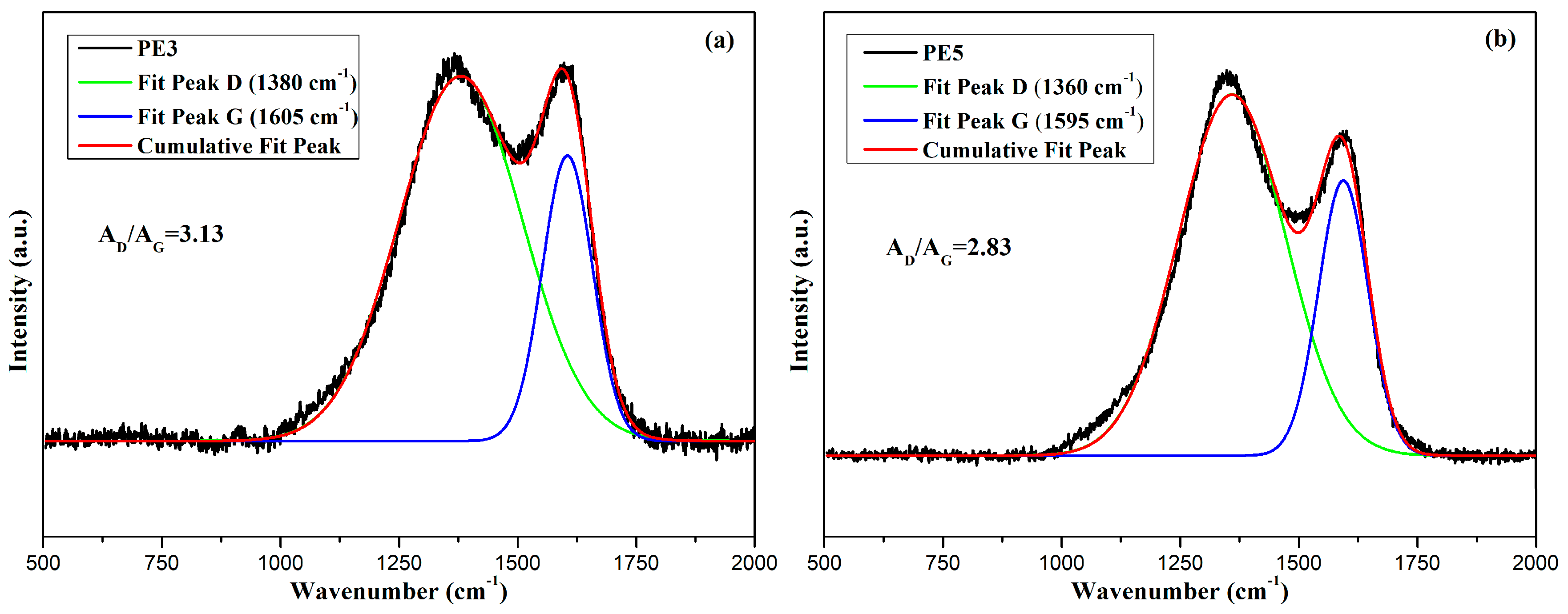

3.5. Characterization of Char Residues

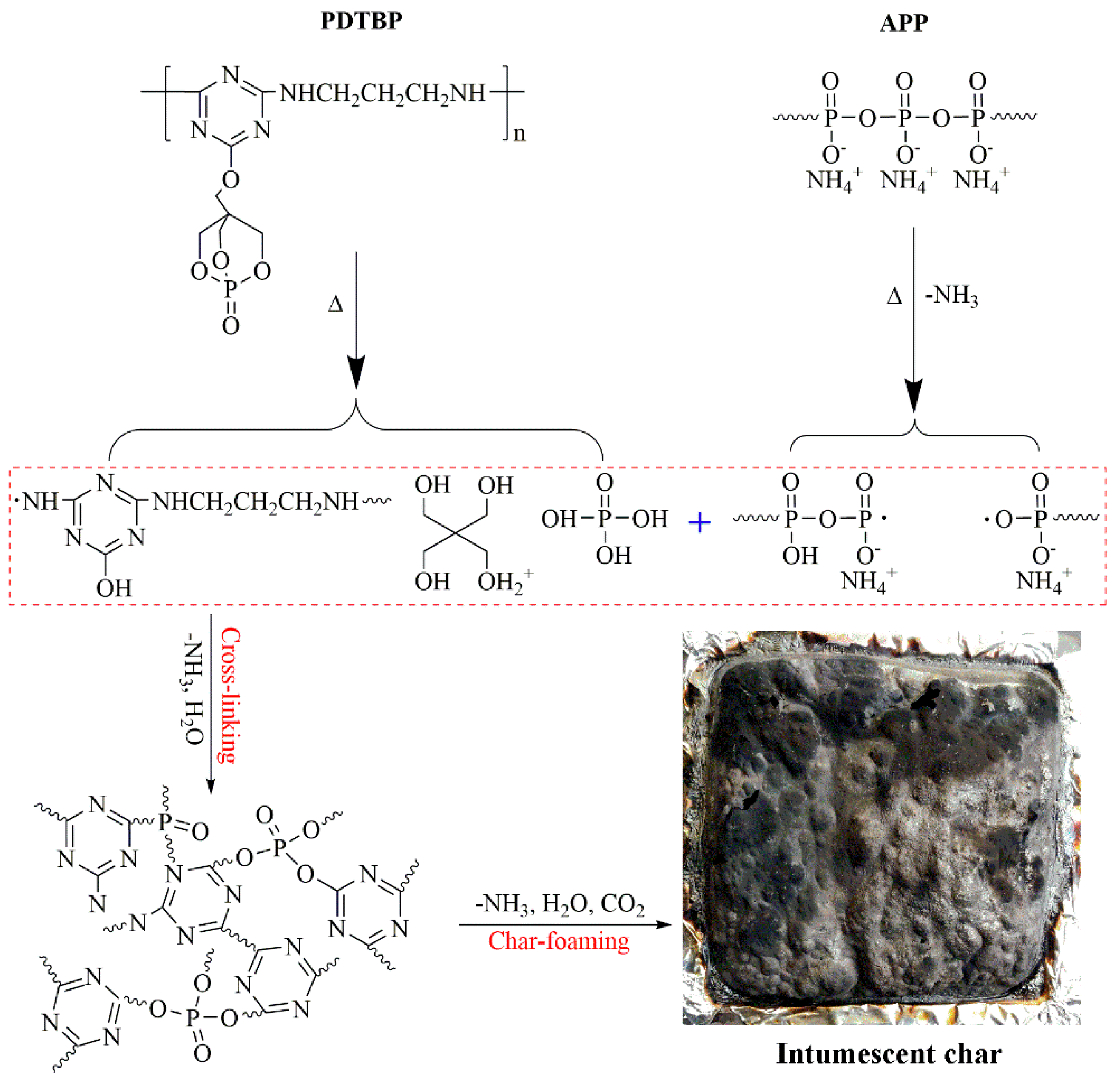

3.6. Flame-Retardant Mechanism

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, D.Y.; Liu, Y.; Wang, Y.Z.; Artiles, C.P.; Hull, T.R.; Price, D. Fire retardancy of a reactively extruded intumescent flame retardant polyethylene system enhanced by metal chelates. Polym. Degrad. Stab. 2007, 92, 1592–1598. [Google Scholar] [CrossRef]

- Cao, Z.; Zhang, Y.; Song, P.; Cai, Y.; Guo, Q.; Fang, Z.; Peng, M. A novel zinc chelate complex containing both phosphorus and nitrogen for improving the flame retardancy of low density polyethylene. J. Anal. Appl. Pyrolysis 2011, 92, 339–346. [Google Scholar] [CrossRef]

- Darshan, T.G.; Veluri, S.; Kartik, B.; Yen-Hsiang, C.; Fang-Chyou, C. Poly(butylene succinate)/high density polyethylene blend-based nanocomposites with enhanced physical properties—Selectively localized carbon nanotube in pseudo-double percolated structure. Polym. Degrad. Stab. 2019, 163, 185–194. [Google Scholar] [CrossRef]

- Liu, Z.; Dai, M.; Zhang, Y.; Xiang, G.; Qi, Z. Preparation and performances of novel waterborne intumescent fire retardant coatings. Prog. Org. Coat. 2016, 95, 100–106. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Y.; Li, J. Preparation of nucleotide-based microsphere and its application in intumescent flame retardant polypropylene. J. Anal. Appl. Pyrolysis 2016, 121, 394–402. [Google Scholar] [CrossRef]

- Chen, L.; Wang, Y.Z. A review on flame retardant technology in China. Part I: Development of flame retardants. Polym. Adv. Technol. 2010, 21, 1–26. [Google Scholar] [CrossRef]

- Almeras, X.; Bras, M.L.; Hornsby, P.; Bourbigot, S.; Marosi, G.; Keszei, S.; Poutch, F. Effect of fillers on the fire retardancy of intumescent polypropylene compounds. Polym. Degrad. Stab. 2003, 82, 325–331. [Google Scholar] [CrossRef]

- Li, B.; He, J.; Guan, L.; Bing, B.; Dai, J. A novel intumescent flame-retardant system for flame-retarded LLDPE/EVA composites. J. Appl. Polym. Sci. 2010, 114, 3626–3635. [Google Scholar] [CrossRef]

- Maqsood, M.; Seide, G. Investigation of the flammability and thermal stability of halogen-free intumescent system in biopolymer composites containing biobased carbonization agent and mechanism of their char formation. Polymers 2018, 11, 48. [Google Scholar] [CrossRef]

- Bourbigot, S.; Bras, M.L.; Delobel, R.; Bréant, P.; Tremillon, J.M. 4A zeolite synergistic agent in new flame retardant intumescent formulations of polyethylenic polymers-study of the effect of the constituent monomers. Polym. Degrad. Stab. 1996, 54, 275–287. [Google Scholar] [CrossRef]

- Yang, R.; Ma, B.; Zhao, H.; Li, J. Preparation, thermal degradation and fire behaviors of intumescent flame retardant polypropylene with a charring agent containing pentaerythritol and triazine. Ind. Eng. Chem. Res. 2016, 55, 5298–5305. [Google Scholar] [CrossRef]

- Chen, H.; Wang, J.; Ni, A.; Ding, A.; Han, X.; Sun, Z. The effects of a macromolecular charring agent with gas phase and condense phase synergistic flame retardant capability on the properties of PP/IFR composites. Materials 2018, 11, 111. [Google Scholar] [CrossRef]

- Kang, T.; Li, J.; Liang, X.; Zhao, X.; Xue, L.; Fan, X.; Yan, Q. A novel phosphazene cyclomatrix network polymer: Design, synthesis and application in flame retardant polylactide. Polym. Degrad. Stab. 2011, 96, 1248–1254. [Google Scholar]

- He, W.; Zhou, Y.; Chen, X.; Guo, J.; Zhou, D.; Chen, S.; Wang, M.; Li, L. Novel intumescent flame retardant masterbatch prepared through different processes and its application in EPDM/PP thermoplastic elastomer: Thermal stability, flame retardancy, and mechanical properties. Polymers 2019, 11, 50. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Jiao, C.; Li, S.; Yuan, H. Preparation and properties of a single molecule intumescent flame retardant. Fire Saf. J. 2013, 58, 208–212. [Google Scholar] [CrossRef]

- Feng, C.; Liang, M.; Zhang, Y.; Jiang, J.; Huang, J.; Liu, H. Synergistic effect of lanthanum oxide on the flame retardant properties and mechanism of an intumescent flame retardant PLA composites. J. Anal. Appl. Pyrolysis 2016, 122, 241–248. [Google Scholar] [CrossRef]

- Chen, Y.; Yuan, L.; Qi, W.; Yin, H.; Aelmans, N.; Kierkels, R. Performance of intumescent flame retardant master batch synthesized through twin-screw reactively extruding technology: Effect of component ratio. Polym. Degrad. Stab. 2003, 81, 215–224. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, Y.; Liu, Y.; Yin, H.; Aelmans, N.; Kierkels, R. Performance of an intumescent-flame-retardant master batch synthesized by twin-screw reactive extrusion: Effect of the polypropylene carrier resin. Polym. Int. 2004, 53, 439–448. [Google Scholar] [CrossRef]

- Li, B.; Xu, M. Effect of a novel charring-foaming agent on flame retardancy and thermal degradation of intumescent flame retardant polypropylene. Polym. Degrad. Stab. 2006, 91, 1380–1386. [Google Scholar] [CrossRef]

- Jing, Z.; Lei, S.; Nie, S.; Yuan, H. Combustion properties and thermal degradation behavior of polylactide with an effective intumescent flame retardant. Polym. Degrad. Stab. 2009, 94, 291–296. [Google Scholar]

- Liu, Y.; Deng, C.L.; Zhao, J.; Wang, J.S.; Chen, L.; Wang, Y.Z. An efficiently halogen-free flame-retardant long-glass-fiber-reinforced polypropylene system. Polym. Degrad. Stab. 2011, 96, 363–370. [Google Scholar] [CrossRef]

- Xie, H.; Lai, X.; Li, H.; Zeng, X. Synthesis of a novel macromolecular charring agent with free-radical quenching capability and its synergism in flame retardant polypropylene. Polym. Degrad. Stab. 2016, 130, 68–77. [Google Scholar] [CrossRef]

- Halpern, Y.; Mott, D.M.; Niswander, R.H. Fire retardancy of thermoplastic materials by intumescence. Ind. Eng. Chem. Prod. Res. Dev. 1984, 23, 233–238. [Google Scholar] [CrossRef]

- Sarannya, V.; Sivasamy, P.; Mathan, N.D.; Rajkumar, T.; Ponraju, D.; Vijayakumar, C.T. Study of thermal properties of intumescent additive. J. Therm. Anal. Calorim. 2010, 102, 1071–1077. [Google Scholar] [CrossRef]

- Lai, X.; Shuang, T.; Li, H.; Zeng, X. Flame-retardant mechanism of a novel polymeric intumescent flame retardant containing caged bicyclic phosphate for polypropylene. Polym. Degrad. Stab. 2015, 113, 22–31. [Google Scholar] [CrossRef]

- Dai, J.; Li, B. Synthesis, thermal degradation, and flame retardance of novel triazine ring-containing macromolecules for intumescent flame retardant polypropylene. J. Appl. Polym. Sci. 2010, 116, 2157–2165. [Google Scholar] [CrossRef]

- Wen, P.; Wang, X.; Xing, W.; Feng, X.; Yu, B.; Shi, Y.; Gang, T.; Yuan, H.; Yuen, R.K.K.; Lei, S. Synthesis of a novel triazine-based hyperbranched char foaming agent and the study of its enhancement on flame retardancy and thermal stability of polypropylene. Ind. Eng. Chem. Res. 2013, 52, 17015–17022. [Google Scholar] [CrossRef]

- Lai, X.; Zeng, X.; Li, H.; Feng, L.; Yin, C.; Zhang, H. Synergistic effect between a triazine-based macromolecule and melamine pyrophosphate in flame retardant polypropylene. Polym. Compos. 2011, 33, 35–43. [Google Scholar] [CrossRef]

- Dasari, A.; Yu, Z.Z.; Cai, G.P.; Mai, Y.W. Recent developments in the fire retardancy of polymeric materials. Prog. Polym. Sci. 2013, 38, 1357–1387. [Google Scholar] [CrossRef]

- Tang, G.; Huang, X.; Ding, H.; Wang, X.; Hu, Y. Combustion properties and thermal degradation behaviors of biobased polylactide composites filled with calcium hypophosphite. RSC Adv. 2014, 4, 8985–8993. [Google Scholar] [CrossRef]

- Schartel, B.; Hull, T.R. Development of fire-retarded materials—Interpretation of cone calorimeter data. Fire Mater. 2007, 31, 327–354. [Google Scholar] [CrossRef]

- Wen, P.; Wang, X.; Wang, B.; Yuan, B.; Zhou, K.; Lei, S.; Yuan, H.; Yuen, R.K.K. One-pot synthesis of a novel s-triazine-based hyperbranched charring foaming agent and its enhancement on flame retardancy and water resistance of polypropylene. Polym. Degrad. Stab. 2014, 110, 165–174. [Google Scholar] [CrossRef]

- Lai, X.; Yin, C.; Li, H.; Zeng, X. Synergistic effect between silicone-containing macromolecular charring agent and ammonium polyphosphate in flame retardant polypropylene. J. Appl. Polym. Sci. 2015, 132, 41580. [Google Scholar] [CrossRef]

- Khanal, S.; Zhang, W.; Ahmed, S.; Ali, M.; Xu, S. Effects of intumescent flame retardant system consisting of tris (2-hydroxyethyl) isocyanurate and ammonium polyphosphate on the flame retardant properties of high-density polyethylene composites. Compos. A 2018, 112, 444–451. [Google Scholar] [CrossRef]

- Feng, C.; Liang, M.; Jiang, J.; Huang, J.; Liu, H. Synergistic effect of a novel triazine charring agent and ammonium polyphosphate on the flame retardant properties of halogen-free flame retardant polypropylene composites. Thermochim. Acta 2016, 627–629, 83–90. [Google Scholar] [CrossRef]

- Nie, S.; Yuan, H.; Lei, S.; He, Q.; Yang, D.; Hao, C. Synergistic effect between a char forming agent (CFA) and microencapsulated ammonium polyphosphate on the thermal and flame retardant properties of polypropylene. Polym. Adv. Technol. 2010, 19, 1077–1083. [Google Scholar] [CrossRef]

- Xu, Z.; Huang, J.; Chen, M.; Tan, Y.; Wang, Y. Flame retardant mechanism of an efficient flame-retardant polymeric synergist with ammonium polyphosphate for polypropylene. Polym. Degrad. Stab. 2013, 98, 2011–2020. [Google Scholar] [CrossRef]

- Bing, L.; Hong, X.; Ming, Z.; Gao, C.; Wang, C.; Tsubaki, N. Synthesis of novel intumescent flame retardant containing phosphorus, nitrogen and boron and its application in polyethylene. Polym. Bull. 2015, 72, 2967–2978. [Google Scholar]

- Ba, M.; Bing, L.; Wang, C. Synthesis and characterization of a novel charring agent and its application in intumescent flame retardant polyethylene system. Fibers Polym. 2017, 18, 907–914. [Google Scholar] [CrossRef]

- Song, P.; Fang, Z.; Tong, L.; Xu, Z. Synthesis of a novel oligomeric intumescent flame retardant and its application in polypropylene. Polym. Eng. Sci. 2010, 49, 1326–1331. [Google Scholar] [CrossRef]

- Deng, C.L.; Du, S.L.; Zhao, J.; Shen, Z.Q.; Deng, C.; Wang, Y.Z. An intumescent flame retardant polypropylene system with simultaneously improved flame retardancy and water resistance. Polym. Degrad. Stab. 2014, 108, 97–107. [Google Scholar] [CrossRef]

- Sadezky, A.; Muckenhuber, H.; Grothe, H.; Niessner, R.; Pöschl, U. Raman microspectroscopy of soot and related carbonaceous materials: Spectral analysis and structural information. Carbon 2005, 43, 1731–1742. [Google Scholar] [CrossRef]

- Yadav, M.; Rhee, K.Y.; Jung, I.H.; Park, S.J. Eco-friendly synthesis, characterization and properties of a sodium carboxymethyl cellulose/graphene oxide nanocomposite film. Cellulose 2013, 20, 687–698. [Google Scholar] [CrossRef]

- Tuinstra, F.; Koenig, J.L. Raman spectrum of graphite. J. Chem. Phys. 1970, 53, 1126–1130. [Google Scholar] [CrossRef]

- Cai, W.; Feng, X.; Wang, B.; Hu, W.; Yuan, B.; Hong, N.; Hu, Y. A novel strategy to simultaneously electrochemically prepare and functionalize graphene with a multifunctional flame retardant. Chem. Eng. J. 2017, 316, 514–524. [Google Scholar] [CrossRef]

- Tian, N.; Wen, X.; Gong, J.; Ma, L.; Tang, T. Synthesis and characterization of a novel organophosphorus flame retardant and its application in polypropylene. Polym. Adv. Technol. 2013, 24, 653–659. [Google Scholar] [CrossRef]

| Samples | HDPE (wt %) | APP (wt %) | PDTBP (wt %) | PER (wt %) |

|---|---|---|---|---|

| PE1 | 100 | 0 | 0 | 0 |

| PE2 | 70 | 15 | 15 | 0 |

| PE3 | 70 | 20 | 10 | 0 |

| PE4 | 70 | 22.5 | 7.5 | 0 |

| PE5 | 70 | 22.5 | 0 | 7.5 |

| Samples | Before Soaking | After Soaking | Migration Percentage (%) | ||

|---|---|---|---|---|---|

| LOI (%) | UL-94 Rating | LOI (%) | UL-94 Rating | ||

| PE1 | 18.3 | No rating | 18.3 | No rating | 0 |

| PE2 | 22.7 | No rating | 20.6 | No rating | 2.1 |

| PE3 | 30.8 | V-0 | 28.5 | V-0 | 2.2 |

| PE4 | 28.6 | V-1 | 25.2 | V-1 | 2.8 |

| PE5 | 23.9 | V-1 | 19.3 | No rating | 4.7 |

| Samples | TTI (s) | TPHRR (s) | PHRR (kW/m2) | THR (MJ/m2) | FPI (s·m2/kW) | Residue (%) |

|---|---|---|---|---|---|---|

| PE1 | 77 | 346 | 603.6 | 161.5 | 0.1276 | 0.3 |

| PE3 | 60 | 166 | 173.5 | 51.8 | 0.3458 | 51.6 |

| PE5 | 58 | 151 | 312.9 | 94.1 | 0.1854 | 22.5 |

| Samples | Nitrogen | Air | ||

|---|---|---|---|---|

| Ti (°C) | Residue at 800 °C (%) | Ti (°C) | Residue at 800 °C (%) | |

| APP | 343.7 | 34.9 | 323.2 | 31.9 |

| PDTBP | 372.7 | 40.4 | 355.9 | 10.4 |

| 1 IFR | 338.2 | 52.1 | 321.5 | 40.5 |

| 2 IFR Calculaiton | 353.2 | 36.7 | 331.1 | 24.7 |

| Samples | Nitrogen | Air | |||||

|---|---|---|---|---|---|---|---|

| Ti (°C) | Tmax (°C) | Residue at 800 °C (%) | Ti (°C) | Tmax1 (°C) | Tmax2 (°C) | Residue at 800 °C (%) | |

| PE1 | 438.3 | 483.8 | 0.1 | 320.8 | 436.5 | 538.5 | 0 |

| PE2 | 375.4 | 482.9 | 12.5 | 327.5 | 469.2 | 564.6 | 3.8 |

| PE3 | 381.3 | 483.7 | 14.7 | 323.3 | 464.4 | 577.9 | 8.9 |

| PE4 | 375.2 | 482.6 | 13.4 | 323.1 | 425.1 | 550.5 | 8.4 |

| PE5 | 316.3 | 486.7 | 11.1 | 273.7 | 447.8 | 568.2 | 3.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Wang, J.; Ni, A.; Chen, H.; Shen, P. Synthesis of a Novel Phosphorous-Nitrogen Based Charring Agent and Its Application in Flame-retardant HDPE/IFR Composites. Polymers 2019, 11, 1062. https://doi.org/10.3390/polym11061062

Chen J, Wang J, Ni A, Chen H, Shen P. Synthesis of a Novel Phosphorous-Nitrogen Based Charring Agent and Its Application in Flame-retardant HDPE/IFR Composites. Polymers. 2019; 11(6):1062. https://doi.org/10.3390/polym11061062

Chicago/Turabian StyleChen, Junlei, Jihui Wang, Aiqing Ni, Hongda Chen, and Penglong Shen. 2019. "Synthesis of a Novel Phosphorous-Nitrogen Based Charring Agent and Its Application in Flame-retardant HDPE/IFR Composites" Polymers 11, no. 6: 1062. https://doi.org/10.3390/polym11061062

APA StyleChen, J., Wang, J., Ni, A., Chen, H., & Shen, P. (2019). Synthesis of a Novel Phosphorous-Nitrogen Based Charring Agent and Its Application in Flame-retardant HDPE/IFR Composites. Polymers, 11(6), 1062. https://doi.org/10.3390/polym11061062