Electrically Controlled Diffraction Grating in Azo Dye-Doped Liquid Crystals

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hecht, E. Optics, 4th ed.; Addison Wesley: San Francisco, CA, USA, 2002. [Google Scholar]

- Lerner, J.M. Imaging spectrometer fundamentals for researchers in the biosciences—A tutorial. Cytometry A 2006, 69, 712–734. [Google Scholar] [CrossRef] [PubMed]

- Brazas, J.C.; Kowarz, M.W. High-resolution laser-projection display system using a grating electromechanical system (GEMS). In Micromachining and Microfabrication; International Society for Optics and Photonics: Bellingham, WA, USA, 2004; pp. 65–75. [Google Scholar]

- Jayaraman, V.; Chuang, Z.M.; Coldren, L.A. Theory, design, and performance of extended tuning range semiconductor lasers with sampled gratings. IEEE J. Quantum Electron. 1993, 29, 1824–1834. [Google Scholar] [CrossRef]

- Tohmori, Y.; Yoshikuni, Y.; Ishii, H.; Kano, F.; Tamamura, T.; Kondo, Y.; Yamamoto, M. Broad-range wavelength-tunable superstructure grating (SSG) DBR lasers. IEEE J. Quantum Electron. 1993, 29, 1817–1823. [Google Scholar] [CrossRef]

- Mason, B.; Fish, G.A.; DenBaars, S.P.; Coldren, L.A. Widely tunable sampled grating DBR laser with integrated electroabsorption modulator. IEEE Photonics Technol. Lett. 1999, 11, 638–640. [Google Scholar] [CrossRef]

- Babin, S.A.; Kablukov, S.I.; Vlasov, A.A. Tunable fiber Bragg gratings for application in tunable fiber lasers. Laser Phys. 2007, 17, 1323–1326. [Google Scholar] [CrossRef]

- Muttikulangara, S.S.; Baranski, M.; Rehman, S.; Hu, L.; Miao, J. MEMS tunable diffraction grating for spaceborne imaging spectroscopic applications. Sensors 2017, 17, 2372. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.S.; Lin, Y.H.; Hu, Y.C.; Liu, C.H. A large-displacement thermal actuator designed for MEMS pitch-tunable grating. J. Micromechanics Microeng. 2008, 19, 015001. [Google Scholar] [CrossRef]

- Shih, W.C.; Kim, S.G.; Barbastathis, G. High-resolution electrostatic analog tunable grating with a single-mask fabrication process. J. Microelectromechanical Syst. 2006, 15, 763–769. [Google Scholar] [CrossRef]

- Schueller, O.J.A.; Duffy, D.C.; Rogers, J.A.; Brittain, S.T.; Whitesides, G.M. Reconfigurable diffraction gratings based on elastomeric microfluidic devices. Sens. Actuators A Phys. 1999, 78, 149–159. [Google Scholar] [CrossRef]

- Wong, C.W.; Jeon, Y.; Barbastathis, G.; Kim, S.G. Analog piezoelectric-driven tunable gratings with nanometer resolution. J. Microelectromechanical Syst. 2004, 13, 998–1005. [Google Scholar] [CrossRef]

- Kocabas, A.; Ay, F.; Dâna, A.; Aydinli, A. An elastomeric grating coupler. J. Opt. A 2005, 8, 85–87. [Google Scholar] [CrossRef]

- Guerrero, R.A.; Oliva, S.Y.C.; Indias, J.M.M. Fluidic actuation of an elastomeric grating. Appl. Opt. 2012, 51, 5812–5817. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Wu, Y.; Yu, A.; Xu, L.; Zheng, L.; Liu, Y.; Li, H.; Wang, Z.L. Self-powered modulation of elastomeric optical grating by using triboelectric nanogenerator. Nano Energy 2017, 38, 91–100. [Google Scholar] [CrossRef]

- Yeh, H.C.; Chen, G.H.; Lee, C.-R.; Mo, T.S. Optically switchable biphotonic gratings based on dye-doped cholesteric liquid crystal films. Appl. Phys. Lett. 2007, 90, 261103. [Google Scholar] [CrossRef]

- Yan, J.; Li, Y.; Wu, S.-T. High-efficiency and fast-response tunable phase grating using a blue phase liquid crystal. Opt. Lett. 2011, 36, 1404–1406. [Google Scholar] [CrossRef] [PubMed]

- Hu, W.; Srivastava, A.; Xu, F.; Sun, J.-T.; Lin, X.-W.; Cui, H.-Q.; Chigrinov, V.; Lu, Y.-Q. Liquid crystal gratings based on alternate TN and PA photoalignment. Opt. Express 2012, 20, 5384–5391. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.-Y.; Zheng, H.-Y.; Yu, K.-Y.; Huang, B.-Y.; Lin, H.-R.; Lee, C.-R.; Kuo, C.-T. Electrically tunable prism grating based on a liquid crystal film with a photoconductive layer. Opt. Mater. Express 2012, 2, 1791–1796. [Google Scholar] [CrossRef]

- Sun, J.; Srivastava, A.K.; Wang, L.; Chigrinov, V.G.; Kwok, H.S. Optically tunable and rewritable diffraction grating with photoaligned liquid crystals. Opt. Lett. 2013, 38, 2342–2344. [Google Scholar] [CrossRef]

- Chen, H.; Tan, G.; Huang, Y.; Weng, Y.; Choi, T.-H.; Yoon, T.-H.; Wu, S.-T. A low voltage liquid crystal phase grating with switchable diffraction angles. Sci. Rep. 2017, 7, 39923. [Google Scholar] [CrossRef]

- Lee, C.-R.; Mo, T.-S.; Cheng, K.-T.; Fu, T.-L.; Fu, A.Y.-G. Electrically switchable and thermally erasable biphotonic holographic gratings in dye-doped liquid crystal films. Appl. Phys. Lett. 2003, 83, 4285–4287. [Google Scholar] [CrossRef]

- Presnyakov, V.; Asatryan, K.; Galstian, T.; Chigrinov, V. Optical polarization grating induced liquid crystal micro-structure using azo-dye command layer. Opt. Express 2006, 14, 10558–10564. [Google Scholar] [CrossRef] [PubMed]

- Ho, T.J.; Chen, C.W.; Khoo, I.C. Polarisation-free and high-resolution holographic grating recording and optical phase conjugation with azo-dye doped blue-phase liquid crystals. Liq. Cryst. 2018, 45, 13–15. [Google Scholar] [CrossRef]

- Bandara, H.M.D.; Burdette, S.C. Photoisomerization in different classes of azobenzene. Chem. Soc. Rev. 2012, 41, 1809–1825. [Google Scholar] [CrossRef] [PubMed]

- Jánossy, I.; Szabados, L. Optical reorientation of nematic liquid crystals in the presence of photoisomerization. Phys. Rev. E 1998, 58, 4598–4604. [Google Scholar] [CrossRef]

- Lee, K.M.; White, T.J. Photochemical mechanism and photothermal considerations in the mechanical response of monodomain, azobenzene-functionalized liquid crystal polymer networks. Macromolecules 2012, 45, 7163–7170. [Google Scholar] [CrossRef]

- Ikeda, T.; Horiuchi, S.; Karanijit, D.B.; Kurihara, S.; Tazuke, S. Photochemically induced isothermal phase transition in polymer liquid crystals with mesogenic phenyl benzoate side chains. 1. Calorimetric studies and order parameters. Macromolecules 1990, 23, 36–42. [Google Scholar] [CrossRef]

- Khoo, I.C.; Li, H.; Liang, Y. Optically induced extraordinarily large negative orientational nonlinearity in dye-doped liquid crystal. IEEE J. Quantum Electron. 1993, 29, 1444–1447. [Google Scholar] [CrossRef]

- Chigrinov, V.; Muravski, A.; Kwok, H.S. Anchoring properties of photoaligned azo-dye materials. Phys. Rev. E 2003, 68, 061702. [Google Scholar] [CrossRef]

- Jiang, H.; Li, C.; Hunag, X. Actuators based on liquid crystalline elastomer materials. Nanoscale 2013, 5, 5225–5240. [Google Scholar] [CrossRef]

- Tien, C.-L.; Lin, R.-J.; Su, S.-H.; Horng, C.-T. Electrically tunable diffraction grating based on liquid crystals. Adv. Condens. Matter Phys. 2018, 2018, 7849529. [Google Scholar] [CrossRef]

- Kogelnik, H. Coupled wave theory for thick hologram gratings. Bell. Syst. Tech. J. 1969, 48, 2909–2947. [Google Scholar] [CrossRef]

- Heilmeier, G.H.; Zanoni, L.A. Guest-host interactions in nematic liquid crystals. A new electro-optic effect. Appl. Phys. Lett. 1968, 13, 91. [Google Scholar] [CrossRef]

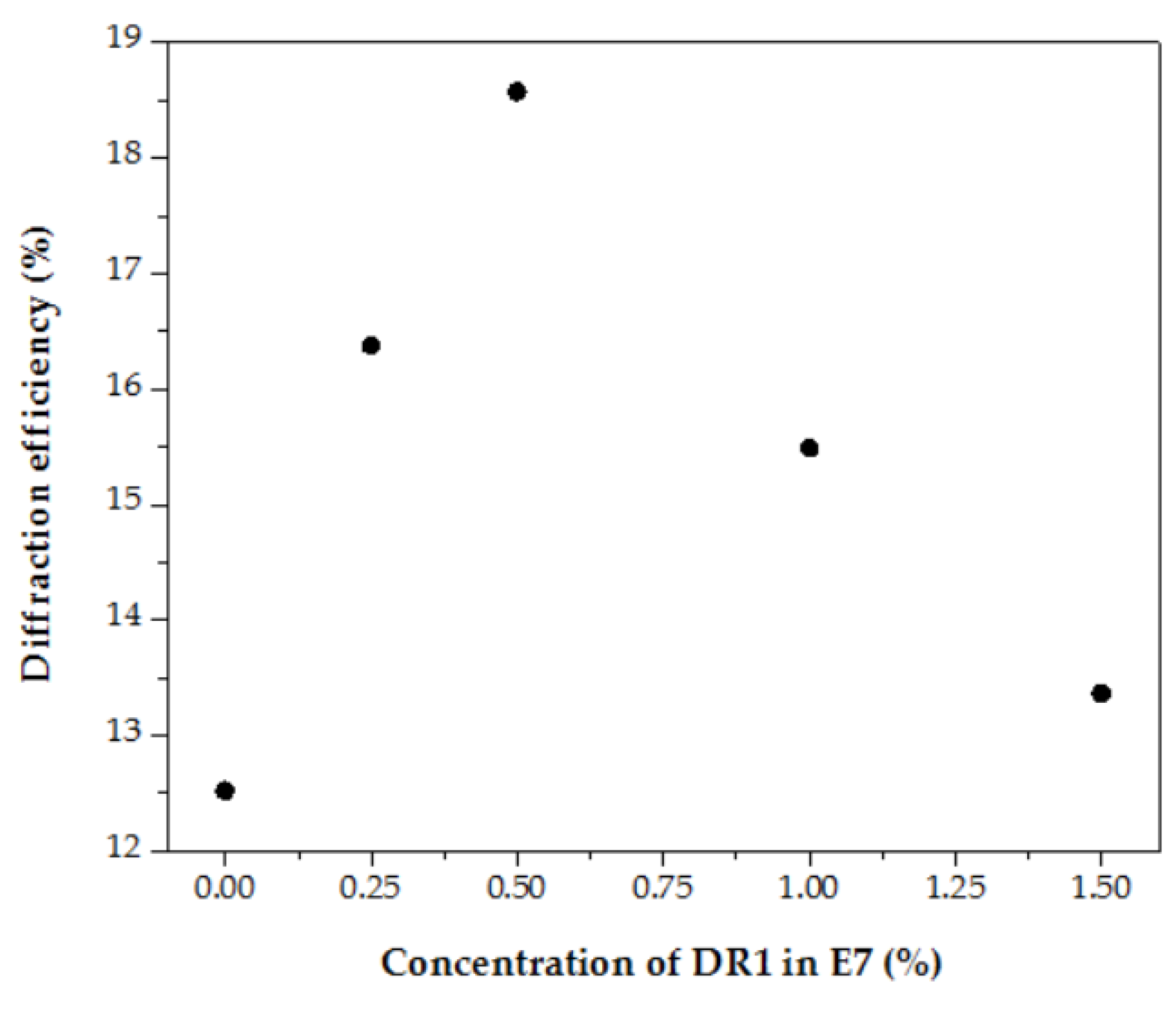

| Concentration of Dye (wt %) | Diffraction Efficiency (%) | Δn |

|---|---|---|

| 0 | 12.5 | 0.0020 |

| 0.25 | 16.2 | 0.0022 |

| 0.50 | 18.2 | 0.0023 |

| 1.00 | 15.6 | 0.0022 |

| 1.50 | 13.4 | 0.0020 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tien, C.-L.; Lin, R.-J.; Kang, C.-C.; Huang, B.-Y.; Kuo, C.-T.; Huang, S.-Y. Electrically Controlled Diffraction Grating in Azo Dye-Doped Liquid Crystals. Polymers 2019, 11, 1051. https://doi.org/10.3390/polym11061051

Tien C-L, Lin R-J, Kang C-C, Huang B-Y, Kuo C-T, Huang S-Y. Electrically Controlled Diffraction Grating in Azo Dye-Doped Liquid Crystals. Polymers. 2019; 11(6):1051. https://doi.org/10.3390/polym11061051

Chicago/Turabian StyleTien, Chuen-Lin, Rong-Ji Lin, Chi-Chung Kang, Bing-Yau Huang, Chie-Tong Kuo, and Shuan-Yu Huang. 2019. "Electrically Controlled Diffraction Grating in Azo Dye-Doped Liquid Crystals" Polymers 11, no. 6: 1051. https://doi.org/10.3390/polym11061051

APA StyleTien, C.-L., Lin, R.-J., Kang, C.-C., Huang, B.-Y., Kuo, C.-T., & Huang, S.-Y. (2019). Electrically Controlled Diffraction Grating in Azo Dye-Doped Liquid Crystals. Polymers, 11(6), 1051. https://doi.org/10.3390/polym11061051