In-Plane Behavior of Auxetic Non-Woven Fabric Based on Rotating Square Unit Geometry under Tensile Load

Abstract

1. Introduction

- by using auxetic fibers/yarns in the conventional process of weaving, knitting, braiding and non-woven production, or

- by inducing special (auxetic) structures (geometry) in the conventional process of weaving, knitting, and non-woven production using conventional fibers/yarns.

- rotating square unit geometry for knitted fabric [5];

2. Materials and Methods

3. Results and Discussion

3.1. Fabric Structure Analysis

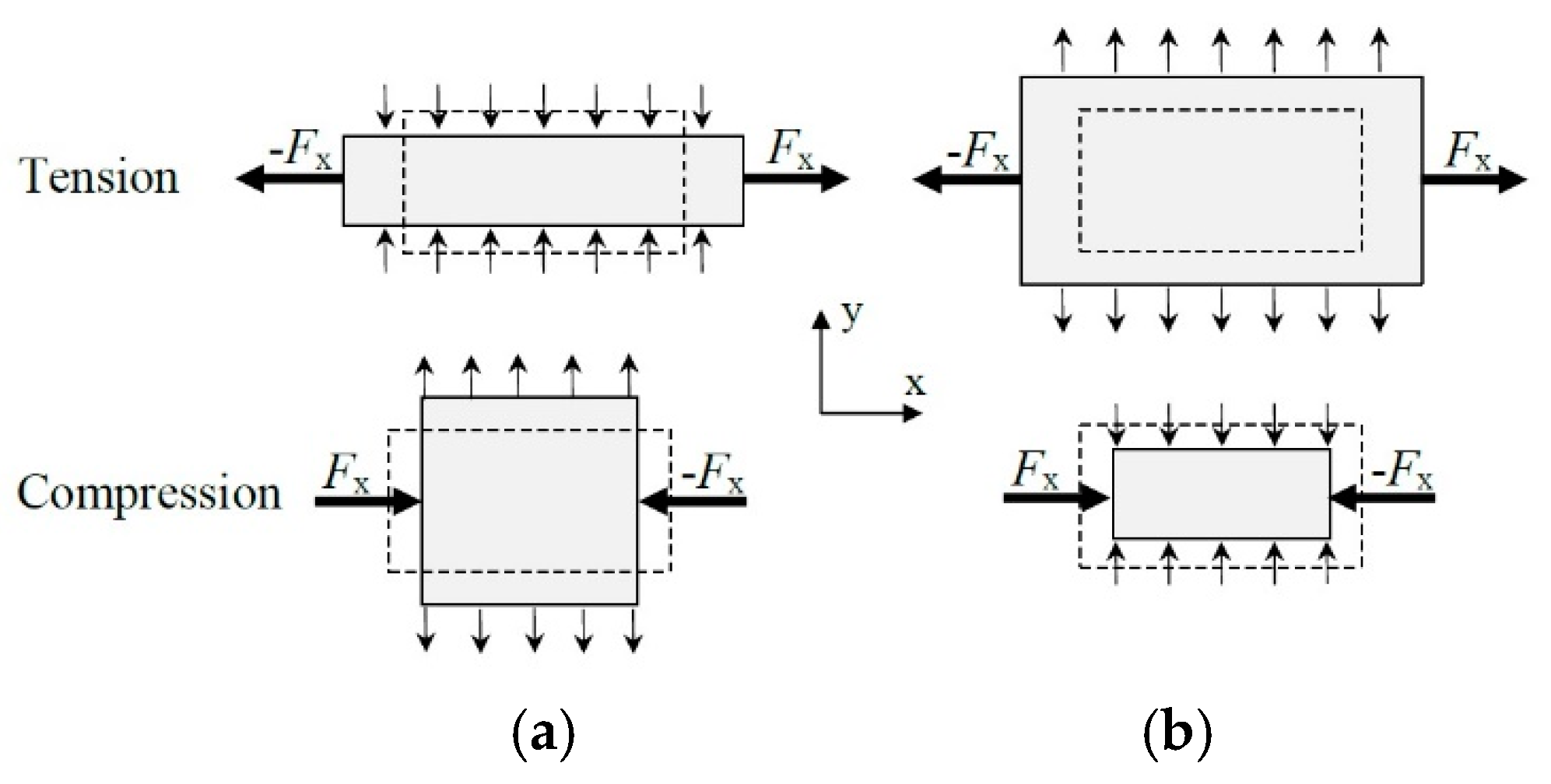

3.2. Auxetic Behaviour Analysis

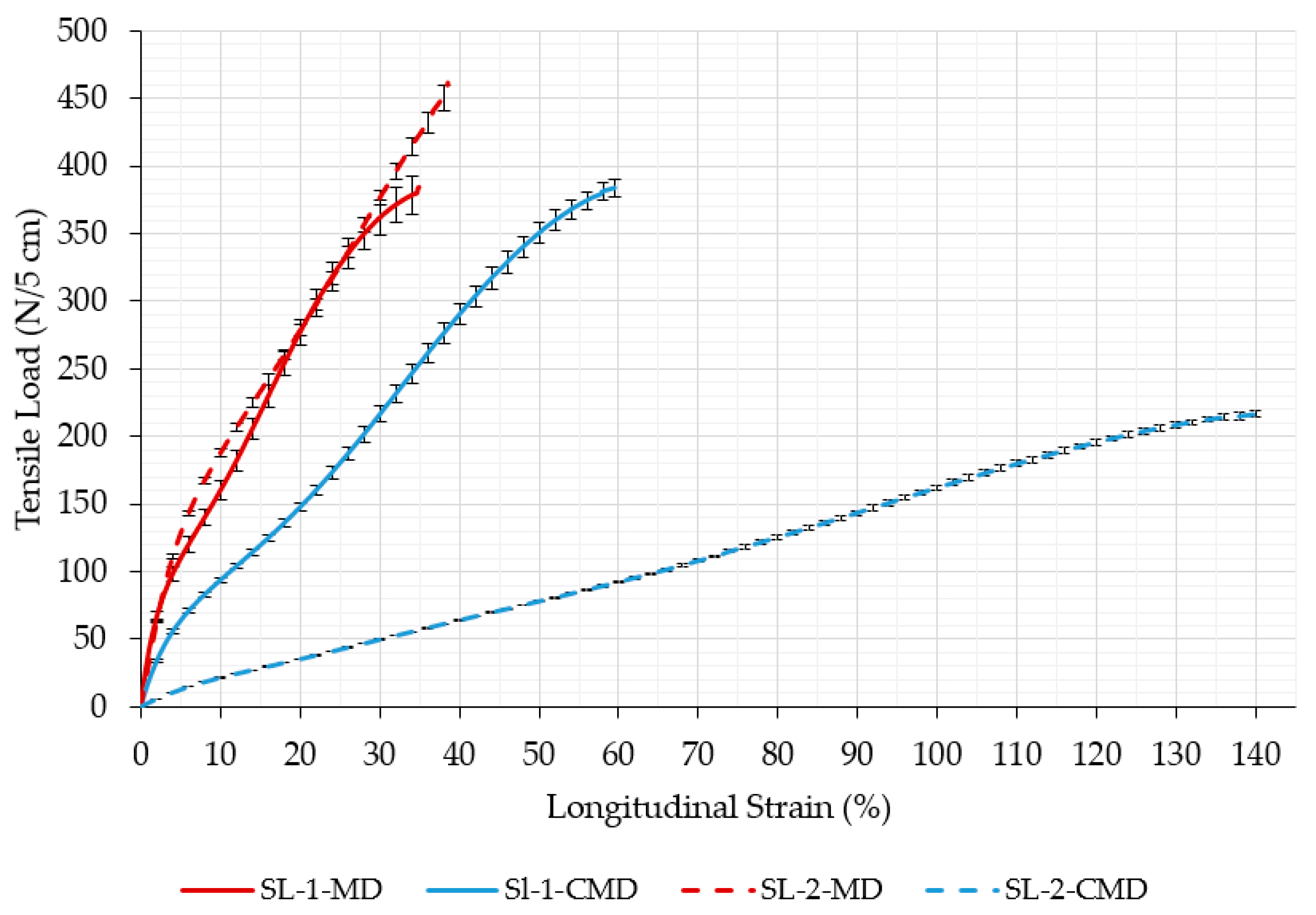

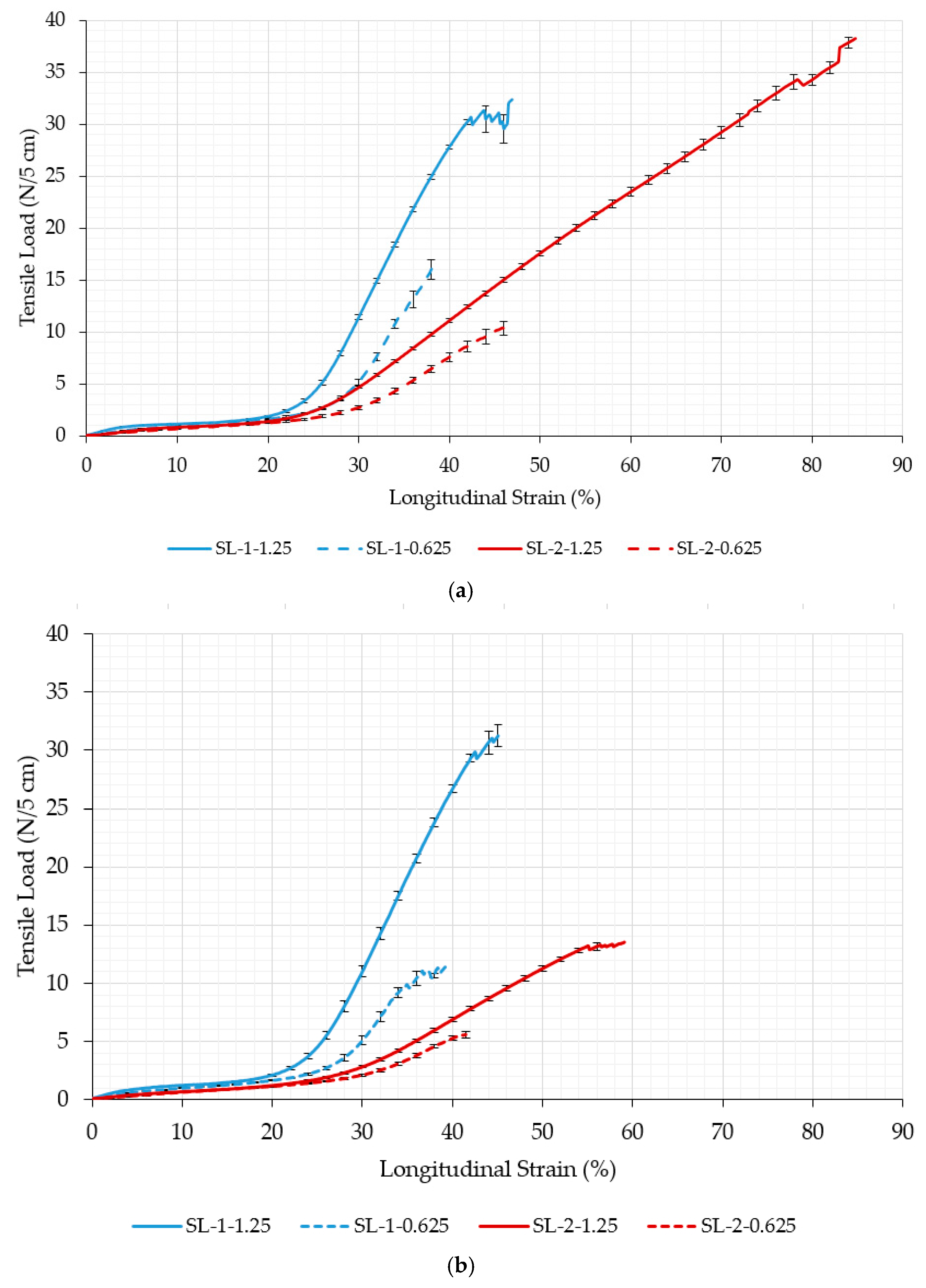

3.3. Breaking Strength and Elongation Analysis

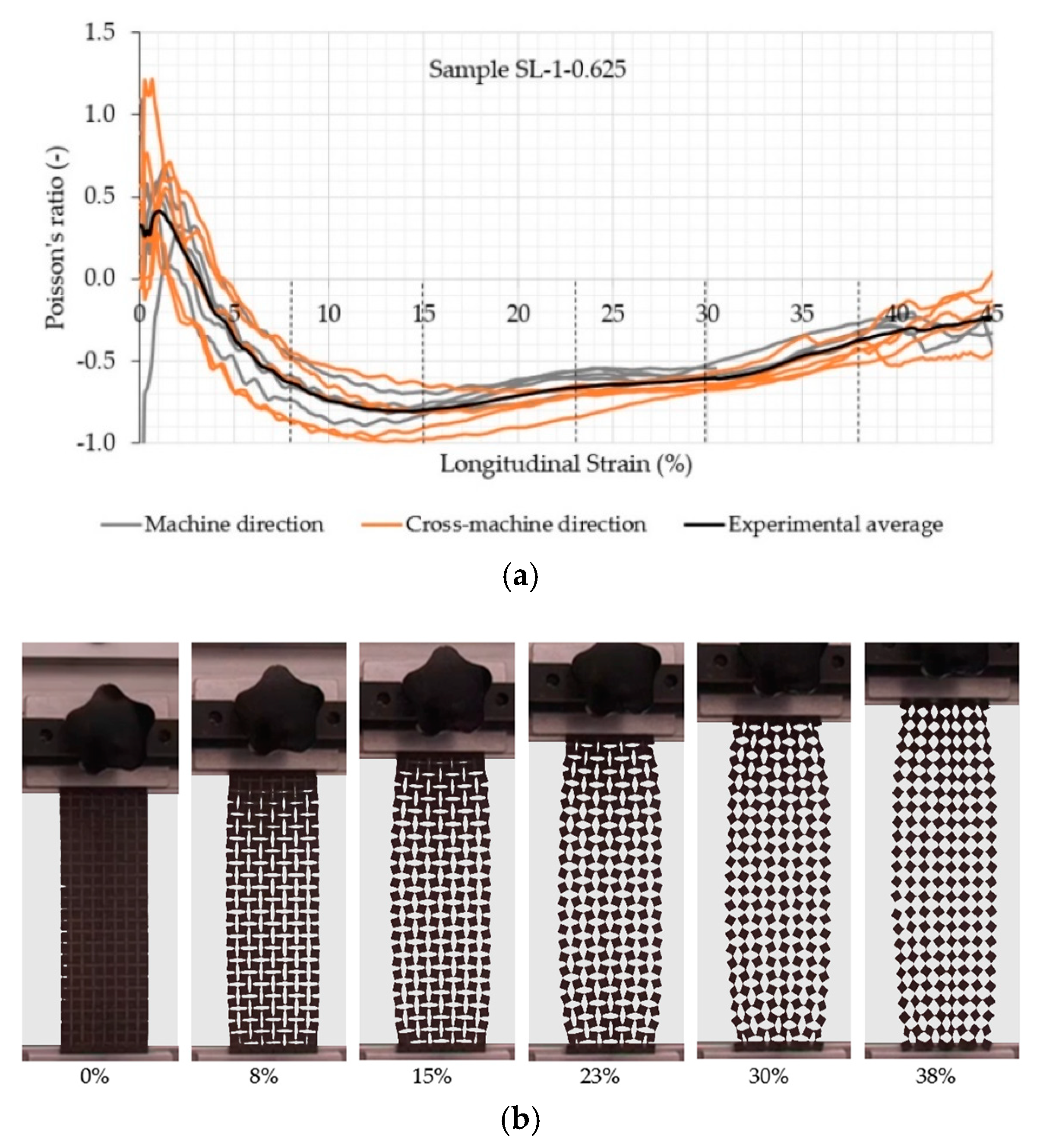

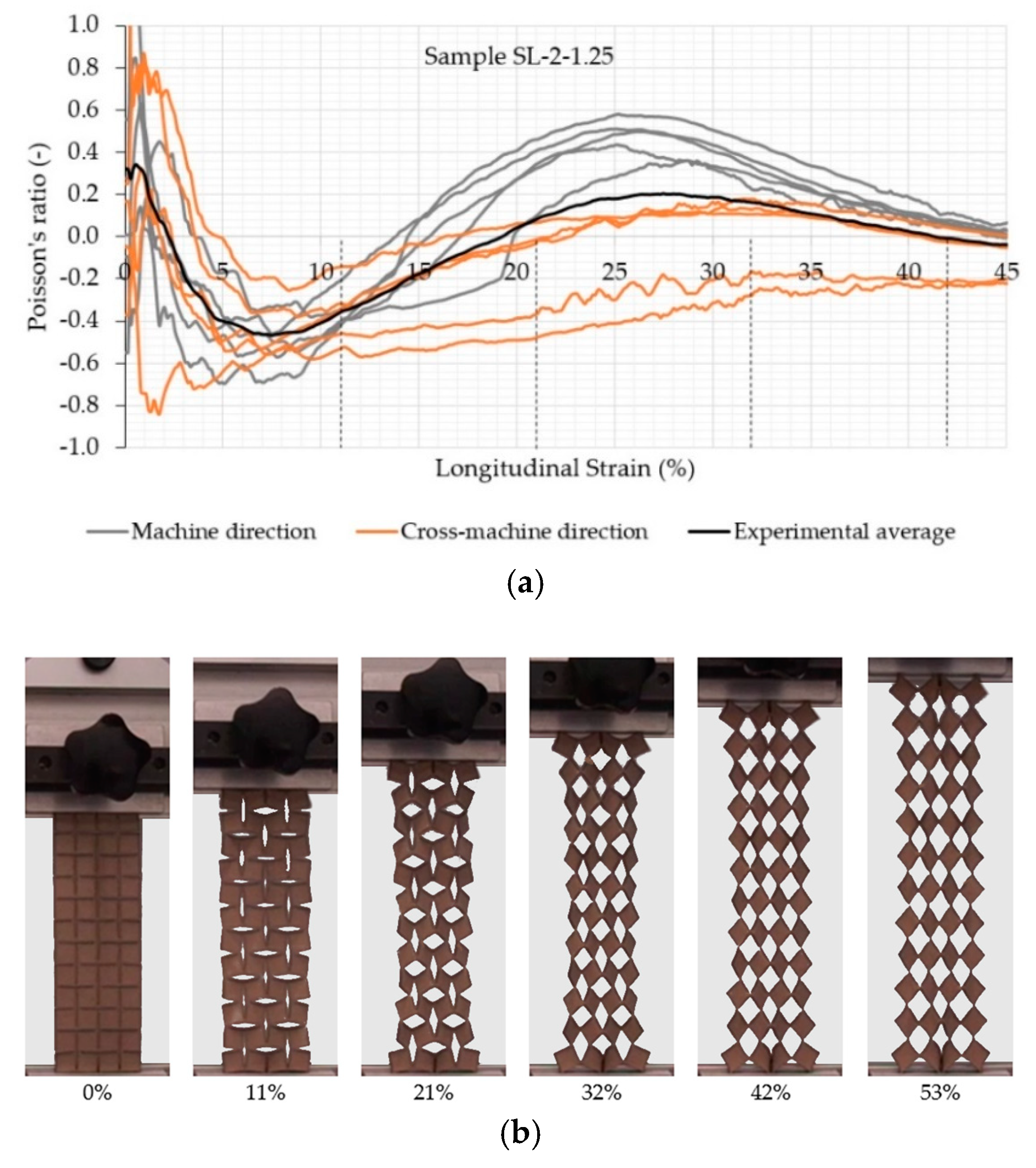

3.4. Poisson’s Ratio Evaluation

4. Conclusions

- laser cutting, which was used to induce auxetic geometry into non-woven fabric, causes a significant reduction in breaking force; therefore, their application is restricted to low tensile loads;

- tested non-woven samples with induced rotating unit cell geometry with a rotating unit size of 0.625 cm exhibit a higher negative Poisson’s ratio (up to −1.0) during tensile loading through the entire longitudinal strain range until rupture;

- non-woven fabric with equal distribution and orientation of fibers offer a better auxetic response with a smaller out-of-plane rotation of unit cells;

- the out-of-plane rotation of unit cells in non-homogenous fabric is higher in the machine direction.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ge, Z.Y.; Hu, H.; Liu, S.R. A novel plied yarn structure with negative poisson’s ratio. J. Text. Inst. 2016, 107, 578–588. [Google Scholar] [CrossRef]

- Novak, N.; Vesenjak, M.; Ren, Z. Auxetic cellular materials—A review. Stroj. Vestn.-J. Mech. Eng. 2016, 62, 485–493. [Google Scholar] [CrossRef]

- Ren, X.; Das, R.; Tran, P.; Ngo, T.D.; Xie, Y.M. Auxetic metamaterials and structures: A review. Smart Mater. Struct. 2018, 27, 38. [Google Scholar] [CrossRef]

- Steffens, F.; Rana, S.; Fangueiro, R. Development of novel auxetic textile structures using high performance fibres. Mater. Des. 2016, 106, 81–89. [Google Scholar] [CrossRef]

- Hu, H.; Wang, Z.Y.; Liu, S. Development of auxetic fabrics using flat knitting technology. Text. Res. J. 2011, 81, 1493–1502. [Google Scholar]

- Ali, M.; Zeeshan, M.; Ahmed, S.; Qadir, B.; Nawab, Y.; Anjum, A.S.; Riaz, R. Development and comfort characterization of 2d-woven auxetic fabric for wearable and medical textile applications. Cloth. Text. Res. J. 2018, 36, 199–214. [Google Scholar] [CrossRef]

- Mercieca, L.A.S.; Formosa, C.; Grima, J.N.; Chockalingam, N.; Gatt, R.; Gatt, A. On the use of auxetics in footwear: Investigating the effect of padding and padding material on forefoot pressure in high heels. Phys. Status Solidi B-Basic Solid State Phys. 2017, 254, 5. [Google Scholar]

- Zeng, J.F.; Hu, H.; Zhou, L. A study on negative poisson’s ratio effect of 3d auxetic orthogonal textile composites under compression. Smart Mater. Struct. 2017, 26, 14. [Google Scholar] [CrossRef]

- Subramani, P.; Rana, S.; Ghiassi, B.; Fangueiro, R.; Oliveira, D.V.; Lourenco, P.B.; Xavier, J. Development and characterization of novel auxetic structures based on re-entrant hexagon design produced from braided composites. Compos. Pt. B-Eng. 2016, 93, 132–142. [Google Scholar] [CrossRef]

- Sloan, M.R.; Wright, J.R.; Evans, K.E. The helical auxetic yarn—A novel structure for composites and textiles; geometry, manufacture and mechanical properties. Mech. Mater. 2011, 43, 476–486. [Google Scholar] [CrossRef]

- Wright, J.R.; Burns, M.K.; James, E.; Sloan, M.R.; Evans, K.E. On the design and characterisation of low-stiffness auxetic yarns and fabrics. Text. Res. J. 2012, 82, 645–654. [Google Scholar] [CrossRef]

- Hu, H.; Zulifqar, A. Auxetic textile materials—A review. J. Text. Eng. Fash. Technol. 2016, 1, 20. [Google Scholar] [CrossRef]

- Strek, T.; Jopek, H.; Fraska, A. Torsion of elliptical composite beams with auxetic phase. Phys. Status Solidi B-Basic Solid State Phys. 2016, 253, 1359–1368. [Google Scholar] [CrossRef]

- Strek, T.; Jopek, H.; Wojciechowski, K.W. The influence of large deformations on mechanical properties of sinusoidal ligament structures. Smart Mater. Struct. 2016, 25, 10. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Hu, H. Auxetic materials and their potential applications in textiles. Text. Res. J. 2014, 84, 1600–1611. [Google Scholar] [CrossRef]

- Ma, P.B.; Chang, Y.P.; Boakye, A.; Jiang, G.M. Review on the knitted structures with auxetic effect. J. Text. Inst. 2017, 108, 947–961. [Google Scholar] [CrossRef]

- Rant, D.; Rijavec, T.; Pavko-Cuden, A. Auxetic textiles. Acta Chim. Slov. 2013, 60, 715–723. [Google Scholar]

- Ali, M.; Zeeshan, M.; Qadir, M.B.; Riaz, R.; Ahmad, S.; Nawab, Y.; Anjum, A.S. Development and mechanical characterization of weave design based 2d woven auxetic fabrics for protective textiles. Fiber. Polym. 2018, 19, 2431–2438. [Google Scholar] [CrossRef]

- Alderson, K.; Alderson, A.; Anand, S.; Simkins, V.; Nazare, S.; Ravirala, N. Auxetic warp knit textile structures. Phys. Status Solidi B-Basic Solid State Phys. 2012, 249, 1322–1329. [Google Scholar] [CrossRef]

- Cao, H.; Zulifqar, A.; Hua, T.; Hu, H. Bi-stretch auxetic woven fabrics based on foldable geometry. Text. Res. J. 2019, 89, 2694–2712. [Google Scholar] [CrossRef]

- Grimmelsmann, N.; Meissner, H.; Ehrmann, A. 3D printed auxetic forms on knitted fabrics for adjustable permeability and mechanical properties. In Proceedings of the Global Conference on Polymer and Composite Materials (PCM), HangZhou, China, 20–23 May 2016; IOP Publishing Ltd.: Hangzhou, China, 2016. [Google Scholar]

- Grima, J.N.; Cauchi, R.; Gatt, R.; Attard, D. Honeycomb composites with auxetic out-of-plane characteristics. Compos. Struct. 2013, 106, 150–159. [Google Scholar] [CrossRef]

- Verma, P.; Shofner, M.L.; Lin, A.; Wagner, K.B.; Griffin, A.C. Inducing out-of-plane auxetic behavior in needle-punched nonwovens. Phys. Status Solidi B-Basic Solid State Phys. 2015, 252, 1455–1464. [Google Scholar] [CrossRef]

- Bhullar, S.K.; Rana, D.; Lekesiz, H.; Bedeloglu, A.C.; Ko, J.; Cho, Y.; Aytac, Z.; Uyar, T.; Jun, M.; Rarnalingam, M. Design and fabrication of auxetic pcl nanofiber membranes for biomedical applications. Mater. Sci. Eng. C-Mater. Biol. Appl. 2017, 81, 334–340. [Google Scholar] [CrossRef] [PubMed]

- Grima, J.N.; Alderson, A.; Evans, K.E. Auxetic behaviour from, rotating rigid units. Phys. Status Solidi B-Basic Solid State Phys. 2005, 242, 561–575. [Google Scholar] [CrossRef]

- Grima, J.N.; Evans, K.E. Auxetic behavior from rotating squares. J. Mater. Sci. Lett. 2000, 19, 1563–1565. [Google Scholar] [CrossRef]

- Grima, J.N.; Evans, K.E. Auxetic behavior from rotating triangles. J. Mater. Sci. 2006, 41, 3193–3196. [Google Scholar] [CrossRef]

- The Accord.Net Framework. Available online: http://accord-framework.net (accessed on 6 May 2019).

| Sample ID | Raw Material | Fabric Mass per Unit Area (g·m−2) | Fabric Thickness (mm) | Fabric Density (g·cm−3) |

|---|---|---|---|---|

| SL-1 | PET fibers | 29 | 0.7 | 0.041 |

| SL-2 | PET fibers | 38 | 0.7 | 0.054 |

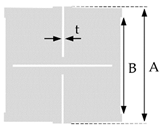

| One Repeat Unit of Rotating Squares Geometry (4 Cells) | Cell Size (cm) | A (mm) | B (mm) | t (mm) |

|---|---|---|---|---|

| 1.25 | 25 | 23 | 0.2 |

| 0.625 | 12.5 | 10.5 | 0.2 |

| Machine Direction (MD) | Cross-Machine Direction (CMD) | ||||

|---|---|---|---|---|---|

| Type of Fabric | Sample Designation | Breaking Force (N/5 cm) | Elongation at Break (%) | Breaking Force (N/5 cm) | Elongation at Break (%) |

| NF * | SL1 | 384.3 ± 27.9 | 36.8 ± 1.7 | 385.1 ± 9.3 | 59.7 ± 2.0 |

| ANF ** | SL-1-1.25 | 32.4 ± 1.4 | 46.9 ± 1.5 | 31.2 ± 2.4 | 45.1 ± 2.3 |

| ANF | SL-1-0.625 | 16.3 ± 2.4 | 38.3 ± 1.0 | 11.6 ± 0.7 | 39.5 ± 1.1 |

| NF | SL-2 | 459.1 ± 35.6 | 39.7 ± 2.6 | 217.0 ± 4.9 | 139.7 ± 4.6 |

| ANF | SL-2-1.25 | 38.3 ± 3.4 | 84.8 ± 4.4 | 13.5 ± 0.2 | 59.1 ± 1.1 |

| ANF | SL-2-0.625 | 10.6 ± 1.6 | 46.7 ± 2.0 | 5.6 ± 0.7 | 41.5 ± 1.1 |

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|

| Corrected Model | 1,639,050.964 * | 11 | 149,004.633 | 859.634 | 0.001 |

| Intercept | 1,030,951.149 | 1 | 1,030,951.149 | 5947.739 | 0.001 |

| Material | 5467.609 | 1 | 5467.609 | 31.544 | 0.001 |

| Geometry | 1,483,019.484 | 2 | 741,509.742 | 4277.900 | 0.001 |

| Direction | 30,602.714 | 1 | 30,602.714 | 176.552 | 0.001 |

| Material & Geometry | 5274.742 | 2 | 2637.371 | 15.215 | 0.001 |

| Material & Direction | 28,392.401 | 1 | 28,392.401 | 163.801 | 0.001 |

| Geometry & Direction | 39,859.432 | 2 | 19,929.716 | 114.978 | 0.001 |

| Material & Geometry & Direction | 42,729.241 | 2 | 21,364.621 | 123.256 | 0.001 |

| Error | 7973.409 | 46 | 173.335 | ||

| Total | 2,650,547.505 | 58 | |||

| Corrected Total | 1,647,024.373 | 57 |

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|

| Corrected Model | 47,005.572 * | 11 | 4273.234 | 713.477 | 0.001 |

| Intercept | 187,114.877 | 1 | 187,114.877 | 31,241.474 | 0.001 |

| Material | 8686.778 | 1 | 8686.778 | 1450.380 | 0.001 |

| Geometry | 6792.977 | 2 | 3396.488 | 567.092 | 0.001 |

| Direction | 3143.862 | 1 | 3143.862 | 524.912 | 0.001 |

| Material & Geometry | 3004.780 | 2 | 1502.390 | 250.845 | 0.001 |

| Material & Direction | 836.336 | 1 | 836.336 | 139.638 | 0.001 |

| Geometry & Direction | 15,760.595 | 2 | 7880.297 | 1315.727 | 0.001 |

| Material & Geometry & Direction | 7093.208 | 2 | 3546.604 | 592.156 | 0.001 |

| Error | 275.508 | 46 | 5.989 | ||

| Total | 237,876.501 | 58 | |||

| Corrected Total | 47,281.080 | 57 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dobnik Dubrovski, P.; Novak, N.; Borovinšek, M.; Vesenjak, M.; Ren, Z. In-Plane Behavior of Auxetic Non-Woven Fabric Based on Rotating Square Unit Geometry under Tensile Load. Polymers 2019, 11, 1040. https://doi.org/10.3390/polym11061040

Dobnik Dubrovski P, Novak N, Borovinšek M, Vesenjak M, Ren Z. In-Plane Behavior of Auxetic Non-Woven Fabric Based on Rotating Square Unit Geometry under Tensile Load. Polymers. 2019; 11(6):1040. https://doi.org/10.3390/polym11061040

Chicago/Turabian StyleDobnik Dubrovski, Polona, Nejc Novak, Matej Borovinšek, Matej Vesenjak, and Zoran Ren. 2019. "In-Plane Behavior of Auxetic Non-Woven Fabric Based on Rotating Square Unit Geometry under Tensile Load" Polymers 11, no. 6: 1040. https://doi.org/10.3390/polym11061040

APA StyleDobnik Dubrovski, P., Novak, N., Borovinšek, M., Vesenjak, M., & Ren, Z. (2019). In-Plane Behavior of Auxetic Non-Woven Fabric Based on Rotating Square Unit Geometry under Tensile Load. Polymers, 11(6), 1040. https://doi.org/10.3390/polym11061040