Shape Memory Behavior of Carbon Black-reinforced Trans-1,4-polyisoprene and Low-density Polyethylene Composites

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of the TPI/LDPE/CB Composites

2.3. Cure Characteristics of the Composites

2.4. Mechanical Characterization

2.5. Differential Scanning Calorimetry (DSC)

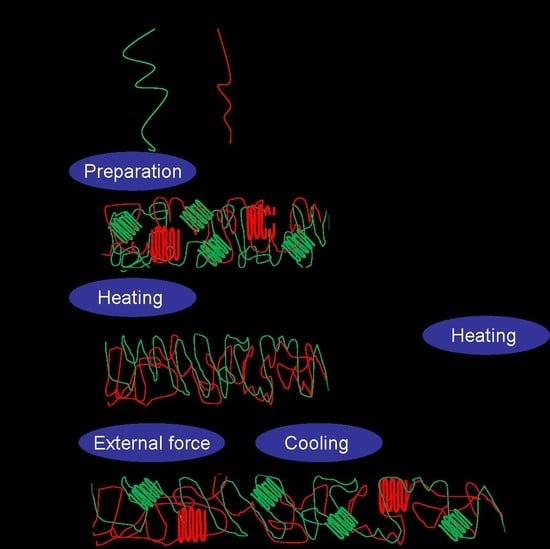

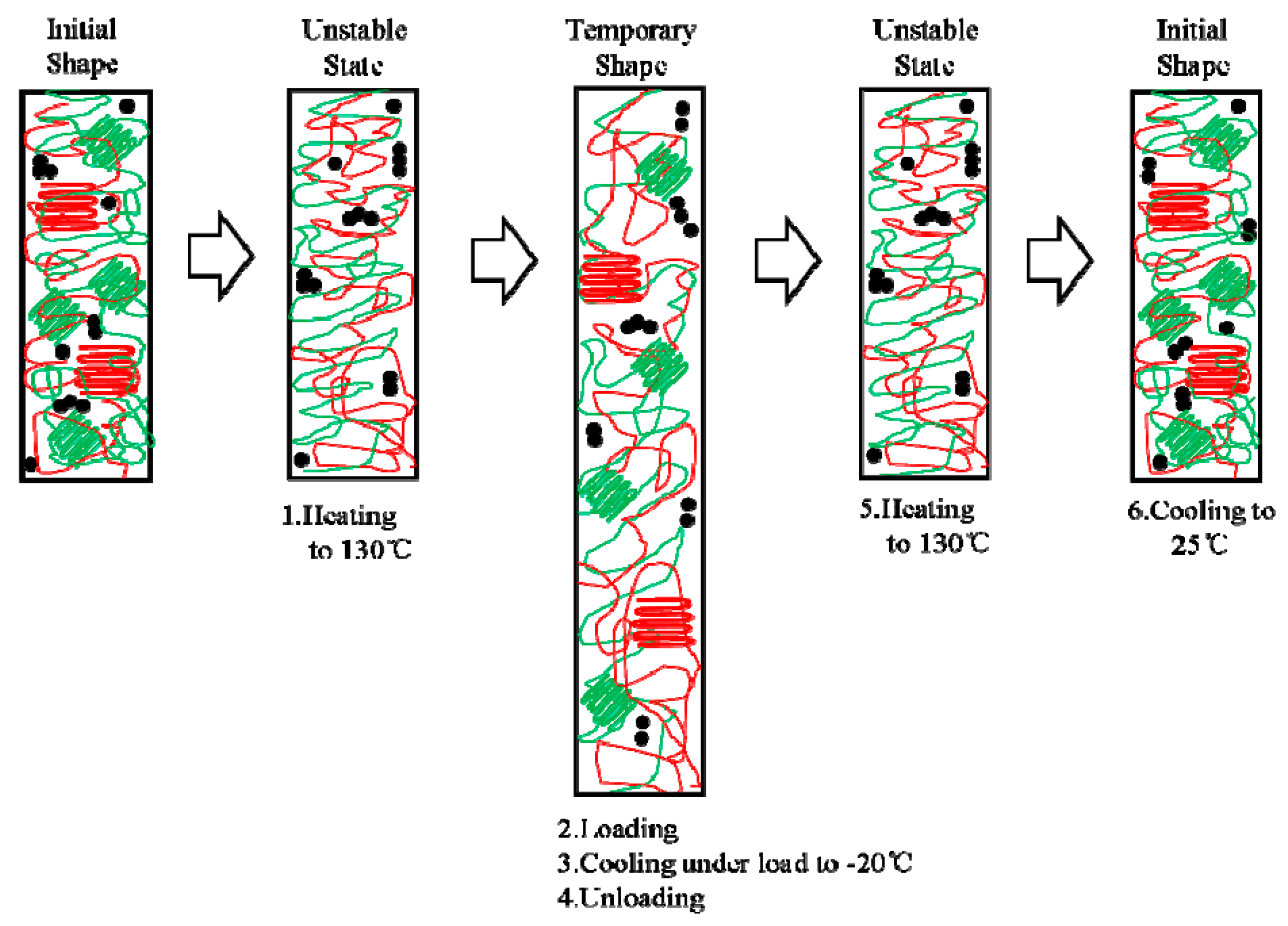

2.6. Shape Memory Effect

3. Result and Discussion

3.1. Curing, Mechanical Properties

3.2. DSC Analysis

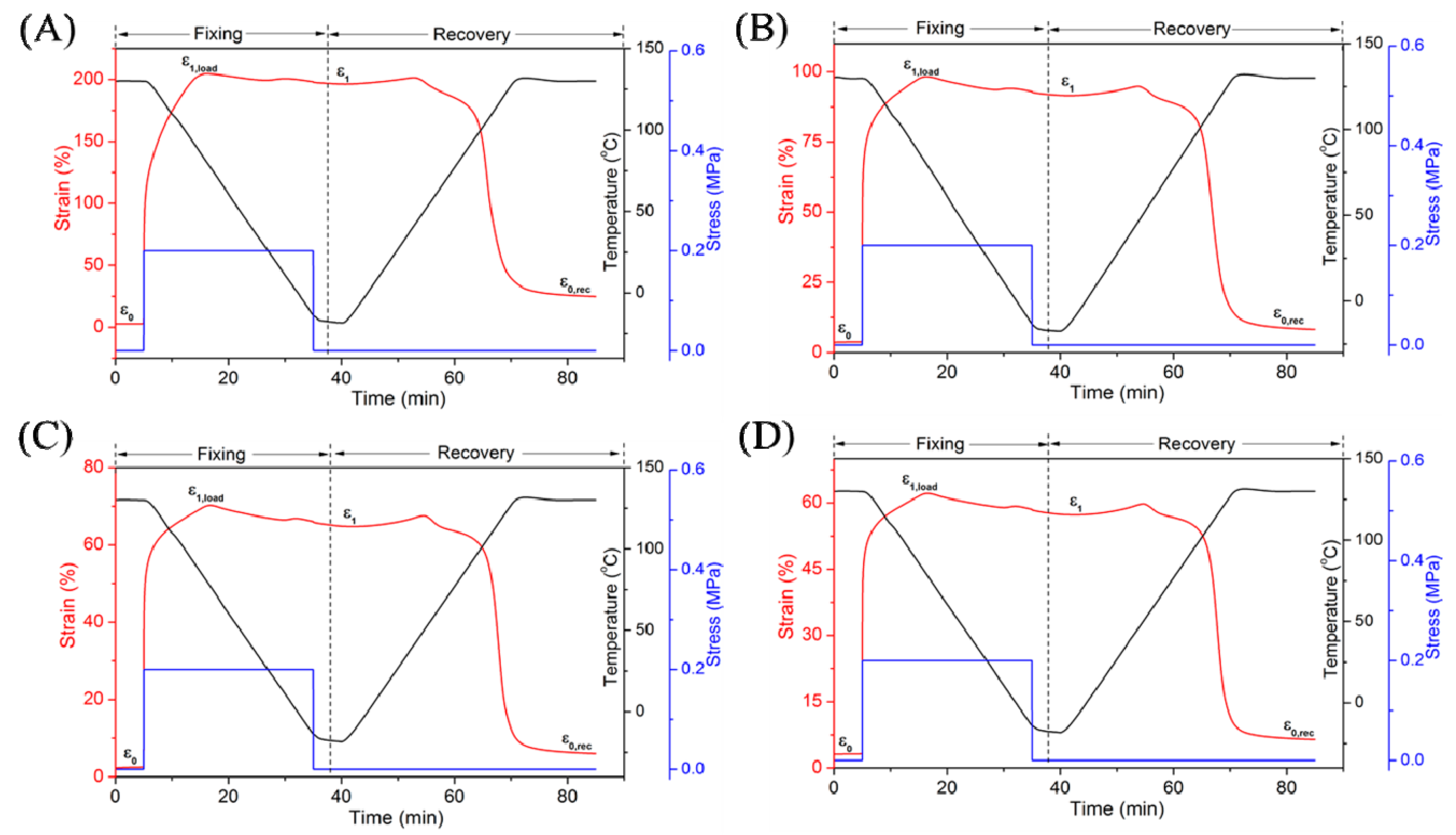

3.3. Shape Memory Effect Analysis

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Pilate, F.; Toncheva, A.; Dubois, P.; Raquez, J.M. Shape-memory polymers for multiple applications in the materials world. Eur. Polym. J. 2016, 80, 268–294. [Google Scholar]

- Liu, Y.; Lv, H.; Lan, X.; Leng, J.; Du, S. Review of electro-active shape-memory polymer composite. Compos. Sci. Technol. 2009, 69, 2064–2068. [Google Scholar]

- Lu, H.; Yao, Y.; Huang, W.M.; Leng, J.; Hui, D. Significantly improving infrared light-induced shape recovery behavior of shape memory polymeric nanocomposite via a synergistic effect of carbon nanotube and boron nitride. Compos. Part B Eng. 2014, 62, 256–261. [Google Scholar] [CrossRef]

- Kumar, U.N.; Kratz, K.; Wagermaier, W.; Behl, M.; Lendlein, A.J. Non-contact actuation of triple-shape effect in multiphase polymer network nanocomposites in alternating magnetic field. Mater. Chem. 2010, 20, 3404–3415. [Google Scholar] [CrossRef]

- Guo, W.; Lu, C.H.; Orbach, R.; Wang, F.; Qi, X.J.; Cecconello, A.; Seliktar, D.; Willner, I. pH-Stimulated DNA Hydrogels Exhibiting Shape-Memory Properties. Adv. Mater. 2015, 27, 73–78. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.; O’Kelly, K.; Chen, B. Poly (vinyl alcohol) particle-reinforced elastomer composites with water-active shape-memory effects. Eur. Polym. J. 2014, 53, 230–237. [Google Scholar] [CrossRef]

- Wu, L.; Jin, C.; Sun, X. Synthesis, properties, and light-induced shape memory effect of multiblock polyesterurethanes containing biodegradable segments and pendant cinnamamide groups. Biomacromolecules 2010, 12, 235–241. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Chen, Z.; Zheng, Z.; Zhu, X.; Wang, H. Shape memory polymer hybrids of SBS/dl-PLA and their shape memory effects. Mater. Chem. Phys. 2013, 137, 750–755. [Google Scholar] [CrossRef]

- Nji, J.; Li, G. A biomimic shape memory polymer based self-healing particulate composite. Polymer 2010, 51, 6021–6029. [Google Scholar] [CrossRef]

- Chen, J.; Fang, L.; Xu, Z.; Lu, C. Self-healing epoxy coatings curing with varied ratios of diamine and monoamine triggered via near-infrared light. Prog. Org. Coat. 2016, 101, 543–552. [Google Scholar] [CrossRef]

- Habault, D.; Zhang, H.; Zhao, Y. Light-triggered self-healing and shape-memory polymers. Chem. Soc. Rev. 2013, 42, 7244–7256. [Google Scholar] [CrossRef]

- Hu, J.; Meng, H.; Li, G.; Ibekwe, S.I. A review of stimuli-responsive polymers for smart textile applications. Smart Mater. Struct. 2012, 21, 053001. [Google Scholar] [CrossRef]

- Liu, Y.; Du, H.; Liu, L.; Leng, J. Shape memory polymers and their composites in aerospace applications: A review. Smart Mater. Struct. 2014, 23, 23001. [Google Scholar] [CrossRef]

- Chan, B.Q.Y.; Low, Z.W.K.; Heng, S.J.W.; Chan, S.Y.; Owh, C.; Loh, X.J. Recent advances in shape memory soft materials for biomedical applications. ACS Appl. Mater. Interfaces 2016, 8, 10070–10087. [Google Scholar] [CrossRef] [PubMed]

- Xie, T. Recent advances in polymer shape memory. Polymer 2011, 52, 4985–5000. [Google Scholar] [CrossRef]

- Hu, J.; Zhu, Y.; Huang, H.; Lu, J. Recent advances in shape–memory polymers: Structure, mechanism, functionality, modeling and applications. Prog. Polym. Sci. 2012, 37, 1720–1763. [Google Scholar] [CrossRef]

- Liu, C.; Qin, H.; Mather, P.T. Review of progress in shape-memory polymers. J. Mater. Chem. 2007, 17, 1543–1558. [Google Scholar] [CrossRef]

- Meng, H.; Li, G. A review of stimuli-responsive shape memory polymer composites. Polymer 2013, 54, 2199–2221. [Google Scholar] [CrossRef]

- Leng, J.; Lan, X.; Liu, Y.; Du, S. Shape-memory polymers and their composites: stimulus methods and applications. Prog. Polym. Sci. 2011, 56, 1077–1135. [Google Scholar] [CrossRef]

- Du, Z.; Zeng, X.M.; Liu, Q.; Schuh, C.A.; Gan, C.L. Superelasticity in micro-scale shape memory ceramic particles. Acta Mater. 2017, 123, 255–263. [Google Scholar] [CrossRef]

- Eggeler, G.; Hornbogen, E.; Yawny, A.; Heckmann, A.; Wagner, M. Structural and functional fatigue of NiTi shape memory alloys. Mat. Sci. Eng. A 2004, 378, 24–33. [Google Scholar] [CrossRef]

- Meng, Q.; Hu, J. A review of shape memory polymer composites and blends. Compos. Part A Appl. Sci. 2009, 40, 1661–1672. [Google Scholar] [CrossRef]

- Zhao, Q.; Qi, H.J.; Xie, T. Recent progress in shape memory polymer: New behavior, enabling materials, and mechanistic understanding. Prog. Polym. Sci. 2015, 49, 79–120. [Google Scholar] [CrossRef]

- Xia, L.; Wang, Y.; Lu, N.; Xin, Z. Facile fabrication of shape memory composites from natural Eucommia rubber and high density polyethylene. Polym. Int. 2017, 66, 653–658. [Google Scholar] [CrossRef]

- Zhao, J.; Chen, M.; Wang, X.; Zhao, X.; Wang, Z.; Dang, Z.; Ma, L.; Hu, G.H.; Chen, F. Triple shape memory effects of cross-linked polyethylene/polypropylene blends with cocontinuous architecture. ACS Appl. Mater. Interfaces 2013, 5, 5550–5556. [Google Scholar] [CrossRef] [PubMed]

- Xia, L.; Xian, J.; Geng, J.; Wang, Y.; Shi, F.; Zhou, Z.; Lu, N.; Du, A.; Xin, Z. Multiple shape memory effects of trans-1, 4-polyisoprene and low-density polyethylene blends. Polym. Int. 2017, 66, 1382–1388. [Google Scholar] [CrossRef]

- Ma, L.; Zhao, J.; Wang, X.; Chen, M.; Liang, Y.; Wang, Z.; Yu, Z.; Hedden, R.C. Effects of carbon black nanoparticles on two-way reversible shape memory in crosslinked polyethylene. Polymer 2015, 56, 490–497. [Google Scholar] [CrossRef]

- Gunes, I.S.; Cao, F.; Jana, S.C. Evaluation of nanoparticulate fillers for development of shape memory polyurethane nanocomposites. Polymer 2008, 49, 2223–2234. [Google Scholar] [CrossRef]

- Rogers, N.; Khan, F. Characterization of deformation induced changes to conductivity in an electrically triggered shape memory polymer. Polym. Test. 2013, 32, 71–77. [Google Scholar] [CrossRef]

- Le, H.H.; Schoß, M.; Ilisch, S.; Gohs, U.; Heinrich, G.; Pham, T.; Radusch, H.J. CB filled EOC/EPDM blends as a shape-memory material: Manufacturing, morphology and properties. Polymer 2011, 52, 5858–5866. [Google Scholar] [CrossRef]

- Qi, X.; Xiu, H.; Wei, Y.; Zhou, Y.; Guo, Y.; Huang, R.; Bai, H.; Fu, Q. Enhanced shape memory property of polylactide/thermoplastic poly (ether) urethane composites via carbon black self-networking induced co-continuous structure. Compos. Sci. Technol. 2017, 139, 8–16. [Google Scholar] [CrossRef]

- Tchoudakov, R.; Breuer, O.; Narkis, M.; Siegmann, A. Conductive polymer blends with low carbon black loading: High impact polystyrene/thermoplastic elastomer (styrene-isoprene-styrene). Polym. Eng. Sci. 1997, 37, 1928–1935. [Google Scholar] [CrossRef]

- Duan, L.; D’hooge, D.R.; Spoerk, M.; Cornillie, P.; Cardon, L. Facile and Low-Cost Route for Sensitive Stretchable Sensors by Controlling Kinetic and Thermodynamic Conductive Network Regulating Strategies. ACS Appl. Mater. Interfaces 2018, 10, 22678–22691. [Google Scholar] [CrossRef]

- Duan, L.; Spoerk, M.; Wieme, T.; Cornillie, P.; Xia, H.; Zhang, J.; D’hooge, D.R. Designing formulation variables of extrusion-based manufacturing of carbon black conductive polymer composites for piezoresistive sensing. Compos. Sci. Technol. 2019, 171, 78–85. [Google Scholar] [CrossRef]

- Xie, T. Tunable polymer multi-shape memory effect. Nature 2010, 464, 267. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Mather, P.T. Triple-shape polymeric composites (TSPCs). Adv. Funct. Mater. 2010, 20, 2649–2656. [Google Scholar] [CrossRef]

- Kolesov, I.S.; Kratz, K.; Lendlein, A.; Radusch, H.J. Kinetics and dynamics of thermally-induced shape-memory behavior of crosslinked short-chain branched polyethylenes. Polymer 2009, 50, 5490–5498. [Google Scholar] [CrossRef]

| Chemicals | A | B | C | D |

|---|---|---|---|---|

| TPI | 60 | 60 | 60 | 60 |

| LDPE | 40 | 40 | 40 | 40 |

| DCP | 0.4 | 0.4 | 0.4 | 0.4 |

| Antioxidant MB | 1.5 | 1.5 | 1.5 | 1.5 |

| CB (N330) | 0 | 5 | 10 | 15 |

| Properties | Dosage of CB (N330) | |||

|---|---|---|---|---|

| A | B | C | D | |

| MH (dN·m) | 4.95 | 5.79 | 6.66 | 7.61 |

| ML (dN·m) | 2.06 | 2.42 | 2.68 | 2.99 |

| MH-ML (dN·m) | 2.89 | 3.37 | 3.98 | 4.62 |

| T10 (min) | 1.30 | 1.15 | 1.07 | 1.03 |

| T90 (min) | 16.00 | 13.67 | 13.02 | 11.83 |

| Cure rate index (min−1) | 6.80 | 7.99 | 8.37 | 9.26 |

| Properties | Dosage of CB (N330) | |||

|---|---|---|---|---|

| A | B | C | D | |

| Tensile strength (MPa) | 14.9 | 17.3 | 18.5 | 19.8 |

| 100% modulus (MPa) | 7.4 | 8.3 | 8.4 | 8.6 |

| 300% modulus (MPa) | 9.7 | 11.4 | 11.7 | 12.5 |

| Elongation at break (%) | 575 | 567 | 602 | 612 |

| Tear strength (kN/m) | 69.2 | 76.2 | 78.2 | 79.4 |

| Properties | Dosage of CB (N330) | |||

|---|---|---|---|---|

| A | B | C | D | |

| Xc (TPI) (%) | 12.3 | 14.4 | 13.7 | 12.7 |

| Tm (TPI) (°C) | 35.19 | 35.45 | 34.95 | 35.61 |

| ΔHm(TPI) (J/g) | 22.91 | 26.91 | 25.62 | 23.78 |

| Xc (LDPE) (%) | 13.4 | 14.7 | 14.4 | 13.1 |

| Tm (LDPE) (°C) | 99.87 | 100.40 | 99.46 | 99.02 |

| ΔHm(LDPE) (J/g) | 37.02 | 40.79 | 39.89 | 36.37 |

| Xc (TPI+LDPE) (%) | 25.7 | 29.1 | 28.1 | 25.8 |

| Properties | Dosage of CB (N330) | |||

|---|---|---|---|---|

| A | B | C | D | |

| Rf (%) | 95.7 | 95.1 | 92.0 | 91.8 |

| Rr (%) | 88.6 | 95.0 | 94.1 | 93.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, L.; Gao, H.; Bi, W.; Fu, W.; Qiu, G.; Xin, Z. Shape Memory Behavior of Carbon Black-reinforced Trans-1,4-polyisoprene and Low-density Polyethylene Composites. Polymers 2019, 11, 807. https://doi.org/10.3390/polym11050807

Xia L, Gao H, Bi W, Fu W, Qiu G, Xin Z. Shape Memory Behavior of Carbon Black-reinforced Trans-1,4-polyisoprene and Low-density Polyethylene Composites. Polymers. 2019; 11(5):807. https://doi.org/10.3390/polym11050807

Chicago/Turabian StyleXia, Lin, Han Gao, Weina Bi, Wenxin Fu, Guixue Qiu, and Zhenxiang Xin. 2019. "Shape Memory Behavior of Carbon Black-reinforced Trans-1,4-polyisoprene and Low-density Polyethylene Composites" Polymers 11, no. 5: 807. https://doi.org/10.3390/polym11050807

APA StyleXia, L., Gao, H., Bi, W., Fu, W., Qiu, G., & Xin, Z. (2019). Shape Memory Behavior of Carbon Black-reinforced Trans-1,4-polyisoprene and Low-density Polyethylene Composites. Polymers, 11(5), 807. https://doi.org/10.3390/polym11050807