The Impact of the Seasoning Conditions on Mechanical Properties of Modified and Unmodified Epoxy Adhesive Compounds

Abstract

1. Introduction

2. Materials and Methods

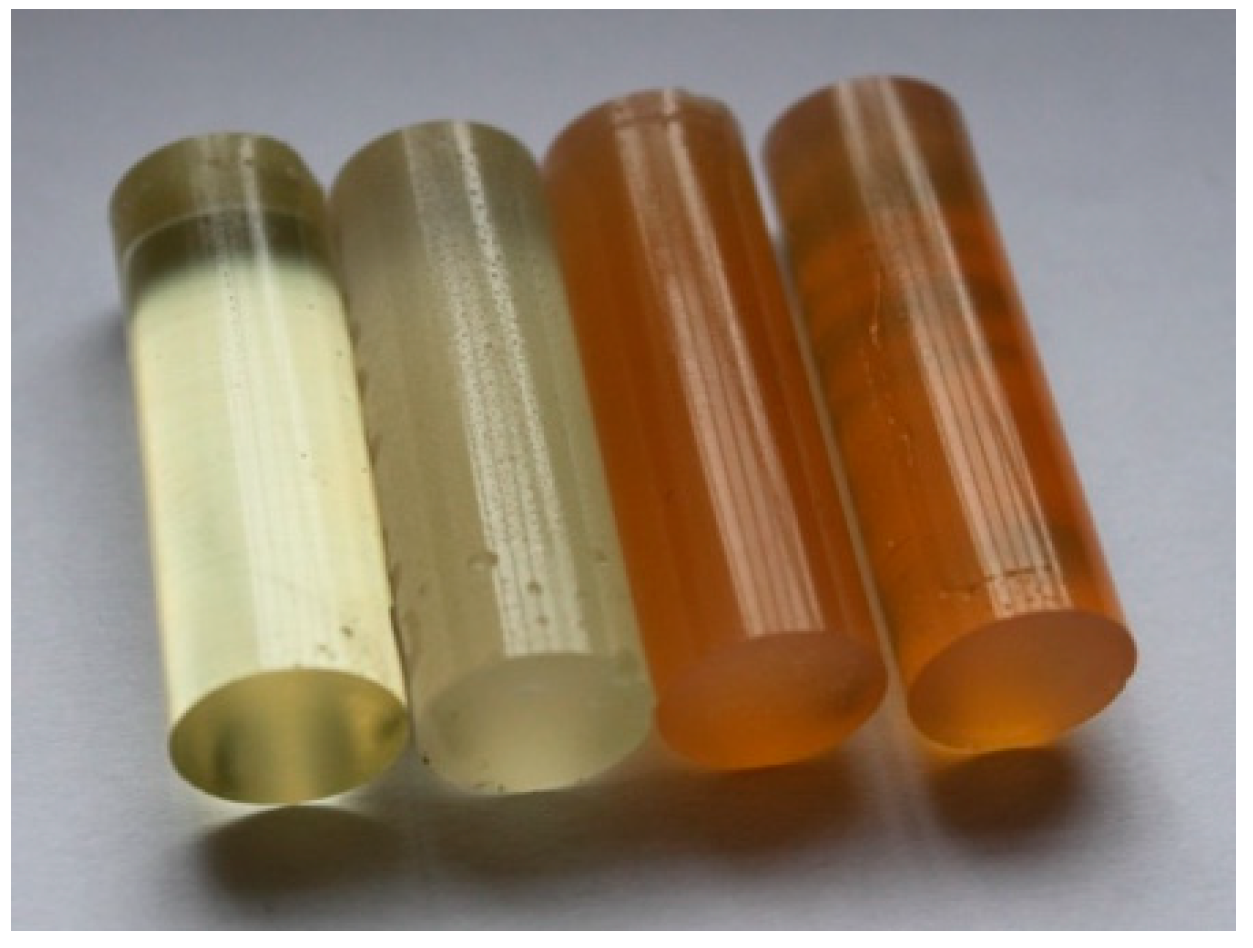

2.1. Characteristics of Adhesive Compounds’ Modification

Epoxy Resin

2.2. Characteristics of Unmodified and Modified Adhesives

2.2.1. Curing Agents

2.2.2. Modifying Agent—Calcium Carbonate

2.3. Characteristics of the Cured Adhesive Compounds Samples

2.4. Preparation of the Cured Adhesive Compounds Samples

2.5. Curing and Seasoning Conditions

2.6. Strength Tests

3. Results and Discussion

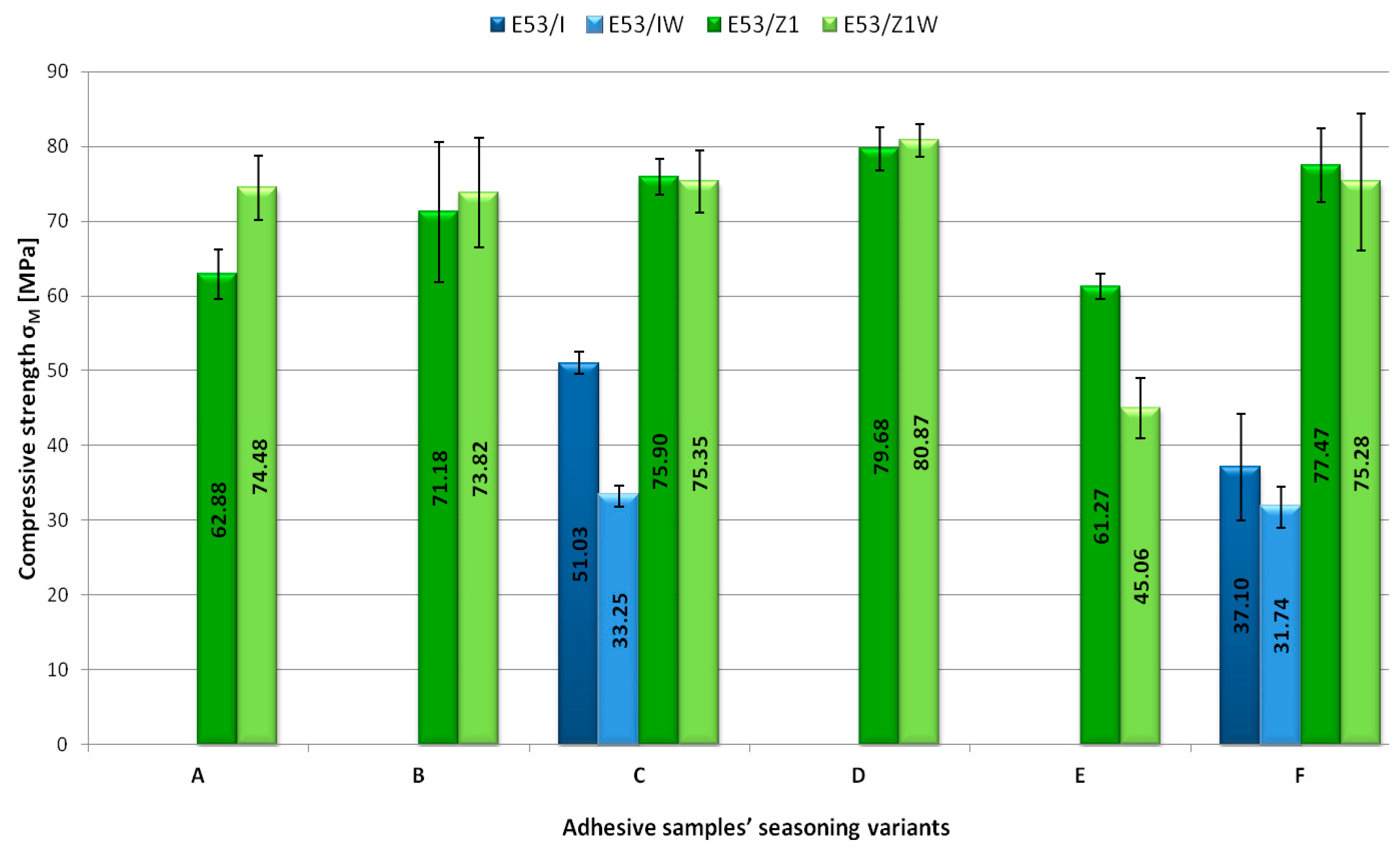

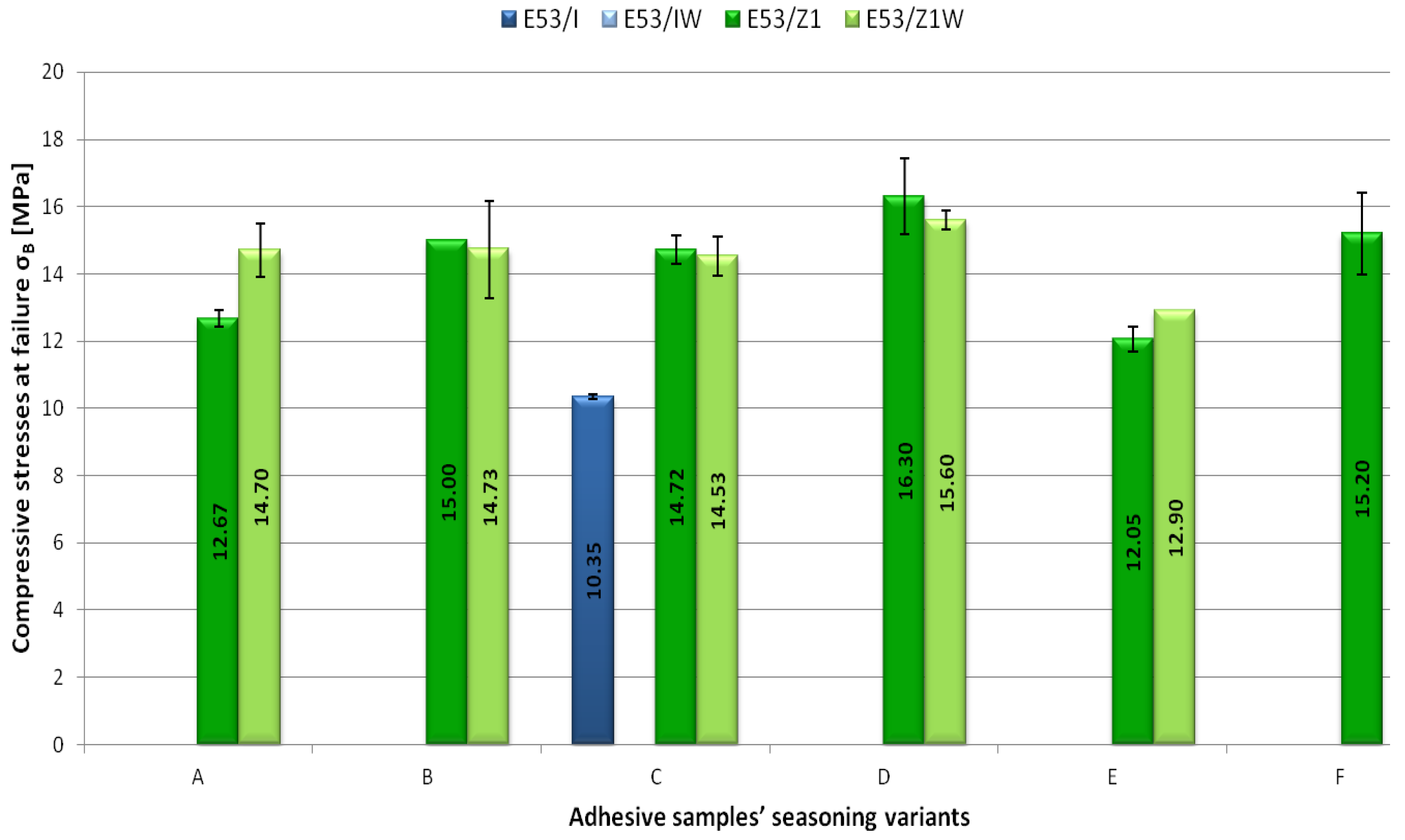

3.1. Mechanical Properties

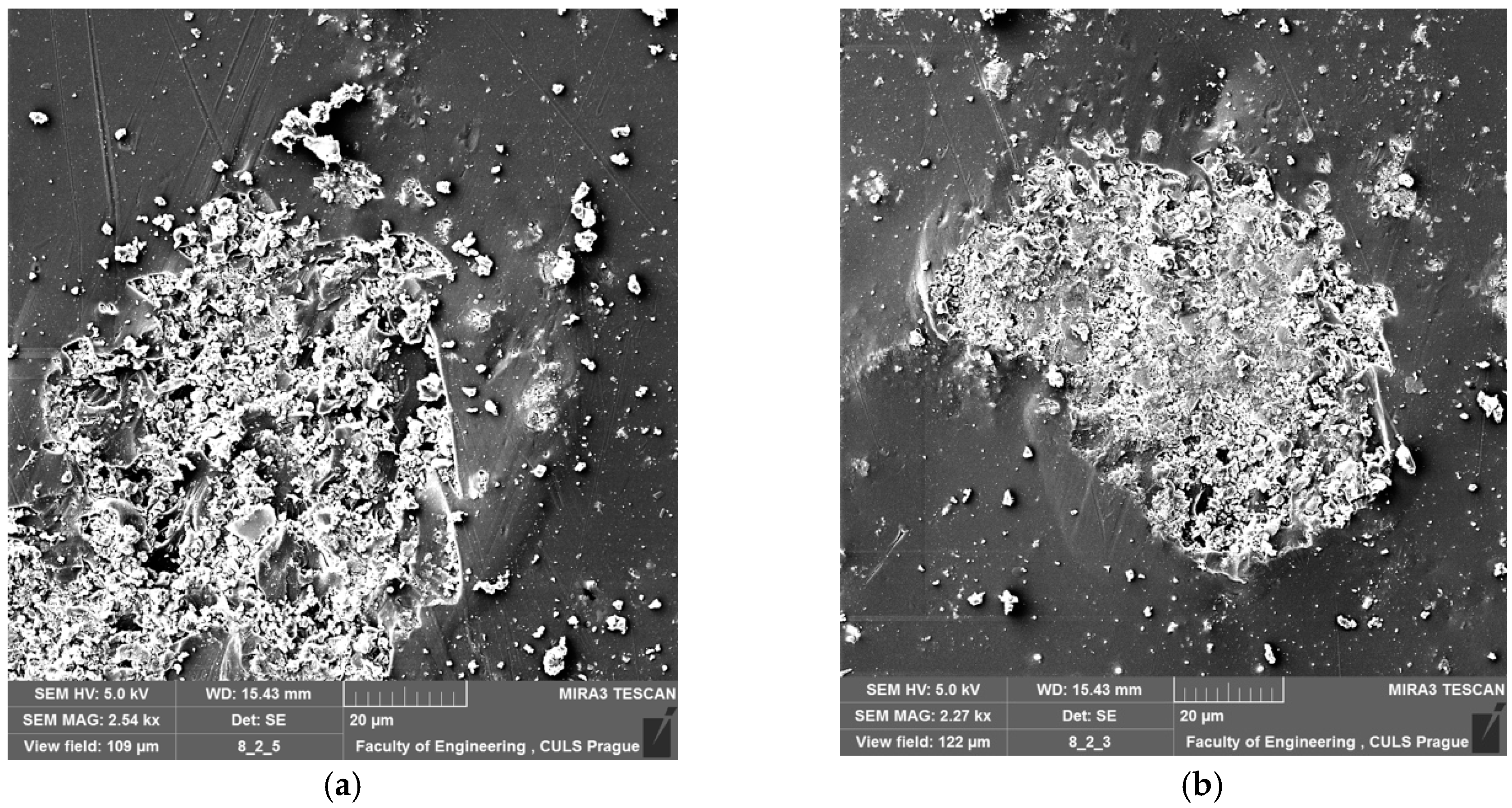

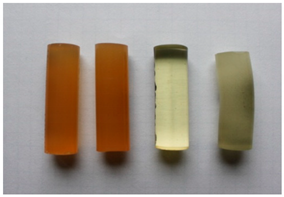

3.2. Visual Analysis

4. Conclusions

- Compressive strength of the samples seasoned at ambient temperature increased as the seasoning time increased.

- Adhesives with addition of the Z1 curing agent and calcium carbonate (modified adhesives) showed a greater compressive strength at ambient temperature than the adhesive compounds cured with the Z1 curing agent but without a modifier.

- The adhesive compound with addition of the IDA curing agent, seasoned for five months at ambient temperature, was characterised by significantly reduced the compressive strength than other adhesive compounds with addition of the Z1 curing agent.

- In the perspective of seasoning for one month, the seasoning temperature of the non-modified adhesive compounds containing IDA curing agent did not have a significant impact on the compressive strength.

- Addition of calcium carbonate to the adhesive compound with Z1 curing agent (seasoned for one month at the temperature of −10 ± 2 °C) caused an almost halving of its compressive strength in comparison to the E53/Z1 adhesive compound seasoned for the same period of time but at ambient temperature.

- Variable seasoning conditions (Variant F) had an insignificant impact on reduction of the adhesives’ compressive strength; this impact was more significant in the case of the E53/Z1/CaCO3 modified adhesive compound.

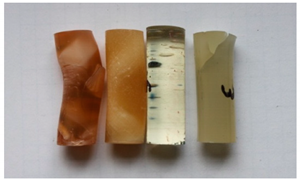

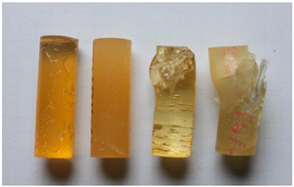

- Among the adhesive compounds, those with addition of the Z1 curing agent showed a tendency to crack and spall. The longer the seasoning time was, the more intense these changes were.

- The samples of the adhesive with addition of the IDA curing agent were susceptible to buckling.

- The negative temperature affected the brittleness of the epoxy compounds, where the effect was visible for the modified adhesive compounds.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- May, C.A. Epoxy Resins, Chemistry and Technology, 2nd ed.; Marcel Dekker: New York, NY, USA, 1988; pp. 9–20, 465–485, 653–670. [Google Scholar]

- Pertie, E.M. Epoxy Adhesive Formulation; McGraw-Hill: New York, NY, USA, 2006; pp. 3–19, 26–41, 43–53, 71–82, 85–98, 207–225, 229–236. [Google Scholar]

- Pizzi, A.; Mittal, K.Z. Handbook of Adhesive Technology; CRS Press Taylor & Frances Group: Boca Raton, FL, USA, 2018; pp. 19–66. [Google Scholar]

- Brockmann, W.; Geiß, P.L.; Klingen, J.; Schröder, B. Adhesive Bonding. Materials, Applications and Technology; Wiley-Vch Press: Weinheim, Germany, 2009; pp. 205–369. [Google Scholar]

- Prolongo, S.G.; del Rosario, G.; Ureña, A. Comparative study on the adhesive properties of different epoxy resins. Int. J. Adhes. Adhes. 2006, 26, 125–132. [Google Scholar]

- Hartshorn, S.R. Structural Adhesives. Chemistry and Technology; Plenum Press: New York, NY, USA; London, UK, 1986; pp. 130–137, 168–174. [Google Scholar]

- Rudawska, A. Epoxy adhesives. In Handbook of Adhesive Technology; Pizzi, A., Mittal, K.Z., Eds.; CRS Press Taylor & Frances Group: Boca Raton, FL, USA, 2018; pp. 415–442. [Google Scholar]

- Adams, R.D. Adhesive Bonding. Science, Technology and Applications; Woodhead Publishing: London, UK, 2010; pp. 221–222. [Google Scholar]

- Czub, P.; Bończa-Tomaszewski, Z.; Penczek, P.; Pielichowski, J. Chemistry and Technology of Epoxy Resins; WNT: Warsaw, Poland, 2002. (In Polish) [Google Scholar]

- Lapique, F.; Redford, K. Curing effects on viscosity and mechanical properties of a commercial epoxy resin adhesive. Int. J. Adhes. Adhes. 2002, 22, 337–346. [Google Scholar] [CrossRef]

- Cavalli, A.; Malavolti, M.; Morosini, A.; Salvini, A. Mechanical performance of full scale steel-timber epoxy joints after exposure to extreme environmental conditions. Int. J. Adhes. Adhes. 2014, 54, 86–92. [Google Scholar] [CrossRef]

- Schneider, B.; Beber, V.C.; Schweer, J.; Brede, M.; Mayer, B. An experimental investigation of the fatigue damage behavior of adhesively bonded joints under the combined effect of variable amplitude stress and temperature variation. Int. J. Adhes. Adhes. 2018, 83, 41–49. [Google Scholar] [CrossRef]

- Blackburn, B.P.; Tatar, J.; Douglas, E.P.; Hamilton, H.R. Effect of hydrothermal conditioning on epoxy adhesives used in FRP composites. Constr. Build. Mater. 2015, 96, 679–689. [Google Scholar] [CrossRef]

- Jiang, X.; Qiang, X.; Kolstein, M.H.; Bijlaard, F.S.K. Experimental investigation on mechanical behavior of FRP-to-steel adhesively-bonded joint under combined loading—Part 2: After hygrothermal ageing. Compos. Struct. 2015, 125, 687–697. [Google Scholar] [CrossRef]

- Tatar, J.; Hamilton, H.R. Comparison of laboratory and field environmental conditioning on FRP-concrete bond durability. Constr. Build. Mater. 2016, 122, 525–536. [Google Scholar] [CrossRef]

- Heshmati, M.; Haghani, R.; Al-Emrani, M. Effects of moisture on the long-term performance of adhesively bonded FRP/steel joints used in bridges. Composites B 2016, 92, 447–462. [Google Scholar] [CrossRef]

- Ameli, A.; Datla, N.V.; Azari, S.; Papini, M.; Spelt, J.K. Prediction of environmental degradation of closed adhesive joints using data from open-faced specimens. Comp. Struct. 2012, 94, 779–786. [Google Scholar] [CrossRef]

- Okba, S.H.; Nasr, E.-S.A.; Helmy, A.I.I.; Yousef, I.A.-L. Effect of thermal exposure on the mechanical properties of polymer adhesives. Constr. Build. Mater. 2017, 135, 490–504. [Google Scholar] [CrossRef]

- Anes, V.; Pedro, R.; Henriques, E.; Freitas, M.; Reis, L. Bonded joints of dissimilar adherends at very low temperatures—An adhesive selection approach. Theor. Appl. Fract. Mech. 2016, 85, 99–112. [Google Scholar] [CrossRef]

- Heshmati, M.; Haghani, R.; Al-Emrani, M. Durability of CFRP/steel joints under cyclic wet-dry and freeze-thaw conditions. Composites B 2017, 126, 211–226. [Google Scholar] [CrossRef]

- Gholami, M.; Sam, A.R.M.; Yatim, J.M.; Tahir, M.M. A review on steel/CFRP strengthening system focusing environmental performance. Constr. Build. Mater. 2013, 47, 301–310. [Google Scholar] [CrossRef]

- Hu, P.; Han, X.; Li, W.D.; Li, L.; Shao, Q. Research on the static strength performance of adhesive single lap joints subjected to extreme temperature environment for automotive industry. Int. J. Adhes. Adhes. 2013, 41, 119–126. [Google Scholar] [CrossRef]

- Popineau, S.; Shanahan, M.E.R. Simple model to estimate adhesion of structural bonding during humid ageing. Int. J. Adhes. Adhes. 2006, 26, 363–370. [Google Scholar] [CrossRef]

- Crocombe, A.D.; Ashcroft, I.A.; Wahab, M.M.A. Environmental degradation, Chapter 8. In Modeling of Adhesively Bonded Joints; Da Silva, L.F.M., Öchsner, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 225–242. [Google Scholar]

- Knox, E.M.; Cowling, M.J. A rapid durability test method for adhesives. Int. J. Adhes. Adhes. 2000, 20, 201–208. [Google Scholar] [CrossRef]

- Da Silva, L.F.M.; Adams, R.D. Joint strength prediction for adhesive joints to be used over wide temperature range. Int. J. Adhes. Adhes. 2007, 27, 362–379. [Google Scholar] [CrossRef]

- Ashcroft, I.A.; Abdel Wahab, M.M.; Crocombe, A.D.; Hughes, D.J.; Shaw, S.J. The effect of environment on fatigue of bonded composite joints. Part 1: Testing and fractography. Composite A 2001, 32, 45–58. [Google Scholar] [CrossRef]

- Da Silva, L.F.M.; Carbas, R.J.C.; Critchlow, G.W.; Figueiredo, M.A.V.; Brown, K. Effect of material, geometry, surface treatment and environment on the shear strength of single lap joints. Int. J. Adhes. Adhes. 2009, 29, 621–632. [Google Scholar] [CrossRef]

- Brewis, D.M.; Comyn, J.; Shalash, R.J.A. The effect of moisture and temperature on the properties of an epoxide-polyamide adhesive in relation to its performance in single lap joints. Int. J. Adhes. Adhes. 1982, 4, 215–222. [Google Scholar] [CrossRef]

- Patil, O.R.; Ameli, A.; Datla, N.V. Predicting environmental degradation of adhesive joints using a cohesive zone finite element model based on accelerated fracture tests. Int. J. Adhes. Adhes. 2017, 76, 54–60. [Google Scholar] [CrossRef]

- Bhowik, S.; Bonin, H.W.; Biu, V.T.; Weir, R.D. Durability of adhesive bonding of titanium in radiation and aerospace environments. Int. J. Adhes. Adhes. 2006, 26, 400–405. [Google Scholar] [CrossRef]

- Grant, L.D.R.; Adams, R.D.; da Silva, L.F.M. Effect of the temperature on the strength of adhesively bonded single lap and T joints for the automotive industry. Int. J. Adhes. Adhes. 2009, 29, 535–542. [Google Scholar] [CrossRef]

- Bordes, M.; Davies, P.; Cognard, J.-Y.; Sohier, L.; Sauvant-Moynot, V.; Galy, J. Prediction of long term strength of adhesively bonded steel/epoxy joints in sea water. Int. J. Adhes. Adhes. 2009, 29, 595–608. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M.; Campilho, R. Effect of temperature on tensile strength and mode I fracture toughness of high temperature epoxy adhesive. J. Adhes. Sci. Technol. 2012, 26, 939–953. [Google Scholar]

- Cagle, C.V. Handbook of Adhesive Bonding; McGraw-Hill: New York, NY, USA, 1973. [Google Scholar]

- Skeist, I. Handbook of Adhesives, 3rd ed.; Chapmann & Hall: New York, NY, USA, 1990. [Google Scholar]

- Lee, H.L.; Neville, H. Handbook of Epoxy Resins; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- Yoon, I.-N.; Lee, Y.; Kang, D.; Min, J.; Won, J.; Kim, M.; Kang, Y.S.; Kim, S.-H.; Kim, J.-J. Modification of hydrogenated Bisphenol A epoxy adhesives using nanomaterials. Int. J. Adhes. Adhes. 2011, 31, 119–125. [Google Scholar] [CrossRef]

- Ciardiello, R.; Tridello, A.; Brunella, V.; Martorana, B.; Paolino, D.S.; Belingardi, G. Impact response of adhesive reversible joints made of thermoplastic nanomodified adhesive. J. Adhes. 2017, 94, 1051–1066. [Google Scholar] [CrossRef]

- Tomuta, A.; Ferrando, F.; Serra, A.; Ramis, X. New aromatic-aliphatic hyperbranched polyesters with vinylic end groups of different length as modifiers of epoxy/anhydride thermosets. Reac. Funct. Polym. 2012, 72, 556–563. [Google Scholar] [CrossRef]

- Shaw, S.J. Additives and modifiers of epoxy resin. In Chemistry and Technology of Epoxy Resins; Ellis, B., Ed.; Springer: Amsterdam, The Netherlands, 1993; pp. 117–143. [Google Scholar]

- Down, J.L. The effect of modifiers on the stability of a vinyl acetate/ethylene copolymer dispersion. Stud. Conver. 2016, 61, 26–45. [Google Scholar] [CrossRef]

- Ciardiello, R.; Belingardi, G.; Martorana, B.; Fondacaro, D.; Brunella, V. A study of physical and mechanical properties of a nano-modified thermoplastic adhesive in normal and accelerated ageing conditions. In Proceedings of the ECCM16 European Conference on Composite Materials, Munich, Germany, 26–30 June 2016. [Google Scholar]

- Tongxiang, L.; Wenli, G.; Yiughui, Y.; Chunhe, T. Electroless palting of silver on graphite powders and the study of its conductive adhesive. Int. J. Adhes. Adhes. 2007, 28, 55–58. [Google Scholar] [CrossRef]

- Müller, M.; Valášek, P.; Rudawska, A.; Chotěborský, R. Effect of active rubber powder on structural two-component epoxy resin and its mechanical properties. J. Adhes. Sci. Technol. 2018, 32, 1531–1547. [Google Scholar] [CrossRef]

- Müller, M.; Valášek, P.; Rudawska, A. Mechanical properties of adhesive bonds reinforced with biological fabric. J. Adhes. Sci. Technol. 2017, 31, 327–344. [Google Scholar] [CrossRef]

- Isarn, I.; Gamardella, F.; Fernàndez-Francos, X.; Serra, A.; Ferrando, F. Thermal conductive composites prepared by addition of several ceramic fillers to thermally cationic curing cycloaliphatic epoxy resins. Polymers 2019, 11, 138. [Google Scholar] [CrossRef]

- Ghalia, M.A.; Hassan, A.; Yussuf, A. Mechanical and thermal properties of calcium carbonate filled PP/LLDPE composite. J. App. Polym. Sci. 2011, 121, 2413–2421. [Google Scholar] [CrossRef]

- Kwon, S.; Kim, K.J.; Kim, H.; Kundu, P.P.; Kim, T.J.; Lee, Y.K.; Lee, B.H.; Choe, S. Tensile property and interfacial dewetting in the calcite filled HDPE, LDPE, and LLDPE composites. Polymer 2002, 43, 6901–6909. [Google Scholar] [CrossRef]

- DeArmitt, C.; Breese, K.D. Filled polypropylene: A cost performance comparison of common fillers. Plast. Add. Comp. 2001, 28–33. [Google Scholar] [CrossRef]

- Rudawska, A.; Haniecka, I.; Jaszek, M.; Osińska-Jaroszuk, M. The influence of biochemical modification on the properties of adhesive compounds. Polymers 2017, 9, 9. [Google Scholar] [CrossRef] [PubMed]

- Mantia, F.P.L.; Morreale, M.; Scaffaro, R.; Tulone, S. Rheological and mechanical behavior of LDPE/calcium carbonate nanocomposites and microcomposites. J. App. Polym. Sci. 2013, 127, 2544–2552. [Google Scholar] [CrossRef]

- Fu, Q.; Wang, G.; Liu, C. Polyethylene toughened by CaCO3 particles: The interface behaviour and fracture mechanism in high density polyethylene/CaCO3 blends. Polymer 1995, 36, 2397–2401. [Google Scholar]

- Krämer, R.H.; Raza, M.A.; Gedde, U.W. Degradation of poly(ethylene-co-methacrylic acid)ecalcium carbonate nanocomposites. Polym. Degrad. Stab. 2007, 92, 1795–1802. [Google Scholar] [CrossRef]

- Rothon, R. Particulate-Filled Polymer Composites; Longman Scientific & Technical: London, UK, 1995. [Google Scholar]

- Rudawska, A.; Haniecka, I.; Jaszek, M.; Stefaniuk, D. The influence of adhesive compounds biochemical modification on the mechanical properties of adhesive joints. Polymers 2018, 10, 344. [Google Scholar] [CrossRef]

- Hamdani, S.; Longuet, C.; Lopez-Cuesta, J.-M.; Ganachaud, F. Calcium and aluminium-based fillers as flame-retardant additives in silicone matrices. I. Blend preparation and thermal properties. Polym. Degrad. Stab. 2010, 95, 1911–1919. [Google Scholar] [CrossRef]

- Guan, Y.; Chen, X.; Li, F.; Gao, H. Study on the curing process and shearing tests of die attachment by Ag-epoxy electrically conductive adhesive. Int. J. Adhes. Adhes. 2010, 30, 80–88. [Google Scholar] [CrossRef]

- Morel, F.; Bounor-Legaré, V.; Espuche, E.; Persyn, O.; Lacroix, M. Surface modification of calcium carbonate nanofillers by fluoro- and alkyl-alkoxysilane: Consequences on the morphology, thermal stability and gas barrier properties of polyvinylidene fluoride nanocomposites. Eur. Polym. J. 2012, 48, 919–929. [Google Scholar] [CrossRef]

- Sahebian, S.; Zebarjad, S.M.; Vahdati Khaki, J.; Sajjadi, S.A. The effect of nano-sized calcium carbonate on thermodynamic parameters of HDPE. J. Mater. Process. Technol. 2009, 209, 1310–1317. [Google Scholar] [CrossRef]

- Xiang, L.; Xiang, Y.; Wang, Z.G.; Jin, Y. Influence of chemical additives on the formation of super-fine calcium carbonate. Pow. Technol. 2002, 126, 129–133. [Google Scholar] [CrossRef]

- Liu, Z.H.; Zhu, G.; Li, Q.; Qi, Z.N.; Wang, F.S. Effect of morphology on the brittle ductile transition of polymer blends: 5. The role of CaCO3 particle size distribution in high density polyethylene/CaCO3 composites. Polymer 1998, 39, 1863–1868. [Google Scholar] [CrossRef]

- Lee, L.; Drzal, L.T. Surface characterization and adhesion of carbon fibers to epoxy and polycarbonate. Int. J. Adhes. Adhes. 2005, 25, 389–394. [Google Scholar] [CrossRef]

- Rudawska, A.; Jakubowska, P.; Koziński, A. Surface free energy of composite materials with high calcium carbonate filler content. Polimery 2017, 62, 434–440. [Google Scholar] [CrossRef]

- González, J.; Albano, C.; Ichazo, M.; Diaz, B. Effects of coupling agents on mechanical and morphological behavior of the PP/HDPE blend with two different CaCO3. Eur. Polym. J. 2002, 38, 2465–2475. [Google Scholar] [CrossRef]

- Morak, M.; Marx, M.; Gschwandl, P.; Fuchs, P.F.; Pfost, M.; Wiesbrock, F. Heat Dissipation in Epoxy/Amine-Based Gradient Composites with Alumina Particles: A Critical Evaluation of Thermal Conductivity Measurements. Polymer 2018, 310, 1131. [Google Scholar] [CrossRef]

- Chen, S.; Feng, J. Epoxy laminated composites reinforced with polyethyleneimineized carbon fiber fabric: Mechanical and thermal properties. Compos. Sci. Technol. 2014, 101, 145–151. [Google Scholar] [CrossRef]

- Ray, B.C. Temperature effect during humid ageing on interfaces of glass and carbon fibers reinforced epoxy composites. J. Coll. Int. Sci. 2006, 298, 111–117. [Google Scholar] [CrossRef] [PubMed]

- Fan-Long, J.; Soo-Jin, P. Interfacial toughness properties of trifunctional epoxy resins/calcium carbonate nanocomposites. Mater. Sci. Eng. A 2008, 475, 190–193. [Google Scholar]

- Khashaba, U.A.; Aljinaidi, A.A.; Hamed, M.A. Fatigue and reliability analysis of nano-modified scarf adhesive joints in carbon fiber composites. Composites B 2017, 120, 103–117. [Google Scholar] [CrossRef]

- Hongwei, H.; Kaixi, L.; Jian, W.; Guohua, P.; Yanqiu, L.; Jianlong, W. Study on thermal and mechanical properties of nano-calcium carbonate/epoxy composites. Mater. Des. 2011, 32, 4521–4527. [Google Scholar]

- Organica-Sarzyna. Available online: http://www.ciechzywice.pl/pl/produkty/chemia-organiczna/zywice/zywice-epoksydowe (accessed on 27 January 2019).

- Calcium Carbonate Properties. Available online: http://www.poch.com.pl/1/wysw/msds_clp.php?A=54982111695e32ba0001%20 (accessed on 10 January 2019).

- Polsiform. Available online: http://www.silikonypolskie.pl/produkt/polsilform/ (accessed on 27 January 2019).

- Klimatest. Available online: http://www.klimatest.eu/katalog/ (accessed on 27 January 2019).

- Standard ISO 604. Plastics. Determination of Compressive Properties. Available online: https://www.iso.org/standard/31261.html (accessed on 26 February 2019).

| No. | Adhesive Compound Designation | Resin Type | Curing Agent Type | Curing Agent Weight Per 100 Resin Weight Molecules | Calcium Carbonate Weight Content Per 100 Resin Weight Molecules |

|---|---|---|---|---|---|

| 1 | E53/IDA | Epidian 53 | IDA | 40 | - |

| 2 | E53/IDA/CaCO3 | 2 | |||

| 3 | E53/Z1 | Z1 | 10 | - | |

| 4 | E53/Z1/CaCO3 | 2 |

| Physicochemical Properties | |

|---|---|

| State of aggregation | liquid |

| Color | light-yellow |

| Smell | characteristic of styrene |

| Epoxide number [mol/100 g] | 0.410 |

| Density at temperature of 20 °C [g/cm3] | 1.110–1.150 |

| Adhesiveness at temperature of 20 °C [mPas] | 900–1500 |

| Time of gelling of 10 g of Epidian 53 + 1.05 g of curing agent Z1 at 20 °C [min] | 200 |

| Initial curing [h] | 6–8 |

| Full curing [days] | 7–14 |

| Properties | Z1 Curing Agent | IDA Curing Agent |

|---|---|---|

| State of aggregation | liquid | liquid |

| Colour | light-yellow | transparent |

| Adhesiveness at temperature of 20 °C [mPas] | - | 150–300 |

| Density at temperature of 20 °C [g/cm3] | 0.978–0.983 | 1.01–1.03 |

| Amine number | Min. 1100 mg KOH/g | 200–350 mg KOH/g |

| No. | Stage | Description |

|---|---|---|

| 1 | Forms’ preparation |

|

| 2 | Adhesive compounds preparation |

|

| 3 | Filling the forms with adhesive compound |

|

| 4 | Adhesive compounds curing |

|

| 5 | Seasoning of the adhesive compound samples | |

| 6 | Material removal processing |

|

| No. | Adhesive Compound | Curing Conditions | Seasoning Conditions |

|---|---|---|---|

| 1 | E53/I/P/1 | 21 ± 1 °C 23 ± 1% | 1 month 23 ± 2 °C 23 ± 1% |

| 2 | E53/IW/P/1 | ||

| 3 | E53/Z1/P/1 | ||

| 4 | E53/Z1W/P/1 |

| No. | Adhesive Compound | Curing Conditions | Seasoning Conditions |

|---|---|---|---|

| 1 | E53/I/P/2 | 21 ± 1 °C 23 ± 1% | 2 months 23 ± 2 °C 23 ± 1% |

| 2 | E53/IW/P/2 | ||

| 3 | E53/Z1/P/2 | ||

| 4 | E53/Z1W/P/2 |

| No. | Adhesive Compound | Curing Conditions | Seasoning Conditions |

|---|---|---|---|

| 1 | E53/I/P/5 | 21 ± 1 °C 23 ± 1% | 5 months 23 ± 2 °C 23 ± 1% |

| 2 | E53/IW/P/5 | ||

| 3 | E53/Z1/P/5 | ||

| 4 | E53/Z1W/P/5 |

| No. | Adhesive Compound | Curing Conditions | Seasoning Conditions |

|---|---|---|---|

| 1 | E53/I/P/8 | 21 ± 1 °C 23 ± 1% | 8 months 23 ± 2 °C 23 ± 1% |

| 2 | E53/IW/P/8 | ||

| 3 | E53/Z1/P/8 | ||

| 4 | E53/Z1W/P/8 |

| No. | Adhesive Compound | Curing Conditions | Seasoning Conditions |

|---|---|---|---|

| 1 | E53/I/-10/1 | 21 ± 1 °C 23 ± 1% | 1 month −10 ± 2 °C |

| 2 | E53/IW/-10/1 | ||

| 3 | E53/Z1/-10/1 | ||

| 4 | E53/Z1W/-10/1 |

| No. | Adhesive Compound | Curing Conditions | Seasoning Conditions |

|---|---|---|---|

| 1 | E53/I/PM/8 | 21 ± 1 °C 23 ± 1% | 3 months: −10 ± 2 °C 5 months: 23 ± 2 °C 23 ± 1% |

| 2 | E53/IW/PM/8 | ||

| 3 | E53/Z1/PM/8 | ||

| 4 | E53/Z1W/PM/8 |

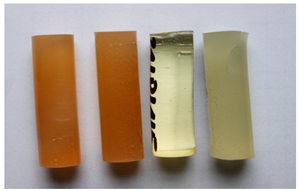

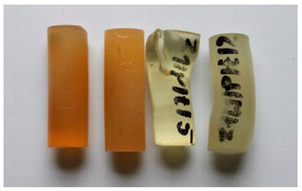

| No. | Variant | The View of Samples After Strength Tests |

|---|---|---|

| 1 | A |  |

| 2 | B |  |

| 3 | C |  |

| 4 | D |  |

| No. | Variant | The View of Samples After Strength Tests |

|---|---|---|

| 5 | E |  |

| 6 | F |  |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rudawska, A. The Impact of the Seasoning Conditions on Mechanical Properties of Modified and Unmodified Epoxy Adhesive Compounds. Polymers 2019, 11, 804. https://doi.org/10.3390/polym11050804

Rudawska A. The Impact of the Seasoning Conditions on Mechanical Properties of Modified and Unmodified Epoxy Adhesive Compounds. Polymers. 2019; 11(5):804. https://doi.org/10.3390/polym11050804

Chicago/Turabian StyleRudawska, Anna. 2019. "The Impact of the Seasoning Conditions on Mechanical Properties of Modified and Unmodified Epoxy Adhesive Compounds" Polymers 11, no. 5: 804. https://doi.org/10.3390/polym11050804

APA StyleRudawska, A. (2019). The Impact of the Seasoning Conditions on Mechanical Properties of Modified and Unmodified Epoxy Adhesive Compounds. Polymers, 11(5), 804. https://doi.org/10.3390/polym11050804