Photo Actuation Performance of Nanotube Sheet Incorporated Azobenzene Crosslinked Liquid Crystalline Polymer Nanocomposite

Abstract

1. Introduction

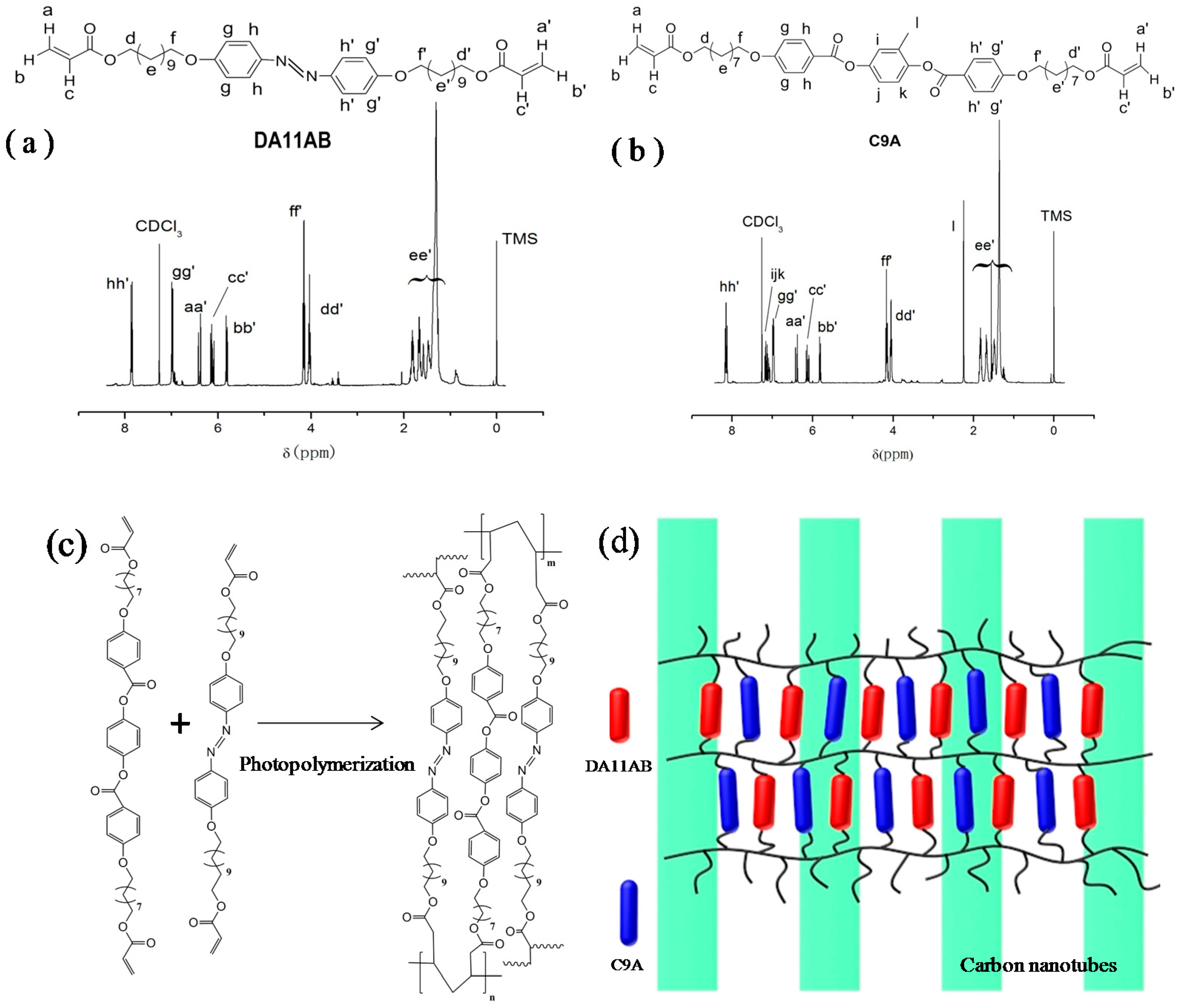

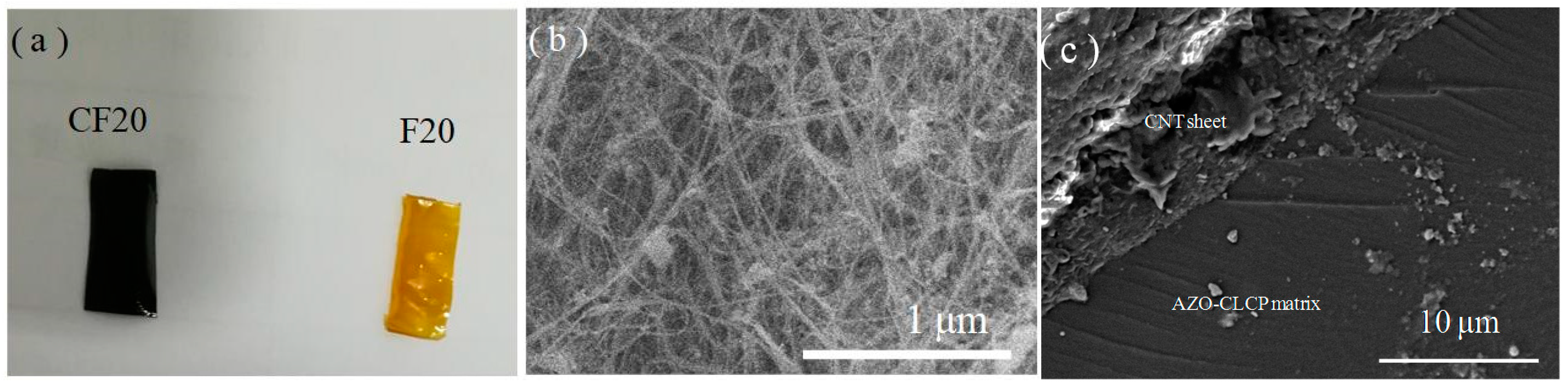

2. Experimental Procedures

2.1. Materials Preparation

2.2. Characterization Methods

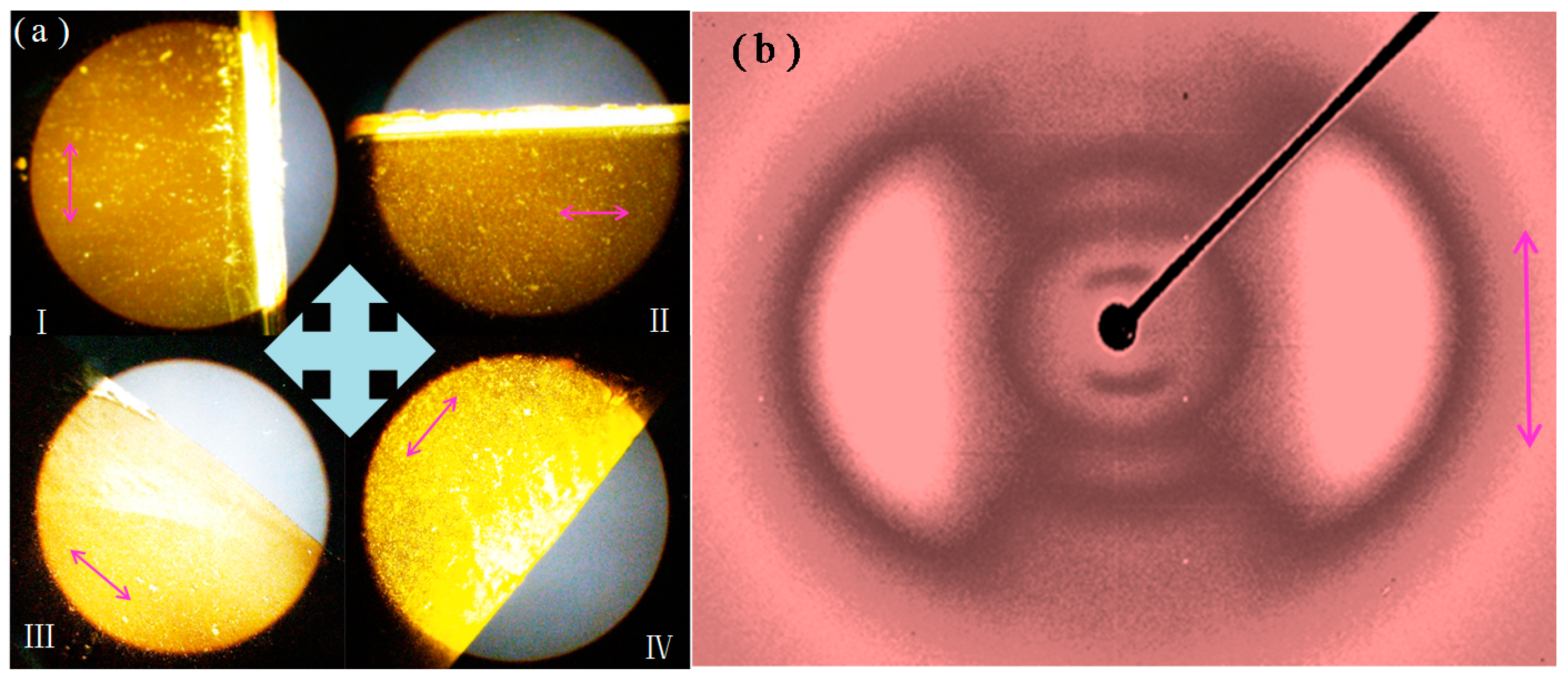

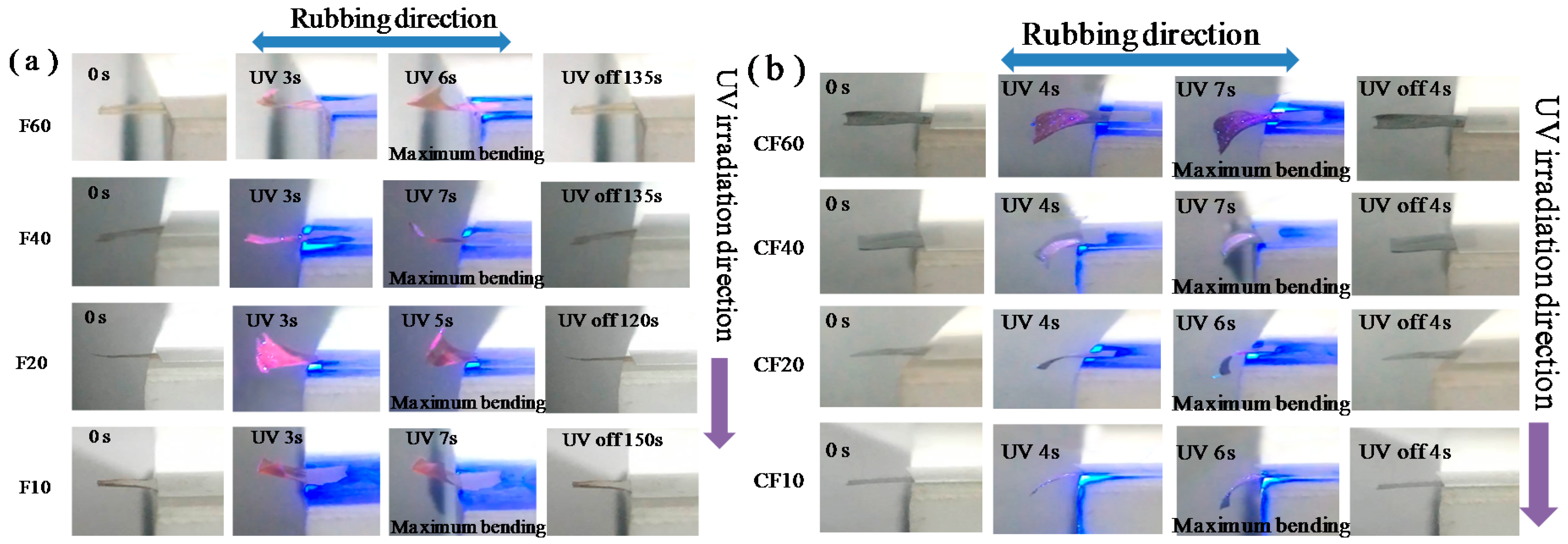

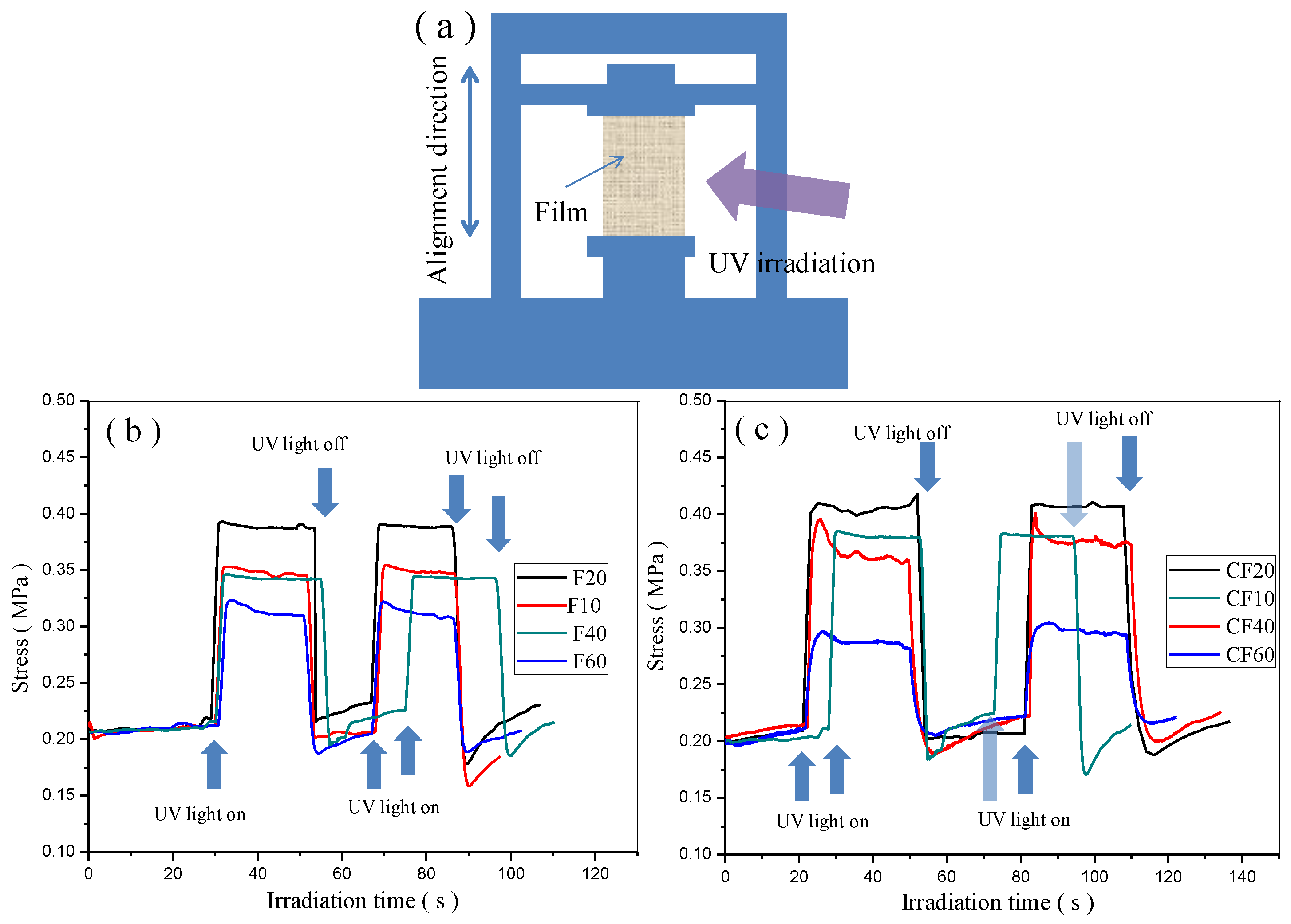

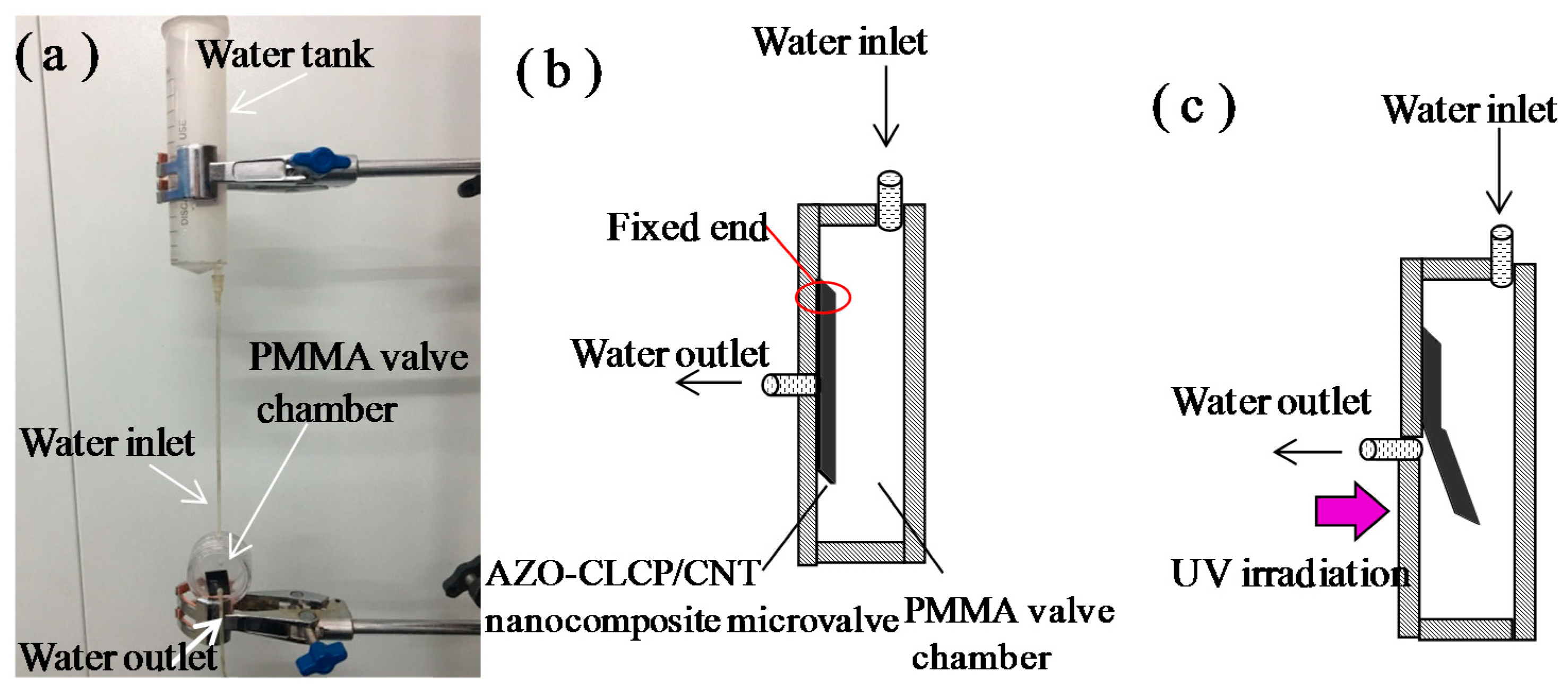

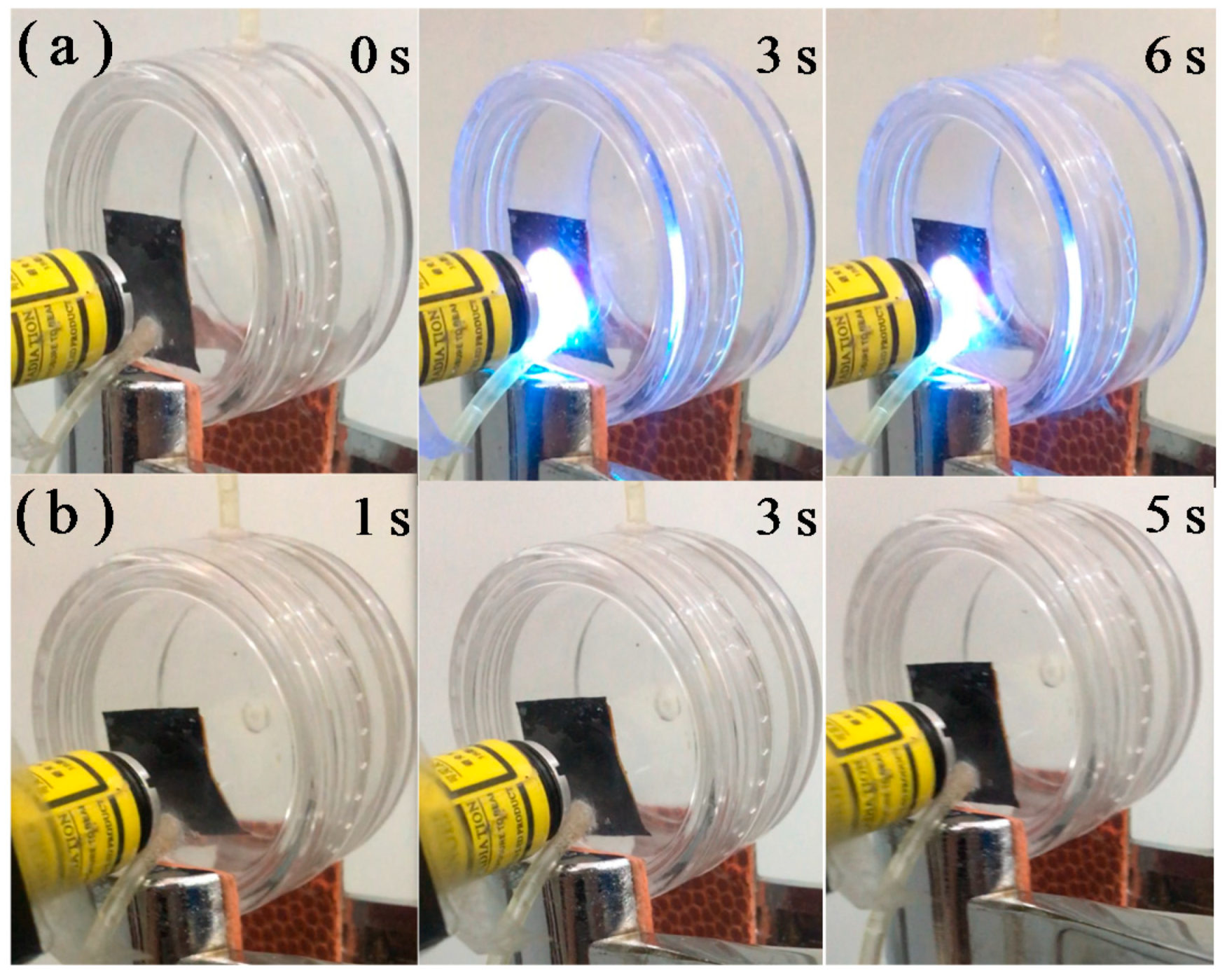

3. Results and Discussions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jiang, H.R.; Li, C.S.; Xue, Z.H. Actuators based on liquid crystalline elastomer materials. Nanoscale 2013, 5, 5225–5240. [Google Scholar] [CrossRef]

- Yu, H.F. Photoresponsive liquid crystalline block copolymers: From photonics to nanotechnology. Prog. Polym. Sci. 2014, 39, 781–815. [Google Scholar] [CrossRef]

- Gu, W.; Wei, J.; Yu, Y.L. Thermo- and photo-driven soft actuators based on crosslinked liquid crystalline polymers. Chin. Phys. B 2016, 25, 096103. [Google Scholar] [CrossRef]

- Ohm, C.; Brehmer, M.; Zentel, R. Liquid crystalline elastomers as actuators and sensors. Adv. Mater. 2010, 22, 3366–3387. [Google Scholar] [CrossRef]

- Yu, H.F.; Ikeda, T. Photocontrollable liquid-crystalline actuators. Adv. Mater. 2011, 23, 2149–2180. [Google Scholar] [CrossRef] [PubMed]

- Pang, X.; Xu, B.; Qing, X.; Wei, J.; Yu, Y. Photo-induced bending behavior of post-crosslinked liquid crystalline polymer/polyurethane blend films. Macromol. Rapid Commun. 2018, 39, 1700237. [Google Scholar] [CrossRef]

- Ube, T.; Yoda, T.; Ikeda, T. Fabrication of photomobile polymer materials with phase-separated structure of crosslinked azobenzene liquid-crystalline polymer and poly(dimethylsiloxane). Liq. Cryst. 2018, 45, 2269–2273. [Google Scholar] [CrossRef]

- Yue, Y.F.; Norikane, Y.; Azumi, R.; Koyama, E. Light-induced mechanical response in crosslinked liquid-crystalline polymers with photoswitchable glass transition temperatures. Nat. Commun. 2018, 9, 3234–3241. [Google Scholar] [CrossRef]

- Ube, T.; Ikeda, T. Photomobile polymer materials with crosslinked liquid-crystalline structures: Molecular design, fabrication, and functions. Angew. Chem. Int. Ed. 2014, 53, 10290–10299. [Google Scholar] [CrossRef]

- White, T.J.; Broer, D.J. Programmable and adaptive mechanics with liquid crystal polymer networks and elastomers. Nat. Mater. 2015, 14, 1087–1098. [Google Scholar] [CrossRef]

- Yu, H.F. Recent advances in photoresponsive liquid crystalline polymers containing azobenzene chromophores. J. Mater. Chem. C 2014, 2, 3047–3054. [Google Scholar] [CrossRef]

- Yu, Y.L.; Nakano, M.; Ikeda, T. Photomechanics: directed bending of a polymer film by light. Nature 2003, 425, 145. [Google Scholar] [CrossRef]

- Lee, K.M.; Smith, M.L.; Koerner, H.; Tabiryan, N.; Vaia, R.A.; Bunning, T.J.; White, T.J. Photodriven, flexural-torsional oscillation of glassy azobenzene liquid crystal polymer networks. Adv. Funct. Mater. 2011, 21, 2913–2918. [Google Scholar] [CrossRef]

- Wie, J.J.; Lee, K.M.; Smith, M.L.; Vaia, R.A.; White, T.J. Torsional mechanical responses in azobenzene functionalized liquid crystalline polymer networks. Soft Matter 2013, 9, 9303–9310. [Google Scholar] [CrossRef]

- Tang, R.; Liu, Z.; Xu, D.; Liu, J.; Yu, L.; Yu, H. Optical pendulum generator based on photomechanical liquid-crystalline actuators. ACS Appl. Mater. Interfaces 2015, 7, 8393–8397. [Google Scholar] [CrossRef] [PubMed]

- Yamada, M.; Kondo, M.; Mamiya, J.; Yu, Y.; Kinoshita, M.; Barrett, C.J.; Ikeda, T. Photomobile polymer materials: Towards light-driven plastic motors. Angew. Chem. Int. Ed. 2008, 47, 4986–4988. [Google Scholar] [CrossRef]

- Yamada, M.; Kondo, M.; Miyasato, R.; Naka, Y.; Mamiya, J.; Kinoshita, M.; Shishido, A.; Yu, Y.L.; Barrett, C.J.; Ikeda, T. Photomobile polymer materials-various three-dimensional movements. J. Mater. Chem. 2009, 19, 60–62. [Google Scholar] [CrossRef]

- Cheng, F.T.; Yin, R.Y.; Zhang, Y.Y.; Yen, C.-C.; Yu, Y.L. Fully plastic microrobots which manipulate objects using only visible light. Soft Matter 2010, 6, 3447–3449. [Google Scholar] [CrossRef]

- Huang, C.L.; Lv, J.-A.; Tian, X.J.; Wang, Y.C.; Yu, Y.L.; Liu, J. Miniaturized swimming soft robot with complex movement actuated and controlled by remote light signals. Sci. Rep. 2015, 5, 17414. [Google Scholar] [CrossRef]

- Wani, O.M.; Zeng, H.; Priimagi, A. A light-driven artificial flytrap. Nat. Commun. 2017, 8, 15546. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Xing, X.; Liu, Z.; Zhu, Y.; Liu, H.; Yu, Y.; Cheng, F. Photodeformable polymer material: Towards light-driven micropump applications. Appl. Phys. A 2010, 100, 39–43. [Google Scholar] [CrossRef]

- Chen, M.L.; Huang, H.T.; Zhu, Y.T.; Liu, Z.; Xing, X.; Cheng, F.T.; Yu, Y.L. Photodeformable CLCP material: study on photo-activated microvalve applications. Appl. Phys. A 2011, 102, 667–672. [Google Scholar] [CrossRef]

- Van Oosten, C.L.; Bastiaansen, C.W.M.; Broer, D.J. Printed artificial cilia from liquid-crystal network actuators modularly driven by light. Nat. Mater. 2009, 8, 677–682. [Google Scholar] [CrossRef]

- Lv, J.A.; Liu, Y.Y.; Wei, J.; Chen, E.Q.; Qin, L.; Yu, Y.L. Photocontrol of fluid slugs in liquid crystal polymer microactuators. Nature 2016, 537, 179–184. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Yao, L.; Yang, T.; Yin, R.; Li, F.; Yu, Y. NIR-light-induced deformation of cross-linked liquid-crystal polymers using upconversion nanophosphors. J. Am. Chem. Soc. 2011, 133, 15810–15813. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Z.; Xu, M.; Li, F.; Yu, Y. Red-light-controllable liquid-crystal soft actuators via low-power excited upconversion based on triplet-triplet annihilation. J. Am. Chem. Soc. 2013, 135, 16446–16453. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Cheng, Z.; Dong, Z.; Zhang, Y.; Yu, H. Photomechanical response of polymer-dispersed liquid crystals/graphene oxide nanocomposites. J. Mater. Chem. C 2014, 2, 8501–8506. [Google Scholar] [CrossRef]

- Cheng, Z.X.; Wang, T.J.; Li, X.; Zhang, Y.H.; Yu, H.F. NIR-Vis-UV light-responsive actuator films of polymer-dispersed liquid crystal/graphene oxide nanocomposites. ACS Appl. Mater. Interf. 2015, 7, 27494–27501. [Google Scholar] [CrossRef] [PubMed]

- Li, C.S.; Huang, X.Z.; Jiang, H.R. Reversible Photo Actuated Composite Bulk with Nematic Liquid Crystalline Elastomer Matrix. Mol. Cryst. Liq. Cryst. 2015, 608, 146–156. [Google Scholar] [CrossRef]

- Zou, W.Q.; Huang, X.Z.; Li, Q.K.; Guo, L.C.; Li, C.S.; Jiang, H.R. Photo-thermo-mechanically actuated liquid crystalline elastomer nanocomposite reinforced by polyurethane fiber-network. Mol. Cryst. Liq. Cryst. 2016, 631, 9–20. [Google Scholar] [CrossRef]

- Sun, X.M.; Sun, H.; Li, H.P.; Peng, H.S. Developing polymer composite materials: carbon nanotubes or graphene? Adv. Mater. 2013, 25, 5153–5176. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Setyowati, K.; Li, A.; Gong, S.; Chen, J. Reversible infrared actuation of carbon nanotube-liquid crystalline elastomer nanocomposites. Adv. Mater. 2008, 20, 2271–2275. [Google Scholar] [CrossRef]

- Ji, Y.; Huang, Y.Y.; Rungsawang, R.; Terentjev, E.M. Dispersion and alignment of carbon nanotubes in liquid crystalline polymers and elastomers. Adv. Mater. 2010, 22, 3436–3440. [Google Scholar] [CrossRef]

- Li, C.; Liu, Y.; Lo, C.-W.; Jiang, H. Reversible white-light actuation of carbon nanotube incorporated liquid crystalline elastomer nanocomposites. Soft Matter 2011, 7, 7511–7516. [Google Scholar] [CrossRef]

- Li, C.; Liu, Y.; Huang, X.; Jiang, H. Direct sun-driven artificial heliotropism for solar energy harvesting based on a photo-thermomechanical liquid-crystal elastomer nanocomposite. Adv. Funct. Mater. 2012, 22, 5166–5174. [Google Scholar] [CrossRef]

- Kohlmeyer, R.R.; Chen, J. Wavelength-selective, IR light-driven hinges based on liquid crystalline elastomer composites. Angew. Chem. Int. Ed. 2013, 52, 9234–9237. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.K.; Zhan, W.J.; Peng, R.G.; He, C.G.; Pang, X.C.; Shi, D.; Jiang, T.; Lin, Z.Q. Graphene-Enabled Superior and Tunable Photomechanical Actuation in Liquid Crystalline Elastomer Nanocomposites. Adv. Mater. 2015, 27, 6376–6381. [Google Scholar] [CrossRef] [PubMed]

- Li, C.S.; Liu, Y.; Huang, X.Z.; Li, C.H.; Jiang, H.R. Light actuation of graphene-oxide incorporated liquid crystalline elastomer nanocomposites. Mol. Cryst. Liq. Cryst. 2015, 616, 83–92. [Google Scholar] [CrossRef]

- Liu, W.; Guo, L.X.; Lin, B.P.; Zhang, X.Q.; Sun, Y.; Yang, H. Near-infrared responsive liquid crystalline elastomers containing photothermal conjugated polymers. Macromolecules 2016, 49, 4023–4030. [Google Scholar] [CrossRef]

- Wang, M.; Sayed, S.M.; Guo, L.X.; Lin, B.P.; Zhang, X.Q.; Sun, Y.; Yang, H. Multi-stimuli responsive carbon nanotube incorporated polysiloxane azobenzene liquid crystalline elastomer composites. Macromolecules 2016, 49, 663–671. [Google Scholar] [CrossRef]

- Wang, Y.C.; Huang, X.Z.; Zhang, J.Q.; Bi, M.; Zhang, J.D.; Niu, H.Y.; Li, C.S.; Yu, H.F.; Wang, B.S.; Jiang, H.R. Two-step crosslinked liquid-crystalline elastomer with reversible two-way shape memory characteristics. Mol. Cryst. Liq. Cryst. 2017, 650, 13–22. [Google Scholar] [CrossRef]

- Wang, W.; Sun, X.M.; Wu, W.; Peng, H.S.; Yu, Y.L. Photoinduced deformation of crosslinked liquid-crystalline polymer film oriented by a highly aligned carbon nanotube sheet. Angew. Chem. Int. Ed. 2012, 51, 4644–4647. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.M.; Wang, W.; Qiu, L.B.; Guo, W.H.; Yu, Y.L.; Peng, H.S. Unusual reversible photomechanical actuation in polymer/nanotube composites. Angew. Chem. Int. Ed. 2012, 51, 8520–8524. [Google Scholar] [CrossRef]

- Li, C.S.; Lo, C.-W.; Zhu, D.F.; Li, C.H.; Liu, Y.; Jiang, H.R. Synthesis of a photoresponsive liquid-crystalline polymer containing azobenzene. Macromol. Rapid Commun. 2009, 30, 1928–1935. [Google Scholar] [CrossRef] [PubMed]

- Moon, J.; Choi, J.; Cho, M. Opto-mechanical behavior and interfacial characteristics of crosslinked liquid crystalline polymer composites with carbon nanotube fillers. Carbon 2017, 121, 181–192. [Google Scholar] [CrossRef]

- Barrett, C.J.; Mamiya, J.I.; Yager, K.G.; Ikeda, T. Photo-mechanical effects in azobenzene-containing soft materials. Soft Matter 2007, 3, 1249–1261. [Google Scholar] [CrossRef]

| Tensile Strength (MPa) | ||||||||

|---|---|---|---|---|---|---|---|---|

| F10 | F20 | F40 | F60 | CF10 | CF20 | CF40 | CF60 | |

| ‖ | 14.62 | 14.74 | 14.81 | 14.86 | 32.51 | 32.64 | 32.71 | 32.79 |

| ┴ | 7.51 | 7.62 | 7.68 | 7.74 | 20.42 | 20.53 | 20.71 | 20.82 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bi, M.; He, Y.; Wang, Y.; Yang, W.; Qin, B.; Xu, J.; Wang, X.; Wang, B.; Dong, Y.; Gao, Y.; et al. Photo Actuation Performance of Nanotube Sheet Incorporated Azobenzene Crosslinked Liquid Crystalline Polymer Nanocomposite. Polymers 2019, 11, 735. https://doi.org/10.3390/polym11040735

Bi M, He Y, Wang Y, Yang W, Qin B, Xu J, Wang X, Wang B, Dong Y, Gao Y, et al. Photo Actuation Performance of Nanotube Sheet Incorporated Azobenzene Crosslinked Liquid Crystalline Polymer Nanocomposite. Polymers. 2019; 11(4):735. https://doi.org/10.3390/polym11040735

Chicago/Turabian StyleBi, Meng, Yifan He, Yuchang Wang, Wenlong Yang, Ban Qin, Jiaojiao Xu, Xiuxiu Wang, Binsong Wang, Yinmao Dong, Yachen Gao, and et al. 2019. "Photo Actuation Performance of Nanotube Sheet Incorporated Azobenzene Crosslinked Liquid Crystalline Polymer Nanocomposite" Polymers 11, no. 4: 735. https://doi.org/10.3390/polym11040735

APA StyleBi, M., He, Y., Wang, Y., Yang, W., Qin, B., Xu, J., Wang, X., Wang, B., Dong, Y., Gao, Y., & Li, C. (2019). Photo Actuation Performance of Nanotube Sheet Incorporated Azobenzene Crosslinked Liquid Crystalline Polymer Nanocomposite. Polymers, 11(4), 735. https://doi.org/10.3390/polym11040735