Development of Injection-Molded Polylactide Pieces with High Toughness by the Addition of Lactic Acid Oligomer and Characterization of Their Shape Memory Behavior

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Manufacturing of OLA-Containing PLA Pieces

2.3. Mechanical Characterization

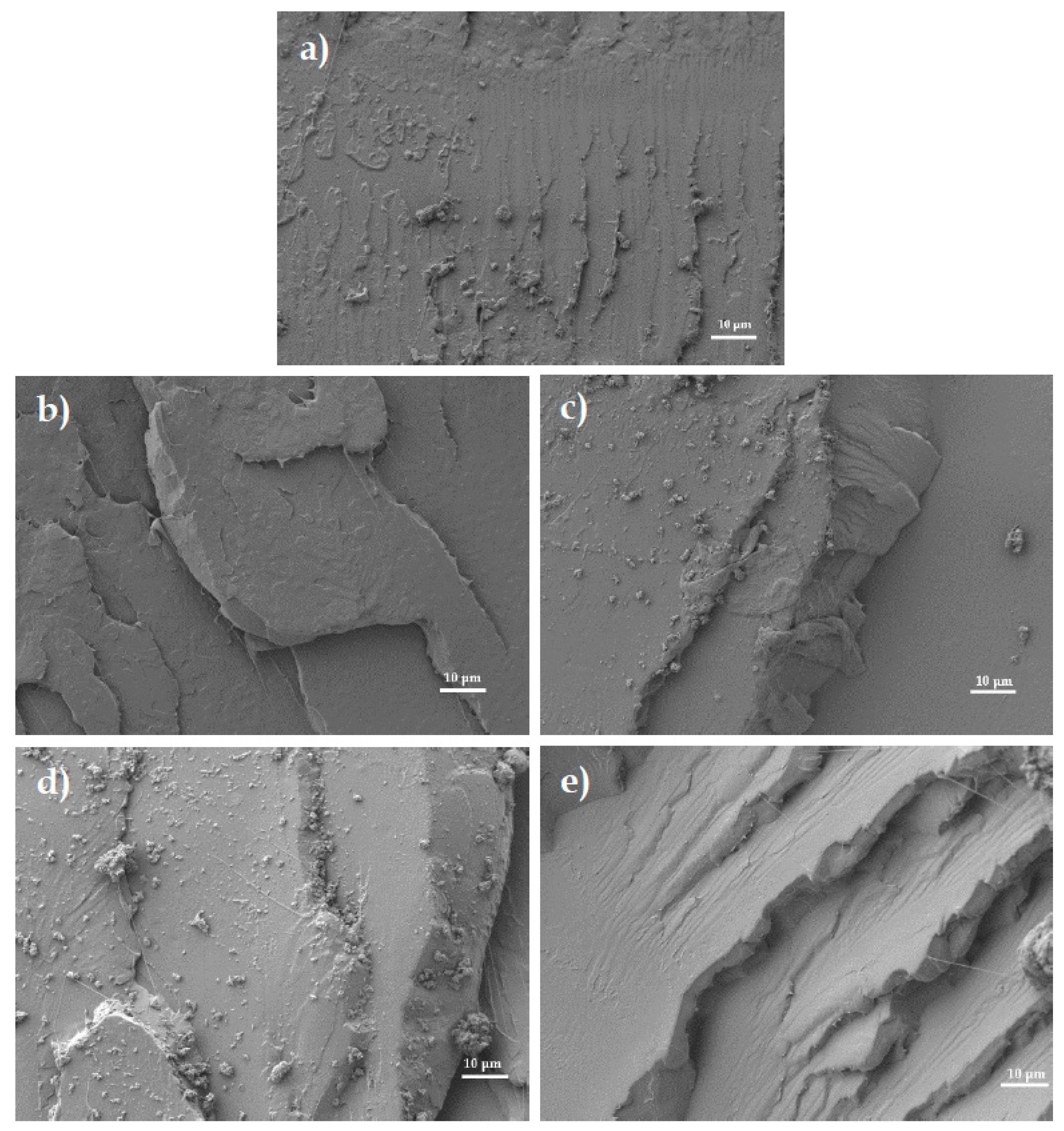

2.4. Microscopy

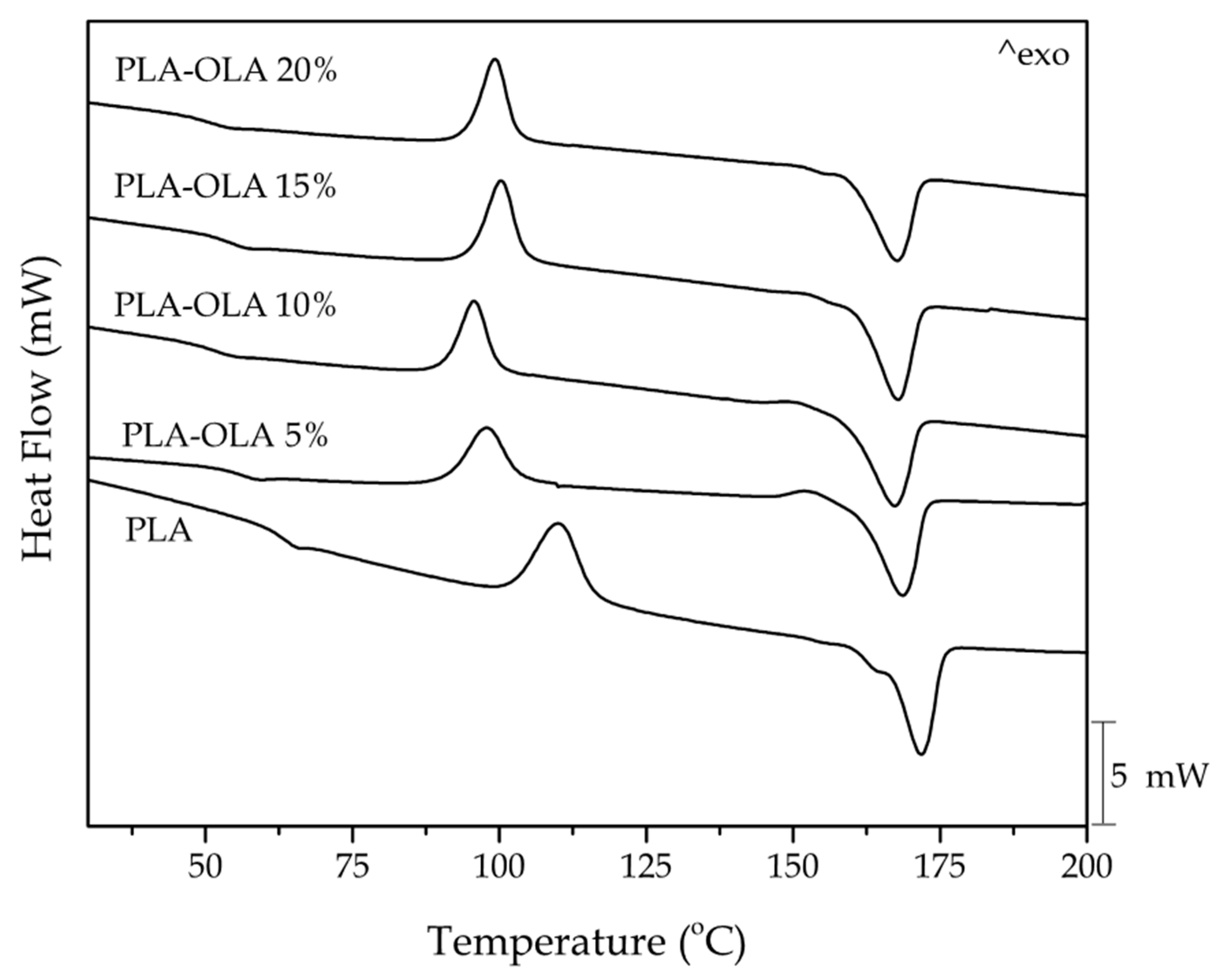

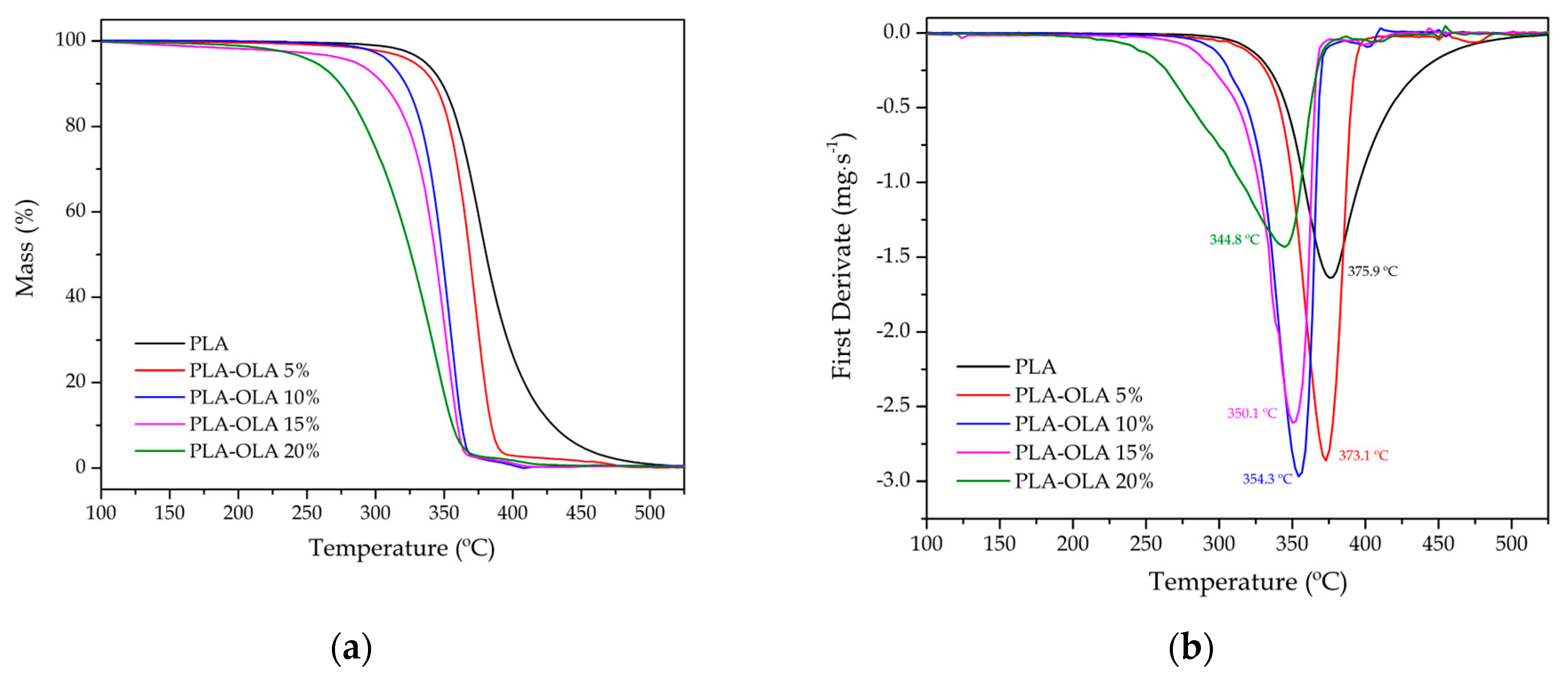

2.5. Thermal Characterization

2.6. Viscosity Characterization

2.7. Thermomechanical Characterization

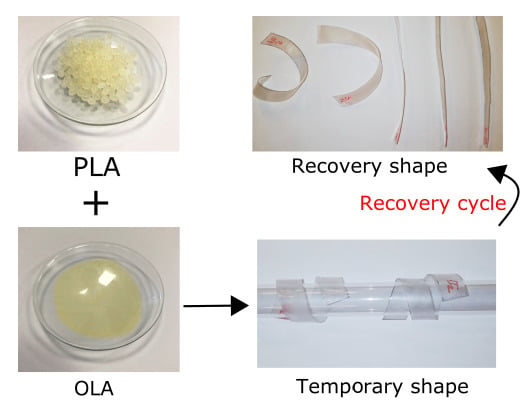

2.8. Characterization of the Shape Memory Behavior

3. Results and Discussion

3.1. Effect of OLA on the Mechanical Properties of PLA

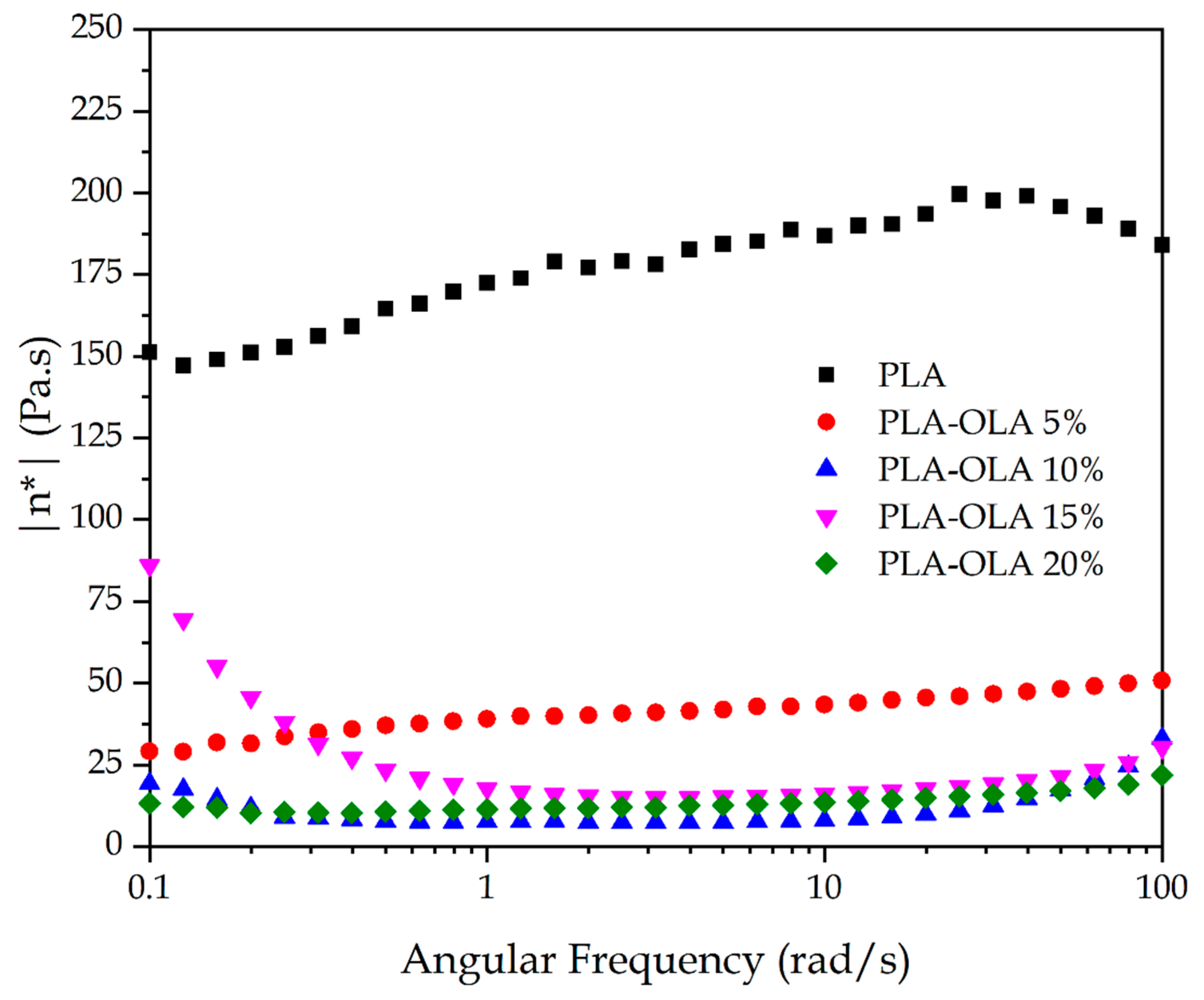

3.2. Effect of OLA on the Thermal and Rheological Properties of PLA

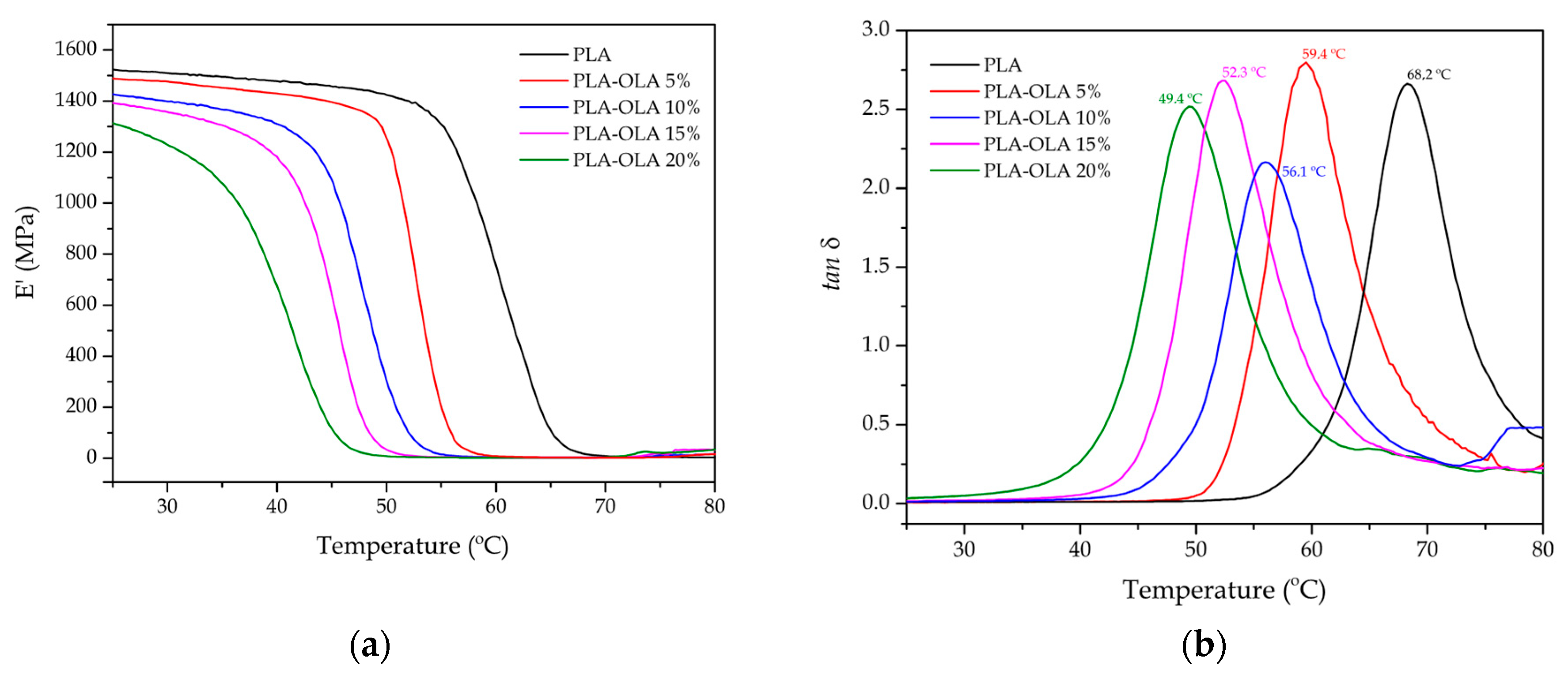

3.3. Effect of OLA on the Thermomechanical Properties of PLA

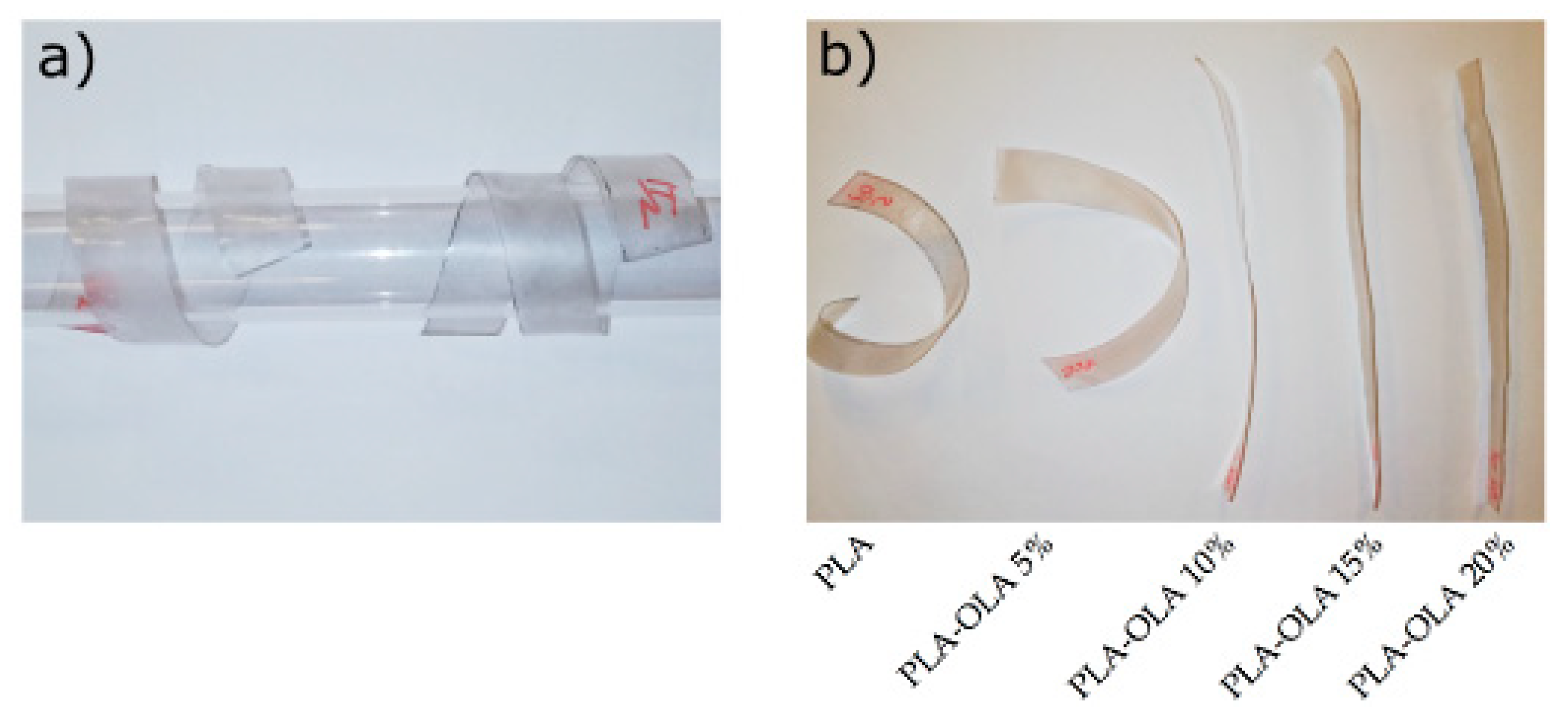

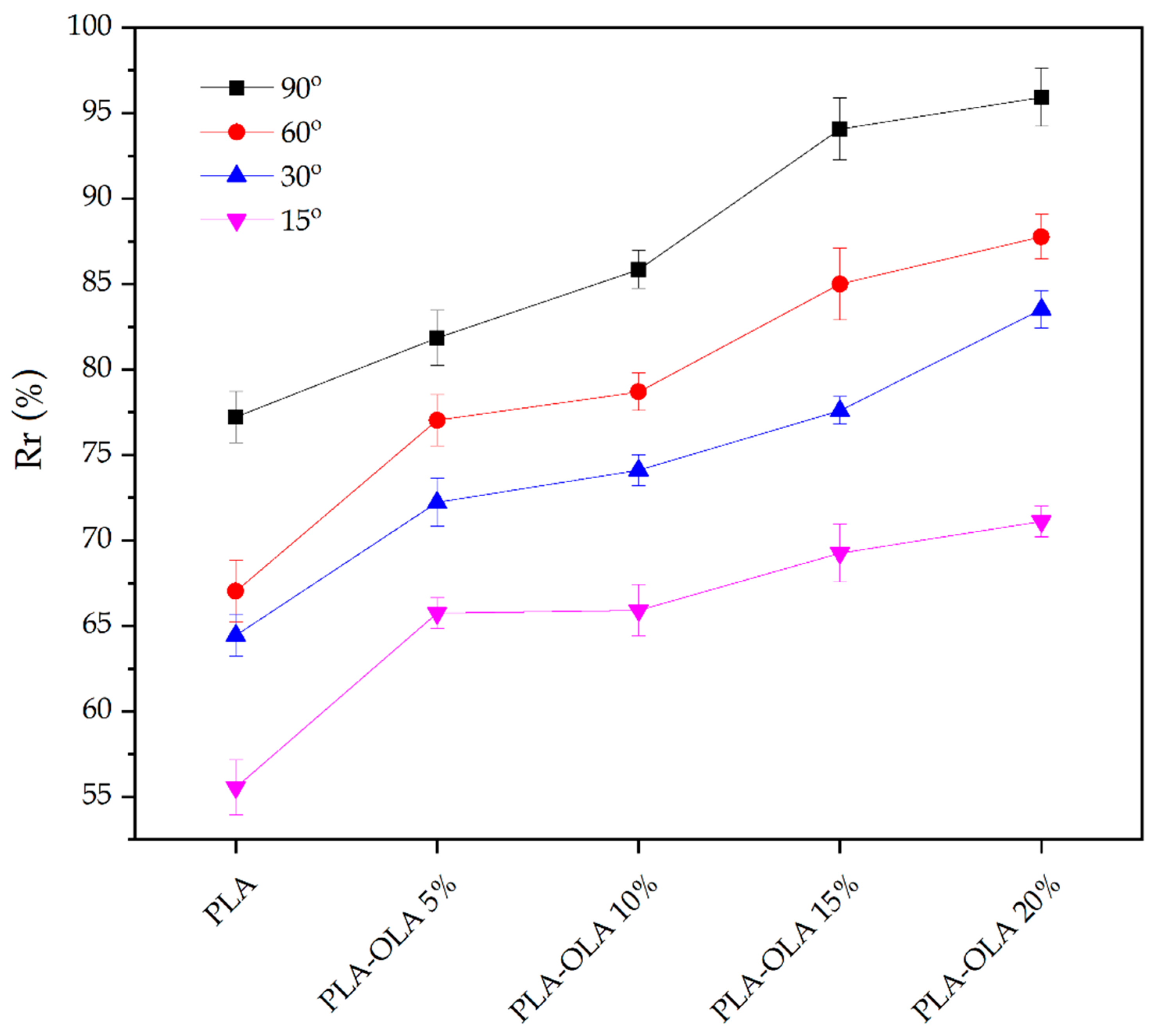

3.4. Effect of OLA on the Shape Memory Behavior of PLA

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dijkstra, P.J.; Du, H.; Feijen, J. Single site catalysts for stereoselective ring-opening polymerization of lactides. Polym. Chem. 2011, 2, 520–527. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Lagaron, J.M.; Balart, R.; Torres-Giner, S. Bioactive multilayer polylactide films with controlled release capacity of gallic acid accomplished by incorporating electrospun nanostructured coatings and interlayers. Appl. Sci. 2019, 9, 533. [Google Scholar] [CrossRef] [Green Version]

- Radusin, T.; Torres-Giner, S.; Stupar, A.; Ristic, I.; Miletic, A.; Novakovic, A.; Lagaron, J.M. Preparation, characterization and antimicrobial properties of electrospun polylactide films containing Allium ursinum L. extract. Food Packag. Shelf Life 2019, 21, 100357. [Google Scholar] [CrossRef]

- Scarfato, P.; Di Maio, L.; Milana, M.R.; Giamberardini, S.; Denaro, M.; Incarnato, L. Performance properties, lactic acid specific migration and swelling by simulant of biodegradable poly(lactic acid)/nanoclay multilayer films for food packaging. Food Addit. Contam. Part A 2017, 34, 1730–1742. [Google Scholar] [CrossRef]

- Scarfato, P.; Di Maio, L.; Incarnato, L. Recent advances and migration issues in biodegradable polymers from renewable sources for food packaging. J. Appl. Polym. Sci. 2015, 132, 42597. [Google Scholar] [CrossRef]

- Tawakkal, I.S.M.A.; Cran, M.J.; Miltz, J.; Bigger, S.W. A review of poly(lactic acid)-based materials for antimicrobial packaging. J. Food Sci. 2014, 79, R1477–R1490. [Google Scholar] [CrossRef]

- Paula, K.T.; Gaal, G.; Almeida, G.F.B.; Andrade, M.B.; Facure, M.H.M.; Correa, D.S.; Ruil, A.; Rodrigues, V.; Mendonca, C.R. Femtosecond laser micromachining of polylactic acid/graphene composites for designing interdigitated microelectrodes for sensor applications. Opt. Laser Technol. 2018, 101, 74–79. [Google Scholar] [CrossRef]

- Jeoung, S.K.; Ha, J.U.; Ko, Y.K.; Kim, B.R.; Yoo, S.E.; Lee, K.D.; Lee, S.N.; Lee, P.C. Aerobic biodegradability of polyester/polylactic acid composites for automotive NVH parts. Int. J. Precis. Eng. Manuf. 2014, 15, 1703–1707. [Google Scholar] [CrossRef]

- Finkenstadt, V.L.; Tisserat, B. Poly(lactic acid) and osage orange wood fiber composites for agricultural mulch films. Ind. Crop. Prod. 2010, 31, 316–320. [Google Scholar] [CrossRef]

- Chang, Y.C.; Chen, Y.; Ning, J.L.; Hao, C.; Rock, M.; Amer, M.; Feng, S.; Falahati, M.; Wang, L.J.; Chen, R.K.; et al. No such thing as trash: A 3D-printable polymer composite composed of oil-extracted spent coffee grounds and polylactic acid with enhanced impact toughness. ACS Sustain. Chem. Eng. 2019, 7, 15304–15310. [Google Scholar] [CrossRef]

- Gao, Y.; Li, Y.; Hu, X.R.; Wu, W.D.; Wang, Z.; Wang, R.G.; Zhang, L.Q. Preparation and properties of novel thermoplastic vulcanizate based on bio-based polyester/polylactic acid, and its application in 3D printing. Polymers 2017, 9, 694. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kumar, S.; Singh, R.; Singh, T.P.; Batish, A. Investigations of polylactic acid reinforced composite feedstock filaments for multimaterial three-dimensional printing applications. Proc. Inst. Mech. Eng. Part C J. Eng. Mech. Eng. Sci. 2019, 233, 5953–5965. [Google Scholar] [CrossRef]

- Matos, B.D.M.; Rocha, V.; da Silva, E.J.; Moro, F.H.; Bottene, A.C.; Ribeiro, C.A.; Dias, D.D.; Antonio, S.G.; do Amaral, A.C.; Cruz, S.A.; et al. Evaluation of commercially available polylactic acid (PLA) filaments for 3d printing applications. J. Therm. Anal. Calorim. 2019, 137, 555–562. [Google Scholar] [CrossRef]

- Bayer, I.S. Thermomechanical properties of polylactic acid-graphene composites: A state-of-the-art review for biomedical applications. Materials 2017, 10, 748. [Google Scholar] [CrossRef] [Green Version]

- Pierchala, M.K.; Makaremi, M.; Tan, H.L.; Pushpamalar, J.; Muniyandy, S.; Solouk, A.; Lee, S.M.; Pasbakhsh, P. Nanotubes in nanofibers: Antibacterial multilayered polylactic acid/halloysite/gentamicin membranes for bone regeneration application. Appl. Clay Sci. 2018, 160, 95–105. [Google Scholar] [CrossRef]

- Chen, Y.F.; Xu, J.Y.; Tan, Q.G.; Zhang, Z.L.; Zheng, J.; Xu, X.Y.; Li, Y. End-group functionalization of polyethylene glycol-polylactic acid copolymer and its application in the field of pharmaceutical carriers. J. Biobased Mater. Bioenergy 2019, 13, 690–698. [Google Scholar]

- Torres-Giner, S.; Martinez-Abad, A.; Gimeno-Alcañiz, J.V.; Ocio, M.J.; Lagaron, J.M. Controlled delivery of gentamicin antibiotic from bioactive electrospun polylactide-based ultrathin fibers. Adv. Eng. Mater. 2012, 14, B112–B122. [Google Scholar] [CrossRef]

- Agüero, A.; Morcillo, M.d.C.; Quiles-Carrillo, L.; Balart, R.; Boronat, T.; Lascano, D.; Torres-Giner, S.; Fenollar, O. Study of the influence of the reprocessing cycles on the final properties of polylactide pieces obtained by injection molding. Polymers 2019, 11, 1908. [Google Scholar] [CrossRef] [Green Version]

- Quiles-Carrillo, L.; Montanes, N.; Garcia-Garcia, D.; Carbonell-Verdu, A.; Balart, R.; Torres-Giner, S. Effect of different compatibilizers on injection-molded green composite pieces based on polylactide filled with almond shell flour. Compos. Part B Eng. 2018, 147, 76–85. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Pineiro, F.; Jorda-Vilaplana, A.; Torres-Giner, S. Ductility and toughness improvement of injection-molded compostable pieces of polylactide by melt blending with poly(ε-caprolactone) and thermoplastic starch. Materials 2018, 11, 2138. [Google Scholar] [CrossRef] [Green Version]

- Bioplastics market data 2018. In Global Production Capacities of Bioplastics 2018–2023; European Bioplastics: Berlin, Germany, 2018; p. 4.

- Valerio, O.; Pin, J.M.; Misra, M.; Mohanty, A.K. Synthesis of glycerol-based biopolyesters as toughness enhancers for polylactic acid bioplastic through reactive extrusion. ACS Omega 2016, 1, 1284–1295. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Bian, X.C.; Xiang, S.; Li, G.; Chen, X.S. Synthesis of PLLA-based block copolymers for improving melt strength and toughness of PLLA by in situ reactive blending. Polym. Degrad. Stab. 2017, 136, 58–70. [Google Scholar] [CrossRef]

- Zou, J.; Qi, Y.Z.; Su, L.L.; Wei, Y.; Li, Z.L.; Xu, H.Q. Synthesis and characterization of poly(ester amide)s consisting of poly(L-lactic acid) and poly(butylene succinate) segments with 2,2′-bis(2-oxazoline) chain extending. Macromol. Res. 2018, 26, 1212–1218. [Google Scholar] [CrossRef]

- Lan, X.R.; Li, X.; Liu, Z.Y.; He, Z.K.; Yang, W.; Yang, M.B. Composition, morphology and properties of poly(lactic acid) and poly(butylene succinate) copolymer system via coupling reaction. J. Macromol. Sci. Part A Pure Appl. Chem. 2013, 50, 861–870. [Google Scholar] [CrossRef]

- Garcia-Campo, M.J.; Quiles-Carrillo, L.; Masia, J.; Reig-Perez, M.J.; Montanes, N.; Balart, R. Environmentally friendly compatibilizers from soybean oil for ternary blends of poly(lactic acid)-PLA, poly(ε-caprolactone)-PCL and poly(3-hydroxybutyrate)-PHB. Materials 2017, 10, 1339. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Campo, M.J.; Quiles-Carrillo, L.; Sanchez-Nacher, L.; Balart, R.; Montanes, N. High toughness poly(lactic acid) (PLA) formulations obtained by ternary blends with poly(3-hydroxybutyrate) (PHB) and flexible polyesters from succinic acid. Polym. Bull. 2019, 76, 1839–1859. [Google Scholar] [CrossRef]

- Sathornluck, S.; Choochottiros, C. Modification of epoxidized natural rubber as a PLA toughening agent. J. Appl. Polym. Sci. 2019, 136, 48267. [Google Scholar] [CrossRef]

- Su, S.; Kopitzky, R.; Tolga, S.; Kabasci, S. Polylactide (PLA) and its blends with poly(butylene succinate) (PBS): A brief review. Polymers 2019, 11, 1193. [Google Scholar] [CrossRef] [Green Version]

- Zhang, B.; Sun, B.; Bian, X.C.; Li, G.; Chen, X.S. High melt strength and high toughness PLLA/PBS blends by copolymerization and in situ reactive compatibilization. Ind. Eng. Chem. Res. 2017, 56, 52–62. [Google Scholar] [CrossRef]

- Fortelny, I.; Ujcic, A.; Fambri, L.; Slouf, M. Phase structure, compatibility, and toughness of PLA/PCL blends: A review. Front. Mater. 2019, 6, 206. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Mei, Y.; Wang, Q.; Wei, W.; Huang, F.; Li, Y.; Li, J.Y.; Zhou, Z.W. Improved fracture toughness and ductility of PLA composites by incorporating a small amount of surface-modified helical carbon nanotubes. Compos. Part B Eng. 2019, 162, 54–61. [Google Scholar] [CrossRef]

- Li, J.J.; Li, J.; Feng, D.J.; Zhao, J.F.; Sun, J.R.; Li, D.G. Excellent rheological performance and impact toughness of cellulose nanofibers/PLA/ionomer composite. RSC Adv. 2017, 7, 28889–28897. [Google Scholar] [CrossRef] [Green Version]

- Gonzalez-Ausejo, J.; Gamez-Perez, J.; Balart, R.; Lagaron, J.M.; Cabedo, L. Effect of the addition of sepiolite on the morphology and properties of melt compounded PHBV/PLA blends. Polym. Compos. 2019, 40, E156–E168. [Google Scholar] [CrossRef]

- Tsou, C.H.; Gao, C.; De Guzman, M.; Wu, D.Y.; Hung, W.S.; Yuan, L.; Suen, M.C.; Yeh, J.T. Preparation and characterization of poly(lactic acid) with adipate ester added as a plasticizer. Polym. Polym. Compos. 2018, 26, 446–453. [Google Scholar] [CrossRef]

- Huang, H.C.; Chen, L.J.; Song, G.L.; Tang, G.Y. An efficient plasticization method for poly(lactic acid) using combination of liquid-state and solid-state plasticizers. J. Appl. Polym. Sci. 2018, 135, 46669. [Google Scholar] [CrossRef]

- Kang, H.L.; Li, Y.S.; Gong, M.; Guo, Y.L.; Guo, Z.; Fang, Q.H.; Li, X. An environmentally sustainable plasticizer toughened polylactide. RSC Adv. 2018, 8, 11643–11651. [Google Scholar] [CrossRef] [Green Version]

- Carbonell-Verdu, A.; Ferri, J.M.; Dominici, F.; Boronat, T.; Sanchez-Nacher, L.; Balart, R.; Torre, L. Manufacturing and compatibilization of PLA/PBAT binary blends by cottonseed oil-based derivatives. Express Polym. Lett. 2018, 12, 808–823. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Blanes-Martínez, M.M.; Montanes, N.; Fenollar, O.; Torres-Giner, S.; Balart, R. Reactive toughening of injection-molded polylactide pieces using maleinized hemp seed oil. Eur. Polym. J. 2018, 98, 402–410. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Duart, S.; Montanes, N.; Torres-Giner, S.; Balart, R. Enhancement of the mechanical and thermal properties of injection-molded polylactide parts by the addition of acrylated epoxidized soybean oil. Mater. Des. 2018, 140, 54–63. [Google Scholar] [CrossRef]

- Ferri, J.M.; Garcia-Garcia, D.; Sanchez-Nacher, L.; Fenollar, O.; Balart, R. The effect of maleinized linseed oil (mlo) on mechanical performance of poly(lactic acid)-thermoplastic starch (PLA-TPS) blends. Carbohydr. Polym. 2016, 147, 60–68. [Google Scholar] [CrossRef]

- Ferri, J.M.; Garcia-Garcia, D.; Montanes, N.; Fenollar, O.; Balart, R. The effect of maleinized linseed oil as biobased plasticizer in poly(lactic acid)-based formulations. Polym. Int. 2017, 66, 882–891. [Google Scholar] [CrossRef]

- Notta-Cuvier, D.; Murariu, M.; Odent, J.; Delille, R.; Bouzouita, A.; Raquez, J.M.; Lauro, F.; Dubois, P. Tailoring polylactide properties for automotive applications: Effects of co-addition of halloysite nanotubes and selected plasticizer. Macromol. Mater. Eng. 2015, 300, 684–698. [Google Scholar] [CrossRef]

- Luzi, F.; Dominici, F.; Armentano, I.; Fortunati, E.; Burgos, N.; Fiori, S.; Jimenez, A.; Kenny, J.M.; Torre, L. Combined effect of cellulose nanocrystals, carvacrol and oligomeric lactic acid in PLA-PHB polymeric films. Carbohydr. Polym. 2019, 223, 115131. [Google Scholar] [CrossRef]

- Burgos, N.; Martino, V.P.; Jimenez, A. Characterization and ageing study of poly(lactic acid) films plasticized with oligomeric lactic acid. Polym. Degrad. Stab. 2013, 98, 651–658. [Google Scholar] [CrossRef]

- Battegazzore, D.; Bocchini, S.; Frache, A. Crystallization kinetics of poly(lactic acid)-talc composites. Express Polym. Lett. 2011, 5, 849–858. [Google Scholar] [CrossRef] [Green Version]

- Kaygusuz, B.; Ozerinc, S. Improving the ductility of polylactic acid parts produced by fused deposition modeling through polyhydroxyalkanoate additions. J. Appl. Polym. Sci. 2019, 136, 48154. [Google Scholar] [CrossRef]

- Lule, Z.; Kim, J. Nonisothermal crystallization of surface-treated alumina and aluminum nitride-filled polylactic acid hybrid composites. Polymers 2019, 11, 1077. [Google Scholar] [CrossRef] [Green Version]

- Quiles-Carrillo, L.; Montanes, N.; Sammon, C.; Balart, R.; Torres-Giner, S. Compatibilization of highly sustainable polylactide/almond shell flour composites by reactive extrusion with maleinized linseed oil. Ind. Crop. Prod. 2018, 111, 878–888. [Google Scholar] [CrossRef]

- Jing, X.; Mi, H.Y.; Peng, X.F.; Turng, L.S. The morphology, properties, and shape memory behavior of polylactic acid/thermoplastic polyurethane blends. Polym. Eng. Sci. 2015, 55, 70–80. [Google Scholar] [CrossRef]

- Shen, T.F.; Liang, L.Y.; Lu, M.G. Novel biodegradable shape memory composites based on PLA and PCL crosslinked by polyisocyanate. In Advances in Biomedical Engineering; Hu, J., Ed.; Information Engineering Research Inst, USA: Newark, NJ, USA, 2011; pp. 302–305. [Google Scholar]

- Zhang, Z.X.; He, Z.Z.; Yang, J.H.; Huang, T.; Zhang, N.; Wang, Y. Crystallization controlled shape memory behaviors of dynamically vulcanized poly(l-lactide)/poly(ethylene vinyl acetate) blends. Polym. Test. 2016, 51, 82–92. [Google Scholar] [CrossRef]

- Shao, L.N.; Dai, J.; Zhang, Z.X.; Yang, J.H.; Zhang, N.; Huang, T.; Wang, Y. Thermal and electroactive shape memory behaviors of poly(l-lactide)/thermoplastic polyurethane blend induced by carbon nanotubes. RSC Adv. 2015, 5, 101455–101465. [Google Scholar] [CrossRef]

- Ambrosio-Martin, J.; Fabra, M.J.; Lopez-Rubio, A.; Lagaron, J.M. An effect of lactic acid oligomers on the barrier properties of polylactide. J. Mater. Sci. 2014, 49, 2975–2986. [Google Scholar] [CrossRef]

- Courgneau, C.; Domenek, S.; Guinault, A.; Averous, L.; Ducruet, V. Analysis of the structure-properties relationships of different multiphase systems based on plasticized poly(lactic acid). J. Polym. Environ. 2011, 19, 362–371. [Google Scholar] [CrossRef]

- Fortunati, E.; Puglia, D.; Iannoni, A.; Terenzi, A.; Kenny, J.M.; Torre, L. Processing conditions, thermal and mechanical responses of stretchable poly(lactic acid)/poly(butylene succinate) films. Materials 2017, 10, 809. [Google Scholar] [CrossRef] [Green Version]

- Ferri, J.M.; Samper, M.D.; García-Sanoguera, D.; Reig, M.J.; Fenollar, O.; Balart, R. Plasticizing effect of biobased epoxidized fatty acid esters on mechanical and thermal properties of poly(lactic acid). J. Mater. Sci. 2016, 51, 5356–5366. [Google Scholar] [CrossRef]

- Chee, W.K.; Ibrahim, N.A.; Zainuddin, N.; Abd Rahman, M.F.; Chieng, B.W. Impact toughness and ductility enhancement of biodegradable poly(lactic acid)/poly(ε-caprolactone) blends via addition of glycidyl methacrylate. Adv. Mater. Sci. Eng. 2013, 2013, 976373. [Google Scholar] [CrossRef] [Green Version]

- Xue, B.; He, H.Z.; Zhu, Z.W.; Li, J.Q.; Huang, Z.X.; Wang, G.Z.; Chen, M.; Zhan, Z.M. A facile fabrication of high toughness poly(lactic acid) via reactive extrusion with poly(butylene succinate) and ethylene-methyl acrylate-glycidyl methacrylate. Polymers 2018, 10, 1401. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Peng, S.X.; Chen, H.; Yu, X.L.; Zhao, X.P. Mechanical properties, rheological behaviors, and phase morphologies of high-toughness PLA/PBAT blends by in-situ reactive compatibilization. Compos. Part B Eng. 2019, 173, 107028. [Google Scholar] [CrossRef]

- Lascano, D.; Quiles-Carrillo, L.; Torres-Giner, S.; Boronat, T.; Montanes, N. Optimization of the curing and post-curing conditions for the manufacturing of partially bio-based epoxy resins with improved toughness. Polymers 2019, 11, 1354. [Google Scholar] [CrossRef] [Green Version]

- Burgos, N.; Tolaguera, D.; Fiori, S.; Jimenez, A. Synthesis and characterization of lactic acid oligomers: Evaluation of performance as poly(lactic acid) plasticizers. J. Polym. Environ. 2014, 22, 227–235. [Google Scholar] [CrossRef] [Green Version]

- Ljungberg, N.; Wesslén, B. The effects of plasticizers on the dynamic mechanical and thermal properties of poly(lactic acid). J. Appl. Polym. Sci. 2002, 86, 1227–1234. [Google Scholar] [CrossRef]

- Xing, Q.; Zhang, X.Q.; Dong, X.; Liu, G.M.; Wang, D.J. Low-molecular weight aliphatic amides as nucleating agents for poly (L-lactic acid): Conformation variation induced crystallization enhancement. Polymer 2012, 53, 2306–2314. [Google Scholar] [CrossRef]

- Maróti, P.; Kocsis, B.; Ferencz, A.; Nyitrai, M.; Lőrinczy, D. Differential thermal analysis of the antibacterial effect of PLA-based materials planned for 3D printing. J. Therm. Anal. Calorim. 2019, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Maiza, M.; Benaniba, M.T.; Quintard, G.; Massardier-Nageotte, V. Biobased additive plasticizing polylactic acid (PLA). Polímeros 2015, 25, 581–590. [Google Scholar] [CrossRef]

- Jia, S.K.; Yu, D.M.; Zhu, Y.; Wang, Z.; Chen, L.G.; Fu, L. Morphology, crystallization and thermal behaviors of pla-based composites: Wonderful effects of hybrid GO/PEG via dynamic impregnating. Polymers 2017, 9, 528. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shi, X.T.; Zhang, G.C.; Phuong, T.V.; Lazzeri, A. Synergistic effects of nucleating agents and plasticizers on the crystallization behavior of poly(lactic acid). Molecules 2015, 20, 1579–1593. [Google Scholar] [CrossRef]

- Lu, X.L.; Sun, Z.J.; Cai, W.; Gao, Z.Y. Study on the shape memory effects of poly(l-lactide-co-ε-caprolactone) biodegradable polymers. J. Mater. Sci. Mater. Med. 2008, 19, 395–399. [Google Scholar] [CrossRef]

- Leones, A.; Sonseca, A.; Lopez, D.; Fiori, S.; Peponi, L. Shape memory effect on electrospun PLA-based fibers tailoring their thermal response. Eur. Polym. J. 2019, 117, 217–226. [Google Scholar] [CrossRef]

| PLA (wt%) | OLA (wt%) | T (°C) Zone 1 | T (°C) Zone 2 | T (°C) Zone 3 | T (°C) Zone 4 | T (°C) Zone 5 | T (°C) Zone 6 | T (°C) Zone 7 |

|---|---|---|---|---|---|---|---|---|

| 100 | 0 | 145 | 150 | 160 | 170 | 175 | 180 | 180 |

| 95 | 5 | 145 | 150 | 160 | 170 | 175 | 180 | 180 |

| 90 | 10 | 145 | 150 | 160 | 170 | 170 | 175 | 175 |

| 85 | 15 | 145 | 150 | 155 | 155 | 160 | 160 | 170 |

| 80 | 20 | 145 | 150 | 155 | 155 | 160 | 160 | 160 |

| PLA (wt%) | OLA (wt%) | T (°C) Zone 1 | T (°C) Zone 2 | T (°C) Zone 3 | T (°C) Zone 4 | Maximum Pressure (Bar) |

|---|---|---|---|---|---|---|

| 100 | 0 | 175 | 180 | 185 | 190 | 93 |

| 95 | 5 | 175 | 180 | 185 | 190 | 90 |

| 90 | 10 | 160 | 165 | 170 | 175 | 118 |

| 85 | 15 | 150 | 155 | 165 | 170 | 120 |

| 80 | 20 | 145 | 150 | 155 | 165 | 125 |

| Piece | Tensile Test | Impact Strength (kJ m−2) | Shore D Hardness | ||

|---|---|---|---|---|---|

| Et (MPa) | σb (MPa) | εb (%) | |||

| PLA | 2251 ± 45 | 64.6 ± 1.1 | 7.9 ± 0.1 | 25.7 ± 2.7 | 78.8 ± 0.9 |

| PLA-OLA 5% | 2272 ± 94 | 52.0 ± 2.1 | 6.8 ± 0.3 | 30.4 ± 3.6 | 81.2 ± 1.4 |

| PLA-OLA 10% | 2300 ± 82 | 42.1 ± 1.7 | 5.6 ±0.2 | 54.2 ± 4.8 | 80.9 ± 2.3 |

| PLA-OLA 15% | 2400 ± 58 | 41.4 ± 1.0 | 5.3 ± 0.3 | 69.7 ± 5.2 | 80.9 ± 0.9 |

| PLA-OLA 20% | 2101 ± 91 | 37.4 ± 2.2 | 5.0 ± 0.2 | 38.4 ± 5.7 | 80.5 ± 0.4 |

| Piece | Tg (°C) | Tcc (°C) | ΔHcc (J g−1) | Tm (°C) | ΔHm (J g−1) | χcmax (%) |

|---|---|---|---|---|---|---|

| PLA | 63.3 ± 1.5 | 109.8 ± 3.8 | 28.6 ± 0.8 | 170.9 ± 1.7 | 33.4 ± 1.6 | 35.6 ± 1.7 |

| PLA-OLA 5% | 55.9 ± 2.4 | 97.8 ± 2.1 | 22.5 ± 5.1 | 168.2 ± 2.4 | 46.2 ± 4.5 | 51.9 ± 4.7 |

| PLA-OLA 10% | 53.9 ± 1.9 | 100.1 ± 2.5 | 21.9 ± 1.7 | 167.1 ± 3.0 | 46.3 ± 4.8 | 54.9 ± 5.3 |

| PLA-OLA 15% | 51.3 ± 0.4 | 96.7 ± 2.1 | 26.3 ± 3.8 | 166.5 ± 2.1 | 42.4 ± 2.1 | 53.2 ± 2.5 |

| PLA-OLA 20% | 50.8 ± 3.2 | 99.1 ± 2.4 | 25.0 ± 2.5 | 166.9 ± 1.8 | 34.3 ± 3.2 | 45.8 ± 4.0 |

| Piece | T5% (°C) | Tdeg (°C) | Residual Mass (%) |

|---|---|---|---|

| PLA | 336.1 ± 2.7 | 375.9 ± 1.9 | 0.11 ± 0.02 |

| PLA-OLA 5% | 327.2 ± 1.2 | 373.1 ± 2.3 | 0.57 ± 0.08 |

| PLA-OLA 10% | 310.1 ± 3.2 | 354.3 ± 3.1 | 0.65 ± 0.12 |

| PLA-OLA 15% | 296.5 ± 3.8 | 350.1 ± 1.8 | 0.39 ± 0.08 |

| PLA-OLA 20% | 254.8 ± 2.8 | 344.8 ± 2.6 | 0.53 ± 0.07 |

| Piece | DMTA | TMA | |||

|---|---|---|---|---|---|

| E’ at 30 °C (MPa) | E’ at 70 °C (MPa) | Tg * (°C) | CLTE below Tg (μm m−1 K−1) | CLTE above Tg (μm m−1 K−1) | |

| PLA | 1500 ± 55 | 4.9 ± 0.3 | 68.2 ± 1.2 | 79.9 ± 3.5 | 155.4 ± 6.2 |

| PLA-OLA 5% | 1467 ± 49 | 2.4 ± 0.2 | 59.4 ± 1.4 | 87.1 ± 4.0 | 166.4 ± 7.9 |

| PLA-OLA 10% | 1389 ± 52 | 4.6 ± 0.4 | 56.1 ± 0.7 | 88.9 ± 3.8 | 173.8 ± 6.2 |

| PLA-OLA 15% | 1343 ± 38 | 5.2 ± 0.6 | 52.3 ± 0.9 | 90.1 ± 1.9 | 179.9 ± 7.1 |

| PLA-OLA 20% | 1197 ± 47 | 9.9 ± 1.1 | 49.4 ± 0.8 | 91.6 ± 3.9 | 184.5 ± 6.8 |

| Sheet | Rf (%) | |||

|---|---|---|---|---|

| θf = 90° | θf = 60° | θf = 30° | θf = 15° | |

| PLA | 99.6 ± 1.3 | 98.9 ± 2.1 | 99.6 ± 1.3 | 88.2 ± 1.1 |

| PLA-OLA 5% | 98.7 ± 1.2 | 98.1 ± 1.3 | 88.2 ± 1.3 | 87.2 ± 2.5 |

| PLA-OLA 10% | 98.4 ± 1.5 | 94.2 ± 2.4 | 96.8 ± 1.5 | 86.7 ± 1.3 |

| PLA-OLA 15% | 99.3 ± 1.4 | 98.1 ± 1.8 | 97.8 ± 2.1 | 85.2 ± 3.6 |

| PLA-OLA 20% | 91.4 ± 2.3 | 96.5 ± 2.4 | 98.4 ± 1.4 | 84.9 ± 1.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lascano, D.; Moraga, G.; Ivorra-Martinez, J.; Rojas-Lema, S.; Torres-Giner, S.; Balart, R.; Boronat, T.; Quiles-Carrillo, L. Development of Injection-Molded Polylactide Pieces with High Toughness by the Addition of Lactic Acid Oligomer and Characterization of Their Shape Memory Behavior. Polymers 2019, 11, 2099. https://doi.org/10.3390/polym11122099

Lascano D, Moraga G, Ivorra-Martinez J, Rojas-Lema S, Torres-Giner S, Balart R, Boronat T, Quiles-Carrillo L. Development of Injection-Molded Polylactide Pieces with High Toughness by the Addition of Lactic Acid Oligomer and Characterization of Their Shape Memory Behavior. Polymers. 2019; 11(12):2099. https://doi.org/10.3390/polym11122099

Chicago/Turabian StyleLascano, Diego, Giovanni Moraga, Juan Ivorra-Martinez, Sandra Rojas-Lema, Sergio Torres-Giner, Rafael Balart, Teodomiro Boronat, and Luis Quiles-Carrillo. 2019. "Development of Injection-Molded Polylactide Pieces with High Toughness by the Addition of Lactic Acid Oligomer and Characterization of Their Shape Memory Behavior" Polymers 11, no. 12: 2099. https://doi.org/10.3390/polym11122099

APA StyleLascano, D., Moraga, G., Ivorra-Martinez, J., Rojas-Lema, S., Torres-Giner, S., Balart, R., Boronat, T., & Quiles-Carrillo, L. (2019). Development of Injection-Molded Polylactide Pieces with High Toughness by the Addition of Lactic Acid Oligomer and Characterization of Their Shape Memory Behavior. Polymers, 11(12), 2099. https://doi.org/10.3390/polym11122099