Interface Reinforcement of Pulp Fiber Based ABS Composite with Hydrogen Bonding Initiated Interlinked Structure via Alkaline Oxidation and tert-Butyl Grafting on Cellulose

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Sample Preparation

2.3. Characterization

3. Results and Discussion

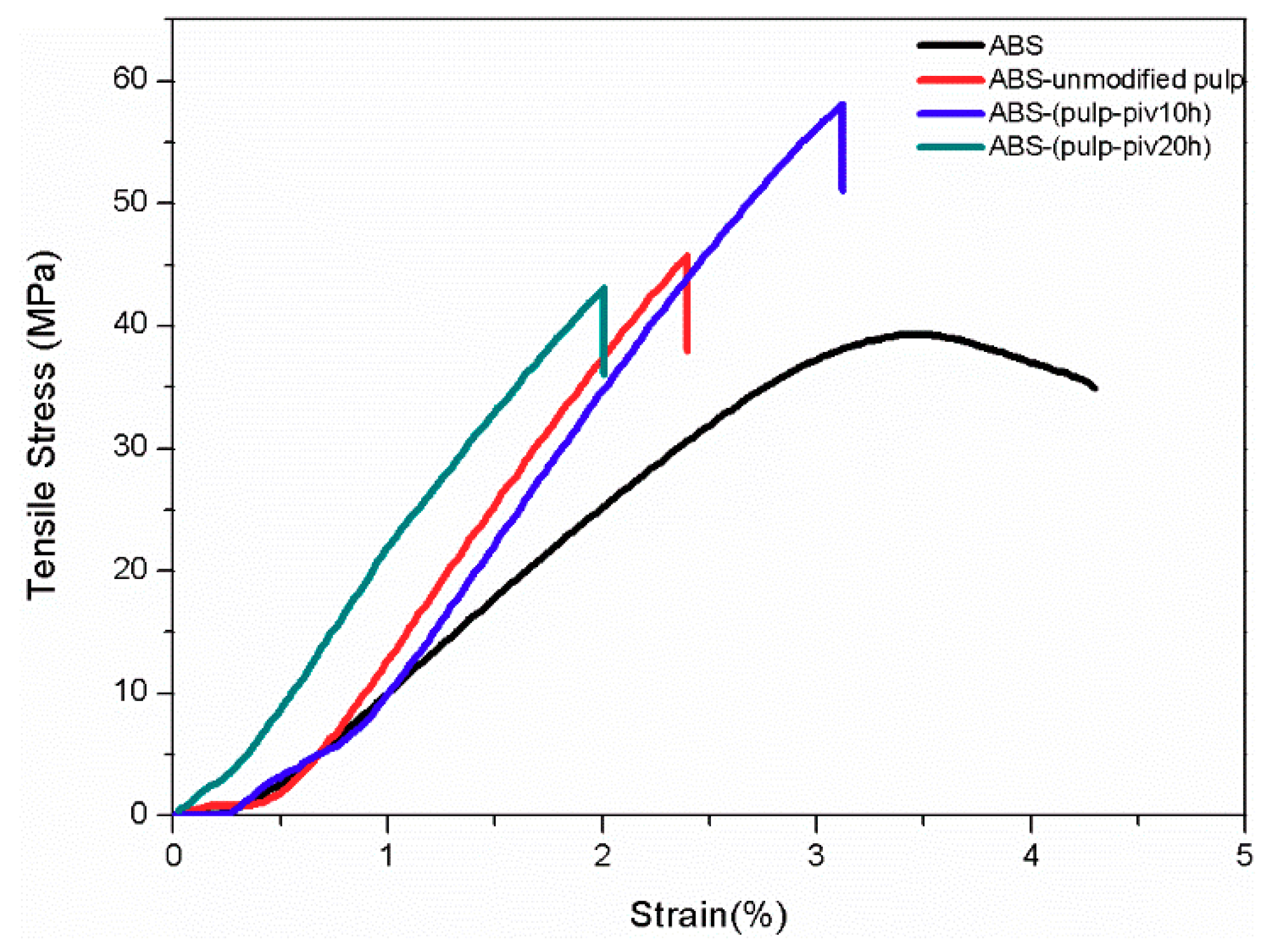

3.1. Tensile Properties

3.2. SEM Observation

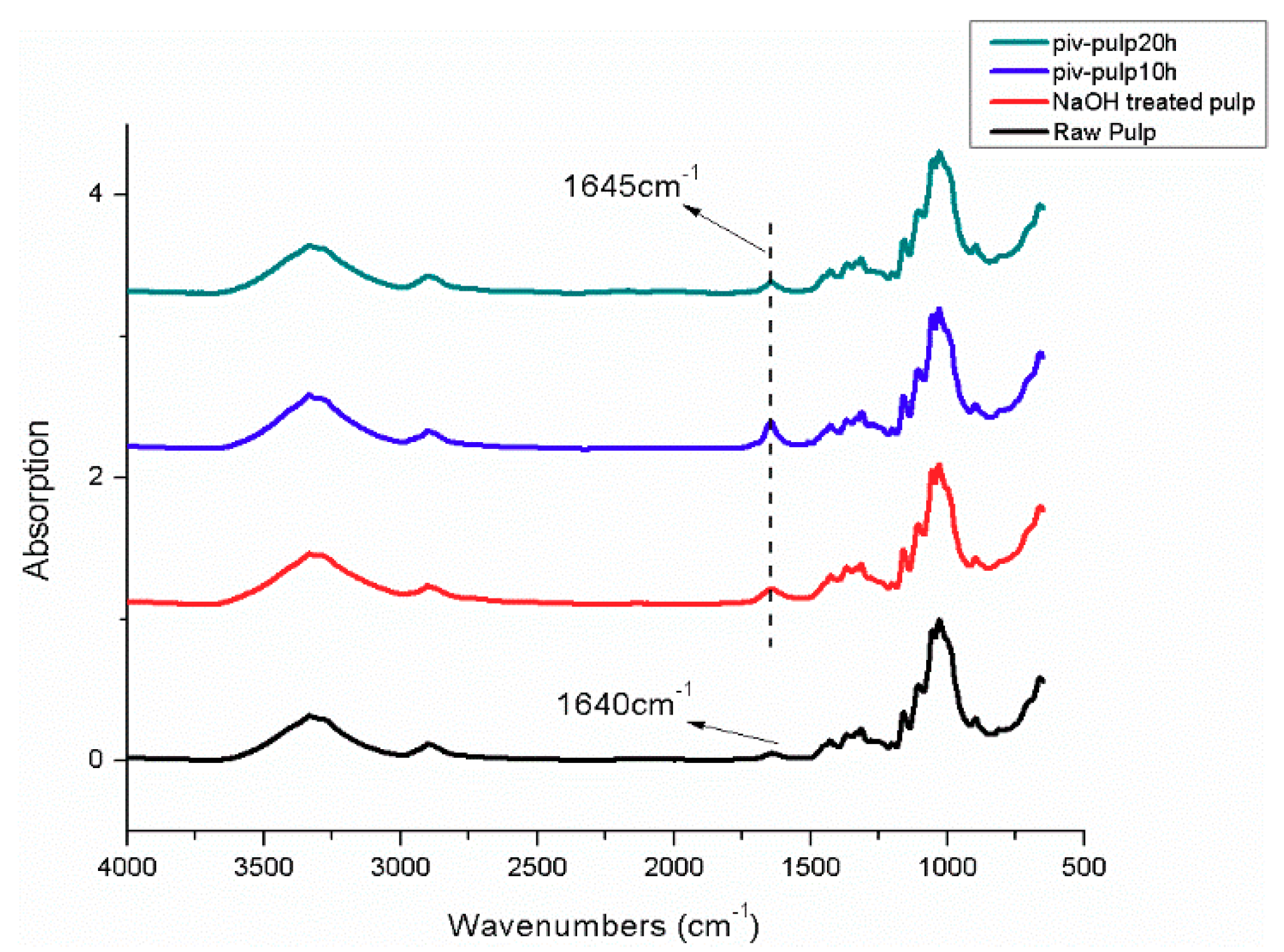

3.3. FTIR Analysis

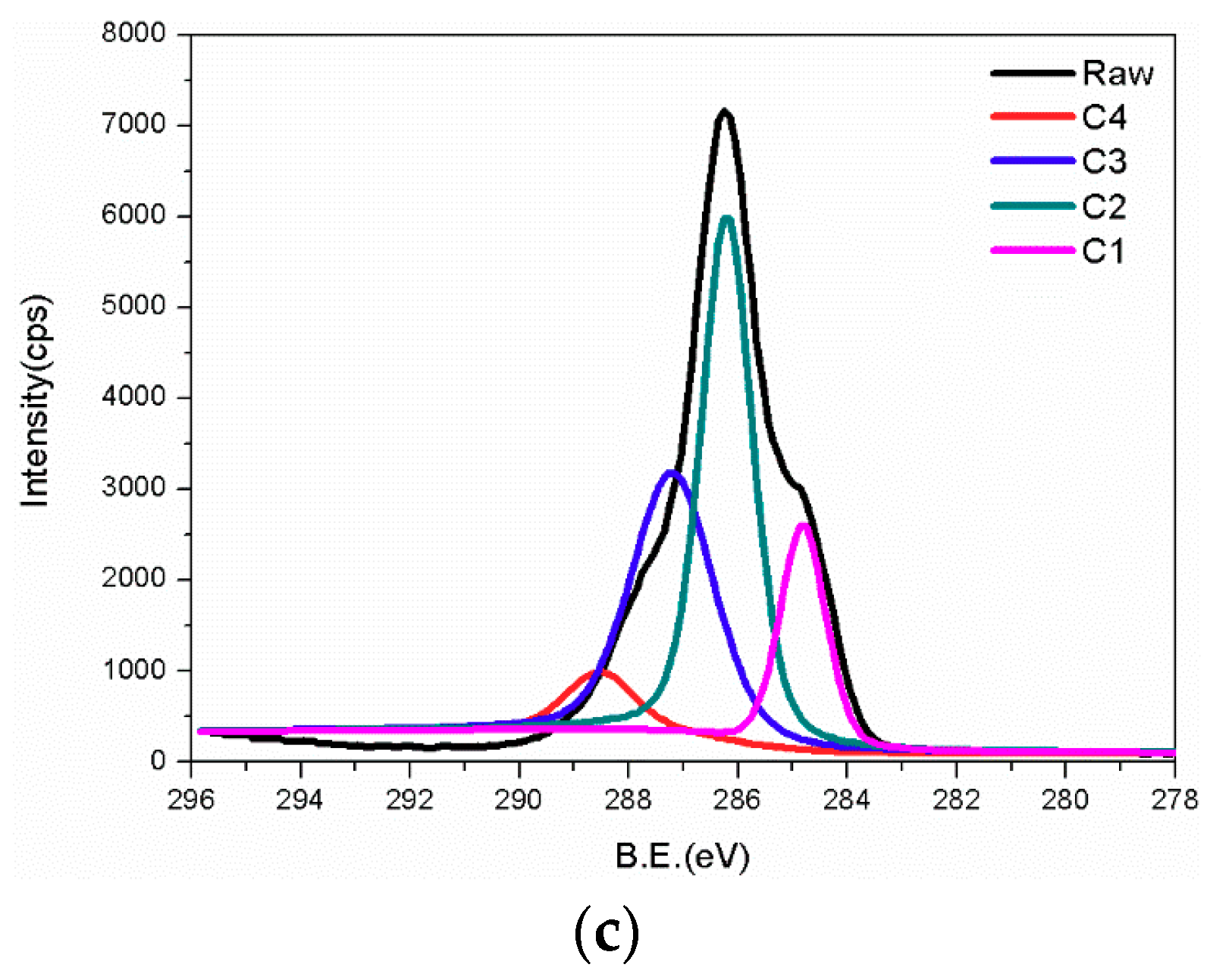

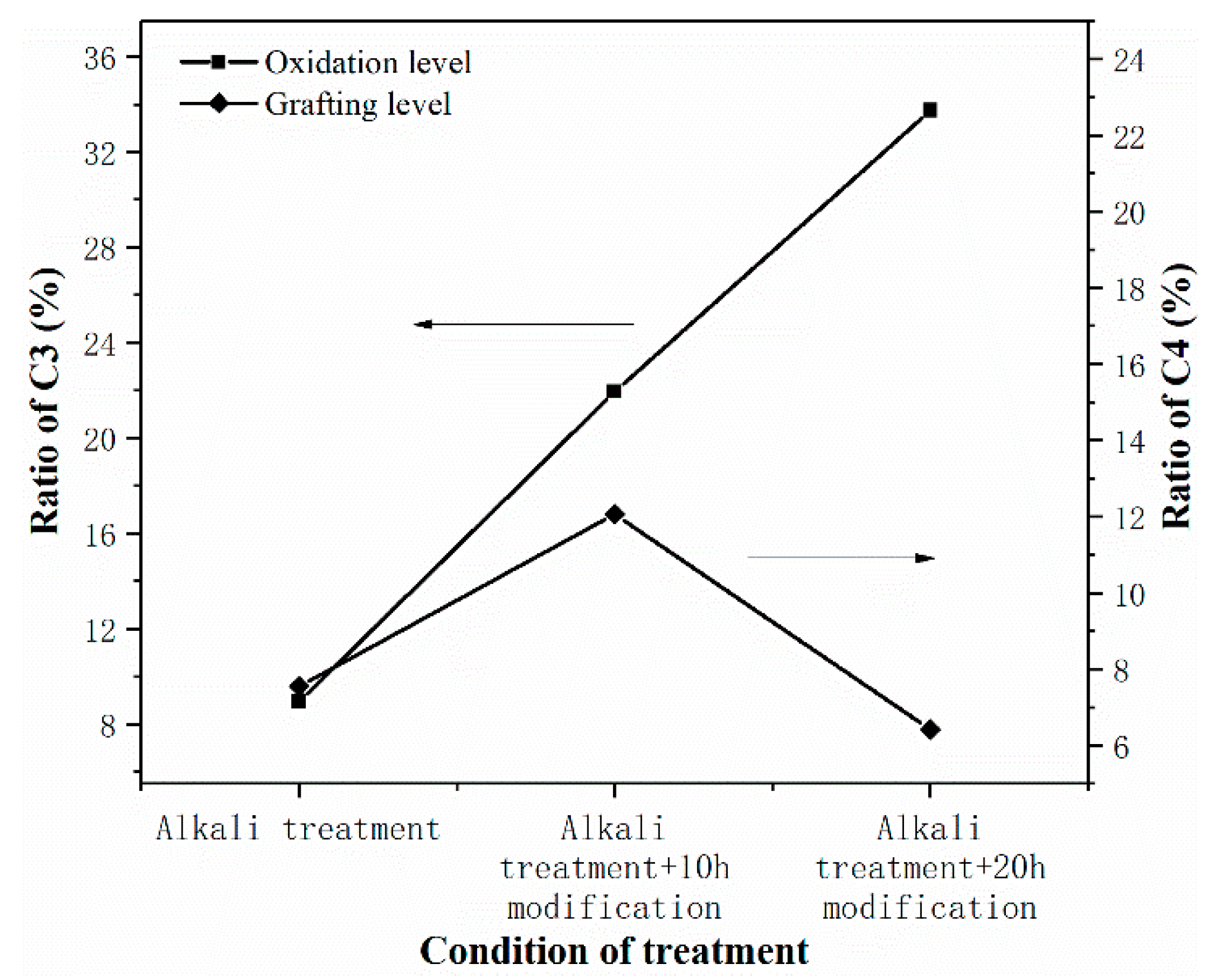

3.4. XPS Analysis

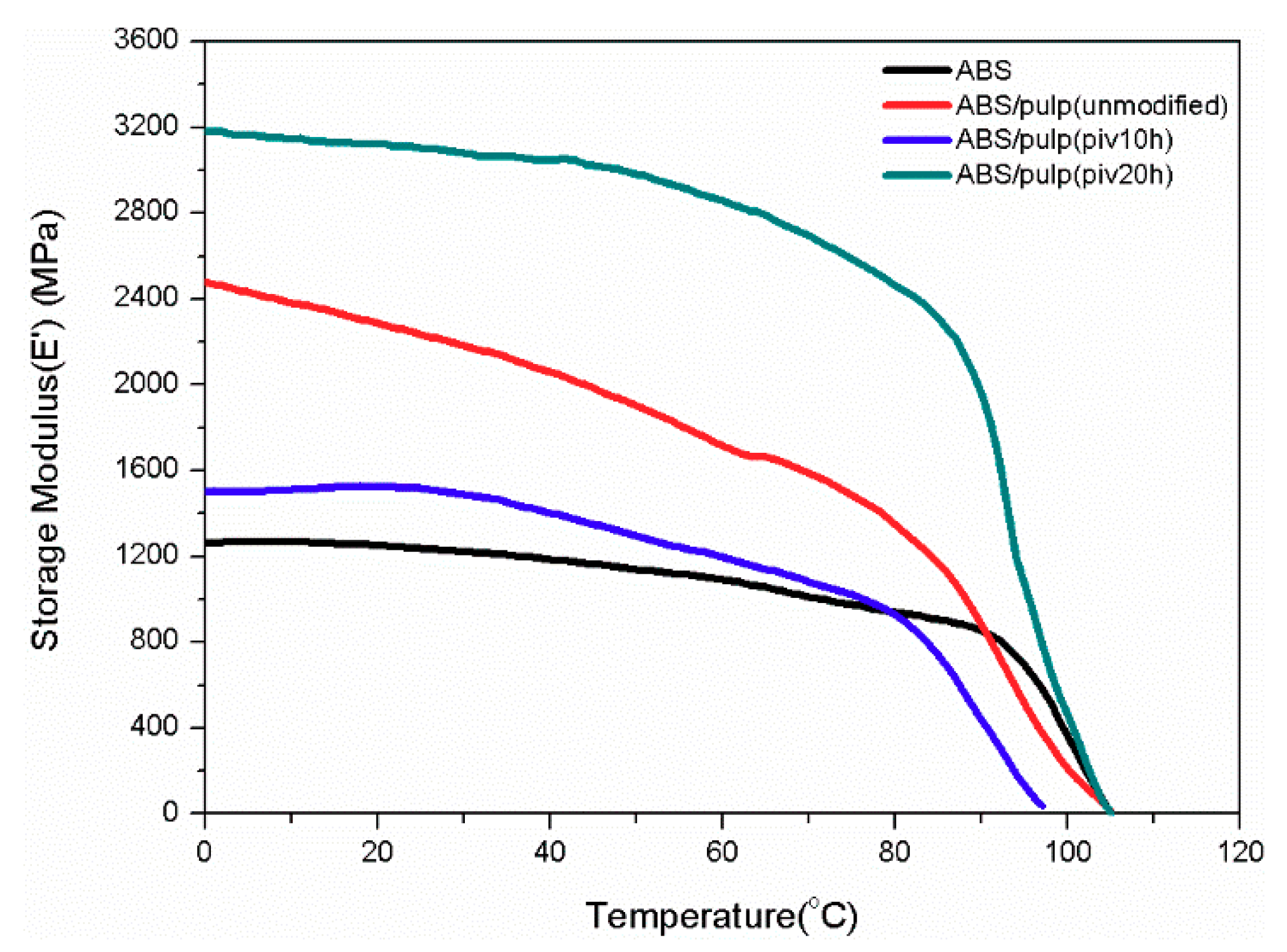

3.5. DMA Test

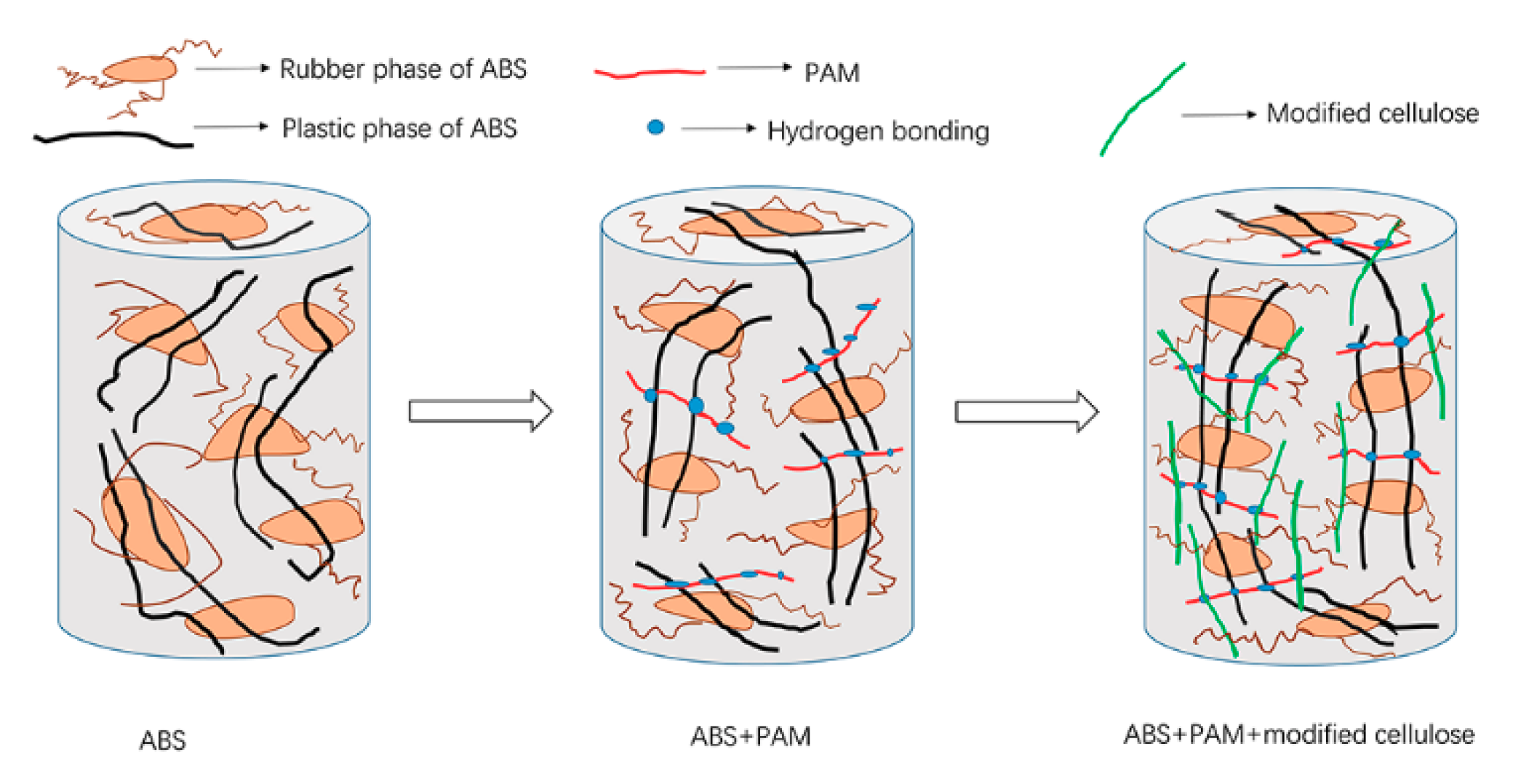

3.6. Structure Design for Composite

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Igarashi, Y.; Sato, A.; Okumura, H.; Nakatsubo, F.; Yano, H. Manufacturing process centered on dry-pulp direct kneading method opens a door for commercialization of cellulose nanofiber reinforced composites. Chem. Eng. J. 2018, 354, 563–568. [Google Scholar] [CrossRef]

- Johari, A.P.; Mohanty, S.; Kurmvanshi, S.K.; Nayak, S.K. Influence of Different Treated Cellulose Fibers on the Mechanical and Thermal Properties of Poly(lactic acid). ACS Sustain. Chem. Eng. 2016, 4, 1619–1629. [Google Scholar] [CrossRef]

- Karmarkar, A.; Chauhan, S.S.; Modak, J.M.; Chanda, M. Mechanical properties of wood–fiber reinforced polypropylene composites: Effect of a novel compatibilizer with isocyanate functional group. Compos. Part A Appl. Sci. Manuf. 2007, 38, 227–233. [Google Scholar] [CrossRef]

- Zhang, K.; Misra, M.; Mohanty, A.K. Toughened Sustainable Green Composites from Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) Based Ternary Blends and Miscanthus Biofiber. ACS Sustain. Chem. Eng. 2014, 2, 2345–2354. [Google Scholar] [CrossRef]

- Akato, K.; Tran, C.D.; Chen, J.; Naskar, A.K. Poly(ethylene oxide)-Assisted Macromolecular Self-Assembly of Lignin in ABS Matrix for Sustainable Composite Applications. ACS Sustain. Chem. Eng. 2015, 3, 3070–3076. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, J.; Feng, J.; Wu, P. Compatibilization of Immiscible Polymer Blends Using Graphene Oxide Sheets. ACS Nano 2011, 5, 5920–5927. [Google Scholar] [CrossRef] [PubMed]

- Xie, L.; Shan, B.; Sun, X.; Tian, Y.; Xie, H.; He, M.; Xiong, Y.; Zheng, Q. Natural Fiber-Anchored Few-Layer Graphene Oxide Nanosheets for Ultrastrong Interfaces in Poly(lactic acid). ACS Sustain. Chem. Eng. 2017, 5, 3279–3289. [Google Scholar] [CrossRef]

- Agustin, M.B.; Nakatsubo, F.; Yano, H. Improving the thermal stability of wood-based cellulose by esterification. Carbohydr. Polym. 2018, 192, 28–36. [Google Scholar] [CrossRef]

- Jayaramudu, J.; Reddy, G.S.M.; Varaprasad, K.; Sadiku, E.R.; Ray, S.S.; Rajulu, A.V. Mechanical properties of uniaxial natural fabric Grewia tilifolia reinforced epoxy based composites: Effects of chemical treatment. Fibers Polym. 2014, 15, 1462–1468. [Google Scholar] [CrossRef]

- Agustin, M.B.; Nakatsubo, F.; Yano, H. Products of low-temperature pyrolysis of nanocellulose esters and implications for the mechanism of thermal stabilization. Cellulose 2016, 23, 2887–2903. [Google Scholar] [CrossRef]

- Shi, S.; Yang, C.; Nie, M. Enhanced Interfacial Strength of Natural Fiber/Polypropylene Composite with Mechanical-Interlocking Interface. ACS Sustain. Chem. Eng. 2017, 5, 10413–10420. [Google Scholar] [CrossRef]

- Song, P.G.; Cao, Z.H.; Meng, Q.R.; Fu, S.Y.; Fang, Z.P.; Wu, Q.; Ye, J.W. Effect of Lignin Incorporation and Reactive Compatibilization on the Morphological, Rheological, and Mechanical Properties of ABS Resin. J. Macromol. Sci. Part B-Phys. 2012, 51, 720–735. [Google Scholar] [CrossRef]

- Dunne, R.; Desai, D.; Sadiku, R. Material characterization of blended sisal-kenaf composites with an ABS matrix. Appl. Acoust. 2017, 125, 184–193. [Google Scholar] [CrossRef]

- Li, W.Y.; Jin, A.X.; Liu, C.F.; Sun, R.C.; Zhang, A.P.; Kennedy, J.F. Homogeneous modification of cellulose with succinic anhydride in ionic liquid using 4-dimethylaminopyridine as a catalyst. Carbohydr. Polym. 2009, 78, 389–395. [Google Scholar] [CrossRef]

- Lv, Y.; Wu, J.; Zhang, J.; Niu, Y.; Liu, C.-Y.; He, J.; Zhang, J. Rheological properties of cellulose/ionic liquid/dimethylsulfoxide (DMSO) solutions. Polymer 2012, 53, 2524–2531. [Google Scholar] [CrossRef]

- Davaritouchaee, M.; Hiscox, W.C.; Martinez-Fernandez, J.; Fu, X.; Mancini, R.J.; Chen, S. Effect of reactive oxygen species on biomass structure in different oxidative processes. Ind. Crops Prod. 2019, 137, 484–494. [Google Scholar] [CrossRef]

- Gupta, A.D.; Pandey, S.; Jaiswal, V.K.; Bhadauria, V.; Singh, H. Simultaneous oxidation and esterification of cellulose for use in treatment of water containing Cu(II) ions. Carbohydr. Polym. 2019, 222, 114964. [Google Scholar] [CrossRef]

- Yousef, M.A. Oxidation of Hydroxyethyl Cellulose with Sodium Hypochlorite. Polym. Plast. Technol. Eng. 1991, 30, 413–423. [Google Scholar] [CrossRef]

- Hosoya, T.; Bacher, M.; Potthast, A.; Elder, T.; Rosenau, T. Insights into degradation pathways of oxidized anhydroglucose units in cellulose by β-alkoxy-elimination: A combined theoretical and experimental approach. Cellulose 2018, 25, 3797–3814. [Google Scholar] [CrossRef] [Green Version]

- Xu, F.; Zhou, Q.-A.; Sun, J.-X.; Liu, C.-F.; Ren, J.-L.; Sun, R.-C.; Curling, S.; Fowler, P.; Baird, M.S. Fractionation and characterization of chlorophyll and lignin from de-juiced Italian ryegrass (Lolium multifolrum) and timothy grass (Phleum pratense). Process Biochem. 2007, 42, 913–918. [Google Scholar] [CrossRef]

- Kotyczka-Morańska, M. Semi-quantitative and multivariate analysis of the thermal degradation of carbon-oxygen double bonds in biomass. J. Energy Inst. 2019, 92, 923–932. [Google Scholar] [CrossRef]

- Toshikj, E.; Tarbuk, A.; Grgić, K.; Mangovska, B.; Jordanov, I. Influence of different oxidizing systems on cellulose oxidation level: Introduced groups versus degradation model. Cellulose 2019, 26, 777–794. [Google Scholar] [CrossRef]

- Labet, M.; Thielemans, W. Improving the reproducibility of chemical reactions on the surface of cellulose nanocrystals: ROP of ε-caprolactone as a case study. Cellulose 2011, 18, 607–617. [Google Scholar] [CrossRef]

- Belgacem, M.N.; Czeremuszkin, G.; Sapieha, S.; Gandini, A. Surface characterization of cellulose fibres by XPS and inverse gas chromatography. Cellulose 1995, 2, 145–157. [Google Scholar] [CrossRef]

- Espino-Pérez, E.; Domenek, S.; Belgacem, N.; Sillard, C.; Bras, J. Green Process for Chemical Functionalization of Nanocellulose with Carboxylic Acids. Biomacromolecules 2014, 15, 4551–4560. [Google Scholar] [CrossRef]

- Kim, S.-H.; Choi, K.; Choi, H.R.; Kim, T.; Suhr, J.; Kim, K.J.; Choi, H.J.; Nam, J.-D. Non-Einstein Viscosity Phenomenon of Acrylonitrile–Butadiene–Styrene Composites Containing Lignin–Polycaprolactone Particulates Highly Dispersed by High-Shear Stress. ACS Omega 2019, 4, 10036–10043. [Google Scholar] [CrossRef]

- Dong, W.; He, M.; Wang, H.; Ren, F.; Zhang, J.; Zhao, X.; Li, Y. PLLA/ABS Blends Compatibilized by Reactive Comb Polymers: Double Tg Depression and Significantly Improved Toughness. ACS Sustain. Chem. Eng. 2015, 3, 2542–2550. [Google Scholar] [CrossRef]

- Zhao, G.; Ni, H.; Jia, L.; Ren, S.; Fang, G. Quantitative Analysis of Relationship between Hansen Solubility Parameters and Properties of Alkali Lignin/Acrylonitrile–Butadiene–Styrene Blends. ACS Omega 2018, 3, 9722–9728. [Google Scholar] [CrossRef]

- Rigoussen, A.; Verge, P.; Raquez, J.-M.; Dubois, P. Natural Phenolic Antioxidants as a Source of Biocompatibilizers for Immiscible Polymer Blends. ACS Sustain. Chem. Eng. 2018, 6, 13349–13357. [Google Scholar] [CrossRef]

- Levenhagen, N.P.; Dadmun, M.D. Improving Interlayer Adhesion in 3D Printing with Surface Segregating Additives: Improving the Isotropy of Acrylonitrile–Butadiene–Styrene Parts. ACS Appl. Polym. Mater. 2019, 1, 876–884. [Google Scholar] [CrossRef]

| Modification Type | Alkali Treatment (40 °C, 1 h) | Conditions of Modification | ||||

|---|---|---|---|---|---|---|

| Concentration (wt %) | Solvent | Piv:Pulp * | Piv:Pyridine * | Temperature (°C) | Time (h) | |

| 1 | 16% | / | / | / | / | / |

| 2 | 16% | NMP | 1:1.6 | 0.4:1 | 80 | 10 |

| 3 | 16% | NMP | 0.9:1 | 1.1:1 | 80 | 20 |

| Sample | Tensile Strength (MPa) | Tensile Modulus (MPa) |

|---|---|---|

| Neat ABS | 39.3 (0.37) | 1574 |

| S1 | 45.8 (0.76) | 2567 |

| S2 | 58.1 (0.85) | 2515 |

| S3 | 43.1 (0.48) | 2640 |

| Proportion of Various Types of Carbon (%) | ||||

|---|---|---|---|---|

| C1 | C2 | C3 | C4 | |

| P1 | 26 | 57 | 9 | 8 |

| P2 | 31 | 35 | 22 | 12 |

| P3 | 17 | 43 | 34 | 6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Q.; Li, D. Interface Reinforcement of Pulp Fiber Based ABS Composite with Hydrogen Bonding Initiated Interlinked Structure via Alkaline Oxidation and tert-Butyl Grafting on Cellulose. Polymers 2019, 11, 2048. https://doi.org/10.3390/polym11122048

Zhu Q, Li D. Interface Reinforcement of Pulp Fiber Based ABS Composite with Hydrogen Bonding Initiated Interlinked Structure via Alkaline Oxidation and tert-Butyl Grafting on Cellulose. Polymers. 2019; 11(12):2048. https://doi.org/10.3390/polym11122048

Chicago/Turabian StyleZhu, Qinrui, and Dagang Li. 2019. "Interface Reinforcement of Pulp Fiber Based ABS Composite with Hydrogen Bonding Initiated Interlinked Structure via Alkaline Oxidation and tert-Butyl Grafting on Cellulose" Polymers 11, no. 12: 2048. https://doi.org/10.3390/polym11122048

APA StyleZhu, Q., & Li, D. (2019). Interface Reinforcement of Pulp Fiber Based ABS Composite with Hydrogen Bonding Initiated Interlinked Structure via Alkaline Oxidation and tert-Butyl Grafting on Cellulose. Polymers, 11(12), 2048. https://doi.org/10.3390/polym11122048