3.1. Technological Characterization and Storage Stability

In order to make a quick comparison of the performance of all modified bitumens, the results of selected technological tests, according to EN 14023, are presented in

Table 3.

By comparing CTR70 with a model neat bitumen of similar penetration range (70/100), the expected positive effects of CTR are revealed: higher softening point (5 °C), improved elasticity (much larger elastic recovery), enhanced low temperature flexibility (reduction of 10 °C in Fraass breaking point) and lower temperature susceptibility (higher penetration index values) [

11,

12]. Unfortunately,

Table 3 also discloses the poor high temperature storage stability of CTR70, as may be easily deduced from the difference of 10 °C between the softening point at the top and bottom sections of the settling tube, which noticeably exceeds the limit of 5 °C established by EN 13399. This well-known phenomenon results from the settling of non-dissolved rubber particles during hot storage and represents one of the main drawbacks that limits the use of rubberised bitumens by the industry [

1,

7].

In this sense, according to the results presented in

Table 3, it is clear that all ethylene copolymers used in this study lead to a notable improvement in hot storage stability in such a way that, with the exception of HS-EMAb, these binders fulfil the stability requirement stabilised by the European standard EN 13399. Furthermore,

Table 3 also points out that technological properties such as penetration, softening point and cohesive energy are greatly improved after the addition of the ethylene copolymer, whereas Fraass breaking point and elastic recovery remain almost unaffected. This result is considered satisfactory since low-temperature properties and elastic recovery are often deteriorated after modification with ethylene-based polymers [

10,

15]. This outcome is in line with force-ductility tests, at 5 °C, reported in

Figure 1. Thus, with the exception of HS-PBEa, all HSs binders give rise to elongations larger than the required 400 mm established by EN13703 and, therefore, improve the observed behaviour for the base rubberised bitumen which breaks before reaching this length.

As expected, all systems exhibit a ductile-like behaviour characterised by an early sharp peak (yield point) in the elongation process followed by a smooth decrease during the plastic deformation period until the rupture point. Even though neat bitumen presents the highest maximum at the yield, the force declines sharply and breaks very rapidly after the yield drop. Despite the fact that CTR70 does not strictly fulfil the breaking criteria, its force-ductility behaviour is very close to the hybrid systems and, in addition, its cohesive energy (area below the resulting force-distance function calculated between 200 and 400 mm,

Table 3) is clearly above the values typically required for a polymer modified bitumen (at least 2 J·cm

−2). Therefore, taking into account that remaining CTR particles usually act as crack initiators leading to a premature breakage during elongation [

16], this result hints at an enhanced digestion of CTR and, therefore, a better homogeneity of the rubberised bitumen. In general, according to

Figure 1 and

Table 3, no direct correlation between the type of polymer and force ductility results can be established, although HS-PBEb and HS-EMAa show the best results in terms of stiffness and cohesion energy.

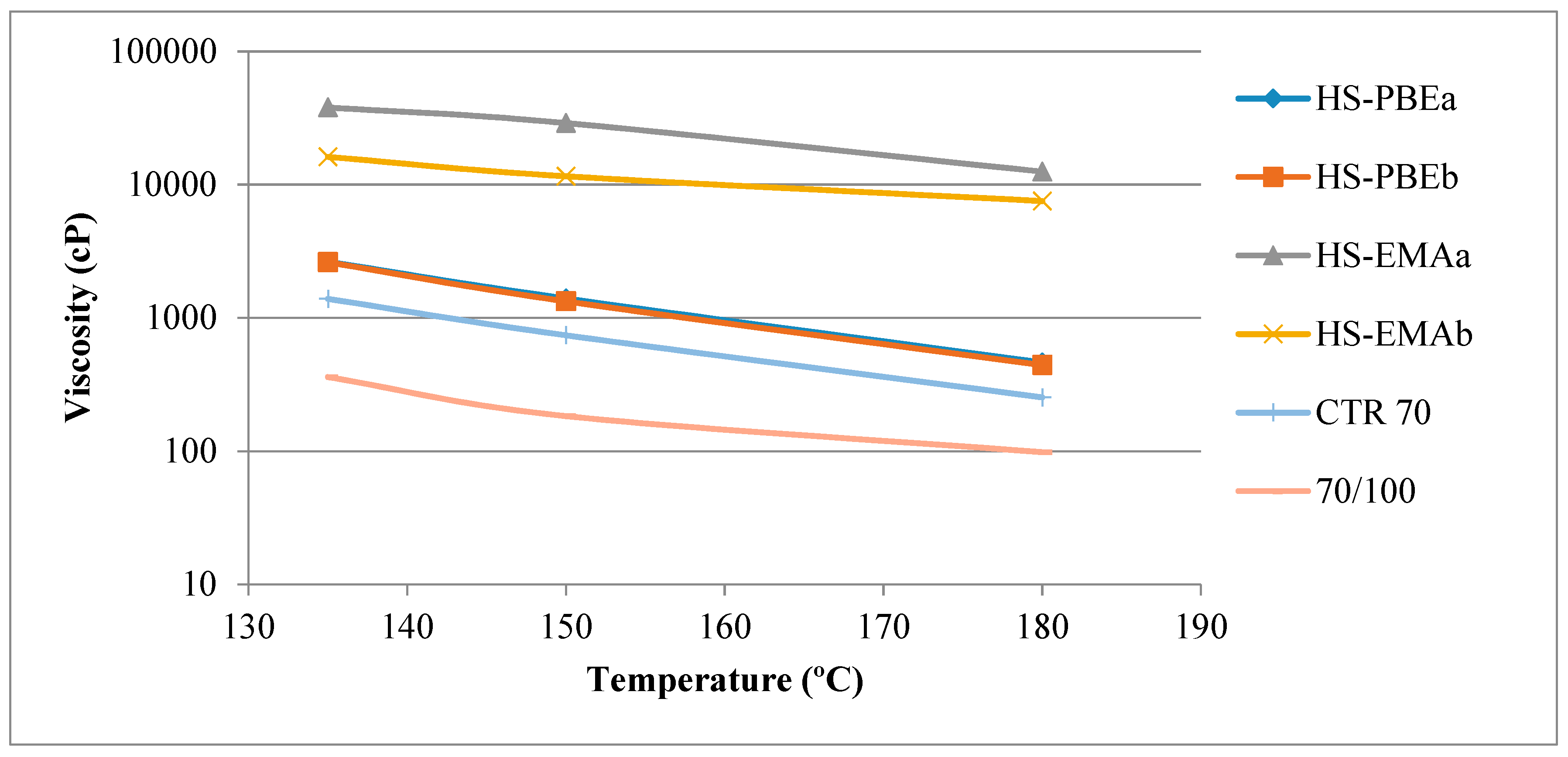

Figure 2 gathers Brookfield viscosity data at 135, 150 and 180 °C, which are of a particular interest for mixing and compaction operations.

By comparing neat bitumen with CTR70, it is clear that CTR addition gives rise to an increase in binder viscosity, mainly attributed to the existence of non-dissolved tyre rubber particles [

7]. Further polymer modification to form HSs yields an additional increase in viscosity that is dependent on the type of polymer used. Thus, while HS-PBEs only present a slight rise, HS-EMAs undergo a remarkable increase in high temperature viscosities, particularly for HS-EMAa. Therefore, all reactive systems (HS-EMAs) fail to meet the Superpave criterion that requires a maximum viscosity of 3 Pa·s at 135 °C, in order to ensure bitumen fluidity for pumping during delivery and workability in plant operations [

12]. This result hints that, as a consequence of chemical processes, EMA polymers develop a polymeric structure able to resist high temperatures. However, since this requirement was developed for Newtonian bitumen, it is not strictly applicable to shear-thinning materials like rubberised bitumen and hence, this limiting viscosity can be exceeded if the bitumen can be pumped and mixed with aggregates [

3].

3.2. Rheological Characterization

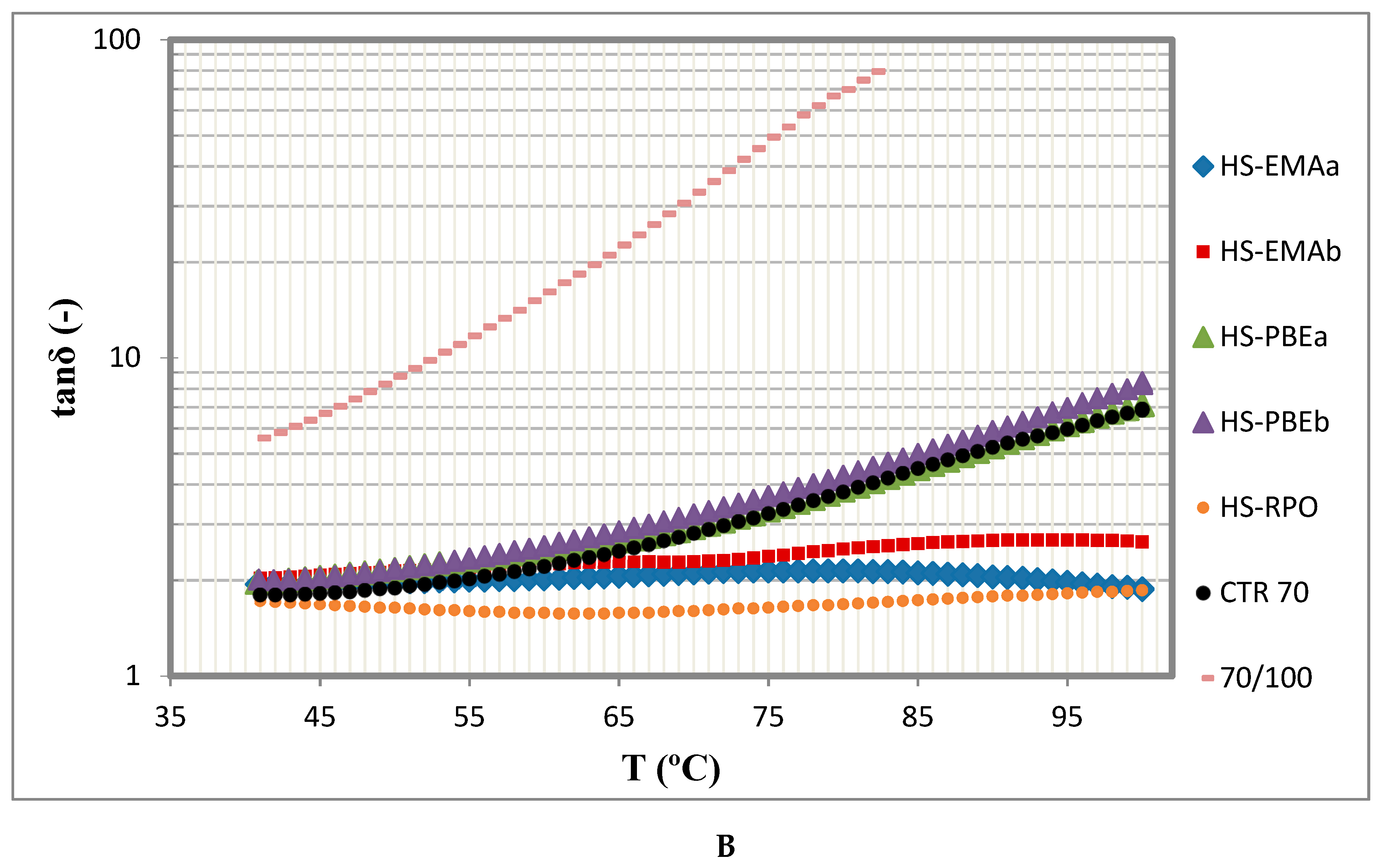

The effects of rubber and polymeric modifiers on the performance of binders over a wide range of temperatures can be easily analysed by means of the dynamic shear temperature sweeps (

Figure 3).

As expected, complex shear modulus undergoes a continuous decrease with testing temperature, from 30 to 100 °C, for all samples (

Figure 3A). Hybrid modification causes a remarkable increase in complex shear modulus (

G*), more evident as temperature is raised, when compared to the reference neat bitumen. As the complex modulus is correlated with the stiffness of the sample, this result points out a better performance in the intermediate and high in-service temperature range, and presumably enhanced resistance to permanent deformation as well [

11,

12]. Furthermore, temperature susceptibility is improved, because the average slope of

G* and loss tangent (tan

δ) vs. temperature lowers (

Figure 3A,B), within the testing interval. Consequently, this sample shows a better resistance to thermal changes and so the resulting pavement [

11].

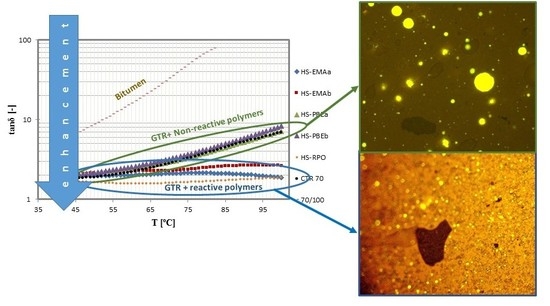

In addition, as loss tangent presents greater sensitivity to modification changes,

Figure 3B may be used to quantify the contribution of every polymer to the global rheological response of the HSs, in the sense that, the lower the values of tan

δ, the better the modification effect is.

Finally,

Figure 3B also allows distinguishing two types of rheological behaviours after polymer addition. On the one hand, CTR70 and HS-PBEs present curves with similar qualitative evolution with temperature than neat bitumen, characterised by a continuous increase of the loss tangent, a prevailing viscous behaviour (tan

δ > 1) and the absence of the “plateau” region, over the entire temperature interval tested. Hence, a direct transition from the glassy to the Newtonian region is a distinctive characteristic of these non-reactive systems. On the other hand, for reactive systems (HS-EMAs and HS-RPO), loss tangent curves become virtually independent of temperature getting values close to 1, which is considered the rheological response of a critical gel [

11].

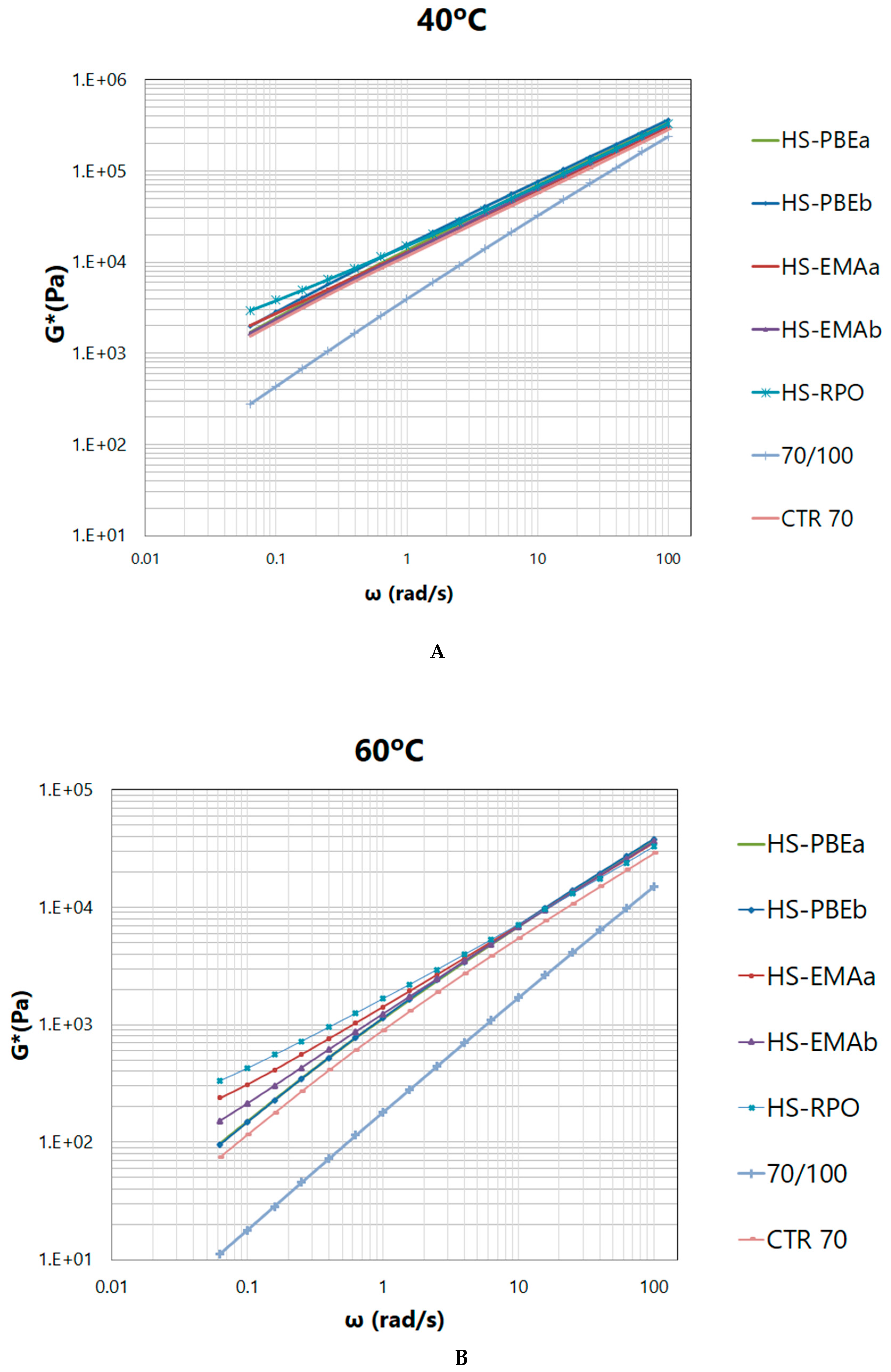

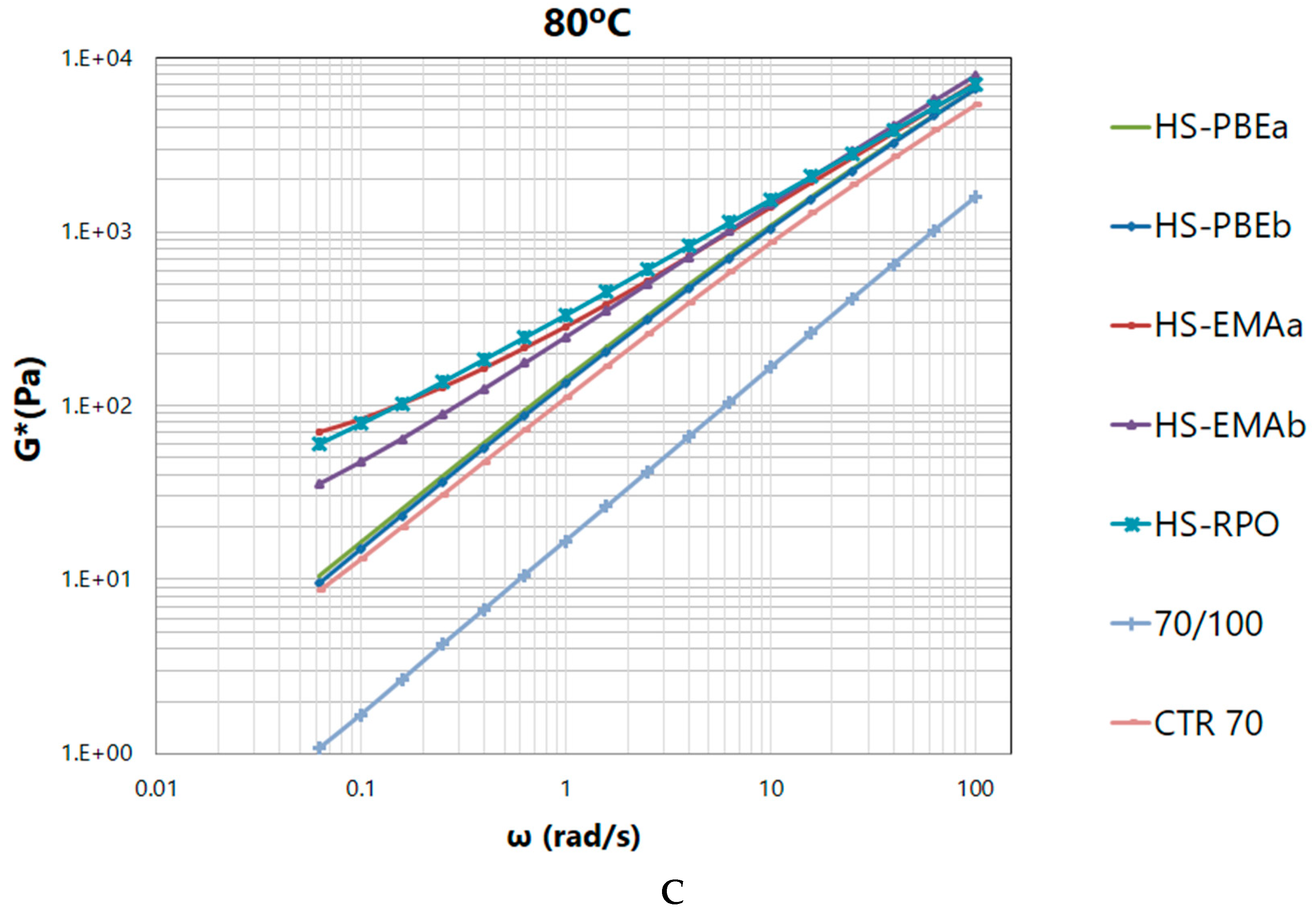

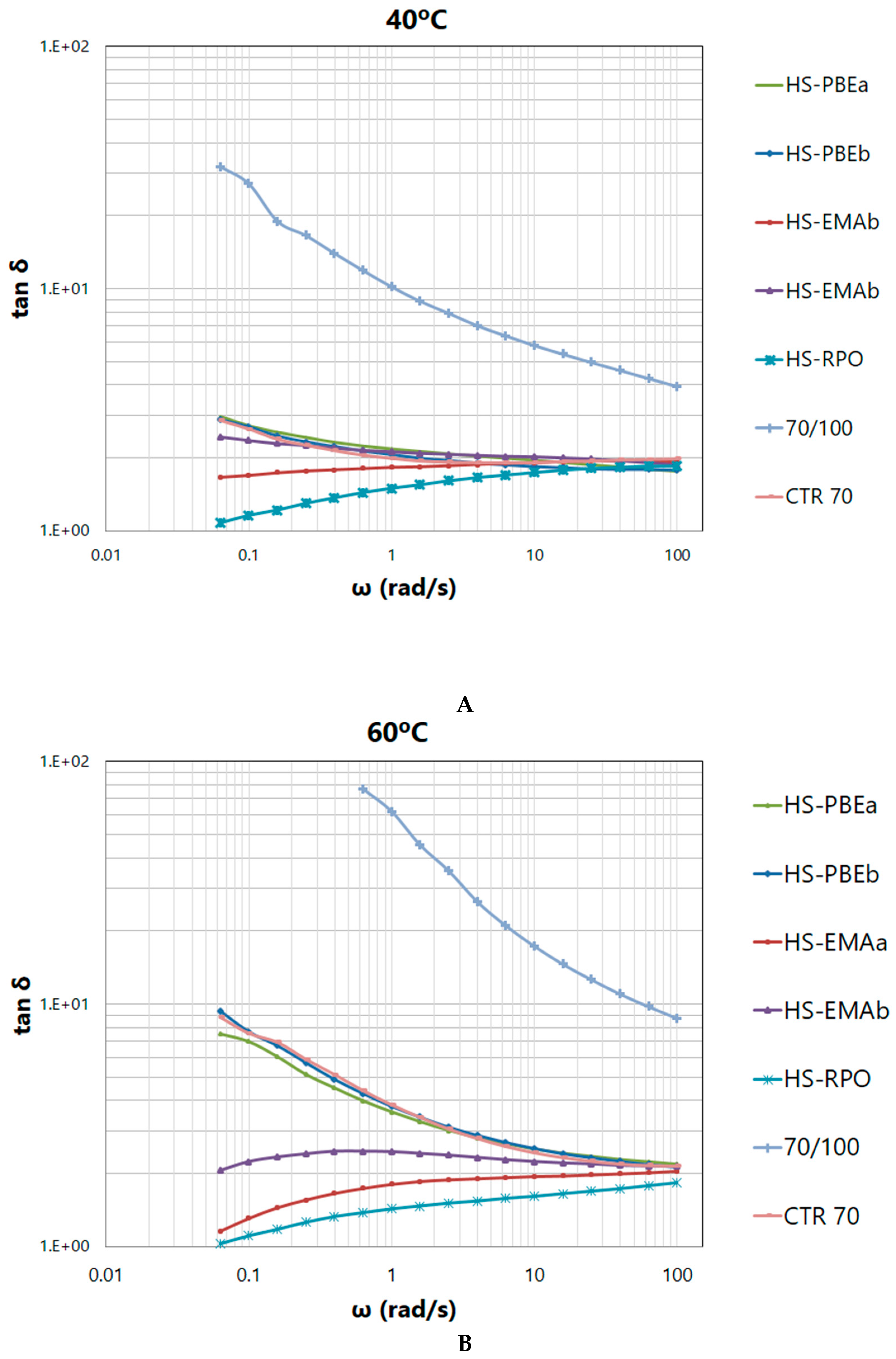

The used frequency (10 rad/s) in accordance with Superpave specifications was chosen for performance criteria because it simulates the deformation rate caused by a car travelling at 60 km/h. However, from a rheological point of view, this value is considered relatively high and may mask differences among samples. In this sense, frequency sweep tests, at selected constant temperatures (40, 60 and 80 °C) were also performed in order to provide a deeper insight into structure formed by crumb rubber and polymers.

Figure 4 shows the typical evolution of G* of bituminous materials at high temperatures (at 40, 60 and 80 °C), characterised by a steady increase of the complex modulus with frequency.

As testing temperature rises and frequency lowers, differences among samples become more apparent, pointing out the effects caused by ethylene copolymers. It is important to note that, once again, two distinctive behaviours are revealed. Thus, the group of the non-reactive samples (neat bitumen, CTR70 and HS-PBEs) is characterised by a predominant viscous character, which is intensified as temperature rises, showing a trend to reach the flow region of the mechanical spectrum, at low frequencies. On the contrary, reactive HSs undergo a flattening on complex shear modulus curves and develop a plateau in the loss tangent, confirming the previously mentioned critical gel-like behaviour.

Taking into account that loss tangent is inversely proportional to the overall elasticity of the sample,

Figure 5 allows samples to be classified with respect to the modification potential of the polymers used, resulting: PBEb ≈ PBEa << EMAb < EMAa < RPO.

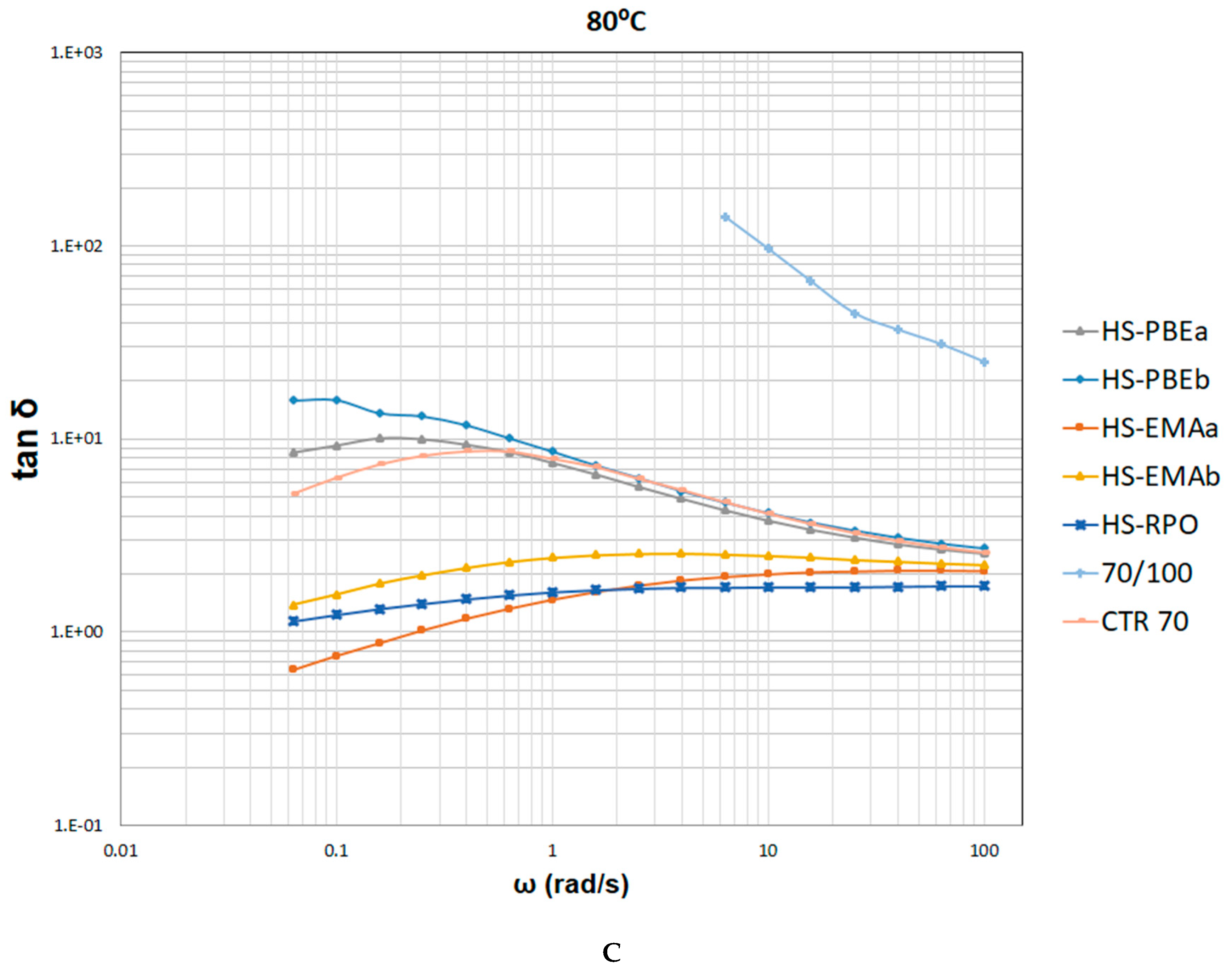

The observed change in the thermomechanical response is more clearly evidenced by the so-called Black diagrams (δ vs. G*, see

Figure 6) where non-reactive (A) and reactive HSs (B) are portrayed separately with 70/100 (neat bitumen) and CTR70 as references. These graphs have been widely employed for modified bitumens not only for verifying the time-temperature superposition principle, but also to evaluate structural changes [

10].

As may be seen in

Figure 6A, whereas neat bitumen presents nicely superposed curves and a transition to a wide Newtonian region (

δ = 90°), non-reactive systems present curves which are not completely overlapped, with a notable modification of the rheological behaviour. Thus, the phase angle is shifted downward, tending to develop a plateau of the phase angle as

G* increases. This fact points out an enhancement in elasticity and is indicative of structural changes in binder microstructure.

Changes in viscoelastic behaviour are much more evident for reactive HSs (

Figure 6B) which hardly present a maximum of

δ in the low

G* region, and phase angle values decrease towards 45° (i.e., towards a predominantly elastic behaviour at low frequencies). In addition, as modification is more intense, isothermal curves do not overlap at all, pointing out a thermorheologically complex behaviour. This outcome is attributed to the different temperature dependences of the relaxation times of the expected dispersed phases (non-dissolved rubber particles and polymer-rich phase) [

3,

10]. Consequently, these results reveal the multiphasic nature of the HSs in which non-dissolved CTR particles and polymer phases play a key role.

It is important to note that HSs present a remarkable improvement in binder elasticity, as may be deduced from the linear viscoelastic behaviour, which is usually related to a better in-service performance. However, taking into account that distresses like pavement rutting take place at stresses larger than those of the lineal viscoelastic range, these functions cannot fully account for the performance characteristics of modified binders and may be inadequate in rating a polymer-modified binder [

17].

With this aim, the multiple stress creep recovery test (MSCR, UNE-EN 16659) has been proposed to evaluate how prone to permanent deformations a binder is. MSCR characterises the recovery and non-recovery properties of the bitumen by means of 10 cycles of 1 s creep followed by 9 s recovery, at two consecutive stress levels (0.1 and 3.2 kPa). The chosen temperature was 60 °C because this value is typically considered the maximum expectable pavement temperature in southern European countries. Taking into account that irreversible deformations of asphalt mixes are highly dependent on the stress levels, rutting itself is a non-linear viscoelastic phenomenon and, therefore, the MSCR test is considered a better method in evaluating the rutting resistance.

As shown in

Figure 7, neat bitumen undergoes large strains and small magnitudes of strain recoveries, forming a staircase pattern, typical of a viscous Newtonian response.

The improved elasticity previously reported for the rubberised bitumen (CTR70) and, especially for HSs, gives rise to a notable modification in strain profiles on MSCR. Thus, in every cycle, delayed elastic strain recoveries are clearly observed, leading to a remarkable non-linear response, since accumulated compliances become stress dependent [

18].

In addition, it is important to underline that strain recoveries results clearly increased, in particular for reactive HSs, in such a way that a sawtooth-shaped profile is disclosed, which is associated to highly modified bitumen with enhanced elastic response. Again, the synergistic effect of non-dissolved CTR particles and the second polymeric phase seems to be the responsibility for the significant change in the creep recovery profile. Regarding the in-service issues, it is noteworthy that the reduced cumulative strains for HSs would lead to an improved rutting resistivity potential of the pavement.

In addition, the MSCR test allows to obtain two important average parameters from every set of 10 cycles, the non-recoverable creep compliance (

Jnr) and the percent of elastic recovery (%

R), which can be employed to characterise the creep response at the selected stress levels (0.1 and 3.2 kPa). The percent of elastic recovery (%

R) quantifies the elastic character of the material, whereas the non-recoverable compliance (

Jnr) measures the quantity of energy dissipated during the recovery runs and, therefore, gives indications of the proneness of asphalt mixtures to undergo permanent deformation damages. Consequently, both parameters enable a quantitative analysis of MSCR results (

Table 4).

In general, all reactive HSs and especially HS-EMAa, exhibit the largest %

R and the lowest

Jnr values in magnitude, at each of the applied test stresses, pointing out a good elastomeric behaviour and a lower rutting susceptibility. In this regard, AASHTO M 332, [

19] introduced a new method to classify binders in terms of their elasticity by means of an exponential function of non–recoverable creep compliance, at the cycle of 3.2 kPa:

Therefore, bitumens with a percent of elastic recovery higher than this limit are expected to have good elastomeric behaviour [

20]. Consequently, according to this criterion, HS-EMAa and HS-RPO present the best performance under rutting conditions. However, it must be noted that this condition only provides a pass or fail criterion and does not allow a quantitative evaluation, because the calculated compliance parameter is calculated from

Jnr, 3.2kPa which changes from binder to binder [

20].

3.3. Correlation of Properties with Microstructure: Optical Microscopy

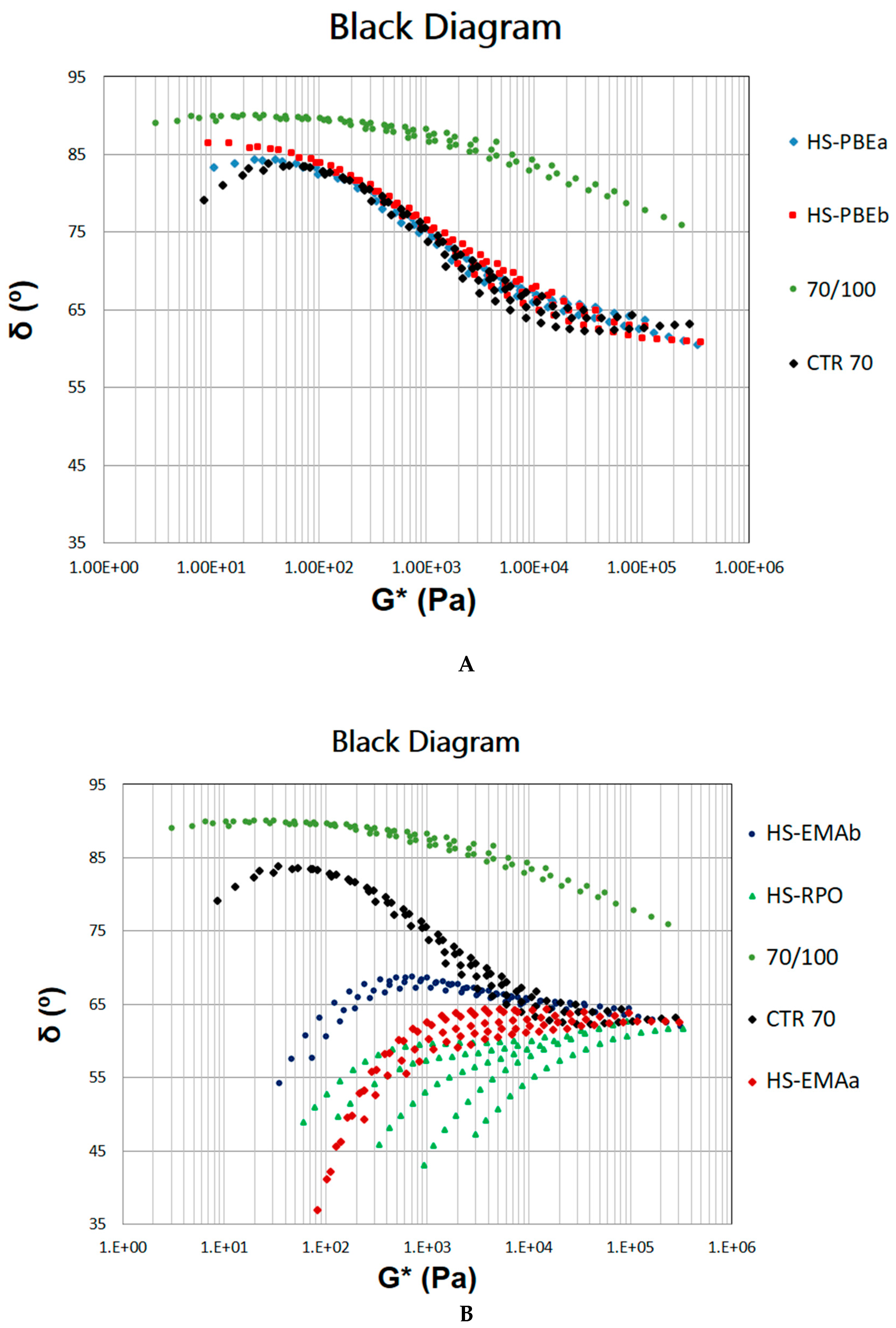

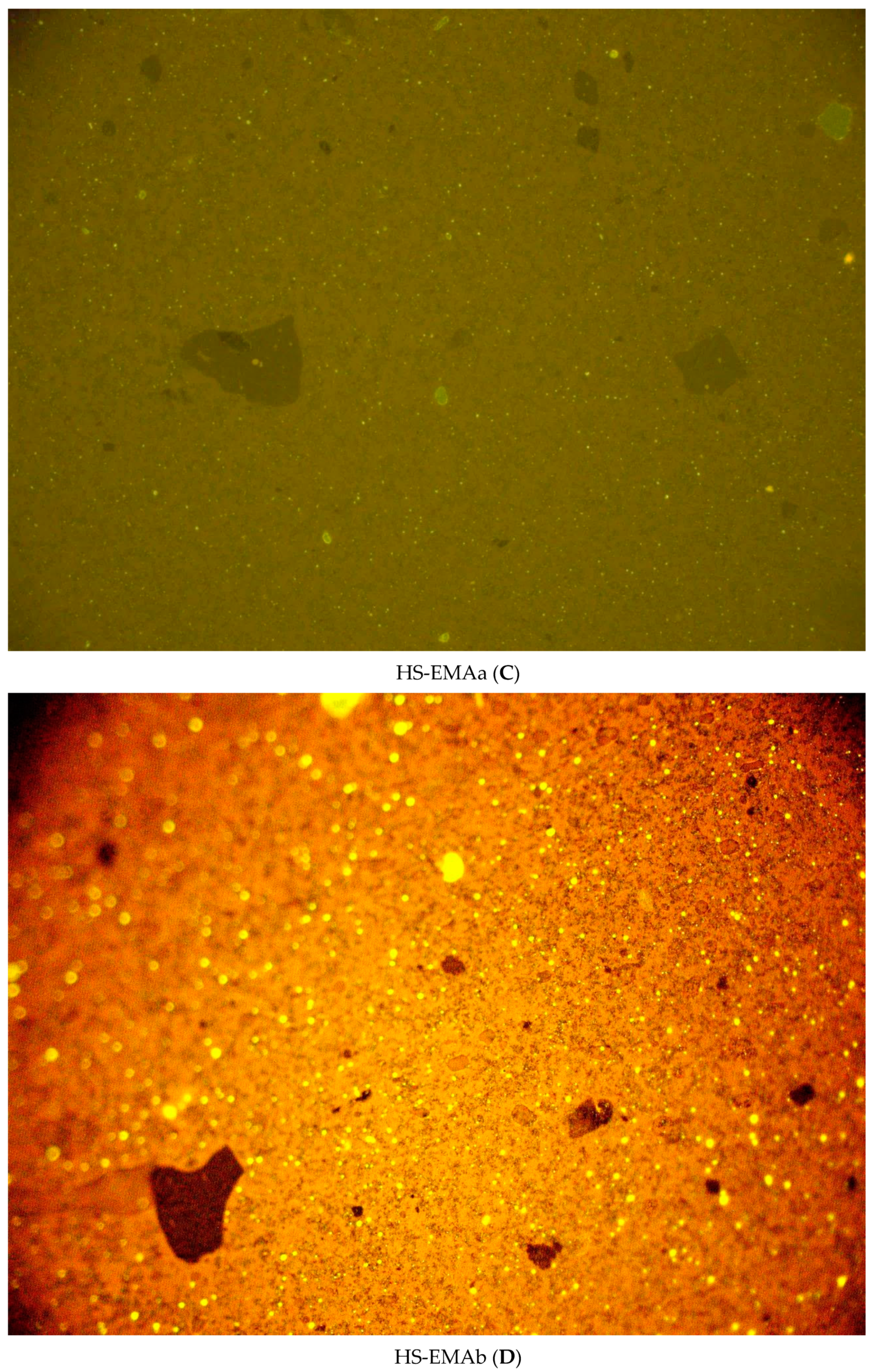

From previous results, it is clear that different improvement degrees are found after the modification of the rubberised bitumen, depending on the type of polymer used. The thermomechanical behaviour of HSs could be explained by the development of a complex multiphasic system formed by polymeric phases of a different nature [

11], as may be supported by fluorescence microscopy (

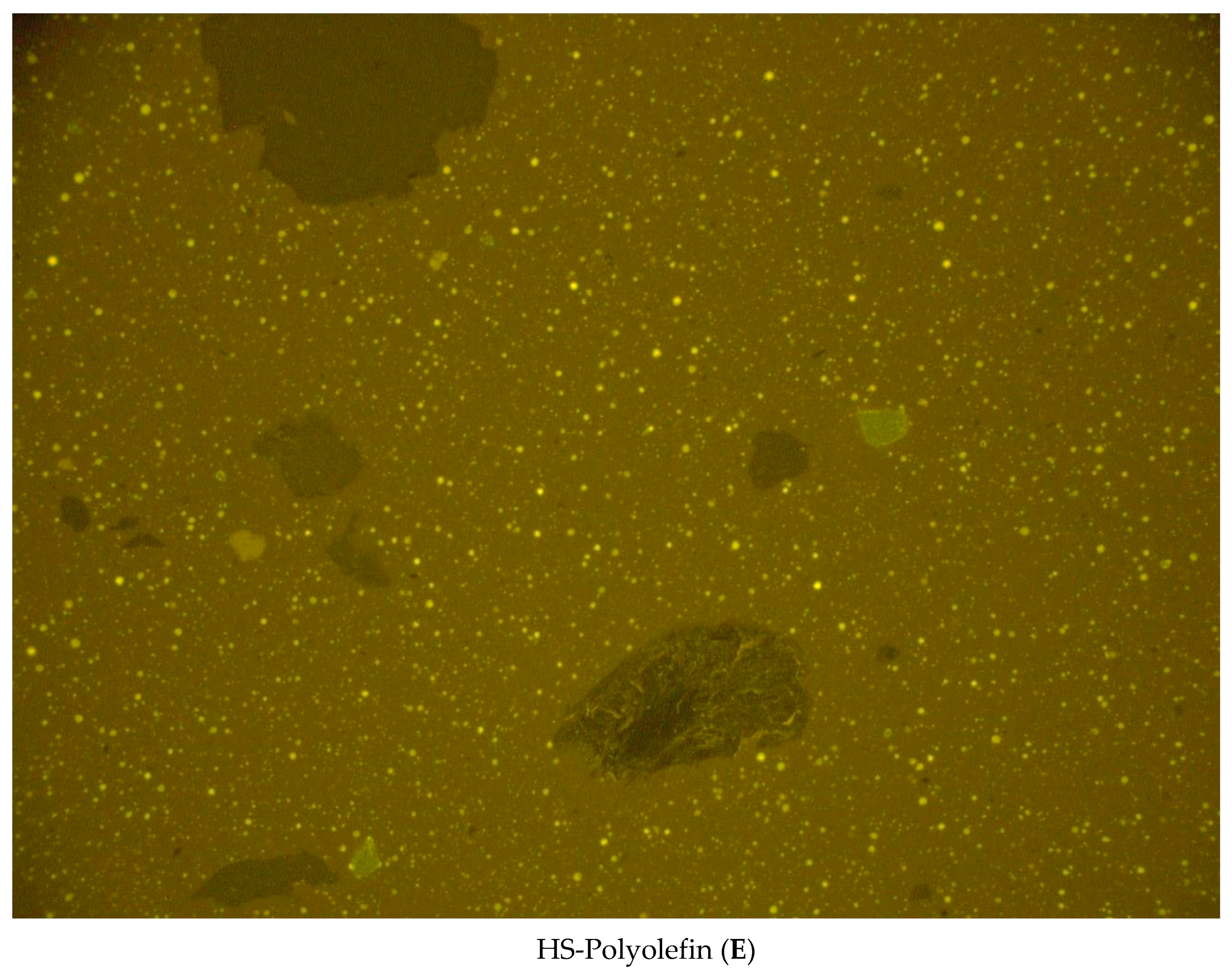

Figure 8).

On the one hand, all HSs presented in

Figure 8 show, as darker colour regions, the presence of non-dissolved CTR particles of different sizes, resulting from the digestion of the original rubber. As it has been widely reported [

2,

11], these fine elastic particles together with the dissolved rubber chains give rise to the observed improvement for CTR70. It is noteworthy that the presence of these particles, far from acting as cracking promoters of the asphalt, contribute to the improvement of the low-temperature properties, as evidenced by the lower Fraass Point compared to a neat bitumen (

Table 3) [

11]. In addition,

Figure 8 also displays the existence of dispersed light-toned regions, pointing out the presence of a polymer-rich phase for all HSs. However, different proportions and size distributions of the polymer-rich phases are clearly distinguished. On the one hand, physical HSs (HS-PBEa and HS-PBEb) present spherical droplets randomly distributed in the bituminous phase, covering a surface fraction of roughly 8%, superior than that of the polymer concentration in the sample (3 wt %). This fact confirms the polymer swelling by maltenic oils and reveals their partial compatibility, which is required to improve the performance [

11]. Thus, for physical HSs, a multiphasic structure is formed by two dispersed phases (non-dissolved CTR particles and polymer-rich droplets) within a continuous bituminous phase. Therefore, the synergistic contribution of these phases would explain the reported rheological and technological results [

10,

21,

22].

On the other hand, in the case of reactive HSs, even though a fluorescent dispersed polymer-rich phase is also recognisable, the morphologies are deeply different. Thus, the surface fractions of the light regions are clearly below the proportion of added polymers (3 wt % for HS-EMAs and 2 wt % for HS-RPO), and microphases present smaller sizes than those of physical HSs. It is well known that if a polymer is physically dissolved in the bituminous matrix, then its original structure is lost during mixing and the macroscopic properties would not be transferred to the modified bitumen [

13]. According to this, the observed morphologies of reactive HSs cannot explain the strong variation of their rheological behaviour. Therefore, although the presence of both polymer-droplets and non-dissolved CTR particles (along with the dissolved rubber chains) would partially contribute to enhance the rheological behaviour, the main origin of the modification seems to be caused by chemical changes that happens at a much lower scale. Thus, new chemical structures, undetectable by optical microscopy, are developed in reactive HSs by forming chemical bonds between polymer molecules and some bituminous compounds.

Regarding HS-EMAs, since these samples were formulated using a maleated copolymer, the reported behaviour can be explained on the basis of the chemistry of reactive pendant groups (free succinic anhydride). As reported in the bibliography, cyclic anhydrides can easily react with hydroxyl and amine groups giving rise to ester and amide bonds, respectively, in a ring opening reaction [

23]. Therefore, as such groups are abundant in bitumen [

24], succinylation reactions are expected to happen, linking copolymer chains covalently to some polar bituminous compounds (resins and asphaltenes). Therefore, new complex chemical structures are developed, leading to structural arrangements at a molecular scale and conferring the reported enhancement of in-service properties. According to this, the observed critical gel-like behaviour is then attributed to the formation of a chemical network. This assumption is consistent with the copolymer composition and it would explain why EMAa is a more effective modifier than EMAb. Thus, the higher proportion of succinic grafted groups in EMAa leads to a superior reactivity and, therefore, modification capacity, despite presenting a higher MFR i.e., lower polymer melt viscosity (

Table 1) [

15].

Finally, regarding the reactive polyolefin HS-RPO, again, the improvement should be attributed to chemical interactions between RPO and bitumen compounds [

14,

25]. In fact, it has been reported that the presence of grafted glycidyl methacrylate groups in olefin copolymers exerts a compatibilizing role with certain bitumen molecules [

26,

27]. Therefore, according to the epoxy chemistry, it is believed that oxiranic rings react with polar nucleophilic bitumen molecules, allowing an improvement of the miscibility between them, a fact that would explain the reported morphology [

25]. Thus, as it has been reported in the bibliography, a ring-open reaction happens between the epoxy group and functional carboxylic acid or hydroxyls groups of polar molecules in bitumen to form ester or ether bonds, respectively, leading to formation of a network [

27].

Taking into account that complex bituminous molecules are grouped forming a micellar structure containing more than one nucleophilic group, a chemical network structure may be built-up by reaction with the grafted groups of the olefinic chains of EMAs and RPO. Therefore, the consolidation of the three-dimensional structure would explain the reported critical gel behaviour and the improved hot storage stability. Thus, the formed network would interact with the non-digested CTR particles probably by entrapping them by physical means, hindering the settling of particles [

10].

3.4. Correlation of Properties with Microstructure: MDSC Characterisation

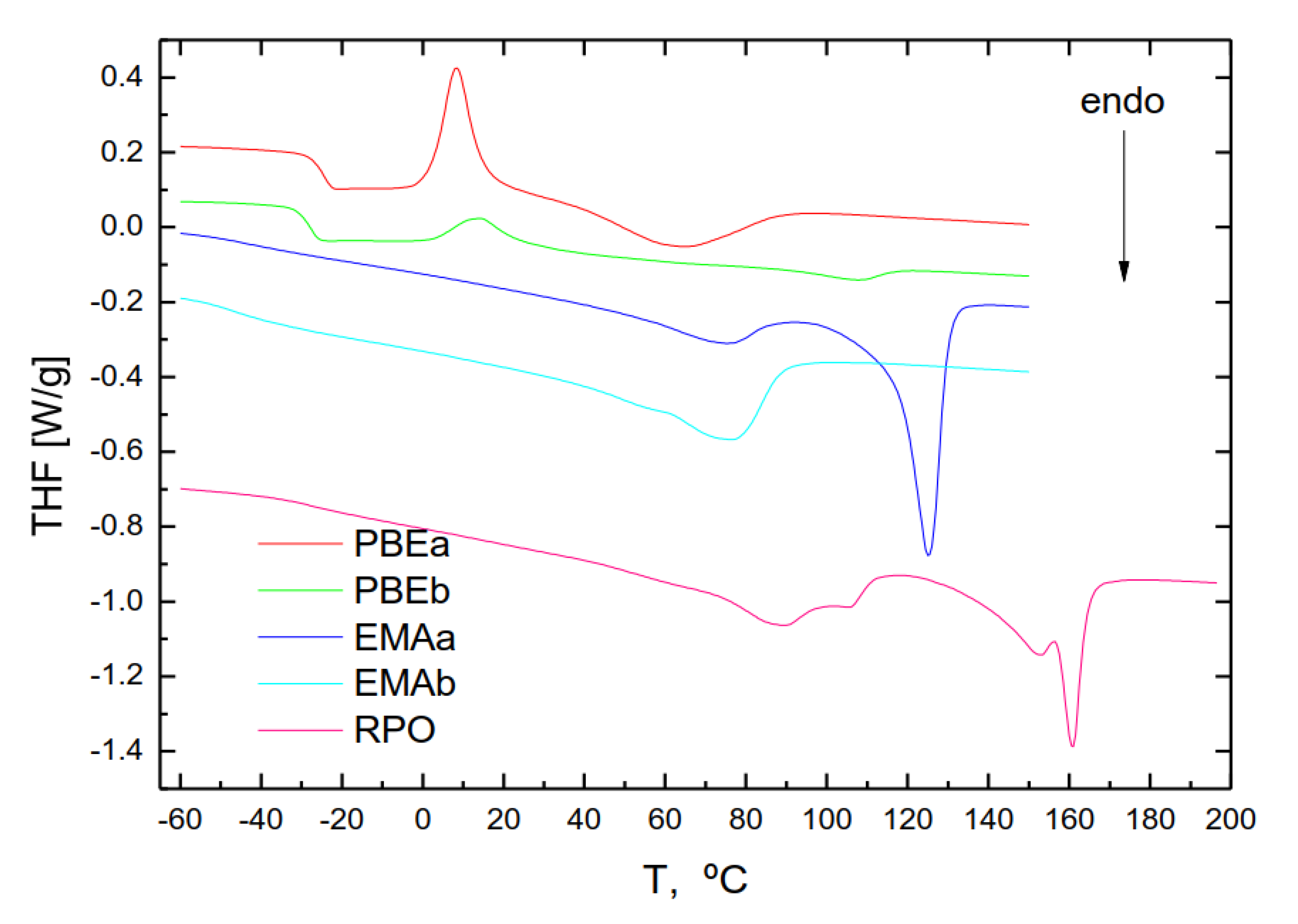

MDSC tests were performed to provide structural information about crystalline and amorphous phases of the polymers and their compatibility and interaction with bitumen compounds [

11]. Total heat flow curves (THF) of pristine PBEs, presented in

Figure 1, point out a similar qualitative pattern characteristic of semi-crystalline ethylene/propylene copolymers, showing a clear glass transition (at −24.1 for PBEa and −27.7 °C for PBEb) followed by a cold crystallization and a single melting process (see

Table 5).

Surprisingly, despite its high polypropylene content (

Table 1), the melting pattern deviates from that of this homopolymer (with a melting process at around 163 °C) showing melting endothermal peaks at much lower temperatures. This result is attributed to the inclusion of ethylene comonomer in propylene backbone that interferes the crystallization process and shifts the melting temperature to lower values, [

28].

Regarding EMA copolymers,

Figure 9 shows the presence of one (EMAb) or two (EMAa) melting peaks. The origin of this distinct behaviour cannot be precisely determined based solely on DSC results, because more experimental techniques are necessary to determine the nature of crystalline phases. However, according to the bibliography, the presence of an extra melting peak may happen in commercial ethylene-octene and ethylene-butene copolymers, reflecting two crystal populations with different thermal stability, and could be indicative of the presence of polymer fractions with different comonomer content in EMAa [

29].

Finally, since RPO is a complex reactive polyolefin mixture, its DCS thermogram shows a multiple-peak pattern corresponding to the melting process of the crystalline fractions of its constituents, isotactic polypropylene, ethylene vinyl acetate copolymer and polyethylene wax.

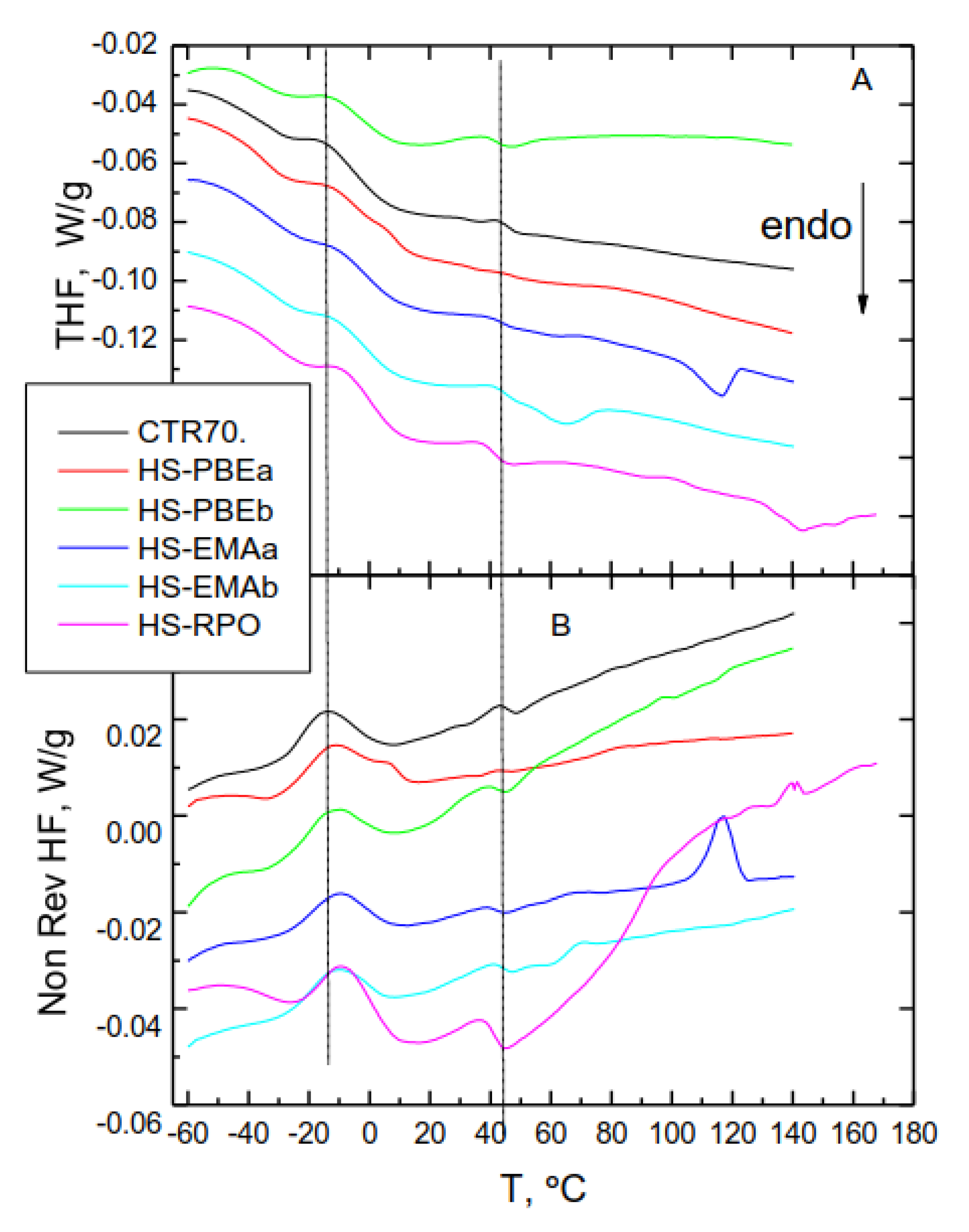

By contrast, total heat flow curves of the HSs presented in

Figure 10A, display multiple thermal events resulting from both bituminous and polymer-rich phases. Firstly, by comparing THF curves of neat polymers and their corresponding HSs, a compatibility analysis of the crystalline fraction with bitumen can be performed. The degree of crystallinity of the polymer phase was calculated from the melting enthalpies of HSs weighted by its mass fraction, divided by 293 J/g for the heat of fusion of 100% crystalline polyethylene (

Table 5). In the case of non-reactive polymers,

Table 5 and

Figure 10 point out a lowering of the melting point (8.3 °C for PBEa and 6.7 °C for PBEb) and a reduction of crystallinity, due to the migration of maltenic molecules to the polymer crystalline regions. However, taking into account their low crystallinity (compared to the homopolymers), this result does not completely explain the reported enhancement in the rheological behaviour of HS-PBEs since conventional polyolefins usually show poor compatibility with bitumen. In fact, the metallocene catalysis polymerization method used for producing PBEs, seems to be behind the moderate compatibility that allows the interdiffusion phenomena that leads to the swollen polymer-rich phase observed in

Figure 8A,B. Thus, the structure of these metallocene-based polyolefins (polydispersity and degree of short-chain branching) favours a better dispersion in the bituminous matrix and improves the in-service properties [

26,

30].

On the other hand, the used reactive polymers and their corresponding modified bitumens display a much higher crystalline fraction than PBEs and HSs (HS-EMAa, HS-EMAb and HS-RPO). Similarly, these systems are characterised by a melting point depression and small reduction in χ

c as well. In spite of this, the observed micromorphologies (

Figure 8C–E) does not seem to reflect this outcome because of the small proportion of light toned regions. However, as micrographs show a lower population of smaller fluorescence drops, this result hints at lower crystallite sizes and improved dispersion of the copolymer. This result, together with the improved reactive compatibility, suggests that the chemical network will also include submicron crystalline domains via covalent chemical bridges between macromolecules. Consequently, this more complex morphology, invisible by optical microscope, would be responsible for the enhancement in the thermomechanical behaviour.

On the other hand, total heat flow (major events) and non-reversing heat flow (minor transitions) curves in

Figure 10 disclose changes induced in the rubberised bitumen microstructure by the addition of the polyolefin copolymer.

Thus, total heat flow curves of HSs result from the contribution of the polymer-rich phase, bituminous phase and remaining CTR particles [

11]. As it was previously discussed, the polymer-rich phase causes the endothermic melting events. By contrast, rubberised bitumen presents several overlapping thermal effects as a consequence of the developed structures, due to time-dependent ordering processes that happen when bitumen is cooled down from the molten state [

3,

10,

30]. These shuttle transitions can be analysed in a better way by using the non-reversing component of heat flow (

Figure 10B) [

11,

30]. First of all, the broad endothermic background observed from −50 to 100 °C, has been mainly attributed to the melting of ordered mesophasic structures developed by simple aromatic bituminous compounds and, in a lower degree, to crystallized saturates. In addition, low and high molecular weight segments of saturated and aromatic compounds undergo the two cold crystallization peaks placed at around −15 and 40 °C, respectively. Additional cold crystallization exothermic peaks, associated to polymer phases, appear for some samples: HS-PBEa (6 °C) and HS-EMAa and b (~117 and 71 °C respectively). Furthermore, a minor endotherm can be viewed approximately at around 50 °C, is associated to larger mesophasic structures, and is found in resin and asphaltene fractions. Although the complex nature of HSs makes difficult a structural analysis, in general, as all these events undergo a modification in their intensities and positions, it can be interpreted as a proof of interactions between bitumen molecules and the added polymer [

3,

10,

11,

26].

This study has shown that the idea of combining CTR with a second polymeric phase to formulate the so-called Hybrid Systems (HSs) seems to be a proper alternative to achieve hot storage stability and to improve binder quality. Therefore, the resulting pavement is expected to present a higher resistance to rutting and thermal cracking and a reduced sensibility to temperature changes.

Non-reactive HSs (HS-PBEa and HS-PBEb), which were formulated with two semi-crystalline ethylene/propylene based elastomers, yield stable binders with improved in-service properties without deteriorating low temperature flexibility.

Reactive HSs (HS-EMAa, HS-EMAb and HS-RPO) use ethylene-based polymers containing functional groups (pendant succinic anhydride in EMAa and EMAb, and epoxy groups in RPO) that react with bitumen polar molecules, leading to a much higher degree of improvement than PBEs.

From a structural point of view, the enhancement in the thermomechanical response is a consequence of the development of a complex multiphasic system formed by non-dissolved CTR particles, a swollen polymer-rich phase and a bituminous phase. Physicochemical interactions and the synergistic effect among these phases contribute to the improved bulk properties, and favour heat storage stability.

Finally, the obtained results allow us to rank samples with respect to the capability of modification of the ethylene polymer as follows: PBEb ≈ PBEa << EMAb < EMAa < RPO.