Silicone Resin Polymer Used in Preventive Maintenance of Asphalt Mixture Based on Fog Seal

Abstract

:1. Introduction

- Characterize the physicochemical properties, including surface micromorphology, element composition and distribution, and physical phase of solidified silicone resin polymer by means of SEM (scanning electron microscopy), XRF (X-ray fluorescence), EPMA (electronic probe microanalyzer) and XRD (X-ray diffractometer).

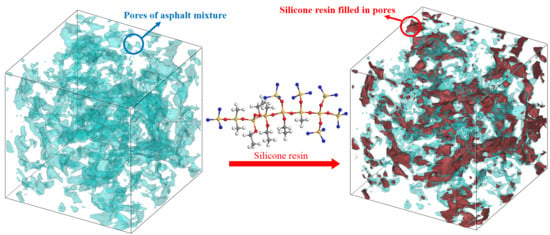

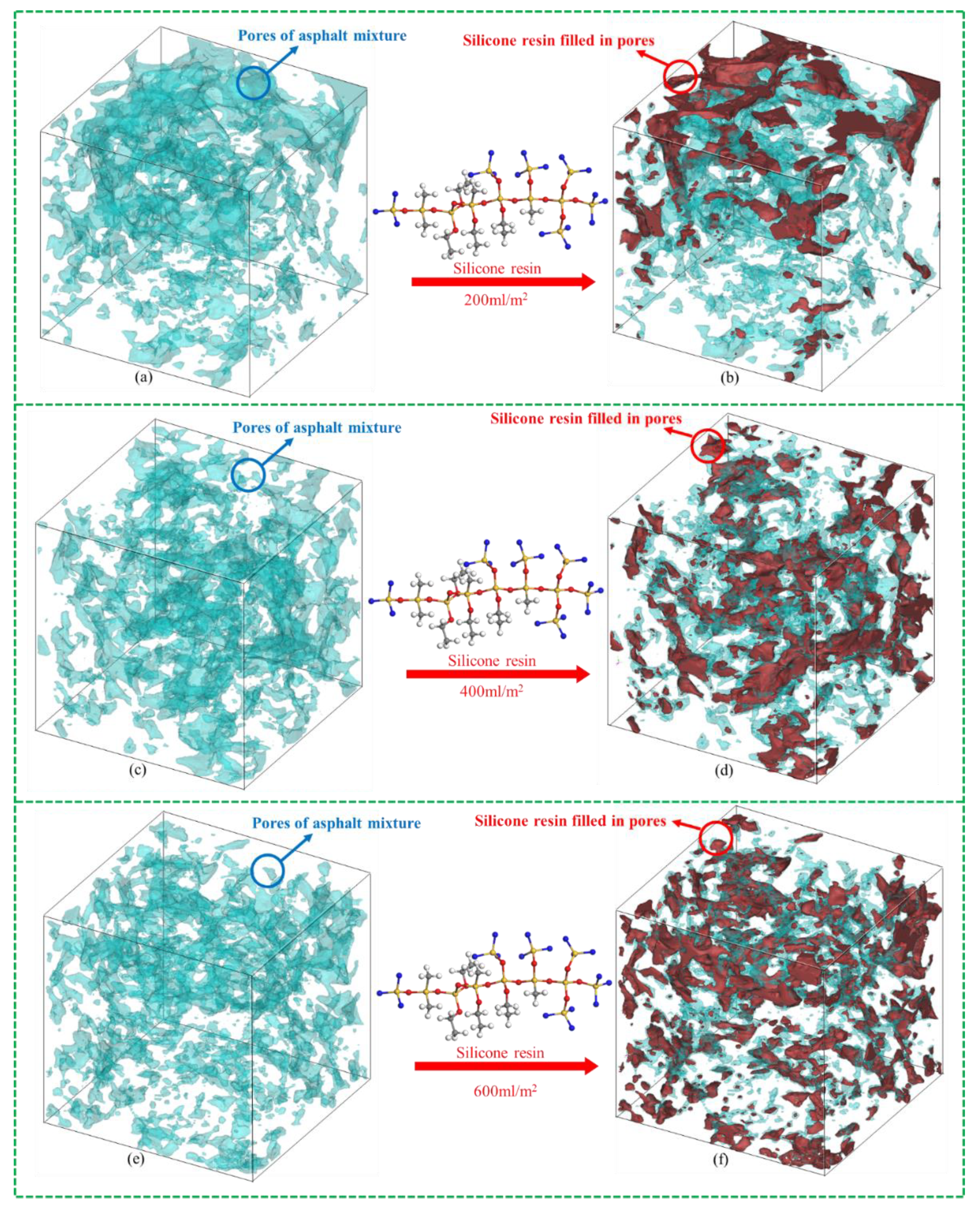

- Investigate the permeability and distribution of silicone resin in the asphalt mixture by X-ray CT (computed tomography) and 3D reconstruction.

- Explore the effect of silicone on the moisture sensitivity and high-temperature stability of the asphalt mixture.

- Determine the optimum silicone dosage for the OGFC mixture in consideration of permeability, distribution, performance of mixture, and economic cost.

2. Materials

2.1. Silicone Resin

2.2. Asphalt, Aggregate, and Asphalt Mixture

3. Experimental Methods

3.1. Characteristics of Silicone Resin

3.2. Permeability and Distribution of Silicone Resin in Mixture

3.3. Moisture Susceptibility

3.4. High-Temperature Performance

4. Results and Discussion

4.1. Characteristics of Silicone Resin

4.1.1. Surface Micromorphology

4.1.2. Element Composition and Distribution

4.1.3. Physical Phase

4.2. Permeability and Distribution of Silicone Resin

4.3. Moisture Susceptibility

4.4. High-Temperature Stability

5. Conclusions

- The surface characteristic of silicone resin can effectively isolate moisture, thereby improving moisture resistance of the asphalt mixture. Elements are distributed quite evenly, indicating that the prepolymer in the liquid silicone is further polymerized to form a multidimensional Si–O–Si structure as the ethanol evaporates. Furthermore, the number of atoms of C, H, N, O, and Si are approximately 10–13, 15–18, 0–1, 2–3, and 1 respectively, in the monomers of solidified silicone resin.

- Silicone resin only distributed on the top of the sample and did not penetrate into most of the pores at the dosage of 200 mL/m2. It was found to be evenly distributed throughout the pores of the sample when the dosage was increased to 400 or 600 mL/m2. The pore filling rate increased by 16.3% when the dosage was changed from 200 to 400 mL/m2, while it only increased by 3.7% when the dosage increased from 400 to 600 mL/m2. The reason is that excess liquid silicone flows away along the pores of the mixture before solidification.

- Moisture damage resistance of the asphalt mixture generally increased as the dosage of silicone was increased. However, as the dosage was increased from 400 to 600 mL/m2, the growth rate in RMS and TSR slowed significantly since the pore filling effect of silicone reached the upper limit. The dosage of silicone resin had little effect on the results of the rutting test while it had a significant influence on HWT. The reason is that the moisture is taken into account in HWT. It was also found that when dosages of silicone are the same, the dynamic stability of HWT is less than that of conventional rutting test resulting from the influence of moisture.

- In consideration of permeability, distribution, performance of mixture, and economic cost, it was found that 400 mL/m2 is the optimum silicone dosage for OGFC-13 mixture.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bazzaz, M.; Darabi, M.K.; Little, D.N.; Garg, N. A straightforward procedure to characterize nonlinear viscoelastic response of asphalt concrete at high temperatures. Transp. Res. Rec. 2018, 2672, 481–492. [Google Scholar] [CrossRef]

- Poursafaei, F.; Bazzaz, M.; Kafshdooz, M.M.; Ejlali, A. Slack clustering for scheduling frame-based tasks on multicore embedded systems. Microelectron. J. 2018, 81, 144–153. [Google Scholar] [CrossRef]

- Pratico, F.G.; Moro, A.; Ammendola, R. Modeling hma bulk specific gravities: A theoretical and experimental investigation. Int. J. Pavement Res. Technol. 2009, 2, 115–122. [Google Scholar]

- Cui, P.; Xiao, Y.; Yan, B.; Li, M.; Wu, S. Morphological characteristics of aggregates and their influence on the performance of asphalt mixture. Constr. Build. Mater. 2018, 186, 303–312. [Google Scholar] [CrossRef]

- White, G.; Tighe, S.; Emery, S.; Yeaman, J. Developing a framework for diagnosis of shear distress in asphalt surfaces. Int. J. Pavement Eng. 2017, 18, 1039–1051. [Google Scholar] [CrossRef]

- Kim, Y.K.; Lee, S.W. Performance evaluation of bonded concrete overlay. Constr. Build. Mater. 2013, 49, 464–470. [Google Scholar] [CrossRef]

- Darabi, M.K.; Huang, C.-W.; Bazzaz, M.; Masad, E.A.; Little, D.N. Characterization and validation of the nonlinear viscoelastic-viscoplastic with hardening-relaxation constitutive relationship for asphalt mixtures. Constr. Build. Mater. 2019, 216, 648–660. [Google Scholar] [CrossRef]

- Cui, P.; Wu, S.; Xiao, Y.; Wang, F.; Wang, F. Quantitative evaluation of active based adhesion in aggregate-asphalt by digital image analysis. J. Adhes. Sci. Technol. 2019, 33, 1544–1557. [Google Scholar] [CrossRef]

- Xu, B.; Li, M.L.; Liu, S.H.; Fang, J.; Ding, R.D.; Cao, D.W. Performance analysis of different type preventive maintenance materials for porous asphalt based on high viscosity modified asphalt. Constr. Build. Mater. 2018, 191, 320–329. [Google Scholar] [CrossRef]

- Zhang, Y.; van de Ven, M.; Molenaar, A.; Wu, S.P. Preventive maintenance of porous asphalt concrete using surface treatment technology. Mater. Des. 2016, 99, 262–272. [Google Scholar] [CrossRef]

- Roh, I.-T.; Jung, K.-C.; Chang, S.-H.; Cho, Y.-H. Characterization of compliant polymer concretes for rapid repair of runways. Constr. Build. Mater. 2015, 78, 77–84. [Google Scholar] [CrossRef]

- Tarefder, R.A.; Ahmad, M. Cost-effectiveness analysis of chip seal with and without millings. Int. J. Pavement Eng. 2018, 19, 893–900. [Google Scholar] [CrossRef]

- Liu, M.M.; Han, S.; Wang, Z.Y.; Ren, W.Y.; Li, W. Performance evaluation of new waterborne epoxy resin modified emulsified asphalt micro-surfacing. Constr. Build. Mater. 2019, 214, 93–100. [Google Scholar] [CrossRef]

- Saghafi, M.; Tabatabaee, N.; Nazarian, S. Performance evaluation of slurry seals containing reclaimed asphalt pavement. Transp. Res. Rec. 2019, 2673, 358–368. [Google Scholar] [CrossRef]

- Geng, L.; Ma, T.; Zhang, J.H.; Huang, X.M.; Hu, P.S. Research on performance of a dense graded ultra-thin wearing course mixture. Appl. Sci. 2017, 7, 800. [Google Scholar] [CrossRef]

- Guo, T.T.; Wang, C.H.; Yang, X.; Sun, X.L. Development and performance of sand fog seal with cooling and air purification effects. Constr. Build. Mater. 2017, 141, 608–618. [Google Scholar] [CrossRef]

- Prapaitrakul, N.; Freeman, T.; Glover, C. Fog seal treatment effectiveness analysis of pavement binders using the t-test statistical approach. Pet. Sci. Technol. 2010, 28, 1895–1905. [Google Scholar] [CrossRef]

- Im, J.H.; Kim, Y.R. Methods for fog seal field test with polymer-modified emulsions development and performance evaluation. Transp. Res. Rec. 2013, 2361, 88–97. [Google Scholar] [CrossRef]

- Qureshi, N.A.; Tran, N.H.; Watson, D.; Jamil, S.M. Effects of rejuvenator seal and fog seal on performance of open-graded friction course pavement. Maejo Int. J. Sci. Technol. 2013, 7, 189–202. [Google Scholar]

- Islam, R.M.; Arafat, S.; Wasiuddin, N.M. Quantification of reduction in hydraulic conductivity and skid resistance caused by fog seal in low-volume roads. Transp. Res. Rec. 2017, 2657, 99–108. [Google Scholar] [CrossRef]

- Motamed, A.; Salomon, D.; Sakib, N.; Bhasin, A. Emulsified asphalt residue recovery and characterization combined use of moisture analyzer balance and dynamic shear rheometer. Transp. Res. Rec. 2014, 2444, 88–96. [Google Scholar] [CrossRef]

- Yang, G.L.; Wang, C.H.; Fu, H.; Yan, Z.B.; Yin, W.Y. Waterborne epoxy resin-polyurethane-emulsified asphalt: Preparation and properties. J. Mater. Civ. Eng. 2019, 31, 04019265. [Google Scholar] [CrossRef]

- Zhao, H.; Li, H.P.; Liao, K.J.; Li, Y.G. The anti-aging performance of emulsified asphalt. Pet. Sci. Technol. 2012, 30, 193–200. [Google Scholar] [CrossRef]

- Colombo, P.; Bernardo, E.; Biasetto, L. Novel microcellular ceramics from a silicone resin. J. Am. Ceram. Soc. 2004, 87, 152–154. [Google Scholar] [CrossRef]

- Qing, Y.C.; Zhou, W.C.; Luo, F.; Zhu, D.M. Microwave-absorbing and mechanical properties of carbonyl-iron/epoxy-silicone resin coatings. J. Magn. Magn. Mater. 2009, 321, 25–28. [Google Scholar] [CrossRef]

- Chen, D.Z.; Chen, F.X.; Hu, X.Y.; Zhang, H.W.; Yin, X.Z.; Zhou, Y.S. Thermal stability, mechanical and optical properties of novel addition cured pdms composites with nano-silica sol and mq silicone resin. Compos. Sci. Technol. 2015, 117, 307–314. [Google Scholar] [CrossRef]

- Lin, J.; Chen, M.; Wu, S. Utilization of silicone maintenance materials to improve the moisture sensitivity of asphalt mixtures. Constr. Build. Mater. 2012, 33, 1–6. [Google Scholar] [CrossRef]

- Zhu, J.; Wu, S.; Zhong, J.; Wang, D. Investigation of asphalt mixture containing demolition waste obtained from earthquake-damaged buildings. Constr. Build. Mater. 2012, 29, 466–475. [Google Scholar] [CrossRef]

- Lin, J.T.; Chen, M.Z.; Wan, L.; Wu, S.P. Effect of silicone maintenance materials on asphalt binders and mixtures. J. Test. Eval. 2012, 40, 78–83. [Google Scholar]

| Properties | Unit | Tested Value | Specification Used | Criteria in China |

|---|---|---|---|---|

| Specific gravity | g/cm3 | 2.855 | ASTM C127 | >2.6 |

| Los Angeles abrasion loss | % | 14.1 | ASTM C535 | <28 |

| Water absorption ratio | % | 0.67 | ASTM C127 | <2.0 |

| Soundness | % | 1.84 | ASTM C88 | <12 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, P.; Wu, S.; Xu, H.; Lv, Y. Silicone Resin Polymer Used in Preventive Maintenance of Asphalt Mixture Based on Fog Seal. Polymers 2019, 11, 1814. https://doi.org/10.3390/polym11111814

Cui P, Wu S, Xu H, Lv Y. Silicone Resin Polymer Used in Preventive Maintenance of Asphalt Mixture Based on Fog Seal. Polymers. 2019; 11(11):1814. https://doi.org/10.3390/polym11111814

Chicago/Turabian StyleCui, Peide, Shaopeng Wu, Haiqin Xu, and Yang Lv. 2019. "Silicone Resin Polymer Used in Preventive Maintenance of Asphalt Mixture Based on Fog Seal" Polymers 11, no. 11: 1814. https://doi.org/10.3390/polym11111814

APA StyleCui, P., Wu, S., Xu, H., & Lv, Y. (2019). Silicone Resin Polymer Used in Preventive Maintenance of Asphalt Mixture Based on Fog Seal. Polymers, 11(11), 1814. https://doi.org/10.3390/polym11111814