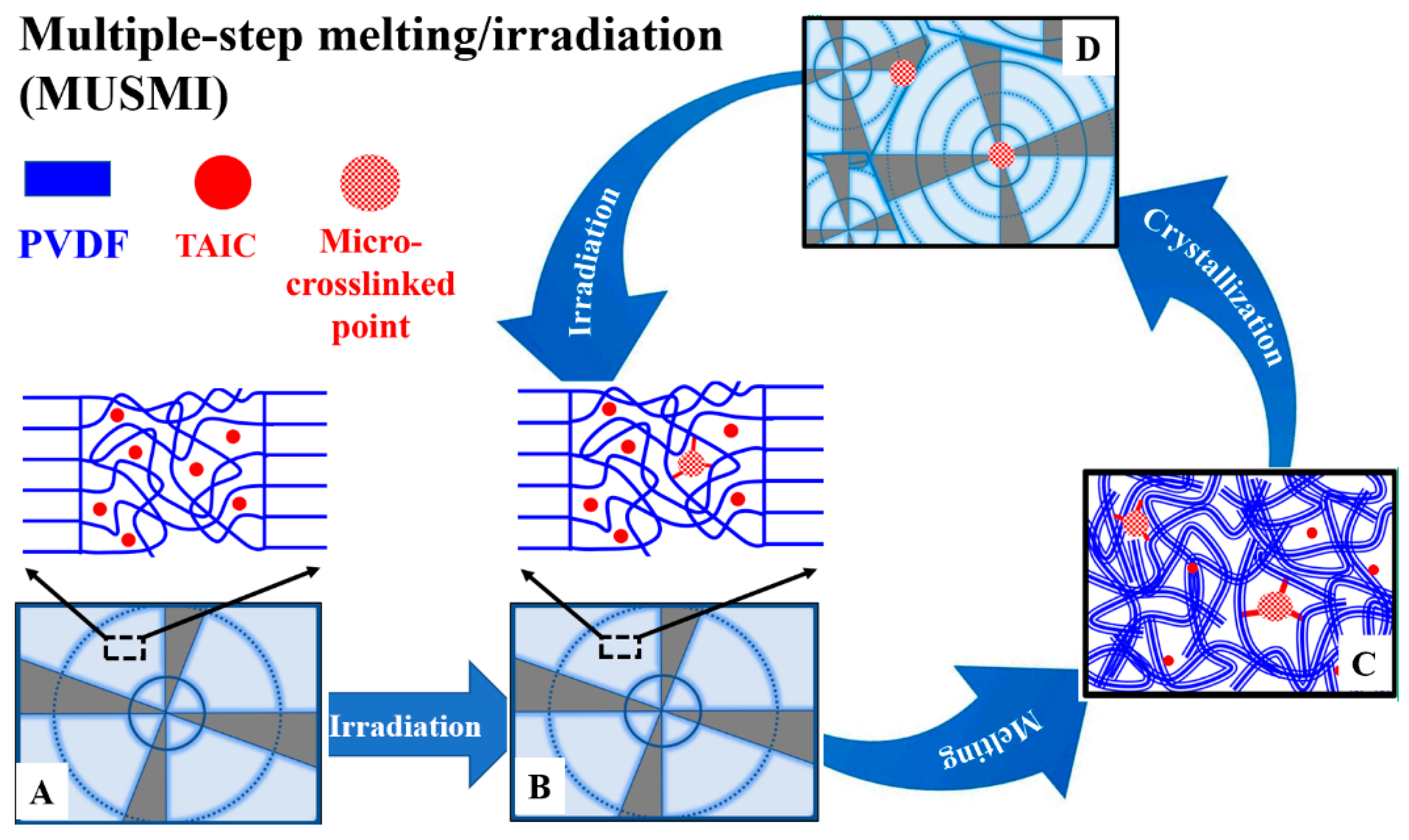

Multiple-Step Melting/Irradiation: A Strategy to Fabricate Thermoplastic Polymers with Improved Mechanical Performance

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

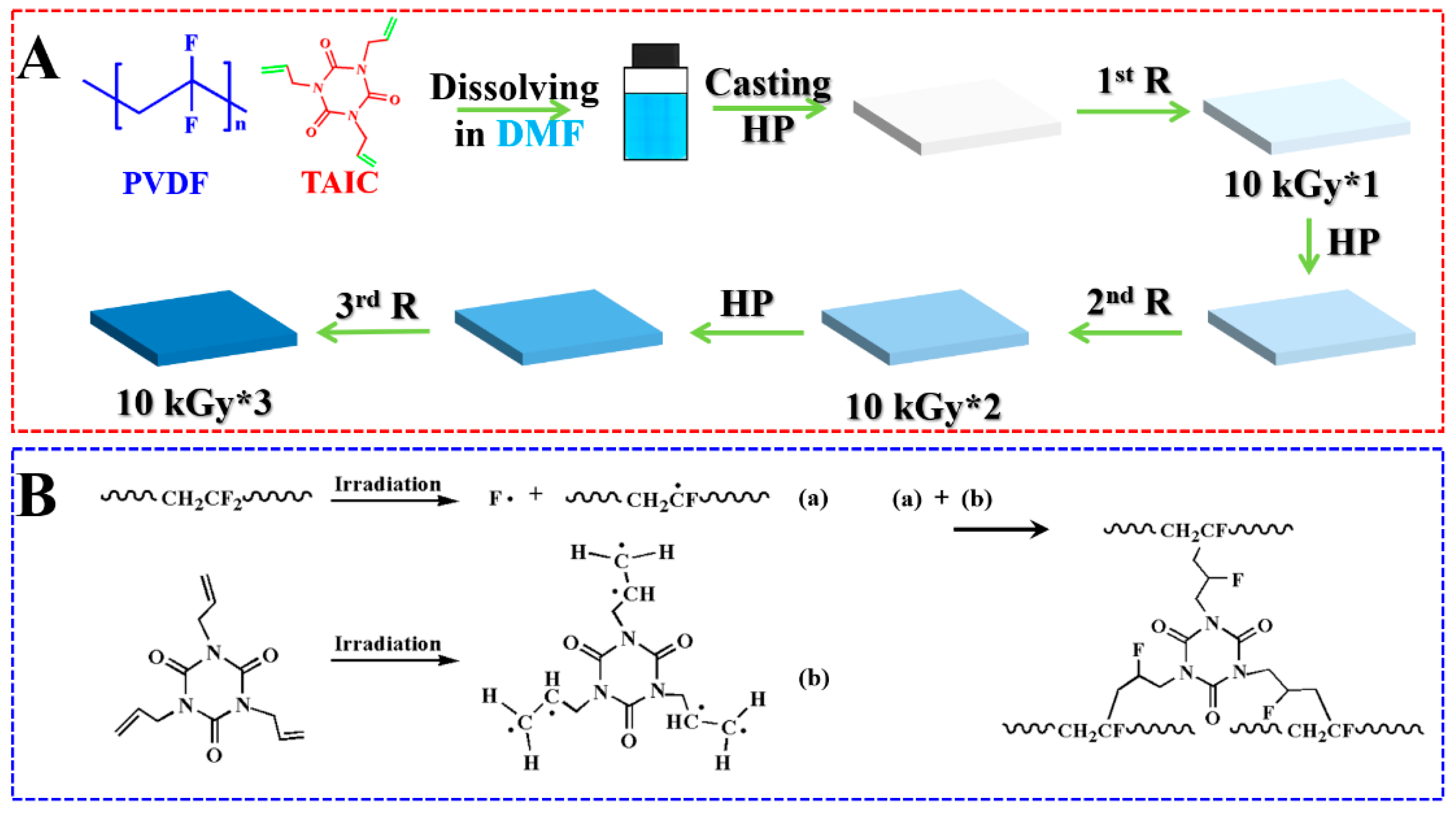

2.2. Sample Preparation

2.3. Characterization

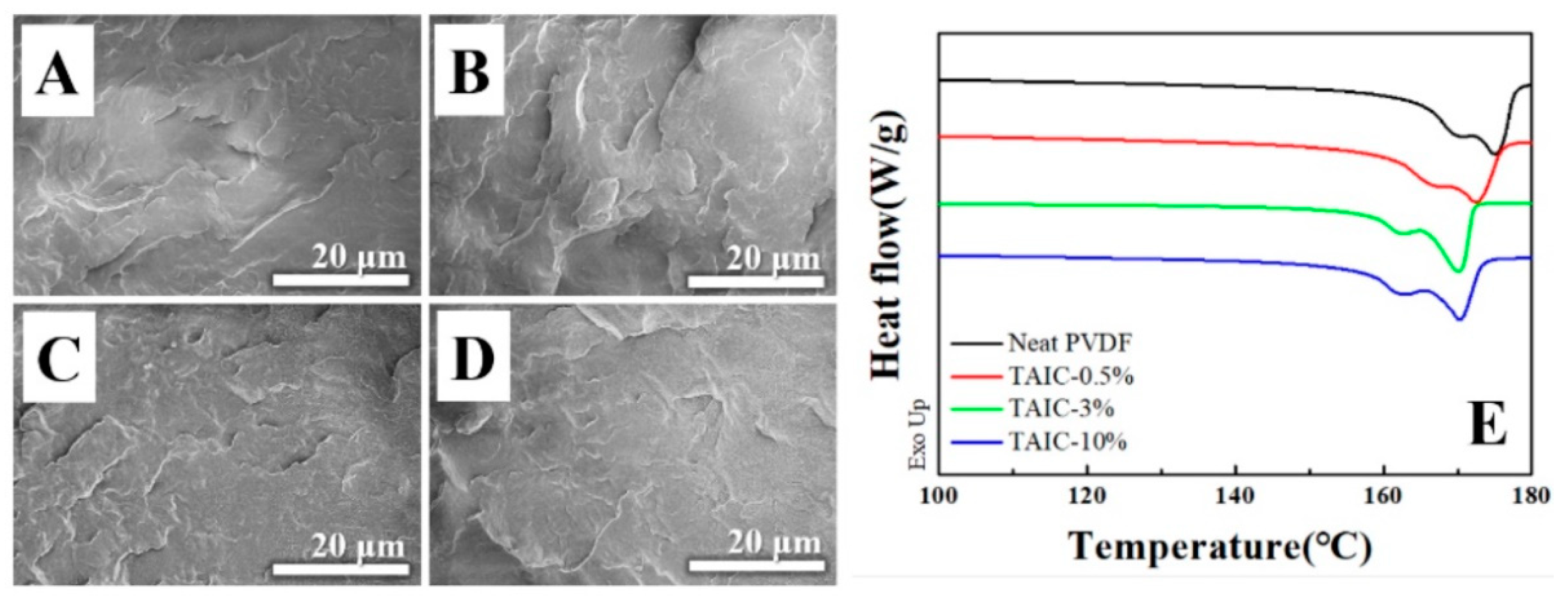

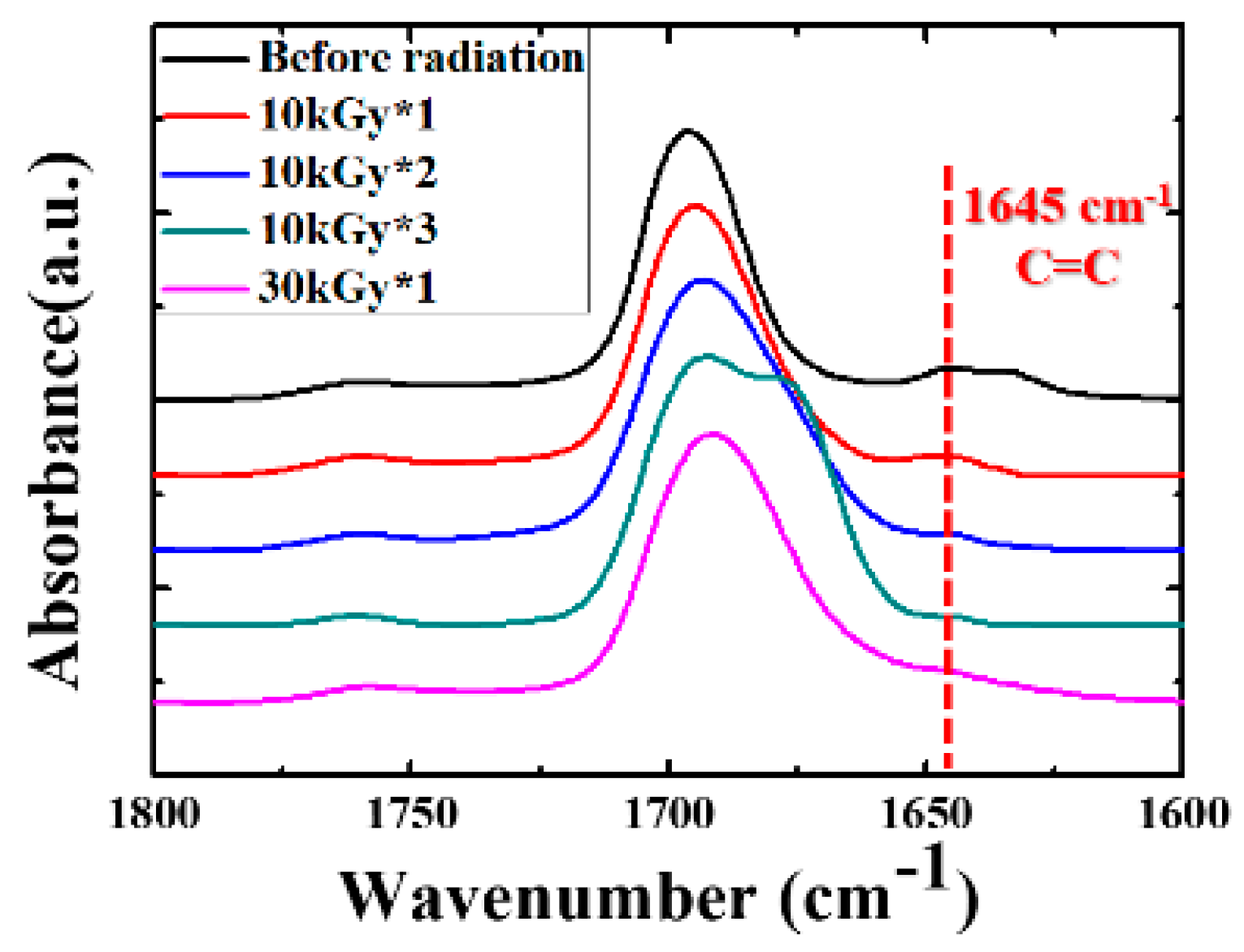

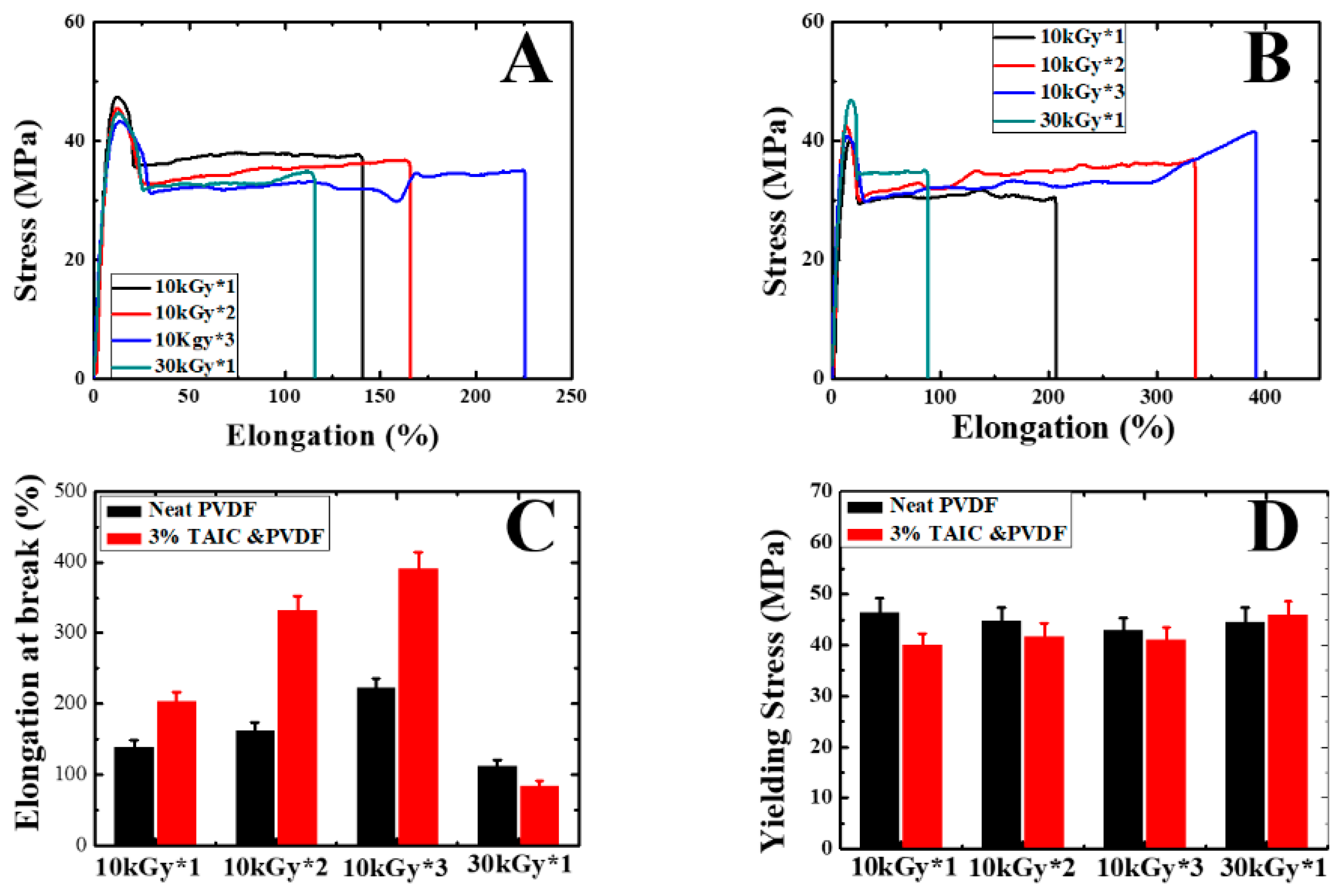

3. Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Ritchie, R. The conflicts between strength and toughness. Nature Mater. 2011, 10, 817–822. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Wang, T.; Li, Y.; Huang, L.; Handschuh-Wang, S. Polydimethylsiloxane/nanodiamond composite sponge for enhanced mechanical or wettability performance. Polymers 2019, 11, 948. [Google Scholar] [CrossRef] [PubMed]

- Anderson, K.S.; Schreck, K.M.; Hillmyer, M.A. Toughening polylactide. Polym. Rev. 2008, 48, 85–108. [Google Scholar] [CrossRef]

- Ovid’ko, I.A.; Valiev, R.Z.; Zhu, Y.T. Review on superior strength and enhanced ductility of metallic nanomaterials. Prog. Polym. Sci. 2018, 94, 462–540. [Google Scholar] [CrossRef]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef]

- Wei, Y.; Li, Y.; Zhu, L.; Liu, Y.; Lei, X.; Wang, G.; Wu, Y.; Mi, Z.; Liu, J.; Wang, H.; et al. Evading the strength–ductility trade-off dilemma in steel through gradient hierarchical nanotwins. Nature Commun. 2014, 5, 3580. [Google Scholar] [CrossRef]

- Kao, Y.C.; Chen, C.H.; Whang, W.T.; Chen, Y.C.; Chen, K.C. Poly(vinyl alcohol)-controlled synthesis of monodispersed crosslinked poly(methyl methacrylate) microparticles with significantly improved mechanical properties. Polym. Int. 2019, 68, 1315–1321. [Google Scholar] [CrossRef]

- Zhang, J.C.; Zhang, T.X.; Dong, M.J.; Liu, G.S.; Dong, Y.Y. Study on degrees of mesomorphic zone of polymer.I.Determination of degrees of crystallinity of Eucommia ulmoides gum and natural rubber by dynamic mechanical thermal analysis. Polym. Test. 2017, 63, 511–520. [Google Scholar]

- Ottesen, V.; Larsson, P.T.; Chinga-Carrasco, G.; Syverud, K.; Gregersen, O.W. Mechanical properties of cellulose nanofibril films: Effects of crystallinity and its modification by treatment with liquid anhydrous ammonia. Cellulose 2019, 26, 6615–6627. [Google Scholar] [CrossRef]

- Miao, Y.G.; Zhang, H.N.; He, H.; Deng, Q. Mechanical behaviors and equivalent configuration of a polyurea under wide strain rate range. Compos. Struct. 2019, 222, 110923. [Google Scholar] [CrossRef]

- Wang, K.; Deng, Q. The thermal and mechanical properties of poly(ethylene-co-vinyl acetate) random copolymers (PEVA) and its covalently crosslinked analogues (cPEVA). Polymers 2019, 11, 1055. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Daelemans, L.; Fiorio, R.; Gou, M.; D’hooge, D.R.; De Clerck, K.; Cardon, L. Improving mechanical properties for extrusion-based additive manufacturing of poly (lactic acid) by annealing and blending with poly (3-hydroxybutyrate). Polymers 2019, 11, 1529. [Google Scholar] [CrossRef] [PubMed]

- Weng, Z.; Wang, J.; Senthil, T.; Wu, L. Mechanical and thermal properties of ABS/montmorillonite nanocomposites for fused deposition modeling 3D printing. Mater. Des. 2016, 102, 276–283. [Google Scholar] [CrossRef]

- Wright, K.J.; Lesser, A.J. Crystallinity and mechanical behavior evolution in Ethylene−Propylene random copolymers. Macromolecules 2001, 34, 3626–3633. [Google Scholar] [CrossRef]

- Jariyavidyanont, K.; Janke, A.; Androsch, R. Crystal self-nucleation in polyamide 11. Thermochim. Acta. 2019, 677, 139–143. [Google Scholar] [CrossRef]

- Acocella, M.R.; Vittore, A.; Maggio, M.; Guerra, G.; Giannini, L.; Tadiello, L. Graphene oxide and oxidized carbon black as catalyst for crosslinking of phenolic resins. Polymers 2019, 11, 1330. [Google Scholar] [CrossRef]

- Buonerba, A.; Speranza, V.; Capacchione, C.; Milione, S.; Grassi, A. Improvement of tensile properties, self-healing and recycle of thermoset styrene/2-vinylfuran copolymers via thermal triggered rearrangement of covalent crosslink. Eur. Polym. J. 2018, 99, 368–377. [Google Scholar] [CrossRef]

- Veazey, D.; Hsu, T.; Gomez, E.D. Enhancing resistance of poly(ether ketone ketone) to high-temperature steam through crosslinking and crystallization control. J. App. Polym. Sci. 2019, 136, 47727. [Google Scholar] [CrossRef]

- Tian, M.; Li, T.; Zhang, L.; Tian, H.; Wu, Y.; Ning, N. Interfacial crystallization and its mechanism in in-situ dynamically vulcanized iPP/POE blends. Polymer 2014, 55, 3068–3074. [Google Scholar] [CrossRef]

- Cui, Y.; Zhao, X.; Tang, X.; Luo, Y. Novel micro-crosslinked poly(organophosphazenes) with improved mechanical properties and controllable degradation rate as potential biodegradable matrix. Biomaterials 2004, 25, 451–457. [Google Scholar] [CrossRef]

- Pae, K.D.; Bhateja, S.K.; Gilbert, J.R. Increase in crystallinity in poly (vinylidene fluoride) by electron beam radiation. J. Polym. Sci. Pol. Phys. 1987, 25, 717–722. [Google Scholar] [CrossRef]

- Salaeh, S.; Cassagnau, P.; Boiteux, G.; Wießner, S.; Nakason, C. Thermoplastic vulcanizates based on poly(vinylidene fluoride)/epoxidized natural rubber blends: Effects of phenolic resin dosage and blend ratio. Mater. Chem. Phys. 2018, 219, 222–232. [Google Scholar] [CrossRef]

- Xu, C.; Wang, Y.; Lin, B.; Liang, X.; Chen, Y. Thermoplastic vulcanizate based on poly(vinylidene fluoride) and methyl vinyl silicone rubber by using fluorosilicone rubber as interfacial compatibilizer. Mater. Design. 2015, 88, 170–176. [Google Scholar] [CrossRef]

- Asandei, A.D. Photomediated controlled radical polymerization and block copolymerization of vinylidene fluoride. Chem. Rev. 2016, 116, 2244–2274. [Google Scholar] [CrossRef]

- Strobl, G.R.; Schneider, M. Model of partial crystallization and melting derived from small-angle X-ray scattering and electron microscopic studies on low-density polyethylene. J. Polym. Sci. Pol. Phys. 1980, 18, 1361–1381. [Google Scholar] [CrossRef]

- Guan, J.; Li, Y.; Li, J. Stretchable ionic-liquid-based gel polymer electrolytes for Lithium ion batteries. Ind. Eng. Chem. Res. 2017, 56, 12456–12463. [Google Scholar] [CrossRef]

- Rusli, A.; Raffi, N.S.M.; Ismail, H. Solubility, miscibility and processability of thermosetting monomers as reactive plasticizers of polyetherimide. Procedia Chem. 2016, 19, 776–781. [Google Scholar] [CrossRef][Green Version]

- Chapiro, A.; Mankowsik, Z.; Schmitt, N. Unusual Swelling Behavior of Films of Polyvinyl- and Polyvinylidene/Fluorides in Various Solvents. J. Polym. Sci. Polym. Chem. Ed. 1982, 20, 1791–1796. [Google Scholar] [CrossRef]

- Taguet, A.; Ameduri, B.; Boutevin, B. Crosslinking of vinylidene fluoride-containing fluoropolymers. Crosslinking in Materials Science 2005, 184, 127–211. [Google Scholar]

- Xiong, B.J.; Lame, O.; Chenal, J.M.; Men, Y.F.; Seguela, R.; Vigier, G. Critical stress and thermal activation of crystal plasticity in polyethylene: Influence of crystal microstructure and chain topology. Polymer 2017, 118, 192–200. [Google Scholar] [CrossRef]

- Nishi, T.; Wang, T.T. Melting point depression and kinetic effects of cooling on crystallization in poly(viny1idene fluoride)-poly (methyl methacrylate) mixtures. Macromolecules 1975, 8, 909–915. [Google Scholar] [CrossRef]

- Zhang, B.W.; Wei, R.M.; Yu, M.; Deng, B.; Li, L.F.; Li, J.Y. Graft co-polymerization of maleic acid and vinyl acetate onto poly(vinylidene fluoride) powder by pre-irradiation technique. Nucl. Sci. Tech. 2012, 23, 103–108. [Google Scholar]

- Li, L.F.; Yu, Y.; Deng, B.; Yu, M.; Xie, L.D.; Li, J.Y. Preparation and characterization of proton exchange membranes from polystyrene grafted poly(vinylidene fluoride) powder. Nucl. Sci. Tech. 2011, 22, 160–164. [Google Scholar] [CrossRef]

- Rozanski, A.; Safandowska, M.; Krajenta, A. DSC/SAXS analysis of the thickness of lamellae of semicrystalline polymers-restrictions in the case of materials with swollen amorphous phase. Polym. Testing 2018, 65, 189–196. [Google Scholar] [CrossRef]

- Wang, Y.T.; Jiang, Z.Y.; Fu, L.L.; Lu, Y.; Men, Y.F. Stretching temperature dependency of lamellar thickness in stress-induced localized melting and recrystallized polybutene-1. Macromolecules 2013, 46, 7874–7879. [Google Scholar] [CrossRef]

- Crossland, E.J.W.; Rahimi, K.; Reiter, G.; Steiner, U.; Ludwigs, S. Systematic control of nucleation density in poly(3-Hexylthiophene) thin films. Adv. Funct. Mater. 2011, 21, 518–524. [Google Scholar] [CrossRef]

- Liu, P.B.; Liu, D.L.; Zou, H.W.; Fan, P.; Xu, W. Structure and properties of closed-cell foam prepared from irradiation crosslinked silicone rubber. J. Appl. Polym. Sci. 2009, 113, 3590–3595. [Google Scholar] [CrossRef]

- Ye, C.C.; Zhao, J.X.; Ye, L.J.; Jiang, Z.Y.; You, J.C.; Li, Y.J. Precise inter-lamellar/inter-fibrillar localization and consequent fabrication of porous membranes with crystallization-modulated pore-size. Polymer 2018, 142, 48–51. [Google Scholar] [CrossRef]

- Taguet, A.; Ameduri, B.; Boutevin, B. Crosslinking of vinylidene fluoride-containing fluoropolymers. Adv. Polym. Sci. 2005, 184, 127–211. [Google Scholar]

- Karabelli, D.; Lepretre, J.C.; Dumas, L.; Rouif, S.; Portinha, D.; Fleury, E.; Sanchez, J.Y. Crosslinking of poly(vinylene fluoride) separators by gamma-irradiation for electrochemical high power charge applications. Electrochim. Acta 2015, 169, 32–36. [Google Scholar] [CrossRef]

- Xing, C.Y.; Zhao, L.P.; You, J.C.; Dong, W.Y.; Cao, X.J.; Li, Y.J. Impact of ionic liquid-modified multiwalled carbon nanotubes on the crystallization behavior of poly(vinylidene fluoride). J. Phys. Chem. B 2012, 116, 8312–8320. [Google Scholar] [CrossRef] [PubMed]

- Kaygusuz, B.; Ozerinc, S. Improving the ductility of polylactic acid parts produced by fused deposition modeling through polyhydroxyalkanoate additions. J. Appl. Polym. Sci. 2019, 136, 48154. [Google Scholar] [CrossRef]

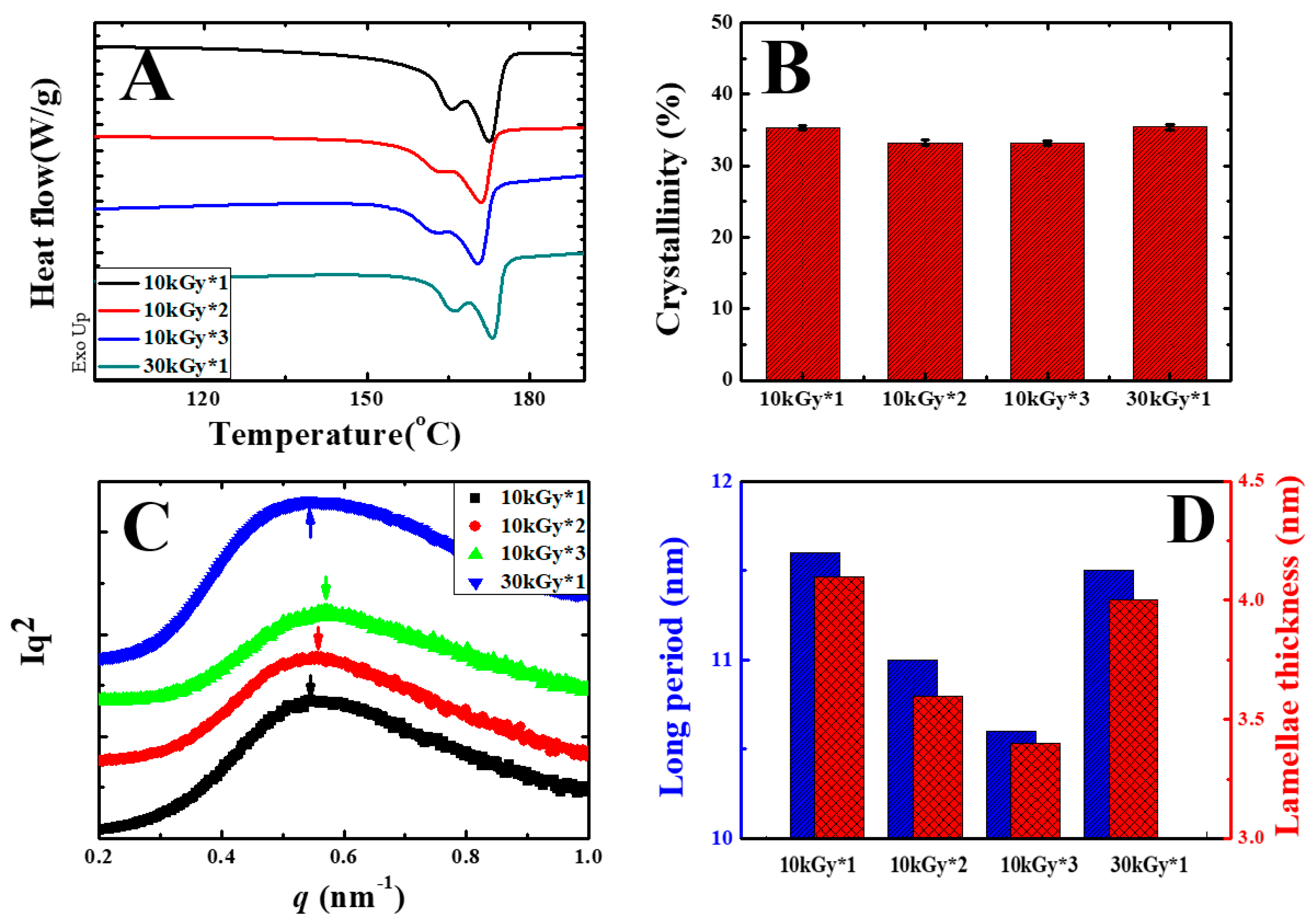

| Sample | Melting Temperature (°C) | Melting Enthalpy (J/g) | Crystallinity (%) | Long Period (nm) | Lamellae Thickness (nm) |

|---|---|---|---|---|---|

| 10 kGy*1 | 172.6 | 35.9 | 35.4 | 11.6 | 4.10 |

| 10 kGy*2 | 171.1 | 33.8 | 33.2 | 11.0 | 3.61 |

| 10 kGy*3 | 170.3 | 33.7 | 33.2 | 10.6 | 3.42 |

| 30 kGy*1 | 172.9 | 35.8 | 35.2 | 11.5 | 4.02 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Wang, J.; Ding, X.; Gu, Y.; Li, Y.; Li, J.; You, J. Multiple-Step Melting/Irradiation: A Strategy to Fabricate Thermoplastic Polymers with Improved Mechanical Performance. Polymers 2019, 11, 1812. https://doi.org/10.3390/polym11111812

Zhao J, Wang J, Ding X, Gu Y, Li Y, Li J, You J. Multiple-Step Melting/Irradiation: A Strategy to Fabricate Thermoplastic Polymers with Improved Mechanical Performance. Polymers. 2019; 11(11):1812. https://doi.org/10.3390/polym11111812

Chicago/Turabian StyleZhao, Jingxin, Jiayao Wang, Xiaojun Ding, Yu Gu, Yongjin Li, Jingye Li, and Jichun You. 2019. "Multiple-Step Melting/Irradiation: A Strategy to Fabricate Thermoplastic Polymers with Improved Mechanical Performance" Polymers 11, no. 11: 1812. https://doi.org/10.3390/polym11111812

APA StyleZhao, J., Wang, J., Ding, X., Gu, Y., Li, Y., Li, J., & You, J. (2019). Multiple-Step Melting/Irradiation: A Strategy to Fabricate Thermoplastic Polymers with Improved Mechanical Performance. Polymers, 11(11), 1812. https://doi.org/10.3390/polym11111812