Influence of the Test Method on the Characterization of the Fatigue Delamination Behavior of a Composite Material under Mixed Mode I/II Fracture

Abstract

1. Introduction

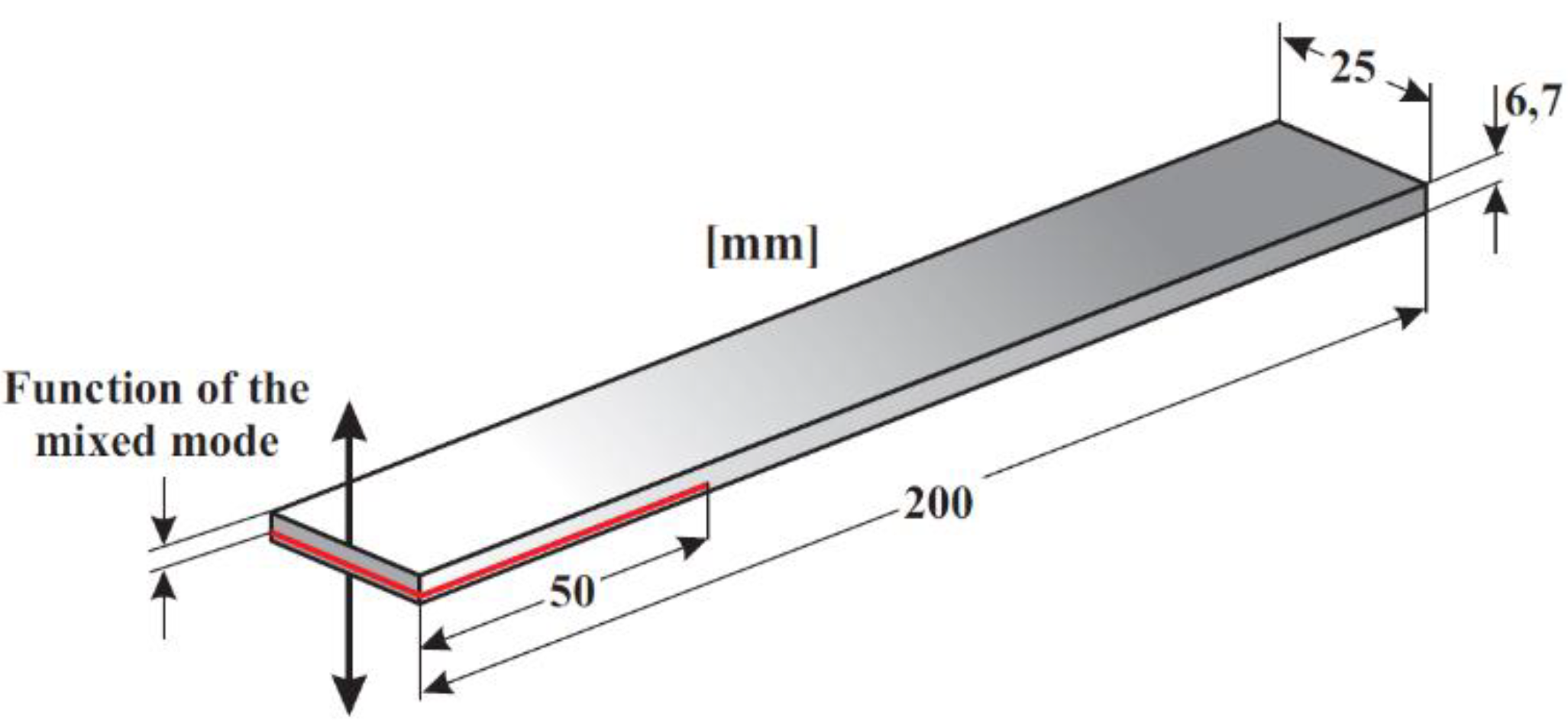

2. Materials and Test Specimens

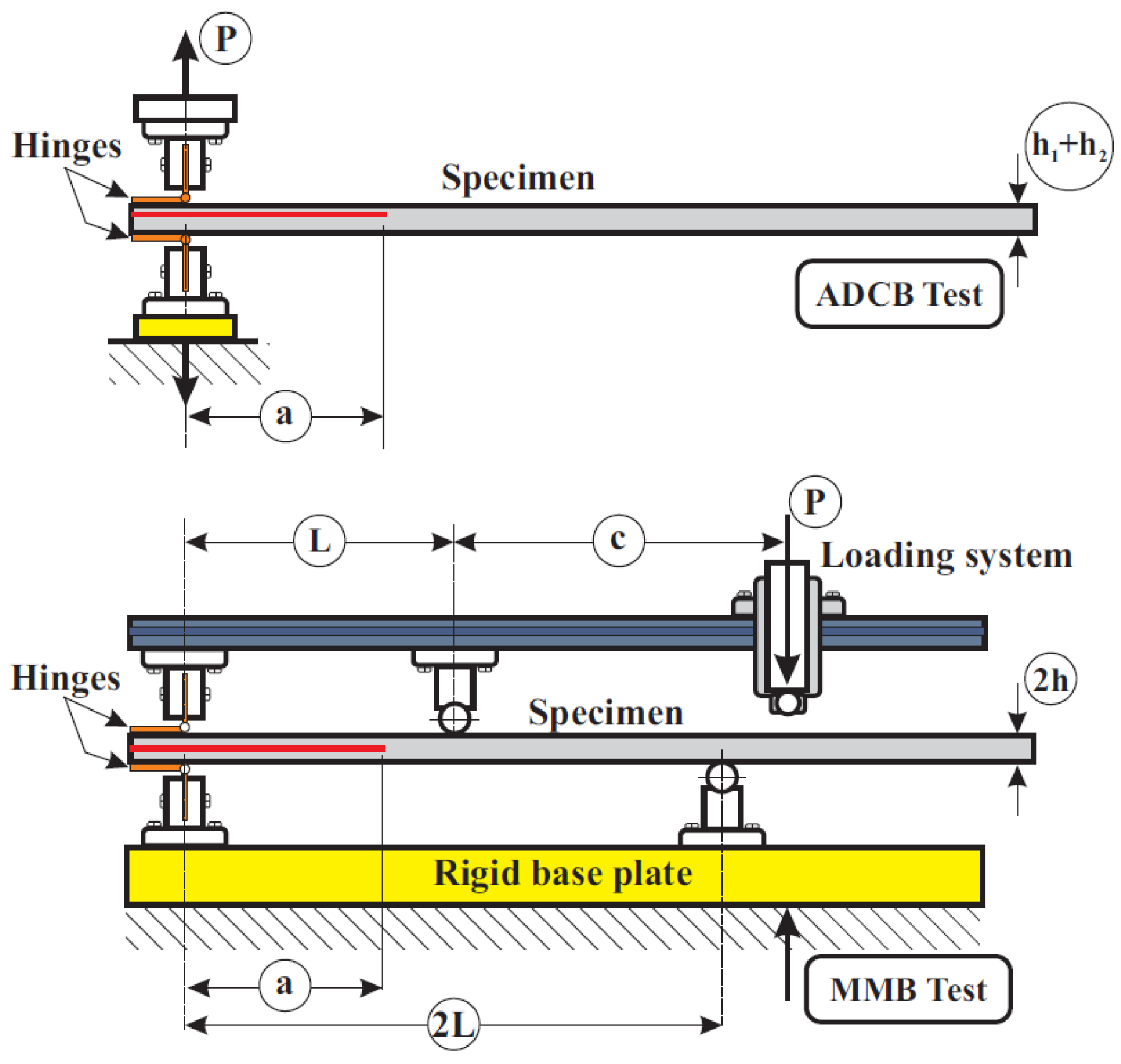

3. Experimental Method

3.1. Characterization under Static Loading

3.2. Fatigue Characterization

4. Experimental Results and Discussion

4.1. Static Loading

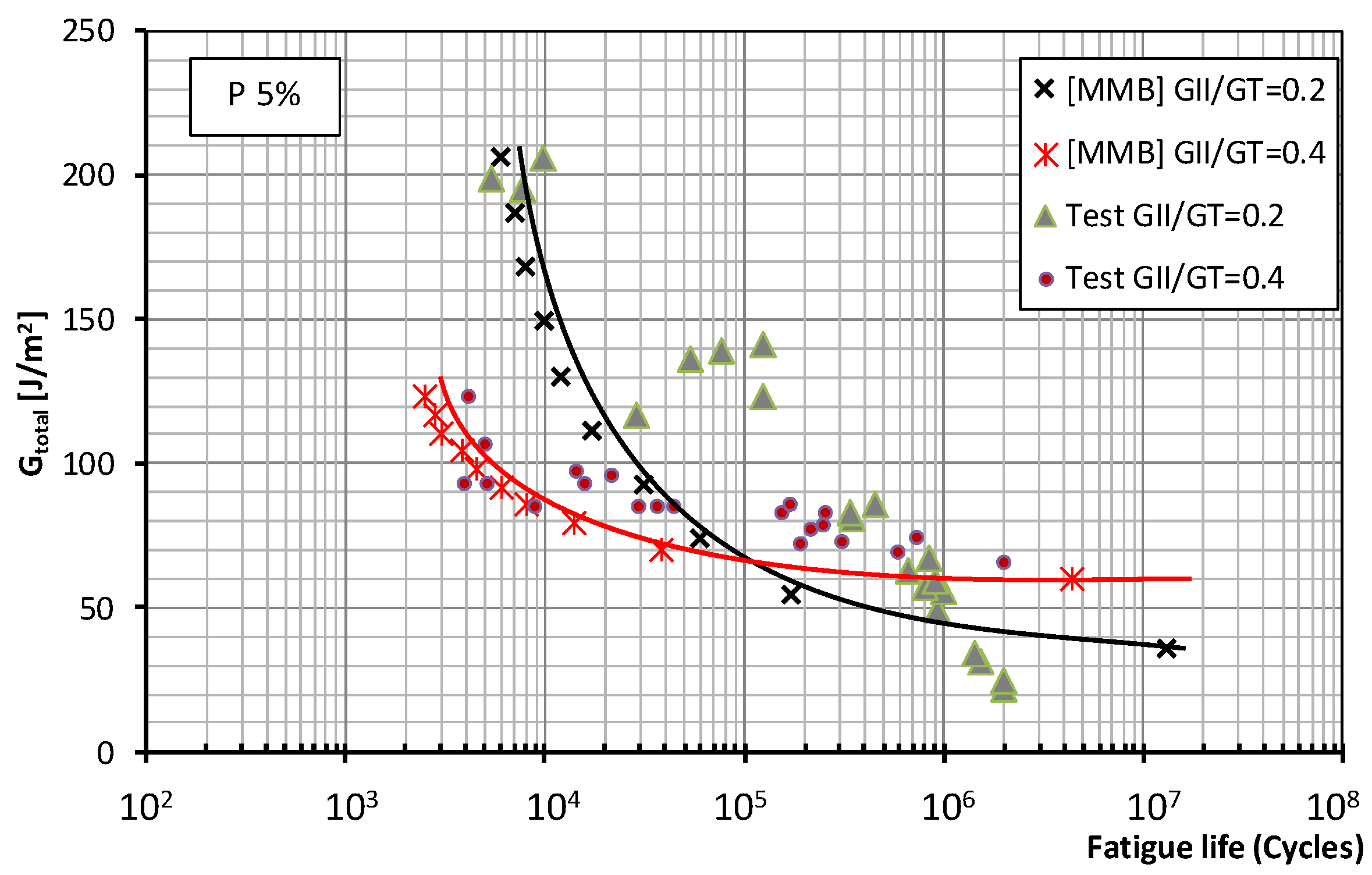

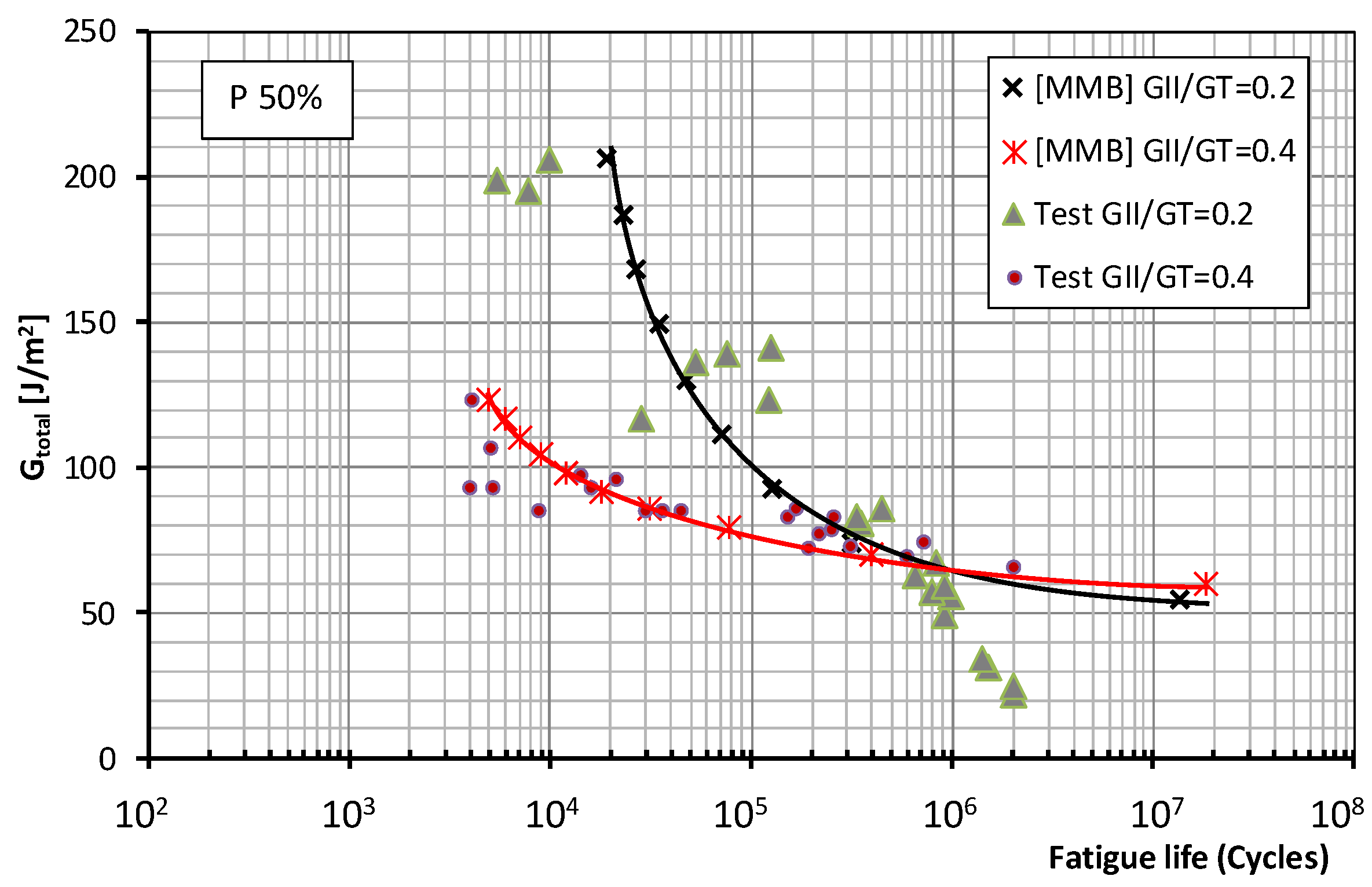

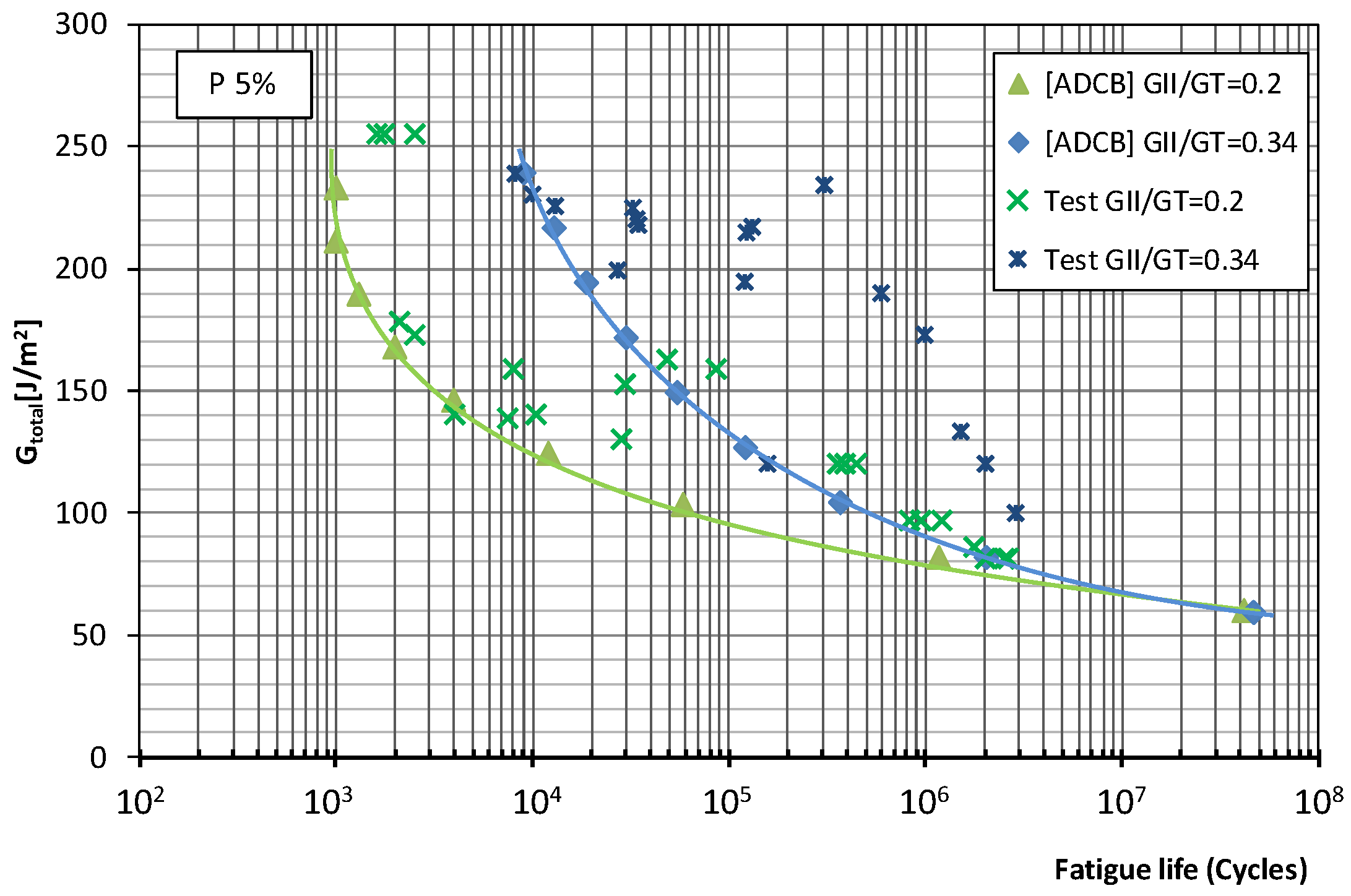

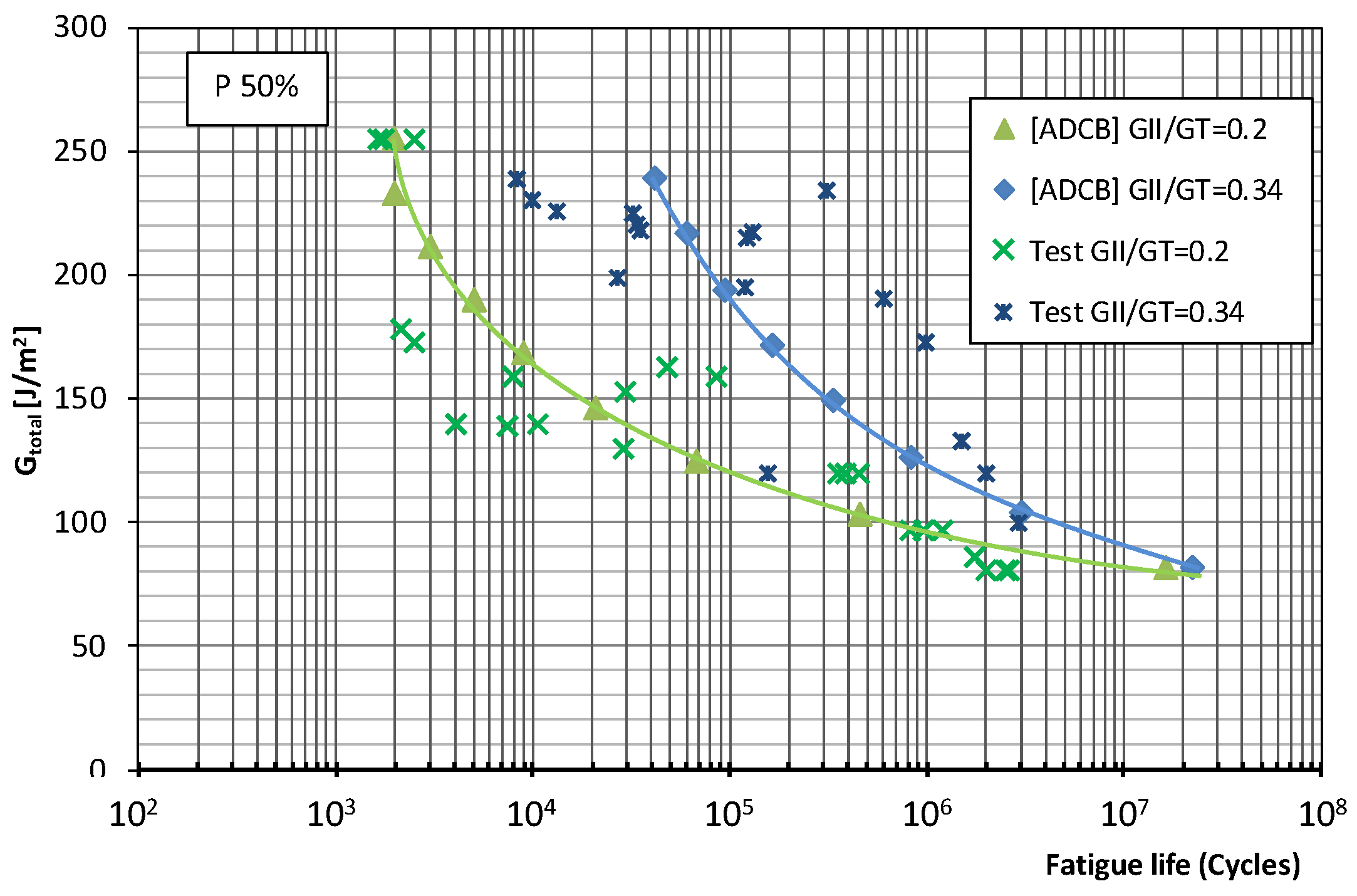

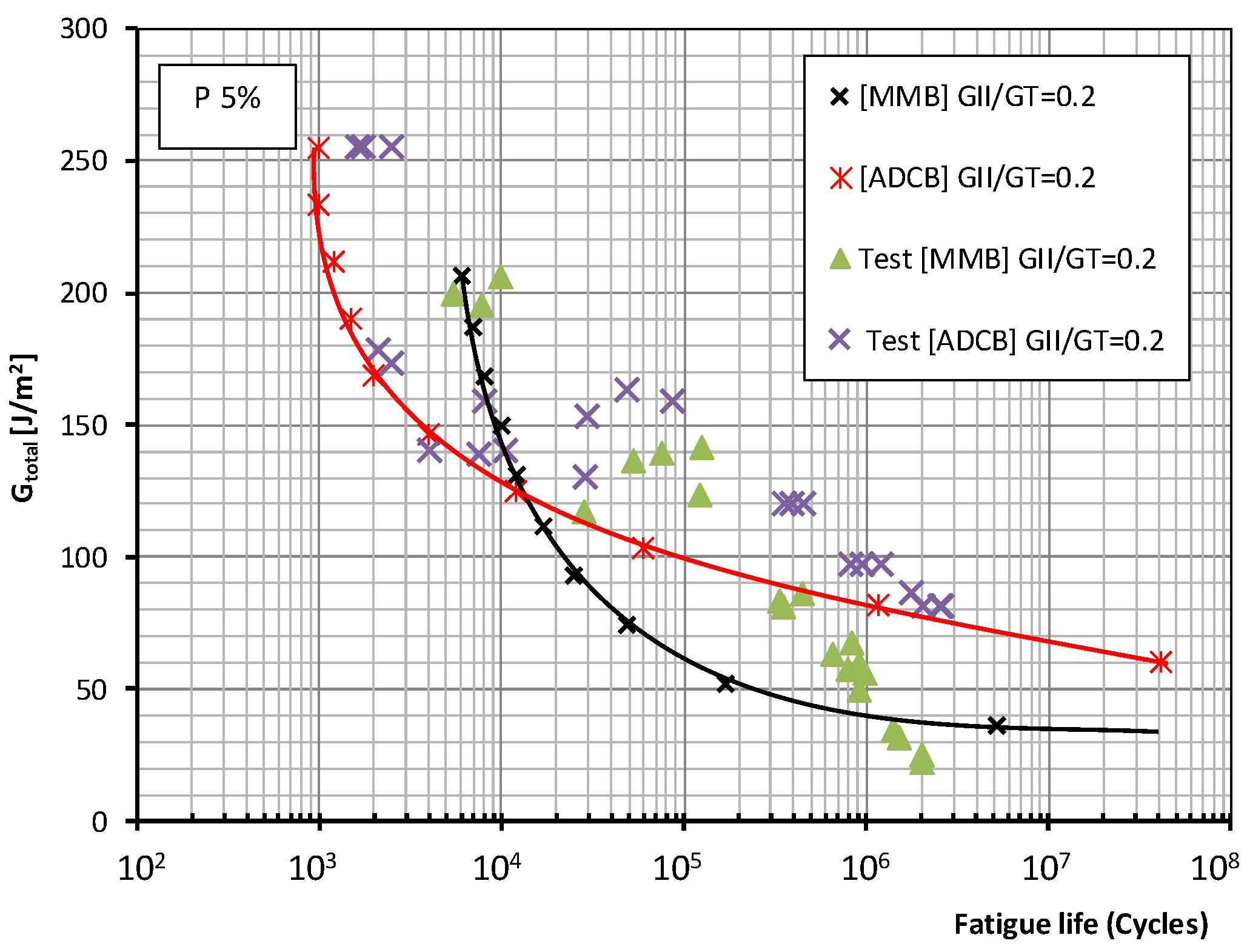

4.2. Dynamic Loading, Fatigue Life

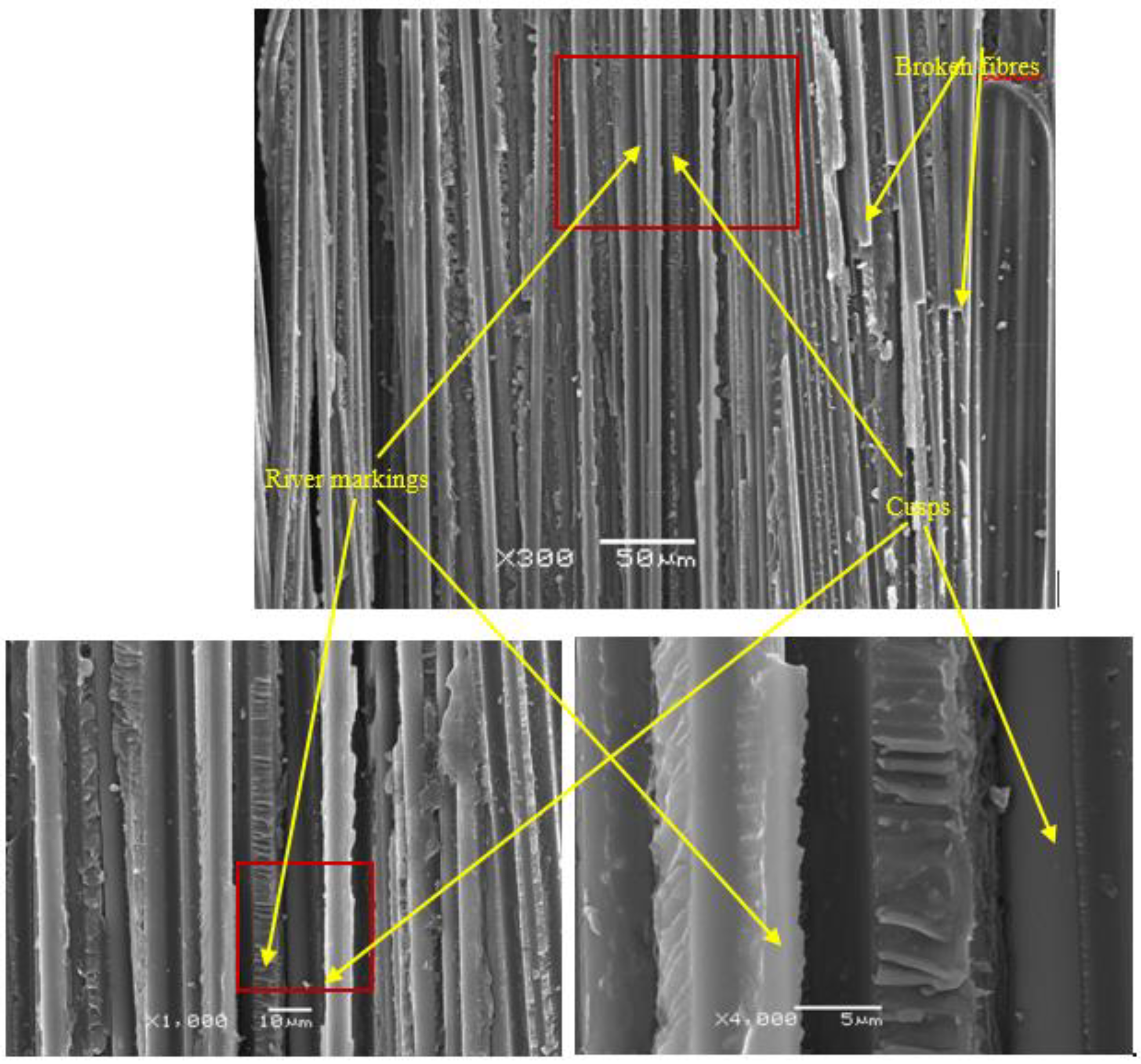

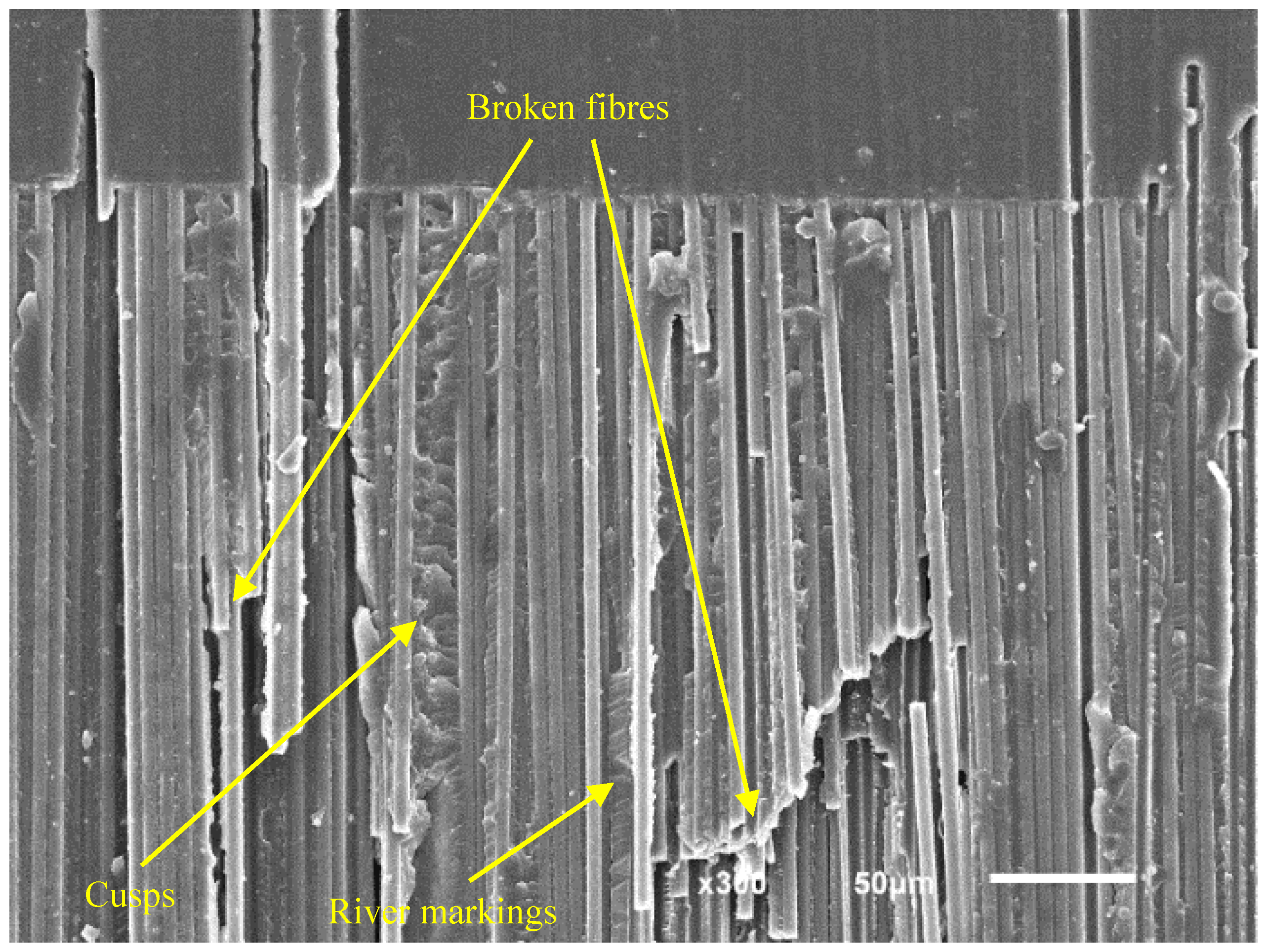

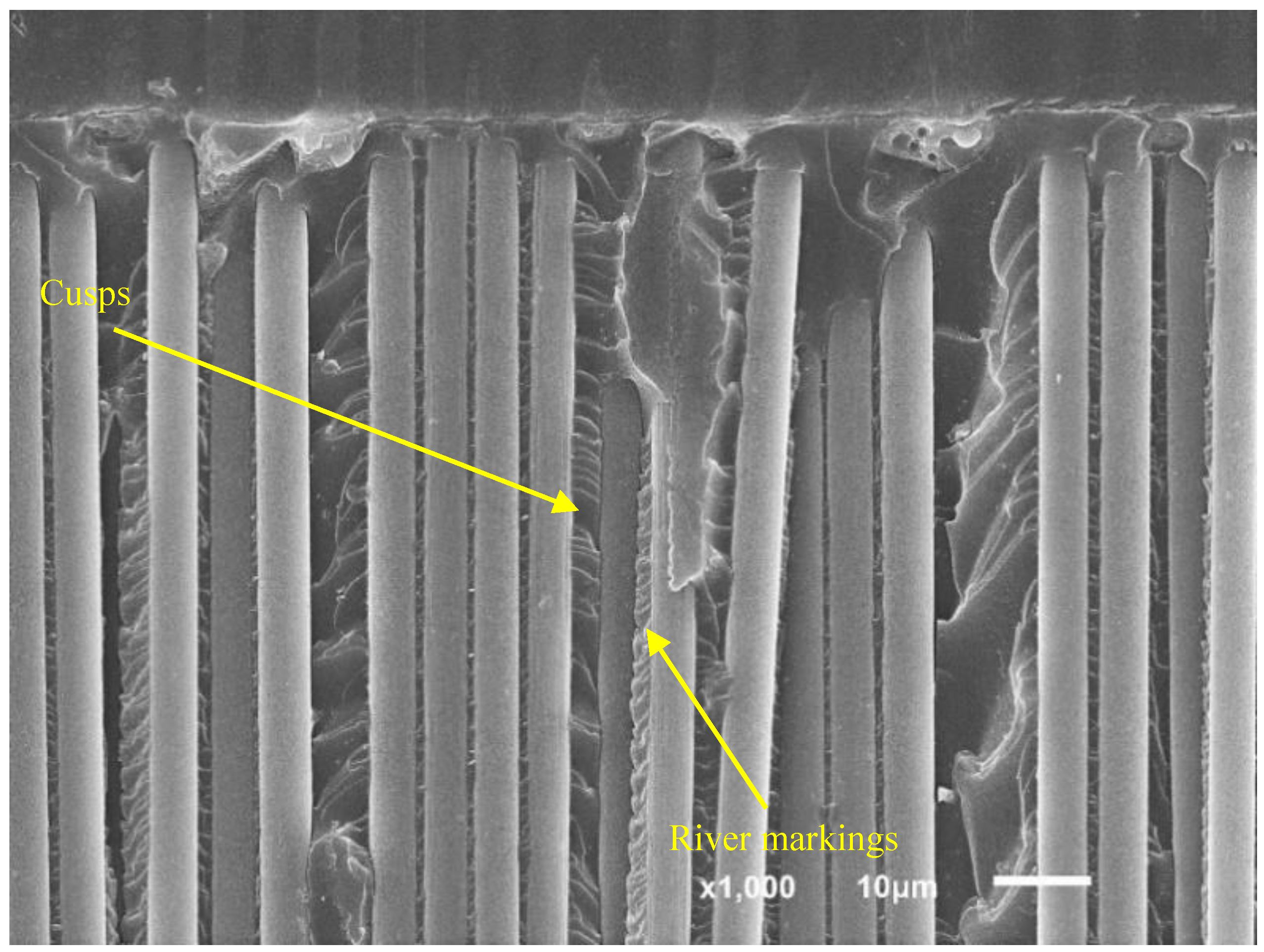

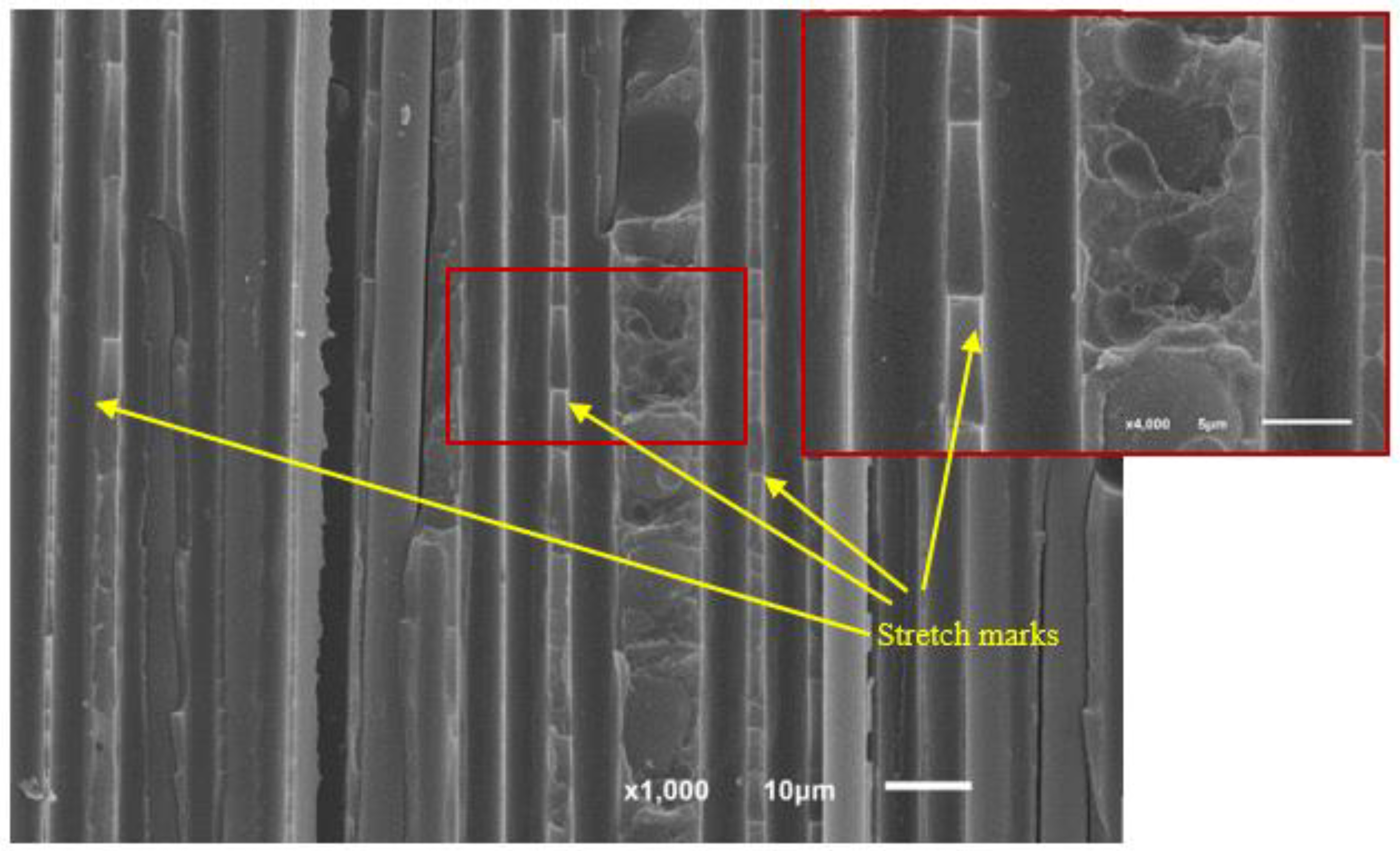

5. Analysis of Fracture Surfaces

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Argüelles, A.; Viña, J.F.; Canteli, A.; Castrillo, M.A.; Bonhomme, J. Interlaminar crack initiation and growth rate in a carbon-fibre epoxy composite under mode-I fatigue loading. Compos. Sci. Technol. 2008, 68, 2325–2331. [Google Scholar] [CrossRef]

- Brunner, A.J.; Stelzer, S.; Pinter, G.; Terrasi, G.P. Mode II fatigue delamination resistance of advanced fiber-reinforced polymer-matrix laminates: Towards the development of a standardized test procedure. Int. J. Fatigue 2013, 50, 57–62. [Google Scholar] [CrossRef]

- López-Menéndez, A.; Viña, J.; Argüelles, A.; Bonhomme, J.; Mollón, V.; Lozano, M. A new methodology for testing composite materials in mode III of fracture. In Proceedings of the 16th European Conference on Composite Materials, Seville, Spain, 22–26 June 2014. [Google Scholar]

- Argüelles, A.; Viña, J.; Fernández-Canteli, A.; Coronado, P.; Mollón, V. Influence of temperature on the delamination process under mode I fracture and dynamic loading of two carbon-epoxy composites. Compos. Part B 2015, 68, 207–214. [Google Scholar] [CrossRef]

- Jones, R.; Stelzer, S.; Brunner, A.J. Mode I, II and mixed mode I/II delamination growth in composites. Compos. Struct. 2014, 110, 317–324. [Google Scholar] [CrossRef]

- Reis, J.P.; de Moura, M.F.S.F.; Moreira, R.D.F.; Silva, F.G.A. Mixed mode I+II interlaminar fracture characterization of carbon-fibre reinforced polyamide composite using the Single-Leg Bending test. Mater. Today Commun. 2019, 19, 476–481. [Google Scholar] [CrossRef]

- Williams, J.G. Observations on the analysis of mixed mode delamination in composites. Procedia Eng. 2015, 114, 189–198. [Google Scholar] [CrossRef]

- Daneshjoo, Z.; Shokrieh, M.M.; Fakoor, M. A micromechanical model for prediction of mixed mode I/II delamination of laminated composites considering fiber bridging effects. Theor. Appl. Fract. Mech. 2018, 94, 46–56. [Google Scholar] [CrossRef]

- Harvey, C.M.; Eplett, M.R.; Wang, S. Experimental assessment of mixed-mode partition theories for generally laminated composite beams. Compos. Struct. 2015, 124, 10–18. [Google Scholar] [CrossRef][Green Version]

- ASTM. D6671/D6671M-13e1 Standard Test Method for Mixed Mode I-Mode II Interlaminar Fracture Toughness of Unidirectional Fiber Reinforced Polymer Matrix Composites; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Bao, G.; Ho, S.; Suo, Z.; Fan, B. The role of material orthotropy in fracture specimens for composites. Int. J. Solids Struct. 1992, 29, 1105–1116. [Google Scholar] [CrossRef]

- Qiao, P.; Chen, F. On the compliance and energy release rate of generically unified beam type fracture specimens. J. Compos. Mater. 2011, 45, 65–101. [Google Scholar] [CrossRef]

- Ducept, F.; Gamby, D.; Davies, P. A mixed-mode failure criterion derived from test on symmetric and asymmetric specimens. Compos. Sci. Technol. 1999, 59, 609–619. [Google Scholar] [CrossRef]

- Prombut, P.; Michel, L.; Lachaud, F.; Barrau, J.J. Delamination of multidirectional composite laminates at 0°/θ° ply interfaces. Eng. Fract. Mech. 2006, 73, 2427–2442. [Google Scholar] [CrossRef]

- Mollón, V.; Bonhomme, J.; Viña, J.; Argüelles, A. Theoretical and experimental analysis of carbon epoxy asymmetric DCB specimens to characterize mixed mode fracture toughness. Polym. Test. 2010, 29, 766–770. [Google Scholar] [CrossRef]

- Mollón, V.; Bonhomme, J.; Viña, J.; Argüelles, A. Mixed mode fracture toughness: An empirical formulation for GI/GII determination in asymmetric DCB specimens. Eng. Struct. 2010, 32, 3699–3703. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Zeinedini, A. A novel method for calculation of strain energy release rate of asymmetric double cantilever laminated composite beams. Appl. Compos. Mater. 2014, 21, 399–415. [Google Scholar] [CrossRef]

- Hua, X.; Li, H.; Lu, Y.; Chen, Y.; Qiu, L.; Tao, J. Interlaminar fracture toughness of GLARE laminates based on asymmetric double cantilever beam (ADCB). Compos. Part B 2019, 163, 175–184. [Google Scholar] [CrossRef]

- Arrese, A.; Boyano, A.; De Gracia, J.; Mújika, F. A novel procedure to determine the cohesive law in DCB tests. Compos. Sci. Technol. 2017, 152, 76–84. [Google Scholar] [CrossRef]

- Gazor, M.S.; Rahimi, G.H.; Farrokhabadi, A. The effect of the arrangement of corrugated composite on the R-curve of the sandwich structures with hybrid corrugated/foam core under mode I loading. Theor. Appl. Fract. Mech. 2018, 96, 326–333. [Google Scholar] [CrossRef]

- Tsokanas, P.; Loutas, T. Hygrothermal effect on the strain energy release rates and mode mixity of asymmetric delaminations in generally layered beams. Eng. Fract. Mech. 2019, 214, 390–409. [Google Scholar] [CrossRef]

- Rubiera, S.; Argüelles, A.; Viña, J.; Rocandio, C.; Bonhomme, J. Fracture behaviour under mixed mode I/II static and dynamic loading of ADCB specimens. J. Reinf. Plast. Compos. 2016, 35, 1513–1523. [Google Scholar] [CrossRef]

- Rubiera, S.; Argüelles, A.; Viña, J.; Rocandio, C. Study of the phenomenon of fatigue delamination in a carbon-epoxy composite under mixed mode I/II fracture employing an asymmetric specimen. Int. J. Fatigue 2018, 114, 74–80. [Google Scholar] [CrossRef]

- Rizov, V.; Mladensky, A. Elastic-plastic analysis of Asymmetric Double Cantilever Beam specimen. Int. J. Mech. Sci. 2015, 92, 44–51. [Google Scholar] [CrossRef]

- Murri, G.B. Evaluation of delamination growth characterization methods under mode I fatigue loading. In Proceedings of the 15th US-Japan Conference on Composites, Arlington, TX, USA, 1–3 October 2012. [Google Scholar]

- Azari, S.; Jhin, G.; Papini, M.; Spelt, J.K. Fatigue threshold and crack growth rate of adhesively bonded joints as a function of load/displacement ratio. Compos. Part A 2014, 57, 59–66. [Google Scholar] [CrossRef]

- Khan, R.; Alderliesten, R.; Badshah, S.; Benedictus, R. Effect of stress ratio or mean stress on fatigue delamination growth in composites: Critical review. Compos. Struct. 2015, 124, 214–227. [Google Scholar] [CrossRef]

- Pegorin, F.; Pingkarawat, K.; Mouritz, A.P. Mixed-mode I/II delamination fatigue strengthening of polymer composites using z-pins. Compos. Part B 2017, 123, 219–226. [Google Scholar] [CrossRef]

- El Amraoui, A.; El Gharad, A.; Bensalah, M.O. On stochastic evaluation of S-N models based on lifetime distribution. Appl. Math. Sci. 2014, 8, 1323–1331. [Google Scholar] [CrossRef]

- Barbosa, J.F.; Correia, J.A.F.O.; Freire Junior, R.C.S.; Zhu, S.-P.; De Jesus, A. Probabilistic S-N fields based on statistical distributions applied to metallic and composite materials: State of the art. Adv. Mech. Eng. 2019, 11, 1–22. [Google Scholar] [CrossRef]

- Apetre, N.; Arcari, A.; Dowling, N.; Iyyer, N.; Phan, N. Probabilistic model of mean stress effects in strain-life fatigue. Procedia Eng. 2015, 114, 538–545. [Google Scholar] [CrossRef]

- Castillo, E.; Fernández-Canteli, A. A general regression model for lifetime evaluation and prediction. Int. J. Fatigue 2001, 107, 117–137. [Google Scholar]

- Castillo, E.; Fernández-Canteli, A.; Pinto, H.; López-Aenlle, M. A general regression model for statistical analysis of strain life fatigue data. Mater. Lett. 2008, 62, 3639–3642. [Google Scholar] [CrossRef]

- Argüelles, A.; Coronado, P.; Canteli, A.F.; Viña, J.; Bonhomme, J. Using a statistical model for the analysis of the influence of the type of matrix carbon-epoxy composites on the fatigue delamination under modes I and II of fracture. Int. J. Fatigue 2013, 56, 54–59. [Google Scholar] [CrossRef]

- Mollón, V.; Bonhomme, J.; Viña, J.; Argüelles, A.; Fernández-Canteli, A. Influence of the principal tensile stresses on delamination fracture mechanisms and their associated morphology for different loading modes in carbon/epoxy composites. Compos. Part B 2012, 43, 1676–1680. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, J.; Liu, G.; Chen, P.; Guo, M. Controlling the crack propagation path of the veil interleaved composite by fusion-bonded dots. Polymers 2019, 11, 1260. [Google Scholar] [CrossRef] [PubMed]

- Al-Khudair, O.; Hadavinia, H.; Waggott, A.; Lewis, E.; Little, C. Characterising mode I/mode II fatigue delamination growth in unidirectional fibre reinforced polymer laminates. Mater. Des. 2015, 66, 93–102. [Google Scholar] [CrossRef]

- Marat-Mendes, R.; Freitas, M. Fractographic observation for various loading modes of fibre reinforced laminates. Mater. Sci. Forum 2013, 730, 337–342. [Google Scholar] [CrossRef]

- Blanco, N.; Gamstedt, F.; Asp, L.; Costa, J. Mixed mode delamination growth in carbon-fibre composite laminates under cyclic loading. Int. J. Solids Struct. 2004, 41, 4219–4235. [Google Scholar] [CrossRef]

- Baas, S. AG14, GARTEUR. In Fractography of Composites; GARTEUR TP (Group for Aeronautical Research and Technology in Europe Technical Report): Hoofddorp, The Netherlands, 1994; Volume 83, pp. 1–169. [Google Scholar]

- Jollivet, T.; Peyrac, C.; Lefebvre, F. Damage of composite materials. Procedia Eng. 2013, 66, 746–758. [Google Scholar] [CrossRef]

- Bonhomme, J.; Argüelles, A.; Viña, J.; Viña, I. Fractography and failure mechanisms in static mode I and mode II delamination testing of unidirectional carbon reinforced composites. Polym. Test. 2009, 28, 612–617. [Google Scholar] [CrossRef]

- Greenhalgh, F. Failure Analysis and Fractography of Polymer Composites; Cambridge Woodhead Publishing: Cambridge, UK, 2008. [Google Scholar]

| Elastic Moduli | Ultimate Tensile Stresses | Shear Modulus | Shear Strength | ||

|---|---|---|---|---|---|

| E11 (GPa) | E22 (GPa) | σ11 (MPa) | σ22 (MPa) | G12 (GPa) | τmax (MPa) |

| 174 | 13 | 2199 | 36 | 5.3 | 93 |

| Gc (J/m2) | GI (J/m2) | GII (J/m2) | ||||

|---|---|---|---|---|---|---|

| GII/Gc | 0.2 | 0.4 | 0.2 | 0.4 | 0.2 | 0.4 |

| Mean | 271 | 469 | 216 | 280 | 54 | 189 |

| S.D. | 23 | 36 | 19 | 21 | 4 | 15 |

| C.V. [%] | 8.5 | 7.6 | 8.8 | 7.5 | 7.4 | 7.9 |

| Gc (J/m2) | GI (J/m2) | GII (J/m2) | ||||

|---|---|---|---|---|---|---|

| GII/Gc | 0.2 | 0.34 | 0.2 | 0.34 | 0.2 | 0.34 |

| Mean | 372 | 480 | 285 | 320 | 87 | 161 |

| S.D. | 25 | 108 | 32 | 21 | 7 | 15 |

| C.V. [%] | 6.7 | 22.5 | 11.2 | 6.5 | 8.0 | 9.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Argüelles, A.; Rocandio, C.; Rubiera, S.; Viña, I.; Viña, J. Influence of the Test Method on the Characterization of the Fatigue Delamination Behavior of a Composite Material under Mixed Mode I/II Fracture. Polymers 2019, 11, 1788. https://doi.org/10.3390/polym11111788

Argüelles A, Rocandio C, Rubiera S, Viña I, Viña J. Influence of the Test Method on the Characterization of the Fatigue Delamination Behavior of a Composite Material under Mixed Mode I/II Fracture. Polymers. 2019; 11(11):1788. https://doi.org/10.3390/polym11111788

Chicago/Turabian StyleArgüelles, Antonio, Clara Rocandio, Silvia Rubiera, Isabel Viña, and Jaime Viña. 2019. "Influence of the Test Method on the Characterization of the Fatigue Delamination Behavior of a Composite Material under Mixed Mode I/II Fracture" Polymers 11, no. 11: 1788. https://doi.org/10.3390/polym11111788

APA StyleArgüelles, A., Rocandio, C., Rubiera, S., Viña, I., & Viña, J. (2019). Influence of the Test Method on the Characterization of the Fatigue Delamination Behavior of a Composite Material under Mixed Mode I/II Fracture. Polymers, 11(11), 1788. https://doi.org/10.3390/polym11111788