Applications of Highly Stretchable and Tough Hydrogels

Abstract

:1. Introduction

2. Highly Stretchable and Tough Hydrogels for Mechanical Sensing

2.1. Gauge Factor

2.2. Healing Time and Efficiency

2.3. Stretchability

3. Highly Stretchable and Tough Hydrogels for Wound Healing

3.1. Healing Properties

3.2. Adhesion Strength

3.3. Additional Mechanical Properties

4. Highly Stretchable and Tough Hydrogels for Drug Delivery

5. Conclusions

Funding

Conflicts of Interest

References

- Liao, I.-C.; Moutos, F.T.; Estes, B.T.; Zhao, X.; Guilak, F. Composite three-dimensional woven scaffolds with interpenetrating network hydrogels to create functional synthetic articular cartilage. Adv. Funct. Mater. 2013, 23, 5833–5839. [Google Scholar] [CrossRef] [PubMed]

- Zhou, M.; Smith, A.M.; Das, A.K.; Hodson, N.W.; Collins, R.F.; Ulijn, R.V.; Gough, J.E. Self-assembled peptide-based hydrogels as scaffolds for anchorage-dependent cells. Biomaterials 2009, 30, 2523–2530. [Google Scholar] [CrossRef] [PubMed]

- Nicolson, P.C.; Vogt, J. Soft contact lens polymers: An evolution. Biomaterials 2001, 22, 3273–3283. [Google Scholar] [CrossRef]

- Ta, H.T.; Dass, C.R.; Larson, I.; Choong, P.F.; Dunstan, D.E. A chitosan hydrogel delivery system for osteosarcoma gene therapy with pigment epithelium-derived factor combined with chemotherapy. Biomaterials 2009, 30, 4815–4823. [Google Scholar] [CrossRef]

- Jen, A.C.; Wake, M.C.; Mikos, A.G. Review: Hydrogels for cell immobilization. Biotechnol. Bioeng. 1996, 50, 357–364. [Google Scholar] [CrossRef]

- Yoshida, R.; Uchida, K.; Kaneko, Y.; Sakai, K.; Kikuchi, A.; Sakurai, Y.; Okano, T. Comb-type grafted hydrogels with rapid deswelling response to temperature changes. Nature 1995, 374, 240–242. [Google Scholar] [CrossRef]

- Irie, M.; Misumi, Y.; Tanaka, T. Stimuli-responsive polymers: Chemical induced reversible phase separation of an aqueous solution of poly(N-isopropylacrylamide) with pendent crown ether groups. Polymer 1993, 34, 4531–4535. [Google Scholar] [CrossRef]

- Lee, K.; Cussler, E.; Marchetti, M.; McHugh, M. Pressure-dependent phase transitions in hydrogels. Chem. Eng. Sci. 1990, 45, 766–767. [Google Scholar] [CrossRef]

- Bohon, K.; Krause, S. An electrorheological fluid and siloxane gel based electromechanical actuator: Working toward an artificial muscle. J. Polym. Sci. Part B Polym. Phys. 1998, 36, 1091–1094. [Google Scholar] [CrossRef]

- Horkay, F.; Tasaki, I.; Basser, P.J. Osmotic swelling of polyacrylate hydrogels in physiological salt solutions. Biomacromolecules 2000, 1, 84–90. [Google Scholar] [CrossRef]

- Gupta, K.M.; Barnes, S.R.; Tangaro, R.A.; Roberts, M.C.; Owen, D.H.; Katz, D.F.; Kiser, P.F. Temperature and pH Sensitive Hydrogels: An Approach Towards Smart Semen-Triggered Vaginal Microbicidal Vehicles. J. Pharm. Sci. 2007, 96, 670–681. [Google Scholar] [CrossRef] [PubMed]

- Hong, W.; Hu, X.; Zhao, B.; Zhang, F.; Zhang, D. Tunable Photonic Polyelectrolyte Colorimetric Sensing for Anions, Cations and Zwitterions. Adv. Mater. 2010, 22, 5043–5047. [Google Scholar] [CrossRef] [PubMed]

- Caló, E.; Khutoryanskiy, V.V. Biomedical applications of hydrogels: A review of patents and commercial products. Eur. Polym. J. 2015, 65, 252–267. [Google Scholar] [CrossRef] [Green Version]

- Sidorenko, A.; Krupenkin, T.; Taylor, A.; Fratzl, P.; Aizenberg, J. Reversible Switching of Hydrogel-Actuated Nanostructures into Complex Micropatterns. Science 2007, 315, 487–490. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maeda, S.; Hara, Y.; Sakai, T.; Yoshida, R.; Hashimoto, S. Self-Walking Gel. Adv. Mater. 2007, 19, 3480–3484. [Google Scholar] [CrossRef]

- Gong, J.P.; Katsuyama, Y.; Kurokawa, T.; Osada, Y. Double-Network Hydrogels with Extremely High Mechanical Strength. Adv. Mater. 2003, 15, 1155–1158. [Google Scholar] [CrossRef]

- Sanabria-DeLong, N.; Crosby, A.J.; Tew, G.N. Photo-Cross-Linked PLA-PEO-PLA Hydrogels from Self-Assembled Physical Networks: Mechanical Properties and Influence of Assumed Constitutive Relationships. Biomacromolecules 2008, 9, 2784–2791. [Google Scholar] [CrossRef] [Green Version]

- Branco, M.C.; Nettesheim, F.; Pochan, D.J.; Schneider, J.P.; Wagner, N.J. Fast Dynamics of Semiflexible Chain Networks of Self-Assembled Peptides. Biomacromolecules 2009, 10, 1374–1380. [Google Scholar] [CrossRef] [Green Version]

- Qiao, Z.; Cao, M.; Michels, K.; Hoffman, L.; Ji, H.-F. Design and Fabrication of Highly Stretchable and Tough Hydrogels. Polym. Rev. 2019, in press. [Google Scholar]

- Frutiger, A.; Muth, J.T.; Vogt, D.M.; Mengüç, Y.; Campo, A.; Valentine, A.D.; Walsh, C.J.; Lewis, J.A. Capacitive Soft Strain Sensors via Multicore-Shell Fiber Printing. Adv. Mater. 2015, 27, 2440–2446. [Google Scholar] [CrossRef]

- Cai, G.; Wang, J.; Qian, K.; Chen, J.; Li, S.; Lee, P.S. Extremely Stretchable Strain Sensors Based on Conductive Self-Healing Dynamic Cross-Links Hydrogels for Human-Motion Detection. Adv. Sci. 2016, 4, 1600190. [Google Scholar] [CrossRef] [Green Version]

- Wang, T.; Zhang, Y.; Liu, Q.; Cheng, W.; Wang, X.; Pan, L.; Xu, B.; Xu, H. A Self-Healable, Highly Stretchable, and Solution Processable Conductive Polymer Composite for Ultrasensitive Strain and Pressure Sensing. Adv. Funct. Mater. 2018, 28, 1705551. [Google Scholar] [CrossRef]

- Zhang, Y.-Z.; Lee, K.H.; Anjum, D.H.; Sougrat, R.; Jiang, Q.; Kim, H.; Alshareef, H.N. MXenes stretch hydrogel sensor performance to new limits. Sci. Adv. 2018, 4, eaat0098. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, S.; Zheng, R.; Chen, S.; Wu, Y.; Liu, H.; Wang, P.; Deng, Z.; Liu, L. A compliant, self-adhesive and self-healing wearable hydrogel as epidermal strain sensor. J. Mater. Chem. C 2018, 6, 4183–4190. [Google Scholar] [CrossRef]

- Shao, C.; Wang, M.; Meng, L.; Chang, H.; Wang, B.; Xu, F.; Yang, J.; Wan, P. Mussel-Inspired Cellulose Nanocomposite Tough Hydrogels with Synergistic Self-Healing, Adhesive, and Strain-Sensitive Properties. Chem. Mater. 2018, 30, 3110–3121. [Google Scholar] [CrossRef]

- Zhang, J.; Wan, L.; Gao, Y.; Fang, X.; Lu, T.; Pan, L.; Xuan, F. Highly Stretchable and Self-Healable MXene/Polyvinyl Alcohol Hydrogel Electrode for Wearable Capacitive Electronic Skin. Adv. Electron. Mater. 2019, 5, 1900285. [Google Scholar] [CrossRef]

- Zhou, H.; Zheng, S.; Qu, C.; Wang, D.; Liu, C.; Wang, Y.; Fan, X.; Xiao, W.; Li, H.; Zhao, D.; et al. Simple and environmentally friendly approach for preparing high-performance polyimide precursor hydrogel with fully aromatic structures for strain sensor. Eur. Polym. J. 2019, 114, 346–352. [Google Scholar] [CrossRef]

- Darabi, M.A.; Khosrozadeh, A.; Mbeleck, R.; Liu, Y.; Chang, Q.; Jiang, J.; Cai, J.; Wang, Q.; Luo, G.; Xing, M. Skin-Inspired Multifunctional Autonomic-Intrinsic Conductive Self-Healing Hydrogels with Pressure Sensitivity, Stretchability, and 3D Printability. Adv. Mater. 2017, 29, 1700533. [Google Scholar] [CrossRef]

- Liu, Y.-J.; Cao, W.-T.; Ma, M.-G.; Wan, P. Ultrasensitive Wearable Soft Strain Sensors of Conductive, Self-healing, and Elastic Hydrogels with Synergistic “Soft and Hard” Hybrid Networks. ACS Appl. Mater. Interfaces 2017, 9, 25559–25570. [Google Scholar] [CrossRef]

- Wang, Q.; Pan, X.; Lin, C.; Lin, D.; Ni, Y.; Chen, L.; Huang, L.; Cao, S.; Ma, X. Biocompatible, self-wrinkled, antifreezing and stretchable hydrogel-based wearable sensor with PEDOT:sulfonated lignin as conductive materials. Chem. Eng. J. 2019, 370, 1039–1047. [Google Scholar] [CrossRef]

- González-Domínguez, J.M.; Martín, C.; Durá, Ó.J.; Merino, S.; Vázquez, E. Smart Hybrid Graphene Hydrogels: A Study of the Different Responses to Mechanical Stretching Stimulus. ACS Appl. Mater. Interfaces 2018, 10, 1987–1995. [Google Scholar] [CrossRef] [PubMed]

- Tian, K.; Bae, J.; Bakarich, S.E.; Yang, C.; Gately, R.D.; Spinks, G.M.; in het Panhuis, M.; Suo, Z.; Vlassak, J.J. 3D Printing of Transparent and Conductive Heterogeneous Hydrogel—Elastomer Systems. Adv. Mater. 2017, 29, 1604827. [Google Scholar] [CrossRef] [PubMed]

- Jing, X.; Mi, H.-Y.; Peng, X.-F.; Turng, L.-S. Biocompatible, self-healing, highly stretchable polyacrylic acid/reduced graphene oxide nanocomposite hydrogel sensors via mussel-inspired chemistry. Carbon 2018, 136, 63–72. [Google Scholar] [CrossRef]

- Jing, X.; Mi, H.-Y.; Lin, Y.-J.; Enriquez, E.; Peng, X.-F.; Turng, L.-S. Highly Stretchable and Biocompatible Strain Sensors Based on Mussel-Inspired Super-Adhesive Self-Healing Hydrogels for Human Motion Monitoring. ACS Appl. Mater. Interfaces 2018, 10, 20897–20909. [Google Scholar] [CrossRef]

- Lin, S.; Yuk, H.; Zhang, T.; Parada, G.A.; Koo, H.; Yu, C.; Zhao, X. Stretchable Hydrogel Electronics and Devices. Adv. Mater. 2016, 28, 4497–4505. [Google Scholar] [CrossRef]

- Bai, R.; Yang, Q.; Tang, J.; Morelle, X.P.; Vlassak, J.; Suo, Z. Fatigue fracture of tough hydrogels. Extrem. Mech. Lett. 2017, 15, 91–96. [Google Scholar] [CrossRef]

- Morelle, X.P.; Illeperuma, W.R.; Tian, K.; Bai, R.; Suo, Z.; Vlassak, J.J. Highly Stretchable and Tough Hydrogels below Water Freezing Temperature. Adv. Mater. 2018, 30, 1801541. [Google Scholar] [CrossRef]

- Guo, J.; Liu, X.; Jiang, N.; Yetisen, A.K.; Yuk, H.; Yang, C.; Khademhosseini, A.; Zhao, X.; Yun, S.-H. Highly Stretchable, Strain Sensing Hydrogel Optical Fibers. Adv. Mater. 2016, 28, 10244–10249. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, X.; Wang, J.; Tang, J.; Hu, J.; Lu, T.; Suo, Z. Fatigue of double-network hydrogels. Eng. Fract. Mech. 2018, 187, 74–93. [Google Scholar] [CrossRef]

- Ge, G.; Zhang, Y.; Shao, J.; Wang, W.; Si, W.; Huang, W.; Dong, X. Stretchable, Transparent, and Self-Patterned Hydrogel-Based Pressure Sensor for Human Motions Detection. Adv. Funct. Mater. 2018, 28, 1802576. [Google Scholar] [CrossRef]

- Peng, H.; Xin, Y.; Xu, J.; Liu, H.; Zhang, J. Ultra-stretchable hydrogels with reactive liquid metals as asymmetric force-sensors. Mater. Horiz. 2019, 6, 618–625. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, H.; Lai, J.; Yan, B.; Liu, H.; Jin, X.; Ma, A.; Zhang, G.; Zhao, W.; Chen, W. Extremely stretchable and electrically conductive hydrogels with dually synergistic networks for wearable strain sensors. J. Mater. Chem. C 2018, 6, 9200–9207. [Google Scholar] [CrossRef]

- Liu, H.; Li, M.; Ouyang, C.; Lu, T.J.; Li, F.; Xu, F. Biofriendly, Stretchable, and Reusable Hydrogel Electronics as Wearable Force Sensors. Small 2018, 14, e1801711. [Google Scholar] [CrossRef] [PubMed]

- Yang, B.; Yuan, W. Highly Stretchable and Transparent Double-Network Hydrogel Ionic Conductors as Flexible Thermal–Mechanical Dual Sensors and Electroluminescent Devices. ACS Appl. Mater. Interfaces 2019, 11, 16765–16775. [Google Scholar] [CrossRef]

- Sarwar, M.S.; Dobashi, Y.; Preston, C.; Wyss, J.K.M.; Mirabbasi, S.; Madden, J.D.W. Bend, stretch, and touch: Locating a finger on an actively deformed transparent sensor array. Sci. Adv. 2017, 3, e1602200. [Google Scholar] [CrossRef] [PubMed]

- Kim, C.-C.; Lee, H.-H.; Oh, K.H.; Sun, J.-Y. Highly stretchable, transparent ionic touch panel. Science 2016, 353, 682–687. [Google Scholar] [CrossRef]

- Larson, C.; Peele, B.; Li, S.; Robinson, S.; Totaro, M.; Beccai, L.; Mazzolai, B.; Shepherd, R. Highly stretchable electroluminescent skin for optical signaling and tactile sensing. Science 2016, 351, 1071–1074. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Tang, T.-C.; Tham, E.; Yuk, H.; Lin, S.; Lu, T.K.; Zhao, X. Stretchable living materials and devices with hydrogel–elastomer hybrids hosting programmed cells. Proc. Natl. Acad. Sci. USA 2017, 114, 2200. [Google Scholar] [CrossRef]

- Wu, Q.; Wei, J.; Xu, B.; Liu, X.; Wang, H.; Wang, W.; Wang, Q.; Liu, W. A robust, highly stretchable supramolecular polymer conductive hydrogel with self-healability and thermo-processability. Sci. Rep. 2017, 7, 41566. [Google Scholar] [CrossRef] [Green Version]

- Jing, X.; Li, H.; Mi, H.-Y.; Liu, Y.-J.; Feng, P.-Y.; Tan, Y.-M.; Turng, L.-S. Highly transparent, stretchable, and rapid self-healing polyvinyl alcohol/cellulose nanofibril hydrogel sensors for sensitive pressure sensing and human motion detection. Sens. Actuators B Chem. 2019, 295, 159–167. [Google Scholar] [CrossRef]

- Yang, N.; Qi, P.; Ren, J.; Yu, H.; Liu, S.-X.; Li, J.; Chen, W.; Kaplan, D.L.; Ling, S. Polyvinyl Alcohol/Silk Fibroin/Borax Hydrogel Ionotronics: A Highly Stretchable, Self-Healable, and Biocompatible Sensing Platform. ACS Appl. Mater. Interfaces 2019, 11, 23632–23638. [Google Scholar] [CrossRef] [PubMed]

- Ten Hallers, E.J.O.; Jansen, J.A.; Marres, H.A.M.; Rakhorst, G.; Verkerke, G.J. Histological assessment of titanium and polypropylene fiber mesh implantation with and without fibrin tissue glue. J. Biomed. Mater. Res. Part A 2007, 80, 372–380. [Google Scholar] [CrossRef]

- Liu, Y.; Meng, H.; Konst, S.; Sarmiento, R.; Rajachar, R.; Lee, B.P. Injectable Dopamine-Modified Poly(ethylene glycol) Nanocomposite Hydrogel with Enhanced Adhesive Property and Bioactivity. ACS Appl. Mater. Interfaces 2014, 6, 16982–16992. [Google Scholar] [CrossRef]

- Sierra, D.H. Fibrin Sealant Adhesive Systems: A Review of Their Chemistry, Material Properties and Clinical Applications. J. Biomater. Appl. 1993, 7, 309–352. [Google Scholar] [CrossRef] [PubMed]

- Wallace, D.G.; Cruise, G.M.; Rhee, W.M.; Schroeder, J.A.; Prior, J.J.; Ju, J.; Maroney, M.; Duronio, J.; Ngo, M.H.; Estridge, T.; et al. A tissue sealant based on reactive multifunctional polyethylene glycol. J. Biomed. Mater. Res. 2001, 58, 545–555. [Google Scholar] [CrossRef]

- Fortelny, R.H.; Petter-Puchner, A.H.; Walder, N.; Mittermayr, R.; Öhlinger, W.; Heinze, A.; Redl, H. Cyanoacrylate tissue sealant impairs tissue integration of macroporous mesh in experimental hernia repair. Surg. Endosc. 2007, 21, 1781–1785. [Google Scholar] [CrossRef]

- Vakalopoulos, K.A.; Wu, Z.; Kroese, L.; Kleinrensink, G.J.; Jeekel, J.; Vendamme, R.; Dodou, D.; Lange, J.F. Mechanical strength and rheological properties of tissue adhesives with regard to colorectal anastomosis: An ex vivo study. Ann. Surg. 2015, 261, 323–331. [Google Scholar] [CrossRef] [PubMed]

- Sakai, S.; Tsumura, M.; Inoue, M.; Koga, Y.; Fukano, K.; Taya, M. Polyvinyl alcohol-based hydrogel dressing gellable on-wound via a co-enzymatic reaction triggered by glucose in the wound exudate. J. Mater. Chem. B 2013, 1, 5067. [Google Scholar] [CrossRef]

- Le, T.M.D.; Duong, H.T.T.; Thambi, T.; Phan, V.G.; Jeong, J.H.; Lee, D.S. Bioinspired pH- and Temperature-Responsive Injectable Adhesive Hydrogels with Polyplexes Promotes Skin Wound Healing. Biomacromolecules 2018, 19, 3536–3548. [Google Scholar] [CrossRef]

- Qu, J.; Zhao, X.; Liang, Y.; Zhang, T.; Ma, P.X.; Guo, B. Antibacterial adhesive injectable hydrogels with rapid self-healing, extensibility and compressibility as wound dressing for joints skin wound healing. Biomaterials 2018, 183, 185–199. [Google Scholar] [CrossRef]

- Ballance, W.C.; Seo, Y.; Baek, K.; Chalifoux, M.; Kim, D.; Kong, H. Stretchable, anti-bacterial hydrogel activated by large mechanical deformation. J. Control. Release 2018, 275, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Celiz, A.D.; Yang, J.; Yang, Q.; Wamala, I.; Whyte, W.; Seo, B.R.; Vasilyev, N.V.; Vlassak, J.J.; Suo, Z.; et al. Tough adhesives for diverse wet surfaces. Science 2017, 357, 378–381. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Han, L.; Lu, X.; Liu, K.; Wang, K.; Fang, L.; Weng, L.-T.; Zhang, H.; Tang, Y.; Ren, F.; Zhao, C.; et al. Mussel-Inspired Adhesive and Tough Hydrogel Based on Nanoclay Confined Dopamine Polymerization. ACS Nano 2017, 11, 2561–2574. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Q.; Chen, T.; Li, M.; Feng, B.; Weng, J.; Duan, K.; Peng, W.; Wang, J. A dynamic-coupling-reaction-based autonomous self-healing hydrogel with ultra-high stretching and adhesion properties. J. Mater. Chem. B 2019, 7, 3044–3052. [Google Scholar] [CrossRef]

- He, X.; Liu, L.; Han, H.; Shi, W.; Yang, W.; Lu, X. Bioinspired and Microgel-Tackified Adhesive Hydrogel with Rapid Self-Healing and High Stretchability. Macromolecules 2019, 52, 72–80. [Google Scholar] [CrossRef]

- Fukao, K.; Nonoyama, T.; Kiyama, R.; Furusawa, K.; Kurokawa, T.; Nakajima, T.; Gong, J.P. Anisotropic Growth of Hydroxyapatite in Stretched Double Network Hydrogel. ACS Nano 2017, 11, 12103–12110. [Google Scholar] [CrossRef]

- Guvendiren, M.; Messersmith, P.B.; Shull, K.R. Self-Assembly and Adhesion of DOPA-Modified Methacrylic Triblock Hydrogels. Biomacromolecules 2008, 9, 122–128. [Google Scholar] [CrossRef]

- Chen, T.; Chen, Y.; Rehman, H.U.; Chen, Z.; Yang, Z.; Wang, M.; Li, H.; Liu, H. Ultratough, Self-Healing, and Tissue-Adhesive Hydrogel for Wound Dressing. ACS Appl. Mater. Interfaces 2018, 10, 33523–33531. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Q.; Ge, J.; Liu, Z. Controlled display of enzyme activity with a stretchable hydrogel. Chem. Commun. 2013, 49, 9815. [Google Scholar] [CrossRef]

- Park, S.-J.; Lim, H.-S.; Lee, Y.M.; Suh, K.-D. Facile synthesis of monodisperse poly(MAA/EGDMA)/Fe3O4 hydrogel microspheres with hollow structures for drug delivery systems: The hollow structure formation mechanism and effects of various metal ions on structural changes. RSC Adv. 2015, 5, 10081–10088. [Google Scholar] [CrossRef]

- Di, J.; Yao, S.; Ye, Y.; Cui, Z.; Yu, J.; Ghosh, T.K.; Zhu, Y.; Gu, Z. Stretch-Triggered Drug Delivery from Wearable Elastomer Films Containing Therapeutic Depots. ACS Nano 2015, 9, 9407–9415. [Google Scholar] [CrossRef] [PubMed]

| Gel | Problems of Traditional Gels that the New Gel Tried to Fix | Design Strategy of the New Gel in the Paper | Gauge Factor (Strain %) | Healing Time and Efficiency | Mechanical Properties | Year | Ref. |

|---|---|---|---|---|---|---|---|

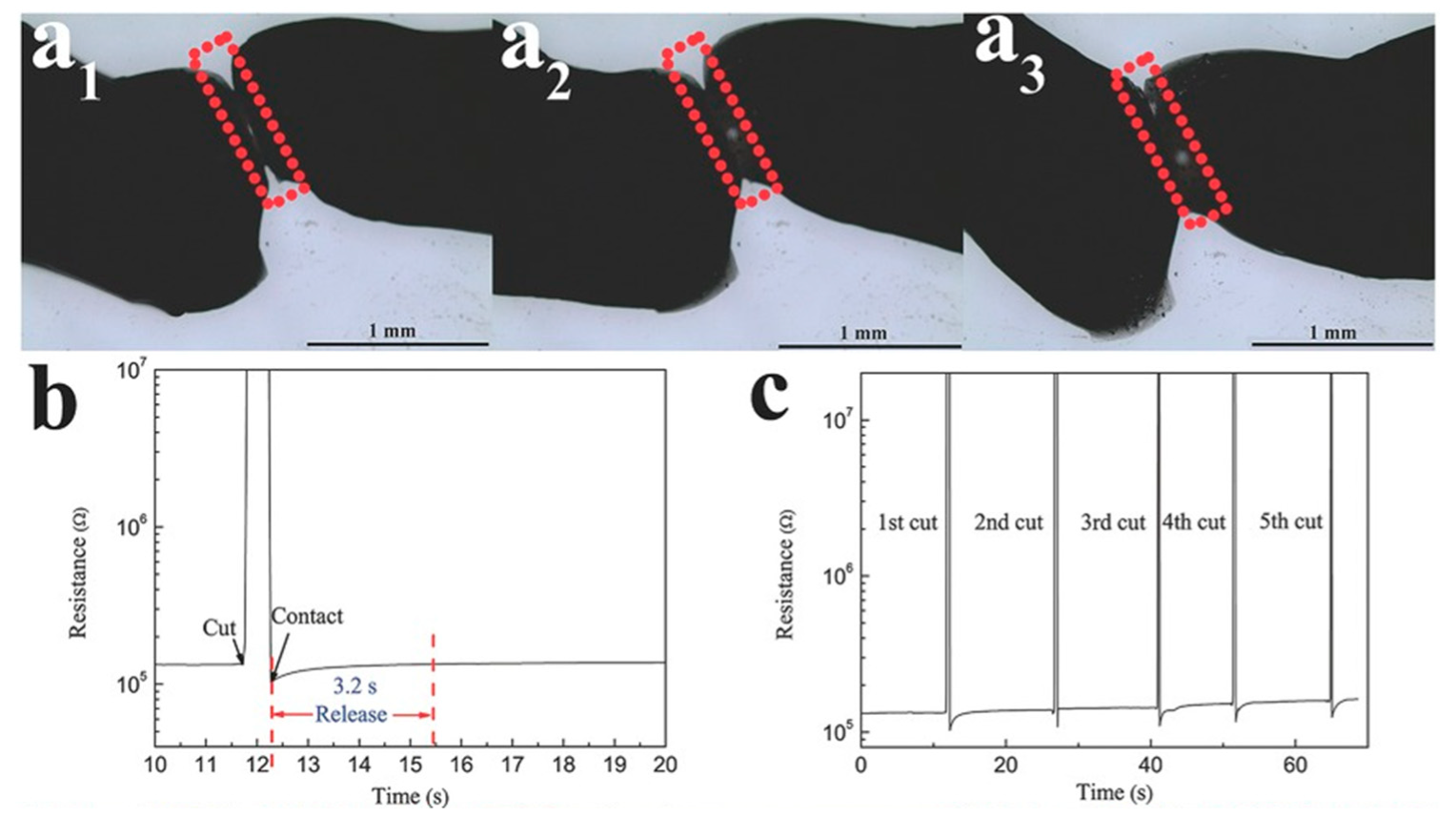

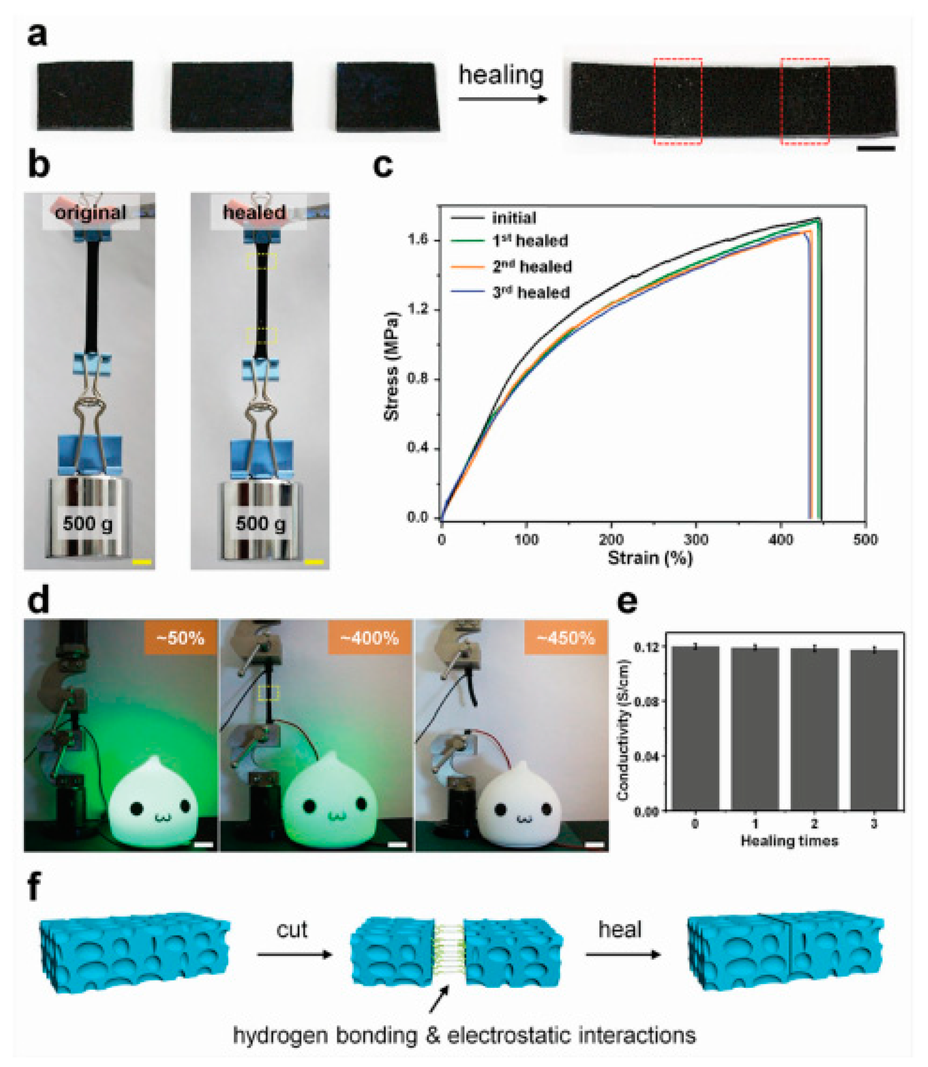

| PVA/SWCNT | No sensing properties over 100% strain, Low Gauge Factor | Introduce SWCNT to increase stretchability, gauge factor, and recovery | 0.24 (100%) 1.51 (1000%) | Electrical Healing: 3.2 s Appearance: 30–60 s Self-Healing Efficiency: ~98% | No change in sensor properties after 1000 cycles at 700% strain Excellent Sensing Performance | 2016 | [21] |

| PVA/Graphene | No sensing properties over 100% strain, Low Gauge Factor | Introduce Graphene to increase stretchability, gauge factor, and recovery | 0.92 (1000%) | - | Excellent Sensing Performance | 2016 | [21] |

| PVA/Silver Nanowire | No sensing properties over 100% strain, Low Gauge Factor | Introduce Silver Nanowire to increase stretchability, gauge factor, and recovery | 2.25 (1000%) | Silver nanowire is easily oxidized by air and water | Excellent Sensing Performance | 2016 | [21] |

| Aromatic Polyamic Acid Salt (PAAS) Hydrogel | Poor Mechanical Properties, Preparation is toxic | Prepare in an environmentally friendly way, Adding p-PDA/s-BPDA enhance mechanical properties | - | Self-healed within 1 min at room temperature | Mechanical stress of 500 kPa at 1350% strain, Storage Modulus of 5 × 105 Pa | 2019 | [27] |

| DCh/PPy/PAA | Low Conductivity, Sensitivity, Mechanical Recovery | Create a mechanically/electrically self-healing hydrogel with pressure/extension sensitivity | - | Mechanical Recovery: 2 min 90% Electrical Recovery: 30 s | Conductivity increases with strength of compression on Hydrogel | 2017 | [28] |

| PVA/PVP/Fe3+ | Low Mechanical Properties, Self-healability, sensitivity | Fabricate a conductive, elastic, self-healing, and strain-sensitive hydrogel | 0.478 (200%) | Self-healing within 5 min, and self-recovery within 30 min | Mechanical Strength of 2.1 MPa of tensile stress | 2017 | [29] |

| PVA/PDA | Low Detection Ranges and sensitivity | A low-modulus PVA hydrogel that is self-healing, PDA makes the hydrogel self-adhesive | - | Self-Healing in 250 ms at ambient temperature | High Sensing Performance in the ranges of Ultralow (0.1%) to High (500%) Strain | 2018 | [24] |

| PEDOT:SL/PAA | Not wearable, Insensitive to pressure/strain Can freeze at subzero temperatures | PEDOT:SL improves softness and elasticity-promotes strain sensitivity | 7 (100%) | - | Stretched to 7 times original length, recovers with negligible residual strain | 2019 | [30] |

| PAAm/Graphene | Poor mechanical consistence and electrical conductivity | Hydrogel acts as potential scaffold for neuronal growth | 9 (30%) | - | Conductivity:5.4 × 10−5 S/cm | 2018 | [31] |

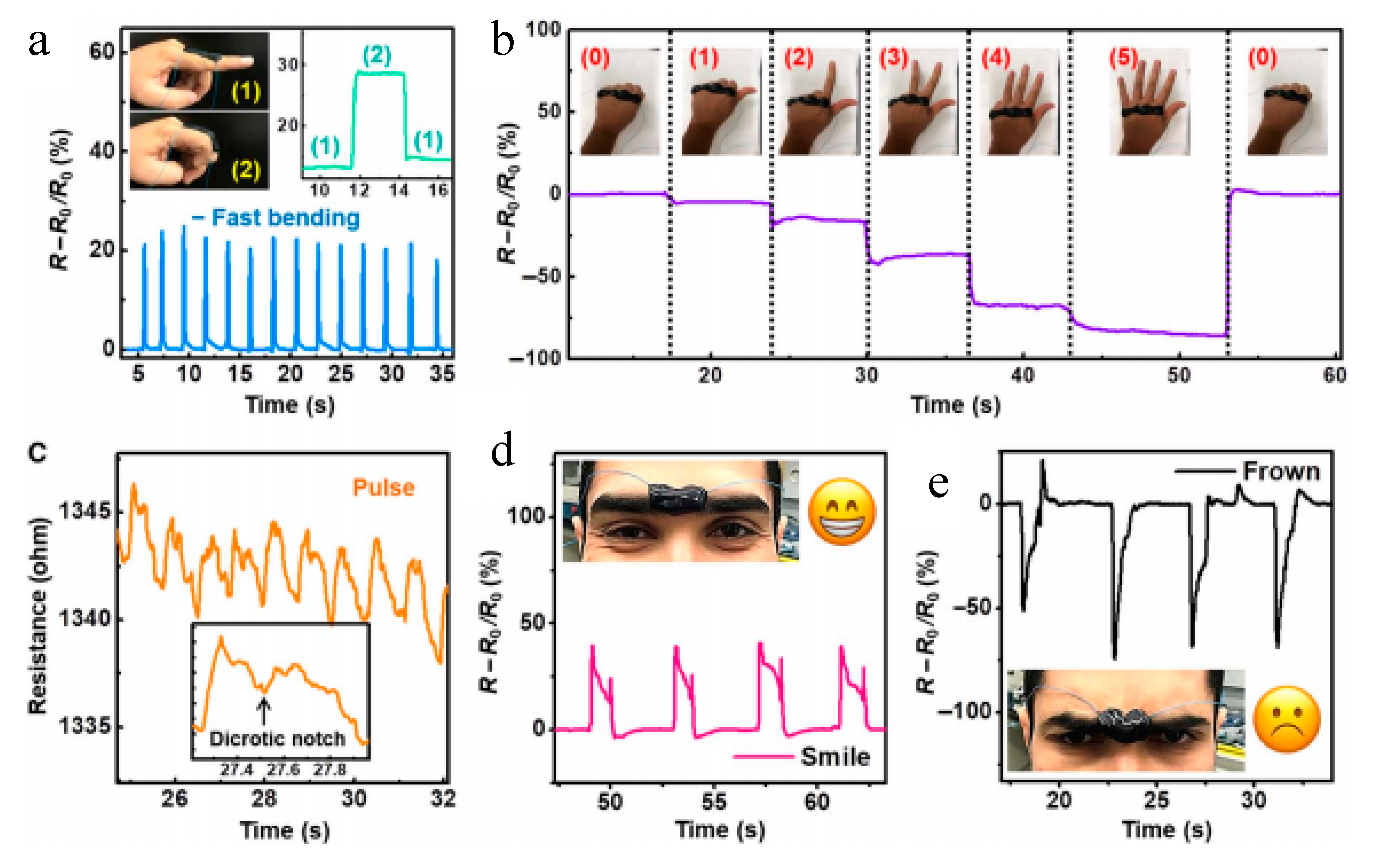

| PAA/PANI | Self-healing electronics have low durability and stretchability | PANI-based self-healing electronic composite with high stretchability and electrical conductivity | 11.6 (Within 100%) 4.7 (Over 100%) | Electrical Conductivity Healing Efficiency: 88.2% in 5 min Mechanical Healing Efficiency: 24.3% in 5 min | Stretchability up to 400% Electrical Conductivity of 0.12 S/cm | 2018 | [22] |

| PAAm/LiCl | Ionogels have lower conductivity than hydrogels | Soft, stretchable electrical devices integrating a conductive hydrogel | 0.84 (40%) | - | Conductivity: 10.39 ± 0.31 S/m | 2017 | [32] |

| PAA/Graphene/Fe3+ | Low stretchability, self-healing, mechanical properties | Covalent bonds -strong, stable network for the hydrogel, Reduced graphene oxide and ions are highly sensitive | 0.31 (100%) 1.32 (500%) | Recovered nearly 100% initial conductivity | Resistance: 5.8 kΩ Strength: ~300 kPa at 45% strain Tensile Strength: ~400 kPa at 300% strain | 2018 | [33,34] |

| PAA/Al3+ | Poor mechanical properties, Require adhesives | Ions allow high sensitivity to large and subtle motions | 5.5 (100%) 7.8 (2000%) | Healing efficiency of 88% at 20 min and 92% at 30 min | Ultra-stretchability with a 2952% fracture strain, Compression Performance: 95% strain without fracture Toughness: 5.60 MJ/m3 | 2018 | [25] |

| Dopamine/Talc/PAAm (DTPAM) | Low stretchability and recoverability | Polydopamine-modified talc particles uniformly disperse in PAAm—Enhance mechanical properties/adhesiveness | 0.125 (100%) 0.693 (1000%) | Appearance healed after 30 min at room temperature | After healing, can still be stretched over 800% Strongly adhesive | 2018 | [34] |

| PAAm/Alginate | Low mechanical robustness and stretchability | PAAm and alginate form a ‘tough’ hydrogel that has a high stretchability and fracture toughness | - | - | Fracture Toughness of ~9000 J/m2 Fatigue Fracture of 53 J/m2 Cycle 1000: Constant resistance to high stretching | 2016 2017 | [35,36] |

| PAAm/Alginate/CaCl2 | Desired properties lost below freezing point of water | Gel soaked in 30 wt % CaCl2 retains stretchability/toughness/conductivity at below 0 °C | - | - | Fracture Toughness of ~5000 J/m2 | 2018 | [37] |

| PAAm/Alginate Optical Fibers | Fragile against external strain, Low mechanical strength | Make a tough hydrogel, which has high stretchability and mechanical strength | - | - | Fracture Energy of ~9000 J/m2 Can be elongated to 700% strain | 2016 | [38] |

| PAMPS/PAAm Double Network Gel | Single network hydrogels showed poor mechanical properties, Fatigue Damage under low cyclic load | Double Network hydrogels have outstanding mechanical properties | - | - | Average Toughness ~3358 J/m2, Fracture Energy 3779 J/m2, Fatigue Threshold 418 J/m2 | 2018 | [39] |

| PVA/PAAm | Low stretchability and sensitivity | Adhesive Wrinkled microarchitectures and interconnected ridges increase contact area | - | - | Stretchability up to 500%, Response time of 150 ms, Sensitivity of 0.05 kPa−1 at 0 to 3.27 kPa | 2018 | [40] |

| AAm/2-hydroxyethylacrylate/Liquid Gallium | Low sensitivity, limited stretchability, and poor stability | Use liquid metals as soft fillers in hydrophilic polymer networks to make highly stretchable, force-sensitive hydrogels | - | - | Tensile Strain ~1500%, Compressive Sensitivity of 0.25 kPa | 2019 | [41] |

| PAA/PANI | Limited by fragile and weak properties, like low flexibility | Highly Stretchable PAA/PANI hydrogel | 0.60 (0–800%) 1.05 (800–1130%) | - | Tensile Deformation: 1160% strain Sensing Range: 0 to 1130% | 2018 | [42] |

| PVA/MXene | Low sensitivity | MXenes have high conductivity and strain sensitivity. MXenes improve mechanical properties | 2, 0 wt % MXene (40%) 25, 4.1 wt % MXene (40%) | Instantaneous Self-Healing | Stretchability of 3400% Conformability and adhesive to various surfaces, including human skin | 2018 | [23] |

| PAAm/Alginate/Eutectic Gallium | Low Conductivity, Stretchability, High Power Consumption | Eutectic Gallium is highly conductive and used in a known tough hydrogel | - | - | Sensitivity of 100 Pa, can be rehydrated to most of its initial weight (>85%) after 30 drying/soaking cycles | 2018 | [43] |

| PAAm/Agar/LiCl | Low stretchability, Opaque, Poor Mechanical Strength | Conductive, Excellent mechanical properties, stretchability, and sensitivity, Transparent | 1.8 (1100%) | - | Stretchability over 1600%, Tension Strength: 0.22 MPa, Compression Strength: 3.5 MPa | 2019 | [44] |

| PDMS/AAm/NaCl | Capacitance and resistance are affected by stretch, bend, and pressure | Low Cost Materials and methods | - | - | Ionic Resistivity of 0.06 Ω | 2017 | [45] |

| PAAm/LiCl | Low Sheet Resistances and transparency, Brittle | Used as an ionic conductor | - | - | Can operate with over 1000% areal strain Elastic Modulus of 12 kPa | 2016 | [46] |

| PAAm/LiCl/Silicone | LED-based systems are limited by low ultimate strain | Fabricate a hyperelastic light-emitting capacitor (HLEC), using a hydrogel | - | - | Stretches to >480% strain | 2016 | [47] |

| PAAm/Alginate/PDMS | Low mechanical robustness and compatibility | Hydrogel–Elastomer Hybrid that is stretchable, robust, and biocompatible | - | - | - | 2017 | [48] |

| PNAGA-PAMPS/PEDOT-PSSa | Conductive Hydrogels (CHs) are mechanically weak and brittle | PNAGA hydrogels demonstrate high strength, thermoplasticity, and self-healability | - | Self-healed after 3 h in a plastic syringe immersed in a 90 °C water bath | 0.22–0.58 MPa tensile strength, 1.02–7.62 MPa compressive strength, 817–1709% breaking strain | 2017 | [49] |

| PVA/CNF | Low sensitivity, stretchability, self-healability, and transparency | Highly sensitive, stretchable, and autonomously self-healing ionic skin—biocompatible | - | Spontaneously Self-Healed in 15 s | Highly Transparent—Transmittance as high as 90%, Modulus of 11.2 kPa, Elongation Rate of 1900% | 2019 | [50] |

| PVA/Borax | Low stretchability, self-healing, water retention, biocompatibility | PVA and Borax: biocompatible/highly stretchable/easily dissolvable in aqueous solution/have good mechanical performance | - | Self-healed 10 times without affecting electrical conduction of gel | Can be stretched to strains over 5000% | 2019 | [51] |

| Gel | Problems the Gel Tried to Fix | Design Strategy | Healing Time | Adhesion Strength (kPa) | Conclusion | Year | Ref. |

|---|---|---|---|---|---|---|---|

| Tyrosine Hydrochloride Gel | Poor mechanical properties and self-healing properties | Use dynamic coupling reaction to improve adhesion and self-healing properties | Self 4 h: 25% 12 h: 68% 24 h: 100% | Pigskin: 453 Glass: 265 Stainless Steel: 265 PTFE:329 | This gel exhibited great self-healing abilities. | 2019 | [64] |

| MR/PAAc-PAM-PDA Hydrogel | Limited adhesion strength | Introduce MR to enhance adhesion and improve mechanical strength | - | 40 after 60 s | Stretch up to 660% at a tensile strength of 110 kPa. Good self-healing properties | 2019 | [65] |

| PEG-D4 Laponite Gel | Weak adhesion, poor biomechanical compatibility. | Add Laponite to PEG-D4 to promote bioactivity increase adhesion and mechanical properties | - | Wt % Laponite 0%: 3.5 1%: 7 2%: 8 | Injectable gel degrades nontoxically. Laponite increases adhesion strength. | 2014 | [53] |

| DOPA gel | Unknown effects of DOPA on cohesion and adhesion | Integrate DOPA to the gel to test cohesive and adhesive properties | - | - | Become worse in adhesion at higher pH levels. | 2008 | [67] |

| OSDA-DA-PAM Hydrogel | Poor mechanical property, lack of tissue adhesiveness | Crosslink OSA-DA and PAM chains to withstand large deformations | Self 6 h: 80% | - | Improved mechanical properties, Useful self-healing ability. | 2018 | [68] |

| PEG-PSMEU Hydrogel | Nuclease degradation, lack of membrane permeability | Combine PEG and PSMEU to better control mechanical properties | longitudinal cutaneous wounds: healed in 7 days | 90 | Higher copolymer concentration leads to higher adhesion strength. | 2018 | [59] |

| QCS/PF Gel | Questionable reliability of dressing materials on wound | Increasing content of PF127-CHO increases adhesive strength | - | 6.1 | Good blood-clotting ability | 2018 | [60] |

| Cur-QCS/PF Gel | Questionable reliability of dressing materials on wound | Loading the gel with Cur will result tunable antioxidant ability. Greater release rate | - | - | Better healing from greater release rate, Better Collagen levels after 15 days | 2018 | [60] |

| PAMPS/PAM DN Gel | Unable to be firmly fixed onto bones by glues. | Inducing bioceramic HAp on the gel surface for robust bonding to bone tissues. | - | - | Bonelike structure by controlling HAp crystal orientation. Bonded to bone tissue. | 2017 | [66] |

| PAM-cyclodextrin Gel | Nonstretchable PAM gel has intrinsic brittleness | Combine cyclodextrin acrylate to increase strain | - | - | Quinine inhibited growth of E. Coli. Stretched 16 times original | 2018 | [61] |

| PVA-Ph Hydrogel | Challenge in situ formation of hydrogel wound dressings | HRP-catalyzed reaction so the gel can form in situ on wound | 7 days: 77% 10 days: 96% | - | Gelated as quickly as 5 s. Easily pour onto wound. Retained mechanical properties. | 2013 | [58] |

| PDA-clay-PAM Hydrogel | Weak adhesive materials and poor mechanical properties | Adding PDA-intercalated clay nanosheets will make it more adhesive | - | Glass: 120 Ti:80.8 PE:80.7 Porcine Skin:28.5 | Strong adhesiveness, High stretchability, Good candidate for delicate surgical adhesive. | 2017 | [63] |

| Tough adhesives | Commercial adhesives have weak adhesion vulnerable to debonding | Fabricate family of tough adhesives that can adhere to wet surfaces. | - | On beating porcine heart: 83 | Hemostatic dressing possible, High adhesion energy High matrix toughness | 2018 | [62] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, Z.; Parks, J.; Choi, P.; Ji, H.-F. Applications of Highly Stretchable and Tough Hydrogels. Polymers 2019, 11, 1773. https://doi.org/10.3390/polym11111773

Qiao Z, Parks J, Choi P, Ji H-F. Applications of Highly Stretchable and Tough Hydrogels. Polymers. 2019; 11(11):1773. https://doi.org/10.3390/polym11111773

Chicago/Turabian StyleQiao, Zhen, Jesse Parks, Phillip Choi, and Hai-Feng Ji. 2019. "Applications of Highly Stretchable and Tough Hydrogels" Polymers 11, no. 11: 1773. https://doi.org/10.3390/polym11111773

APA StyleQiao, Z., Parks, J., Choi, P., & Ji, H.-F. (2019). Applications of Highly Stretchable and Tough Hydrogels. Polymers, 11(11), 1773. https://doi.org/10.3390/polym11111773