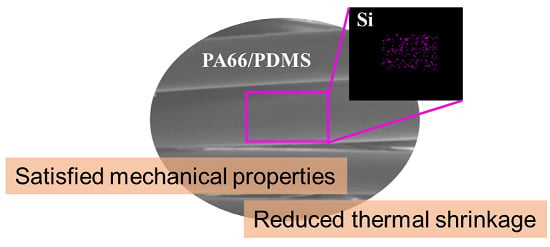

Influence of Incorporated Polydimethylsiloxane on Properties of PA66 Fiber and Its Fabric Performance

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of PA66/PDMS Blend Fibers

2.3. Methods

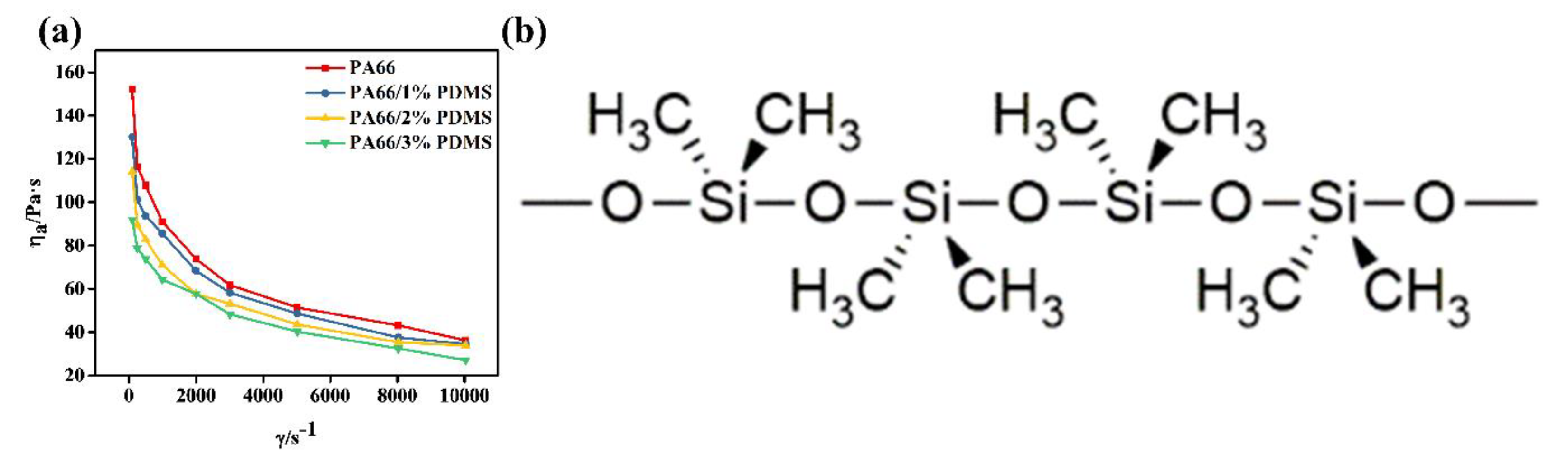

2.3.1. Capillary Rheological Performance Measurement of PA66/PDMS Blends

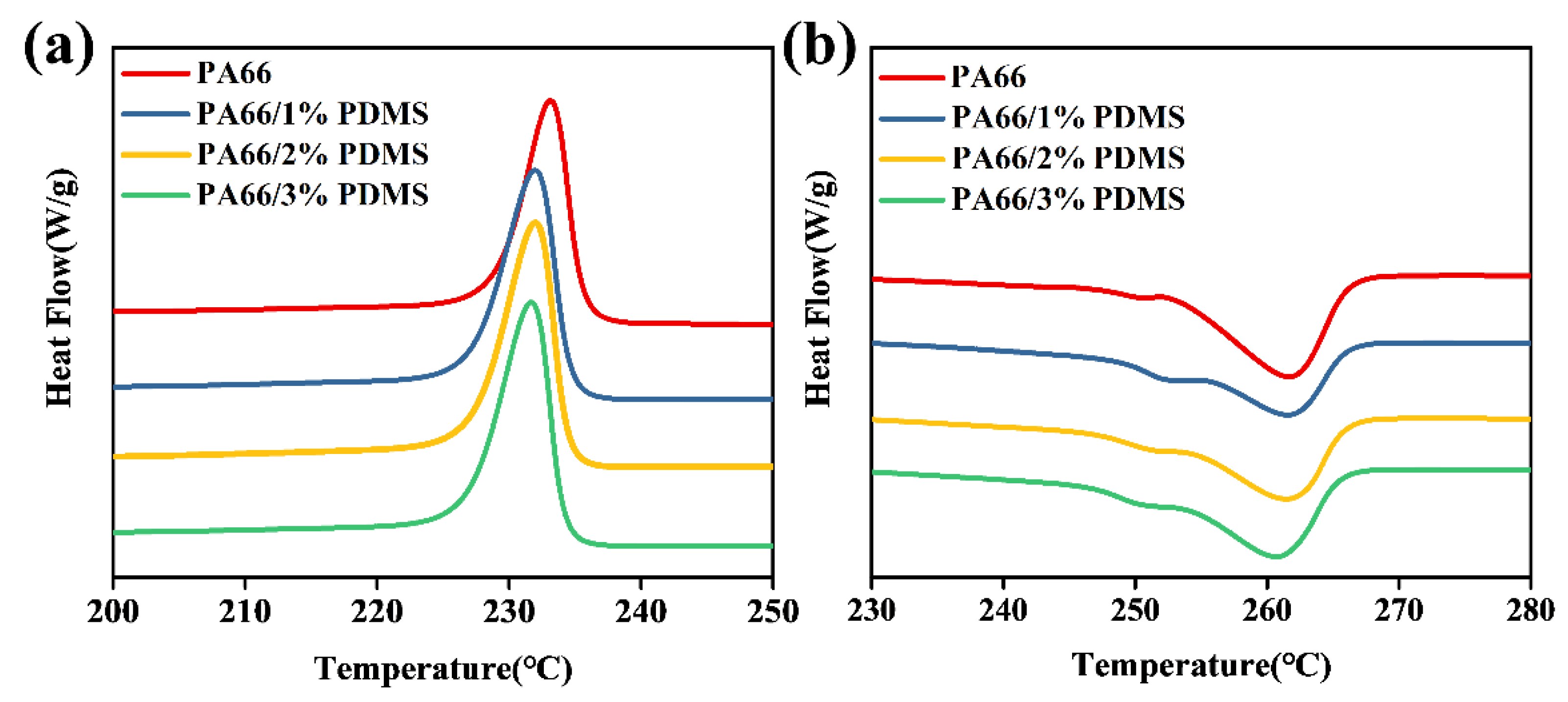

2.3.2. Differential Scanning Calorimetry (DSC)

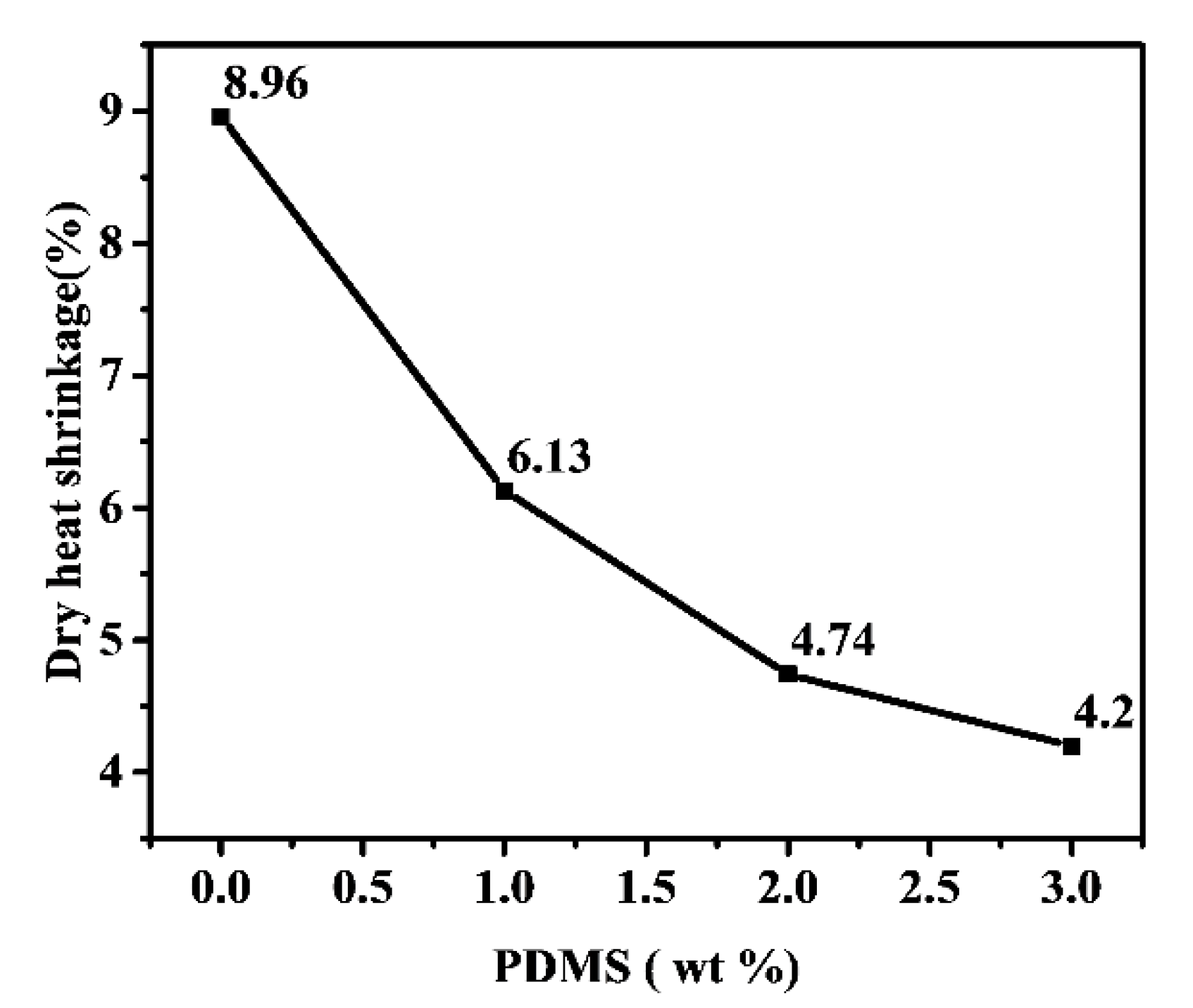

2.3.3. Thermal Shrinkage

2.3.4. Preparation of PA66/PDMS Blend Fibrous Fabric

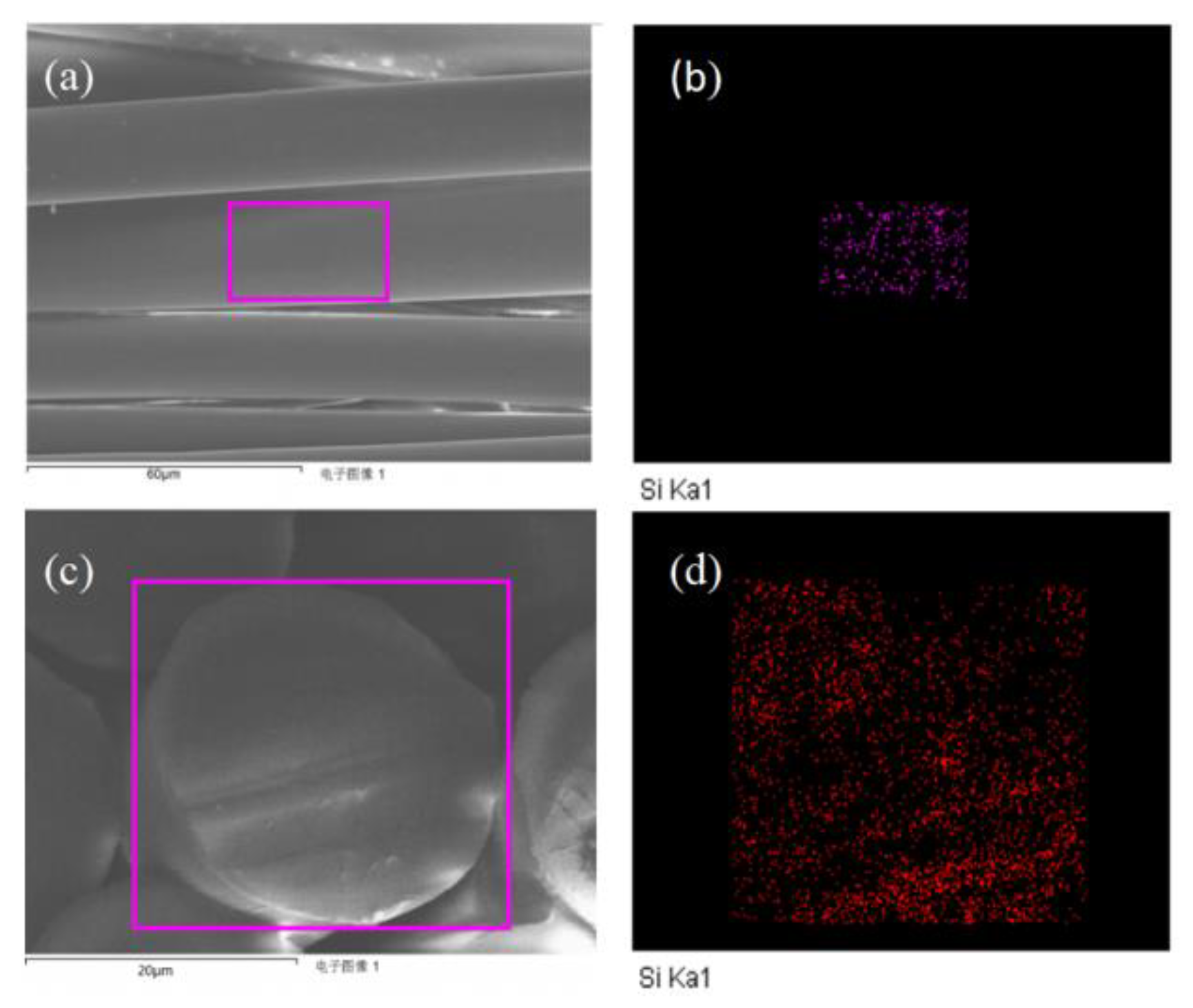

2.3.5. Silicon Analysis by Energy Dispersive Spectra-Meter (EDS)

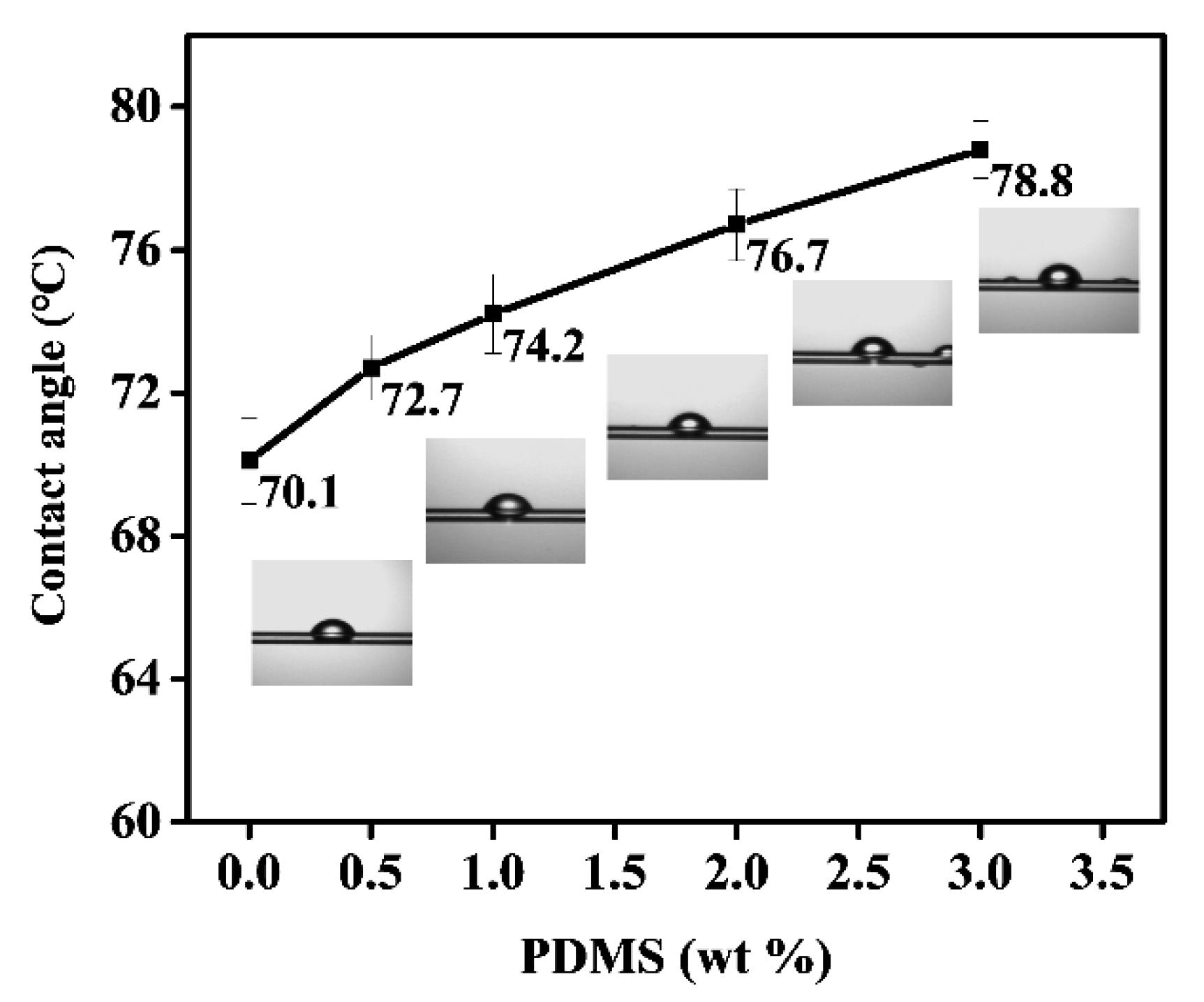

2.3.6. Water Contact Angle on Fiber

2.3.7. Friction Coefficient of Fiber Surface

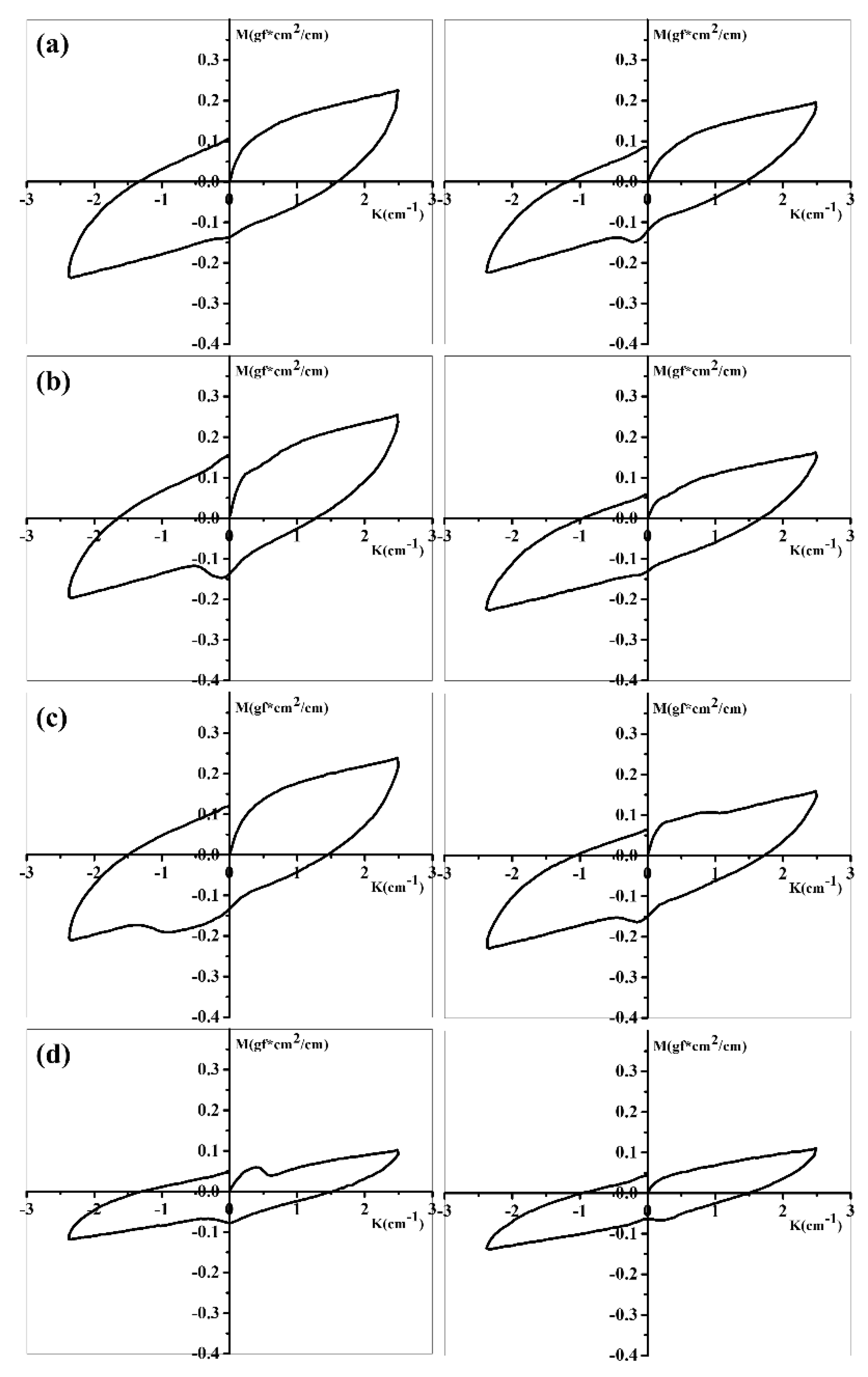

2.3.8. Bending Properties of Fabrics

2.3.9. Compression Performance of Fabrics

3. Results and Discussion

3.1. Effects of PDMS on Flowing Behavior of PA66 Melt

3.2. Thermal Properties of PA66/PDMS

3.3. Mechanical Properties of PA66/PDMS Blend Fibers

3.4. Surface Properties of PA66/PDMS Blend Fibers

3.5. Bending Deformation Properties of PA66/PDMS Blend Fibrous Fabrics

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Owen, M.J.; Evans, J.I. Industrial applications of the surface activity of polydimethylsiloxanes. Br. Polym. J. 1975, 7, 235–245. [Google Scholar] [CrossRef]

- Zięba, M.; Małysa, A.; Wasilewski, T.; Ogorzałek, M. Effects of Chemical Structure of Silicone Polyethers Used as Fabric Softener Additives on Selected Utility Properties of Cotton Fabric. Autex Res. J. 2019, 19, 1–7. [Google Scholar] [CrossRef]

- Kamelian, F.S.; Mohammadi, T.; Naeimpoor, F. Fast, facile and scalable fabrication of novel microporous silicalite-1/PDMS mixed matrix membranes for efficient ethanol separation by pervaporation. Sep. Purif. Technol. 2019, 229. [Google Scholar] [CrossRef]

- Li, S.; Liu, X.; Li, L.; Zhang, H.; Qiu, C. Drag-reductive and anti-corrosive superhydrophobic surface fabricated on aluminum with thin PDMS/SiO2 coating. Mater. Res. Express 2019, 6. [Google Scholar] [CrossRef]

- Hager, R. A Novel Product Concept: Silicone Gum Pekkets as Addutuves for Thermoplasts. Plast. Addit. 2004, 6, 6. [Google Scholar]

- Ji-min, S.U.; Xiao-rui, L.I.; Hai-hua, W.; Gui-qiang, F.E.I. Preparation of Organosilicon Emulsion Stabilized with Hydrophilic Polyether Silicon Oil and Its Defoaming and Foam Suppression Properties. Trans. China Pulp Pap. 2009, 24, 51–55. [Google Scholar]

- Jörn, D.; Kohorst, P.; Besdo, S.; Rücker, M.; Stiesch, M.; Borchers, L. Influence of lubricant on screw preload and stresses in a finite element model for a dental implant. J. Prosthet. Dent. 2014, 112, 340–348. [Google Scholar] [CrossRef] [PubMed]

- Wan, H.; Ye, Y.; Chen, L.; Chen, J.; Zhou, H. Influence of Polyfluo-Wax on the Friction and Wear Behavior of Polyimide/Epoxy Resin–Molybdenum Disulfide Bonded Solid Lubricant Coating. Tribol. Trans. 2016, 59, 889–895. [Google Scholar] [CrossRef]

- Zuber, M.; Zia, K.M.; Tabassum, S.; Jamil, T.; Barkaat-ul-Hasin, S.; Khosa, M.K. Preparation of rich handles soft cellulosic fabric using amino silicone based softener, part II: Colorfastness properties. Int. J. Biol. Macromol. 2011, 49, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Zia, K.M.; Tabassum, S.; Barkaat-ul-Hasin, S.; Zuber, M.; Jamil, T.; Jamal, M.A. Preparation of rich handles soft cellulosic fabric using amino silicone based softener. Part-I: Surface smoothness and softness properties. Int. J. Biol. Macromol. 2011, 48, 482–487. [Google Scholar] [CrossRef] [PubMed]

- Murugan, R.; Ramesh, R.; Padmanabhan, K. Influence of Stacking Sequence on Mechanical Properties and Vibration Characteristics of Glass/Carbon Hybrid Plates with Different Fabric Areal Densities. Struct. Integr. Assess. 2019, 87–97. [Google Scholar] [CrossRef]

- Katiyar, P.; Mishra, S.; Srivastava, A.; Prasad, N.E. Preparation of TiO2-SiO2 Hybrid Nanosols Coated Flame-Retardant Polyester Fabric Possessing Dual Contradictory Characteristics of Superhydrophobicity and Self Cleaning Ability. J. Nanosci. Nanotechnol. 2020, 20, 1780–1789. [Google Scholar] [CrossRef] [PubMed]

| Sample | Drawing Ratio | Tensile Strength (cN/dtex) | Elongation (%) |

|---|---|---|---|

| PA66 | 3.5 | 4.3 | 28.5 |

| PA66/0.5%PDMS | 3.5 | 4.5 | 35.2 |

| PA66/1%PDMS | 3.5 | 4.4 | 36.9 |

| PA66 | 3.7 | 4.5 | 26.9 |

| PA66/0.5%PDMS | 3.7 | 4.7 | 29.5 |

| PA66/1%PDMS | 3.7 | 4.7 | 30.4 |

| PA66 | 3.9 | 5.3 | 22.1 |

| PA66/0.5%PDMS | 3.9 | 5.5 | 23.9 |

| PA66/1%PDMS | 3.9 | 5.4 | 24.4 |

| PA66 | 4.1 | 5.6 | 18.6 |

| PA66/0.5%PDMS | 4.1 | 5.8 | 18.9 |

| PA66/1%PDMS | 4.1 | 5.7 | 19.1 |

| Sample | fs/10-3cN | µs | fd/10-3cN | µd |

|---|---|---|---|---|

| PA66 | 137.5 | 0.3712 | 127.0 | 0.3217 |

| PA66/1%PDMS | 110.8 | 0.2572 | 105.9 | 0.2404 |

| PA66/2%PDMS | 101.8 | 0.2276 | 98.2 | 0.2155 |

| PA66/3%PDMS | 99.8 | 0.2203 | 96.8 | 0.2110 |

| Sample | B (cN·cm2/cm) | 2HB (cN·cm/cm) | ||

|---|---|---|---|---|

| Warp | Weft | Warp | Weft | |

| PA66 | 0.0549 | 0.0496 | 0.2000 | 0.1656 |

| PA66/1% PDMS | 0.0571 | 0.0447 | 0.1967 | 0.1596 |

| PA66/2% PDMS | 0.0277 | 0.0322 | 0.2191 | 0.1741 |

| PA66/3% PDMS | 0.0283 | 0.0313 | 0.0872 | 0.0931 |

| Sample | LC | WC (cN·cm/cm2) | RC (%) |

|---|---|---|---|

| PA66 | 0.28 | 0.17 | 29.4 |

| PA66/1% PDMS | 0.25 | 0.17 | 31.6 |

| PA66/2% PDMS | 0.26 | 0.15 | 30.7 |

| PA66/3% PDMS | 0.22 | 0.12 | 33.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, W.; Qian, Y.; Zhou, T.; Yang, S.; Jin, J.; Li, G. Influence of Incorporated Polydimethylsiloxane on Properties of PA66 Fiber and Its Fabric Performance. Polymers 2019, 11, 1735. https://doi.org/10.3390/polym11111735

Peng W, Qian Y, Zhou T, Yang S, Jin J, Li G. Influence of Incorporated Polydimethylsiloxane on Properties of PA66 Fiber and Its Fabric Performance. Polymers. 2019; 11(11):1735. https://doi.org/10.3390/polym11111735

Chicago/Turabian StylePeng, Wei, Ying Qian, Tong Zhou, Shenglin Yang, Junhong Jin, and Guang Li. 2019. "Influence of Incorporated Polydimethylsiloxane on Properties of PA66 Fiber and Its Fabric Performance" Polymers 11, no. 11: 1735. https://doi.org/10.3390/polym11111735

APA StylePeng, W., Qian, Y., Zhou, T., Yang, S., Jin, J., & Li, G. (2019). Influence of Incorporated Polydimethylsiloxane on Properties of PA66 Fiber and Its Fabric Performance. Polymers, 11(11), 1735. https://doi.org/10.3390/polym11111735