Synthesis of K-Carrageenan Flame-Retardant Microspheres and Its Application for Waterborne Epoxy Resin with Functionalized Graphene

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

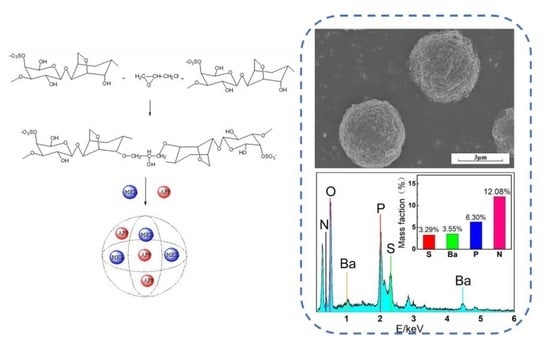

2.2.1. Synthesis of KC-IFR

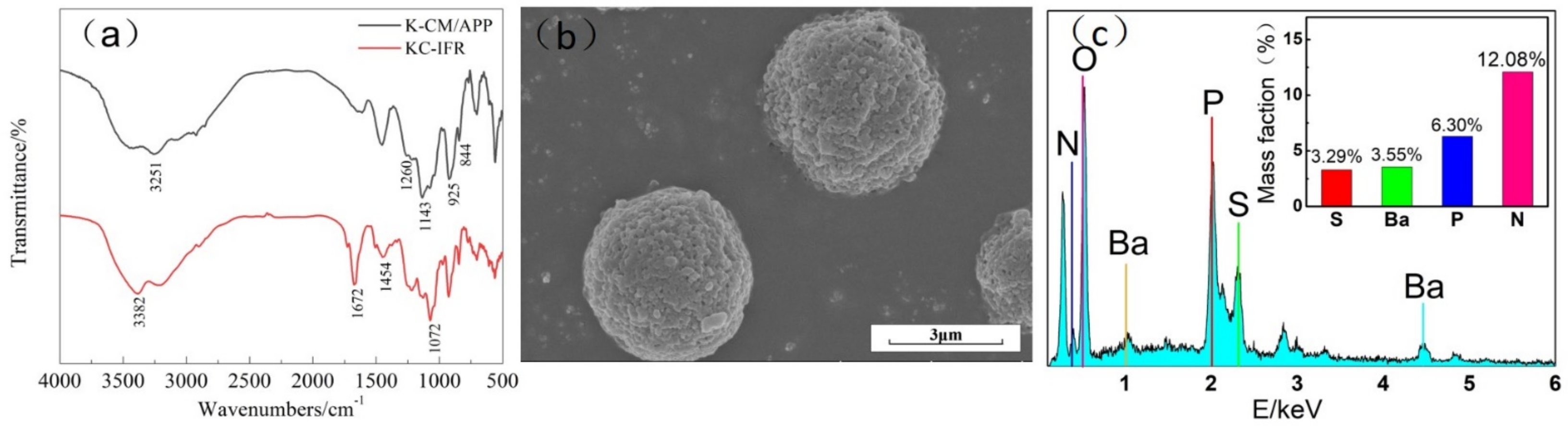

2.2.2. Synthesis of BFG

2.2.3. Preparation of Flame-Retardant Coating

2.2.4. Characterization

3. Results and Discussion

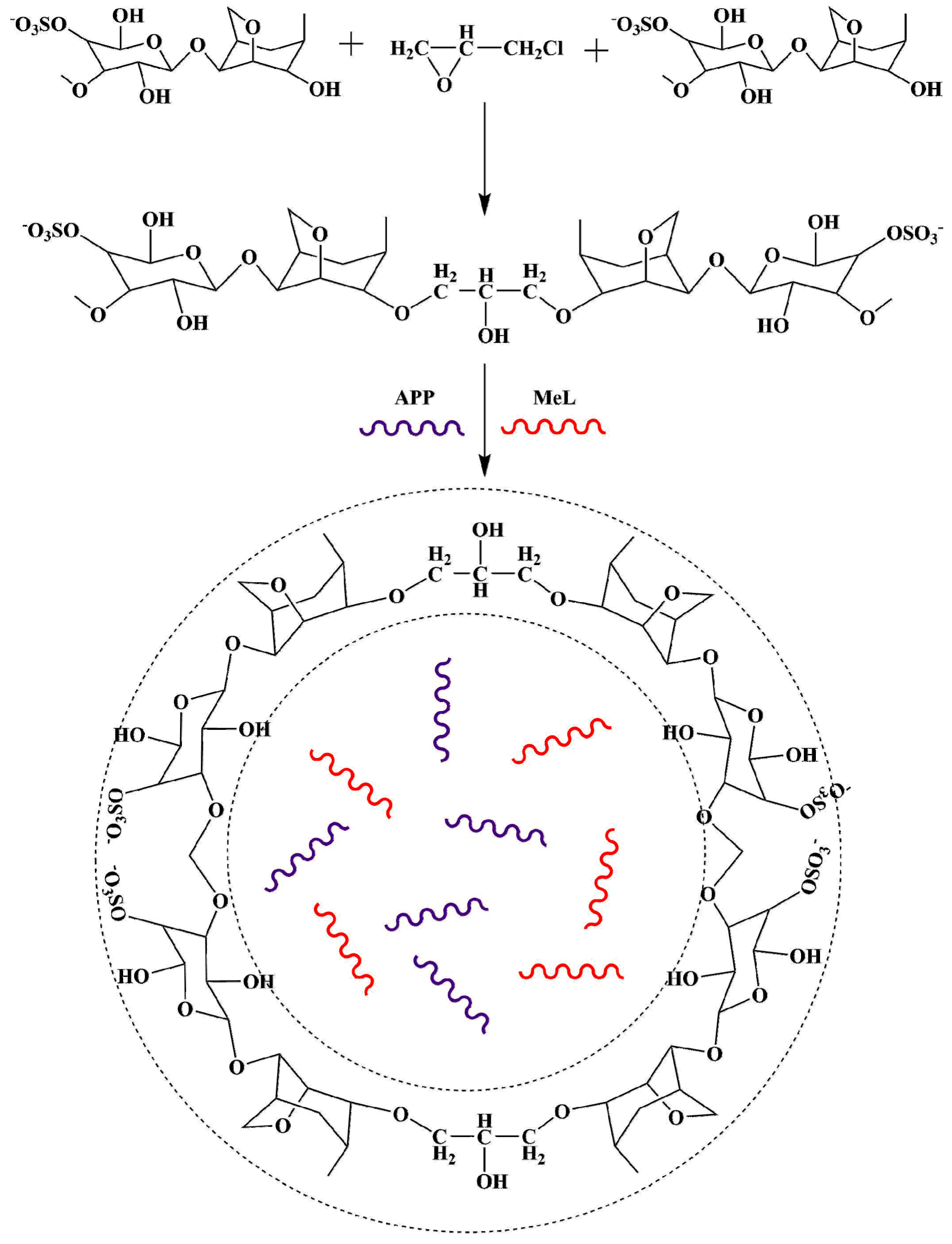

3.1. Characterization of KC-IFR

3.2. Characterization of BFG

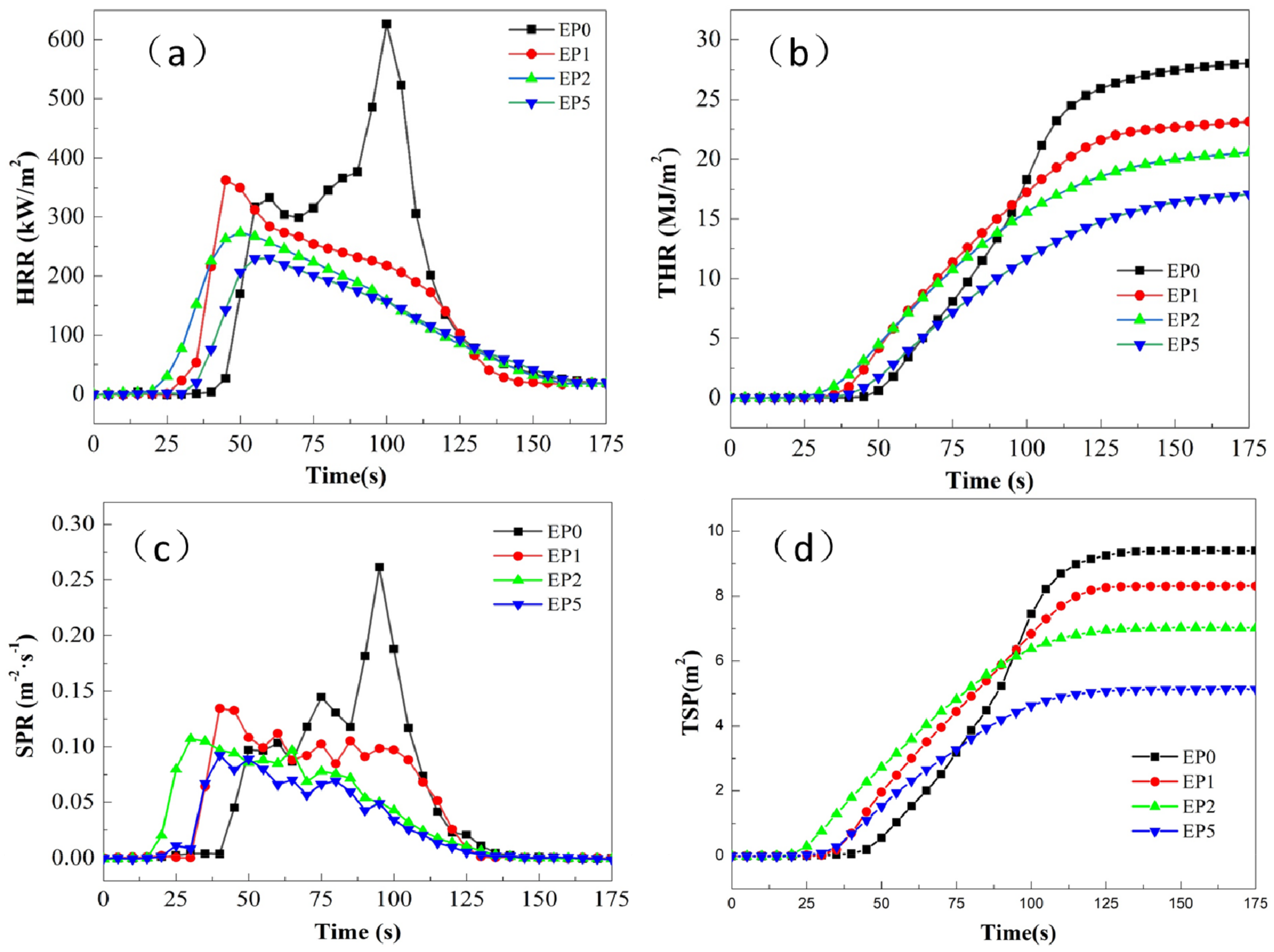

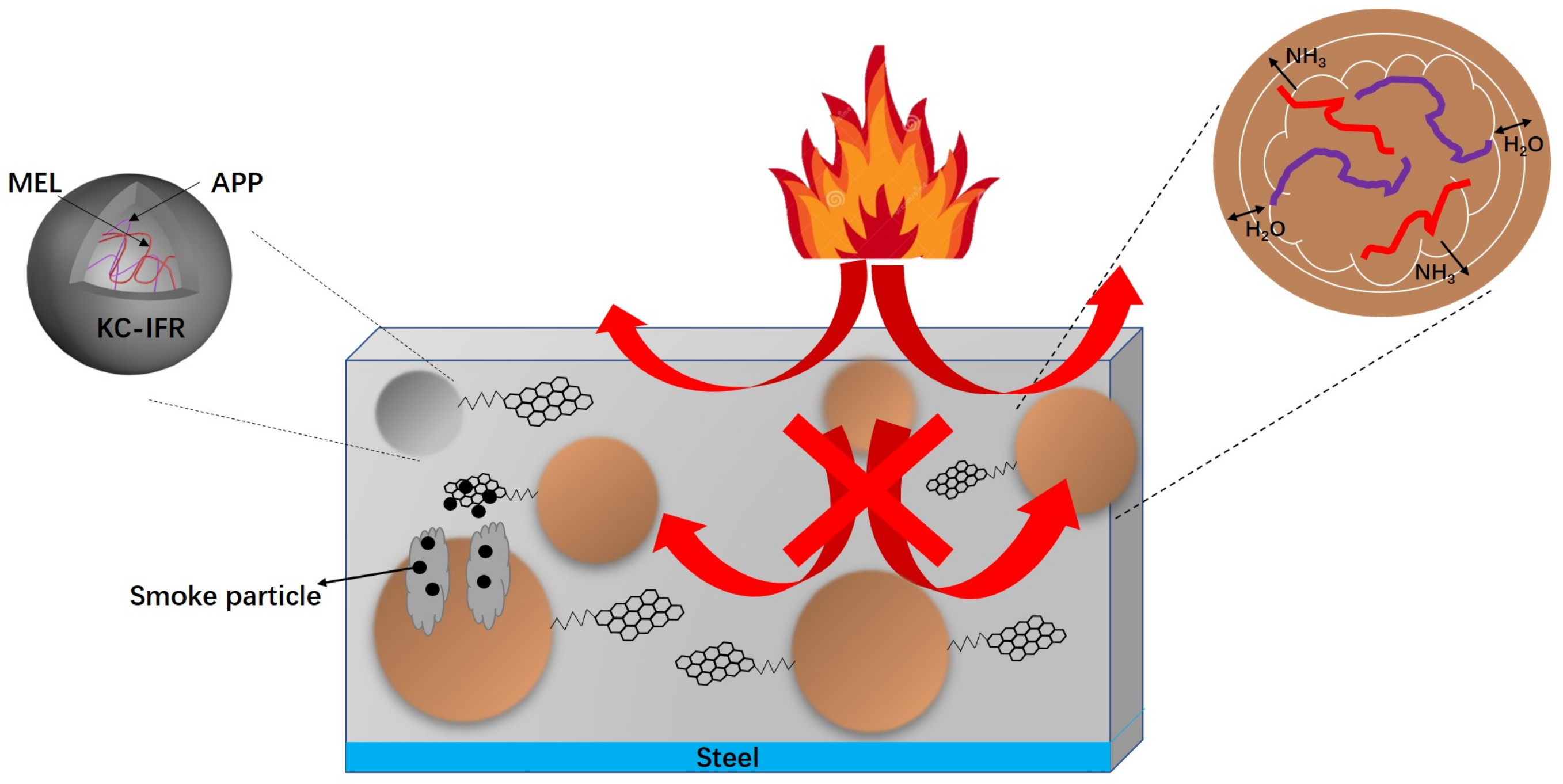

3.3. Intrinsic Fire Behavior of Flame-Retardant Coating

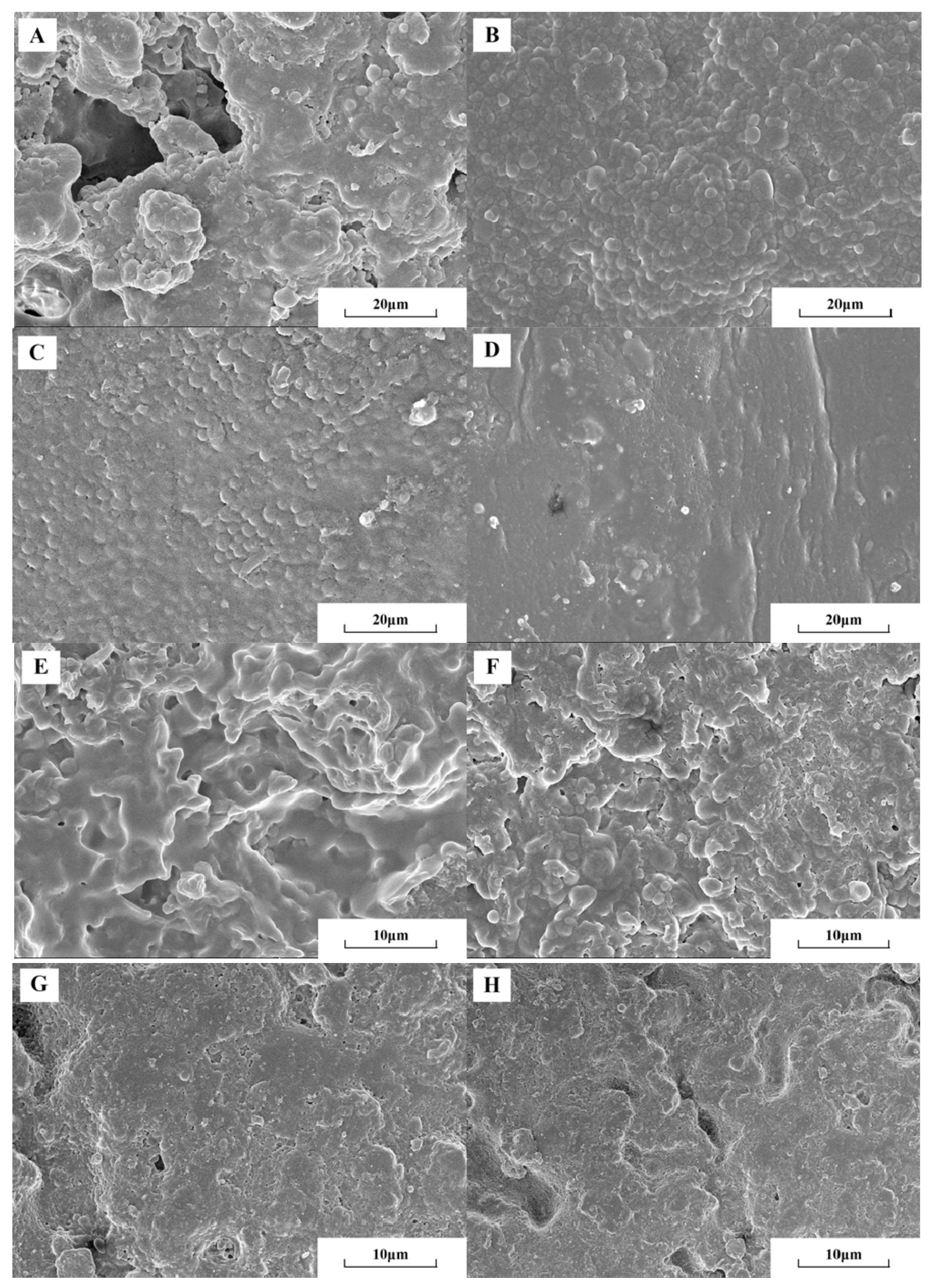

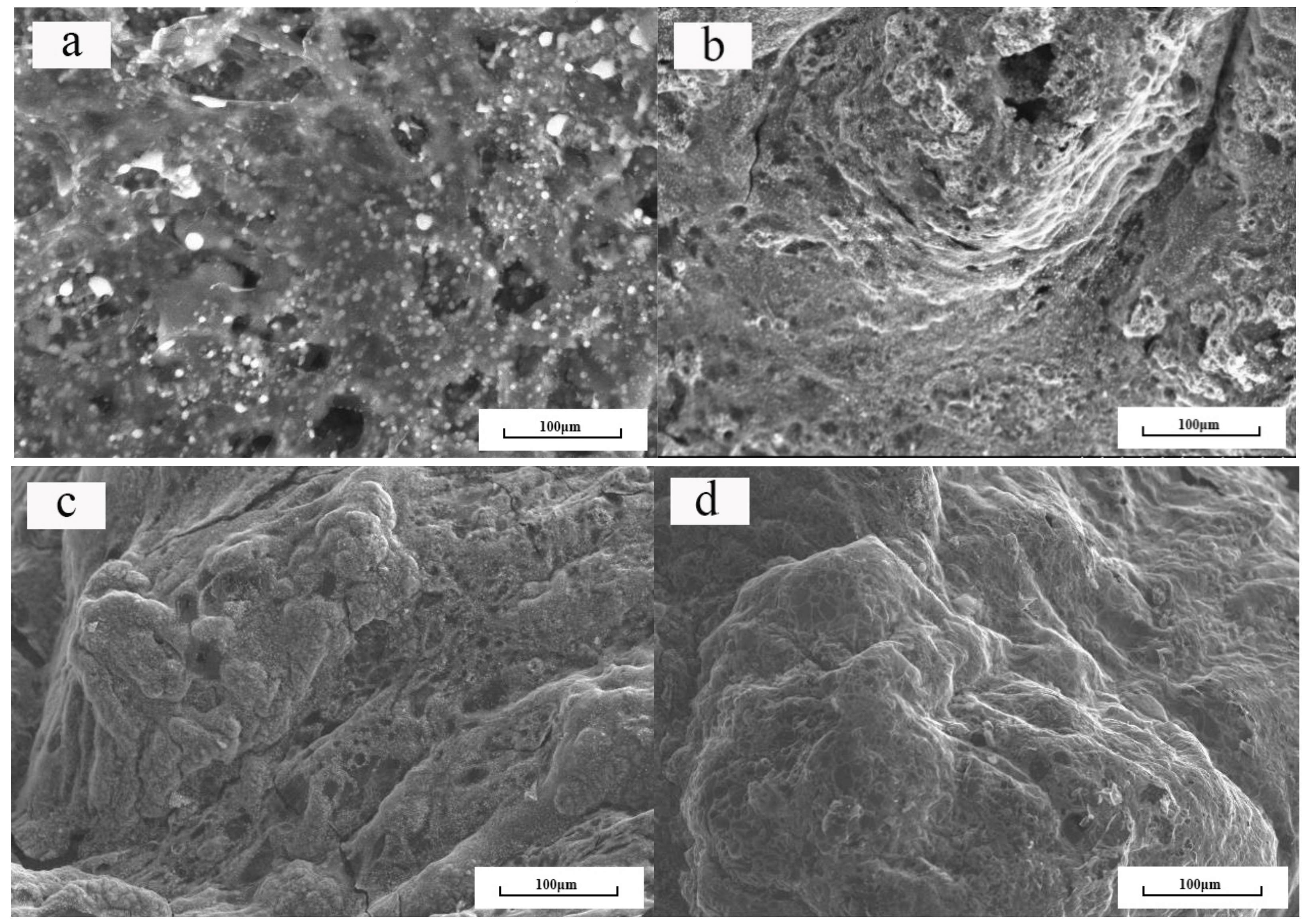

3.4. Analysis of Micromorphology

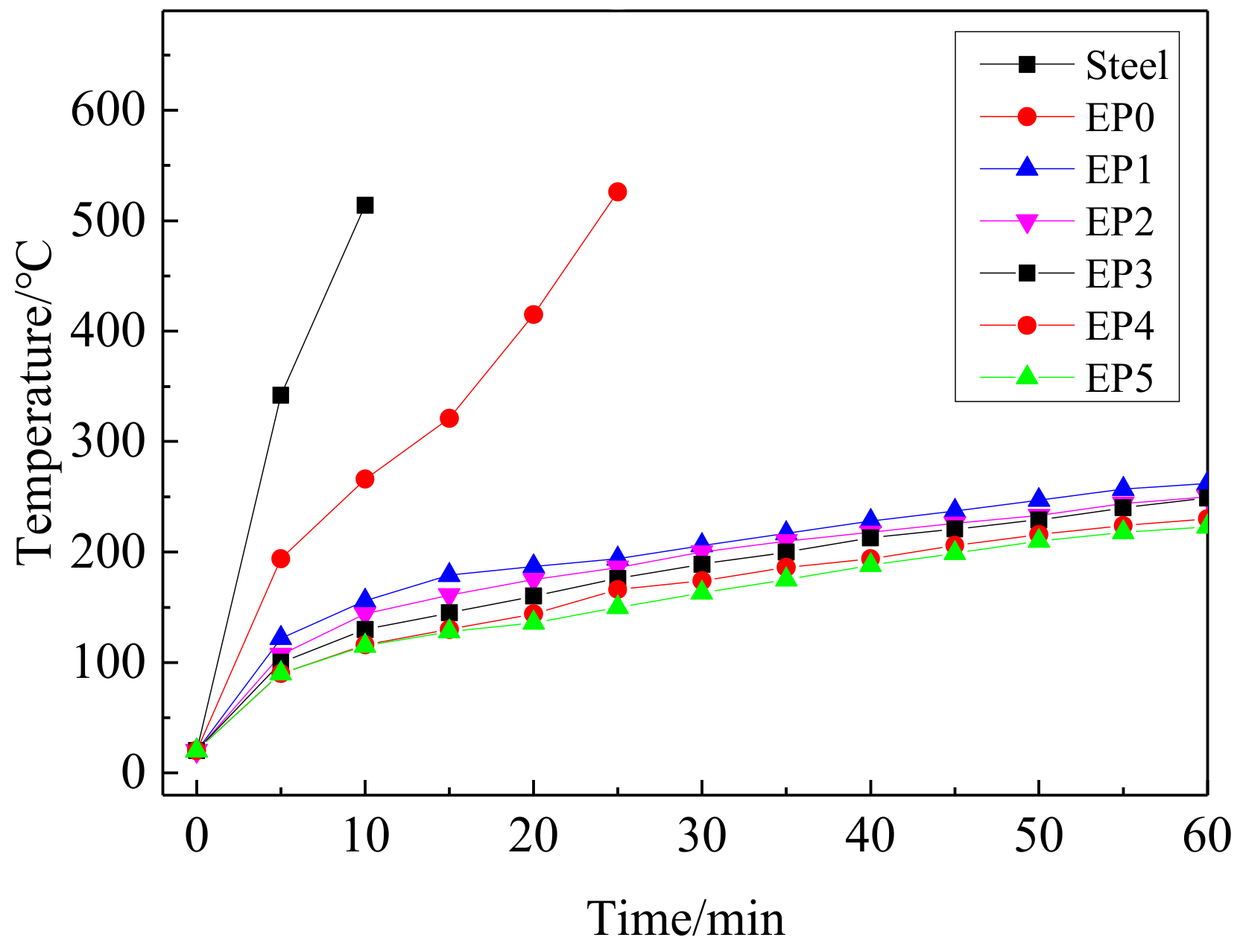

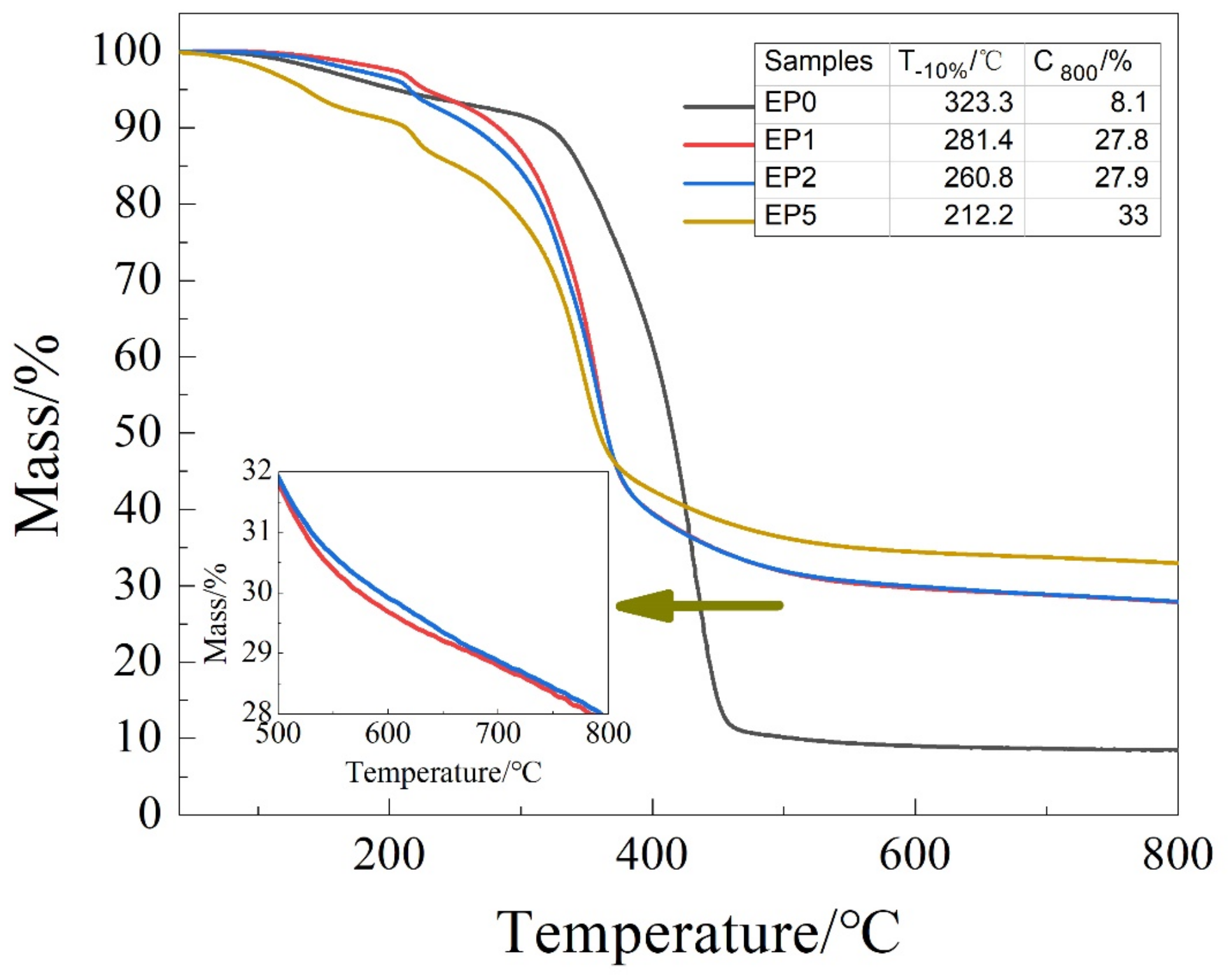

3.5. Thermal Stability of Flame-Retardant Coating

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Xu, Z.; Chu, Z.; Long, Y. Enhancing the flame-retardant and smoke suppression properties of transparent intumescent fire-retardant coatings by introducing boric acid as synergistic agent. J. Therm. Anal. Calorim. 2018, 133, 1241–1252. [Google Scholar] [CrossRef]

- Nasir, K.M.; Sulong, N.H.R.; Johan, M.R.; Afifi, A.M. An investigation into waterborne intumescent coating with different fillers for steel application. Pigment Resin Technol. 2018, 47, 142–153. [Google Scholar] [CrossRef]

- Yan, L.; Xu, Z.; Wang, X. Synergistic flame-retardant and smoke suppression effects of zinc borate in transparent intumescent fire-retardant coatings applied on wood substrates. J. Therm. Anal. Calorim. 2018, 136, 1563–1574. [Google Scholar] [CrossRef]

- Gu, J.W.; Zhang, G.C.; Dong, S.L.; Zhang, Q.Y.; Kong, J. Study on preparation and fire-retardant mechanism analysis of intumescent flame-retardant coatings. Surf. Coat. Technol. 2007, 201, 7835–7841. [Google Scholar] [CrossRef]

- Chen, S.; Li, X.; Li, Y.; Sun, J. Intumescent flame-retardant and self-healing superhydrophobic coatings on cotton fabric. Acs Nano 2015, 9, 4070–4076. [Google Scholar] [CrossRef]

- Lu, L.; Nan, G.; Qian, X.; Yang, S.; Wang, X.; Jing, J.; Shao, G. Thermal degradation and combustion behavior of intumescent flame-retardant polypropylene with novel phosphorus-based flame retardants. J. Appl. Polym. Sci. 2018, 135, 45962. [Google Scholar] [CrossRef]

- Na, W.; Wu, Y.; Long, M.; Jing, Z.; Li, X.; Fang, Q. The influence of silicone shell on double-layered microcapsules in intumescent flame-retardant natural rubber composites. J. Therm. Anal. Calorim. 2014, 118, 349–357. [Google Scholar]

- Wang, N.; Xu, G.; Wu, Y.; Zhang, J.; Hu, L.; Luan, H.; Fang, Q. The influence of expandable graphite on double-layered microcapsules in intumescent flame-retardant natural rubber composites. J. Therm. Anal. Calorim. 2016, 123, 1–13. [Google Scholar] [CrossRef]

- Han, L.; Wu, W.; Qi, Y.; Qu, H.; Xu, J. Synergistic flame retardant effect of bifeo3 in intumescent flame-retardant polypropylene composites. Polym. Compos. 2017, 38, 2771–2778. [Google Scholar] [CrossRef]

- Xu, J.; Jie, L.; Li, K. Functionalized graphene oxide in flame-retardant polypropylene. J. Vinyl Addit. Technol. 2015, 21, 278–284. [Google Scholar] [CrossRef]

- Wang, N.; Zhang, M.; Kang, P.; Zhang, J.; Fang, Q.; Li, W. Synergistic effect of graphene oxide and mesoporous structure on flame retardancy of nature rubber/ifr composites. Materials 2018, 11, 1005. [Google Scholar] [CrossRef] [PubMed]

- Yue, X.; Jian, L.; Liu, P.; Lin, Y.; Xin, D. Study on the performance of flame-retardant esterified starch-modified cassava dregs-pbs composites. J. Appl. Polym. Sci. 2018, 135, 44849. [Google Scholar] [CrossRef]

- Gholipour-Mahmoudaliloua, M.; Roghani-Mamaqani, H.; Azimi, R.; Abdollahi, A. Synthesis of hyperbranched poly (amidoamine)-grafted graphene nanolayers as a composite and curing agent for epoxy resin. Appl. Surf. Sci. 2018, 428, 1061–1069. [Google Scholar] [CrossRef]

- Feng, Y.; He, C.; Wen, Y.; Ye, Y.; Zhou, X.; Xie, X.; Mai, Y.W. Improving thermal and flame retardant properties of epoxy resin by functionalized graphene containing phosphorous, nitrogen and silicon elements. Compos. Part A Appl. Sci. Manuf. 2017, 103, 74–83. [Google Scholar] [CrossRef]

- Li, M.; Zhang, H.; Wu, W.; Li, M.; Xu, Y.; Chen, G.; Dai, L. A novel poss-based copolymer functionalized graphene: An effective flame retardant for reducing the flammability of epoxy resin. Polymers 2019, 11, 241. [Google Scholar] [CrossRef] [PubMed]

- Jiao, L.Y.; Wu, Z.J. Alkali lignin as a carbonization agent on the thermal degradation and flame retardancy of intumescent flame retardant coating. Adv. Mater. Res. 2013, 750, 1385–1388. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, X.; Jin, X.; Li, H.; Sun, J.; Gu, X. The novel application of chitosan: Effects of cross-linked chitosan on the fire performance of thermoplastic polyurethane. Carbohydr. Polym. 2018, 189, 313–321. [Google Scholar] [CrossRef]

- Shi, X.; Jiang, S.; Hu, Y.; Peng, X.; Yang, H.; Qian, X. Phosphorylated chitosan-cobalt complex: A novel green flame retardant for polylactic acid. Polym. Adv. Technol. 2018, 29, 860–866. [Google Scholar] [CrossRef]

- Wang, N.; Yang, F.; Zhang, J.; Fang, Q. Inflame-retardant Water-borne Epoxy Resin of APP Microsphere with Carrageenan Cladding. Chem. J. Chin. Univ. 2019, 40, 385–392. [Google Scholar]

- Wang, N.; Teng, H.; Li, L.; Zhang, J.; Kang, P. Synthesis of phosphated k-carrageenan and its application for flame-retardant waterborne epoxy. Polymers 2018, 10, 1268. [Google Scholar] [CrossRef]

- Maryam, J.; Qiaoliang, B.; Jia-Xiang, Y.; Kian Ping, L. Structure-directing role of graphene in the synthesis of metal-organic framework nanowire. J. Am. Chem. Soc. 2010, 132, 14487–14495. [Google Scholar]

- Wang, Z.; Sui, X.; Jie, G.; Jiang, P. Effect of app microcapsules on flame retardant and mechanical properties of epoxy resins. Polym. Mater. Sci. Eng. 2012, 28, 39–42. [Google Scholar]

- Jing, J.; Zhang, Y.; Fang, Z.P.; Wang, D.Y. Core-shell flame retardant/graphene oxide hybrid: A self-assembly strategy towards reducing fire hazard and improving toughness of polylactic acid. Compos. Sci. Technol. 2018, 165, 161–167. [Google Scholar] [CrossRef]

- Zhou, T.; Wu, T.; Xiang, H.; Li, Z.; Xu, Z.; Kong, Q.; Zhang, J.; Li, Z.; Pan, Y.; Wang, D. Simultaneously improving flame retardancy and dynamic mechanical properties of epoxy resin nanocomposites through synergistic effect of zirconium phenylphosphate and poss. J. Therm. Anal. Calorim. 2018, 135, 2117–2124. [Google Scholar] [CrossRef]

- Bao, C.; Guo, Y.; Yuan, B.; Yuan, H.; Lei, S. Functionalized graphene oxide for fire safety applications of polymers: A combination of condensed phase flame retardant strategies. J. Mater. Chem. 2012, 22, 23057. [Google Scholar] [CrossRef]

- Biswas, B.; Kandola, B.K. The effect of chemically reactive type flame retardant additives on flammability of pes toughened epoxy resin and carbon fibre-reinforced composites. Polym. Adv. Technol. 2011, 22, 1192–1204. [Google Scholar] [CrossRef]

- Guo, W.; Wang, X.; Pan, Y.; Cai, W.; Xing, W.; Song, L.; Hu, Y. Polyaniline-coupled graphene/nickel hydroxide nanohybrids as flame retardant and smoke suppressant for epoxy composites. Polym. Adv. Technol. 2019, 30, 1959–1967. [Google Scholar] [CrossRef]

- Zhang, J.; Kong, Q.; Yang, L.; Wang, D.-Y. Few layered co(oh)2 ultrathin nanosheet-based polyurethane nanocomposites with reduced fire hazard: From eco-friendly flame retardance to sustainable recycling. Green Chem. 2016, 18, 3066–3074. [Google Scholar] [CrossRef]

- Li, H.; Hu, Z.; Sheng, Z.; Gu, X.; Wang, H.; Peng, J.; Qian, Z. Effects of titanium dioxide on the flammability and char formation of water-based coatings containing intumescent flame retardants. Prog. Org. Coat. 2015, 78, 318–324. [Google Scholar] [CrossRef]

| Sample | m (EP)/g | m (Curing Agent)/g | m (H2O)/g | m (KC-IFR)/g | M (GO)/g | m (BFG)/g |

|---|---|---|---|---|---|---|

| EP0 | 60.0 | 20.0 | 20.0 | - | - | - |

| EP1 | 45.0 | 15.0 | 20.0 | 20.0 | - | - |

| EP2 | 45.0 | 15.0 | 20.0 | 19.0 | 1.0 | - |

| EP3 | 45.0 | 15.0 | 20.0 | 19.0 | - | 1.0 |

| EP4 | 45.0 | 15.0 | 20.0 | 18.5 | - | 1.5 |

| EP5 | 45.0 | 15.0 | 20.0 | 18.0 | - | 2.0 |

| Sample | EP0 | EP1 | EP2 | EP3 | EP4 | EP5 |

|---|---|---|---|---|---|---|

| LOI/% | 19.7 | 28.7 | 28.9 | 29.1 | 29.5 | 29.8 |

| UL-94 | No rating | V-0 | V-0 | V-0 | V-0 | V-0 |

| Droplet | Yes | No | No | No | No | No |

| Sample | pHRR (kW/m2) | THR (MJ/m2) | pSPR (m−2·s−1) | TSP (m2) |

|---|---|---|---|---|

| EP0 | 627 | 28 | 0.26 | 9.41 |

| EP1 | 362 | 23 | 0.13 | 8.36 |

| EP2 | 273 | 21 | 0.11 | 7.02 |

| EP5 | 229 | 17 | 0.09 | 5.13 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, N.; Teng, H.; Yang, F.; You, J.; Zhang, J.; Wang, D. Synthesis of K-Carrageenan Flame-Retardant Microspheres and Its Application for Waterborne Epoxy Resin with Functionalized Graphene. Polymers 2019, 11, 1708. https://doi.org/10.3390/polym11101708

Wang N, Teng H, Yang F, You J, Zhang J, Wang D. Synthesis of K-Carrageenan Flame-Retardant Microspheres and Its Application for Waterborne Epoxy Resin with Functionalized Graphene. Polymers. 2019; 11(10):1708. https://doi.org/10.3390/polym11101708

Chicago/Turabian StyleWang, Na, Haiwei Teng, Fei Yang, Jiaqi You, Jing Zhang, and Deyi Wang. 2019. "Synthesis of K-Carrageenan Flame-Retardant Microspheres and Its Application for Waterborne Epoxy Resin with Functionalized Graphene" Polymers 11, no. 10: 1708. https://doi.org/10.3390/polym11101708

APA StyleWang, N., Teng, H., Yang, F., You, J., Zhang, J., & Wang, D. (2019). Synthesis of K-Carrageenan Flame-Retardant Microspheres and Its Application for Waterborne Epoxy Resin with Functionalized Graphene. Polymers, 11(10), 1708. https://doi.org/10.3390/polym11101708