Blowing Properties and Functionality of Thermoplastic Polyester Film Using Thermally Expandable Microcapsules

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Specimens Manufacture

2.2. Characterizations

2.2.1. Specific Gravity and Blowing Efficiency

2.2.2. Tensile Strength and Elongation

2.2.3. Surface Analysis

2.2.4. Linear Dimensional Change

2.2.5. Curl

2.2.6. Friction Coefficient

2.2.7. Water Vapor Permeability and Water Resistance

3. Results and Discussion

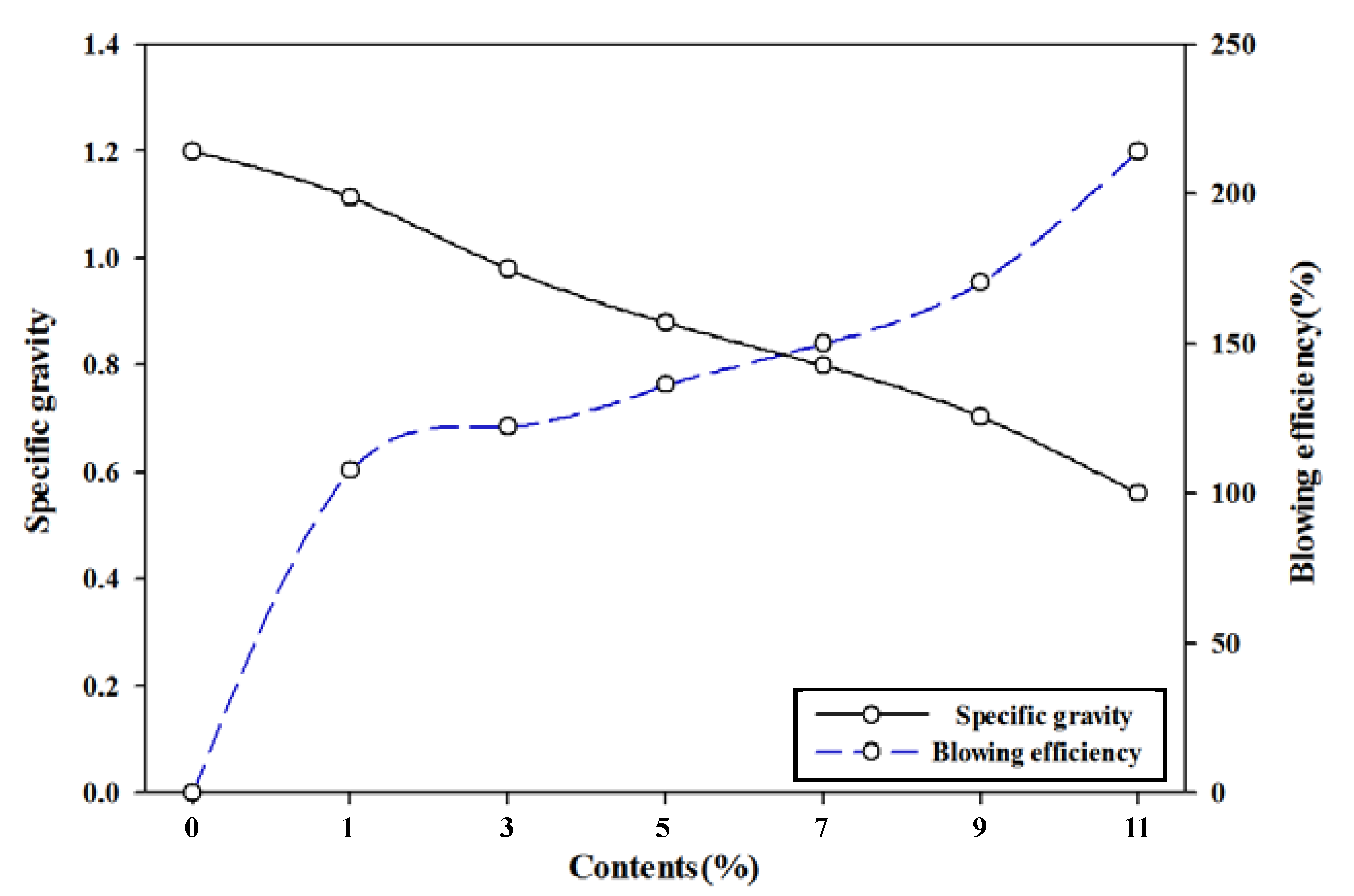

3.1. Specific Gravity and Blowing Efficiency

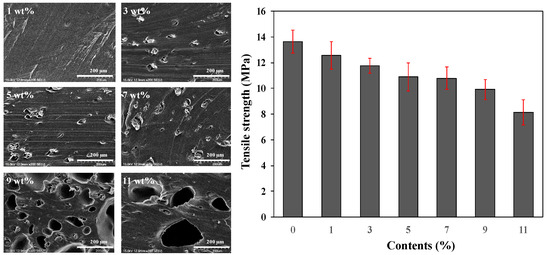

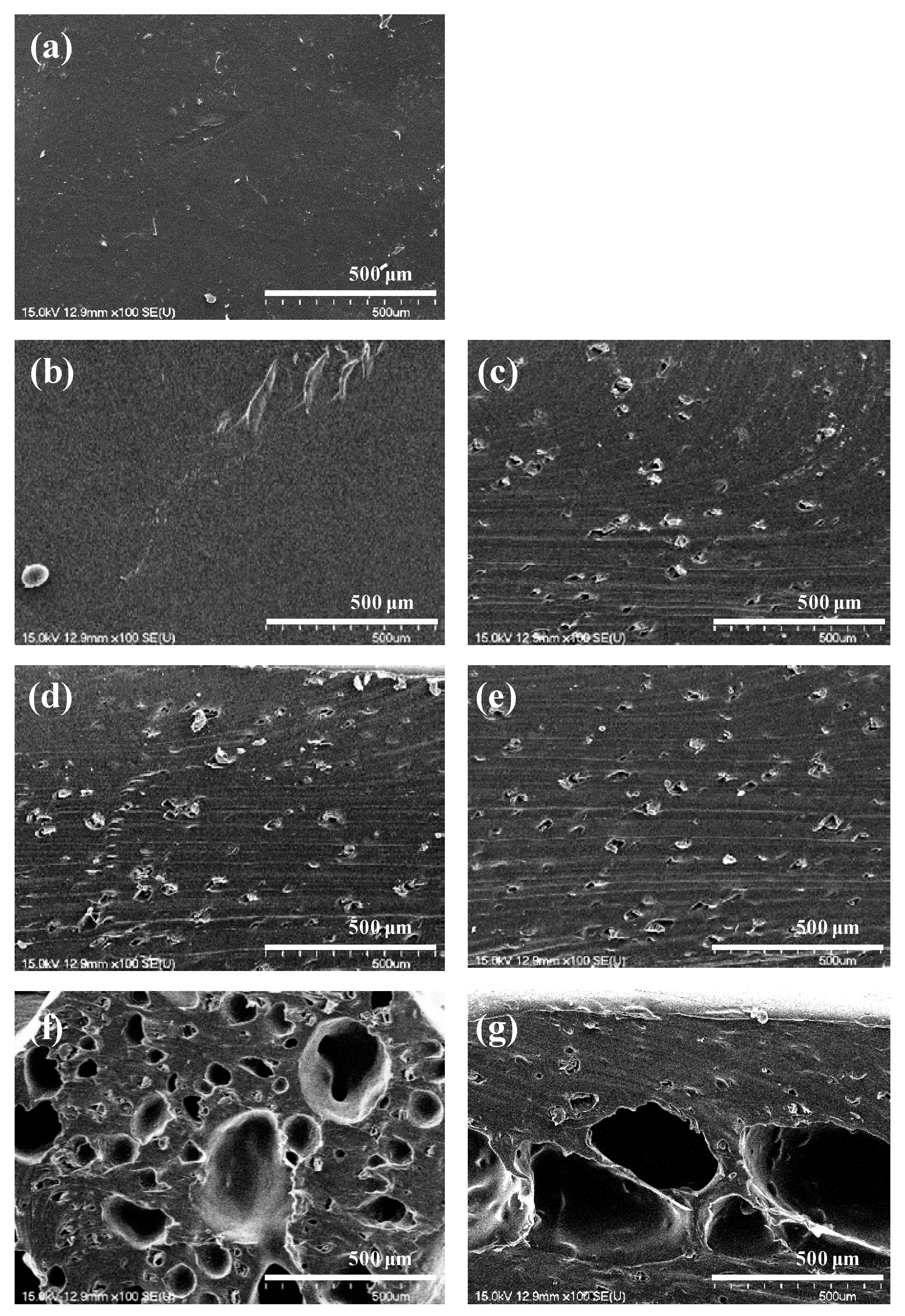

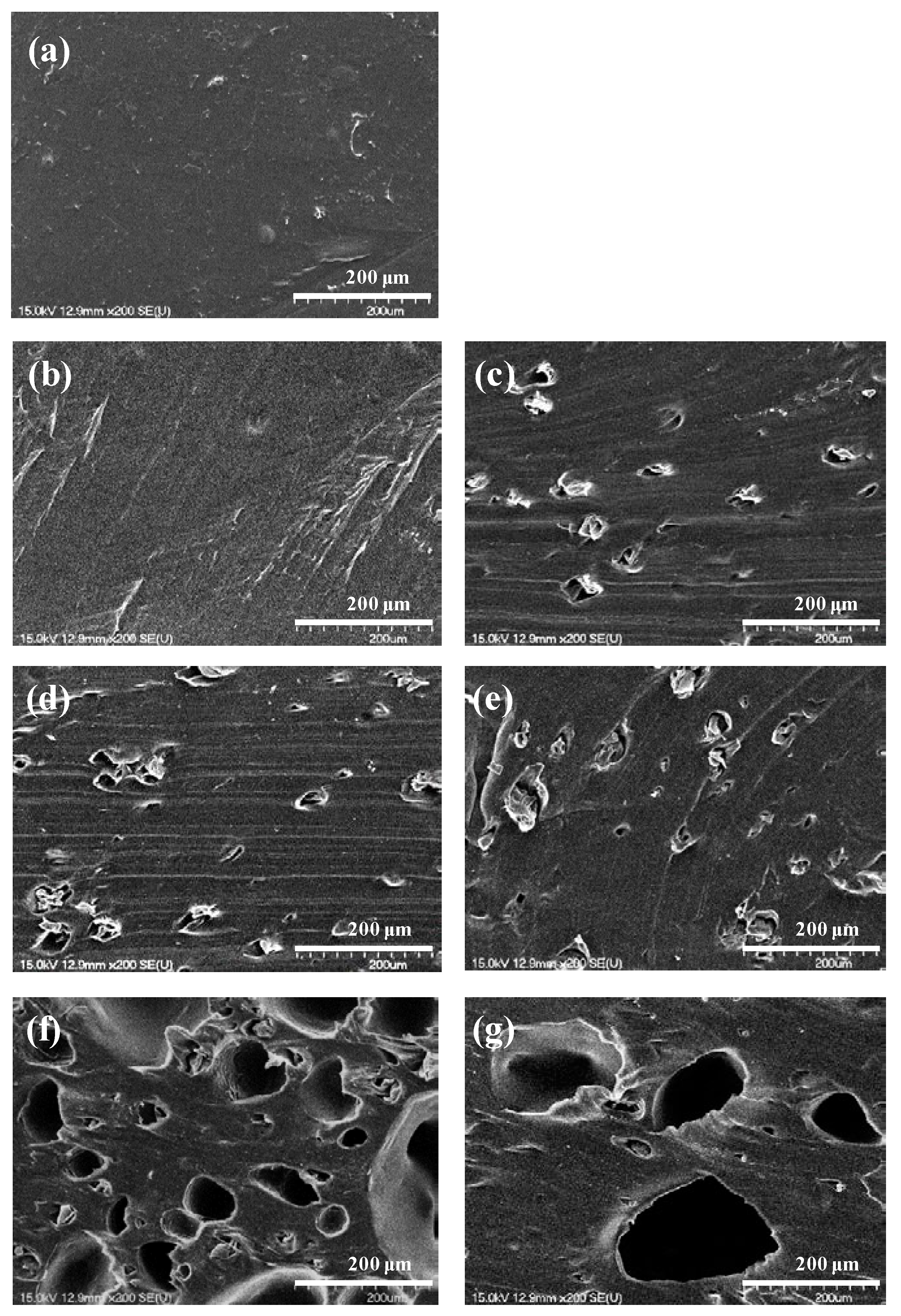

3.2. Foam Cell Shape and Distribution

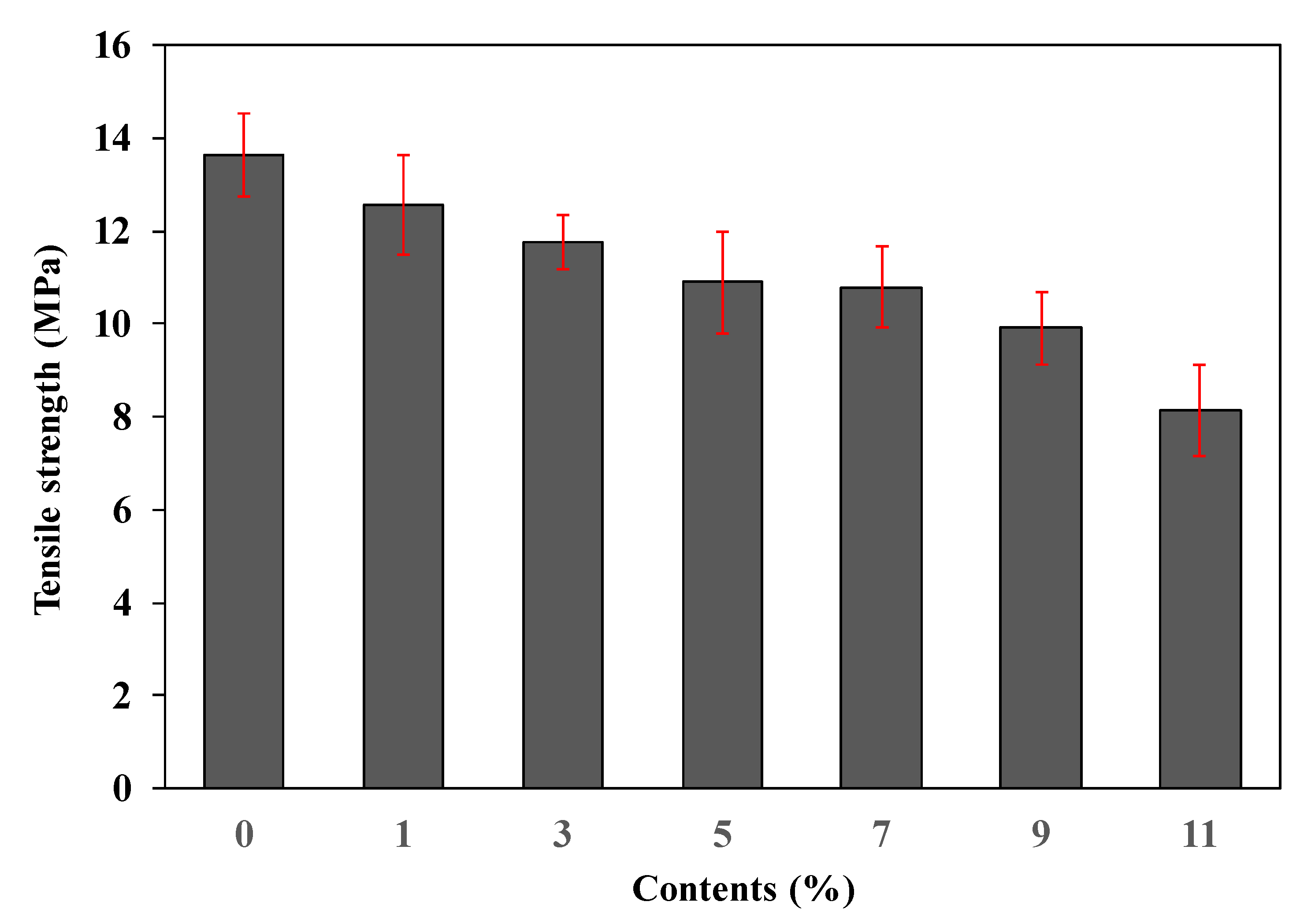

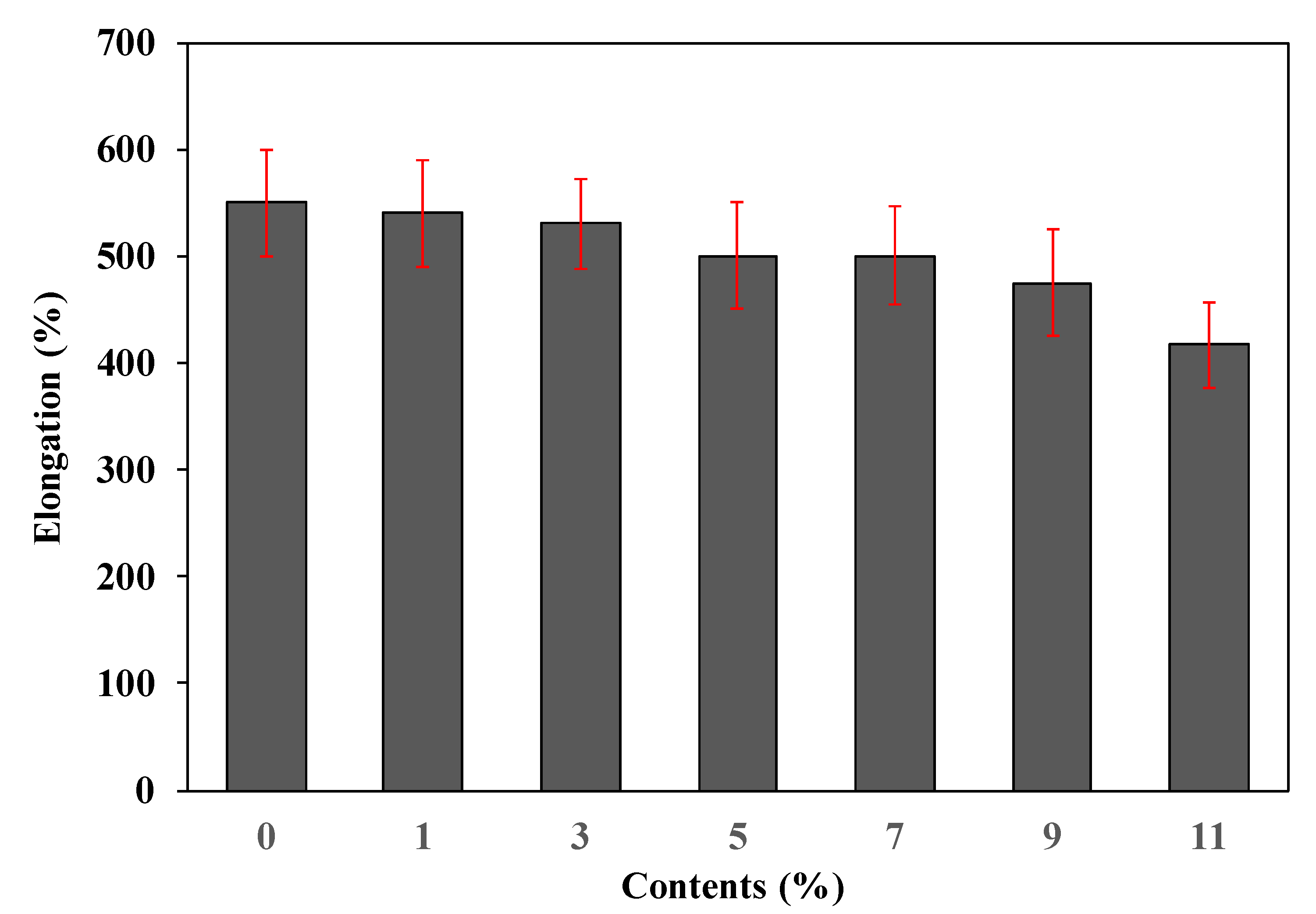

3.3. Tensile Strength and Elongation

3.4. Linear Dimensional Change

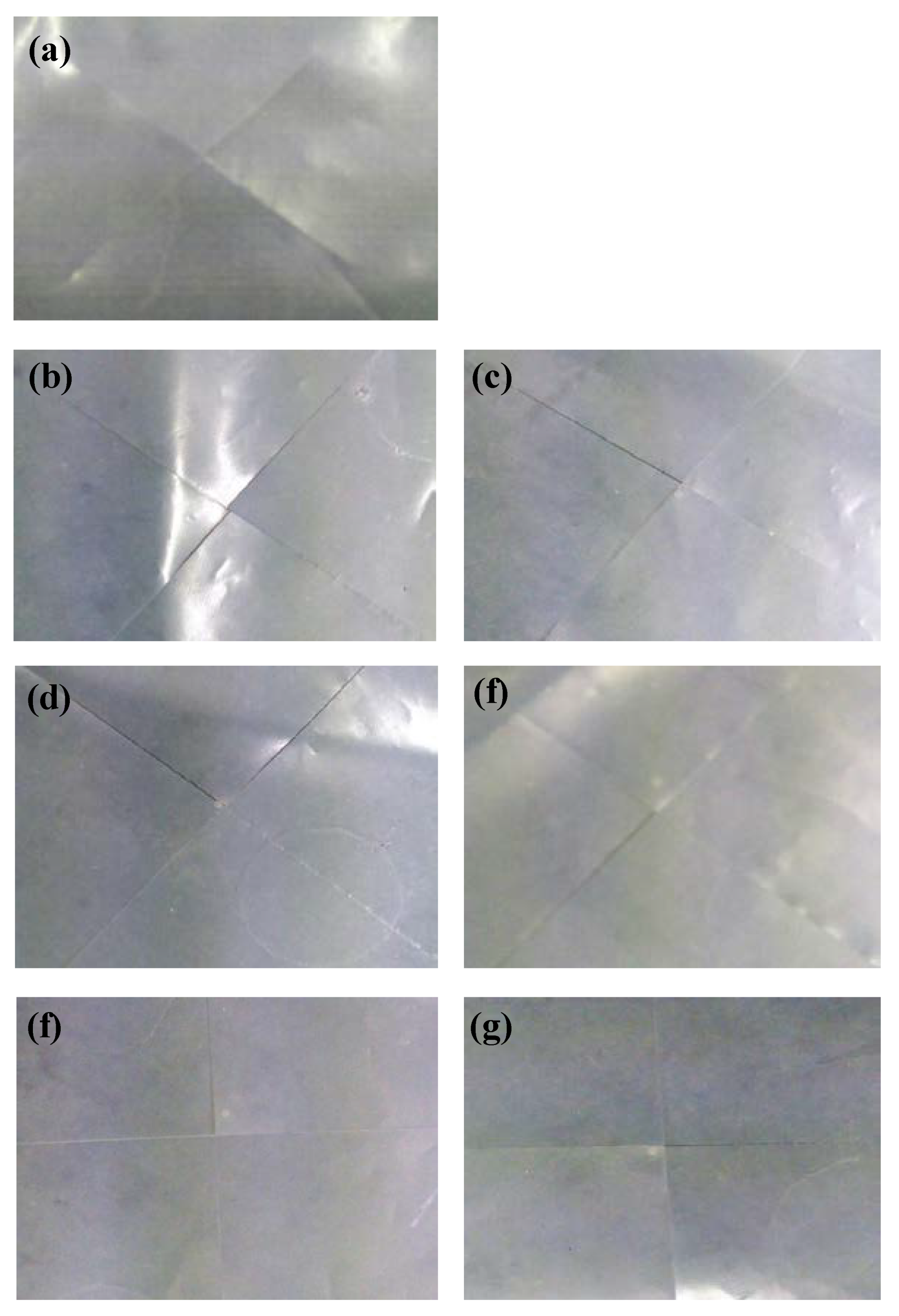

3.5. Curl

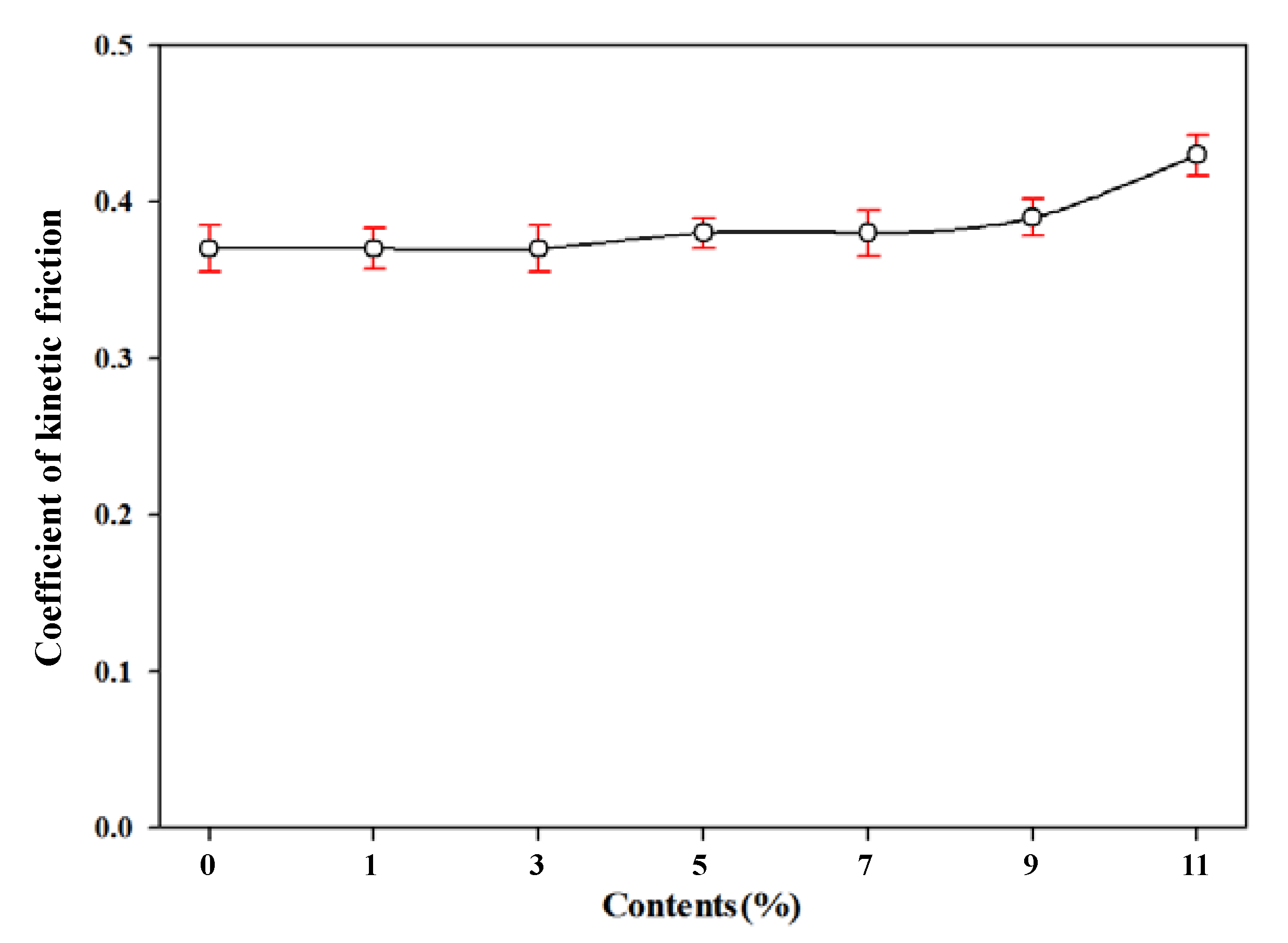

3.6. Coefficient of Kinetic Friction

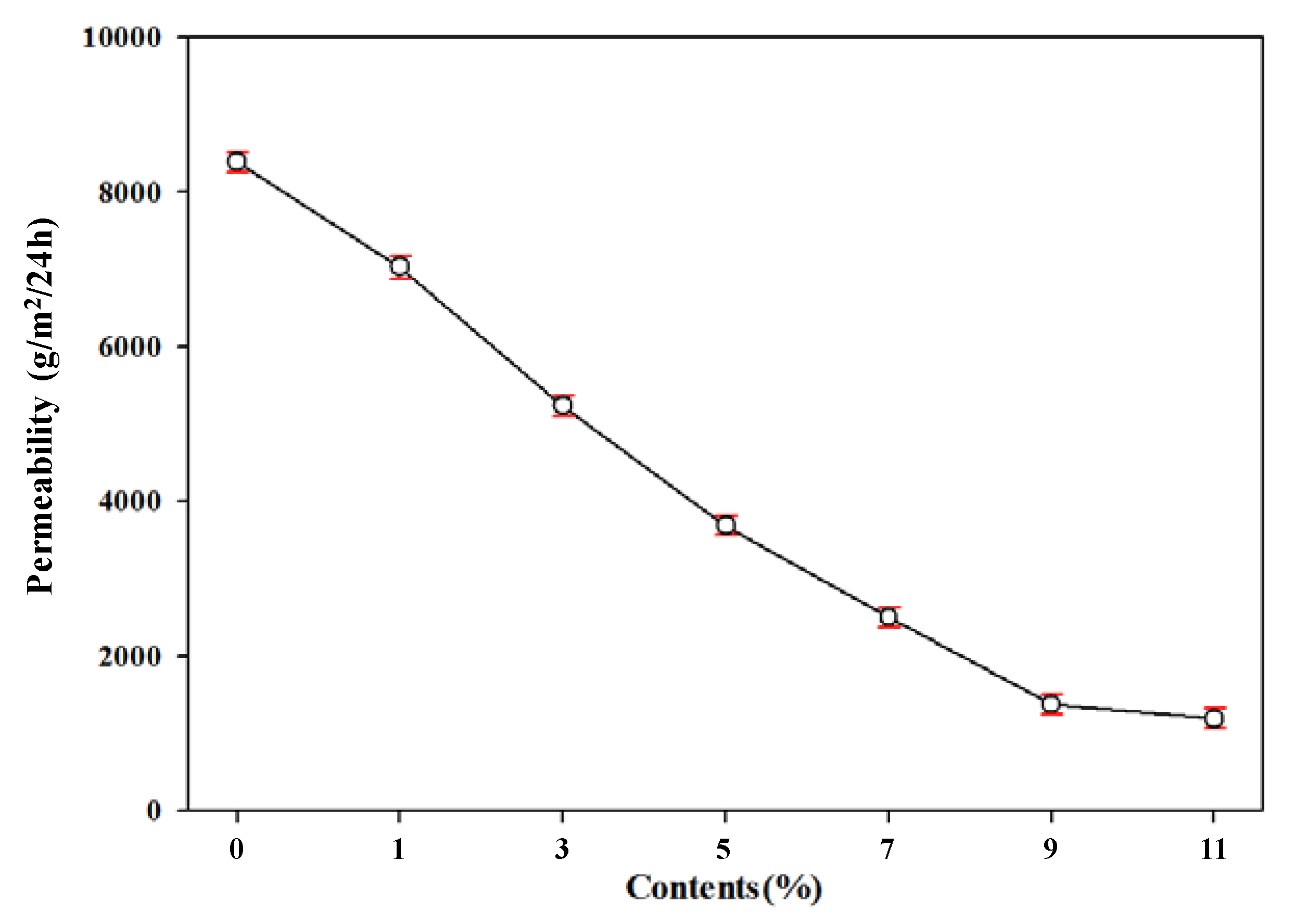

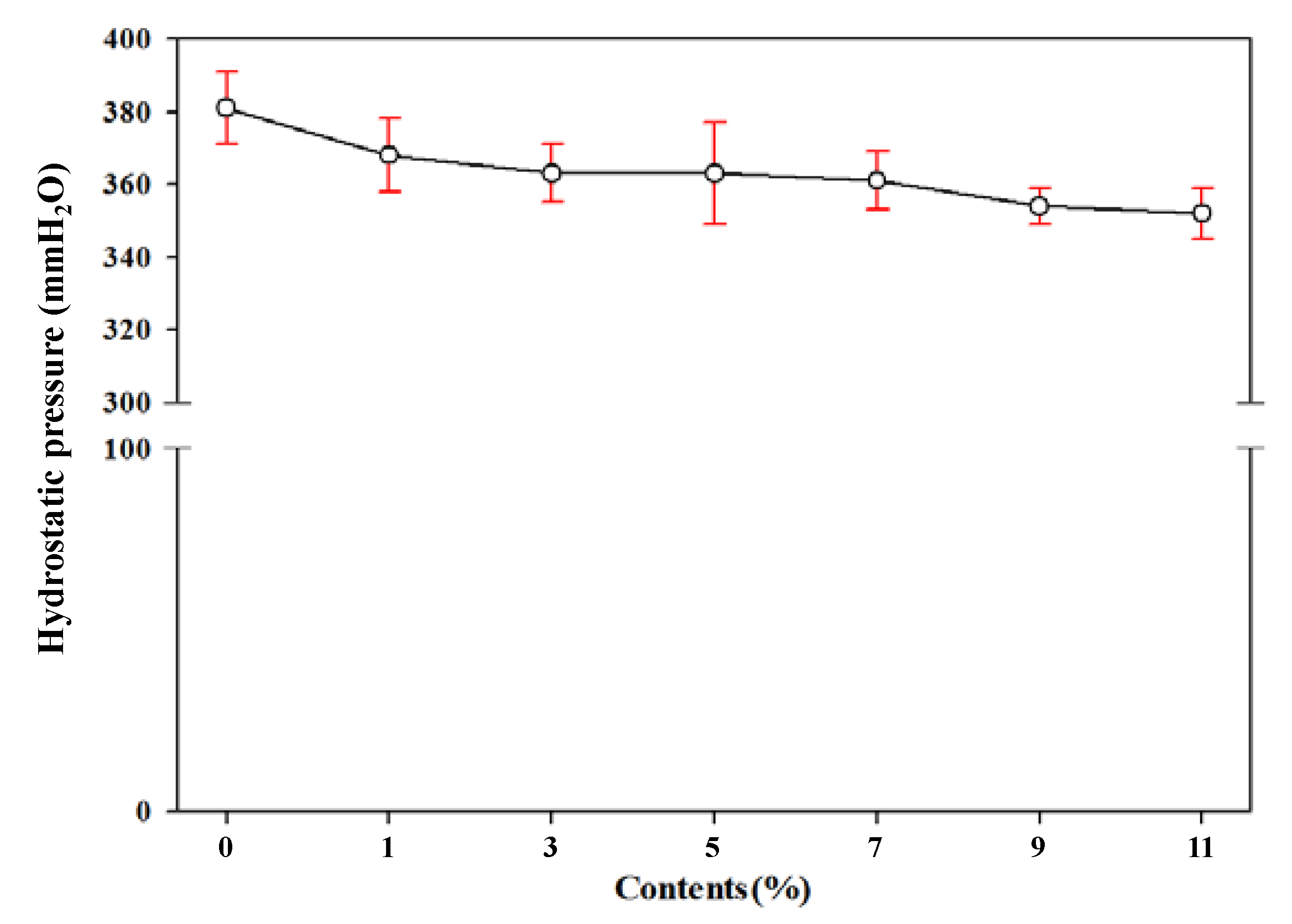

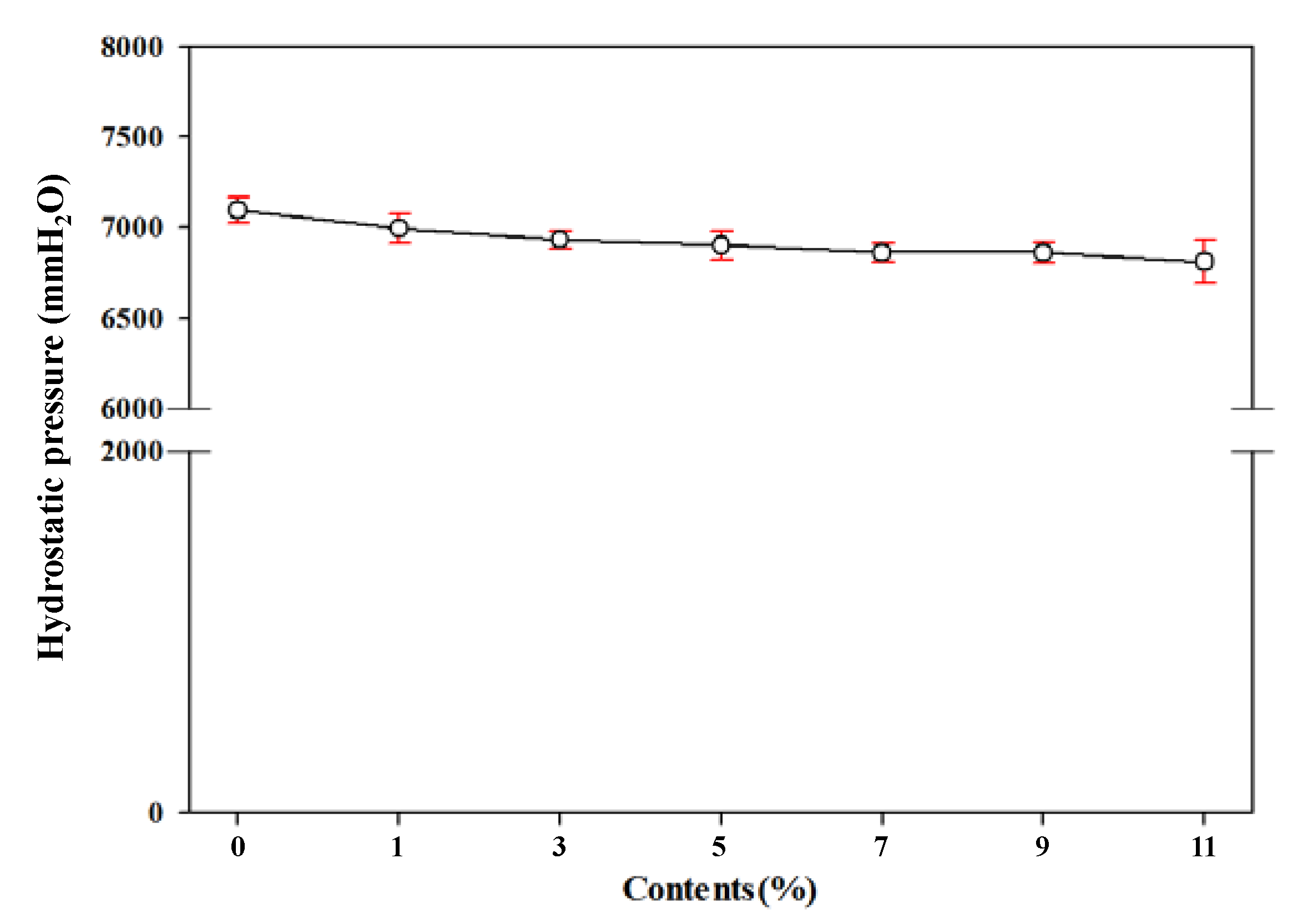

3.7. Water Vapor Permeability and Water Resistance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ha, J.U.; Jeoung, S.K.; Lee, P.-C.; Hwang, Y.J.; Nam, B.K.; Han, I.-S.; Kwak, S.B.; Lee, J.Y. Physical Properties of Polypropylene Foam Blended with Thermally Expandable Microcapsules. Polymer (Korea) 2014, 39, 64–70. [Google Scholar] [CrossRef]

- Dios, J.R.; Garcia-Astrain, C.; Costa, P.; Viana, J.C.; Lanceros-Mendez, S. Carbonaceous Filler Type and Content Dependence of the Physical-Chemical and Electromechanical Properties of Thermoplastic Elastomer Polymer Composites. Materials 2019, 12, 1405. [Google Scholar] [CrossRef] [PubMed]

- Leber, A.; Cholst, B.; Sandt, J.; Vogel, N.; Kolle, M. Stretchable Thermoplastic Elastomer Optical Fibers for Sensing of Extreme Deformations. Adv. Funct. Mater. 2019, 29, 201802629. [Google Scholar] [CrossRef]

- Parida, K.; Thangavel, G.; Cai, G.F.; Zhou, X.R.; Park, S.; Xiong, J.Q.; Lee, P.S. Extremely stretchable and self-healing conductor based on thermoplastic elastomer for all-three-dimensional printed triboelectric nanogenerator. Nat. Commun. 2019, 10, 2158. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.Y.; Lu, W.; Goodwin, A.; Wang, H.Q.; Yin, P.C.; Kang, N.G.; Hong, K.L.; Mays, J.W. Recent advances in thermoplastic elastomers from living polymerizations: Macromolecular architectures and supramolecular chemistry. Prog. Polym. Sci. 2019, 95, 1–31. [Google Scholar] [CrossRef]

- Watts, A.; Hillmyer, M.A. Aliphatic Polyester Thermoplastic Elastomers Containing Hydrogen Bonding Ureidopyrimidinone Endgroups. Biomacromolecules 2019, 20, 2598–2609. [Google Scholar] [CrossRef]

- Smolka, P.; Musilova, L.; Mracek, A.; Sedlacek, T. Stability of Aqueous Polymeric Dispersions for Ultra-Thin Coating of Bi-Axially Oriented Polyethylene Terephthalate Films. Coatings 2017, 7, 234. [Google Scholar] [CrossRef]

- Lee, Y.; Jeong, J.; Park, J. A Trend of R & D in Enviromental Thermoplastic Elastomer. Elastom. Compos. 2010, 45, 245–249. [Google Scholar]

- Sabahy, J.E.; Castellan, G.; Ricoul, F.; Jousseaume, V. Porous SiOCH Thin Films Obtained by Foaming. J. Phys. Chem. C 2016, 120, 9184–9191. [Google Scholar] [CrossRef]

- Kwon, D.E.; Park, B.K.; Lee, Y.W. Solid-State Foaming of Acrylonitrile-Butadiene-Styrene/Recycled Polyethylene Terephthalate Using Carbon Dioxide as a Blowing Agent. Polymers (Basel) 2019, 11, 291. [Google Scholar] [CrossRef]

- Landrock, A.H. Handbook of Plastic Foams; Noyes: Saddle River, NJ, USA, 1995. [Google Scholar]

- Chen, C.-X.; Liu, Q.-Q.; Xin, X.; Guan, Y.-X.; Yao, S.-J. Pore formation of poly(ε-caprolactone) scaffolds with melting point reduction in supercritical CO2 foaming. J. Supercrit. Fluids 2016, 117, 279–288. [Google Scholar] [CrossRef]

- Weaire, D.; Hutzler, S. The Physics of Foams; Oxford University Press: Oxford, UK, 2001. [Google Scholar]

- Choe, K.H.; Lee, D.S.; Seo, W.J.; Kim, W.N. Properties of rigid polyurethane foams with blowing agents and catalysts. Polym. J. 2004, 36, 368–373. [Google Scholar] [CrossRef]

- Hou, T.H.; Weiser, E.S.; Siochi, E.J.; St. Clair, T.L. Processing characteristics of TEEK polyimide foam. High Perform. Polym. 2004, 16, 487–504. [Google Scholar] [CrossRef]

- Patel, J.P.; Xiang, Z.G.; Hsu, S.L.; Schoch, A.B.; Carleen, S.A.; Matsumoto, D. Path to Achieving Molecular Dispersion in a Dense Reactive Mixture. J. Polym. Sci. Pol. Phys. 2015, 53, 1519–1526. [Google Scholar] [CrossRef]

- Thirumal, M.; Khastgir, D.; Singha, N.K.; Manjunath, B.S.; Naik, Y.P. Effect of foam density on the properties of water blown rigid polyurethane foam. J. Appl. Polym. Sci. 2008, 108, 1810–1817. [Google Scholar] [CrossRef]

- Morehouse, D.S.; Tetreault, R.J.U.S. Expansible Thermoplastic Polymer Particles Containing Volatile Fluid Foaming Agent and Method of Foaming the Same. U.S. Patent 3,615,972, 26 October 1971. [Google Scholar]

- Jiao, S.Z.; Sun, Z.C.; Li, F.R.; Yan, M.J.; Cao, M.J.; Li, D.S.; Liu, Y.; Li, L.H. Preparation and Application of Conductive Polyaniline-Coated Thermally Expandable Microspheres. Polymers (Basel) 2019, 11, 22. [Google Scholar] [CrossRef] [PubMed]

- Bonaldo, J.; Banea, M.D.; Carbas, R.J.C.; Da Silva, L.F.M.; De Barros, S. Functionally graded adhesive joints by using thermally expandable particles. J. Adhes. 2019, 95, 995–1014. [Google Scholar] [CrossRef]

- Ha, J.U.; Hwang, Y.J.; Jeoung, S.K.; Lee, P.C.; Kim, S.Y.; Park, J.K.; Kim, J.T.; Yeom, J.H. Study on functional microcapsules containing catalysts for controlling the curing time and temperature of epoxy resin. J. Appl. Polym. Sci. 2019, 136, 47499. [Google Scholar] [CrossRef]

- Jonsson, M.; Nordin, O.; Kron, A.L.; Malmstrom, E. Influence of Crosslinking on the Characteristics of Thermally Expandable Microspheres Expanding at High Temperature. J. Appl. Polym. Sci. 2010, 118, 1219–1229. [Google Scholar] [CrossRef]

- Jonsson, M.; Nordin, O.; Malmstrom, E.; Hammer, C. Suspension polymerization of thermally expandable core/shell particles. Polymer 2006, 47, 3315–3324. [Google Scholar] [CrossRef]

- Kawaguchi, Y.; Itamura, Y.; Onimura, K.; Oishi, T. Effects of the chemical structure on the heat resistance of thermoplastic expandable microspheres. J. Appl. Polym. Sci. 2005, 96, 1306–1312. [Google Scholar] [CrossRef]

- Kawaguchi, Y.; Oishi, T. Synthesis and properties of thermoplastic expandable microspheres: The relation between crosslinking density and expandable property. J. Appl. Polym. Sci. 2004, 93, 505–512. [Google Scholar] [CrossRef]

- Tomalino, M.; Bianchini, G. Heat-expandable microspheres for car protection production. Prog. Org. Coat. 1997, 32, 17–24. [Google Scholar] [CrossRef]

- Mark, H.F.; Bikales, N.M.; Overberger, C.G.; Menges, G.; Kroschwitz, J.I. Encyclopedia of Polymer Science and Engineering; Wiley: Hoboken, NJ, USA, 1985. [Google Scholar]

- Senses, E.; Faraone, A.; Akcora, P. Microscopic Chain Motion in Polymer Nanocomposites with Dynamically Asymmetric Interphases. Sci. Rep. (UK) 2016, 6, 29326. [Google Scholar] [CrossRef] [PubMed]

- Patel, J.P.; Hsu, S.L. Development of low field NMR technique for analyzing segmental mobility of crosslinked polymers. J. Polym. Sci. Pol. Phys. 2018, 56, 639–642. [Google Scholar] [CrossRef]

- Bennemann, C.; Donati, C.; Baschnagel, J.; Glotzer, S.C. Growing range of correlated motion in a polymer melt on cooling towards the glass transition. Nature 1999, 399, 246–249. [Google Scholar] [CrossRef]

- Cho, E.H.; Kim, T.H.; Baek, S.-H. Polyester Film and Method for Manufacturing. PCT WO2015102354A1, 9 July 2015. [Google Scholar]

- Jeong, T.-Y.; Lee, E.-G.; Lee, S.-S.; Cho, G.-S. Characteristics of Rustling Sound of Laminated Fabric Utilizing Nano-web. Fash. Text. Res. J. 2013, 15, 620–629. [Google Scholar] [CrossRef]

- Nagai, Y.; Ogawa, T.; Nishimoto, Y.; Ohishi, F. Analysis of weathering of a thermoplastic polyester elastomer II. Factors affecting weathering of a polyether-polyester elastomer. Polym. Degrad. Stab. 1999, 65, 217–224. [Google Scholar] [CrossRef]

- Lee, K.; Yoon, B.; Lee, S. Changes in Waterproofness and Breathability after Repeated Laundering and Durability of Electrospun Nanofiber Web Laminates. Fash. Text. Res. J. 2012, 14, 122–129. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pak, A.R.; Park, J.H.; Lee, S.G. Blowing Properties and Functionality of Thermoplastic Polyester Film Using Thermally Expandable Microcapsules. Polymers 2019, 11, 1652. https://doi.org/10.3390/polym11101652

Pak AR, Park JH, Lee SG. Blowing Properties and Functionality of Thermoplastic Polyester Film Using Thermally Expandable Microcapsules. Polymers. 2019; 11(10):1652. https://doi.org/10.3390/polym11101652

Chicago/Turabian StylePak, A Ram, Jung Hyun Park, and Seung Geol Lee. 2019. "Blowing Properties and Functionality of Thermoplastic Polyester Film Using Thermally Expandable Microcapsules" Polymers 11, no. 10: 1652. https://doi.org/10.3390/polym11101652

APA StylePak, A. R., Park, J. H., & Lee, S. G. (2019). Blowing Properties and Functionality of Thermoplastic Polyester Film Using Thermally Expandable Microcapsules. Polymers, 11(10), 1652. https://doi.org/10.3390/polym11101652