Use of Grafted Voltage Stabilizer to Enhance Dielectric Strength of Cross-Linked Polyethylene

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

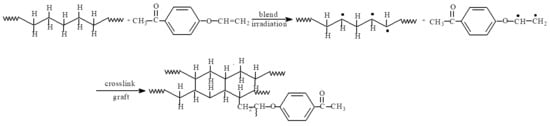

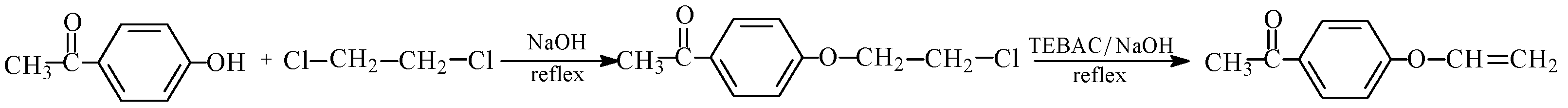

2.2. Preparation of VPE

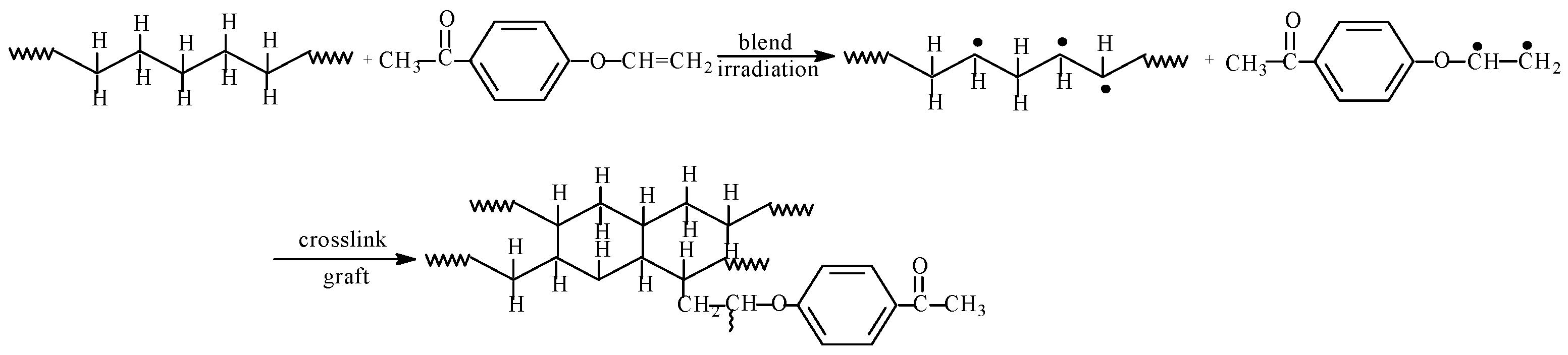

2.3. Preparation of VPE/XLPE

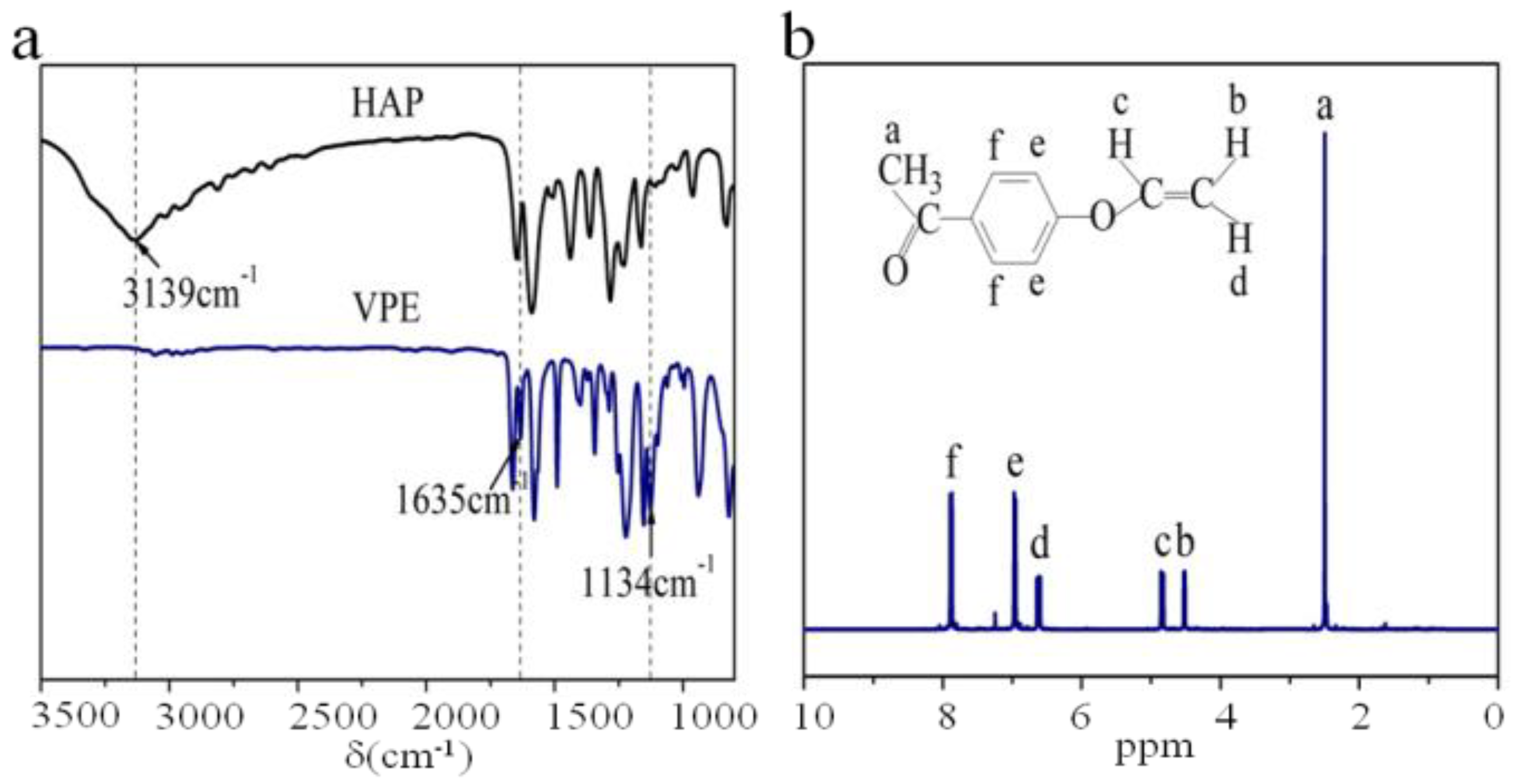

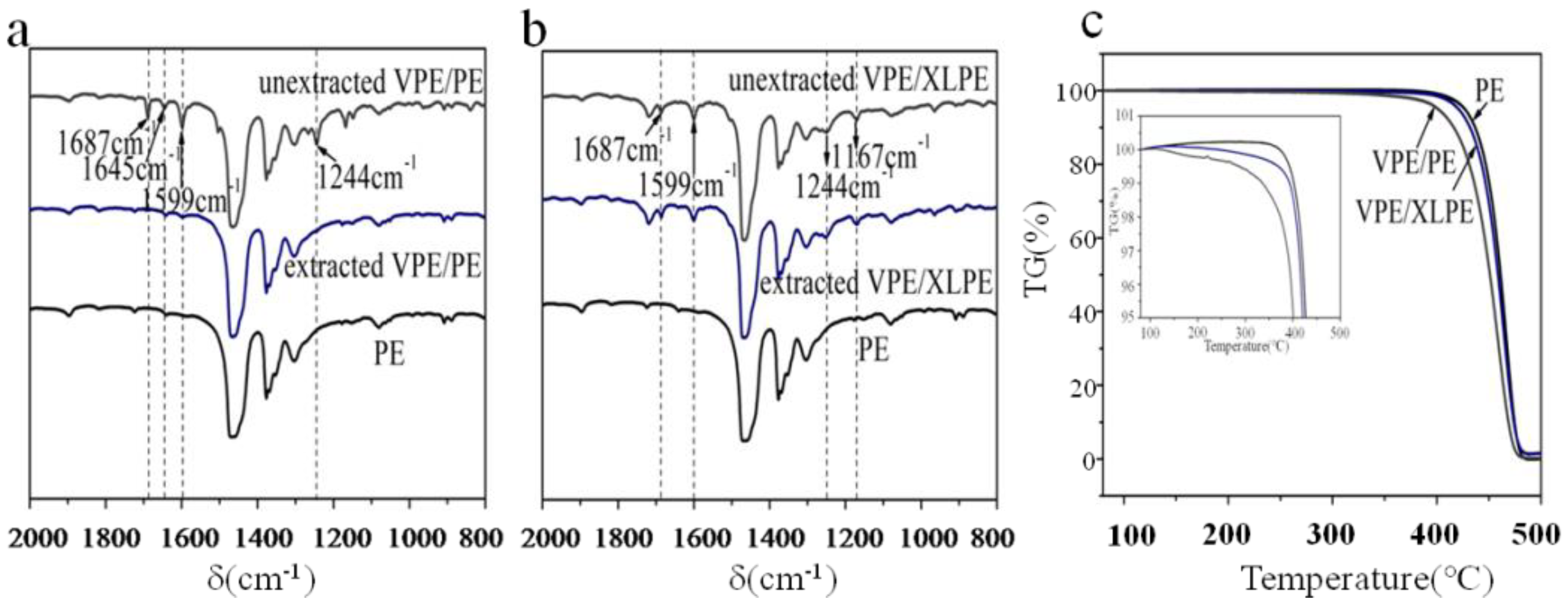

2.4. Fourier-Transform Infrared Spectroscopy (FTIR)

2.5. Nuclear Magnetic Resonance Hydrogen (1H NMR) spectroscopy

2.6. Samples Extraction

2.7. Thermogravimetric Analysis (TGA)

2.8. AC Breakdown Strength

2.9. Electrical Tree Test

2.10. γ-Ray Irradiation

2.11. Thermal Aging of the Samples

3. Results

3.1. VPE Structural Characterization

3.2. VPE Graft Characterization

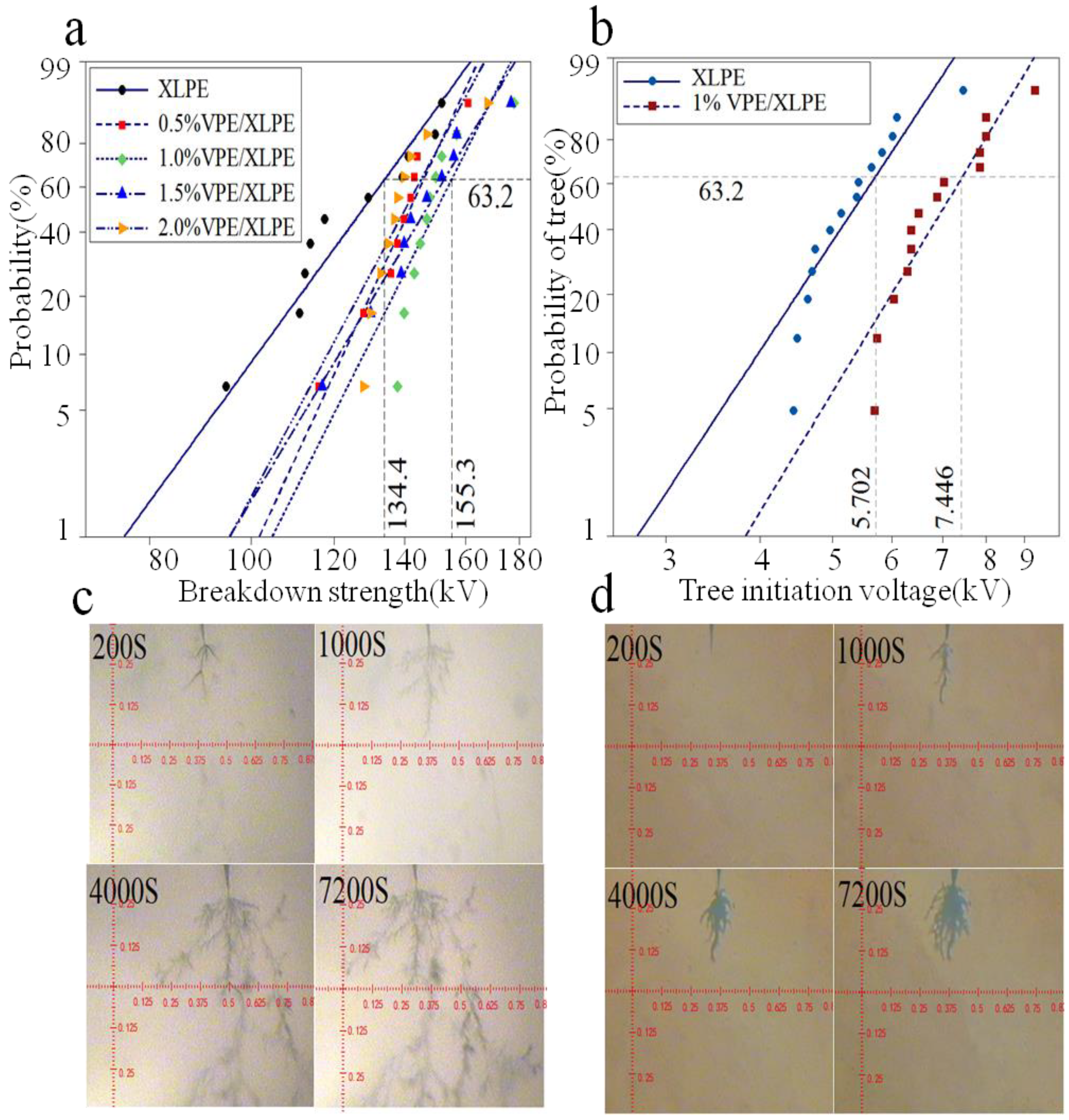

3.3. Electrical Properties of Composite Materials

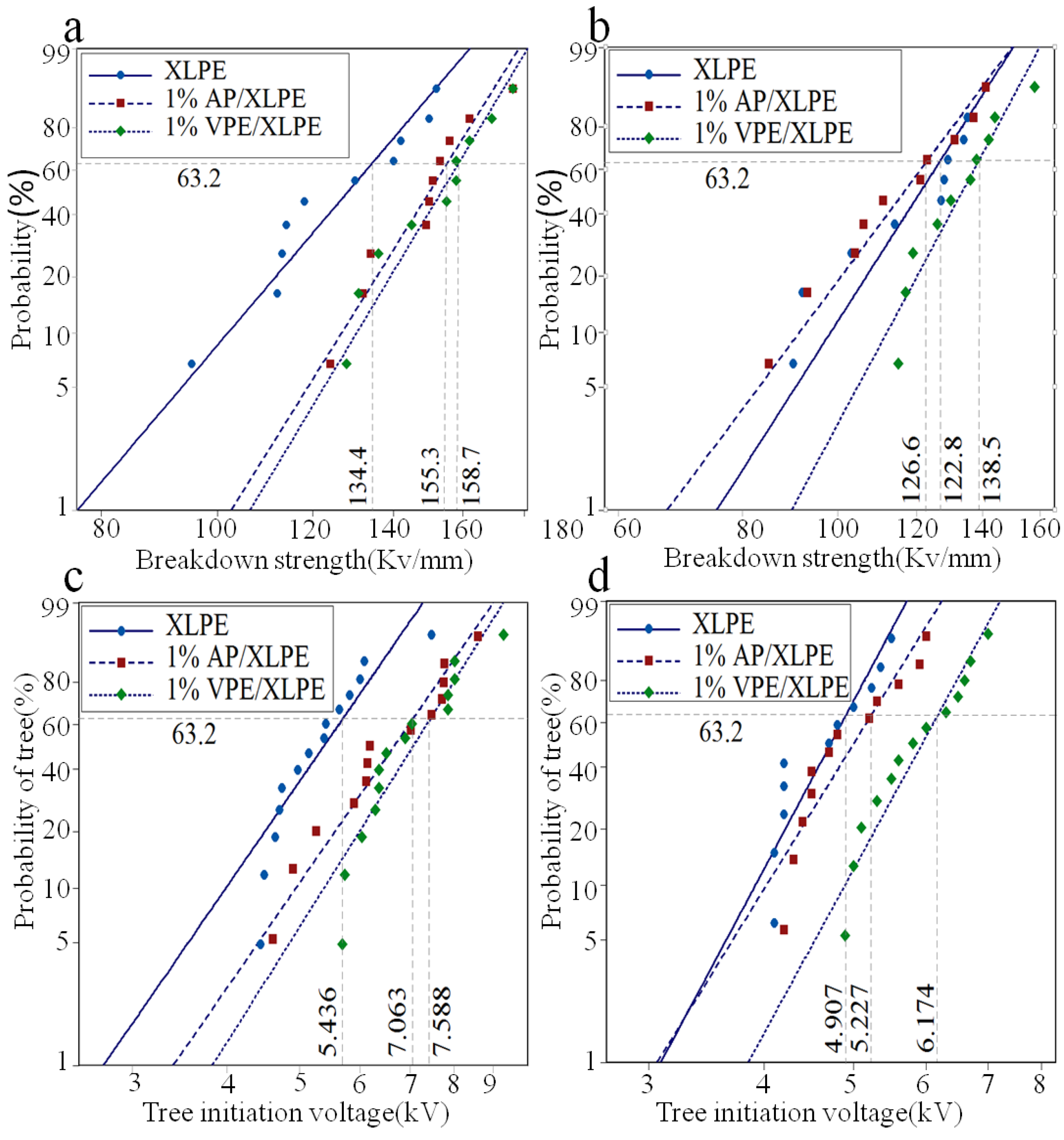

3.4. Thermal Aging

4. Conclusions

Author Contribution

Funding

Conflicts of Interest

References

- Dissado, L.A. Understanding electrical trees in solids: From experiment to theory. IEEE Trans. Dielectr. Electr. Insul. 2002, 9, 483–497. [Google Scholar] [CrossRef]

- Bahadoorsingh, S.; Rowland, S.M. Investigating the impact of harmonics on the breakdown of epoxy resin through electrical tree growth. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1576–1584. [Google Scholar] [CrossRef]

- Sarathi, R.; Nandini, A.; Tanaka, T. Understanding electrical treeing phenomena in XLPE cable insulation under harmonic AC voltages adopting UHF technique. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 903–909. [Google Scholar] [CrossRef]

- Du, B.X.; Ma, Z.L.; Gao, Y.; Han, T. Effect of ambient temperature on electrical treeing characteristics in silicone rubber. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 401–407. [Google Scholar] [CrossRef]

- Chen, X.R.; Mantsch, A.R.; Hu, L.B.; Gubanski, S.M. Electrical treeing behavior of DC and thermally aged polyethylenes utilizing wire-plane electrode geometries. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 45–52. [Google Scholar] [CrossRef]

- Liu, Y.; Cao, X.L. Electrical tree growth characteristics in XLPE cable insulation under DC voltage conditions. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 3676–3684. [Google Scholar] [CrossRef]

- Ashtiani, M.B.; Shahrtash, S.M. On-line decision tree-based insulation assessment employing mathematical morphology filters for HV cables. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1347–1355. [Google Scholar] [CrossRef]

- Zheng, X.Q.; Chen, G. Propagation mechanism of electrical tree in XLPE cable insulation by investigating a double electrical tree structure. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 800–807. [Google Scholar] [CrossRef] [Green Version]

- Zhou, K.; Huang, M.; Tao, W.B.; He, M. A possible water tree initiation mechanism for service-aged XLPE cables: Conversion of electrical tree to water tree. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1854–1861. [Google Scholar] [CrossRef]

- Yamano, Y. Control of electrical tree at initiation stage in LDPE by mixed addition of Al2O3 nano-particle and azobenzoic compound. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 209–216. [Google Scholar] [CrossRef]

- Bostrom, J.O.; Marsden, E.; Hampton, R.N.; Nilsson, U. Electrical stress enhancement of contaminants in XLPE insulation used for power cables. IEEE Electr. Insul. Mag. 2003, 19, 6–12. [Google Scholar] [CrossRef]

- Chen, X.; Murdany, D.; Liu, D. AC and DC pre-stressed electrical trees in LDPE and its aluminum oxide nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1506–1514. [Google Scholar] [CrossRef]

- Wang, S.J.; Zha, J.W.; Li, W.K.; Dang, Z.M. Distinctive electrical properties in sandwich-structured Al2O3/low density polyethylene nanocomposites. Appl. Phys. Lett. 2016, 108, 1–5. [Google Scholar] [CrossRef]

- Li, S.; Min, D.; Wang, W. Linking traps to dielectric breakdown through charge dynamics for polymer nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2777–2785. [Google Scholar] [CrossRef]

- Helal, E.; David, E.; Frechette, M.; Demarquette, N.R. Thermoplastic elastomer nanocomposites with controlled nanoparticles dispersion for HV insulation systems: Correlation between rheological, thermal, electrical and dielectric properties. Eur. Polym. J. 2017, 94, 68–86. [Google Scholar] [CrossRef]

- Liu, D.; Hoang, A.T.; Pourrahimi, A.M. Influence of nanoparticle surface coating on electrical conductivity of LDPE/Al2O3 nanocomposites for HVDC cable insulations. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1396–1404. [Google Scholar] [CrossRef]

- Liu, D.; Pallon, L.K.H.; Pourrahimi, A.M.; Zhang, P. Cavitation in strained polyethylene/aluminium oxide nanocomposites. Eur. Polym. J. 2016, 87, 255–265. [Google Scholar] [CrossRef]

- Wutzel, H.; Jarvid, M.J.; Bjuggren, M.; Johansson, A. Thioxanthone derivatives as stabilizers against electrical breakdown in cross-linked polyethylene for high voltage cable applications. Polym. Degrad. Stab. 2015, 112, 63–69. [Google Scholar] [CrossRef]

- Zhang, H.; Shang, Y.; Zhao, H.; Han, B.Z. Study of the effect of valence bond isomerizations on electrical breakdown by adding acetophenone to polyethylene as voltage stabilizers. Comput. Theor. Chem. 2015, 1062, 99–104. [Google Scholar] [CrossRef]

- Englund, V.; Huuva, R.; Gubanski, S.M.; Hjertberg, T. High efficiency voltage stabilizers for XLPE cable insulation. Polym. Degrad. Stab. 2009, 94, 823–833. [Google Scholar] [CrossRef]

- Yamano, Y.; Iizuka, M. Suppression of Electrical Tree Initiation in LDPE by Additives of Polycyclic Compound. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 189–198. [Google Scholar] [CrossRef]

- Jarvid, M.; Johansson, A.; Kroon, R. A new application area for fullerenes: Voltage stabilizers for power cable insulation. Adv. Mater. 2014, 27, 897–902. [Google Scholar] [CrossRef] [PubMed]

- Jarvid, M.; Johansson, A.; Englund, V. High electron affinity: A guiding criterion for voltage stabilizer design. J. Mater. Chem. A 2015, 3, 7273–7286. [Google Scholar] [CrossRef]

- Zhang, H.; Shang, Y.; Zhao, H.; Han, B.Z.; Li, Z.S. Mechanisms on electrical breakdown strength increment of polyethylene by acetophenone and its analogues addition: A theoretical study. J. Mol. Model. 2013, 19, 4477–4485. [Google Scholar] [CrossRef]

- Englund, V.; Hjertberg, T.; Andersson, M. Polyolefin composition for medium/high/extra high voltage cables comprising benzil-type voltage stabiliser. U.S. Patent No. 11705815.6, 21 August 2013. [Google Scholar]

- Jarvid, M.; Johansson, A.; Bjuggren, J.M.; Wutzel, H. Tailored side-chain architecture of benzil voltage stabilizers for enhanced dielectric strength of cross-linked polyethylene. J. Polym. Sci. Part B 2014, 52, 1047–1054. [Google Scholar] [CrossRef]

- Englund, V.; Huuva, R.; Gubanski, S.; Hjertberg, T. Synthesis and efficiency of voltage stabilizers for XLPE cable insulation. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 1455–1461. [Google Scholar] [CrossRef]

- Zhang, H.; Shang, Y.; Li, M.X.; Zhao, H. Theoretical study on the radical reaction mechanism in the cross-linking process of polyethylene. RSC Adv. 2015, 5, 90343–90353. [Google Scholar] [CrossRef]

- Zhang, H.; Shang, Y.; Zhao, H.; Wang, X. Theoretical study on the reaction of maleic anhydride in the UV radiation cross-linking process of polyethylene. Polymer 2017, 133, 232–239. [Google Scholar] [CrossRef]

- Gurnule, W.B.; Rahangdale, P.K.; Paliwal, L.J.; Kharat, R.B. Synthesis, characterization and ion-exchange properties of 4-hydroxyacetophenone, biuret and formaldehyde terpolymer resins. React. Funct. Polym. 2003, 55, 255–265. [Google Scholar] [CrossRef]

- Yamano, Y. Roles of polycyclic compounds in increasing breakdown strength of LDPE film. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 773–781. [Google Scholar] [CrossRef]

| Sample | Shape | AC Breakdown Strength (kV/mm) |

|---|---|---|

| XLPE | 8.14 | 134.4 |

| 0.5% VPE/XLPE | 12.78 | 146.0 |

| 1% VPE/XLPE | 11.11 | 155.3 |

| 1.5% VPE/XLPE | 9.79 | 152.8 |

| 2% VPE/XLPE | 10.98 | 145.3 |

| Sample | Shape | Electrical Tree Initiation Voltage (kV) |

|---|---|---|

| XLPE | 6.30 | 5.702 |

| 1% VPE/XLPE | 6.92 | 7.446 |

| Sample | AC Breakdown Strength before Thermal Aging (kV) | AC Breakdown Strength After Thermal Aging (kV) | Heat Aging Loss Ratio (%) |

|---|---|---|---|

| XLPE | 134.4 | 126.6 | 5.8 |

| AP/XLPE | 155.3 | 122.8 | 20.9 |

| VPE/XLPE | 158.7 | 138.5 | 12.7 |

| Sample | Tree Initiation Voltage before Thermal Aging (kV) | Tree Initiation Voltage after Thermal Aging (kV) | Heat Aging Loss Ratio (%) |

|---|---|---|---|

| XLPE | 5.436 | 4.907 | 12.5 |

| AP/XLPE | 7.063 | 5.227 | 26.0 |

| VPE/XLPE | 7.588 | 6.174 | 18.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, W.; Wang, X.; Tian, B.; Liu, Y.; Jiang, Z.; Li, Z.; Zhou, W. Use of Grafted Voltage Stabilizer to Enhance Dielectric Strength of Cross-Linked Polyethylene. Polymers 2019, 11, 176. https://doi.org/10.3390/polym11010176

Dong W, Wang X, Tian B, Liu Y, Jiang Z, Li Z, Zhou W. Use of Grafted Voltage Stabilizer to Enhance Dielectric Strength of Cross-Linked Polyethylene. Polymers. 2019; 11(1):176. https://doi.org/10.3390/polym11010176

Chicago/Turabian StyleDong, Wei, Xuan Wang, Bo Tian, Yuguang Liu, Zaixing Jiang, Zhigang Li, and Wei Zhou. 2019. "Use of Grafted Voltage Stabilizer to Enhance Dielectric Strength of Cross-Linked Polyethylene" Polymers 11, no. 1: 176. https://doi.org/10.3390/polym11010176

APA StyleDong, W., Wang, X., Tian, B., Liu, Y., Jiang, Z., Li, Z., & Zhou, W. (2019). Use of Grafted Voltage Stabilizer to Enhance Dielectric Strength of Cross-Linked Polyethylene. Polymers, 11(1), 176. https://doi.org/10.3390/polym11010176