1. Introduction

Fused deposition modelling is an extrusion 3D printing process, mostly based on polymers in the filament form. However, it can also use the raw feedstock materials in the pellet form, which drastically reduces the material costs, as the production of a uniform filament is time consuming and relatively expensive. However, not all polymeric materials are suitable for processing from the pellet form. In this paper a biopolymer composite based on polybutyrate-adipate-terephthalate–polymer (PBAT) or polybutyrate is evaluated for possible use as a raw material in the pellet form for processing by extrusion 3D printing. PBAT is copolymer made up of adipic acid, butanediol, and terephthalic acid and though synthetic, is biodegradable [

1]. Terephthalic acid gives rise to high thermal stability and mechanical properties while adipic acid and butanediol impart flexibility and biodegradability.

Biopolymer composite films made by polylactide (PLA)/PBAT blends filled with finely ground Babassu powders were analyzed by Franca et al. [

1] as alternatives for cost effective packing solutions. Evaluation of specimens made by solvent casting techniques showed acceptable mechanical properties but evidence of immiscibility in the Fourier-transform infrared spectroscopy (FTIR) and differential scanning calorimetry (DSC) results. An addition of 10% of Babassu to the PLA/PBAT blend was found to be the most optimum and cost-effective solution. Polymer composites based on PBAT and cellulose nanocrystals were analyzed by small amplitude oscillatory shear experiments showing that the elastic behavior enhances with increasing amounts of the nano-cellulose, revealing a reinforcing effect of the nano particles [

2]. Spatial reorganization of the nano-rods was observed further to a thermal annealing treatment at 170 °C for 30 min. Polybutyrate is a flexible and tough biodegradable polymer and in the current study, wood flour will be used as the filler material while extrusion 3D printing from the pellet form.

Cicala et al. developed Polythermide (PEI) blends based on either polycarbonate (PC) or polyethylene terephthalate glycol-modified (PETG) and evaluated the same for processing by fused deposition modelling in comparison with the commercial Ultem 9085 material option by Stratasys [

3]. Based on rheological, morphological, and thermomechanical responses, the PEI/PC blends with 10% by weight of the modifier were proved to exhibit viscous behavior close to the commercial Ultem material, while PEI blends with PC contents lower than 20% by weight were found to be better than the commercial Ultem in terms of thermomechanical responses. Cicala et al. also evaluated three commercial grade PLA filaments in terms of the quality of printing a complex shape with overhang features [

4]. Evaluations based on shear thinning studies, scanning electron microscope (SEM), and thermo-gravimetric analysis proved that the filaments with mineral fillers result in the best printing quality.

Matsuzaki et al. experimented composite fiber materials infused into PLA for 3D printing, targeting better mechanical properties for the printed parts [

5]. A FDM printer was modified in order to impregnate the filament with composite fibers during extrusion. The reinforcing fiber was heated using a nichrome wire before it entered the nozzle to enhance the permeation of the fiber bundles with the thermoplastic resin. The resin filament is melted by the heater inside the nozzle, consolidating the reinforcing fibers and the resin in the heating chamber. Final results show superior Young’s modulus and strengths compared with materials fabricated using commercial 3D printers. Guo et al. also adopted wood-plastic composites for selective laser sintering (SLS) [

6]. The main composition consisted of wood flour and a co-polyester powder that accounted for over 90% of the mass. The overall void fraction was obtained to be 51%, prior to post processing. Wax infiltration was shown to reduce the void fraction to 7%. The final components produced were reported to have relatively high dimensional accuracy with sufficient strength.

There was little evidence of PBAT processed by additive technologies in the past, but other conventional methods were attempted. Ludvik et al. investigated the addition of cellulose fibers in PBAT with bentonite clay to improve fiber dispersion and result in a higher water resistance [

7]. The average modulus of the composite material was reported to be higher than that of the composition without the cellulose fiber. However, the strength and elongation at break displayed the opposite relationship, which could potentially be overcome by surface modifications of the fiber-matrix. It was noted that weak adhesion between the cellulose fiber and the thermoplastic/clay matrix after the drying stage could cause the fiber to clump during processing, unless a special binder was implemented. Yeh et al. studied the compatibility, crystallization, and tensile properties of PLA/PBAT blends in different proportions produced by melt blending [

8]. The results showed PBAT to be effective in increasing the toughness of PLA.

The focus of this article is to establish the feasibility of the combination PBAT-wood flour blends to be processed by extrusion 3D printing and establishing the ideal process conditions for the best quality of the printed samples. The emphasis is on the conjoined attributes possible by combining PBAT and wood flour, a biodegradable polymer fibrous material. Blends of the two constituents in different compositions will be evaluated in the pellet form for extrusion 3D printing with varying process conditions.

2. Materials and Methodology

2.1. Materials

The biodegrade material under investigation in this paper is PBAT with different wood flour compositions as listed in

Table 1 infused into the base polymer. The polymer composites are developed and compounded by twin screw extrusion at Scion (Rotorua, New Zealand). The extrusion was carried out on a 26 mm co-rotating twin-screw extruder (Labtech Engineering Ltd, Praksa, Muang, Samutprakarn, Thailand) with a L/D ratio of 40. The compositions of wood flour used include 0 wt % (Neat), 5 wt %, 10 wt %, and 20 wt %.

2.2. Basic Print Parameters

The melting temperature of the material was identified to be 120 °C from the data sheet of ecoflex

® F Blend C1200. The material was preheated at 50 °C for 15 min using an electric oven, to remove residual moisture that may have accumulated [

9]. A homemade extrusion 3D printer developed at AUT was used in these experimental trials [

10]. The extrusion chamber was also preheated to the specified melting temperature of the material (120 °C), allowing time for the chamber to reach a steady state temperature and enabling a consistent heat transfer into the polymer to melt progressively and attain a uniform flow.

Mesostructures resulting from the constrained coalescence between strands [

11] and certain process parameters [

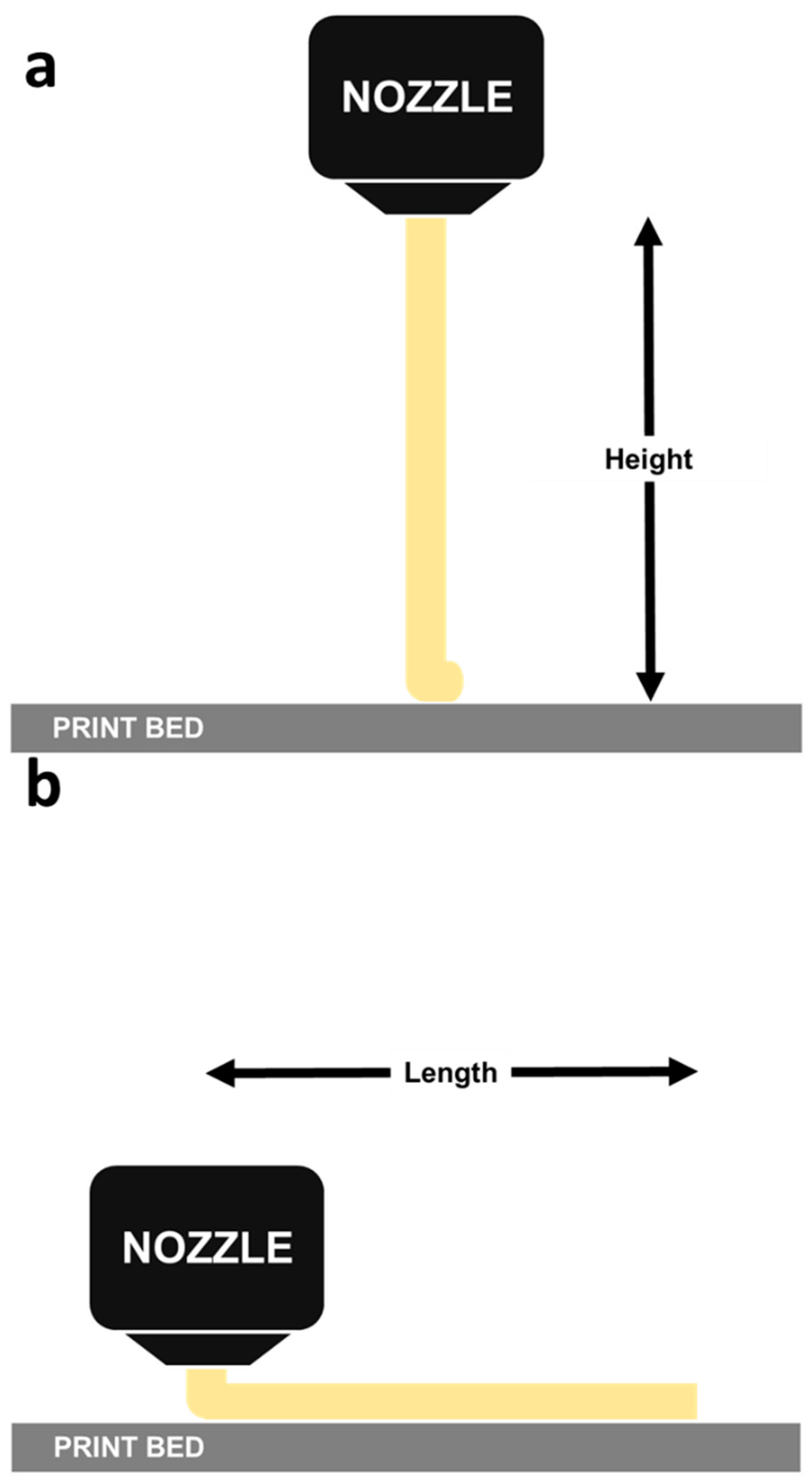

12] were reported to be critical in controlling the quality of parts produced by fused deposition modelling. For consistent material deposition and consolidation, the extrusion (spindle speed) and print velocities should be synchronized. This is to ensure no build-up of excess material (bulging) due to a faster extrusion rate with a slower printing speed. A slower extrusion rate with a high printing speed would cause the filament to be stretched, which is also undesired. To identify the extrusion velocity, the nozzle was positioned at a fixed vertical height (200 mm) from the print bed. Using initial spindle speed of 1300 RPM, the time taken for a filament to travel the height was recorded, from which the experimental extrusion velocity could be calculated, as illustrated in

Figure 1a. This height must be relatively small as at elevated distances, gravitational forces would have a more significant impact on the end result. To identify the print velocity, the nozzle was positioned at a fixed horizontal distance (200 mm) from one end of the print bed, the time taken for the nozzle to travel the fixed distance as shown in

Figure 1b was recorded. The experiment was repeated with different distances and the data generated was used to establish the printing and extrusion velocities as 1300 RPM and 540 mm/min respectively. Multiple trials were conducted to ensure reliable data generation.

2.3. Critical Temperature Settings

Printing trials began first with the base polymer, PBAT100 and then extended to the polymer composites with increasing wood flour content, PBAT95, PBAT90, and PBAT80. Once the printer is prepared and after reaching the desired temperatures, the heated polymer pellets were slowly fed into the hopper of the FDM printer. As the pellets move through the length of the feed chamber the temperature gradually rises and finally the plasticized pool of polymer gets collected in the extrusion chamber. Due to the pressure building up from the continuous accumulation, the semi-solid material is extruded from the nozzle tip (2 mm diameter) onto the print bed. Initially, the extrusion and bed temperatures were set to 110 °C and 90 °C respectively, as identified from the data sheet. However, the extrusion temperature at 110 °C proved to be insufficient, as the polymer was sticking to the surfaces and causing problems to the screw feeding. As a result, the temperature of the extruder was increased by 5 °C intervals until a continuous filament was produced, eventually at 125 °C.

2.4. Filament Settings

The diameter of the extruded polymer filament was found to increase with prolonged exposure to moisture, with a certain absorption rate. The moisture would cause aeration during extrusion, as the water vaporizes at high temperatures, air bubbles form within the filament resulting in an increase in the diameter. It would also weaken the overall structure with the addition of internal porosities. To remove the residual moisture that may have accumulated from the environment, the material was preheated in an oven at 60 °C for 15 min prior to printing.

Ideally, during extrusion, the viscosity should be low enough for continuous flow at high temperatures, but not too low that the flow behavior is non-uniform. However, during printing, the viscosity should be high enough that it is able to promote sintering, without drastic variations in the shape of the polymer strand [

13]. The ability of the polymer to maintain an appropriate viscosity value throughout the various stages of printing dictates the quality of the polymer sintering, which has a direct impact on the mechanical properties of the printed components.

Using the optimized extrusion temperature, a continuous strand was made to observe the printing behavior and consistency. The distance between the nozzle tip and the print bed (air gap) was determined by visual examination, to accommodate the size variation of the filament with an additional gap to provide clearance between the part and the nozzle, to avoid physical contact. The distance between each subsequent strand (strand gap) was also determined visually. A small overlap of about 10% between adjacent strands was included to promote inter-strand sintering based on the print quality at the best extrusion temperature identified, 125 °C. The next step was to print single layer rectangular samples (20 × 50 mm) to observe the sintering behavior on a preliminary level. Multi-layer samples (4 mm thick) were then printed to examine how the parameters interact when printing three dimensionally.

3. Initial Experimental Results

3.1. Optimal Printing Parameters

The optimal settings for the critical printing parameters; extrusion temperature, bed temperature, extrusion velocity (spindle speed), print velocity, strand gap, and air gap were identified mainly based on visual inspection during the initial printing process. The parameter levels identified are as listed in

Table 2. It is important that the extruded filament remains in a semi-solid state, where the material has a moderately high viscosity and will retain its cylindrical shape [

11,

12,

13,

14,

15,

16]. This is to help facilitate interlayer sintering between neighboring strands. If the filament is either in a solid or liquid state, the component will not sinter properly or have immense dimensional variations respectively. The nozzle and chamber were both exposed to the atmospheric conditions, hence the actual temperature inside the chamber may be lower than the indicated temperature. This would explain the discrepancy between the specified melting temperature from the data sheet and the actual extrusion temperature, which was caused by heat loss from the chamber. The heating element is located only near the bottom of the nozzle.

The base platform is heated, otherwise the sample will be cooled prematurely causing it to shrink and lift off the platform. This issue was problematic during multilayer samples, as the heat from the platform is not sufficiently able to be transferred through the multiple layers. This caused the sample to lift off the platform during the printing of another layer. Increasing the base temperature causes the polymer to melt as the base temperature approaches the melting temperature. To resolve this problem, masking tape was applied to the platform for additional surface resistance and frictional forces. The heated temperature should be just below the glass transition temperature to keep the filament in a semi-solid state (110 °C). The glass transition temperature is mainly associated with amorphous polymers, which is the temperature that provides sufficient energy for the ions to move without restriction. It was difficult to maintain this temperature with the multilayer samples, as the print chamber is not completely enclosed.

3.2. Strand Continuity

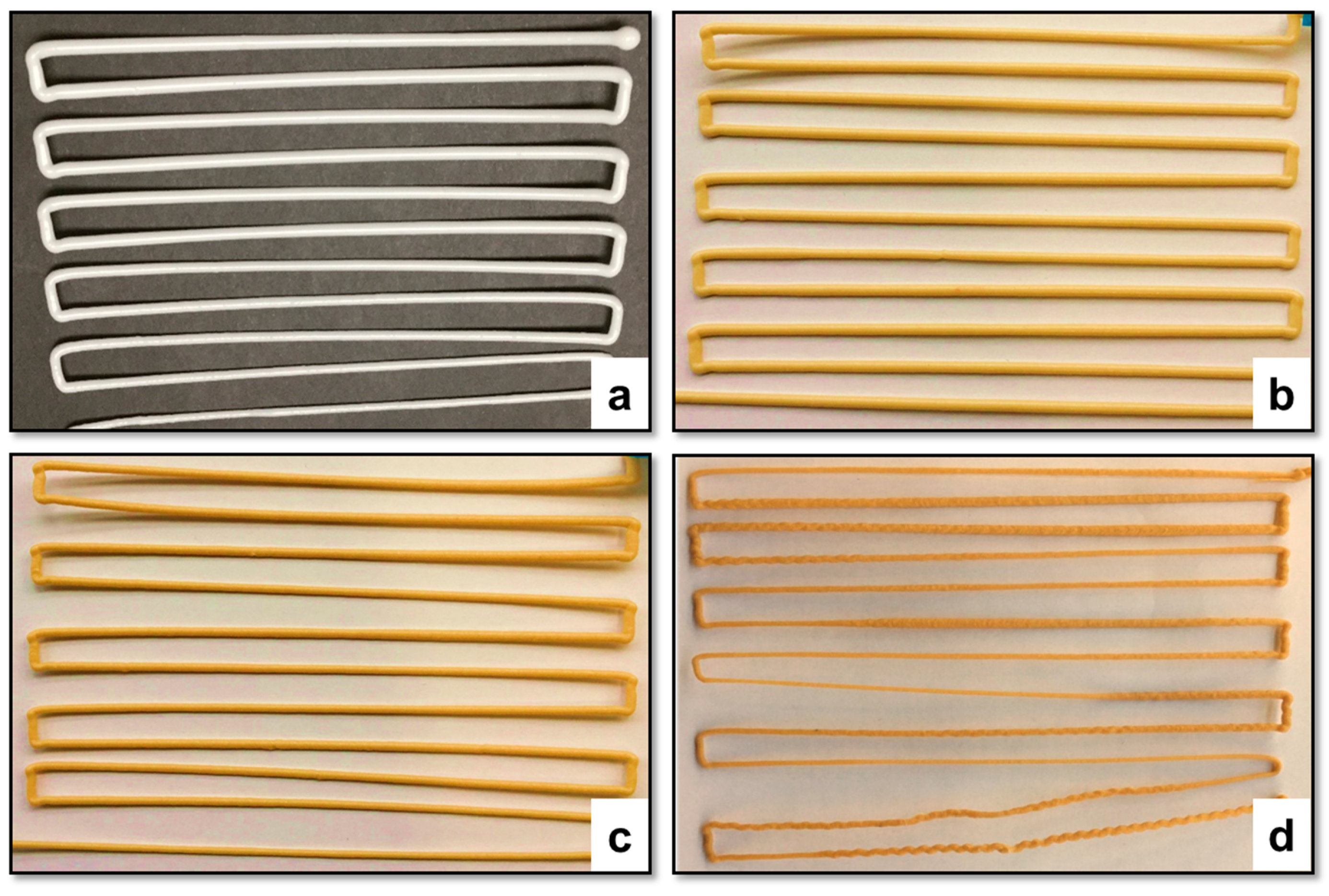

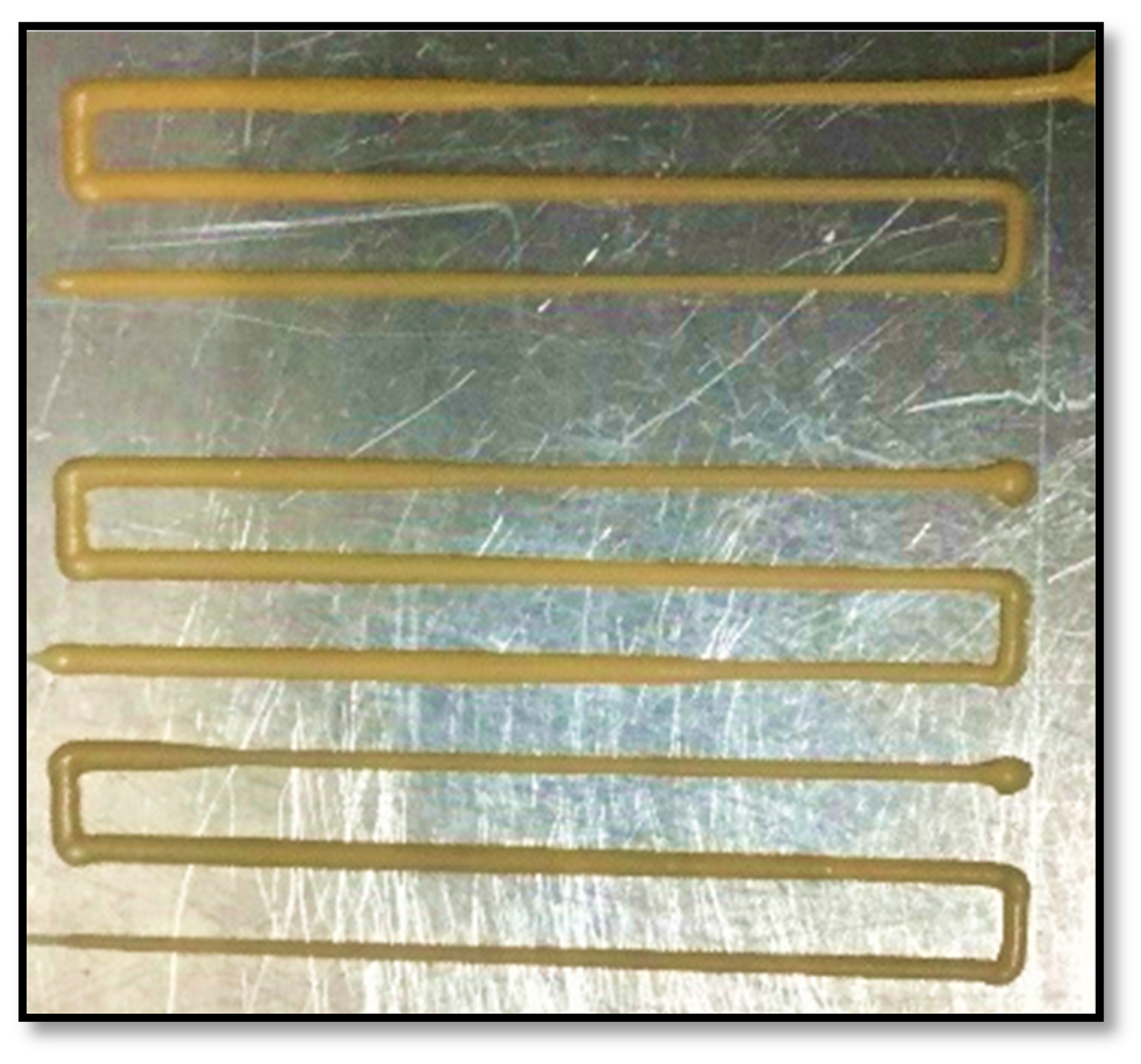

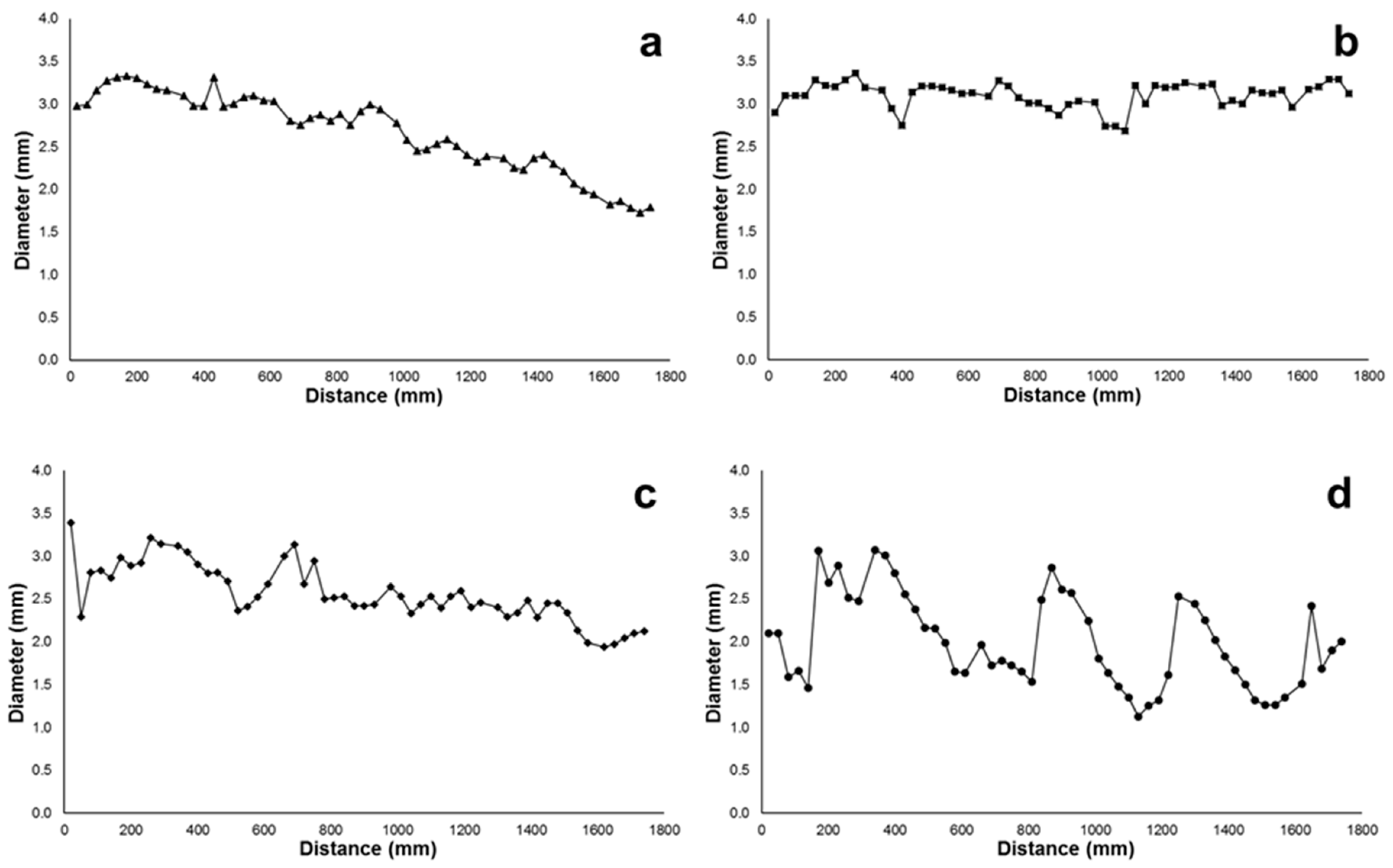

Pellet-based extrusion 3D printing using polymer composites loaded with filler materials often gives rise to problems in the continuity of the extruded filament. Experiments based on continuously printing the filament were conducted to observe the dimensional stability of the strand generated as shown in

Figure 2. A material with a good stability during extrusion would have almost a constant filament diameter with minimal variation. As seen in

Figure 2, PBAT95 (b) and PBAT90 (c), produced the most uniform filament strands, while the diameter of PBAT100 (a) continued to decrease gradually. PBAT80 (d) had an unusual result, where the filament diameter was continuously changing somewhat arbitrarily and at certain points the filament became wavy.

The pure PBAT and the PBAT-wood flour composites at higher filler content behaved in similar ways in terms of the filament consistency. With time, the polymer develops blockage through the nozzle, either due to the accumulation of the partly solidified mass in the case of pure PBAT or the filler material in the case of the PBAT-wood-floor composites with excessive filler materials such as the PBAT80 in this case. In between, the other two cases at 5% and 10% filler contents showed the best extrusion characteristics of the polymer composite. Clearly, small quantities of the wood-flour when added to the base polymer help improve the extrusion responses of the composite. However, beyond 10 percent by weight, solid wood particles aggregate in the nozzle and destabilize the extruded filament characteristics and consequently the printing process.

3.3. Single Layer Samples

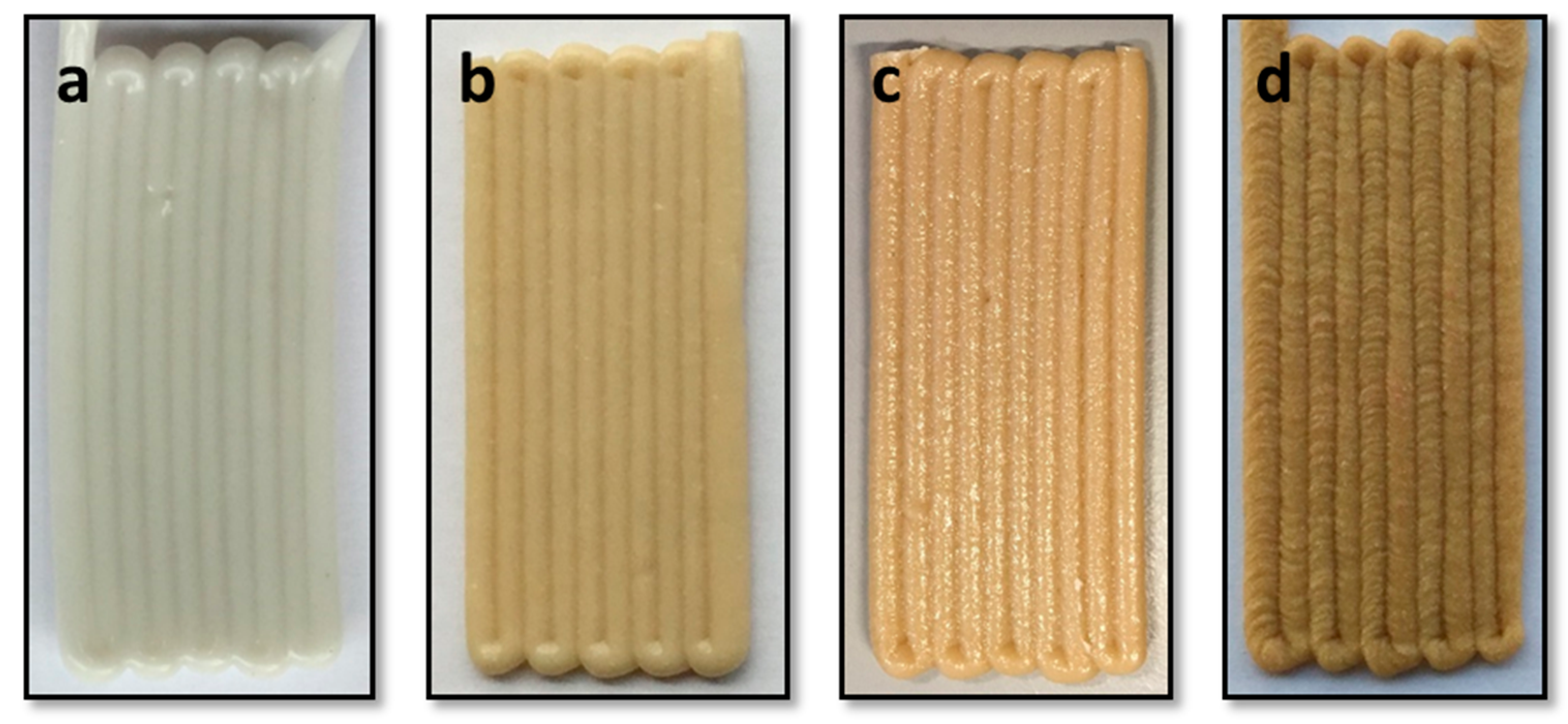

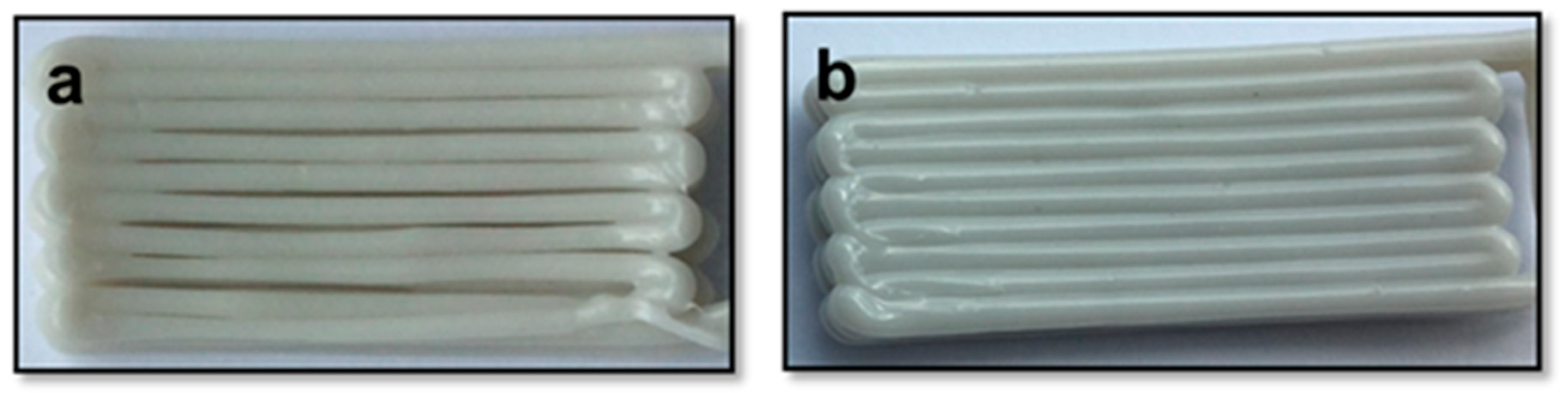

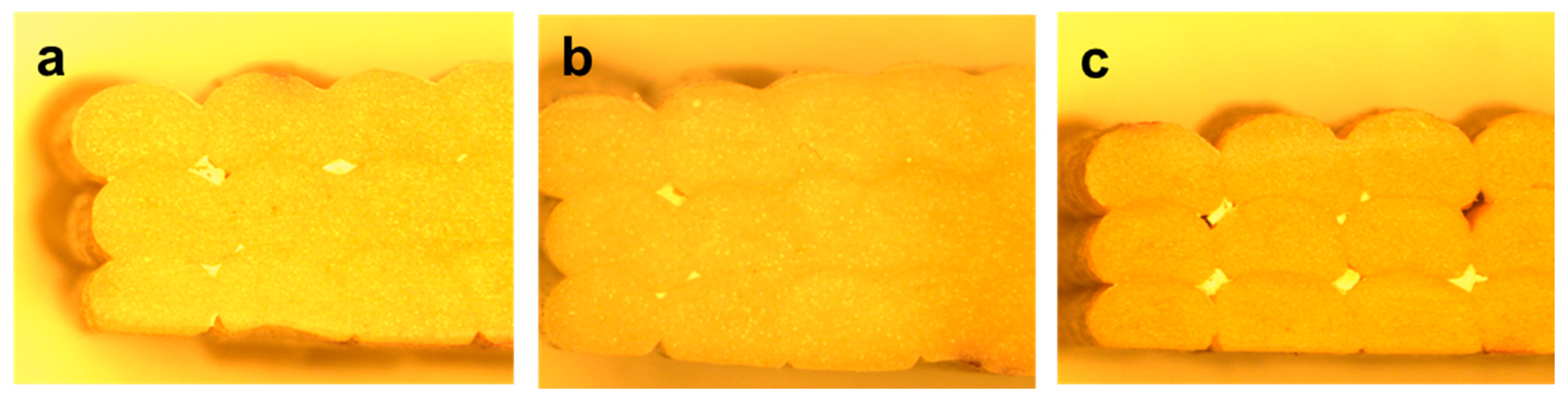

Single layer samples (20 × 50 mm) were printed to observe the sintering behavior at a preliminary level. All the materials could be printed as single layer samples to a high degree of quality as may be noted in

Figure 3, by adjusting the process parameters as listed in

Table 2.

3.4. Multilayer Samples

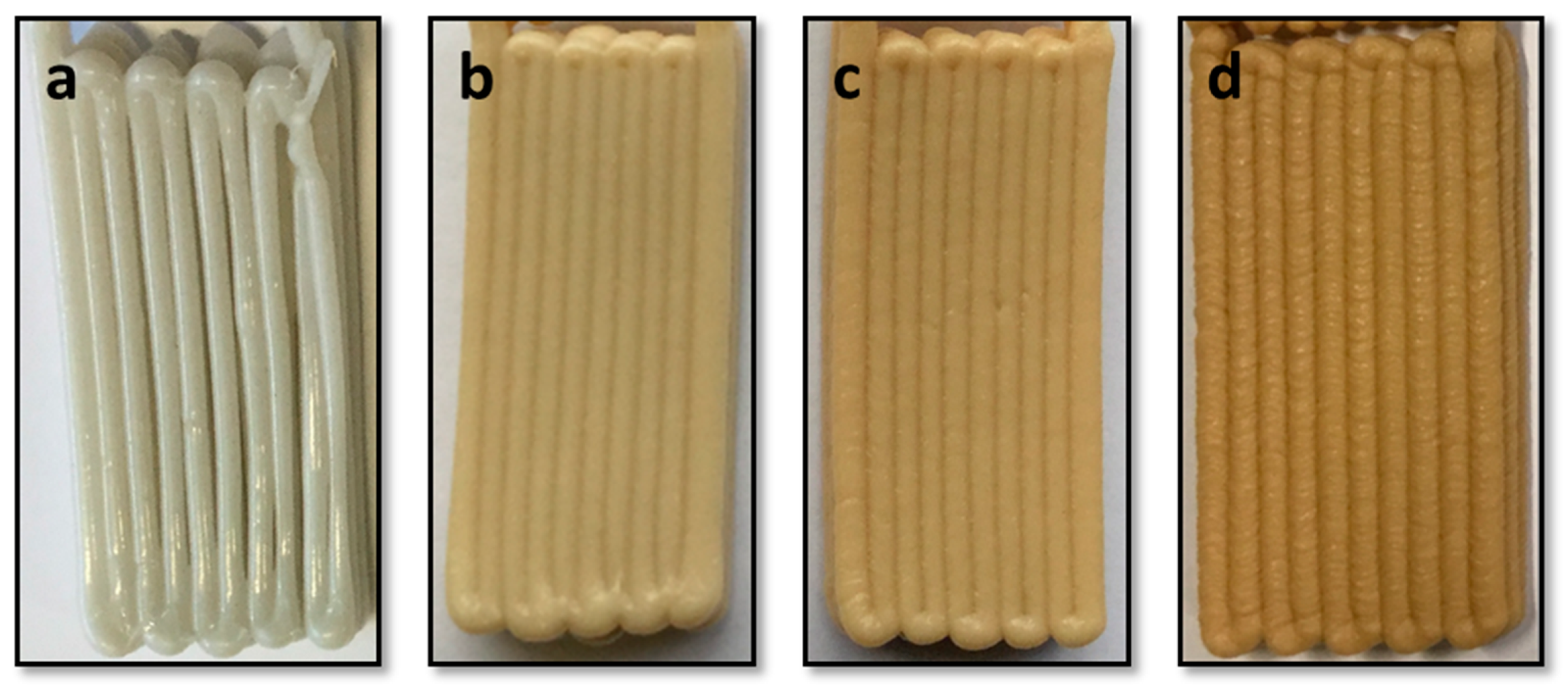

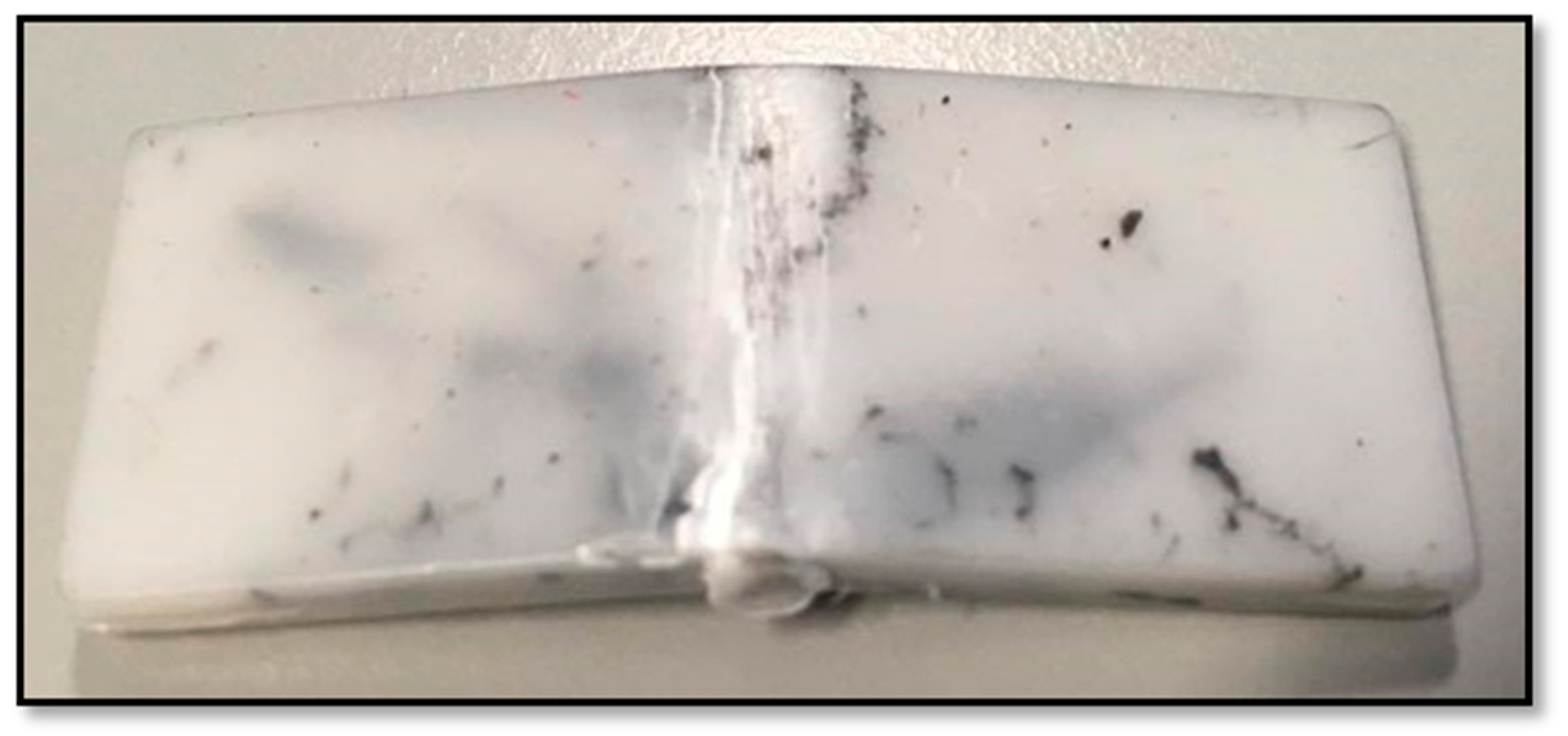

Multi-layer samples with 3 layers (6 mm in thickness) were printed to examine how the parameters interact while achieving the inter-layer coalescence. As shown in

Figure 4a, PBAT100 had difficulties when printing multiple layers. This is due to a gradual decrease in the filament diameter as may be observed in

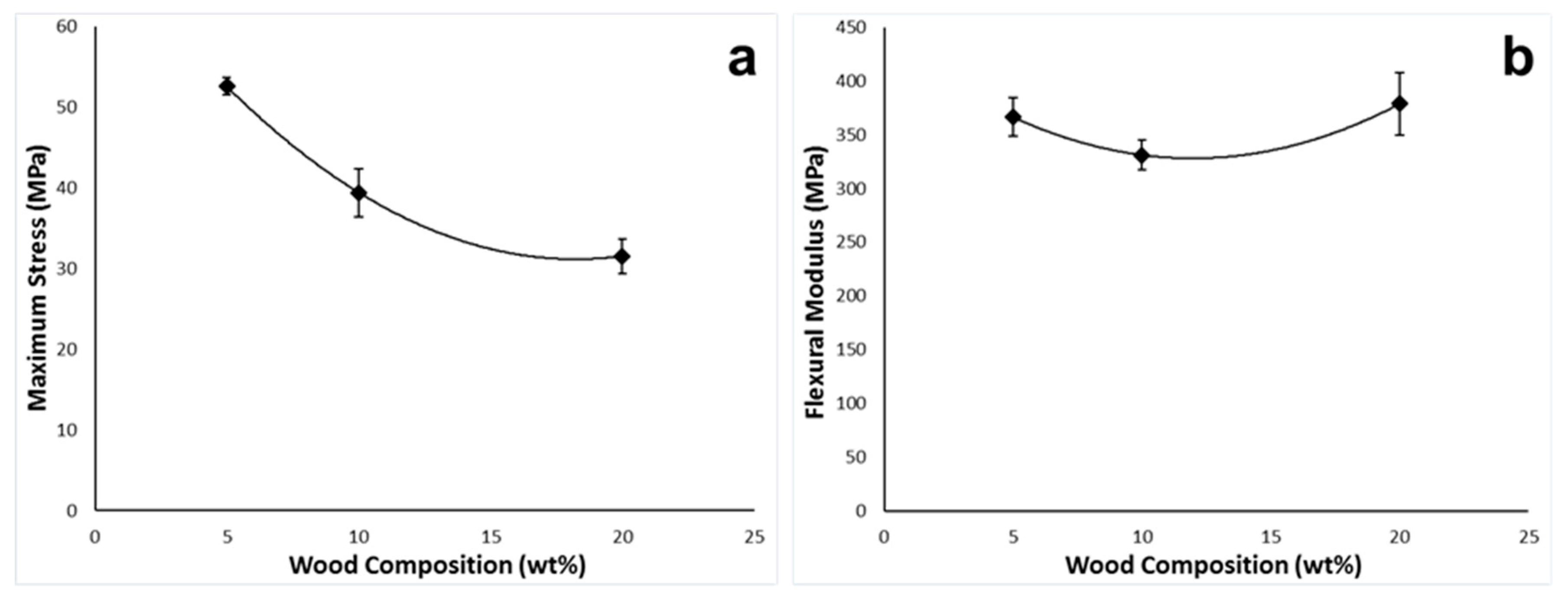

Figure 3a. The first two layers of the sample could be printed successfully, but, during the final layer, the material flow began depleting. The neighboring filament strands would not come into contact with each other, leading to a clear lack of inter-strand coalescence. The other three samples with varying amounts of the filler material showed clear evidence of improved consolidation. In particular, samples with 5% and 10% wood contents gave the best results in terms of the inter-strand coalescence. With further increase in the wood-flour content, the polymer loses some of the thixotropic nature, leading to premature solidification and lack of coalescence between adjacent strands.

The dimensional variation of the overall sample was evaluated using digital caliper measurements central to the length of the sample [

17]. As per the CAD model, the dimensions of the samples should be 6 mm in thickness and 20 mm in width. The results presented in

Table 3, show that both thickness and width increased, which is probably due to the aeration and expansion of the filament upon exit from the nozzle. Relatively, the thickness of the three layered samples decreased with the amount of wood flour content, while the width of the sample increased. It was also noted that the thickness of PBAT80 was below the designed value, whereas the other material compositions resulted in measurements above the theoretical values. This may have been caused by the elevated extrusion temperature, resulting in a loss of viscosity of the material and the ‘running away’ of the relatively soft substrate. This is also reflected in the width of PBAT80, where it substantially increased compared to the other samples.

6. Conclusions

PBAT and food-flour composites are evaluated for 3D printing by extruding from the pellet form. The results are generally positive, indicating the suitability of the polymer composite for 3D printing directly from pellet forms. However, the mechanical properties of the printed parts are poor relative to the injection molded counterparts, though it is always the case with any printed object, considering the meso-structural lapses. Pure PBAT exhibited lack of filament consistencies and consequent loss of print quality. Adding filler materials up to a certain extent was proved to improve the extrusion characteristics significantly, which has also reflected in the enhanced print quality. The maximum strength of the printed parts gradually decreased with increasing wood filler content. Samples printed extruding the 95% PBAT and 5% wood-flour filler resulted in the optimum response levels at the best coalescence, higher strength, and ductility levels.