Modeling of Flexible Polyurethane Foam Shrinkage for Bra Cup Moulding Process Control

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Microscopy Analysis

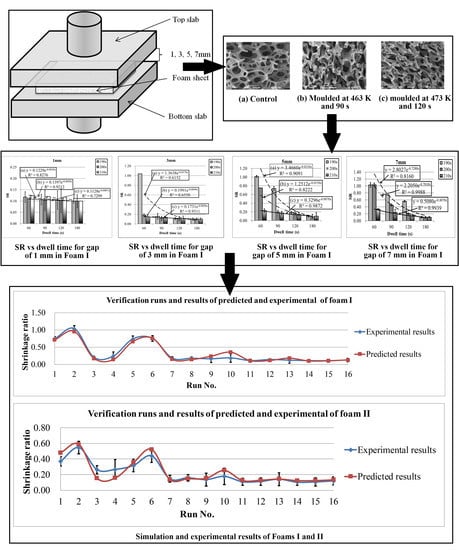

2.3. Moulding of PU Foam Specimens

2.4. Heat Transfer Mechanisms

2.5. Thickness Measurement

2.6. Shrinkage Ratio

3. Results and Discussion

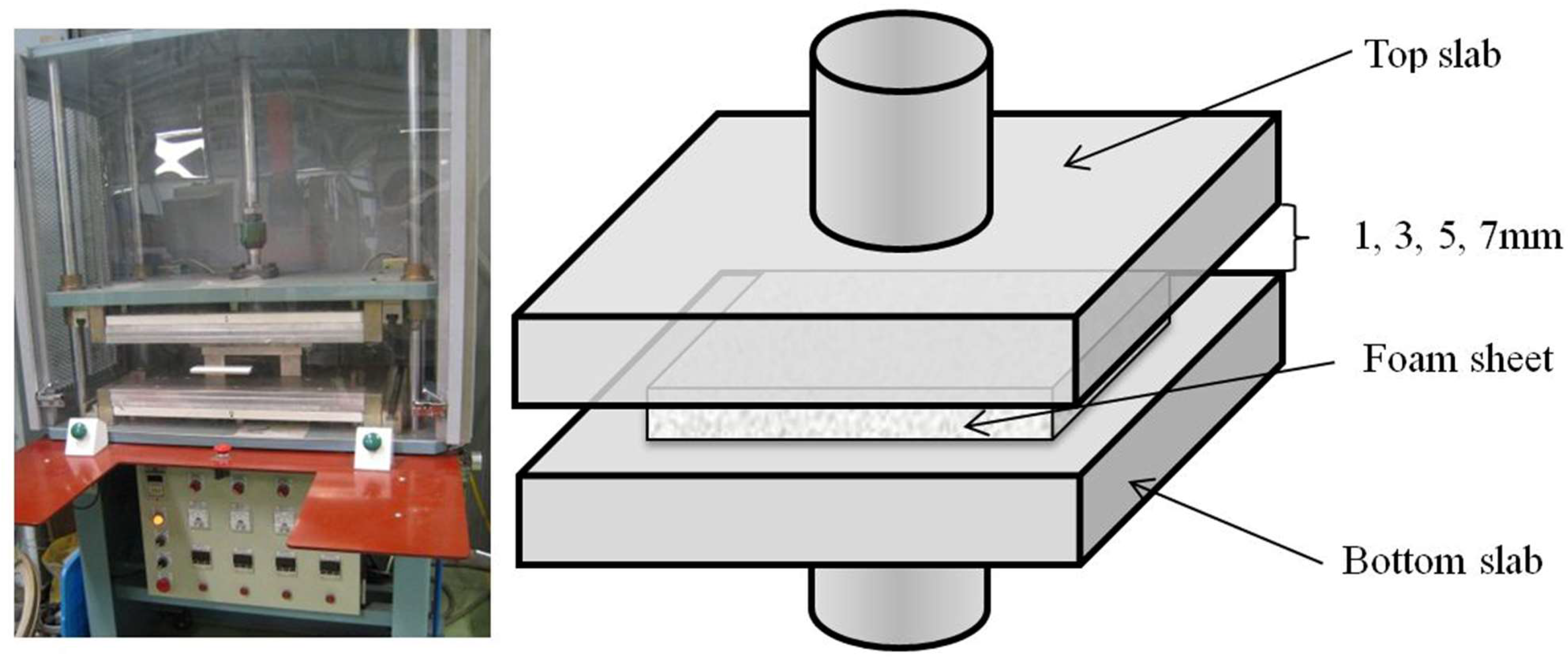

3.1. Scanning Electron Microscopy (SEM)

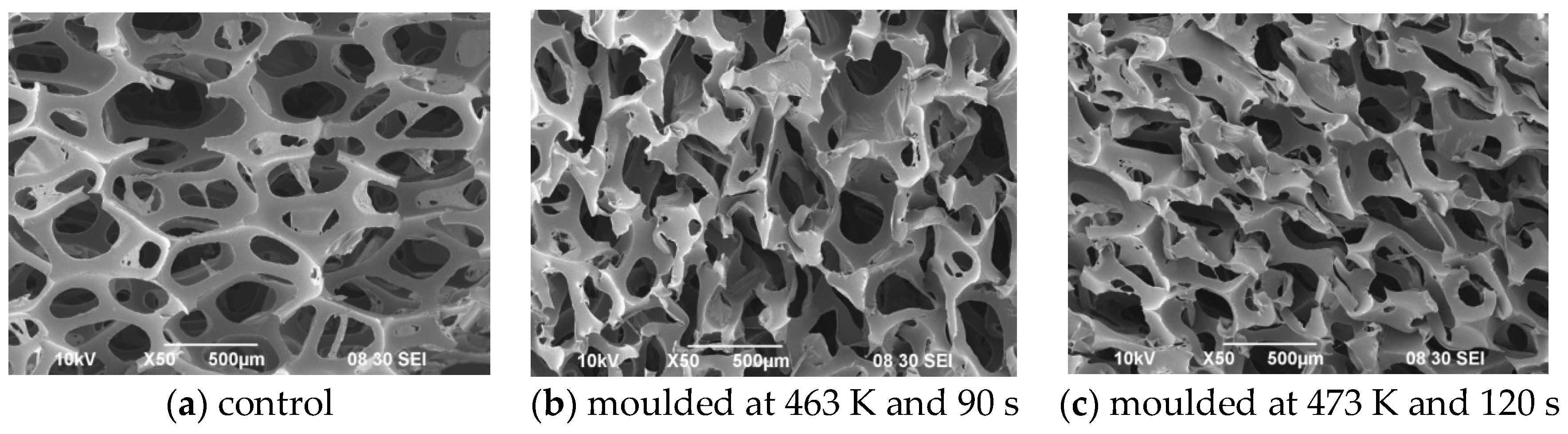

3.2. Shrinkage Ratio and Dwell Time

3.3. Thermal Conduction Analysis

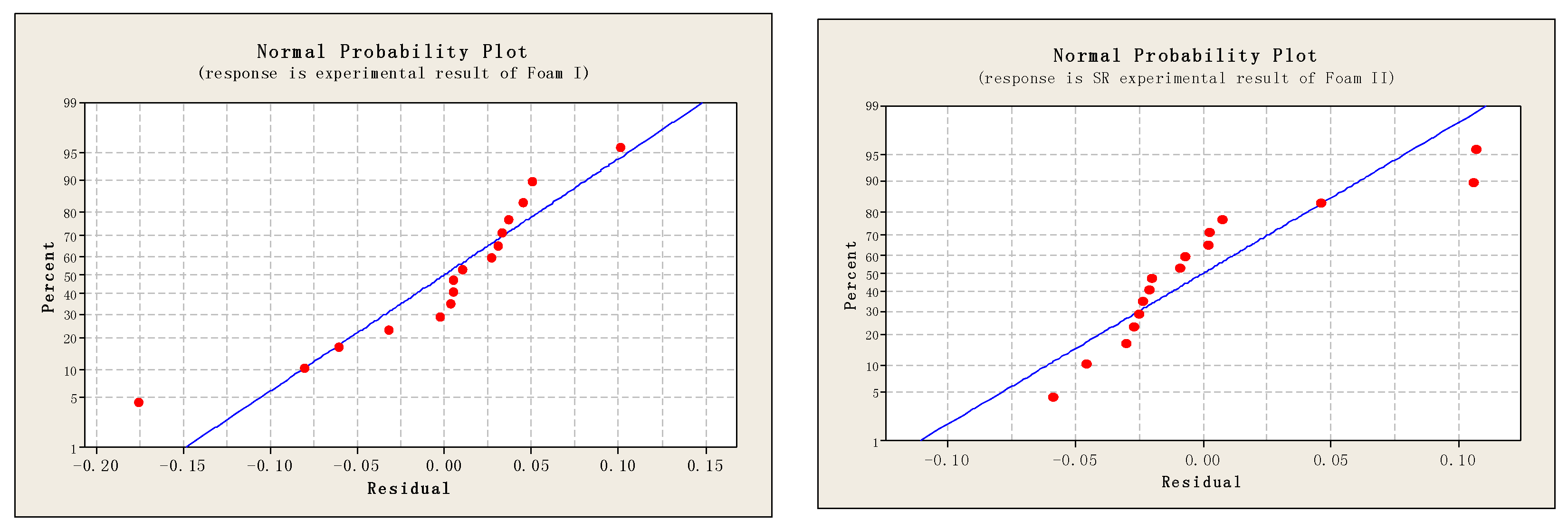

3.4. Regression Model

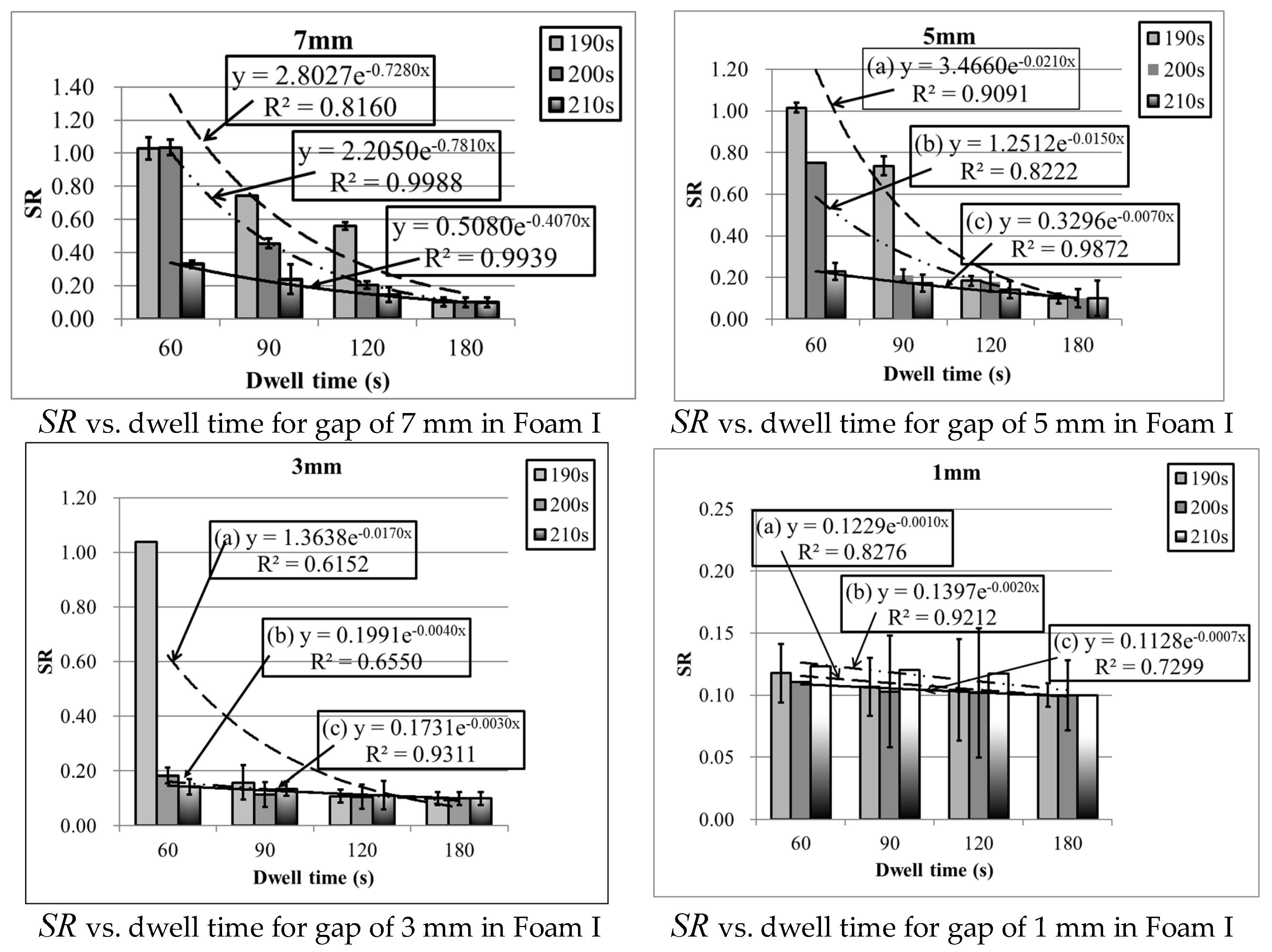

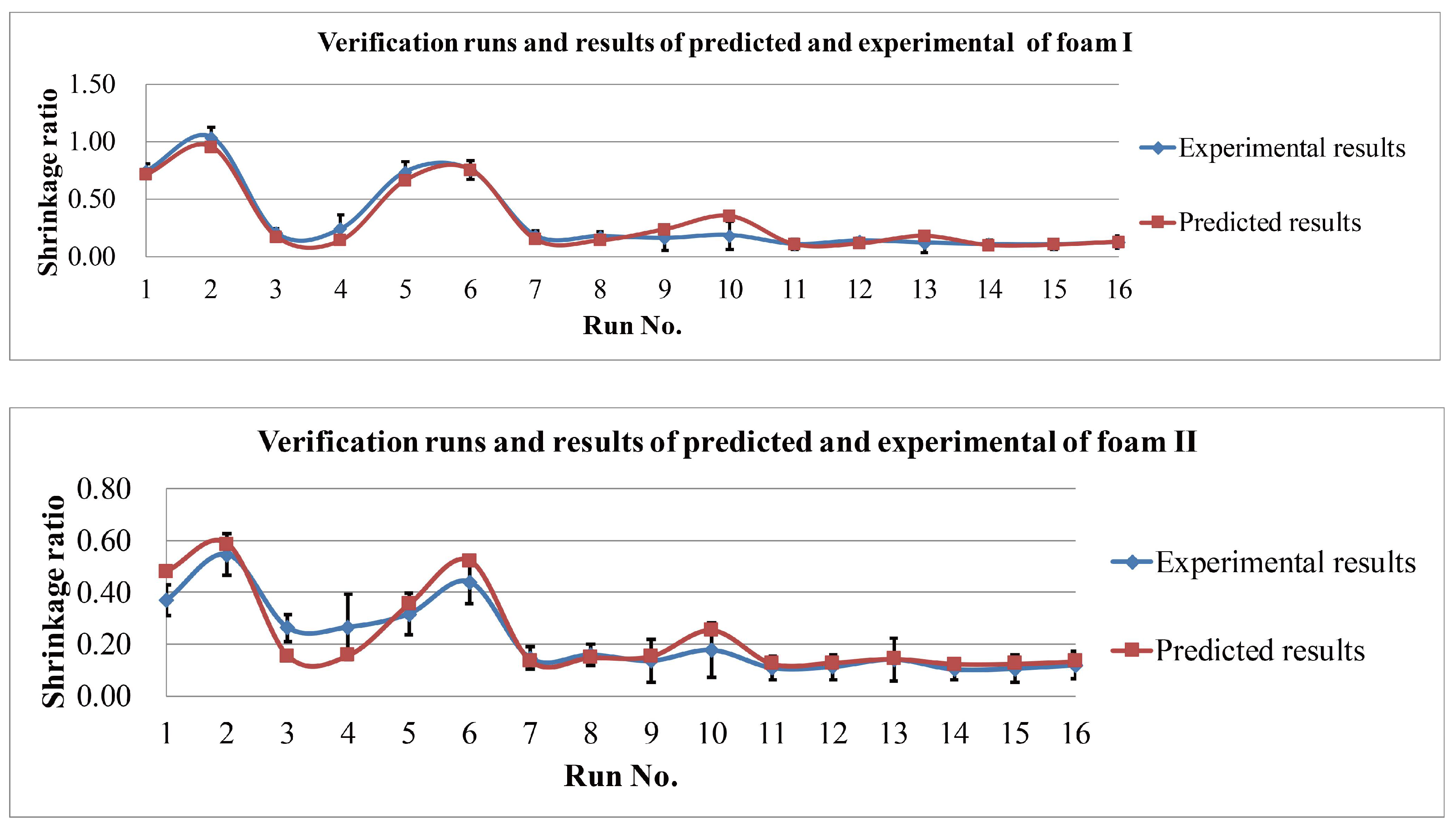

3.5. Verification of the Shrinkage Ratio Model

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Vidal, F.; González, R.; Fontán, M.; Rico, P.; Piñeiro, D. Development of a flexible robotic cell for laser cutting of 3D foam and preformed fabric. Robot. Smart Manuf. 2013, 371, 91–100. [Google Scholar]

- Elkholy, G.A.; Hafny, S. Study of Fabrics Properties for Intimate Apparel Application. Int. J. Sci. Eng. Investig. 2017, 62, 139–144. [Google Scholar]

- Deng, R.; Davis, P.; Bajag, A.K. Flexible polyurethane foam modeling and viscoelastic parameters identification for automotive seating applications. J. Sound Vib. 2003, 262, 391–417. [Google Scholar] [CrossRef]

- Yu, W.M. The Effect of Polyurethane Foam Properties and Moulding Conditions on the Shape Characteristics of Brassiere Cups. Ph.D. Thesis, The University of Leeds, Leeds, UK, 1996. [Google Scholar]

- Yick, K.L.; Yu, W.; Ng, S.P.; Yip, J.; Wu, L. Foam moulding performance and conditions for seamless bra cup. In Proceedings of the 86th Textile Institute World Conference, Hong Kong, China, 18–21 November 2008. [Google Scholar]

- Yip, J.; Ng, S.P. Study of three-dimensional spacer fabrics: Molding properties for intimate apparel application. J. Mater. Process. Technol. 2009, 209, 58–62. [Google Scholar] [CrossRef]

- Yick, K.L.; Ng, S.P.; Zhou, X.J.; Yu, W.; Chan, D. Wire frame representation of 3D moulded bra cup and its application to example-based design. Fibers Polym. 2008, 9, 653–658. [Google Scholar] [CrossRef]

- Yick, K.L.; Wu, L.; Yip, J.; Ng, S.P.; Yu, W. Study of thermal-mechanical properties of polyurethane foam and the three-dimensional shape of molded bra cups. J. Mater. Process. Technol. 2010, 210, 116–121. [Google Scholar] [CrossRef]

- Dawson, A.; Rides, M.; Nottay, J. The effect of pressure on the thermal conductivity of polymer melts. Polym. Test. 2006, 26, 268–275. [Google Scholar] [CrossRef]

- Tseng, C.J.; Yamaguchi, M.; Ohmori, T. Thermal conductivity of polyurethane foams from room temperature to 20 K. Cryogenics 1997, 37, 305–312. [Google Scholar] [CrossRef]

- Ogam, E.; Fellah, Z.E.A.; Baki, P. The inverse problem of acoustic wave scattering by an air-saturated poroelastic cylinder. J. Acoust. Soc. Am. 2013, 133, 1443–1457. [Google Scholar] [CrossRef] [PubMed]

- Fellah, Z.E.A.; Fellah, M.; Depollier, C.; Ogam, E.; Mitri, F.G. Wave Propagation in Porous Materials. In Computational and Experimental Studies of Acoustic Waves (Chapter 6); InTech: London, UK, 2018; pp. 99–119. [Google Scholar]

- Placido, E.; Arduini-Schuster, M.; Kuhn, J. Thermal properties predictive model for insulating foams. Infrared Phys. Technol. 2005, 46, 219–231. [Google Scholar] [CrossRef]

- Wu, J.W.; Sung, W.F.; Chu, H.S. Thermal conductivity of polyurethane foams. Int. J. Heat Mass Transf. 1999, 42, 2211–2217. [Google Scholar] [CrossRef]

- Tao, W.H.; Hsu, H.C.; Chang, C.C.; Hsu, C.L.; Lin, Y.S. Measurement and prediction of thermal conductivity of open cell rigid polyurethane foam. J. Cell Plast. 2001, 37, 310–332. [Google Scholar] [CrossRef]

- Wang, M.; Pan, N. Modeling and prediction of the Effective Thermal Conductivity of Random Open-cell Porous Foams. Int. J. Heat Mass Transf. 2008, 51, 1325–1331. [Google Scholar] [CrossRef]

- Yu, W.M.; Yeung, K.W.; Harlock, S.C.; Leaf, G.A.V. Predicting energy requirements for moulding flexible polyurethane foam sheets. Text. Res. J. 1998, 68, 289–295. [Google Scholar] [CrossRef]

- Dawson, A.; Rides, M.; Allen, C.R.G.; Urquhart, J.M. Polymer-mould interface heat transfer coefficient measurements for polymer processing. Polym. Test. 2008, 27, 555–565. [Google Scholar] [CrossRef]

- Nylund, C.; Meinander, K. The influence of heat transfer coefficient on cooling time in injection molding. Int. J. Heat Mass Transf. 2005, 41, 428–431. [Google Scholar] [CrossRef]

- Rauwendaal, C. Important Polymer Properties. In Polymer Extrusion, 2nd ed.; Hanser Publisher: Munich, Germany, 1990; pp. 191–253. [Google Scholar]

- Menges, G.; Mohren, P. The Heat Exchange System. In How to Make Injection Molds, 3rd ed.; Hanser Publishers: Munich, Germany, 2001; pp. 271–312. [Google Scholar]

- Throne, J.L. Polyumeric materials. In Thermoforming; Hanser Publishers: Munich, Germany, 1987; pp. 39–57. [Google Scholar]

- Bicerano, J. Thermal conductivity and thermal diffusivity. In Prediction of Polymer Properties, 3rd ed.; Marcel Dekker Inc.: New York, NY, USA, 2002; pp. 503–512. [Google Scholar]

- Wassiljewa, A. Wärmeleitung in gasgemischen. Phys. Z. 1904, 5, 737–742. [Google Scholar]

- Hillyard, N.C.; Cunnigham, A. Heat transfer in foams. In Low Density Cellular Plastics; Chapman and Hall: London, UK, 1994; pp. 104–139. [Google Scholar]

- Sinofsky, M. Property Measurement and Thermal Performance Predictiong of Foam Insulation. Master’s Thesis, MIT, Cambridge, UK, 1984. [Google Scholar]

- Chamkha, A.J.; Mujtaba, M.; Quadri, A.; Issa, C. Thermal radiation effects on MHD forced convection flow adjacent to a non-isothermal wedge in the presence of a heat source or sink. Int. J. Heat Mass Transf. 2003, 39, 305–312. [Google Scholar] [CrossRef]

- Skochdopole, R.E. The thermal conductivity of foam plastics. Eng. Prog. 1961, 57, 55–59. [Google Scholar]

- Yu, W.M.; Yeung, K.W.; Harlock, S.C.; Leaf, G.A.V. Mathematical measures of shape conformity. J. China Text I 1997, 14, 21–27. [Google Scholar]

- Rodriguez-Perez, M.A.; Alonso, O.; Souto, J.; Saja, J.A.D. Thermal conductivity of physically crosslinked closed cell polyolefin foams. Polym. Test. 1997, 16, 287–298. [Google Scholar] [CrossRef]

- Chang, L.C.; Sain, M.; Kortschot, M. Effect of mixing conditions on the morphology and performance of fiber-reinforced polyurethane foam. J. Cell Plast. 2015, 51, 103–119. [Google Scholar] [CrossRef]

- Chong, R. Moulding & Lamination Technology Handbook for Lingerie Industry; HongKong Productivity Council: Hong Kong, China, 2009; pp. 83–84. [Google Scholar]

- Bilbao, R.; Mastral, J.F.; Ceamanos, J.; Aldea, M.E. Kinetics of the thermal decomposition of polyurethane foams in nitrogen and air atmospheres. J. Anal. Appl. Pyrol. 1996, 37, 69–82. [Google Scholar] [CrossRef]

- Jarfelt, U.; Ramnas, O. Thermal conductivity of polyurethane foam—Best performance. In Proceedings of the 10th International Symposium on District Heating and Cooling, Hanover, Germany, 3–5 September 2006. [Google Scholar]

| Style | Density (kg/m3) | Cell count (cells per 25 mm) | Tensile strength at 8% strain (kPa) | Compression stress at 40% strain (kPa) | Hardness (°ShD) | Cell type |

|---|---|---|---|---|---|---|

| Test standard | ISO845-1988 | AS2282.5-1999 | ISO1798-1983 | ISO3386/1-1986 | ASTM D2240-05 | |

| Foam I | 45.07 | 44.30 | 4.80 | 4.27 | 43.98 | open |

| Foam II | 28.23 | 46.20 | 2.80 | 2.16 | 21.96 | open |

| Foam type | Gap (m) | Temp. (K) | (W/mK) | (W/mK) | (W/mK) | (W/mK) | |||

|---|---|---|---|---|---|---|---|---|---|

| I | 0.007 | 463 | 4.136 | 0.020 | 0.935 | 0.006 | 0.030 | 0.013 | 0.048 |

| I | 0.007 | 473 | 2.718 | 0.019 | 0.952 | 0.006 | 0.031 | 0.014 | 0.050 |

| I | 0.007 | 483 | 0.570 | 0.010 | 0.958 | 0.006 | 0.031 | 0.015 | 0.052 |

| I | 0.005 | 463 | 3.466 | 0.021 | 0.909 | 0.008 | 0.030 | 0.008 | 0.046 |

| I | 0.005 | 473 | 1.251 | 0.015 | 0.822 | 0.008 | 0.031 | 0.008 | 0.047 |

| I | 0.005 | 483 | 0.330 | 0.007 | 0.987 | 0.008 | 0.031 | 0.009 | 0.048 |

| I | 0.003 | 463 | 1.364 | 0.017 | 0.615 | 0.014 | 0.030 | 0.004 | 0.047 |

| I | 0.003 | 473 | 0.199 | 0.004 | 0.655 | 0.014 | 0.031 | 0.004 | 0.048 |

| I | 0.003 | 483 | 0.173 | 0.003 | 0.931 | 0.014 | 0.031 | 0.004 | 0.049 |

| I | 0.001 | 463 | 0.123 | 0.001 | 0.828 | 0.041 | 0.030 | 0.001 | 0.071 |

| I | 0.001 | 473 | 0.113 | 0.001 | 0.730 | 0.041 | 0.031 | 0.001 | 0.072 |

| I | 0.001 | 483 | 0.140 | 0.002 | 0.921 | 0.041 | 0.031 | 0.001 | 0.073 |

| II | 0.007 | 463 | 2.466 | 0.017 | 0.918 | 0.004 | 0.030 | 0.016 | 0.049 |

| II | 0.007 | 473 | 1.029 | 0.013 | 0.901 | 0.004 | 0.031 | 0.017 | 0.051 |

| II | 0.007 | 483 | 0.819 | 0.012 | 0.964 | 0.004 | 0.031 | 0.018 | 0.053 |

| II | 0.005 | 463 | 1.965 | 0.018 | 0.874 | 0.005 | 0.030 | 0.009 | 0.044 |

| II | 0.005 | 473 | 0.736 | 0.012 | 0.908 | 0.005 | 0.031 | 0.010 | 0.046 |

| II | 0.005 | 483 | 0.393 | 0.008 | 0.881 | 0.005 | 0.031 | 0.011 | 0.047 |

| II | 0.003 | 463 | 0.594 | 0.011 | 0.638 | 0.009 | 0.030 | 0.004 | 0.043 |

| II | 0.003 | 473 | 0.203 | 0.004 | 0.789 | 0.009 | 0.031 | 0.005 | 0.044 |

| II | 0.003 | 483 | 0.149 | 0.003 | 0.702 | 0.009 | 0.031 | 0.005 | 0.045 |

| II | 0.001 | 463 | 0.146 | 0.002 | 0.620 | 0.026 | 0.030 | 0.001 | 0.056 |

| II | 0.001 | 473 | 0.112 | 0.001 | 0.857 | 0.026 | 0.031 | 0.001 | 0.057 |

| II | 0.001 | 483 | 0.134 | 0.002 | 0.869 | 0.026 | 0.031 | 0.001 | 0.058 |

| Run No. | Type | (W/mK) | (W/mK) | Time (s) | Gap (m) | Temp. (K) | ||

|---|---|---|---|---|---|---|---|---|

| 1 | Foam I | 0.00585 | 0.01288 | 90 | 0.007 | 463 | 0.7415 | 0.7117 |

| 2 | 0.00585 | 0.01373 | 60 | 0.007 | 473 | 1.0343 | 0.9535 | |

| 3 | 0.00585 | 0.01373 | 120 | 0.007 | 473 | 0.2031 | 0.1728 | |

| 4 | 0.00585 | 0.01462 | 90 | 0.007 | 483 | 0.2383 | 0.1393 | |

| 5 | 0.00819 | 0.00778 | 90 | 0.005 | 463 | 0.7363 | 0.6633 | |

| 6 | 0.00819 | 0.00829 | 60 | 0.005 | 473 | 0.7502 | 0.7553 | |

| 7 | 0.00819 | 0.00829 | 120 | 0.005 | 473 | 0.1794 | 0.1481 | |

| 8 | 0.00819 | 0.00883 | 90 | 0.005 | 483 | 0.1737 | 0.1390 | |

| 9 | 0.01366 | 0.00361 | 90 | 0.003 | 463 | 0.1579 | 0.2355 | |

| 10 | 0.01366 | 0.00385 | 60 | 0.003 | 473 | 0.1829 | 0.3508 | |

| 11 | 0.01366 | 0.00385 | 120 | 0.003 | 473 | 0.1057 | 0.1055 | |

| 12 | 0.01366 | 0.00410 | 90 | 0.003 | 483 | 0.1356 | 0.1115 | |

| 13 | 0.04097 | 0.00070 | 60 | 0.001 | 463 | 0.1178 | 0.1783 | |

| 14 | 0.04097 | 0.00070 | 120 | 0.001 | 463 | 0.1041 | 0.0979 | |

| 15 | 0.04097 | 0.00074 | 90 | 0.001 | 473 | 0.1029 | 0.1015 | |

| 16 | 0.04097 | 0.00079 | 60 | 0.001 | 483 | 0.1230 | 0.1282 | |

| 1 | Foam II | 0.00367 | 0.01550 | 90 | 0.007 | 463 | 0.3707 | 0.4821 |

| 2 | 0.00367 | 0.01653 | 60 | 0.007 | 473 | 0.5457 | 0.5872 | |

| 3 | 0.00367 | 0.01653 | 120 | 0.007 | 473 | 0.2628 | 0.1554 | |

| 4 | 0.00367 | 0.01760 | 90 | 0.007 | 483 | 0.2657 | 0.1577 | |

| 5 | 0.00513 | 0.00936 | 90 | 0.005 | 463 | 0.3166 | 0.3541 | |

| 6 | 0.00513 | 0.00998 | 60 | 0.005 | 473 | 0.4396 | 0.5227 | |

| 7 | 0.00513 | 0.00998 | 120 | 0.005 | 473 | 0.1456 | 0.1381 | |

| 8 | 0.00513 | 0.01062 | 90 | 0.005 | 483 | 0.1585 | 0.1480 | |

| 9 | 0.00855 | 0.00435 | 90 | 0.003 | 463 | 0.1358 | 0.1537 | |

| 10 | 0.00855 | 0.00464 | 60 | 0.003 | 473 | 0.1767 | 0.2539 | |

| 11 | 0.00855 | 0.00464 | 120 | 0.003 | 473 | 0.1082 | 0.1252 | |

| 12 | 0.00855 | 0.00494 | 90 | 0.003 | 483 | 0.1123 | 0.1290 | |

| 13 | 0.02566 | 0.00084 | 60 | 0.001 | 463 | 0.1407 | 0.1434 | |

| 14 | 0.02566 | 0.00084 | 120 | 0.001 | 463 | 0.1022 | 0.1241 | |

| 15 | 0.02566 | 0.00089 | 90 | 0.001 | 473 | 0.1055 | 0.1245 | |

| 16 | 0.02566 | 0.00095 | 60 | 0.001 | 483 | 0.1186 | 0.1337 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, L.; Yick, K.-L.; Ng, S.; Sun, Y. Modeling of Flexible Polyurethane Foam Shrinkage for Bra Cup Moulding Process Control. Polymers 2018, 10, 472. https://doi.org/10.3390/polym10050472

Wu L, Yick K-L, Ng S, Sun Y. Modeling of Flexible Polyurethane Foam Shrinkage for Bra Cup Moulding Process Control. Polymers. 2018; 10(5):472. https://doi.org/10.3390/polym10050472

Chicago/Turabian StyleWu, Long, Kit-Lun Yick, Sunpui Ng, and Yue Sun. 2018. "Modeling of Flexible Polyurethane Foam Shrinkage for Bra Cup Moulding Process Control" Polymers 10, no. 5: 472. https://doi.org/10.3390/polym10050472

APA StyleWu, L., Yick, K.-L., Ng, S., & Sun, Y. (2018). Modeling of Flexible Polyurethane Foam Shrinkage for Bra Cup Moulding Process Control. Polymers, 10(5), 472. https://doi.org/10.3390/polym10050472