The Effect of Alkali Treatment on Properties of Dopamine Modification of Bamboo Fiber/Polylactic Acid Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

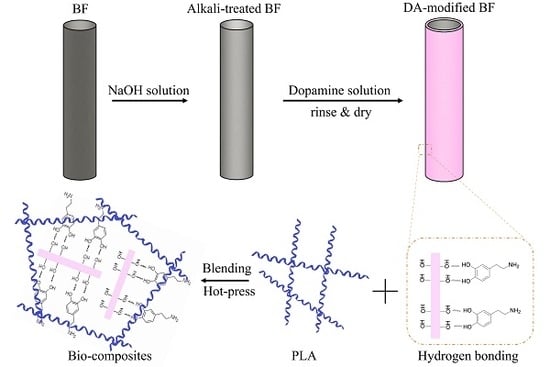

2.2. Preparation of Alkali-Treated and DA-Modified Bamboo Fiber

2.3. Preparation of the Bamboo Fiber/PLA Composites

2.4. Characterization

2.4.1. Fourier Transform Infrared Spectroscopy (FTIR)

2.4.2. X-ray Diffraction Procedure and Analysis (XRD)

2.4.3. Mechanical Characterization

2.4.4. Thermogravimetric (TG) Analysis

2.4.5. Differential Scanning Calorimetry (DSC)

2.4.6. Interfacial Morphology Analysis (SEM)

3. Results and Discussion

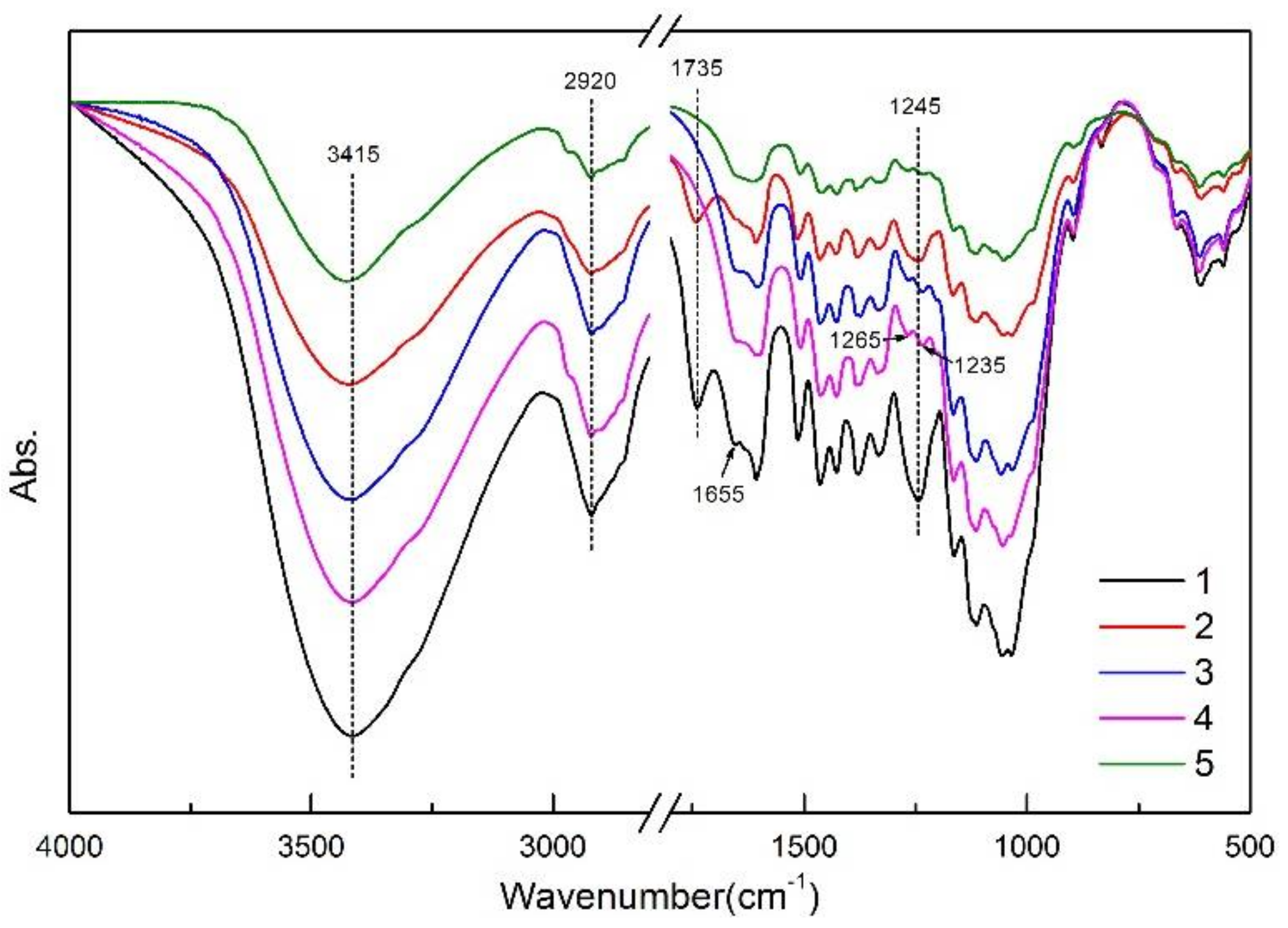

3.1. FTIR Analyses of the Bamboo Fiber

3.2. XRD Analyses of the Bamboo Fiber

3.3. Effect of BF Treatments on Mechanical Properties of BF/PLA Composites

3.4. The Effect of BF Treatments on the Thermal Properties of BF/PLA Composites

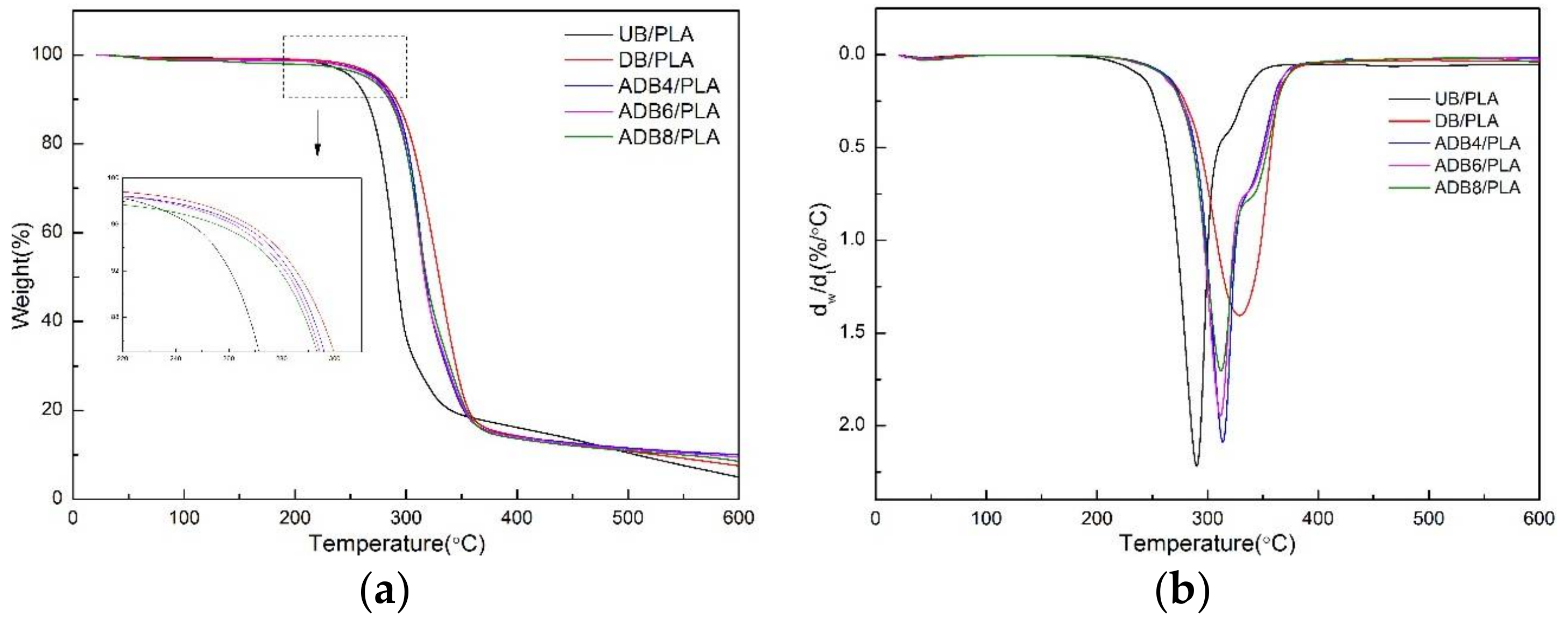

3.4.1. Thermogravimetric Analysis (TG)

3.4.2. Differential Scanning Calorimetry (DSC)

3.5. The Effect of BF Treatments on Fracture Surfaces of BF/PLA Composites

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Li, H.; Sain, D.M. High stiffness natural fiber-reinforced hybrid polypropylene composites. J. Macromol. Sci. Part D Rev. Polym. Process. 2003, 42, 853–862. [Google Scholar] [CrossRef]

- Khalil, H.P.S.A.; Bhat, I.U.H.; Jawaid, M.; Zaidon, A.; Hermawan, D.; Hadi, Y.S. Bamboo fibre reinforced biocomposites: A review. Mater. Des. 2012, 42, 353–368. [Google Scholar] [CrossRef]

- Wang, F.; Li, X.; Zhang, J.; Li, L.; Keer, L.M. Micromechanical modelling of the progressive failure in unidirectional composites reinforced with bamboo fibres. Mech. Mater. 2016, 94, 180–192. [Google Scholar] [CrossRef]

- Westman, M.P.; Fifield, L.S.; Simmons, K.L.; Laddha, S.; Kafentzis, T.A. Natural Fiber Composites: A review. Tech. Rep. 2010. [Google Scholar] [CrossRef]

- Hassan, E.; You, W.; He, J.; Yu, M.H. Plant fibers reinforced poly(lactic acid) (PLA) as a green composites: Review. Int. J. Eng. Sci. Technol. 2012, 4, 4429–4439. [Google Scholar]

- Murariu, M.; Dubois, P. PLA composites: From production to properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef] [PubMed]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Effect of various chemical treatments on the fibre structure and tensile properties of industrial hemp fibres. Compos. Part A Appl. Sci. Manuf. 2011, 42, 888–895. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Bledzki, A.K. The effects of acetylation on properties of flax fibre and its polypropylene composites. Express Polym. Lett. 2008, 2, 413–422. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Mamun, A.A.; Bledzki, A.K. Micro fibre reinforced PLA and PP composites: Enzyme modification, mechanical and thermal properties. Compos. Sci. Technol. 2013, 78, 10–17. [Google Scholar] [CrossRef]

- Tokoro, R.; Vu, D.M.; Okubo, K.; Tanaka, T.; Fujii, T.; Fujiura, T. How to improve mechanical properties of polylactic acid with bamboo fibers. J. Mater. Sci. 2008, 43, 775–787. [Google Scholar] [CrossRef]

- Asumani, O.M.L.; Reid, R.G.; Paskaramoorthy, R. The effects of alkali–silane treatment on the tensile and flexural properties of short fibre non-woven kenaf reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1431–1440. [Google Scholar] [CrossRef]

- Islam, M.S.; Hamdan, S.; Hasan, M.; Ahmed, A.S.; Rahman, M.R. Effect of coupling reactions on the mechanical and biological properties of tropical wood polymer composites (WPC). Int. Biodeterior. Biodegrad. 2012, 72, 108–113. [Google Scholar] [CrossRef]

- Islam, M.S.; Hamdan, S.; Jusoh, I.; Rahman, M.R.; Ahmed, A.S. The effect of alkali pretreatment on mechanical and morphological properties of tropical wood polymer composites. Mater. Des. 2012, 33, 419–424. [Google Scholar] [CrossRef]

- Waite, J.H.; Qin, X. Polyphosphoprotein from the adhesive pads of Mytilus edulis. Biochemistry 2001, 40, 2887–2893. [Google Scholar] [CrossRef] [PubMed]

- Yoo, H.Y.; Huang, J.; Li, L.; Foo, M.; Zeng, H.; Hwang, D.S. Nanomechanical contribution of collagen and von Willebrand Factor A in marine underwater adhesion and its implication for collagen manipulation. Biomacromolecules 2016, 17, 946–953. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Dellatore, S.M.; Miller, W.M.; Messersmith, P.B. Mussel-inspired surface chemistry for multifunctional coatings. Science 2007, 318, 426–430. [Google Scholar] [CrossRef] [PubMed]

- Waite, J.H. Surface chemistryMussel power. Nat. Mater. 2008, 7, 8–9. [Google Scholar] [CrossRef] [PubMed]

- Ingole, P.G.; Choi, W.; Kim, K.H.; Park, C.H.; Choi, W.K.; Lee, H.K. Synthesis, characterization and surface modification of PES hollow fiber membrane support with polydopamine and thin film composite for energy generation. Chem. Eng. J. 2014, 243, 137–146. [Google Scholar] [CrossRef]

- Yi, M.; Sun, H.; Zhang, H.; Deng, X.; Cai, Q.; Yang, X. Flexible fiber-reinforced composites with improved interfacial adhesion by mussel-inspired polydopamine and poly(methyl methacrylate) coating. Mater. Sci. Eng. C Mater. Biol. Appl. 2016, 58, 742–749. [Google Scholar] [CrossRef] [PubMed]

- Hong, G.; Meng, Y.; Yang, Z.; Cheng, H.; Zhang, S.; Song, W. Mussel-inspired polydopamine modification of bamboo fiber and its effect on the properties of bamboo fiber/polybutylene succinate composites. Bioresources 2017, 12, 8419–8442. [Google Scholar]

- Zhou, M.; Li, Y.; He, C.; Jin, T.; Wang, K.; Fu, Q. Interfacial crystallization enhanced interfacial interaction of Poly (butylene succinate)/ramie fiber biocomposites using dopamine as a modifier. Compos. Sci. Technol. 2014, 91, 22–29. [Google Scholar] [CrossRef]

- Manalo, A.C.; Wani, E.; Zukarnain, N.A.; Karunasena, W.; Lau, K.T. Effects of alkali treatment and elevated temperature on the mechanical properties of bamboo fibre–polyester composites. Compos. Part B Eng. 2015, 80, 73–83. [Google Scholar] [CrossRef]

- Shinoj, S.; Visvanathan, R.; Panigrahi, S.; Kochubabu, M. Oil palm fiber (OPF) and its composites: A review. Ind. Crops Prod. 2011, 33, 7–22. [Google Scholar] [CrossRef]

- Pickering, K.L.; Sawpan, M.A.; Jayaraman, J.; Fernyhough, A. Influence of loading rate, alkali fibre treatment and crystallinity on fracture toughness of random short hemp fibre reinforced polylactide bio-composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1148–1156. [Google Scholar] [CrossRef]

- Troedec, M.L.; Sedan, D.; Peyratout, C.; Bonnet, J.P.; Smith, A.; Guinebretiere, R.; Gloaguen, V.; Krausz, P. Influence of various chemical treatments on the composition and structure of hemp fibres. Compos. Part A Appl. Sci. Manuf. 2008, 39, 514–522. [Google Scholar] [CrossRef]

- Fischer, E.W.; Sterzel, H.J.; Wegner, G. Investigation of the structure of solution grown crystals of lactide copolymers by means of chemical reactions. Kolloid Z. Z. Polym. 1973, 251, 980–990. [Google Scholar] [CrossRef]

- Joseph, P.V.; Mathew, G.; Joseph, K.; Groeninckx, G.; Thomas, S. Dynamic mechanical properties of short sisal fibre reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2003, 34, 275–290. [Google Scholar] [CrossRef]

- Rana, D.; Kim, H.L.; Kwag, H.; Choe, S. Hybrid blends of similar ethylene 1-octene copolymers. Polymer 2000, 41, 7067–7082. [Google Scholar] [CrossRef]

- Sgriccia, N.; Hawley, M.C.; Misra, M. Characterization of natural fiber surfaces and natural fiber composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1632–1637. [Google Scholar] [CrossRef]

- Deshpande, A.P.; Bhaskar Rao, M.; Lakshmana Rao, C. Extraction of bamboo fibers and their use as reinforcement in polymeric composites. J Appl. Polym. Sci. 2015, 76, 83–92. [Google Scholar] [CrossRef]

- Fei, M.E.; Xie, T.; Liu, W.; Chen, H.; Qiu, R. Erratum to: Surface grafting of bamboo fibers with 1,2-epoxy-4-vinylcyclohexane for reinforcing unsaturated polyester. Cellulose 2017, 24, 5515–5516. [Google Scholar] [CrossRef]

- Kushwaha, P.K.; Kumar, R. Effect of silanes on mechanical properties of bamboo fiber-epoxy composites. J. Reinf. Plast. Compos. 2010, 29, 718–724. [Google Scholar] [CrossRef]

- Kushwaha, P.K.; Kumar, R. Influence of chemical treatments on the mechanical and water absorption properties of bamboo fiber composites. J. Reinf. Plast. Compos. 2010, 30, 73–85. [Google Scholar] [CrossRef]

- Rana, D.; Lee, C.H.; Cho, K.; Lee, B.H.; Choe, S. Thermal and mechanical properties for binary blends of metallocene polyethylene with conventional polyolefins. J. Appl. Polym. Sci. 1998, 69, 2441–2450. [Google Scholar] [CrossRef]

- Rana, D.; Cho, K.; Woo, T.; Lee, B.H.; Choe, S. Blends of ethylene 1-octene copolymer synthesized by Ziegler–Natta and metallocene catalysts. I. Thermal and mechanical properties. J. Appl. Polym. Sci. 2015, 74, 1169–1177. [Google Scholar] [CrossRef]

- Han, S.O.; Karevan, M.; Sim, I.N.; Bhuiyan, M.A.; Jang, Y.H.; Ghaffar, J.; Kalaitzidou, K. Understanding the reinforcing mechanisms in kenaf fiber/PLA and kenaf fiber/PP composites: A comparative study. Int. J. Ploym. Sci. 2012, 2012, 10178–10182. [Google Scholar] [CrossRef]

- Rana, D.; And, B.M.M.; Bhattacharyya, S.N. Analogue calorimetric studies of blends of poly(vinyl ester)s and polyacrylates. Macromolecules 1996, 29, 1579–1583. [Google Scholar] [CrossRef]

- Rana, D.; Mandal, B.M.; Bhattacharyya, S.N. Miscibility and phase diagrams of poly(phenyl acrylate) and poly(styrene-co-acrylonitrile) blends. Polymer 1993, 34, 1454–1459. [Google Scholar] [CrossRef]

- Rana, D.; Kim, H.L.; Kwag, H.; Rhee, J.; Cho, K.; Woo, T.; Lee, B.H.; Choe, S. Blends of ethylene 1-octene copolymer synthesized by Ziegler-Natta and metallocene catalysts. II. Rheology and morphological behaviors. J. Appl. Polym. Sci. 2000, 76, 1950–1964. [Google Scholar] [CrossRef]

- Zhang, Y.-C.; Wu, H.-Y.; Qiu, Y.-P. Morphology and properties of hybrid composites based on polypropylene/polylactic acid blend and bamboo fiber. Bioresour. Technol. 2010, 101, 7944–7950. [Google Scholar]

- Khan, Z.; Yousif, B.F.; Islam, M. Fracture behaviour of bamboo fiber-reinforced epoxy composites. Compos. Part B Eng. 2017, 116, 186–199. [Google Scholar] [CrossRef]

- Tran, D.T.; Nguyen, D.M.; Thuc, C.N.H.; Dang, T.T. Effect of coupling agents on the properties of bamboo fiber-reinforced unsaturated polyester resin composites. Compos. Interface 2013, 20, 343–353. [Google Scholar] [CrossRef]

| Sample Designation | Fiber Treatment Condition | ||

|---|---|---|---|

| General | Specific | DA Concentration (wt %) | Alkali Concentration (wt %) |

| UB/PLA | UB/PLA | No treatment | No treatment |

| DB/PLA | DB/PLA | 1 | No treatment |

| ADB/PLA | ADB4/PLA | 1 | 4 |

| ADB6/PLA | 1 | 6 | |

| ADB8/PLA | 1 | 8 | |

| Sample | Flexural Strength (MPa) | Flexural Modulus (GPa) | Tensile Strength (MPa) | Tensile Modulus (GPa) | Impact Strength (kJ/m2) |

|---|---|---|---|---|---|

| UB/PLA | 55.32(1.98) c | 4.29(0.31) a | 29.39(2.49) c | 1.71(0.08) d | 8.13(0.62) a |

| DB/PLA | 62.62(2.99) ab | 4.44(0.30) a | 37.35(3.15) a | 2.07(0.12) ab | 6.46(0.59) b |

| ADB4/PLA | 64.25(3.78) a | 4.53(0.34) a | 39.51(2.61) a | 2.17(0.15) a | 8.43(0.48) a |

| ADB6/PLA | 58.81(2.16) abc | 4.41(0.32) a | 38.47(2.36) a | 2.03(0.12) b | 8.65(0.76) a |

| ADB8/PLA | 56.75(2.77) bc | 4.24(0.56) a | 32.87(3.03) b | 1.87(0.07) c | 8.89(1.09) a |

| Sample | UB/PLA | DB/PLA | ADB4/PLA | ADB6/PLA | ADB8/PLA |

|---|---|---|---|---|---|

| Onset pyrolysis temperature (°C) | 270.73 | 296.33 | 295.47 | 293.71 | 291.58 |

| Maximum rate temperature (°C) | 290.09 | 329.32 | 313.82 | 311.62 | 310.17 |

| Sample | Tg (°C) | Tc (°C) | ΔHc (J/g) | Tm (°C) | ΔHm (J/g) | XC (%) |

|---|---|---|---|---|---|---|

| UB/PLA | 58.78 | 97.42 | 4.964 | 166.01 | 28.86 | 51.33% |

| DB/PLA | 61.52 | 107.32 | 11.28 | 168.09 | 24.57 | 43.70% |

| ADB4/PLA | 60.89 | 108.51 | 13.96 | 168.89 | 22.36 | 39.78% |

| ADB6/PLA | 60.93 | 108.14 | 13.67 | 167.76 | 21.34 | 37.96% |

| ADB8/PLA | 60.98 | 108.97 | 12.83 | 167.12 | 20.02 | 35.61% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, J.; Yang, Z.; Hu, X.; Hong, G.; Zhang, S.; Song, W. The Effect of Alkali Treatment on Properties of Dopamine Modification of Bamboo Fiber/Polylactic Acid Composites. Polymers 2018, 10, 403. https://doi.org/10.3390/polym10040403

Lin J, Yang Z, Hu X, Hong G, Zhang S, Song W. The Effect of Alkali Treatment on Properties of Dopamine Modification of Bamboo Fiber/Polylactic Acid Composites. Polymers. 2018; 10(4):403. https://doi.org/10.3390/polym10040403

Chicago/Turabian StyleLin, Jianyong, Zexun Yang, Xiaoxia Hu, Gonghua Hong, Shuangbao Zhang, and Wei Song. 2018. "The Effect of Alkali Treatment on Properties of Dopamine Modification of Bamboo Fiber/Polylactic Acid Composites" Polymers 10, no. 4: 403. https://doi.org/10.3390/polym10040403

APA StyleLin, J., Yang, Z., Hu, X., Hong, G., Zhang, S., & Song, W. (2018). The Effect of Alkali Treatment on Properties of Dopamine Modification of Bamboo Fiber/Polylactic Acid Composites. Polymers, 10(4), 403. https://doi.org/10.3390/polym10040403