Preparation and Characterization of Self-Colored Waterborne Polyurethane and Its Application in Eco-Friendly Manufacturing of Microfiber Synthetic Leather Base

Abstract

1. Introduction

2. Experimental

2.1. Materials

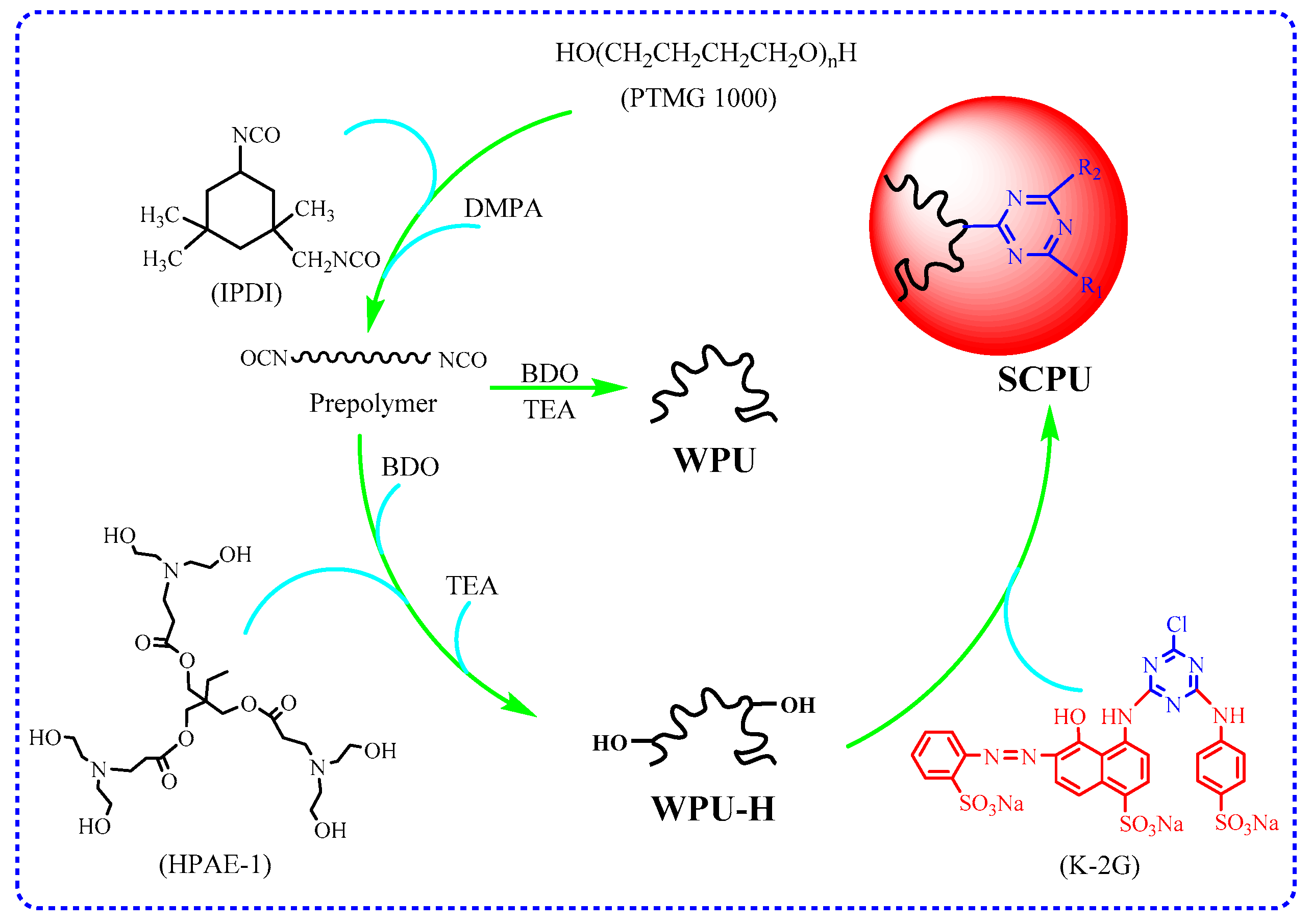

2.2. Synthesis of Self-Colored Waterborne Polyurethane (SCPU)

2.2.1. Synthesis of Waterborne Polyurethane (WPU)

2.2.2. Preparation of Waterborne Polyurethane Modified by HPAE-1 (WPU-H)

2.2.3. Preparation of Self-Colored Waterborne Polyurethane (SCPU)

2.3. Characterizations of Polyurethanes

2.3.1. FTIR Spectrum

2.3.2. Particle Size Analysis

2.3.3. X-ray Diffraction Characterization

2.3.4. Thermal Performances

2.4. Preparation and Characterization of MS-Leather Base

3. Results and Discussion

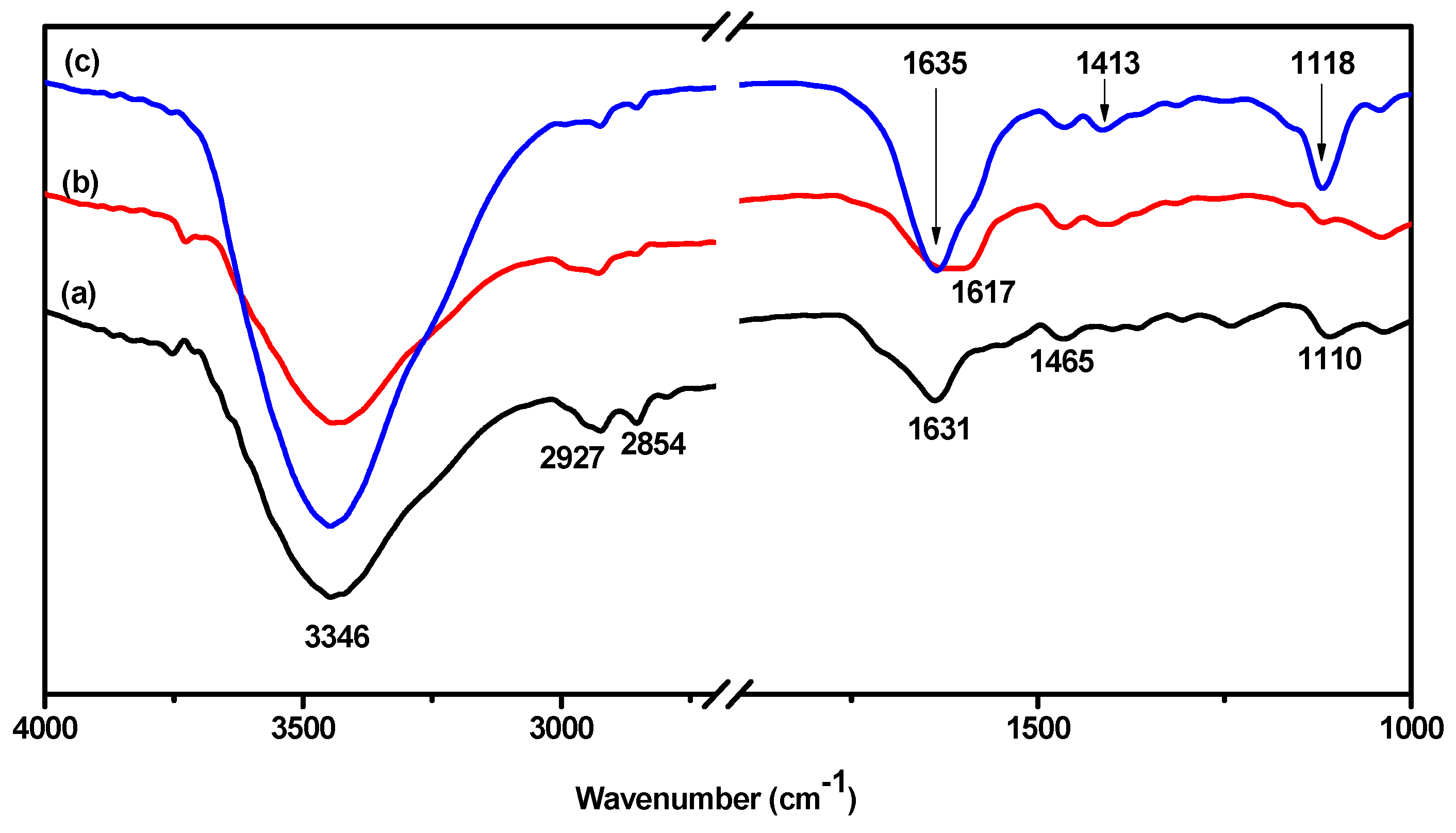

3.1. FTIR Analysis

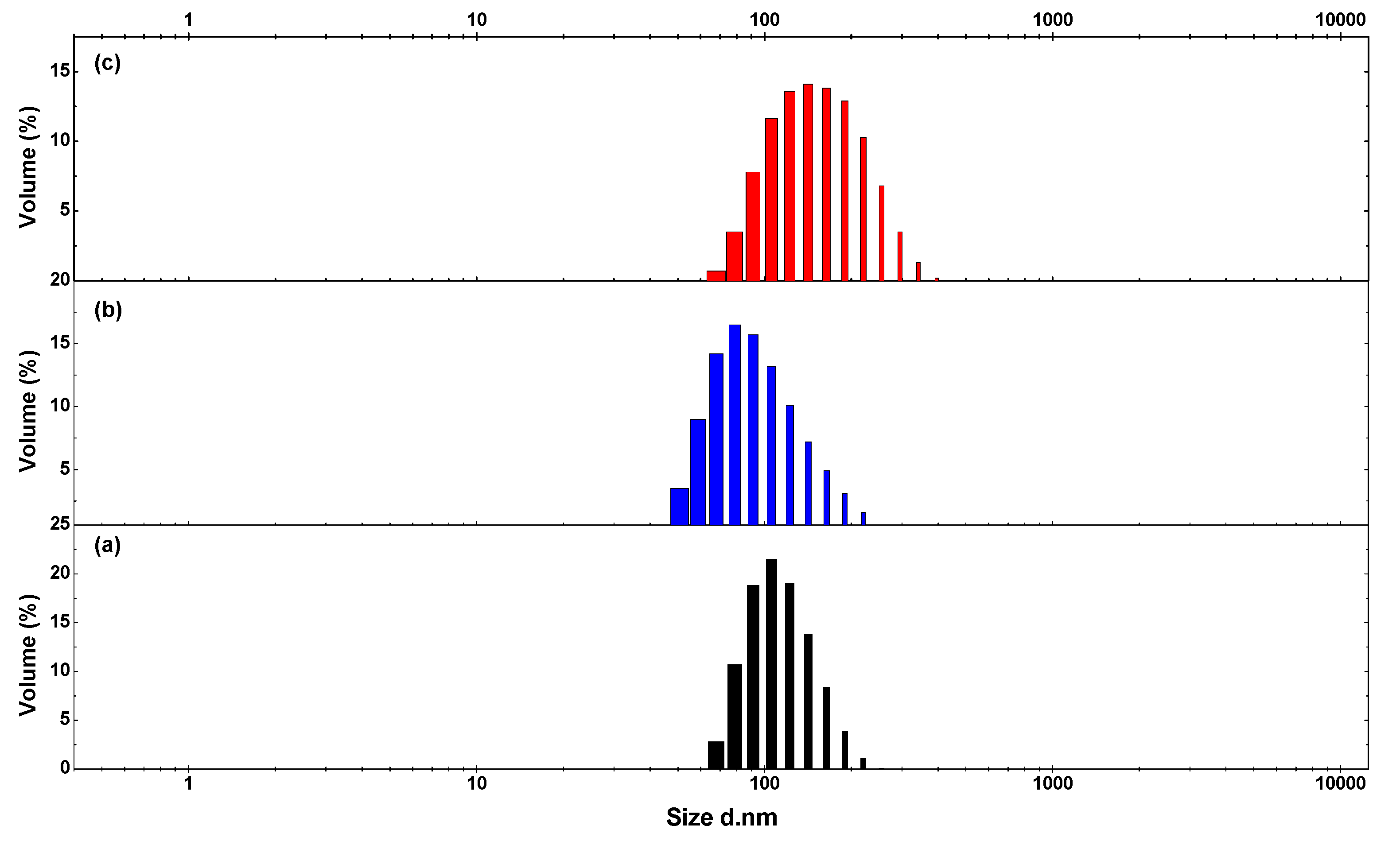

3.2. Particle Size Distribution

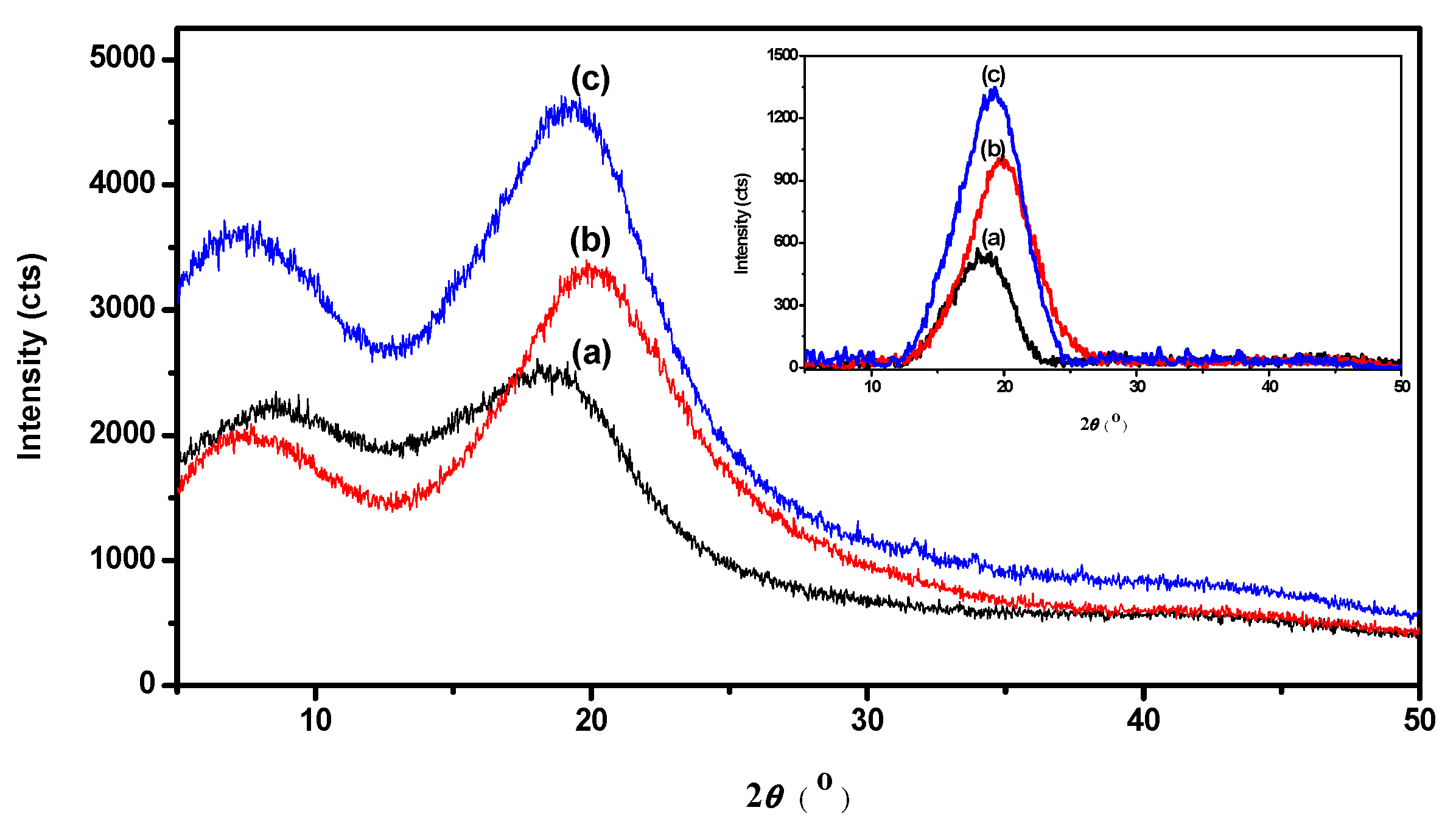

3.3. XRD Characterization

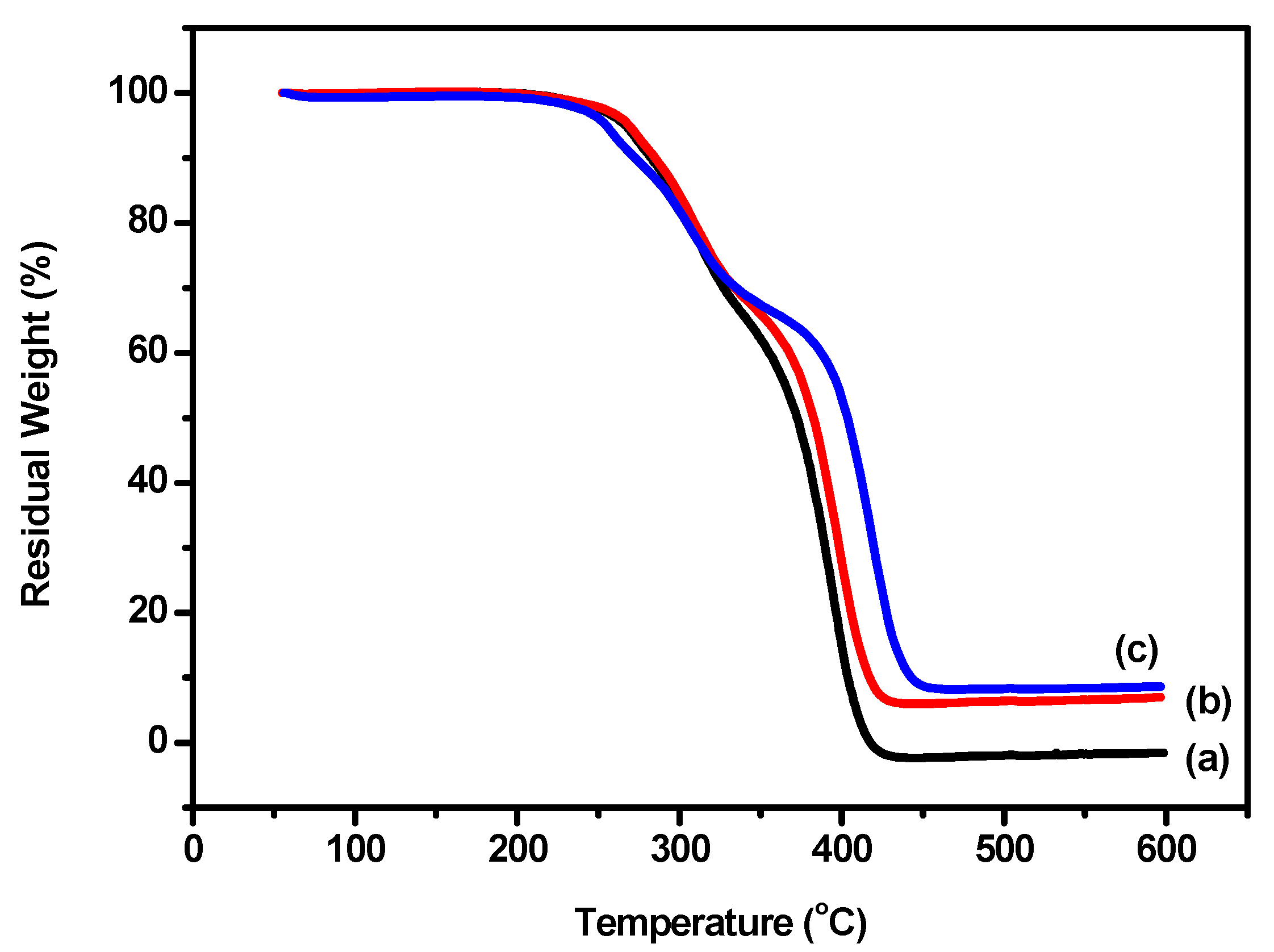

3.4. Thermal Properties

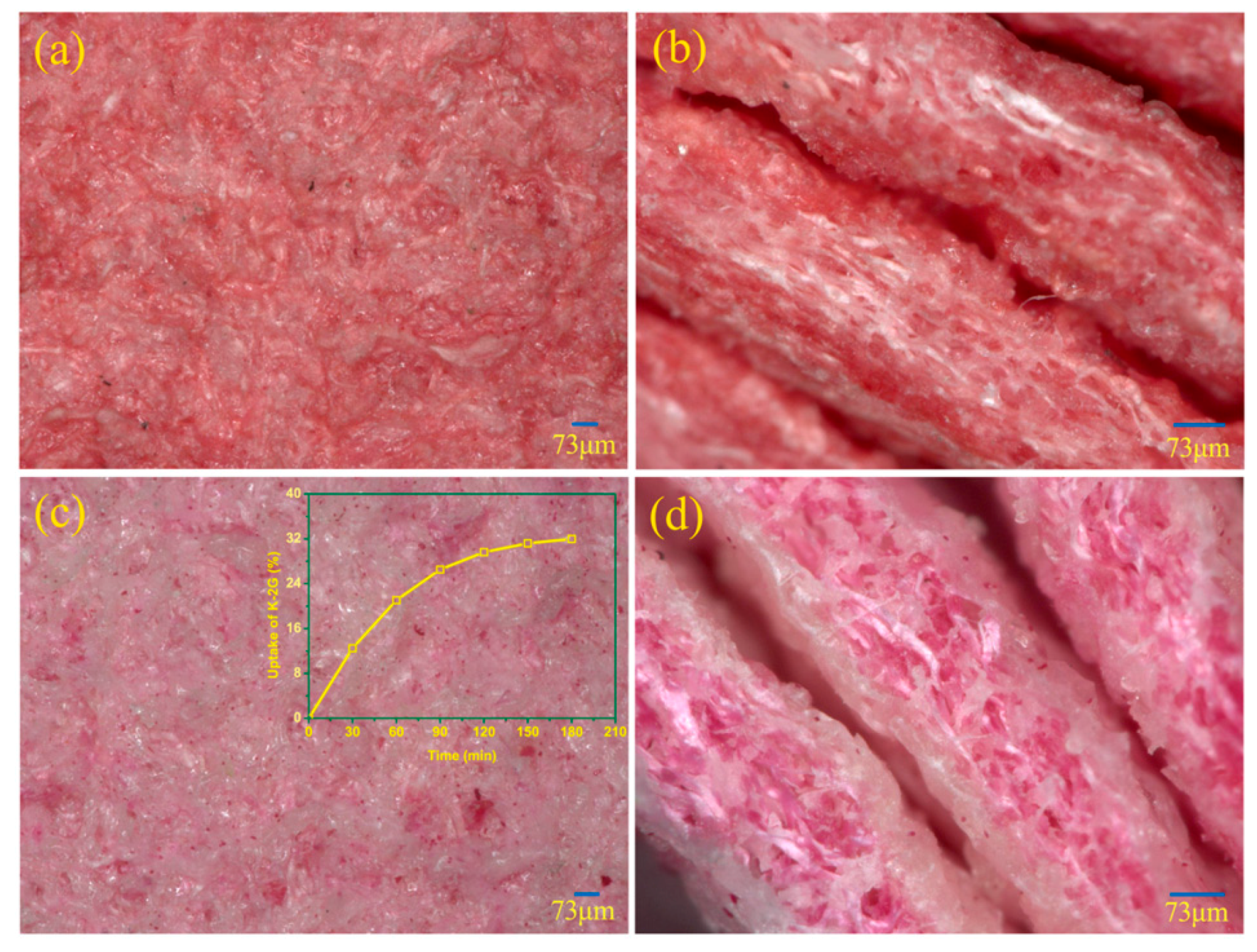

3.5. The Micromorphologies of MS-Leather Base

3.6. The Color Fastness to Washing of CLB

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Burkinshaw, S.M.; Hewitt, A.D.; Blackburn, R.S.; Russell, S.J. The dyeing of nonwoven fabrics part 1: Initial studies. Dyes Pigment. 2012, 94, 592–598. [Google Scholar] [CrossRef]

- Mao, N.; Russell, S.J.; Poudeyhimi, B. Characterisation, testing and modelling of nonwoven fabrics. In Handbook of Nonwovens; Russell, S.J., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2007; pp. 401–514. ISBN 9781855736030. [Google Scholar]

- Liu, R.; Chen, Y.; Fan, H. Design, Characterization, dyeing properties, and application of acid-dyeable polyurethane in the manufacture of microfiber synthetic leather. Fibers Polym. 2015, 16, 1970–1980. [Google Scholar] [CrossRef]

- Xu, X.; Wang, Z. Environmental cost analysis and upgrading research of synthetic leather industry. Energy Procedia 2011, 5, 1341–1347. [Google Scholar] [CrossRef][Green Version]

- Burkinshaw, S.M. Chemical Principles of Synthetic Fiber Dyeing; Chapman & Hall: Glasgow, UK, 1995; ISBN 9789401105934. [Google Scholar]

- Qu, J.B.; Zhang, C.B.; Feng, J.Y.; Gao, F.T. Natural and synthetic Leather: A microstructural comparison. J. Soc. Leather Technol. Chem. 2008, 92, 8–13. [Google Scholar]

- Zhang, Q.; Huang, C.; Wei, Y.; Zhu, Q.; Tian, W.; Wang, C. Risk assessment of N,N-dimethylformamide on residents living near synthetic leather factories. Environ. Sci. Pollut. Res. Int. 2014, 21, 3534–3539. [Google Scholar] [CrossRef] [PubMed]

- Jyothi, K.; Kalyani, D.; Nachiappan, V. Effect of acute exposure of N,N-dimethylformamide, an industrial solvent on lipid peroxidation and antioxidants in liver and kidney of rats. Indian J. Biochem. Biophys. 2012, 49, 279–284. [Google Scholar] [PubMed]

- Hamada, M.; Abe, M.; Tokumoto, Y.; Miyake, T.; Murakami, H.; Hiasa, Y.; Matsuura, B.; Sato, K.; Onji, M. Occupational liver injury due to N,N-dimethylformamide in the synthetics industry. Intern. Med. 2009, 48, 1647–1650. [Google Scholar] [CrossRef] [PubMed]

- Kilo, S.; Göen, T.; Drexler, H. Cross-sectional study on N,N-dimethylformamide (DMF); effects on liver and alcohol intolerance. Int. Arch. Occup. Environ. Health 2016, 89, 1309–1320. [Google Scholar] [CrossRef] [PubMed]

- European Chemicals Agency (ECHA). SVHC Support Document-DMF. 2012. Available online: http://echa.europa.eu/documents/10162/3f575bea-5a96-4f18-a110-d294d37422c7 (accessed on 25 February 2018).

- He, J.; Wang, P.; Zhu, J.; Wu, G.; Ji, J.; Xue, Y. Role of urinary biomarkers of N,N-dimethylformamide in the early detection of hepatic injury among occupational exposed workers. Int. Arch. Occup. Environ. Health 2010, 83, 399–406. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Tian, W.; Zheng, Y.; Zhang, Q.; Jiang, L.; Wu, Z.C. Modelling of urban ambient N,N-dimethylformamide concentrations in a small-scale synthetic leather industrial zone. J. Zhejiang Univ. Sci. A 2011, 12, 374–389. [Google Scholar] [CrossRef]

- Kawata, K.; Ibaraki, T.; Tanabe, A.; Yasuhara, A. Distribution of 1,4-Dioxane and N,N-Dimethylformamide in River Water from Niigata, Japan. Bull. Environ. Contam. Toxicol. 2003, 70, 876–882. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.T.; Lin, K.L. Assessment of the strategies for reducing VOCs emission from polyurea-formaldehyde resin synthetic fiber leather industry in Taiwan. Resour. Conserv. Recycl. 2006, 46, 321–334. [Google Scholar] [CrossRef]

- Park, D.H.; Oh, J.K.; Kim, S.B.; Kim, W.N. Synthesis and characterization of sulfonated polyol-based waterborne polyurethane-polyacrylate hybrid emulsions. Macromol. Res. 2013, 21, 1247–1253. [Google Scholar] [CrossRef]

- Ren, L.; Zhao, G.; Qiang, T.; Wang, X.; Wang, N. Synthesis of amino-terminated hyperbranched polymers and their application in microfiber synthetic leather base dyeing. Text. Res. J. 2013, 83, 381–395. [Google Scholar] [CrossRef]

- Vasanthan, N. Effect of the microstructure on the dye diffusion and mechanical properties of polyamide-6 fibers. J. Polym. Sci. Part B Polym. Phys. 2007, 45, 349–357. [Google Scholar] [CrossRef]

- Baig, G.A. A study on the exhaust dyeing of various synthetic fibres with indigo. Color. Technol. 2012, 128, 114–120. [Google Scholar] [CrossRef]

- Burkinshaw, S.M.; Son, Y.A. The dyeing of supermicrofibre nylon with acid and vat dyes. Dyes Pigment. 2010, 87, 132–138. [Google Scholar] [CrossRef]

- Petrović, Z.S.; Ferguson, J. Polyurethane elastomers. Prog. Polym. Sci. 1991, 16, 695–836. [Google Scholar] [CrossRef]

- Atav, R.; Çay, A.; Körlü, A.E.; Duran, K. Comparison of the effects of various presettings on the colour of polyamide 6.6 dyed with acid dyestuffs. Color. Technol. 2006, 122, 277–281. [Google Scholar] [CrossRef]

- Fung, K.Y.; Lee, C.M.; Ng, K.M.; Wibowo, C.; Deng, Z. Process development of treatment plants for dyeing wastewater. AIChE J. 2012, 58, 2726–2742. [Google Scholar] [CrossRef]

- Zheng, J.; Liu, X.; Brady, P.R. One-bath union dyeing of wool/polytrimethylene terephthalate blends. Color. Technol. 2008, 124, 204–210. [Google Scholar] [CrossRef]

- Merdan, N.; Akalin, M.; Kocak, D.; Usta, I. Effects of ultrasonic energy on dyeing of polyamide (microfibre)/Lycra blends. Ultrasonics 2004, 42, 165–168. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Chen, Y.; Fan, H.; Yan, J.; Wang, F.; Li, C. Application of cationic waterborne polyurethane as impregnation material for microfiber synthetic leather base. J. Donghua Univ. (Eng. Ed.) 2017, 34, 298–303. [Google Scholar]

- Ren, L.F.; Zhao, G.H.; Wang, X.C.; Qiang, T.T.; Wang, N. Study on dyeing improvements on microfiber synthetic leathers using amino-terminated hyperbranched polymers. J. Chem. Eng. Chin. Univ. 2014, 28, 1138–1146. [Google Scholar]

- Qiang, T.T.; Wang, X.Q.; Wang, X.C.; Ren, J.; Ren, L.F. Study on the effect of dyeing properties of microfiber synthetic leather base by hydrolyzed collagen. J. Funct. Mater. 2014, 45, 14066–14071. [Google Scholar]

- Lee, S.K.; Lee, H.Y.; Kim, S.D. Dyeing properties of mixture of ultrafine nylon and polyurethane with different types of dye. Fibers Polym. 2013, 14, 2020–2026. [Google Scholar] [CrossRef]

- Yen, M.S.; Chen, P.Y.; Tsai, H.C. Synthesis, properties, and dyeing application of nonionic waterborne polyurethanes with different chain length of ethyldiamines as the chain extender. J. Appl. Polym. Sci. 2003, 90, 2824–2833. [Google Scholar] [CrossRef]

- Wang, H.H.; Lin, L.E. Modified polyurethane with improvement of acid dye dyeability. J. Appl. Polym. Sci. 2003, 89, 1397–1404. [Google Scholar] [CrossRef]

- Wang, X.C.; Yuan, X.Z.; Qiang, T.T.; Chen, X. Hyperbranched poly(amine-ester) polyol: Synthesis, characterization, thermal stability, solubility and surface activity. e-Polymers 2009, 9, 1363–1377. [Google Scholar]

- Wang, Y. Synthesis, Properties and application in leather colouration of novel polymeric dye based on hyperbranched poly (amine-ester). J. Soc. Leather Technol. Chem. 2017, 101, 183–189. [Google Scholar]

- Oprea, S. Molecular dynamcis, thermo-mechanical and optical studies on benzidine chain extended polyurethane-urea. J. Polym. Res. 2011, 18, 1777–1785. [Google Scholar] [CrossRef]

- Wang, H.H.; Tzun, I.S. Modified polyurethane with a covalent bond of dye molecule. J. Appl. Polym. Sci. 1999, 73, 245–253. [Google Scholar] [CrossRef]

- Wang, S.; Shi, H.; Fan, H.; Shi, B. Influence of hard segment content on properties of waterborne polyurethane. China Leather 2011, 40, 18–22. [Google Scholar]

- Wang, X.; Fu, Y.; Ren, L.; Qiang, T.; Ren, J. Synthesis and characterization of PTMG aliphatic hyperbranched polyurethane. J. Funct. Mater. 2013, 44, 289–293. [Google Scholar]

- Kuang, H.C.; Su, H.Y.; Ma, C.C.M. Synthesis and characterization of polysilicic acid nanoparticles/waterborne polyurethane nanocomposite. J. Mater. Sci. 2005, 40, 6063–6070. [Google Scholar] [CrossRef]

- Bao, L.H.; Lan, Y.J.; Zhang, S.F. Synthesis and properties of waterborne polyurethane dispersions with ions in the soft segments. J. Polym. Res. 2006, 13, 507–514. [Google Scholar] [CrossRef]

- Wang, C.; Li, X.; Du, B.; Li, P.; Lai, X.; Niu, Y. Preparation and properties of a novel waterborne fluorinated polyurethane–acrylate hybrid emulsion. Colloid Polym. Sci. 2014, 292, 579–587. [Google Scholar] [CrossRef]

- Asif, A.; Hu, L.; Shi, W. Synthesis, rheological, and thermal properties of waterborne hyperbranched polyurethane acrylate dispersions for UV curable coatings. Colloid Polym. Sci. 2009, 287, 1041–1049. [Google Scholar] [CrossRef]

- Mohammad, M.R. Stability and properties of waterborne polyurethane/clay nanocomposite dispersions. J. Coat. Technol. Res. 2017, 14, 1357–1368. [Google Scholar]

- Zhang, J.; Hu, C.P. Synthesis, characterization and mechanical properties of polyester-based aliphatic polyurethane elastomers containing hyperbranched polyester segments. Eur. Polym. J. 2008, 44, 3708–3714. [Google Scholar] [CrossRef]

- Lai, X.; Li, X.; Wang, L.; Shen, Y. Synthesis and characterizations of waterborne polyurethane modified with 3-aminopropyltriethoxysilane. Polym. Bull. 2010, 65, 45–57. [Google Scholar]

- Xu, J.; Jiang, Y.; Qiu, F.; Dai, Y.; Yang, D.; Yu, Z.; Yang, P. Synthesis, mechanical properties and iron surface conservation behavior of UV-curable waterborne polyurethane-acrylate coating modified with inorganic carbonate. Polym. Bull. 2018. [Google Scholar] [CrossRef]

- Jiang, Z.; Yuan, K.; Li, S.; Zhou, Y. Study of FTIR spectra and thermal analysis of polyurethane. Spectrosc. Spectr. Anal. 2006, 26, 624–628. [Google Scholar]

- EN ISO 105-A05, Textiles—Tests for Colour Fastness. Part A05: Instrumental Assessment of Change of Colour for Determination of Grey Scale Rating; British Standards Institution: London, UK, 2003.

| Sample | Content of Dye (mg/g) | C* | a | DE* | b |

|---|---|---|---|---|---|

| CLB | 7.80 | 53.88 | 53.75 | 82.33 | 82.26 |

| 53.81 | 82.32 | ||||

| 53.57 | 82.13 | ||||

| DLB | 13.54 | 39.04 | 39.43 | 61.72 | 62.28 |

| 39.26 | 62.03 | ||||

| 39.99 | 63.08 |

| Sample | L* | a* | b* | DE* | a | ΔE |

|---|---|---|---|---|---|---|

| CLB | 56.78 | 50.58 | 17.95 | 82.33 | 82.26 | / |

| 56.94 | 50.76 | 17.87 | 82.32 | |||

| 56.69 | 50.52 | 17.80 | 82.13 | |||

| CLB washed by water | 56.82 | 50.29 | 17.51 | 81.73 | 81.33 | 0.93 |

| 56.71 | 49.73 | 18.02 | 81.21 | |||

| 57.02 | 49.78 | 17.72 | 81.06 | |||

| CLB washed by soap solution | 56.99 | 47.99 | 14.70 | 78.29 | 78.05 | 4.21 |

| 57.41 | 47.79 | 14.56 | 77.82 | |||

| 56.97 | 47.78 | 14.72 | 78.05 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Jin, L. Preparation and Characterization of Self-Colored Waterborne Polyurethane and Its Application in Eco-Friendly Manufacturing of Microfiber Synthetic Leather Base. Polymers 2018, 10, 289. https://doi.org/10.3390/polym10030289

Wang Y, Jin L. Preparation and Characterization of Self-Colored Waterborne Polyurethane and Its Application in Eco-Friendly Manufacturing of Microfiber Synthetic Leather Base. Polymers. 2018; 10(3):289. https://doi.org/10.3390/polym10030289

Chicago/Turabian StyleWang, Yulu, and Liqiang Jin. 2018. "Preparation and Characterization of Self-Colored Waterborne Polyurethane and Its Application in Eco-Friendly Manufacturing of Microfiber Synthetic Leather Base" Polymers 10, no. 3: 289. https://doi.org/10.3390/polym10030289

APA StyleWang, Y., & Jin, L. (2018). Preparation and Characterization of Self-Colored Waterborne Polyurethane and Its Application in Eco-Friendly Manufacturing of Microfiber Synthetic Leather Base. Polymers, 10(3), 289. https://doi.org/10.3390/polym10030289