Mechanical Properties of Rice Husk Biochar Reinforced High Density Polyethylene Composites

Abstract

1. Introduction

2. Experiment

2.1. Materials

2.2. Preparation of Composites

2.3. Measurements and Characterization

2.3.1. Microscopy and Structure

2.3.2. Non-Isothermal Crystallization Behavior

2.3.3. Mechanical Properties

3. Results and Discussion

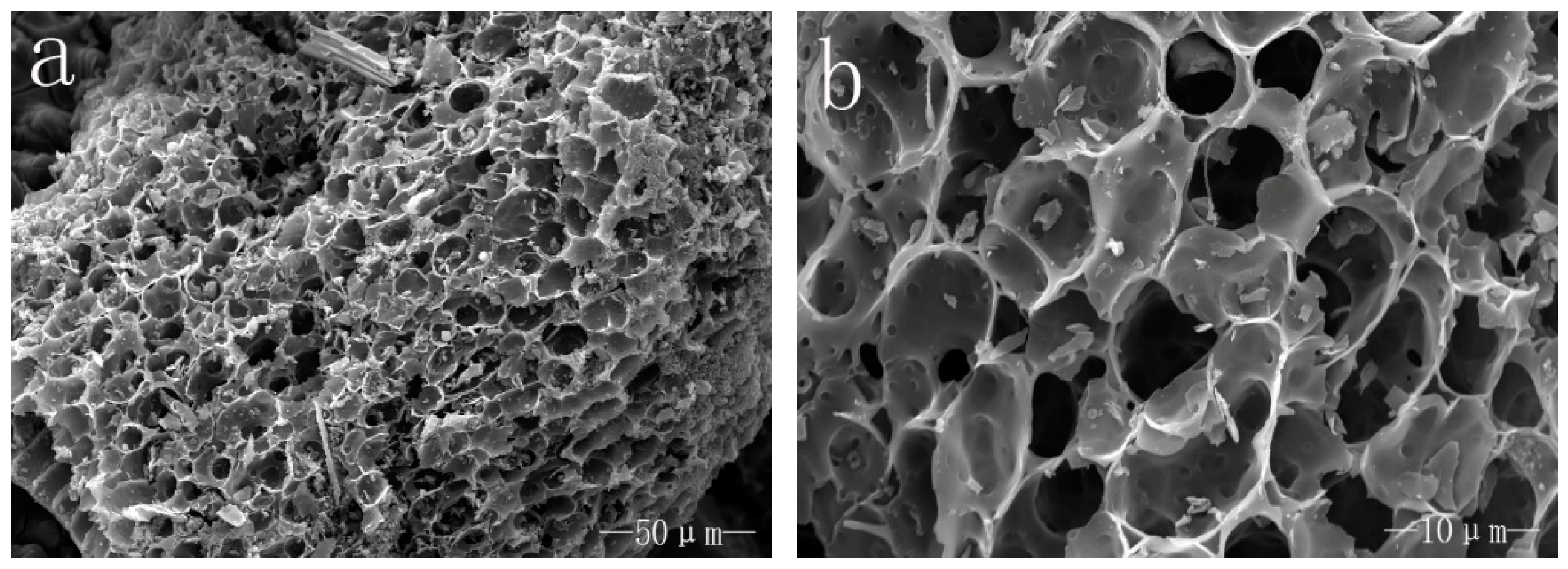

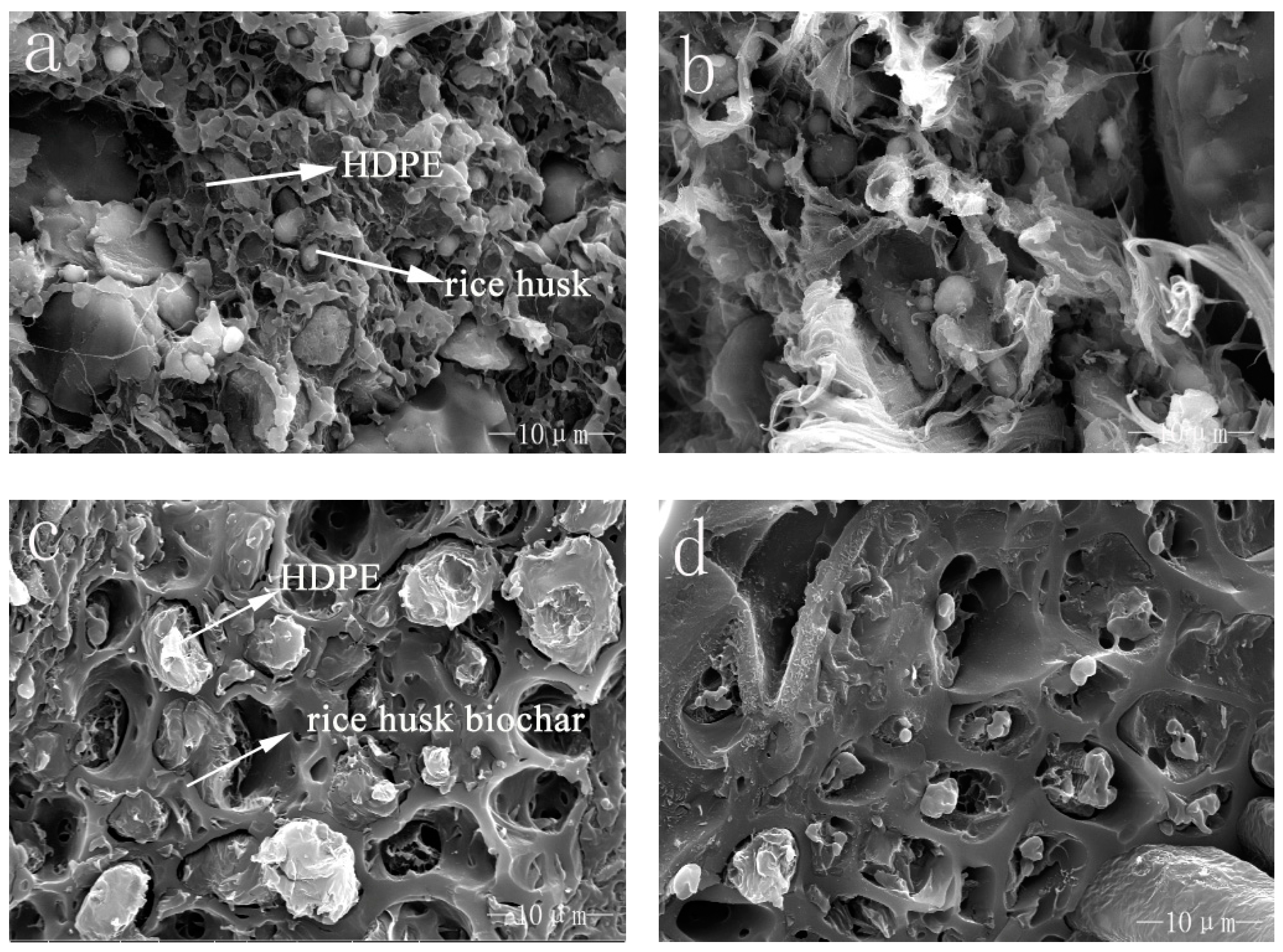

3.1. SEM Observations

3.2. Non-Isothermal Crystallization Behavior

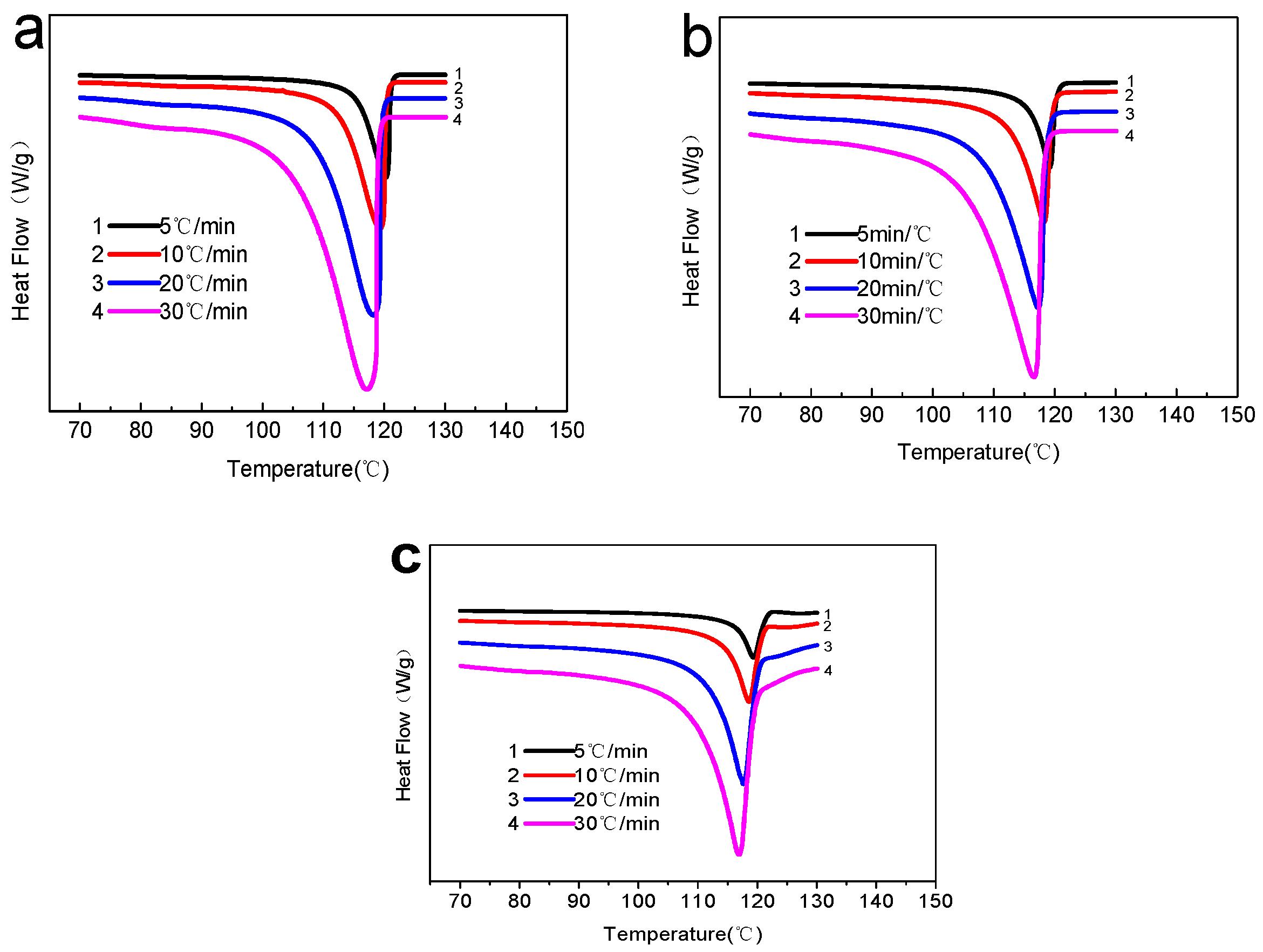

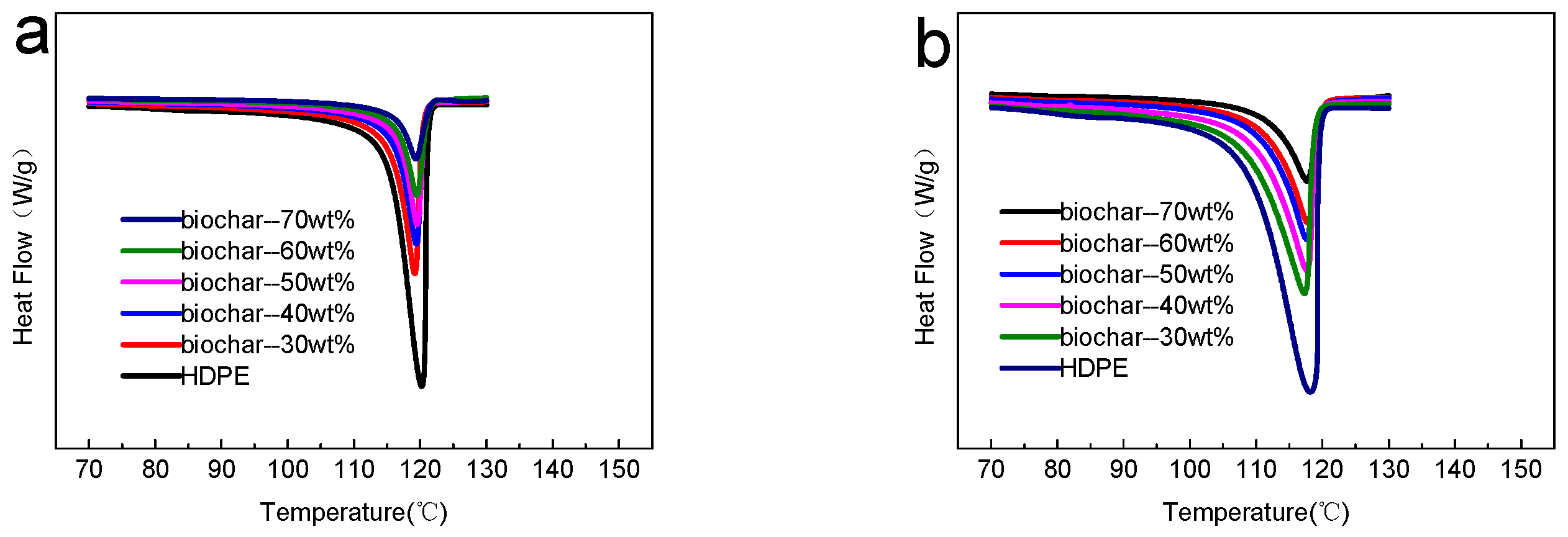

3.2.1. Crystallization Behavior

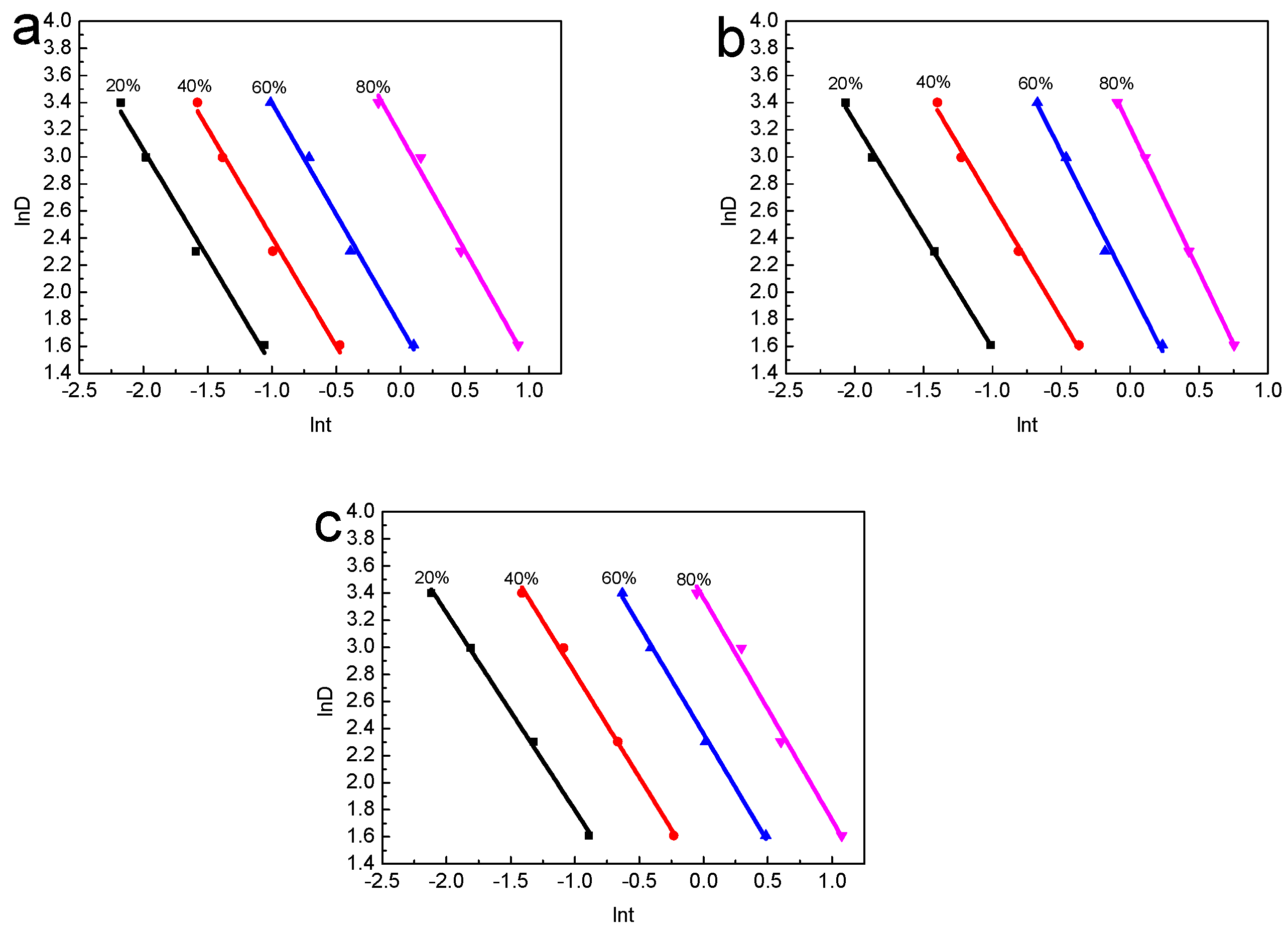

3.2.2. Non-Isothermal Crystallization Kinetics

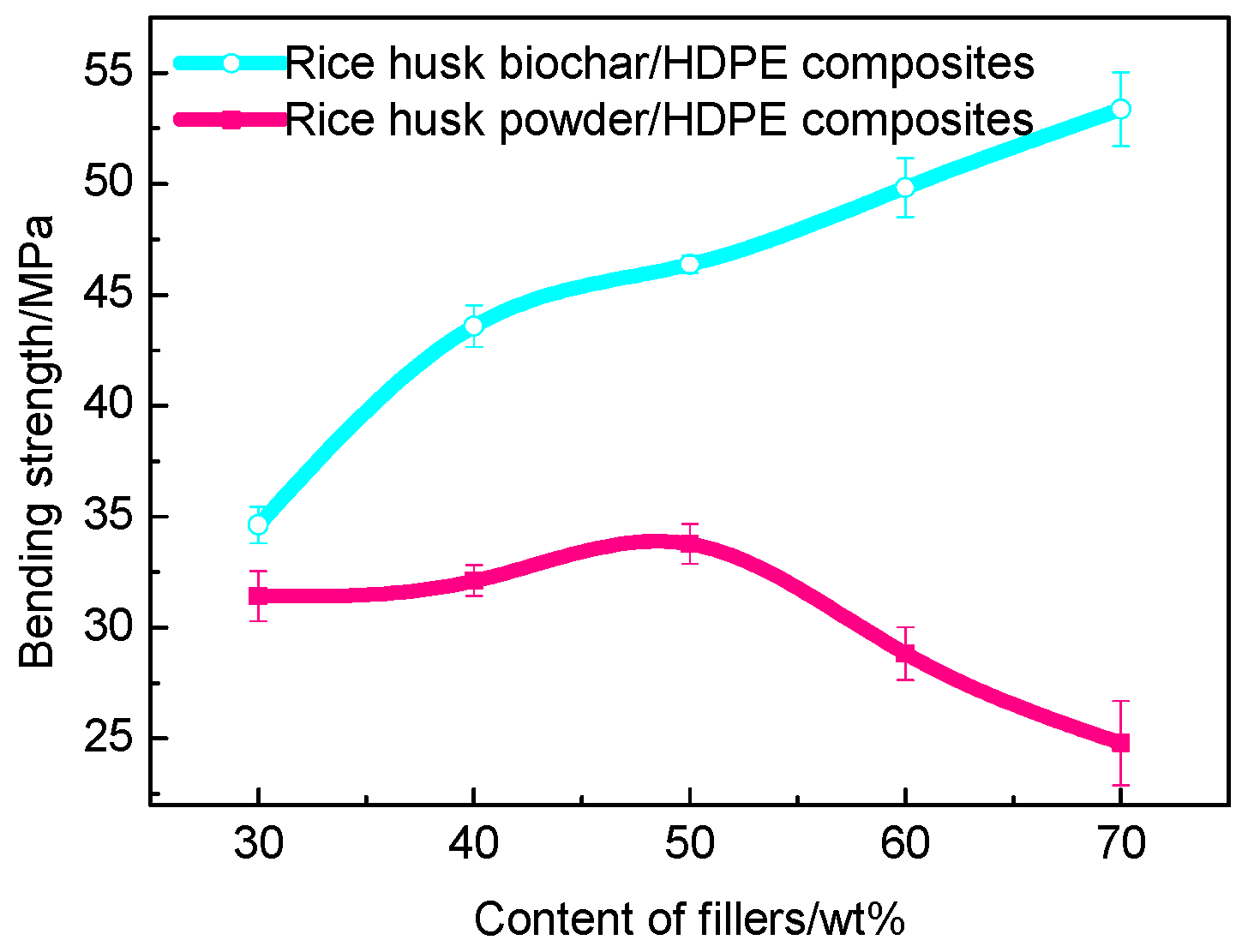

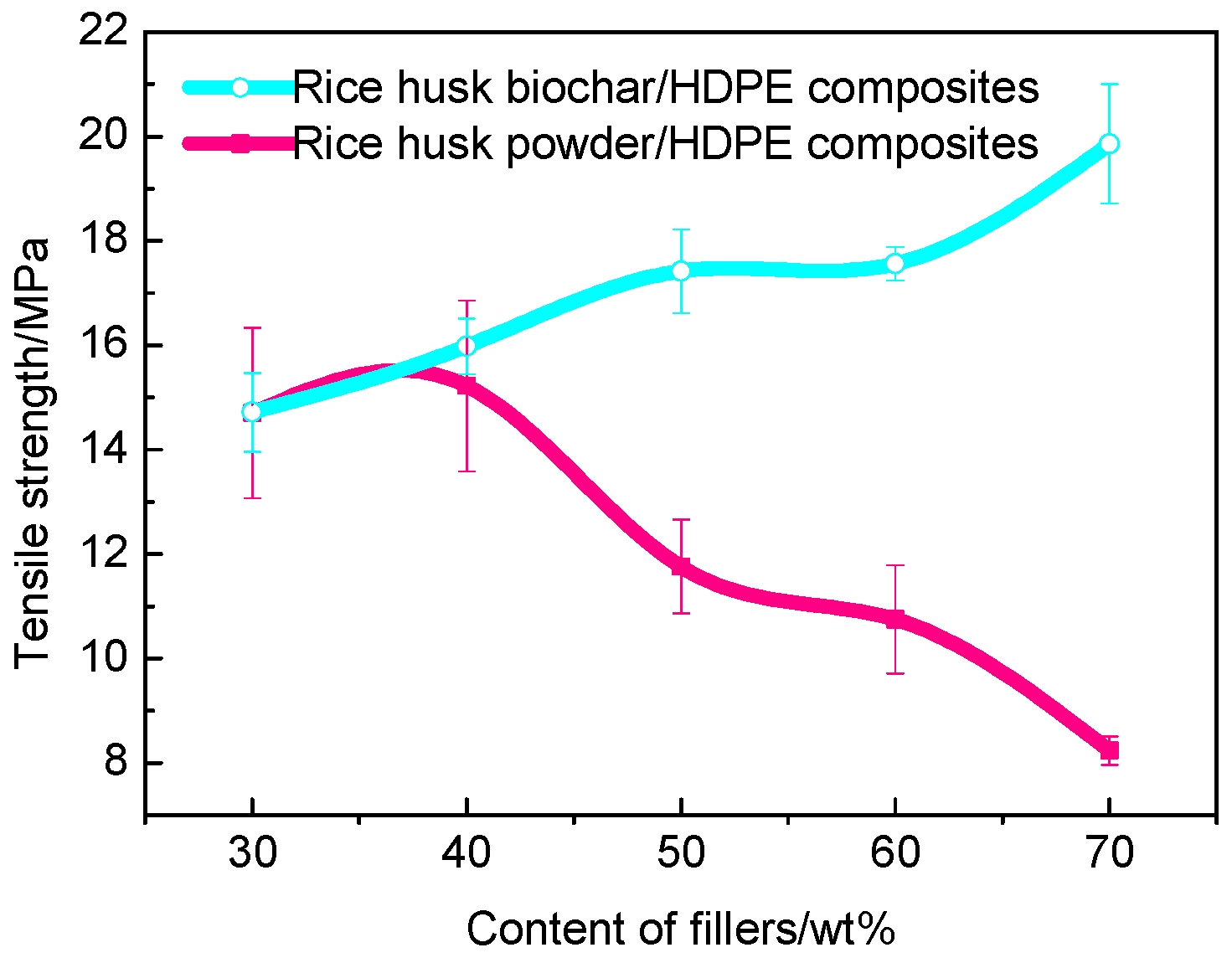

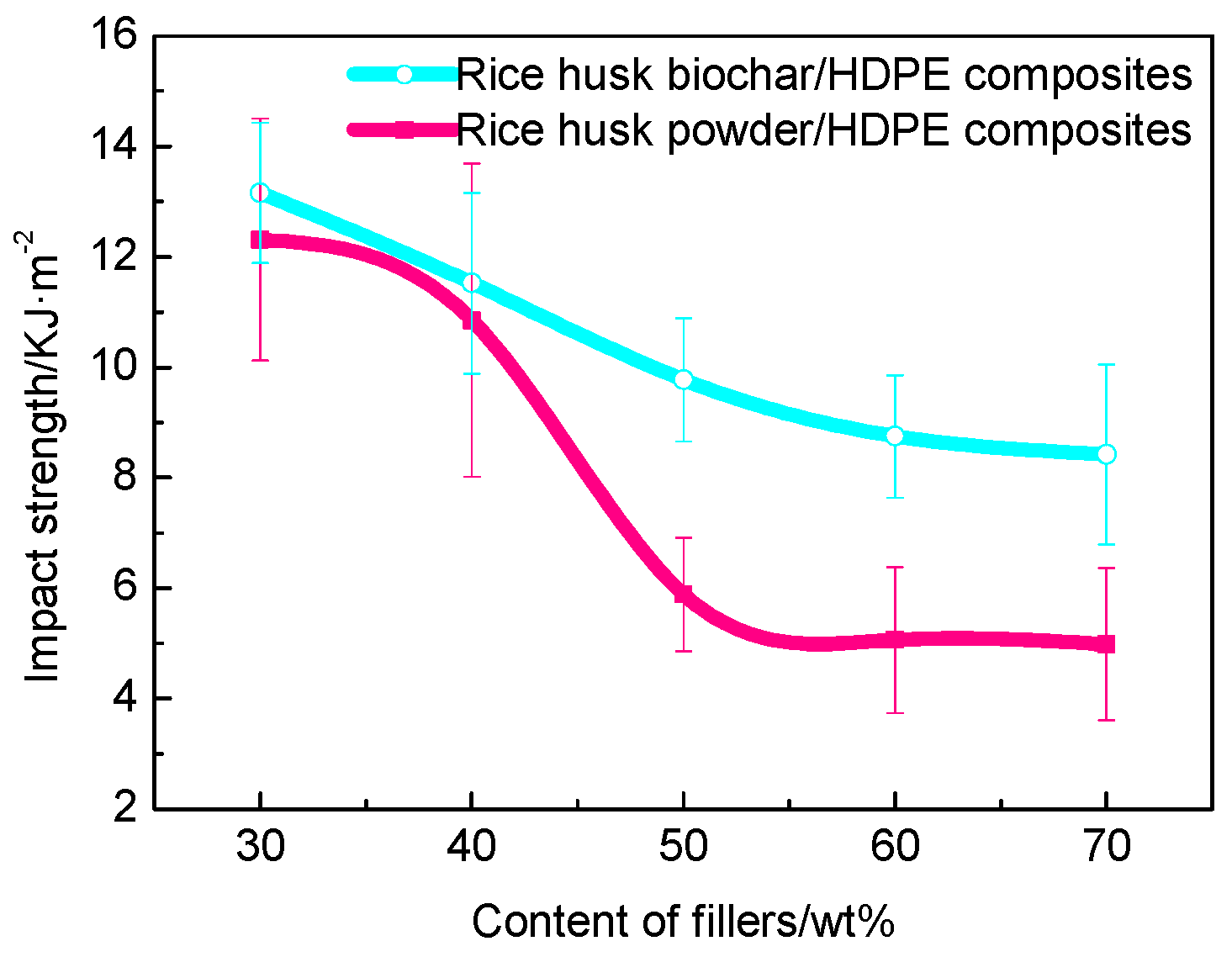

3.3. Mechanical Properties

3.3.1. Bending Strength

3.3.2. Tensile Strength

3.3.3. Impact Strength

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Cicala, G.; Saccullo, G.; Blanco, I.; Samal, S.; Battiato, S.; Dattilo, S.; Saake, B. Polylactide/lignin blends: Effects of processing conditions on structure and thermo-mechanical properties. J. Therm. Anal. Calorim. 2017, 130, 515–524. [Google Scholar] [CrossRef]

- Cicala, G.; Tosto, C.; Latteri, A.; La Rosa, A.D.; Blanco, I.; Elsabbagh, A.; Russo, P.; Ziegmann, G. Green Composites Based on Blends of Polypropylene with Liquid Wood Reinforced with Hemp Fibers: Thermomechanical Properties and the Effect of Recycling Cycles. Materials 2017, 10, 998. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Li, X.; Deng, Q.; Li, D. Three kinds of charcoal powder reinforced ultra-high molecular weight polyethylene composites with excellent mechanical and electrical properties. Mater. Des. 2015, 85, 54–59. [Google Scholar] [CrossRef]

- Nguila, I.G.; Petrissans, M.; Gerardin, P. Chemical reactivity of heat-treated wood. Wood Sci. Technol. 2007, 41, 157–168. [Google Scholar] [CrossRef]

- Hu, R.; Lim, J.-K. Fabrication and Mechanical Properties of Completely Biodegradable Hemp Fiber Reinforced PLA Composites. J. Compos. Mater. 2007, 41, 1655–1669. [Google Scholar] [CrossRef]

- Jayamani, E.; Bakri, M.K.B. Dielectric Properties of Lignocellulosic Fibers Reinforced Polymer Composites: Effect of Fiber Loading and Alkaline Treatment. Mater. Today Proc. 2015, 2, 2757–2766. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.; Gu, C.; Liu, J.; Liu, Y.; Li, M.; Lu, Y. Enhancement of the Mechanical Properties of Basalt Fiber-Wood-Plastic Composites via Maleic Anhydride Grafted High-Density Polyethylene (MAPE) Addition. Materials 2013, 6, 2483–2496. [Google Scholar] [CrossRef] [PubMed]

- Schirp, A.; Stender, J. Properties of extruded wood-plastic composites based on refiner wood fibres (TMP fibres) and hemp fibres. Eur. J. Wood Wood Prod. 2010, 68, 219–231. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. A novel approach in organic waste utilization through biochar addition in wood/polypropylene composites. Waste Manag. 2015, 38, 132–140. [Google Scholar] [CrossRef] [PubMed]

- Colantoni, A.; Evic, N.; Lord, R.; Retschitzegger, S.; Proto, A.R.; Gallucci, F.; Monarca, D. Characterization of biochars produced from pyrolysis of pelletized agricultural residues. Renew. Sustain. Energy Rev. 2016, 64, 187–194. [Google Scholar] [CrossRef]

- Srinivasan, P.; Sarmah, A.K. Characterisation of agricultural waste-derived biochars and their sorption potential for sulfamethoxazole in pasture soil: A spectroscopic investigation. Sci. Total Environ. 2015, 502, 471–480. [Google Scholar] [CrossRef] [PubMed]

- Krishnakumar, S.; Rajalakshmi, A.G.; Balaganesh, B.; Manikandan, P.; Vinoth, C.; Rajendran, V. Impact of Biochar on Soil Health. Int. J. Adv. Res. 2014, 2, 933–950. [Google Scholar]

- Sarmah, A.K.; Srinivasan, P.; Smernik, R.J.; Manleyharris, M.; Antal, M.J., Jr.; Downie, A.; Zwieten, L.V.; Krull, E.; Singh, B.; Joseph, S. Retention capacity of biochar-amended New Zealand dairy farm soil for an estrogenic steroid hormone and its primary metabolite. Aust. J. Soil Res. 2010, 48, 648–658. [Google Scholar] [CrossRef]

- Das, O.; Bhattacharyya, D.; Hui, D.; Lau, K.T. Mechanical and flammability characterisations of biochar/polypropylene biocomposites. Compos. Part B Eng. 2016, 106, 120–128. [Google Scholar] [CrossRef]

- Ikram, S.; Das, O.; Bhattacharyya, D. A parametric study of mechanical and flammability properties of biochar reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2016, 91, 177–188. [Google Scholar] [CrossRef]

- Zhang, Q.; Cai, H.; Ren, X.; Kong, L.; Liu, J.; Jiang, X. The Dynamic Mechanical Analysis of Highly Filled Rice Husk Biochar/High-Density Polyethylene Composites. Polymers 2017, 9, 628. [Google Scholar] [CrossRef]

- Khan, A.; Savi, P.; Quaranta, S.; Rovere, M.; Giorcelli, M.; Tagliaferro, A.; Rosso, C.; Jia, C. Low-Cost Carbon Fillers to Improve Mechanical Properties and Conductivity of Epoxy Composites. Polymers 2017, 9, 642. [Google Scholar] [CrossRef]

- Rao, A.K.; Ahmad, S.; Savi, P.; Tulliani, J.M.; Giorcelli, M.; Ferro, G.A. Improvement in electromagnetic interference shielding effectiveness of cement composites using carbonaceous nano/micro inerts. Constr. Build. Mater. 2015, 85, 208–216. [Google Scholar]

- Li, S.; Li, D. Carbon fiber reinforced highly filled charcoal powder/ultra high molecular weight polyethylene composites. Mater. Lett. 2014, 134, 99–102. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, H.; He, L.; Lu, K.; Sarmah, A.; Li, J.; Bolan, N.S.; Pei, J.; Huang, H. Using biochar for remediation of soils contaminated with heavy metals and organic pollutants. Environ. Sci. Pollut. Res. 2013, 20, 8472–8483. [Google Scholar] [CrossRef] [PubMed]

- Mo, Z. A method for the non-isothermal crystallization kinetics of polymers. Acta Polym. Sin. 2008, 008, 656–661. [Google Scholar] [CrossRef]

- Huttepain, M.; Oberlin, A. Microtexture of nongraphitizing carbons and tem studies of some activated samples. Carbon 1990, 28, 103–111. [Google Scholar] [CrossRef]

- Kyotani, T. Control of pore structure in carbon. Carbon 2000, 38, 269–286. [Google Scholar] [CrossRef]

- Liou, T.H. Preparation and characterization of nano-structured silica from rice husk. Mater. Sci. Eng. A 2004, 364, 313–323. [Google Scholar] [CrossRef]

- You, Z.; Li, D. The dynamical viscoelasticity and tensile property of new highly filled charcoal powder/ultra-high molecular weight polyethylene composites. Mater. Lett. 2013, 112, 197–199. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Jaszkiewicz, A.; Scherzer, D. Mechanical properties of PLA composites with man-made cellulose and abaca fibres. Compos. Part A Appl. Sci. Manuf. 2009, 40, 404–412. [Google Scholar] [CrossRef]

- Sewda, K.; Maiti, S.N. Crystallization and melting behavior of HDPE in HDPE/teak wood flour composites and their correlation with mechanical properties. J. Appl. Polym. Sci. 2010, 118, 2264–2275. [Google Scholar] [CrossRef]

- Huang, L.; Wang, H.; Wang, Q. The non-isothermal crystallization kinetics analysis of polypropylene based wood plastic composite. Eng. Sci. 2014, 16, 21–24. [Google Scholar]

- Joshi, M.; Butola, B.S. Studies on nonisothermal crystallization of HDPE/POSS nanocomposites. Polymer 2004, 45, 4953–4968. [Google Scholar] [CrossRef]

- Ou, R.; Xie, Y.; Guo, C.; Wang, Q. Isothermal crystallization kinetics of Kevlar fiber-reinforced wood flour/high-density polyethylene composites. J. Appl. Polym. Sci. 2012, 126, E2–E9. [Google Scholar] [CrossRef]

- Shi, X.; Wang, J.; Jiang, B.; Yang, Y. Influence of nanofiller dimensionality on the crystallization behavior of HDPE/carbon nanocomposites. J. Appl. Polym. Sci. 2013, 128, 3609–3618. [Google Scholar] [CrossRef]

- Ahmad, I.; Chong, E.L.; Mohd, D.H.; Abdullah, I. Electron-beam-irradiated rice husk powder as reinforcing filler in natural rubber/high-density polyethylene (NR/HDPE) composites. Compos. Part B Eng. 2012, 43, 3069–3075. [Google Scholar] [CrossRef]

- Kord, B. Nanofiller reinforcement effects on the thermal, dynamic mechanical, and morphological behavior of hdpe/rice husk flour composites. Bioresources 2011, 6, 1351–1358. [Google Scholar]

- Lu, J.Z.; Wu, Q.; Negulescu, I.I. Wood-fiber/high-density-polyethylene composites: Coupling agent performance. J. Appl. Polym. Sci. 2010, 96, 93–102. [Google Scholar] [CrossRef]

- Nurshamila, S.B.; Ismail, H.; Othman, N. The effect of Rattan filler loading on properties of Rattan powder filled polypropylene composites. Bioresources 2012, 7, 5677–5690. [Google Scholar] [CrossRef]

| Cooling Rate °C/min | Maximum Crystallization Peak Temperature °C | |||||

|---|---|---|---|---|---|---|

| HDPE | Biochar—30% | Biochar—40% | Biochar—50% | Biochar—60% | Biochar—70% | |

| 5 | 120.22 | 119.19 | 119.44 | 119.53 | 119.49 | 119.39 |

| 10 | 119.33 | 118.25 | 118.59 | 118.55 | 118.54 | 118.62 |

| 20 | 118.31 | 117.37 | 117.69 | 117.65 | 117.78 | 117.71 |

| 30 | 117.23 | 116.68 | 116.32 | 117.01 | 117.45 | 116.98 |

| Relative Crystallinity | HDPE | BPC (Biochar—30 wt %) | BPC (Biochar—70 wt %) | |||

|---|---|---|---|---|---|---|

| a | F(T) | a | F(T) | a | F(T) | |

| 20% | 1.60 | 0.87 | 1.67 | 0.92 | 1.46 | 1.62 |

| 40% | 1.61 | 2.22 | 1.71 | 2.58 | 1.53 | 5.37 |

| 60% | 1.65 | 5.75 | 2.00 | 7.65 | 1.60 | 11.36 |

| 80% | 1.70 | 23.48 | 2.12 | 24.90 | 1.64 | 29.69 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Yi, W.; Li, Z.; Wang, L.; Cai, H. Mechanical Properties of Rice Husk Biochar Reinforced High Density Polyethylene Composites. Polymers 2018, 10, 286. https://doi.org/10.3390/polym10030286

Zhang Q, Yi W, Li Z, Wang L, Cai H. Mechanical Properties of Rice Husk Biochar Reinforced High Density Polyethylene Composites. Polymers. 2018; 10(3):286. https://doi.org/10.3390/polym10030286

Chicago/Turabian StyleZhang, Qingfa, Weiming Yi, Zhihe Li, Lihong Wang, and Hongzhen Cai. 2018. "Mechanical Properties of Rice Husk Biochar Reinforced High Density Polyethylene Composites" Polymers 10, no. 3: 286. https://doi.org/10.3390/polym10030286

APA StyleZhang, Q., Yi, W., Li, Z., Wang, L., & Cai, H. (2018). Mechanical Properties of Rice Husk Biochar Reinforced High Density Polyethylene Composites. Polymers, 10(3), 286. https://doi.org/10.3390/polym10030286