Fluorinated Polymers as Smart Materials for Advanced Biomedical Applications

Abstract

1. Introduction

2. Poly(vinylidene fluoride) and Its Copolymers

Processing Techniques and Resulting Structures

3. Representative Biomedical Applications

3.1. Medical Device Instrumentation

3.2. Tissue Engineering

3.3. Microfluidic Systems

3.4. Drug Delivery

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Hansen, N.M.L.; Jankova, K.; Hvilsted, S. Fluoropolymer materials and architectures prepared by controlled radical polymerizations. Eur. Polym. J. 2007, 43, 255–293. [Google Scholar] [CrossRef]

- Teng, H.X. Overview of the development of the fluoropolymer industry. Appl. Sci. (Basel) 2012, 2, 496–512. [Google Scholar] [CrossRef]

- Dietrich, K. High performance polymers: Their origin and development. Acta Polym. 1988, 39, 152. [Google Scholar]

- Ebnesajjad, S. Fluoroplastics; William Andrew Publishing: Oxford, UK, 2015; Volume 1. [Google Scholar]

- Dhara, M.G.; Banerjee, S. Fluorinated high-performance polymers: Poly(arylene ether)s and aromatic polyimides containing trifluoromethyl groups. Prog. Polym. Sci. 2010, 35, 1022–1077. [Google Scholar] [CrossRef]

- Imae, T. Fluorinated polymers. Curr. Opin. Colloid Interface Sci. 2003, 8, 307–314. [Google Scholar] [CrossRef]

- Leivo, E.; Wilenius, T.; Kinos, T.; Vuoristo, P.; Mantyla, T. Properties of thermally sprayed fluoropolymer PVDF, ECTFE, PFA and FEP coatings. Prog. Org. Coat. 2004, 49, 69–73. [Google Scholar] [CrossRef]

- Fluoropolymers Division of the Society of the Plastics Industry. Guide to Safe Handling of Fluoropolymer Resins; Society of the Plastics Industry: Washington, DC, USA, 2005. [Google Scholar]

- Cui, Z.; Drioli, E.; Lee, Y.M. Recent progress in fluoropolymers for membranes. Prog. Polym. Sci. 2014, 39, 164–198. [Google Scholar] [CrossRef]

- Gardiner, J. Fluoropolymers: Origin, production, and industrial and commercial applications. Aust. J. Chem. 2015, 68, 13–22. [Google Scholar] [CrossRef]

- Hu, J.H.; Chen, W.J.; Zhao, B.; Yang, D.Q. Buildings with ETFE foils: A review on material properties, architectural performance and structural behavior. Constr. Build. Mater. 2017, 131, 411–422. [Google Scholar] [CrossRef]

- Ameduri, B.; Boutevin, B.; Kostov, G. Fluoroelastomers: Synthesis, properties and applications. Prog. Polym. Sci. 2001, 26, 105–187. [Google Scholar] [CrossRef]

- Ribeiro, C.; Correia, D.M.; Ribeiro, S.; Sencadas, V.; Botelho, G.; Lanceros-Méndez, S. Piezoelectric poly(vinylidene fluoride) microstructure and poling state in active tissue engineering. Eng. Life Sci. 2015. [Google Scholar] [CrossRef]

- Lin, J.; Zheng, C.; Ye, W.J.; Wang, H.Q.; Feng, D.Y.; Li, Q.Y.; Huan, B.W. A facile dip-coating approach to prepare SiO2/fluoropolymer coating for superhydrophobic and superoleophobic fabrics with self-cleaning property. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Ameduri, B. Chapter 10 chlorotrifluoroethylene copolymers for energy-applied materials. In Fluorinated Polymers: Volume 2: Applications; The Royal Society of Chemistry: London, UK, 2017; Volume 2, pp. 265–300. [Google Scholar]

- Carbonell, J.M.; Martin, I.S.; Santos, A.; Pujol, A.; Sanz-Moliner, J.D.; Nart, J. High-density polytetrafluoroethylene membranes in guided bone and tissue regeneration procedures: A literature review. Int. J. Oral Maxillofac. Surg. 2014, 43, 75–84. [Google Scholar] [CrossRef] [PubMed]

- Kuzharov, A.S. Polytetrafluoroethylene fiber-based composite antifriction coatings. Ind. Eng. Chem. Res. 1993, 32, 763–773. [Google Scholar] [CrossRef]

- Harris, K.L.; Pitenis, A.A.; Sawyer, W.G.; Krick, B.A.; Blackman, G.S.; Kasprzak, D.J.; Junk, C.P. PTFE tribology and the role of mechanochemistry in the development of protective surface films. Macromolecules 2015, 48, 3739–3745. [Google Scholar] [CrossRef]

- Bureau, C.; Garcia-Pagan, J.C.; Otal, P.; Pomier-Layrargues, G.; Chabbert, V.; Cortez, C.; Perreault, P.; Peron, J.M.; Abraldes, J.G.; Bouchard, L.; et al. Improved clinical outcome using polytetrafluoroethylene-coated stents for tips: Results of a randomized study. Gastroenterology 2004, 126, 469–475. [Google Scholar] [CrossRef] [PubMed]

- Sugama, T.; Gawlik, K. Poly(tetrafluoroethylene)/(hexafluoropropylene) coatings for mitigating the corrosion of steel in a simulated geothermal environment. Prog. Org. Coat. 2001, 42, 202–208. [Google Scholar] [CrossRef]

- Menzel, B.; Blanchet, T.A. Enhanced wear resistance of gamma-irradiated PTFE and FEP polymers and the effect of post-irradiation environmental handling. Wear 2005, 258, 935–941. [Google Scholar] [CrossRef]

- Hu, J.H.; Li, Y.P.; Li, C.; Chen, W.J.; Yang, D.Q. Mechanical properties of fluorinated ethylene propylene (FEP) foils in use for neutrino detector project. Polym. Test. 2017, 59, 362–370. [Google Scholar] [CrossRef]

- Akinci, A.; Cobanoglu, E. Coating of al mould surfaces with polytetrafluoroethylene (PTFE), fluorinated ethylene propylene (FEP), perfluoroalkoxy (PFA) and ethylene-tetrafluoroethylene (ETFE). e-Polymers 2009, 9. [Google Scholar] [CrossRef]

- Stojkovic, G.; Krivec, M.; Vesel, A.; Marinsek, M.; Znidarsic-Plazl, P. Surface cell immobilization within perfluoroalkoxy microchannels. Appl. Surf. Sci. 2014, 320, 810–817. [Google Scholar] [CrossRef]

- Ko, B.S.; Sohn, J.Y.; Nho, Y.C.; Shin, J. Radiolytic: Preparation of ETFE and PFA based anion exchange membranes for alkaline fuel cell. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2011, 269, 2509–2513. [Google Scholar] [CrossRef]

- Meng, X.; Liu, Y.S.; Huang, M.Y.; Cao, J.P. Flexible perfluoroalkoxy films filled with carbon nanotubes and their electric heating property. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Saneinejad, S.; Shoichet, M.S. Patterned poly(chlorotrifluoroethylene) guides primary nerve cell adhesion and neurite outgrowth. J. Biomed. Mater. Res. 2000, 50, 465–474. [Google Scholar] [CrossRef]

- Anderson, J.E.; Montgomery, J.B.; Yee, R. Enhanced poly(chlorotrifluoroethylene) composite electrodes. Anal. Chem. 1991, 63, 653–656. [Google Scholar] [CrossRef]

- Chohan, M.H.; Siddiqui, M.A.; Hussain, R.; Munir, A. Synthesis and electrical behaviour of poly(chlorotrifluoroethylene). Indian J. Eng. Mater. Sci. 1999, 6, 170–172. [Google Scholar]

- Li, L.; Bowler, N.; Kessler, M.R.; Yoon, S.H. Dielectric response of PTFE and ETFE wiring insulation to thermal exposure. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1234–1241. [Google Scholar] [CrossRef]

- Hu, J.H.; Li, Y.P.; Chen, W.J.; Zhao, B.; Yang, D.Q. Effects of temperature and stress on creep properties of ethylene tetrafluoroethylene (ETFE) foils for transparent buildings. Polym. Test. 2017, 59, 268–276. [Google Scholar] [CrossRef]

- Nasef, M.M.; Saidi, H.; Dahlan, K.Z.M. Electron beam irradiation effects on ethylene-tetrafluoroethylene copolymer films. Radiat. Phys. Chem. 2003, 68, 875–883. [Google Scholar] [CrossRef]

- Hu, J.H.; Chen, W.J.; Liu, Y.; Zhao, B.; Gao, C.J.; Yang, D.Q. Dynamic mechanical analysis of ethylene tetrafluoroethylene (ETFE) foils in use for transparent membrane buildings. Polym. Test. 2017, 59, 118–126. [Google Scholar] [CrossRef]

- Aronson, M.T.; Berger, L.L.; Honsberg, U.S. Effects of chain structure on the melting characteristics of poly(vinyl fluoride). Polymer 1993, 34, 2546–2553. [Google Scholar] [CrossRef]

- Sacher, E. Dielectric properties of poly(vinyl fluoride). J. Polym. Sci. A-2 1968, 6, 1813–1816. [Google Scholar] [CrossRef]

- Hanes, M.D.; Lando, J.B. Thermal-analysis of poly(vinyl fluoride). J. Appl. Polym. Sci. 1993, 49, 1223–1232. [Google Scholar] [CrossRef]

- Mather, B.D.; Reinartz, N.M.; Shiflett, M.B. Polymerization of vinyl fluoride in ionic liquid and ionic solutions. Polymer 2016, 82, 295–304. [Google Scholar] [CrossRef]

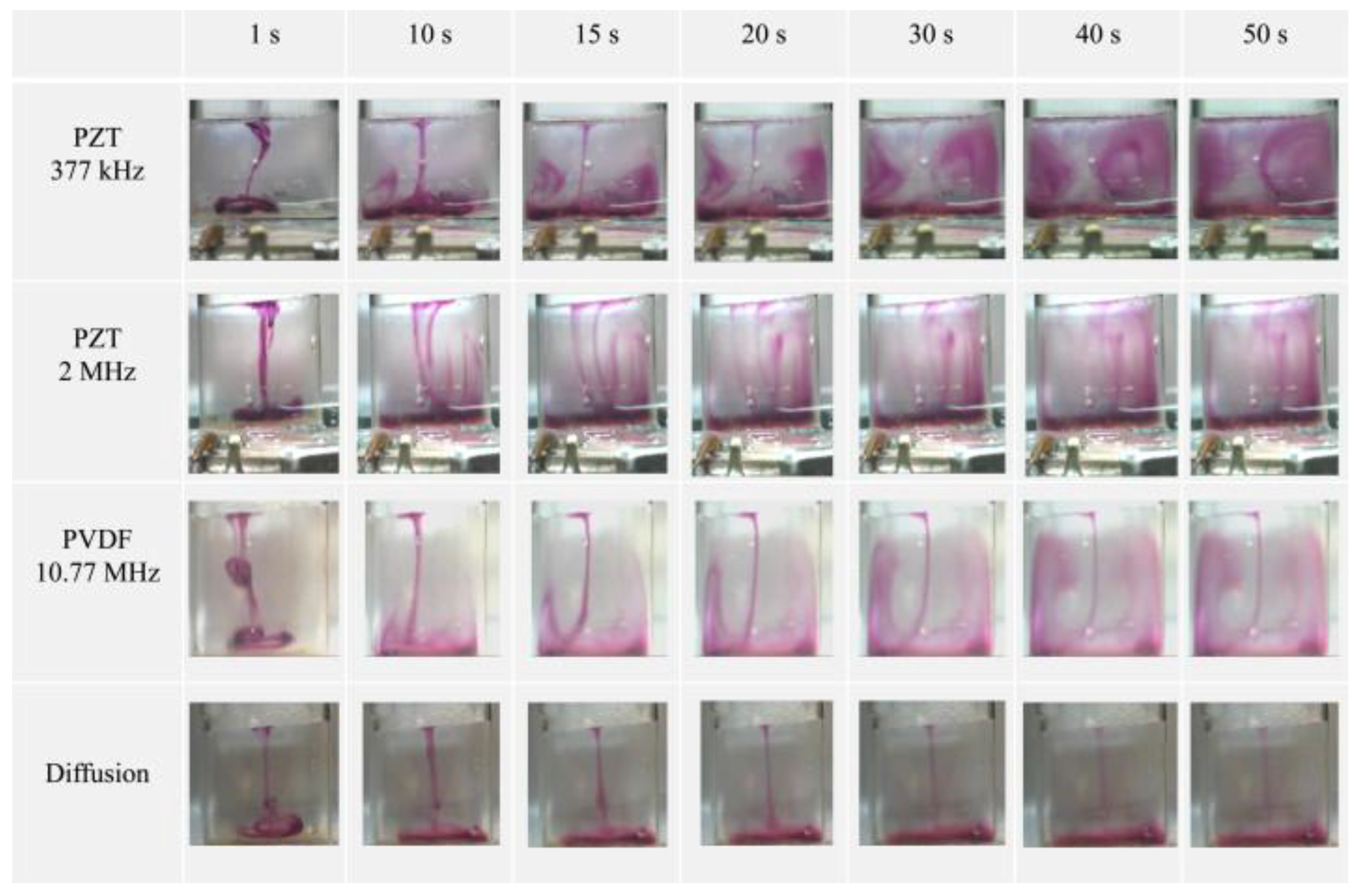

- Cardoso, V.F.; Catarino, S.O.; Nunes, J.S.; Rebouta, L.; Rocha, J.G.; Lanceros-Méndez, S.; Minas, G. Lab-on-a-chip with β-poly(vinylidene fluoride) based acoustic microagitation. IEEE Trans. Biomed. Eng. 2010, 57, 1184–1190. [Google Scholar] [CrossRef] [PubMed]

- Costa, C.M.; Nunes-Pereira, J.; Sencadas, V.; Silva, M.M.; Lanceros-Méndez, S. Effect of fiber orientation in gelled poly(vinylidene fluoride) electrospun membranes for Li-ion battery applications. J. Mater. Sci. 2013, 48, 6833–6840. [Google Scholar] [CrossRef]

- Li, J.F.; Zhou, X.M.; Huang, G.L.; Hu, G.K. Acoustic metamaterials capable of both sound insulation and energy harvesting. Smart Mater. Struct. 2016, 25, 045013. [Google Scholar] [CrossRef]

- Lau, S.F.; Suzuki, H.; Wunderlich, B. The thermodynamic properties of polytetrafluoroethylene. J. Polym. Sci. B 1984, 22, 379–405. [Google Scholar]

- Speerschneider, C.J.; Li, C.H. A correlation of mechanical properties and microstructure of polytetrafluoroethylene at various temperatures. J. Appl. Phys. 1963, 34, 3004. [Google Scholar] [CrossRef]

- Veeramasuneni, S.; Drelich, J.; Miller, J.D.; Yamauchi, G. Hydrophobicity of ion-plated PTFE coatings. Prog. Org. Coat. 1997, 31, 265–270. [Google Scholar] [CrossRef]

- Wei, W.; Sun, M.Y.; Zhang, L.; Zhao, S.F.; Wu, J.D.; Wang, J.P. Underwater oleophobic PTFE membrane for efficient and reusable emulsion separation and the influence of surface wettability and pore size. Sep. Purif. Technol. 2017, 189, 32–39. [Google Scholar] [CrossRef]

- Qing, W.H.; Shi, X.N.; Deng, Y.J.; Zhang, W.D.; Wang, J.Q.; Tang, C.Y.Y. Robust superhydrophobic-superoleophilic polytetrafluoroethylene nanofibrous membrane for oil/water separation. J. Membr. Sci. 2017, 540, 354–361. [Google Scholar] [CrossRef]

- Hatzikiriakos, S.G. Rheology and processing of tetrafluoroethylene/hexafluoropropylene copolymers. Int. Polym. Process. 2012, 27, 167–180. [Google Scholar] [CrossRef]

- Korinek, P.M. Properties and applications of perfluoroalkoxy copolymers. Kunstst. Ger. Plast. 1987, 77, 588–590. [Google Scholar]

- Chen, X.Y.; Yuan, W.Z.; Li, H.; Zhang, Y.M. Rheological study on tetrafluoroethylene/hexafluoropropylene copolymer and its implication for processability. J. Appl. Polym. Sci. 2012, 125, 3361–3367. [Google Scholar] [CrossRef]

- He, Y.; Farokhzadeh, K.; Edrisy, A. Characterization of thermal, mechanical and tribological properties of fluoropolymer composite coatings. J. Mater. Eng. Perform. 2017, 26, 2520–2534. [Google Scholar] [CrossRef]

- Inagaki, N.; Tasaka, S.; Park, Y.W. Effects of the surface modification by remote hydrogen plasma on adhesion in the electroless copper/tetrafluoroethylene-hexafluoropropylene copolymer (FEP) system. J. Adhes. Sci. Technol. 1998, 12, 1105–1119. [Google Scholar] [CrossRef]

- Park, Y.W.; Tasaka, S.; Inagaki, N. Surface modification of tetrafluoroethylene-hexafluoropropylene (FEP) copolymer by remote H2, N2, O2, and Ar plasmas. J. Appl. Polym. Sci. 2002, 83, 1258–1267. [Google Scholar] [CrossRef]

- Galante, A.M.S.; Galante, O.L.; Campos, L.L. Study on application of PTFE, FEP and PFA fluoropolymers on radiation dosimetry. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Dect. Assoc. Equip. 2010, 619, 177–180. [Google Scholar] [CrossRef]

- Okamoto, Y.; Teng, H.X. Synthesis and properties of amorphous perfluorinated polymers. Chim. Oggi-Chem. Today 2009, 27, 46–48. [Google Scholar]

- Zhang, H.; Weber, S.G. Teflon AF materials. In Fluorous Chemistry; Horvath, I.T., Ed.; Springer: Berlin, Germany, 2012; Volume 308, pp. 307–337. [Google Scholar]

- Lugert, E.C.; Lodge, T.P.; Buhlmann, P. Plasticization of amorphous perfluoropolymers. J. Polym. Sci. B 2008, 46, 516–525. [Google Scholar] [CrossRef]

- Tokarev, A.V.; Bondarenko, G.N.; Yampol’skii, Y.P. Chain structure and stiffness of Teflon AF glassy amorphous fluoropolymers. Polym. Sci. Ser. A 2007, 49, 909–920. [Google Scholar] [CrossRef]

- Li, L.Z.; Abdukerim, N.; Rochette, M. Chalcogenide optical microwires cladded with fluorine-based cytop. Opt. Express 2016, 24, 18931–18937. [Google Scholar] [CrossRef] [PubMed]

- Lacraz, A.; Polis, M.; Theodosiou, A.; Koutsides, C.; Kalli, K. Femtosecond laser inscribed bragg gratings in low loss CYTOP polymer optical fiber. IEEE Photonics Technol. Lett. 2015, 27, 693–696. [Google Scholar] [CrossRef]

- Bae, H.S.; Kim, C.; Rhee, I.; Jo, H.J.; Kim, D.H.; Hong, S. Enhancement of the cigs solar cell’s efficiency by anti-reflection coating with Teflon AF. J. Korean Phys. Soc. 2014, 65, 1517–1519. [Google Scholar] [CrossRef]

- Hoffman, J.D.; Weeks, J.J. The specific volume and degree of crystallinity of poly-(chlorotrifluoroethylene). J. Polym. Sci. 1958, 28, 472–475. [Google Scholar] [CrossRef]

- Miyamoto, Y.; Nakafuku, C.; Takemura, T. Crystallization of poly(chlorotrifluoroethylene). Polym. J. 1972, 3, 122–128. [Google Scholar] [CrossRef]

- Hoffman, J.D.; Weeks, J.J. Specific volume and degree of crystallinity of semicrystalline poly(chlorotrifluoroethylene), and estimated specific volumes of the pure amorphous and crystalline phases. J. Res. Natl. Bur. Stand. 1958, 60, 465–479. [Google Scholar] [CrossRef]

- De Focatiis, D.S.A.; Gubler, L. Uniaxial deformation and orientation of ethylene-tetrafluoroethylene films. Polym. Test. 2013, 32, 1423–1435. [Google Scholar] [CrossRef]

- Suzuki, A.; Hayashi, H. Ethylene tetrafluoroethylene nanofibres prepared by CO2 laser supersonic drawing. Express Polym. Lett. 2013, 7, 519–527. [Google Scholar] [CrossRef]

- Hu, J.H.; Chen, W.J.; Zhao, B.; Wang, K. Uniaxial tensile mechanical properties and model parameters determination of ethylene tetrafluoroethylene (ETFE) foils. Constr. Build. Mater. 2015, 75, 200–207. [Google Scholar] [CrossRef]

- Galliot, C.; Luchsinger, R.H. Uniaxial and biaxial mechanical properties of ETFE foils. Polym. Test. 2011, 30, 356–365. [Google Scholar] [CrossRef]

- Gupta, A.K.; Bajpai, R.; Keller, J.M. Morphological, crystallization and plasticization studies on isomorphic blends of poly(vinyl fluoride) (PVF) and poly(vinylidene difluoride) (PVDF): Using microhardness, XRD and SEM techniques. J. Mater. Sci. 2006, 41, 5857–5861. [Google Scholar] [CrossRef]

- Lando, J.B.; Hanes, M.D. X-ray-analysis of poly(vinyl fluoride). Macromolecules 1995, 28, 1142–1151. [Google Scholar] [CrossRef]

- Wang, J.; Lu, Y.F.; Li, H.F.; Yuan, H.L. Influences of molecular weight and particle morphology on film processing properties of polyvinyl fluoride. J. Appl. Polym. Sci. 2006, 102, 1780–1786. [Google Scholar] [CrossRef]

- Stallings, J.P.; Paradis, R.A. Solventless processing of modified poly(vinyl fluoride) and its properties. J. Appl. Polym. Sci. 1970, 14, 461–470. [Google Scholar] [CrossRef]

- Kochervinskii, V.V. Piezoelectricity in crystallizing ferroelectric polymers: Poly(vinylidene fluoride) and its copolymers (a review). Crystallogr. Rep. 2003, 48, 649–675. [Google Scholar] [CrossRef]

- Martins, P.; Lopes, A.C.; Lanceros-Mendez, S. Electroactive phases of poly(vinylidene fluoride): Determination, processing and applications. Prog. Polym. Sci. 2014, 39, 683–706. [Google Scholar] [CrossRef]

- Rabuni, M.F.; Sulaiman, N.M.N.; Aroua, M.K.; Chee, C.Y.; Hashim, N.A. Impact of in situ physical and chemical cleaning on PVDF membrane properties and performances. Chem. Eng. Sci. 2015, 122, 426–435. [Google Scholar] [CrossRef]

- Rabuni, M.F.; Sulaiman, N.M.N.; Aroua, M.K.; Hashim, N.A. Effects of alkaline environments at mild conditions on the stability of pvdf membrane: An experimental study. Ind. Eng. Chem. Res. 2013, 52, 15874–15882. [Google Scholar] [CrossRef]

- Cardoso, V.F.; Minas, G.; Costa, C.M.; Tavares, C.J.; Lanceros-Mendez, S. Micro and nanofilms of poly(vinylidene fluoride) with controlled thickness, morphology and electroactive crystalline phase for sensor and actuator applications. Smart Mater. Struct. 2011, 20, 087002. [Google Scholar] [CrossRef]

- Cardoso, V.F.; Minas, G.; Lanceros-Méndez, S. Multilayer spin-coating deposition of poly(vinylidene fluoride) films for controlling thickness and piezoelectric response. Sens. Actuators A Phys. 2013, 192, 76–80. [Google Scholar] [CrossRef]

- Cardoso, V.F.; Costa, C.M.; Minas, G.; Lanceros-Mendez, S. Improving the optical and electroactive response of poly(vinylidene fluoride-trifluoroethylene) spin-coated films for sensor and actuator applications. Smart Mater. Struct. 2012, 21, 085020. [Google Scholar] [CrossRef]

- Cardoso, V.F.; Botelho, G.; Lanceros-Mendez, S. Nonsolvent induced phase separation preparation of poly(vinylidene fluoride-co-chlorotrifluoroethylene) membranes with tailored morphology, piezoelectric phase content and mechanical properties. Mater. Des. 2015, 88, 390–397. [Google Scholar] [CrossRef]

- Cardoso, V.F.; Lopes, A.C.; Botelho, G.; Lanceros-Méndez, S. Poly(vinylidene fluoride-trifluoroethylene) porous films: Tailoring microstructure and physical properties by solvent casting strategies. Soft Mater. 2015, 13, 243–253. [Google Scholar] [CrossRef]

- Correia, D.M.; Ribeiro, C.; Sencadas, V.; Botelho, B.; Carabineiro, S.A.C.; Gomes Ribelles, J.L.; Lanceros-Méndez, S. Influence of oxygen plasma treatment parameters on poly(vinylidene fluoride) electrospun fiber mats wettability. Prog. Org. Coat. 2015, 85, 151–158. [Google Scholar] [CrossRef]

- Sencadas, V.; Ribeiro, C.; Bdikin, I.K.; Kholkin, A.L.; Lanceros-Mendez, S. Local piezoelectric response of single poly(vinylidene fluoride) electrospun fibres. Phys. Status Solidi (A) Appl. Mater. Sci. 2012, 209, 2605–2609. [Google Scholar] [CrossRef]

- Liu, M.; Wang, S.; Jiang, L. Nature-inspired superwettability systems. Nat. Rev. Mater. 2017, 2, 17036. [Google Scholar] [CrossRef]

- Wei, Q.; Schlaich, C.; Prévost, S.; Schulz, A.; Böttcher, C.; Gradzielski, M.; Qi, Z.; Haag, R.; Schalley, C.A. Supramolecular polymers as surface coatings: Rapid fabrication of healable superhydrophobic and slippery surfaces. Adv. Mater. 2014, 26, 7358–7364. [Google Scholar] [CrossRef] [PubMed]

- Xiong, Z.; Lin, H.; Liu, F.; Xiao, P.; Wu, Z.; Li, T.; Li, D. Flexible PVDF membranes with exceptional robust superwetting surface for continuous separation of oil/water emulsions. Sci. Rep. 2017, 7, 14099. [Google Scholar] [CrossRef] [PubMed]

- Schlaich, C.; Cuellar Camacho, L.; Yu, L.; Achazi, K.; Wei, Q.; Haag, R. Surface-independent hierarchical coatings with superamphiphobic properties. ACS Appl. Mater. Interfaces 2016, 8, 29117–29127. [Google Scholar] [CrossRef] [PubMed]

- Ju, J.; Zheng, Y.; Jiang, L. Bioinspired one-dimensional materials for directional liquid transport. Acc. Chem. Res. 2014, 47, 2342–2352. [Google Scholar] [CrossRef] [PubMed]

- Yabu, H.; Shimomura, M. Single-step fabrication of transparent superhydrophobic porous polymer films. Chem. Mater. 2005, 17, 5231–5234. [Google Scholar] [CrossRef]

- Yao, X.; Dunn, S.S.; Kim, P.; Duffy, M.; Alvarenga, J.; Aizenberg, J. Fluorogel elastomers with tunable transparency, elasticity, shape-memory, and antifouling properties. Angew. Chem. Int. Ed. 2014, 53, 4418–4422. [Google Scholar] [CrossRef] [PubMed]

- Tourkine, P.; Merrer, M.L.; Quéré, D. Delayed freezing on water repellent materials. Langmuir 2009, 25, 7214–7216. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhang, J.; Zhu, S.; Dong, H.; Wang, Z.; Sun, Z.; Guo, J.; Yang, B. Bioinspired silicon hollow-tip arrays for high performance broadband anti-reflective and water-repellent coatings. J. Mater. Chem. 2009, 19, 1806–1810. [Google Scholar] [CrossRef]

- Cho, H.J.; Preston, D.J.; Zhu, Y.; Wang, E.N. Nanoengineered materials for liquid-vapour phase-change heat transfer. Nat. Rev. Mater. 2016, 2, 16092. [Google Scholar] [CrossRef]

- De Angelis, F.; Gentile, F.; Mecarini, F.; Das, G.; Moretti, M.; Candeloro, P.; Coluccio, M.L.; Cojoc, G.; Accardo, A.; Liberale, C.; et al. Breaking the diffusion limit with super-hydrophobic delivery of molecules to plasmonic nanofocusing SERS structures. Nat. Photonics 2011, 5, 682–687. [Google Scholar] [CrossRef]

- Yang, S.; Dai, X.; Stogin, B.B.; Wong, T.S. Ultrasensitive surface-enhanced Raman scattering detection in common fluids. Proc. Natl. Acad. Sci. USA 2016, 113, 268–273. [Google Scholar] [CrossRef] [PubMed]

- Nakajima, T.; Groult, H. Fluorinated Materials for Energy Conversion; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Kepler, R.G.; Anderson, R.A. Ferroelectric polymers. Adv. Phys. 1992, 41, 1–57. [Google Scholar] [CrossRef]

- Pukada, E. History and recent progress in piezoelectric polymers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2000, 47, 1277–1290. [Google Scholar]

- Banerjee, S. Handbook of Specialty Fluorinated Polymers: Preparation, Properties, and Applications; Elsevier: Amsterdam, The Netherlands, 2015; pp. 1–329. [Google Scholar]

- Lando, J.B.; Doll, W.W. The polymorphism of poly(vinylidene fluoride). I. The effect of head-to-head structure. J. Macromol. Sci. B 1968, 2, 205–218. [Google Scholar] [CrossRef]

- Pierre, U. Pvdf piezoelectric polymer. Sens. Rev. 2001, 21, 118–126. [Google Scholar]

- Dmitriev, I.Y.; Lavrentyev, V.K.; Elyashevich, G.K. Polymorphic transformations in poly(vinylidene fluoride) films during orientation. Polym. Sci. Ser. A 2006, 48, 272–277. [Google Scholar] [CrossRef]

- Salimi, A.; Yousefi, A.A. Ftir studies of β-phase crystal formation in stretched PVDF films. Polym. Test. 2003, 22, 699–704. [Google Scholar] [CrossRef]

- Gandini, A.; Botaro, V.; Zeno, E.; Bach, S. Semi-crystalline fluorinated polymers. Polym. Int. 2001, 50, 10–26. [Google Scholar]

- Correia, H.M.G.; Ramos, M.M.D. Quantum modelling of poly(vinylidene fluoride). Comput. Mater. Sci. 2005, 33, 224–229. [Google Scholar] [CrossRef]

- Sajkiewicz, P.; Wasiak, A.; Goclowski, Z. Phase transitions during stretching of poly(vinylidene fluoride). Eur. Polym. J. 1999, 35, 423–429. [Google Scholar] [CrossRef]

- Lovinger, A.J. Developments in Crystalline Polymers; Springer: London, UK, 1982; pp. 559–560. [Google Scholar]

- Costa, R.; Ribeiro, C.; Lopes, A.C.; Martins, P.; Sencadas, V.; Soares, R.; Lanceros-Mendez, S. Osteoblast, fibroblast and in vivo biological response to poly(vinylidene fluoride) based composite materials. J. Mater. Sci. Mater. Med. 2013, 24, 395–403. [Google Scholar] [CrossRef] [PubMed]

- Martins, P.M.; Ribeiro, S.; Ribeiro, C.; Sencadas, V.; Gomes, A.C.; Gama, F.M.; Lanceros-Méndez, S. Effect of poling state and morphology of piezoelectric poly(vinylidene fluoride) membranes for skeletal muscle tissue engineering. RSC Adv. 2013, 3, 17938–17944. [Google Scholar] [CrossRef]

- Parssinen, J.; Hammarén, H.; Rahikainen, R.; Sencadas, V.; Ribeiro, C.; Vanhatupa, S.; Miettinen, S.; Lanceros-Méndez, S.; Hytönen, V.P. Enhancement of adhesion and promotion of osteogenic differentiation of human adipose stem cells by poled electroactive poly(vinylidene fluoride). J. Biomed. Mater. Res. A 2015, 103, 919–928. [Google Scholar] [CrossRef] [PubMed]

- Li, J.Y.; Liu, Y.M.; Zhang, Y.H.; Cai, H.L.; Xiong, R.G. Molecular ferroelectrics: Where electronics meet biology. Phys. Chem. Chem. Phys. 2013, 15, 20786–20796. [Google Scholar] [CrossRef] [PubMed]

- Nix, E.L.; Ward, I.M. The measurement of the shear piezoelectric coefficients of polyvinylidene fluoride. Ferroelectrics 1986, 67, 137–141. [Google Scholar] [CrossRef]

- Ameduri, B. From vinylidene fluoride (VDF) to the applications of vdf-containing polymers and copolymers: Recent developments and future trends. Chem. Rev. 2009, 109, 6632–6686. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, C.; Parssinen, J.; Sencadas, V.; Correia, V.; Miettinen, S.; Hytonen, V.P.; Lanceros-Mendez, S. Dynamic piezoelectric stimulation enhances osteogenic differentiation of human adipose stem cells. J. Biomed. Mater. Res. A 2015, 103, 2172–2175. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, C.; Sencadas, V.; Correia, D.M.; Lanceros-Méndez, S. Piezoelectric polymers as biomaterials for tissue engineering applications. Colloids Surf. B Biointerfaces 2015, 136, 46–55. [Google Scholar] [CrossRef] [PubMed]

- Liao, Y.; Wang, R.; Tian, M.; Qiu, C.Q.; Fane, A.G. Fabrication of polyvinylidene fluoride (PVDF) nanofiber membranes by electro-spinning for direct contact membrane distillation. J. Membr. Sci. 2013, 425, 30–39. [Google Scholar] [CrossRef]

- Buonomenna, M.G.; Figoli, A.; Spezzano, I.; Davoli, M.; Drioli, E. New pvdf microcapsules for application in catalysis. Appl. Catal. B Environ. 2008, 80, 185–194. [Google Scholar] [CrossRef]

- Gao, K.; Hu, X.G.; Dai, C.S.; Yi, T.F. Crystal structures of electrospun pvdf membranes and its separator application for rechargeable lithium metal cells. Mater. Sci. Eng. B Solid State Mater. Adv. Technol. 2006, 131, 100–105. [Google Scholar] [CrossRef]

- Wang, Y.R.; Zheng, J.M.; Ren, G.Y.; Zhang, P.H.; Xu, C. A flexible piezoelectric force sensor based on PVDF fabrics. Smart Mater. Struct. 2011, 20. [Google Scholar] [CrossRef]

- Hurlebaus, S.; Gaul, L. Smart layer for damage diagnostics. J. Intell. Mater. Syst. Struct. 2004, 15, 729–736. [Google Scholar] [CrossRef]

- Gu, H.; Zhao, Y.; Wang, M.L. A wireless smart pvdf sensor for structural health monitoring. Struct. Control Health Monit. 2005, 12, 329–343. [Google Scholar] [CrossRef]

- Weber, N.; Lee, Y.S.; Shanmugasundaram, S.; Jaffe, M.; Arinzeh, T.L. Characterization and in vitro cytocompatibility of piezoelectric electrospun scaffolds. Acta Biomater. 2010, 6, 3550–3556. [Google Scholar] [CrossRef] [PubMed]

- Costa, C.M.; Rodrigues, L.C.; Sencadas, V.; Silva, M.M.; Rocha, J.G.; Lanceros-Méndez, S. Effect of degree of porosity on the properties of poly(vinylidene fluoride-trifluorethylene) for Li-ion battery separators. J. Membr. Sci. 2012, 407–408, 193–201. [Google Scholar] [CrossRef]

- Ferreira, A.; Silva, J.; Sencadas, V.; Gomez-Ribelles, J.L.; Lanceros-Méndez, S. Poly(vinylidene fluoride-trifluoroethylene) (72/28) interconnected porous membranes obtained by crystallization from solution. Mater. Res. Soc. Symp. Proc. 2011, 1312, 125–130. [Google Scholar] [CrossRef]

- Bae, S.H.; Kahya, O.; Sharma, B.K.; Kwon, J.; Cho, H.J.; Ozyilmaz, B.; Ahn, J.H. Graphene-P(VDF-TrFE) multilayer film for flexible applications. ACS Nano 2013, 7, 3130–3138. [Google Scholar] [CrossRef] [PubMed]

- Sharma, T.; Je, S.S.; Gill, B.; Zhang, J.X.J. Patterning piezoelectric thin film PVDF-TrFE based pressure sensor for catheter application. Sens. Actuator A Phys. 2012, 177, 87–92. [Google Scholar] [CrossRef]

- Zheng, L.B.; Wang, J.; Li, J.; Zhang, Y.; Li, K.; Wei, Y.S. Preparation, evaluation and modification of PVDF-CTFE hydrophobic membrane for MD desalination application. Desalination 2017, 402, 162–172. [Google Scholar] [CrossRef]

- Zheng, L.B.; Wu, Z.J.; Wei, Y.S.; Zhang, Y.; Yuan, Y.; Wang, J. Preparation of PVDF-CTFE hydrophobic membranes for MD application: Effect of LiCl-based mixed additives. J. Membr. Sci. 2016, 506, 71–85. [Google Scholar] [CrossRef]

- Sousa, R.E.; Kundu, M.; Goren, A.; Silva, M.M.; Liu, L.F.; Costa, C.M.; Lanceros-Mendez, S. Poly(vinylidene fluoride-co-chlorotrifluoroethylene) (PVDF-CTFE) lithium-ion battery separator membranes prepared by phase inversion. RSC Adv. 2015, 5, 90428–90436. [Google Scholar] [CrossRef]

- Tian, X.Z.; Zhu, B.K.; Xu, Y.Y. P(VDF-co-HFP) membrane for recovery of aroma compounds from aqueous solutions by pervaporation—I. Ethyl acetate/water system. J. Membr. Sci. 2005, 248, 109–117. [Google Scholar] [CrossRef]

- Feng, C.S.; Wang, R.; Shi, B.L.; Li, G.M.; Wu, Y.L. Factors affecting pore structure and performance of poly(vinylidene fluoride-co-hexafluoro propylene) asymmetric porous membrane. J. Membr. Sci. 2006, 277, 55–64. [Google Scholar] [CrossRef]

- Nunes-Pereira, J.; Costa, C.M.; Lanceros-Méndez, S. Polymer composites and blends for battery separators: State of the art, challenges and future trends. J. Power Sources 2015, 281, 378–398. [Google Scholar] [CrossRef]

- Costa, C.M.; Gomez Ribelles, J.L.; Lanceros-Méndez, S.; Appetecchi, G.B.; Scrosati, B. Poly(vinylidene fluoride)-based, co-polymer separator electrolyte membranes for lithium-ion battery systems. J. Power Sources 2014, 245, 779–786. [Google Scholar] [CrossRef]

- Costa, C.M.; Silva, M.M.; Lanceros-Méndez, S. Battery separators based on vinylidene fluoride (VDF) polymers and copolymers for lithium ion battery applications. RSC Adv. 2013, 3, 11404–11417. [Google Scholar]

- Neese, B.; Wang, Y.; Chu, B.; Ren, K.; Liu, S.; Zhang, Q.M.; Huang, C.; West, J. Piezoelectric responses in poly(vinylidene fluoride/hexafluoropropylene) copolymers. Appl. Phys. Lett. 2007, 90, 242917. [Google Scholar] [CrossRef]

- Boschin, F.; Blanchemain, N.; Bria, M.; Delcourt-Debrayne, E.; Morcellet, M.; Hildebrand, H.F.; Martel, B. Improved drug delivery properties of pvdf membranes functionalized with β-cyclodextrin—Application to guided tissue regeneration in periodontology. J. Biomed. Mater. Res. Part A 2006, 79, 78–85. [Google Scholar] [CrossRef] [PubMed]

- Nunes-Pereira, J.; Ribeiro, S.; Ribeiro, C.; Gombek, C.J.; Gama, F.M.; Gomes, A.C.; Patterson, D.A.; Lanceros-Mendez, S. Poly(vinylidene fluoride) and copolymers as porous membranes for tissue engineering applications. Polym. Test. 2015, 44, 234–241. [Google Scholar] [CrossRef]

- Ribeiro, C.; Sencadas, V.; Ribelles, J.L.G.; Lanceros-Méndez, S. Influence of processing conditions on polymorphism and nanofiber morphology of electroactive poly(vinylidene fluoride) electrospun membranes. Soft Mater. 2010, 8, 274–287. [Google Scholar] [CrossRef]

- Agarwal, S.; Wendorff, J.H.; Greiner, A. Use of electrospinning technique for biomedical applications. Polymer 2008, 49, 5603–5621. [Google Scholar] [CrossRef]

- Spasova, M.; Manolova, N.; Markova, N.; Rashkov, I. Superhydrophobic pvdf and PVDF-HFP nanofibrous mats with antibacterial and anti-biofouling properties. Appl. Surface Sci. 2016, 363, 363–371. [Google Scholar] [CrossRef]

- Cardoso, V.F.; Knoll, T.; Velten, T.; Rebouta, L.; Mendes, P.M.; Lanceros-Méndez, S.; Minas, G. Polymer-based acoustic streaming for improving mixing and reaction times in microfluidic applications. RSC Adv. 2014, 4, 4292–4300. [Google Scholar] [CrossRef]

- Salazar, H.; Nunes-Pereira, J.; Correia, D.M.; Cardoso, V.F.; Goncalves, R.; Martins, P.M.; Ferdov, S.; Martins, M.D.; Botelho, G.; Lanceros-Mendez, S. Poly(vinylidene fluoride-hexafluoropropylene)/bayerite composite membranes for efficient arsenic removal from water. Mater. Chem. Phys. 2016, 183, 430–438. [Google Scholar] [CrossRef]

- Gopal, R.; Kaur, S.; Ma, Z.; Chan, C.; Ramakrishna, S.; Matsuura, T. Electrospun nanofibrous filtration membrane. J. Membr. Sci. 2006, 281, 581–586. [Google Scholar] [CrossRef]

- Jing, W.Q.; Fang, F.; Yang, W. Strengthening of electromechanical properties for poly(vinylidene fluoride-trifluoroethylene) films under tailored electric cycling. J. Appl. Polym. Sci. 2018, 135, 45926. [Google Scholar] [CrossRef]

- Munirasu, S.; Banat, F.; Durrani, A.A.; Abu Haija, M. Intrinsically superhydrophobic PVDF membrane by phase inversion for membrane distillation. Desalination 2017, 417, 77–86. [Google Scholar] [CrossRef]

- Correia, D.M.; Ribeiro, C.; Sencadas, V.; Vikingsson, L.; Oliver Gasch, M.; Gómez Ribelles, J.L.; Botelho, G.; Lanceros-Méndez, S. Strategies for the development of three dimensional scaffolds from piezoelectric poly(vinylidene fluoride). Mater. Des. 2016, 92, 674–681. [Google Scholar] [CrossRef]

- Cardoso, V.F.; Machado, A.R.; Pinto, V.C.; Sousa, P.J.; Botelho, G.; Minas, G.A.; Lanceros-Mendez, S. From superhydrophobic- to superhydrophilic-patterned poly(vinylidene fluoride-co-chlorotrifluoroethylene) architectures as a novel platform for biotechnological applications. J. Polym. Sci. B 2016, 54, 1802–1810. [Google Scholar] [CrossRef]

- Correia, D.M.; Golcalves, R.; Ribeiro, C.; Sencadas, V.; Botelho, G.L.; Gomez-Ribelles, J.L.; lanceros-mendez, S. Electrosprayed poly(vinylidene fluoride) microspheres for tissue engineering applications. RSC Adv. 2014, 4, 33013–33021. [Google Scholar] [CrossRef]

- Sencadas, V.; Gregorio Filho, R.; Lanceros-Mendez, S. Processing and characterization of a novel nonporous poly(vinilidene fluoride) films in the β phase. J. Non-Cryst. Solids 2006, 352, 2226–2229. [Google Scholar] [CrossRef]

- Sousa, R.E.; Ferreira, J.C.C.; Costa, C.M.; Machado, A.V.; Silva, M.M.; Lanceros-Mendez, S. Tailoring poly(vinylidene fluoride-co-chlorotrifluoroethylene) microstructure and physicochemical properties by exploring its binary phase diagram with dimethylformamide. J. Polym. Sci. B 2015, 53, 761–773. [Google Scholar] [CrossRef]

- Sousa, R.E.; Nunes-Pereira, J.; Ferreira, J.C.C.; Costa, C.M.; Machado, A.V.; Silva, M.M.; Lanceros-Mendez, S. Microstructural variations of poly(vinylidene fluoride co-hexafluoropropylene) and their influence on the thermal, dielectric and piezoelectric properties. Polym. Test. 2014, 40, 245–255. [Google Scholar] [CrossRef]

- Akcan, M.I.; Topacli, C. Pyroelectric and dielectric properties of spin-coated thin films of vinylidene fluoride- trifluoroethylene copolymers. Polym. Int. 2001, 50, 835–840. [Google Scholar] [CrossRef]

- He, X.; Yao, K.; Gan, B.K. Ferroelectric poly(vinylidene fluoride-hexafluoropropylene) thin films on silicon substrates. Sens. Actuators A Phys. 2007, 139, 158–161. [Google Scholar] [CrossRef]

- Ben-David, M.; Engel, L.; Shacham-Diamand, Y. Spectroscopic ellipsometry study of spin coated P(VDF-TrFE-CTFE) thin films and P(VDF-TrFE-CTFE)/PMMA blends. Microelectr. Eng. 2017, 171, 37–43. [Google Scholar] [CrossRef]

- Gonçalves, B.F.; Oliveira, J.; Costa, P.; Correia, V.; Martins, P.; Botelho, G.; Lanceros-Mendez, S. Development of water-based printable piezoresistive sensors for large strain applications. Compos. B 2017, 112, 344–352. [Google Scholar] [CrossRef]

- Gören, A.; Mendes, J.; Rodrigues, H.M.; Sousa, R.E.; Oliveira, J.; Hilliou, L.; Costa, C.M.; Silva, M.M.; Lanceros-Méndez, S. High performance screen-printed electrodes prepared by a green solvent approach for lithium-ion batteries. J. Power Sources 2016, 334, 65–77. [Google Scholar] [CrossRef]

- Sousa, R.E.; Costa, C.M.; Lanceros-Méndez, S. Advances and future challenges in printed batteries. ChemSusChem 2015, 8, 3539–3555. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.; Tinku, S.; Lorenzelli, L.; Dahiya, R.S. Flexible tactile sensors using screen-printed P(VDF-TrFE) and MWCNT/PDMS composites. IEEE Sens. J. 2015, 15, 3146–3155. [Google Scholar] [CrossRef]

- Ferreira, C.G.; Cardoso, V.F.; Lopes, A.C.; Botelho, G.; Lanceros-Mendez, S. Tailoring microstructure and physical properties of poly(vinylidene fluoride-hexafluoropropylene) porous films. J. Mater. Sci. 2015, 50, 5047–5058. [Google Scholar] [CrossRef]

- Sousa, R.; Nunes-Pereira, J.; Costa, C.M.; Silva, M.M.; Lanceros-Mendez, S.; Hassoun, J.; Scrosati, B.; Appetecchi, G.B. Influence of the porosity degree of poly(vinylidene fluoride-co-hexafluoropropylene) separators in the performance of Li-ion batteries. J. Power Sources 2014, 263, 29–36. [Google Scholar] [CrossRef]

- Ferreira, J.C.C.; Monteiro, T.S.; Lopes, A.C.; Costa, C.M.; Silva, M.M.; Machado, A.V.; Lanceros-Mendez, S. Variation of the physicochemical and morphological characteristics of solvent casted poly(vinylidene fluoride) along its binary phase diagram with dimethylformamide. J. Non-Cryst. Solids 2015, 412, 16–23. [Google Scholar] [CrossRef]

- California, A.; Cardoso, V.F.; Costa, C.M.; Sencadas, V.; Botelho, G.; Gómez-Ribelles, J.L.; Lanceros-Mendez, S. Tailoring porous structure of ferroelectric poly(vinylidene fluoride-trifluoroethylene) by controlling solvent/polymer ratio and solvent evaporation rate. Eur. Polym. J. 2011, 47, 2442–2450. [Google Scholar] [CrossRef]

- Sencadas, V.; Ribeiro, C.; Nunes-Pereira, J.; Correia, V.; Lanceros-Méndez, S. Fiber average size and distribution dependence on the electrospinning parameters of poly(vinylidene fluoride-trifluoroethylene) membranes for biomedical applications. Appl. Phys. A Mater. Sci. Process. 2012, 109, 685–691. [Google Scholar] [CrossRef]

- Spasova, M.; Manolova, N.; Markova, N.; Rashkov, I. Tuning the properties of PVDF or PVDF-HFP fibrous materials decorated with zno nanoparticles by applying electrospinning alone or in conjunction with electrospraying. Fibres Polym. 2017, 18, 649–657. [Google Scholar] [CrossRef]

- Lee, H.; Alcoutlabi, M.; Watson, J.V.; Zhang, X. Polyvinylidene fluoride-co-chlorotrifluoroethylene and polyvinylidene fluoride-co-hexafluoropropylene nanofiber-coated polypropylene microporous battery separator membranes. J. Polym. Sci. B 2013, 51, 349–357. [Google Scholar] [CrossRef]

- Baqeri, M.; Abolhasani, M.M.; Mozdianfard, M.R.; Guo, Q.; Oroumei, A.; Naebe, M. Influence of processing conditions on polymorphic behavior, crystallinity, and morphology of electrospun poly(vinylidene fluoride) nanofibres. J. Appl. Polym. Sci. 2015, 132, 274–287. [Google Scholar] [CrossRef]

- Goncalves, R.; Martins, P.; Correia, D.M.; Sencadas, V.; Vilas, J.L.; Leon, L.M.; Botelho, G.; Lanceros-Mendez, S. Development of magnetoelectric CoFe2O4/poly(vinylidene fluoride) microspheres. RSC Adv. 2015, 5, 35852–35857. [Google Scholar] [CrossRef]

- Zhang, L.; Zha, D.-A.; Du, T.; Mei, S.; Shi, Z.; Jin, Z. Formation of superhydrophobic microspheres of poly(vinylidene fluoride-hexafluoropropylene)/graphene composite via gelation. Langmuir 2011, 27, 8943–8949. [Google Scholar] [CrossRef] [PubMed]

- Tao, M.-M.; Liu, F.; Ma, B.-R.; Xue, L.-X. Effect of solvent power on PVDF membrane polymorphism during phase inversion. Desalination 2013, 316, 137–145. [Google Scholar] [CrossRef]

- Coster, H.G.L.; Farahani, T.D.; Chilcott, T.C. Production and characterization of piezo-electric membranes. Desalination 2011, 283, 52–57. [Google Scholar] [CrossRef]

- Fontananova, E.; Bahattab, M.A.; Aljlil, S.A.; Alowairdy, M.; Rinaldi, G.; Vuono, D.; Nagy, J.B.; Drioli, E.; Di Profio, G. From hydrophobic to hydrophilic polyvinylidenefluoride (PVDF) membranes by gaining new insight into material’s properties. RSC Adv. 2015, 5, 56219–56231. [Google Scholar] [CrossRef]

- Zheng, J.; He, A.; Li, J.; Han, C.C. Polymorphism control of poly(vinylidene fluoride) through electrospinning. Macromol. Rapid Commun. 2007, 28, 2159–2162. [Google Scholar] [CrossRef]

- Lolla, D.; Lolla, M.; Abutaleb, A.; Shin, H.U.; Reneker, D.H.; Chase, G.G. Fabrication, polarization of electrospun polyvinylidene fluoride electret fibres and effect on capturing nanoscale solid aerosols. Materials 2016, 9, 671. [Google Scholar] [CrossRef] [PubMed]

- Sencadas, V.; Costa, C.M.; Moreira, V.; Monteiro, J.; Mendiratta, S.K.; Mano, J.F.; Lanceros-Méndez, S. Poling of β-poly(vinylidene fluoride): Dielectric and ir spectroscopy studies. e-Polymers 2005, 5, 1–12. [Google Scholar] [CrossRef]

- Rajesh, P.S.M.; Bodkhe, S.; Kamle, S.; Verma, V. Enhancing beta-phase in PVDF through physicochemical modification of cellulose. Electron. Mater. Lett. 2014, 10, 315–319. [Google Scholar] [CrossRef]

- Martins, P.M.; Gomez, V.; Lopes, A.C.; Tavares, C.J.; Botelho, G.; Irusta, S.; Lanceros-Mendez, S. Improving photocatalytic performance and recyclability by development of Er-doped and Er/Pr-codoped TiO2/poly(vinylidene difluoride)-trifluoroethylene composite membranes. J. Phys. Chem. C 2014, 118, 27944–27953. [Google Scholar] [CrossRef]

- Haines, C.S.; Li, N.; Spinks, G.M.; Aliev, A.E.; Di, J.T.; Baughman, R.H. New twist on artificial muscles. Proc. Natl. Acad. Sci. USA 2016, 113, 11709–11716. [Google Scholar] [CrossRef] [PubMed]

- Mirfakhrai, T.; Madden, J.D.W.; Baughman, R.H. Polymer artificial muscles. Mater. Today 2007, 10, 30–38. [Google Scholar] [CrossRef]

- Baniasadi, M.; Huang, J.; Xu, Z.; Moreno, S.; Yang, X.; Chang, J.; Quevedo-Lopez, M.A.; Naraghi, M.; Minary-Jolandan, M. High-performance coils and yarns of polymeric piezoelectric nanofibres. ACS Appl. Mater. Interfaces 2015, 7, 5358–5366. [Google Scholar] [CrossRef] [PubMed]

- Harris, G.R.; Preston, R.C.; DeReggi, A.S. The impact of piezoelectric pvdf on medical ultrasound exposure measurements, standards, and regulations. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2000, 47, 1321–1335. [Google Scholar] [CrossRef] [PubMed]

- Ackermann, D.; Schmitz, G. Investigation of kerfless PZT and PVDF based ultrasound arrays. Biomed. Technol. 2012, 57, 119–122. [Google Scholar] [CrossRef]

- Qiu, X.L. Patterned piezo-, pyro-, and ferroelectricity of poled polymer electrets. J. Appl. Phys. 2010, 108, 011101. [Google Scholar] [CrossRef]

- Woodward, B.; Chandra, R.C. Underwater acoustic measurements on polyvinylidene fluoride transducers. Electrocompon. Sci. Technol. 1978, 5, 149–157. [Google Scholar] [CrossRef]

- Lockwood, G.R.; Ryan, L.K.; Hunt, J.W.; Foster, F.S. Measurement of the ultrasonic properties of vascular tissues and blood from 35–65 MHZ. Ultrasound Med. Biol. 1991, 17, 653–666. [Google Scholar] [CrossRef]

- Foster, F.S.; Harasiewicz, E.A.; Sherar, M.D. A history of medical and biological imaging with polyvinylidene fluoride (PVDF) transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2000, 47, 1363–1371. [Google Scholar] [CrossRef] [PubMed]

- Jackson, V.P.; Kellyfry, E.; Rothschild, P.A.; Holden, R.W.; Clark, S.A. Automated breast sonography using a 7.5 mhz PVDF transducer—Preliminary clinical-evaluation—Work in progress. Radiology 1986, 159, 679–684. [Google Scholar] [CrossRef] [PubMed]

- Vogt, M.; Ermert, H.; El Gammal, S.; Kaspar, K.; Hoffmann, K.; Altmeyer, P. Structural analysis of the skin using high frequency, broadband ultrasound in the range from 30 to 140 MHz. In Proceedings of the 1998 IEEE Ultrasonics Symposium, Sendai, Japan, 5–8 October 1998; Schneider, S.C., Levy, M., McAvoy, B.R., Eds.; Volume 1–2, pp. 1685–1688. [Google Scholar]

- Oh, J.T.; Li, M.L.; Zhang, H.F.; Maslov, K.; Stoica, G.; Wang, L.H.V. Three-dimensional imaging of skin melanoma in vivo by dual-wavelength photoacoustic microscopy. J. Biomed. Opt. 2006, 11, 34032. [Google Scholar] [CrossRef] [PubMed]

- Fleischman, A.; Modi, R.; Nair, A.; Talman, J.; Lockwood, G.; Roy, S. Miniature high frequency focused ultrasonic transducers for minimally invasive imaging procedures. Sens. Actuator A Phys. 2003, 103, 76–82. [Google Scholar] [CrossRef]

- Jung, M.; Kim, M.G.; Lee, J.H.; IEEE. Micromachined ultrasonic transducer using piezoelectric PVDF film to measure the mechanical properties of bio cells. In Proceedings of the 2009 IEEE Sensors, Christchurch, New Zealand, 25–28 October 2009; pp. 1225–1228. [Google Scholar]

- Laroche, G.; Marois, Y.; Schwarz, E.; Guidoin, R.; King, M.W.; Paris, E.; Douville, Y. Polyvinylidene fluoride monofilament sutures—Can they be used safely for long-term anastomoses in the thoracic aorta. Artif. Organs 1995, 19, 1190–1199. [Google Scholar] [CrossRef] [PubMed]

- Lambertz, A.; Schroder, K.M.; Schob, D.S.; Binnebosel, M.; Anurov, M.; Klinge, U.; Neumann, U.P.; Klink, C.D. Polyvinylidene fluoride as a suture material: Evaluation of comet tail-like infiltrate and foreign body granuloma. Eur. Surg. Res. 2015, 55, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Laroche, G.; Marois, Y.; Guidoin, R.; King, M.W.; Martin, L.; How, T.; Douville, Y. Polyvinylidene fluoride (PVDF) as a biomaterial—From polymeric raw-material to monofilament vascular suture. J. Biomed. Mater. Res. 1995, 29, 1525–1536. [Google Scholar] [CrossRef] [PubMed]

- Sokhanvar, S.; Packirisamy, M.; Dargahi, J. A multifunctional PVDF-based tactile sensor for minimally invasive surgery. Smart Mater. Struct. 2007, 16, 989–998. [Google Scholar] [CrossRef]

- Qasaimeh, M.A.; Sokhanvar, S.; Dargahi, J.; Kahrizi, M. PVDF-based microfabricated tactile sensor for minimally invasive surgery. J. Microelectromech. Syst. 2009, 18, 195–207. [Google Scholar] [CrossRef]

- Suaste-Gomez, E.; Rodriguez-Roldan, G.; Reyes-Cruz, H.; Teran-Jimenez, O. Developing an ear prosthesis fabricated in polyvinylidene fluoride by a 3D printer with sensory intrinsic properties of pressure and temperature. Sensors 2016, 16, 332. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.M.; He, J.X.; Wang, H.B.; Qi, K.; Nan, N.; You, X.L.; Shao, W.L.; Wang, L.D.; Ding, B.; Cui, S.Z. Highly sensitive, self-powered and wearable electronic skin based on pressure-sensitive nanofiber woven fabric sensor. Sci. Rep. 2017, 7, 12949. [Google Scholar] [CrossRef] [PubMed]

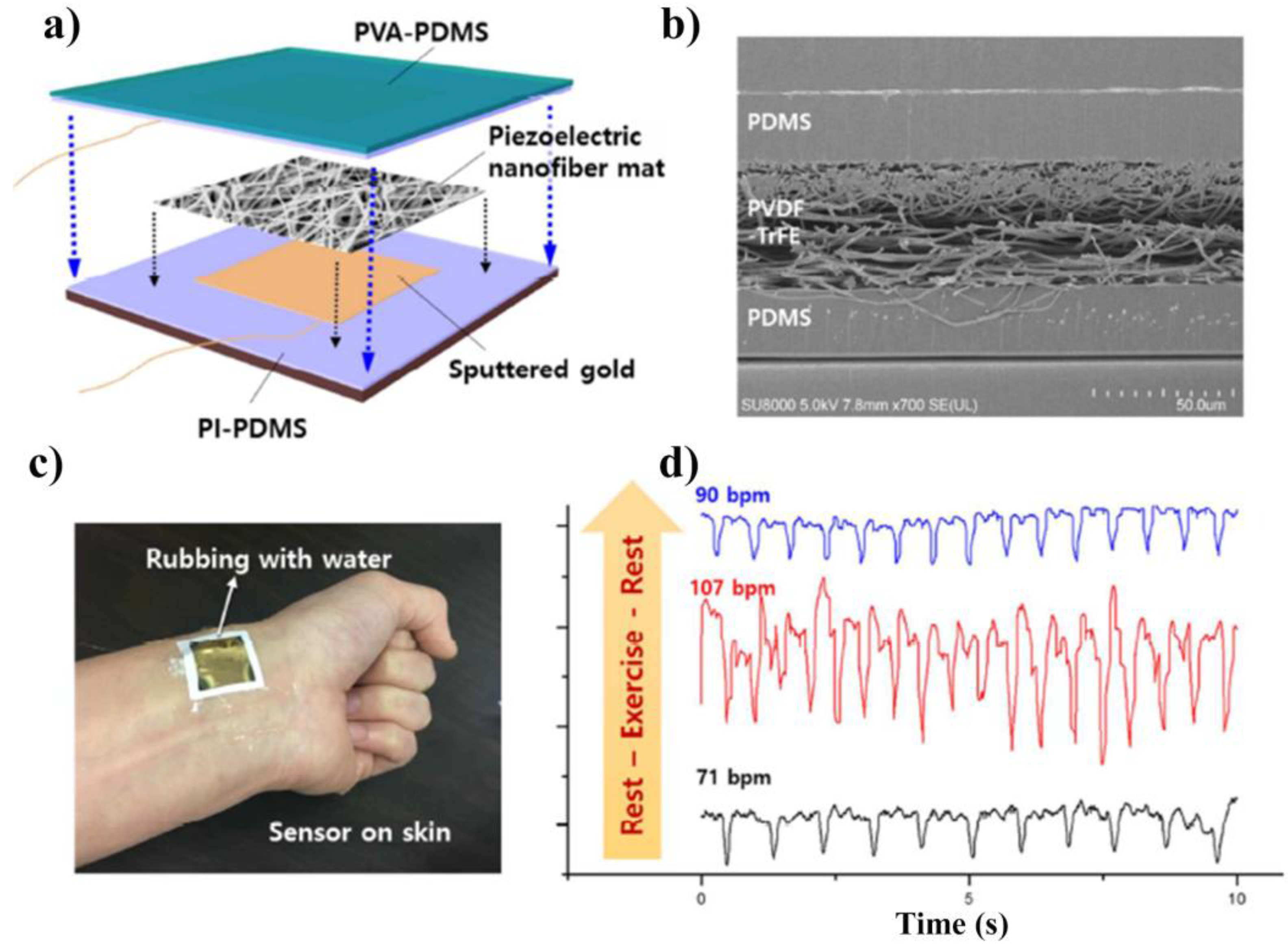

- Park, S.-H.; Lee, H.B.; Yeon, S.M.; Park, J.; Lee, N.K. Flexible and stretchable piezoelectric sensor with thickness-tunable configuration of electrospun nanofiber mat and elastomeric substrates. ACS Appl. Mater. Interfaces 2016, 8, 24773–24781. [Google Scholar] [CrossRef] [PubMed]

- Rajabi, A.H.; Jaffe, M.; Arinzeh, T.L. Piezoelectric materials for tissue regeneration: A review. Acta Biomater. 2015, 24, 12–23. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.S.; Collins, G.; Livingston Arinzeh, T. Neurite extension of primary neurons on electrospun piezoelectric scaffolds. Acta Biomater. 2011, 7, 3877–3886. [Google Scholar] [CrossRef] [PubMed]

- Hitscherich, P.; Wu, S.; Gordan, R.; Xie, L.H.; Arinzeh, T.; Lee, E.J. The effect of pvdf-trfe scaffolds on stem cell derived cardiovascular cells. Biotechnol. Bioeng. 2016, 113, 1577–1585. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.F.; Li, Z.S.; Dong, S.W.; Chen, W.J.; Deng, L.; Wang, Y.F.; Ying, D.J. Piezoelectric pu/pvdf electrospun scaffolds for wound healing applications. Colloids Surf. B Biointerfaces 2012, 96, 29–36. [Google Scholar] [CrossRef] [PubMed]

- Augustine, R.; Dan, P.; Sosnik, A.; Kalarikkal, N.; Tran, N.; Vincent, B.; Thomas, S.; Menu, P.; Rouxel, D. Electrospun poly(vinylidene fluoride-trifluoroethylene)/zinc oxide nanocomposite tissue engineering scaffolds with enhanced cell adhesion and blood vessel formation. Nano Res. 2017, 10, 3358–3376. [Google Scholar] [CrossRef]

- Ribeiro, C.; Moreira, S.; Correia, V.; Sencadas, V.; Rocha, J.G.; Gama, F.M.; Gómez Ribelles, J.L.; Lanceros-Méndez, S. Enhanced proliferation of pre-osteoblastic cells by dynamic piezoelectric stimulation. RSC Adv. 2012, 2, 11504–11509. [Google Scholar] [CrossRef]

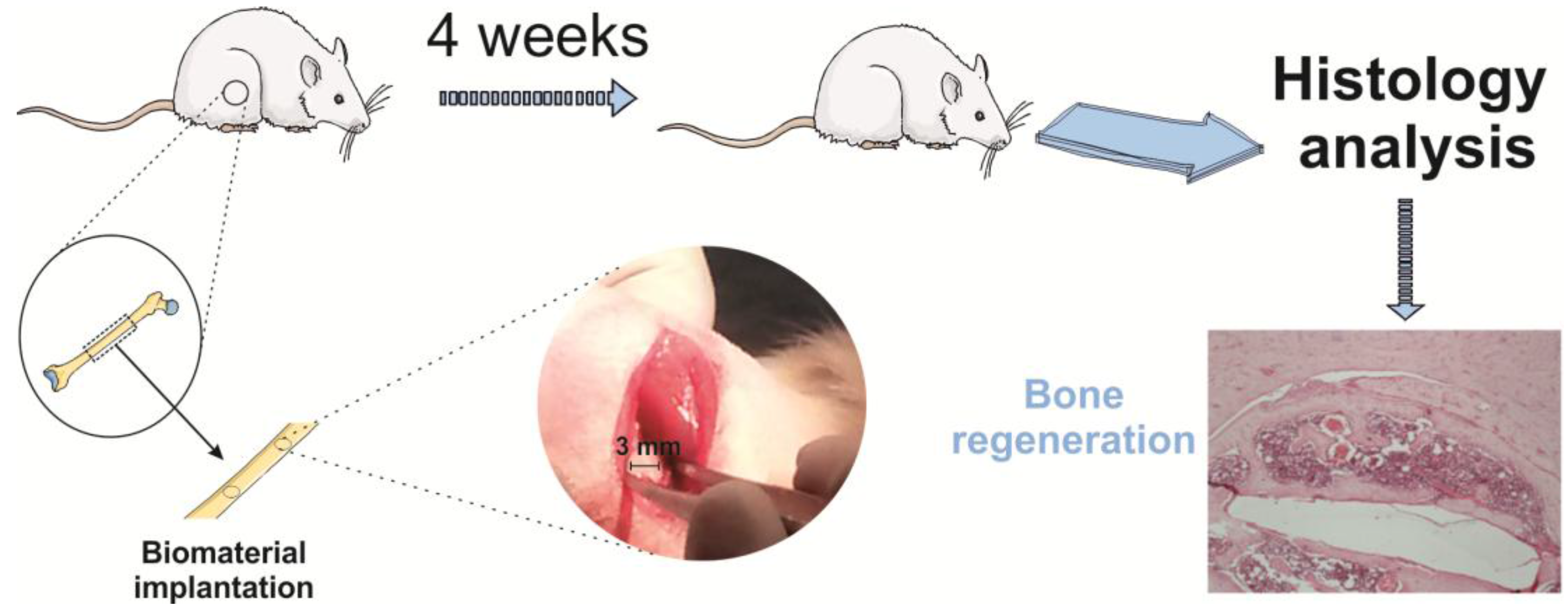

- Ribeiro, C.; Correia, D.M.; Rodrigues, I.; Guardao, L.; Guimaraes, S.; Soares, R.; Lanceros-Mendez, S. In vivo demonstration of the suitability of piezoelectric stimuli for bone reparation. Mater. Lett. 2017, 209, 118–121. [Google Scholar] [CrossRef]

- Lee, Y.S.; Arinzeh, T.L. The influence of piezoelectric scaffolds on neural differentiation of human neural stem/progenitor cells. Tissue Eng. Part A 2012, 18, 2063–2072. [Google Scholar] [CrossRef] [PubMed]

- Fernandez-Yague, M.A.; Vallejo-Giraldo, C.; Aceret, G.O.; Pandit, A.; Biggs, M.J. Biological activity on piezoelectric PVDF. In Electrically Active Materials for Medical Devices; World Scientific: Singapore, 2016; pp. 167–176. [Google Scholar]

- Tofail, S.A.M.; Bauer, J. Electrically Active Materials for Medical Devices; World Scientific: Singapore, 2016; pp. 1–547. [Google Scholar]

- Royo-Gascon, N.; Wininger, M.; Scheinbeim, J.I.; Firestein, B.L.; Craelius, W. Piezoelectric substrates promote neurite growth in rat spinal cord neurons. Ann. Biomed. Eng. 2013, 41, 112–122. [Google Scholar] [CrossRef] [PubMed]

- Valentini, R.F.; Vargo, T.G.; Gardella, J.A.; Aebischer, P. Electrically charged polymeric substrates enhance nerve-fiber outgrowth invitro. Biomaterials 1992, 13, 183–190. [Google Scholar] [CrossRef]

- Hoop, M.; Chen, X.Z.; Ferrari, A.; Mushtaq, F.; Ghazaryan, G.; Tervoort, T.; Poulikakos, D.; Nelson, B.; Pane, S. Ultrasound-mediated piezoelectric differentiation of neuron-like PC12 cells on PVDF membranes. Sci. Rep. 2017, 7, 4028. [Google Scholar] [CrossRef] [PubMed]

- Fine, E.G.; Valentini, R.F.; Bellamkonda, R.; Aebischer, P. Improved nerve regeneration through piezoelectric vinylidenefluoride-trifluoroethylene copolymer guidance channels. Biomaterials 1991, 12, 775–780. [Google Scholar] [CrossRef]

- Cardoso, V.F.; Catarino, S.O.; Martins, P.; Rebouta, L.; Lanceros-Mendéz, S.; Minas, G. Biological microdevice with fluidic acoustic streaming for measuring uric acid in human saliva. In Proceedings of the 31st Annual International Conference of the IEEE Engineering in Medicine and Biology Society: Engineering the Future of Biomedicine (EMBC 2009), Minneapolis, MN, USA, 3–6 September 2009; pp. 5879–5882. [Google Scholar]

- Sackmann, E.K.; Fulton, A.L.; Beebe, D.J. The present and future role of microfluidics in biomedical research. Nature 2014, 507, 181–189. [Google Scholar] [CrossRef] [PubMed]

- Byun, C.K.; Abi-Samra, K.; Cho, Y.K.; Takayama, S. Pumps for microfluidic cell culture. Electrophoresis 2014, 35, 245–257. [Google Scholar] [CrossRef] [PubMed]

- Hilber, W. Stimulus-active polymer actuators for next-generation microfluidic devices. Appl. Phys. A Mater. Sci. Process. 2016, 122, 751. [Google Scholar] [CrossRef]

- Wiklund, M.; Green, R.; Ohlin, M. Acoustofluidics 14: Applications of acoustic streaming in microfluidic devices. Lab Chip 2012, 12, 2438–2451. [Google Scholar] [CrossRef] [PubMed]

- Van den Berg, A.; Lammerink, T.S.J. Micro total analysis systems: Microfluidic aspects, integration concept and applications. In Microsystem Technology in Chemistry and Life Science; Manz, A., Becker, H., Eds.; Springer: Berlin, Germany, 1998; Volume 194, pp. 21–49. [Google Scholar]

- Cardoso, V.F.; Ribeiro, C.; Lanceros-Mendez, S. Metamorphic biomaterials. In Bioinspired Materials for Medical Applications; Elsevier: Amsterdam, The Netherlands, 2016; pp. 69–99. [Google Scholar]

- Xia, F.; Tadigadapa, S.; Zhang, Q.M. Electroactive polymer based microfluidic pump. Sens. Actuator A Phys. 2006, 125, 346–352. [Google Scholar] [CrossRef]

- Zhao, B.; Cui, X.Y.; Ren, W.; Xu, F.; Liu, M.; Ye, Z.G. A controllable and integrated pump-enabled microfluidic chip and its application in droplets generating. Sci. Rep. 2017, 7, 11319. [Google Scholar] [CrossRef] [PubMed]

- Catarino, S.O.; Silva, L.R.; Mendes, P.M.; Miranda, J.M.; Lanceros-Mendez, S.; Minas, G. Piezoelectric actuators for acoustic mixing in microfluidic devices—Numerical prediction and experimental validation of heat and mass transport. Sens. Actuators B Chem. 2014, 205, 206–214. [Google Scholar] [CrossRef]

- Wang, H.H.; Wu, T.J.; Lin, S.J.; Gu, J.T.; Lee, C.K.; Cheng, I.C.; Hsu, Y.H. Dual light-activated microfluidic pumps based on an optopiezoelectric composite. J. Micromech. Microeng. 2017, 27, 125003. [Google Scholar] [CrossRef]

- Pabst, O.; Perelaer, J.; Beckert, E.; Schubert, U.S.; Eberhardt, R.; Tunnermann, A. All inkjet-printed piezoelectric polymer actuators: Characterization and applications for micropumps in lab-on-a-chip systems. Org. Electron. 2013, 14, 3423–3429. [Google Scholar] [CrossRef]

- Pabst, O.; Holzer, S.; Beckert, E.; Perelaer, J.; Schubert, U.S.; Eberhardt, R.; Tunnermann, A. Inkjet printed micropump actuator based on piezoelectric polymers: Device performance and morphology studies. Org. Electron. 2014, 15, 3306–3315. [Google Scholar] [CrossRef]

- Chang, W.Y.; Chu, C.H.; Lin, Y.C. A flexible piezoelectric sensor for microfluidic applications using polyvinylidene fluoride. IEEE Sens. J. 2008, 8, 495–500. [Google Scholar] [CrossRef]

- Wejinya, U.C.; Shen, Y.T.; Xi, N.; Lai, K.W.C.; Zhang, J.B. An efficient approach of handling and deposition of micro and nano entities using sensorized microfluidic end-effector system. Sens. Actuator A Phys. 2008, 147, 6–16. [Google Scholar] [CrossRef]

- Zhang, L.L.; Yu, X.L.; You, S.J.; Liu, H.Q.; Zhang, C.C.; Cai, B.; Xiao, L.; Liu, W.; Guo, S.S.; Zhao, X.Z. Highly sensitive microfluidic flow sensor based on aligned piezoelectric poly(vinylidene fluoride-trifluoroethylene) nanofibres. Appl. Phys. Lett. 2015, 107, 242901. [Google Scholar] [CrossRef]

- Webber, M.J.; Langer, R. Drug delivery by supramolecular design. Chem. Soc. Rev. 2017, 46, 6600–6620. [Google Scholar] [CrossRef] [PubMed]

- Priya James, H.; John, R.; Alex, A.; Anoop, K.R. Smart polymers for the controlled delivery of drugs—A concise overview. Acta Pharm. Sin. B 2014, 4, 120–127. [Google Scholar] [CrossRef] [PubMed]

- Barbosa, J.; Correia, D.M.; Gonçalves, R.; Ribeiro, C.; Botelho, G.; Martins, P.; Lanceros-Mendez, S. Magnetically controlled drug release system through magnetomechanical actuation. Adv. Healthc. Mater. 2016, 5, 3027–3034. [Google Scholar] [CrossRef] [PubMed]

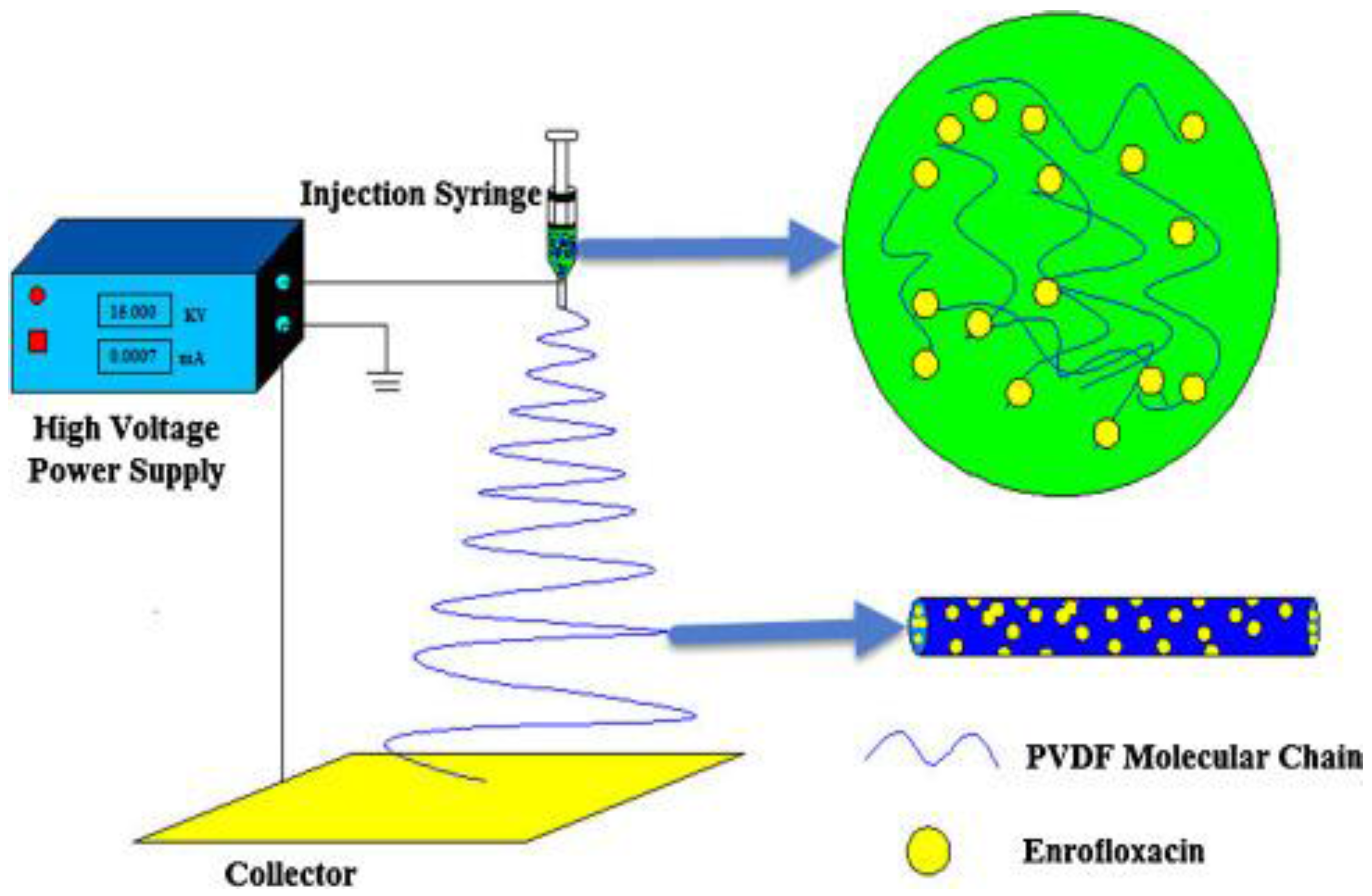

- He, T.; Wang, J.; Huang, P.; Zeng, B.; Li, H.; Cao, Q.; Zhang, S.; Luo, Z.; Deng, D.Y.B.; Zhang, H.; et al. Electrospinning polyvinylidene fluoride fibrous membranes containing anti-bacterial drugs used as wound dressing. Colloids Surf. B Biointerfaces 2015, 130, 278–286. [Google Scholar] [CrossRef] [PubMed]

- Goncalves, R.; Martins, P.; Moya, X.; Ghidini, M.; Sencadas, V.; Botelho, G.; Mathur, N.D.; Lanceros-Mendez, S. Magnetoelectric CoFe2O4/polyvinylidene fluoride electrospun nanofibres. Nanoscale 2015, 7, 8058–8061. [Google Scholar] [CrossRef] [PubMed]

| Perfluorinated | Partially fluorinated | ||||||

|---|---|---|---|---|---|---|---|

| PTFE | FEP | PFA | PCTFE | ETFE | PVF | PVDF | |

| Monomer unit | TFE | TFE + HFP | TFE + PPVE | CTFE | Ethylene + TFE | VF | VDF |

| Density (g·cm−3) | 2.16 | 2.15 | 2.15 | 2.10 | 1.70 | 1.40 | 1.75 |

| Melting point (°C) | 327 | 260 | 310 | 210 | 270 | 190 | 170 |

| Continuous-use temperature (°C) | 260 | 200 | 260 | 150 | 150 | 107 | 150 |

| Tensile strength (MPa) | 20–35 | 20–30 | 25–35 | 34–41 | 38–48 | 50–110 | 30–70 |

| Refractive index | 1.35 | 1.34 | 1.34 | 1.44 | 1.40 | 1.46 | 1.42 |

| Dielectric constant at 1 MHz | 2.1 | 2.1 | 2.1 | 2.6 | 2.5 | 8.5–11.0 | 8.4 |

| Examples of typical applications | Membranes, wire and cable insulation, chemical resistant components | Chemical resistant components, cable insulation | Chemical resistant components, cable insulation | Packaging, barrier, sealing films | Moulded component, wire and cable insulation | Packaging, protecting films, solar panels | Sensors, actuators, wire and cable insulation |

| References | [16,17,18,19] | [20,21,22,23] | [23,24,25,26] | [27,28,29] | [30,31,32,33] | [34,35,36,37] | [13,38,39,40] |

| Polymer | Chemical structure | Properties [72] | Applications |

|---|---|---|---|

| PVDF | –[CH2–CF2]n– | d31 (pC·N−1) = 8 to 22 d33 (pC·N−1) = −24 to −34 k33 = 0.20 ɛ′ = 6–12 | Tissue engineering [108,112,113], membrane distillation [114], microcapsules for catalysis [115], membranes for rechargeable lithium metal cells [116], films for human-related sensor [117], wireless smart sensor for structural health monitoring [118,119] |

| P(VDF-TrFe) | –[CH2–CF2]m–[CHF–CF2]n– | d31 (pC·N−1) = 12 d33 (pC·N−1) = −38 k33 = 0.29 ɛ′ = 18 | Tissue engineering [120], membrane separators for lithium ion batteries [121,122], transparent acoustic actuator and nanogenerator [123], thin film for pressure sensor for catheter application [124] |

| P(VDF-CTFE) | –[CH2–CF2]m–[CF2–CFCl]n– | d31 (pC·N−1) = 5.5% 1 d33 (pC·N−1) = −140 k33 = 0.39 ɛ′ = 13 | Hydrophobic flat-sheet membranes for distillation and desalinization [125,126], membranes as lithium-ion battery separator [127] |

| P(VDF-HFP) | –[CH2–CF2]m–[CF2–CF(CF3)]n– | d31 (pC·N−1) = 30 d33 (pC·N−1) = −24 k33 = 0.36 ɛ′ = 11 | Microporous membranes for membrane contactors for pervaporation [128], membrane distillation [129], battery separator [130,131,132] |

| Morphology | Method | Ref. |

|---|---|---|

| Films | Doctor blade | [147,148,149] |

| Spin coating | [75,76,77,150,151,152] | |

| Printing | [153,154,155,156] | |

| Porous films | Non-solvent induced phase separation (NIPS) | [78,135,157,158] |

| Temperature induced phase separation (TIPS) | [149,159,160] | |

| Salt leaching | [144] | |

| Nylon template | ||

| Freeze extraction | ||

| Replica moulding | [145] | |

| Fibres | Electrospinning | [136,161,162,163,164] |

| Microspheres | Electrospray | [146,165] |

| Gelation | [166] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cardoso, V.F.; Correia, D.M.; Ribeiro, C.; Fernandes, M.M.; Lanceros-Méndez, S. Fluorinated Polymers as Smart Materials for Advanced Biomedical Applications. Polymers 2018, 10, 161. https://doi.org/10.3390/polym10020161

Cardoso VF, Correia DM, Ribeiro C, Fernandes MM, Lanceros-Méndez S. Fluorinated Polymers as Smart Materials for Advanced Biomedical Applications. Polymers. 2018; 10(2):161. https://doi.org/10.3390/polym10020161

Chicago/Turabian StyleCardoso, Vanessa F., Daniela M. Correia, Clarisse Ribeiro, Margarida M. Fernandes, and Senentxu Lanceros-Méndez. 2018. "Fluorinated Polymers as Smart Materials for Advanced Biomedical Applications" Polymers 10, no. 2: 161. https://doi.org/10.3390/polym10020161

APA StyleCardoso, V. F., Correia, D. M., Ribeiro, C., Fernandes, M. M., & Lanceros-Méndez, S. (2018). Fluorinated Polymers as Smart Materials for Advanced Biomedical Applications. Polymers, 10(2), 161. https://doi.org/10.3390/polym10020161