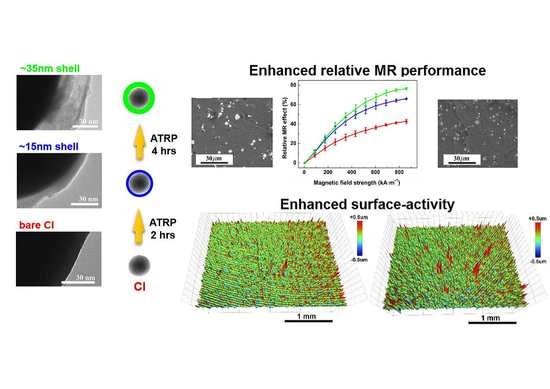

Tailoring Performance, Damping, and Surface Properties of Magnetorheological Elastomers via Particle-Grafting Technology

Abstract

1. Introduction

2. Materials and Methods

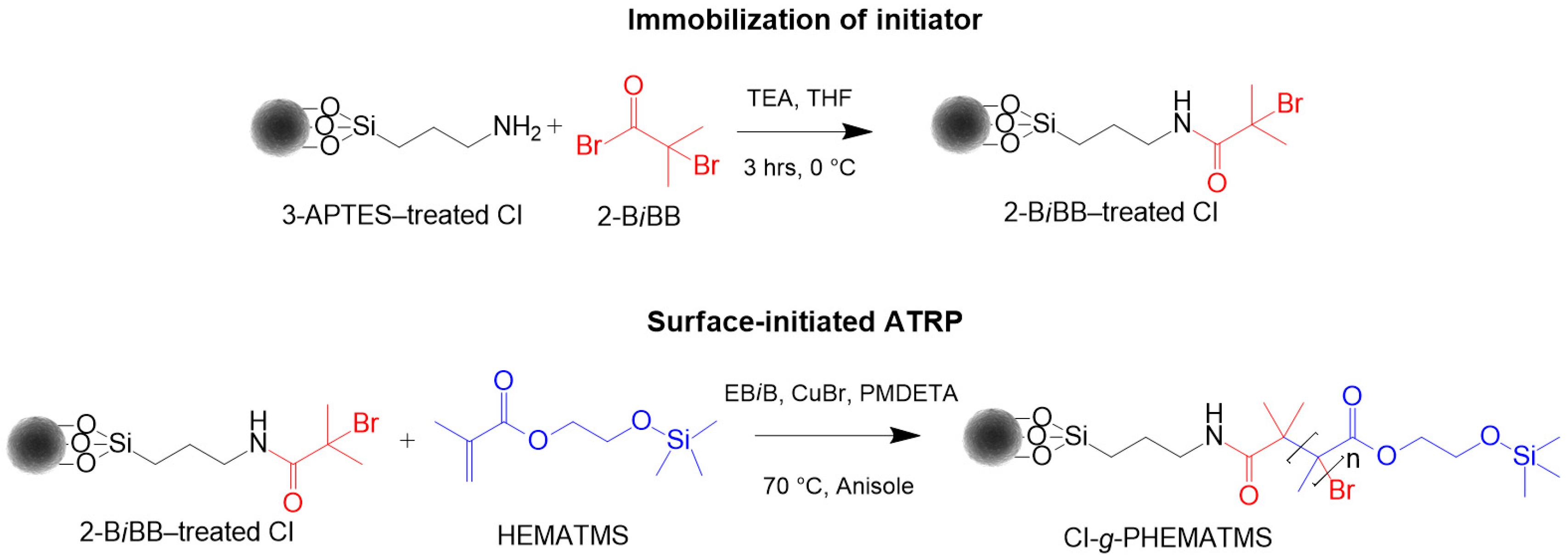

2.1. Monomer Synthesis and Preparation of CI-g-PHEMATMS Particles

2.2. Fabrication of MREs

2.3. Characterization of PHEMATMS Coatings

2.4. Characterization of Core-Shell Particles

2.5. Characterization of MREs

3. Results

3.1. Synthesis

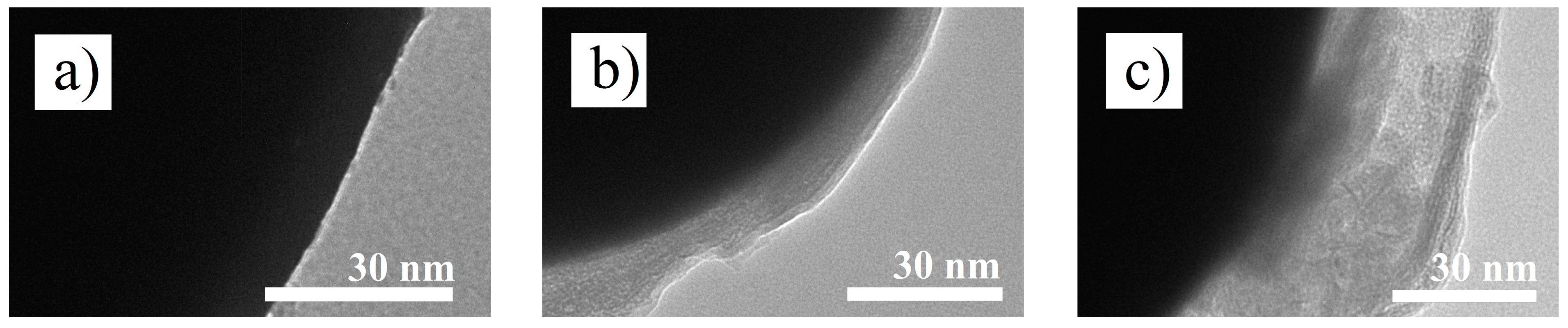

3.2. Thicknesses of Grafted Layers

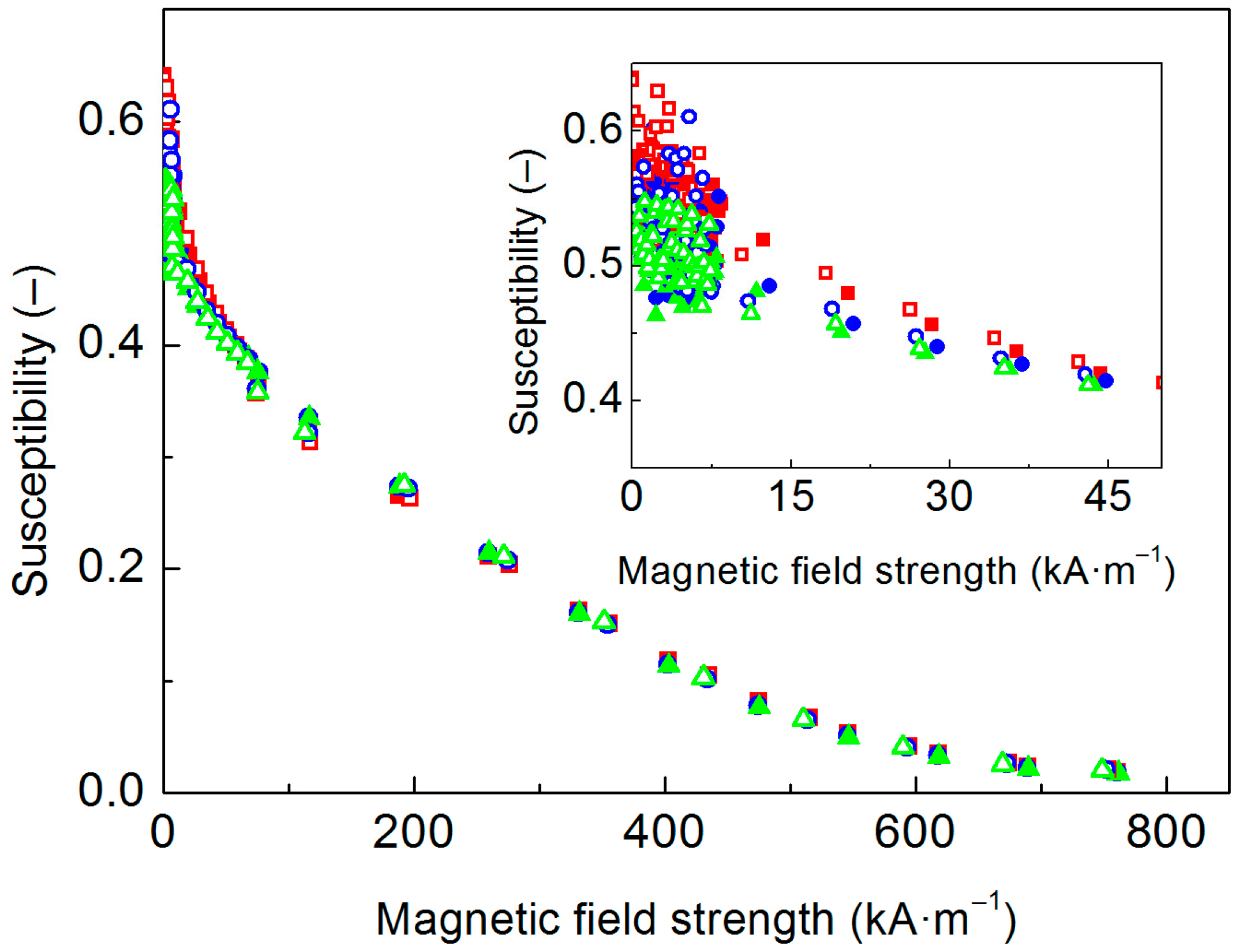

3.3. Magnetic Properties

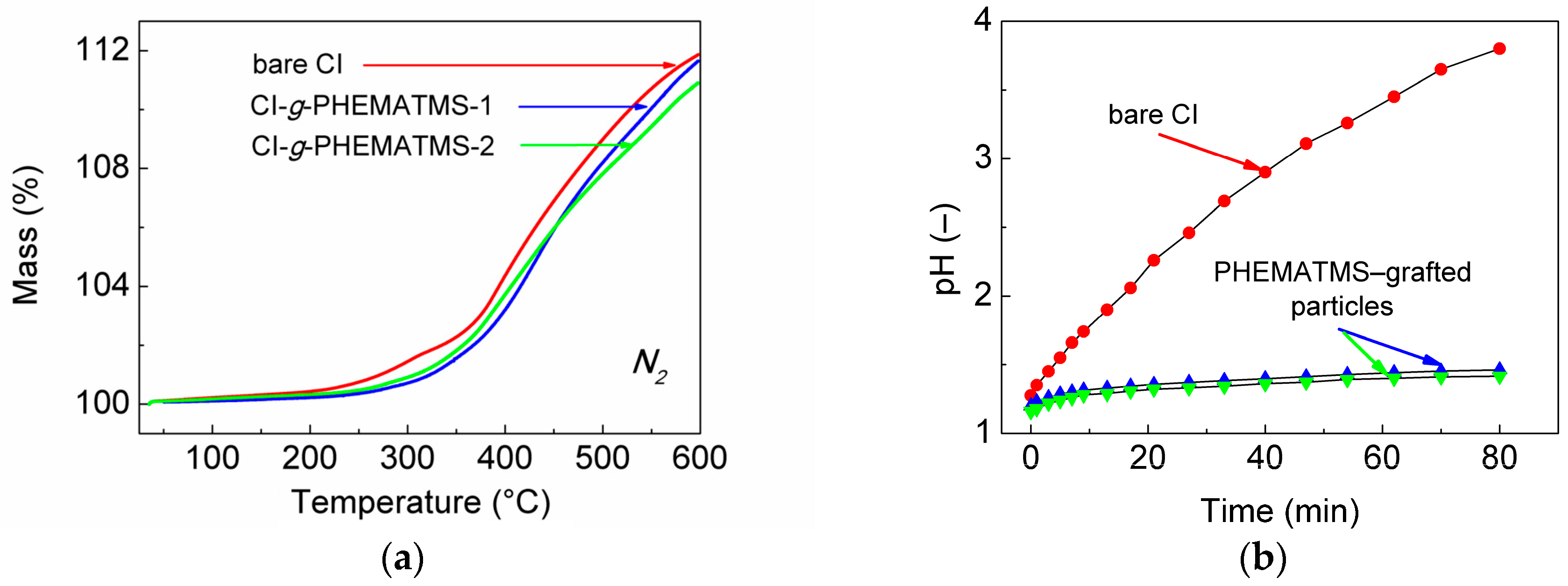

3.4. Stability Properties of CI-g-PHEMATMS

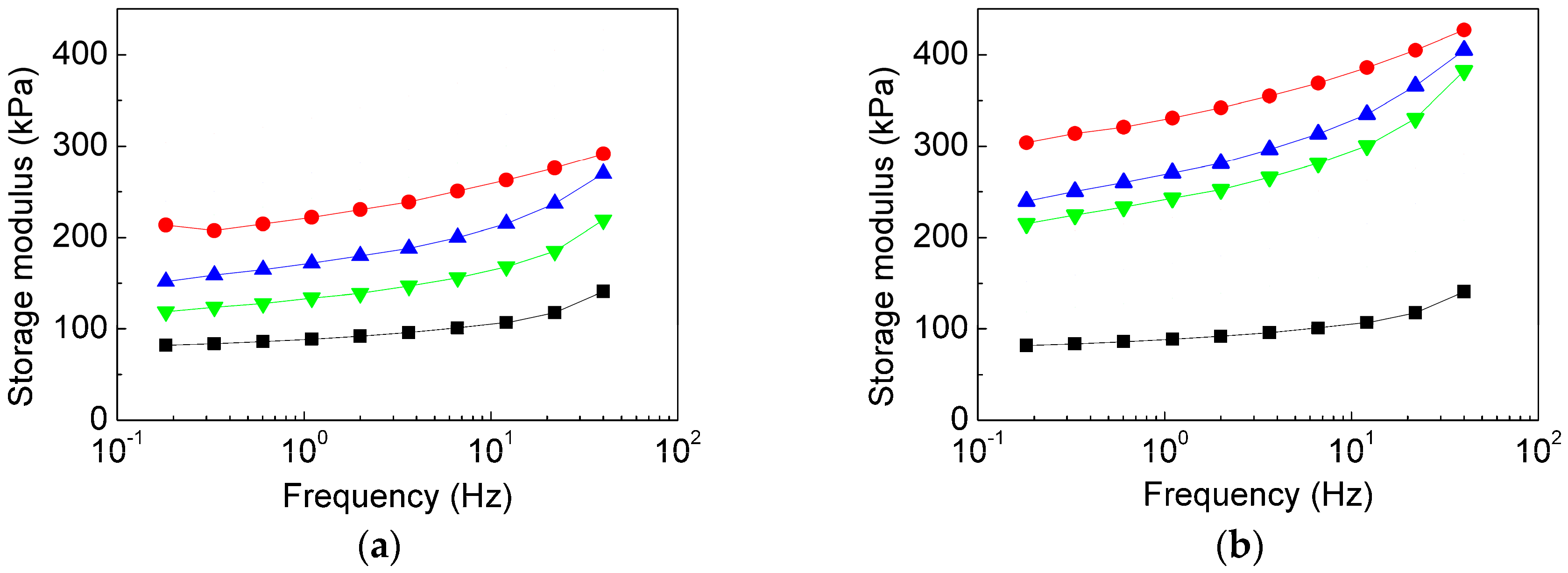

3.5. Magnetorheological Performance

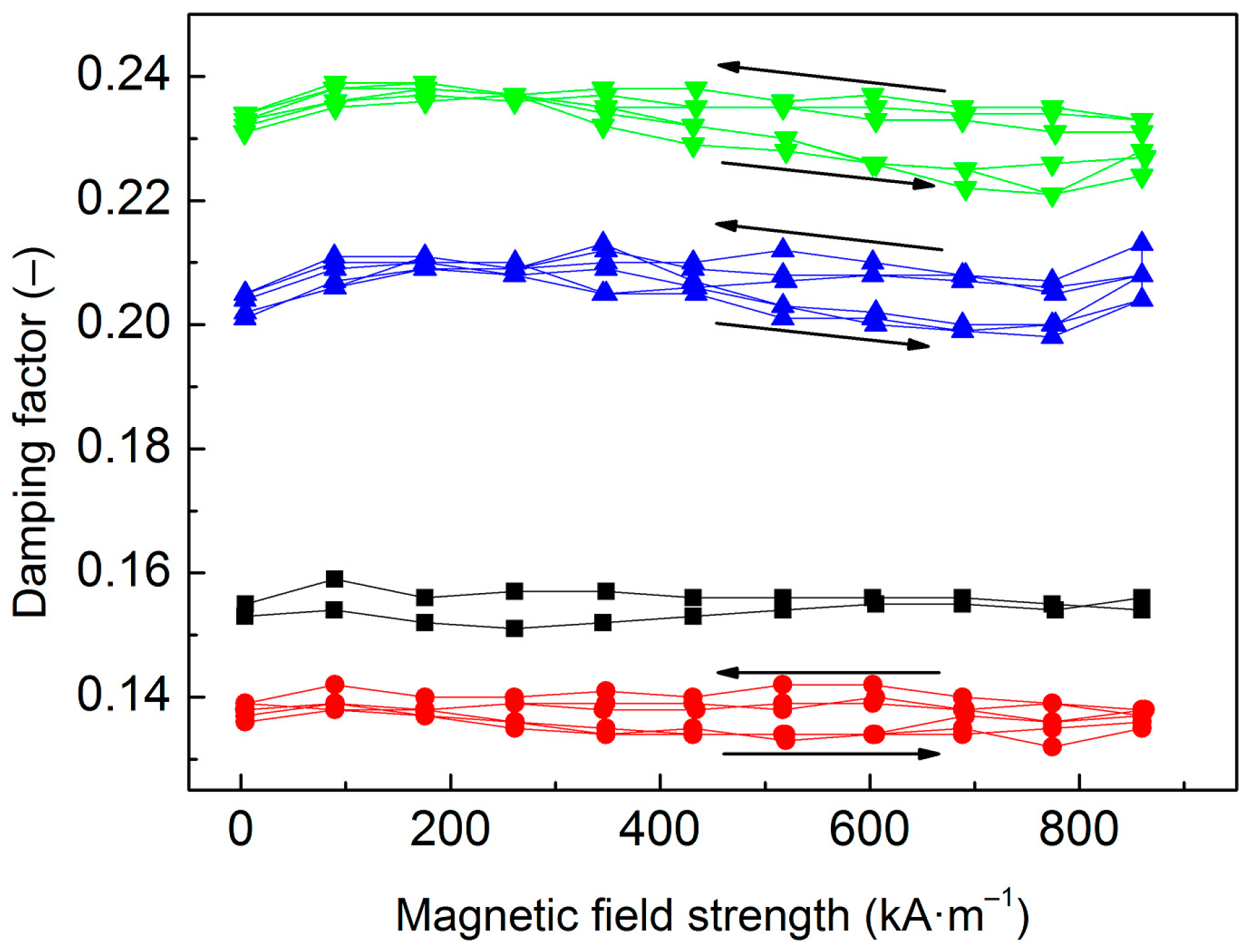

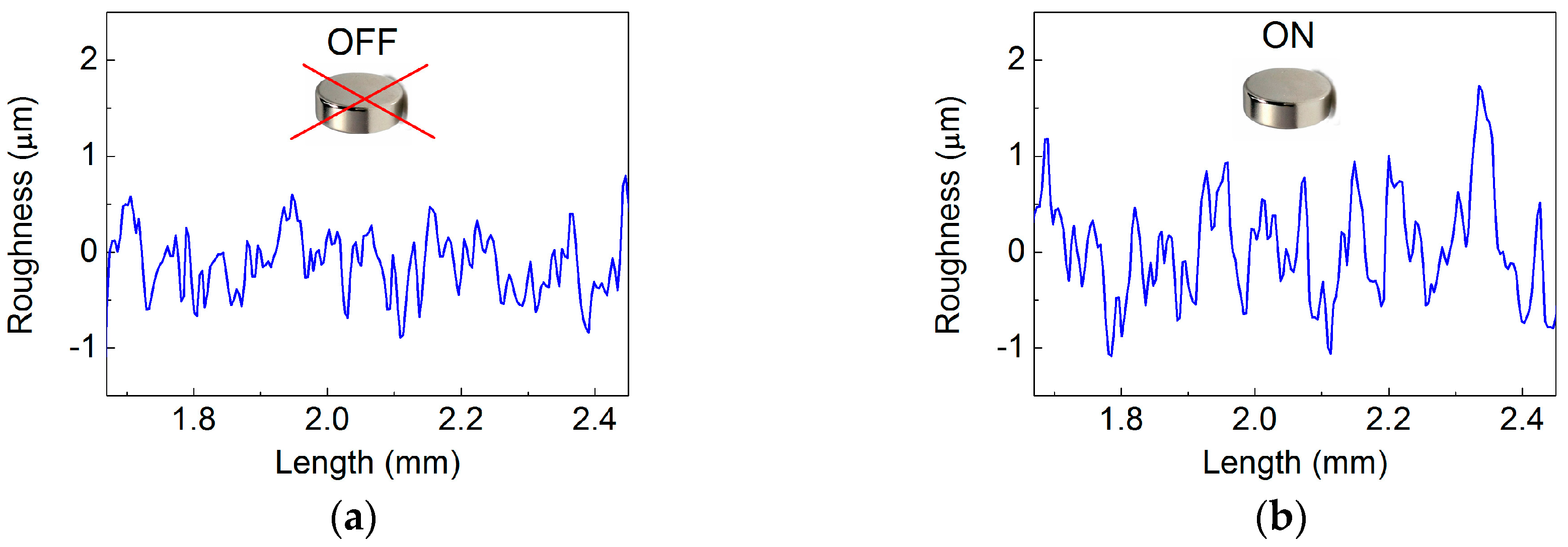

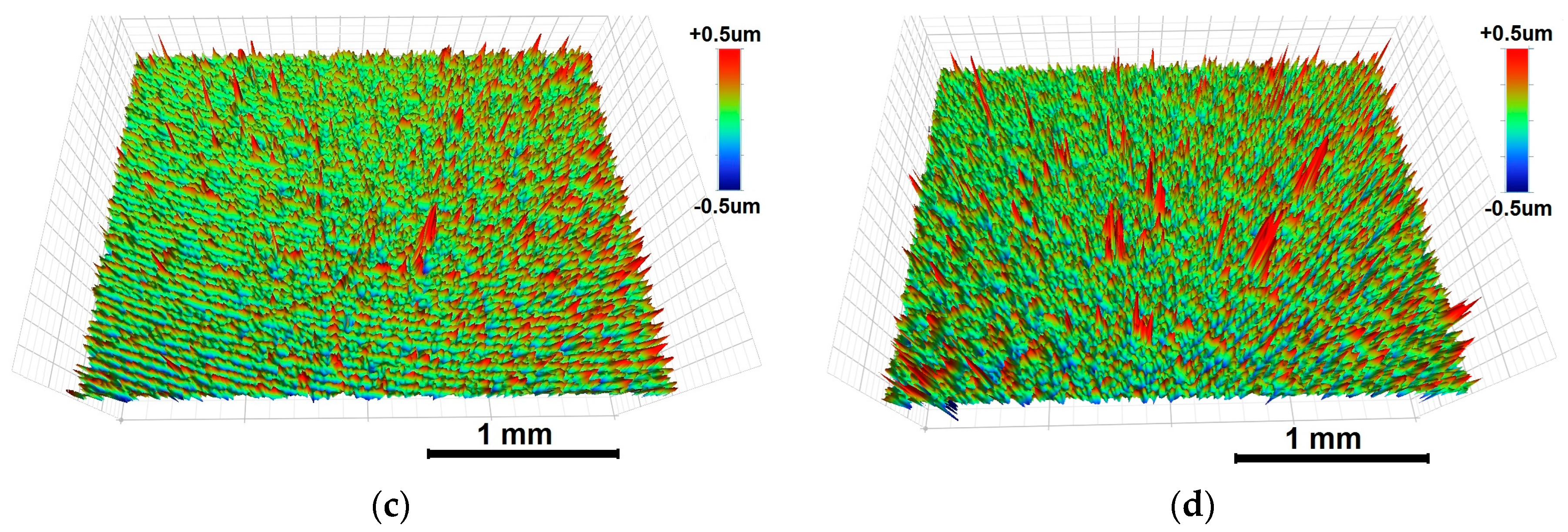

3.6. Field-Induced Changes in Surface Topography

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Boczkowska, A.; Awietjan, S.F.; Wroblewski, R. Microstructure-property relationships of urethane magnetorheological elastomers. Smart Mater. Struct. 2007, 16, 1924–1930. [Google Scholar] [CrossRef]

- Cvek, M.; Mrlik, M.; Pavlinek, V. A rheological evaluation of steady shear magnetorheological flow behavior using three-parameter viscoplastic models. J. Rheol. 2016, 60, 687–694. [Google Scholar] [CrossRef]

- de Vicente, J.; Klingenberg, D.J.; Hidalgo-Alvarez, R. Magnetorheological fluids: A review. Soft Matter 2011, 7, 3701–3710. [Google Scholar] [CrossRef]

- Cvek, M.; Moucka, R.; Sedlacik, M.; Pavlinek, V. Electromagnetic, magnetorheological and stability properties of polysiloxane elastomers based on silane-modified carbonyl iron particles with enhanced wettability. Smart Mater. Struct. 2017, 26, 105003. [Google Scholar] [CrossRef]

- Li, Y.C.; Li, J.C.; Li, W.H.; Du, H.P. A state-of-the-art review on magnetorheological elastomer devices. Smart Mater. Struct. 2014, 23, 123001. [Google Scholar] [CrossRef]

- Park, B.J.; Fang, F.F.; Choi, H.J. Magnetorheology: Materials and application. Soft Matter 2010, 6, 5246–5253. [Google Scholar] [CrossRef]

- Bose, H.; Rabindranath, R.; Ehrlich, J. Soft magnetorheological elastomers as new actuators for valves. J. Intell. Mater. Syst. Struct. 2012, 23, 989–994. [Google Scholar] [CrossRef]

- Dyniewicz, B.; Bajkowski, J.M.; Bajer, C.I. Semi-active control of a sandwich beam partially filled with magnetorheological elastomer. Mech. Syst. Signal Process. 2015, 60–61, 695–705. [Google Scholar] [CrossRef]

- Choi, S.B.; Li, W.H.; Yu, M.; Du, H.P.; Fu, J.; Do, P.X. State of the art of control schemes for smart systems featuring magneto-rheological materials. Smart Mater. Struct. 2016, 25, 043001. [Google Scholar] [CrossRef]

- Khimi, S.R.; Pickering, K.L. Comparison of dynamic properties of magnetorheological elastomers with existing antivibration rubbers. Compos. Part B 2015, 83, 175–183. [Google Scholar] [CrossRef]

- Zrinyi, M.; Szabo, D. Muscular contraction mimiced by magnetic gels. Int. J. Mod. Phys. B 2001, 15, 557–563. [Google Scholar] [CrossRef]

- Behrooz, M.; Gordaninejad, F. A flexible micro fluid transport system featuring magnetorheological elastomer. Smart Mater. Struct. 2016, 25, 025011. [Google Scholar] [CrossRef]

- Cvek, M.; Moucka, R.; Sedlacik, M.; Babayan, V.; Pavlinek, V. Enhancement of radio-absorbing properties and thermal conductivity of polysiloxane-based magnetorheological elastomers by the alignment of filler particles. Smart Mater. Struct. 2017, 26, 095005. [Google Scholar] [CrossRef]

- Keshoju, K.; Sun, L. Mechanical characterization of magnetic nanowire-polydimethylsiloxane composites. J. Appl. Phys. 2009, 105, 023515. [Google Scholar] [CrossRef]

- Bica, I.; Anitas, E.M.; Bunoiu, M.; Vatzulik, B.; Juganaru, I. Hybrid magnetorheological elastomer: Influence of magnetic field and compression pressure on its electrical conductivity. J. Ind. Eng. Chem. 2014, 20, 3994–3999. [Google Scholar] [CrossRef]

- Khimi, S.R.; Pickering, K.L.; Mace, B.R. Dynamic properties of magnetorheological elastomers based on iron sand and natural rubber. J. Appl. Polym. Sci. 2015, 132, 41506. [Google Scholar] [CrossRef]

- Chertovich, A.V.; Stepanov, G.V.; Kramarenko, E.Y.; Khokhlov, A.R. New composite elastomers with giant magnetic response. Macromol. Mater. Eng. 2010, 295, 336–341. [Google Scholar] [CrossRef]

- Fan, Y.C.; Gong, X.L.; Xuan, S.H.; Qin, L.J.; Li, X.F. Effect of cross-link density of the matrix on the damping properties of magnetorheological elastomers. Ind. Eng. Chem. Res. 2013, 52, 771–778. [Google Scholar] [CrossRef]

- Plachy, T.; Kratina, O.; Sedlacik, M. Porous magnetic materials based on EPDM rubber filled with carbonyl iron particles. Compos. Struct. 2018, 192, 126–130. [Google Scholar] [CrossRef]

- Fan, Y.C.; Gong, X.L.; Jiang, W.Q.; Zhang, W.; Wei, B.; Li, W.H. Effect of maleic anhydride on the damping property of magnetorheological elastomers. Smart Mater. Struct. 2010, 19, 055015. [Google Scholar] [CrossRef]

- Gong, X.L.; Fan, Y.C.; Xuan, S.H.; Xu, Y.G.; Peng, C. Control of the damping properties of magnetorheological elastomers by using polycaprolactone as a temperature-controlling component. Ind. Eng. Chem. Res. 2012, 51, 6395–6403. [Google Scholar] [CrossRef]

- Khairi, M.H.A.; Mazlan, S.A.; Ubaidillah; Ahmad, K.Z.K.; Choi, S.B.; Aziz, S.A.A.; Yunus, N.A. The field-dependent complex modulus of magnetorheological elastomers consisting of sucrose acetate isobutyrate ester. J. Intell. Mater. Syst. Struct. 2017, 28, 1993–2004. [Google Scholar] [CrossRef]

- Rabindranath, R.; Bose, H. On the mobility of iron particles embedded in elastomeric silicone matrix. In Proceedings of the 13th International Conference on Electrorheological Fluids and Magnetorheological Suspensions, Ankara, Turkey, 2–6 July 2012; Unal, H.I., Ed.; Iop Publishing Ltd.: Bristol, UK, 2013. [Google Scholar] [CrossRef]

- Yang, D.L.; Pacheco, R.; Henderson, K.; Hubbard, K.; Devlin, D. Diffusion and sorption of nitroplasticizers in vinyl copolymer elastomer and its composites. J. Appl. Polym. Sci. 2014, 131, 40729. [Google Scholar] [CrossRef]

- Ocalan, M.; McKinley, G.H. High-flux magnetorheology at elevated temperatures. Rheol. Acta 2013, 52, 623–641. [Google Scholar] [CrossRef]

- Cvek, M.; Mrlik, M.; Ilcikova, M.; Mosnacek, J.; Munster, L.; Pavlinek, V. Synthesis of silicone elastomers containing silyl-based polymer grafted carbonyl iron particles: An efficient way to improve magnetorheological, damping, and sensing performances. Macromolecules 2017, 50, 2189–2200. [Google Scholar] [CrossRef]

- Cvek, M.; Mrlik, M.; Ilcikova, M.; Plachy, T.; Sedlacik, M.; Mosnacek, J.; Pavlinek, V. A facile controllable coating of carbonyl iron particles with poly(glycidyl methacrylate): A tool for adjusting MR response and stability properties. J. Mater. Chem. C 2015, 3, 4646–4656. [Google Scholar] [CrossRef]

- Tan, R.X.; Fan, Z.Q.; Xie, Z.Y.; Zhang, M.Y.; He, K.J.; Huang, Q.H. Fabrication of large-sized high density bulk isotropic pyrocarbon materials of a special composite microstructure by fixed-bed chemical vapor deposition. Carbon 2016, 101, 439–448. [Google Scholar] [CrossRef]

- Sorokin, V.V.; Stepanov, G.V.; Shamonin, M.; Monkman, G.J.; Khokhlov, A.R.; Kramarenko, E.Y. Hysteresis of the viscoelastic properties and the normal force in magnetically and mechanically soft magnetoactive elastomers: Effects of filler composition, strain amplitude and magnetic field. Polymer 2015, 76, 191–202. [Google Scholar] [CrossRef]

- Matyjaszewski, K. Atom Transfer Radical Polymerization (ATRP): Current status and future perspectives. Macromolecules 2012, 45, 4015–4039. [Google Scholar] [CrossRef]

- Mousazadeh, H.; Safa, K.D.; Ghadari, R. Synthesis, spectroscopic characterization, and DFT studies of 1,2,3-triazole-based organosilicon compounds. J. Molec. Struct. 2018, 1167, 200–208. [Google Scholar] [CrossRef]

- Cvek, M.; Mrlik, M.; Ilcikova, M.; Mosnacek, J.; Babayan, V.; Kucekova, Z.; Humpolicek, P.; Pavlinek, V. The chemical stability and cytotoxicity of carbonyl iron particles grafted with poly(glycidyl methacrylate) and the magnetorheological activity of their suspensions. RSC Adv. 2015, 5, 72816–72824. [Google Scholar] [CrossRef]

- Kim, Y.H.; Ahn, W.J.; Choi, H.J.; Seo, Y. Fabrication and magnetic stimuli-response of polydopamine-coated core-shell structured carbonyl iron microspheres. Colloid Polym. Sci. 2016, 294, 329–337. [Google Scholar] [CrossRef]

- de Vicente, J.; Bossis, G.; Lacis, S.; Guyot, M. Permeability measurements in cobalt ferrite and carbonyl iron powders and suspensions. J. Magn. Magn. Mater. 2002, 251, 100–108. [Google Scholar] [CrossRef]

- Stepanov, G.V.; Borin, D.Y.; Raikher, Y.L.; Melenev, P.V.; Perov, N.S. Motion of ferroparticles inside the polymeric matrix in magnetoactive elastomers. J. Phys. Condens. Matter 2008, 20, 204121. [Google Scholar] [CrossRef] [PubMed]

- Bodnaruk, A.V.; Brunhuber, A.; Kalita, V.M.; Kulyk, M.M.; Snarskii, A.A.; Lozenko, A.F.; Ryabchenko, S.M.; Shamonin, M. Temperature-dependent magnetic properties of a magnetoactive elastomer: Immobilization of the soft-magnetic filler. J. Appl. Phys. 2018, 123, 115118. [Google Scholar] [CrossRef]

- Abshinova, M.A.; Kazantseva, N.E.; Saha, P.; Sapurina, I.; Kovarova, J.; Stejskal, J. The enhancement of the oxidation resistance of carbonyl iron by polyaniline coating and consequent changes in electromagnetic properties. Polym. Degrad. Stab. 2008, 93, 1826–1831. [Google Scholar] [CrossRef]

- Konig, R.; Muller, S.; Dinnebier, R.E.; Hinrichsen, B.; Muller, P.; Ribbens, A.; Hwang, J.; Liebscher, R.; Etter, M.; Pistidda, C. The crystal structures of carbonyl iron powde—Revised using in situ synchrotron XRPD. Z. Kristallogr. Cryst. Mater. 2017, 232, 835–842. [Google Scholar] [CrossRef]

- Plachy, T.; Kutalkova, E.; Sedlacik, M.; Vesel, A.; Masar, M.; Kuritka, I. Impact of corrosion process of carbonyl iron particles on magnetorheological behavior of their suspensions. J. Ind. Eng. Chem. 2018, 66, 362–369. [Google Scholar] [CrossRef]

- Sedlacik, M.; Mrlik, M.; Babayan, V.; Pavlinek, V. Magnetorheological elastomers with efficient electromagnetic shielding. Compos. Struct. 2016, 135, 199–204. [Google Scholar] [CrossRef]

- Fu, S.Y.; Feng, X.Q.; Lauke, B.; Mai, Y.W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate-polymer composites. Compos. Part B 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Gorodov, V.V.; Kostrov, S.A.; Kamyshinskii, R.A.; Kramarenko, E.Y.; Muzafarov, A.M. Modification of carbonyl iron particles by carboxyl-containing polydimethylsiloxanes. Russ. Chem. Bull. 2018, 67, 1639–1647. [Google Scholar] [CrossRef]

- Laun, H.M.; Gabriel, C.; Schmidt, G. Primary and secondary normal stress differences of a magnetorheological fluid (MRF) up to magnetic flux densities of 1 T. J. Non-Newton. Fluid Mech. 2008, 148, 47–56. [Google Scholar] [CrossRef]

- Poojary, U.R.; Hegde, S.; Gangadharan, K.V. Experimental investigation on the effect of carbon nanotube additive on the field-induced viscoelastic properties of magnetorheological elastomer. J. Mater. Sci. 2018, 53, 4229–4241. [Google Scholar] [CrossRef]

- Zhou, G.Y. Shear properties of a magnetorheological elastomer. Smart Mater. Struct. 2003, 12, 139–146. [Google Scholar] [CrossRef]

- Shuib, R.K.; Pickering, K.L. Investigation and modelling of damping mechanisms of magnetorheological elastomers. J. Appl. Polym. Sci. 2016, 133, 43247. [Google Scholar] [CrossRef]

- Schoeck, G. Internal friction due to precipitation. Phys. Status Solidi 1969, 32, 651–658. [Google Scholar] [CrossRef]

- Lavernia, E.J.; Perez, R.J.; Zhang, J. Damping behavior of discontinuously reinforced al-alloy metal-matrix composites. Metall. Mater. Trans. A 1995, 26, 2803–2818. [Google Scholar] [CrossRef]

- Aziz, S.A.A.; Ubaidillah; Mazlan, S.A.; Ismail, N.I.N.; Choi, S.B. Implementation of functionalized multiwall carbon nanotubes on magnetorheological elastomer. J. Mater. Sci. 2018, 53, 10122–10134. [Google Scholar] [CrossRef]

- Jolly, M.R.; Carlson, J.D.; Munoz, B.C. A model of the behaviour of magnetorheological materials. Smart Mater. Struct. 1996, 5, 607–614. [Google Scholar] [CrossRef]

- Khimi, S.R.; Pickering, K.L. The effect of silane coupling agent on the dynamic mechanical properties of iron sand/ natural rubber magnetorheological elastomers. Compos. Part B 2016, 90, 115–125. [Google Scholar] [CrossRef]

- Moucka, R.; Sedlacik, M.; Cvek, M. Dielectric properties of magnetorheological elastomers with different microstructure. Appl. Phys. Lett. 2018, 122, 112901. [Google Scholar] [CrossRef]

- Pickering, K.L.; Khimi, S.R.; Ilanko, S. The effect of silane coupling agent on iron sand for use in magnetorheological elastomers Part 1: Surface chemical modification and characterization. Compos. Part A 2015, 68, 377–386. [Google Scholar] [CrossRef]

- Sorokin, V.V.; Ecker, E.; Stepanov, G.V.; Shamonin, M.; Monkman, G.J.; Kramarenko, E.Y.; Khokhlov, A.R. Experimental study of the magnetic field enhanced Payne effect in magnetorheological elastomers. Soft Matter 2014, 10, 8765–8776. [Google Scholar] [CrossRef] [PubMed]

- Glavan, G.; Salamon, P.; Belyaeva, I.A.; Shamonin, M.; Drevensek-Olenik, I. Tunable surface roughness and wettability of a soft magnetoactive elastomer. J. Appl. Polym. Sci. 2018, 135, 46221. [Google Scholar] [CrossRef]

- Maman, M.; Ponsinet, V. Wettability of magnetically susceptible surfaces. Langmuir 1999, 15, 259–265. [Google Scholar] [CrossRef]

- Lee, S.; Yim, C.; Kim, W.; Jeon, S. Magnetorheological elastomer films with tunable wetting and adhesion properties. ACS Appl. Mater. Interfaces 2015, 7, 19853–19856. [Google Scholar] [CrossRef] [PubMed]

- Nagappan, S.; Ha, C.S. Emerging trends in superhydrophobic surface based magnetic materials: Fabrications and their potential applications. J. Mater. Chem. A 2015, 3, 3224–3251. [Google Scholar] [CrossRef]

| Sample Code | M 1 | I 1 | CuBr | L 1 | Anisole (vol.%) | Time (h) |

|---|---|---|---|---|---|---|

| CI-g-PHEMATMS-1 | 100 | 1 | 1 | 1 | 50 | 2 |

| CI-g-PHEMATMS-2 | 300 | 1 | 1 | 1 | 50 | 2 |

| Sample Code | Conversion 1 (%) | (g·mol−1) | (g·mol−1) | Đ (−) |

|---|---|---|---|---|

| CI-g-PHEMATMS-1 | 90 | 11,800 | 9200 | 1.28 |

| CI-g-PHEMATMS-2 | 75 | 23,500 | 17,900 | 1.31 |

| MRE filler | Bare CI | CI-g-PHEMATMS-1 | CI-g-PHEMATMS-2 | |||

|---|---|---|---|---|---|---|

| Magnet | OFF | ON | OFF | ON | OFF | ON |

| (μm) | 10.1 | 11.5 | 9.98 | 14.9 | 10.6 | 17.7 |

| Δ (%) | 14 | 49 | 67 | |||

| (μm) | 0.39 | 0.44 | 0.41 | 0.56 | 0.43 | 0.70 |

| Δ (%) | 13 | 37 | 63 | |||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cvek, M.; Mrlik, M.; Sevcik, J.; Sedlacik, M. Tailoring Performance, Damping, and Surface Properties of Magnetorheological Elastomers via Particle-Grafting Technology. Polymers 2018, 10, 1411. https://doi.org/10.3390/polym10121411

Cvek M, Mrlik M, Sevcik J, Sedlacik M. Tailoring Performance, Damping, and Surface Properties of Magnetorheological Elastomers via Particle-Grafting Technology. Polymers. 2018; 10(12):1411. https://doi.org/10.3390/polym10121411

Chicago/Turabian StyleCvek, Martin, Miroslav Mrlik, Jakub Sevcik, and Michal Sedlacik. 2018. "Tailoring Performance, Damping, and Surface Properties of Magnetorheological Elastomers via Particle-Grafting Technology" Polymers 10, no. 12: 1411. https://doi.org/10.3390/polym10121411

APA StyleCvek, M., Mrlik, M., Sevcik, J., & Sedlacik, M. (2018). Tailoring Performance, Damping, and Surface Properties of Magnetorheological Elastomers via Particle-Grafting Technology. Polymers, 10(12), 1411. https://doi.org/10.3390/polym10121411