The High Density Polyethylene Composite with Recycled Radiation Cross-Linked Filler of rHDPEx

Abstract

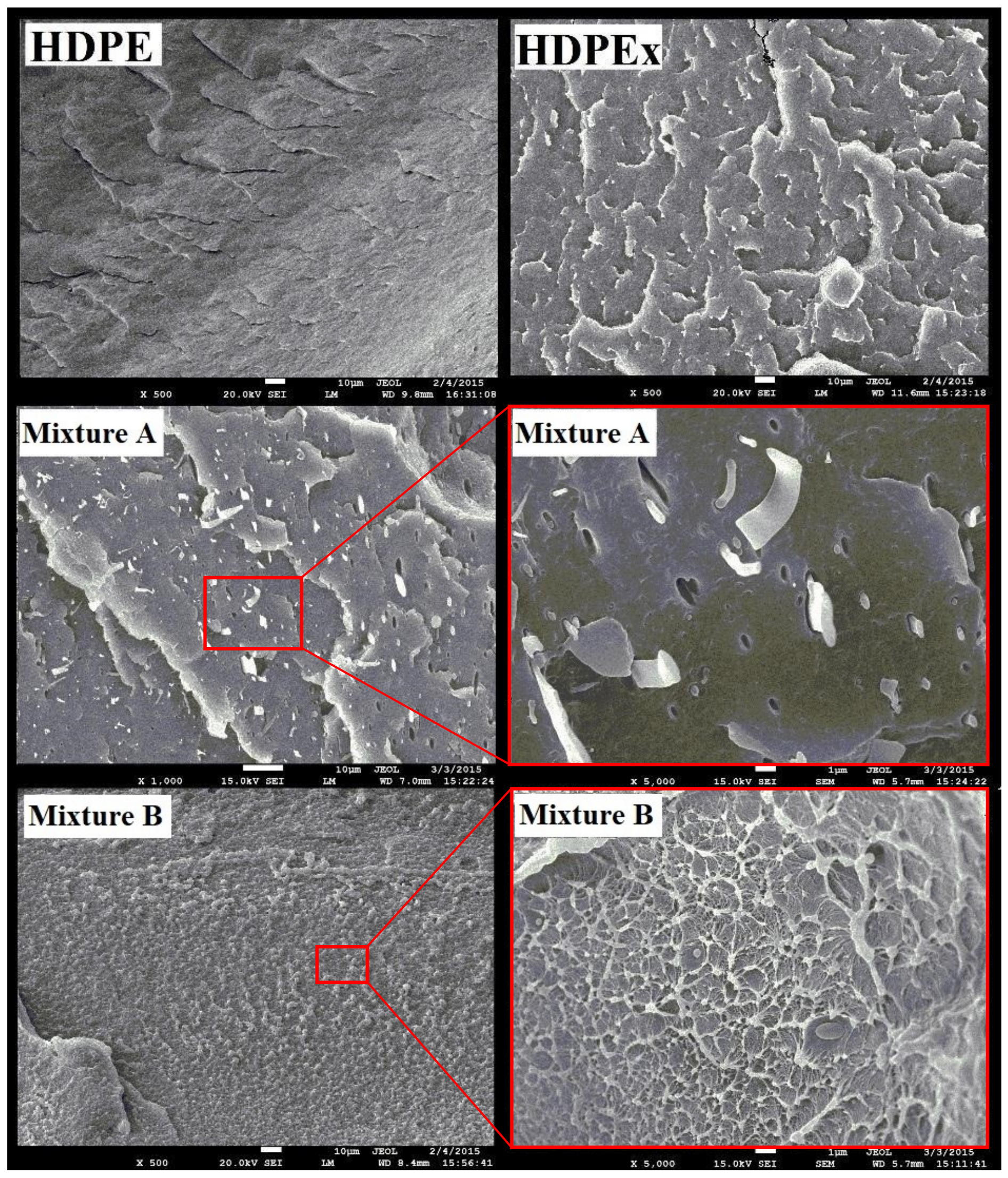

1. Introduction

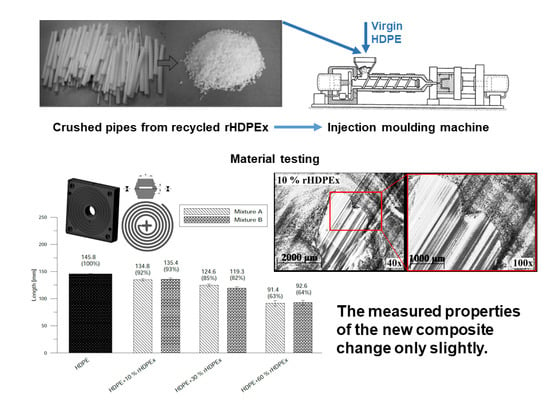

2. Materials and Methods

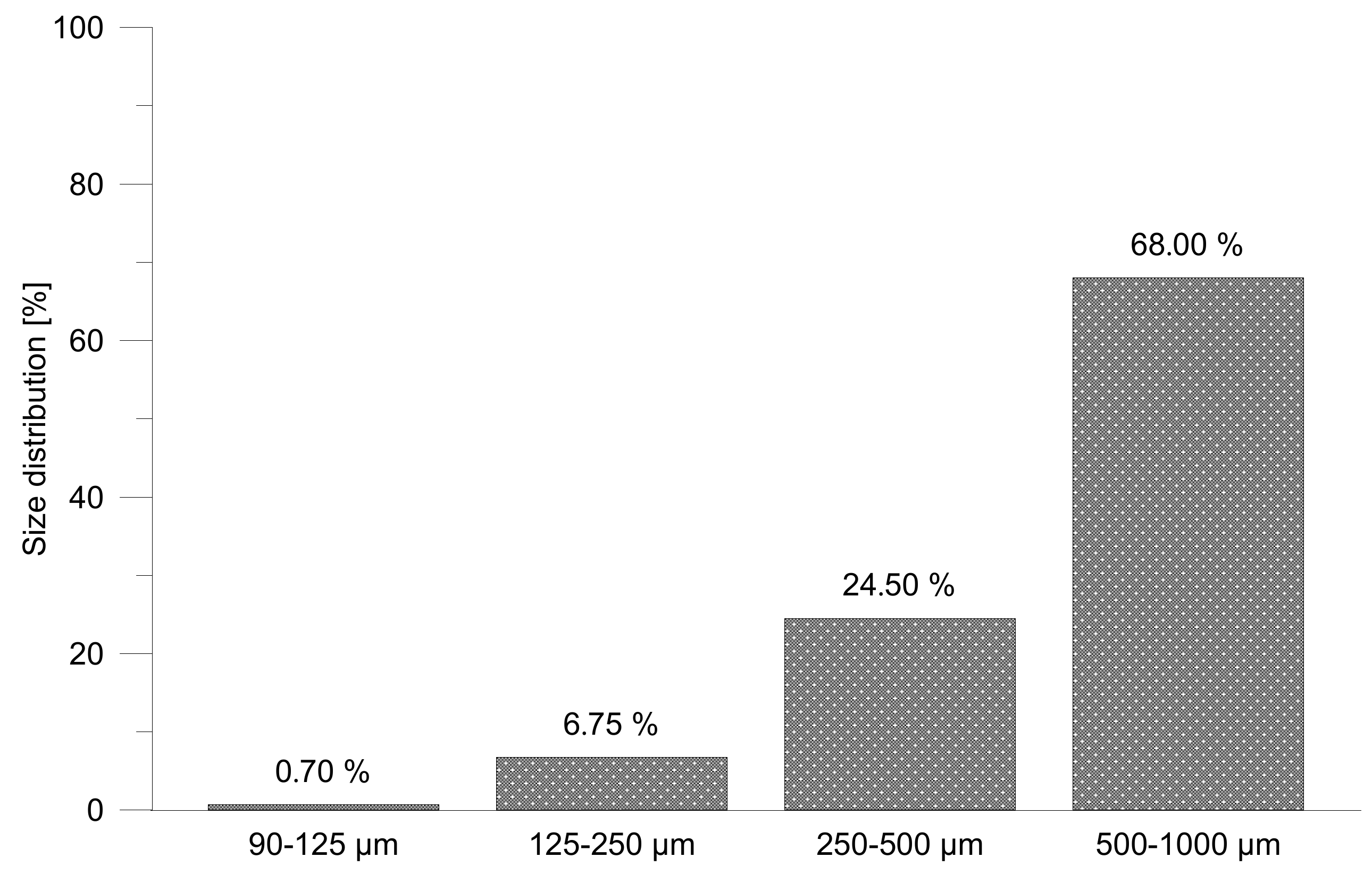

2.1. Material

2.2. Irradiation

2.3. Specimen Preparation

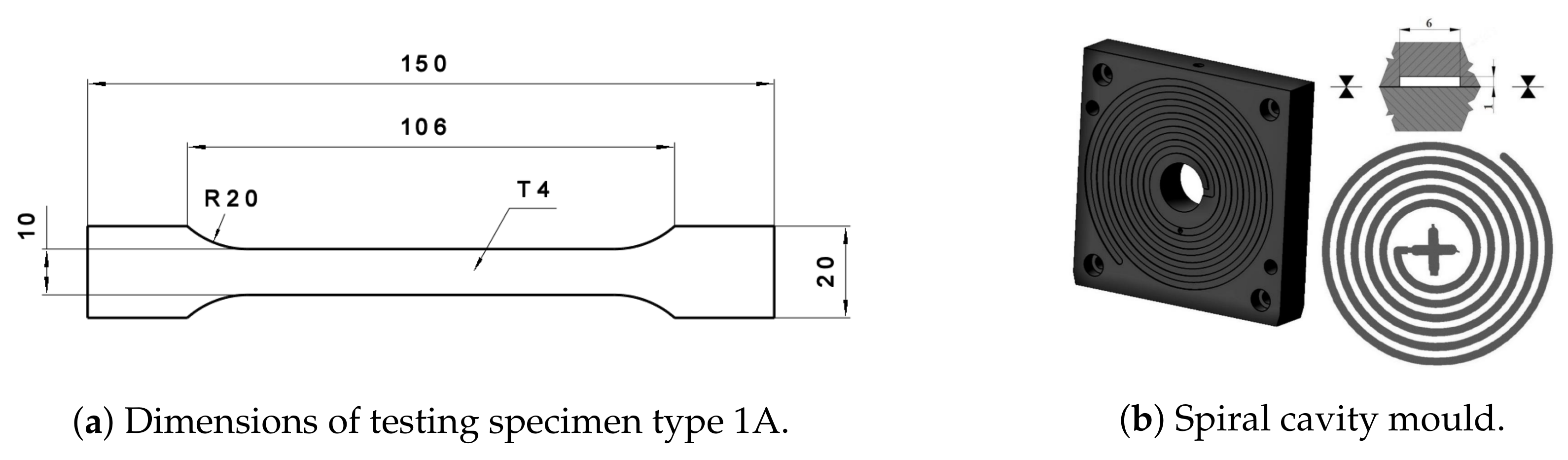

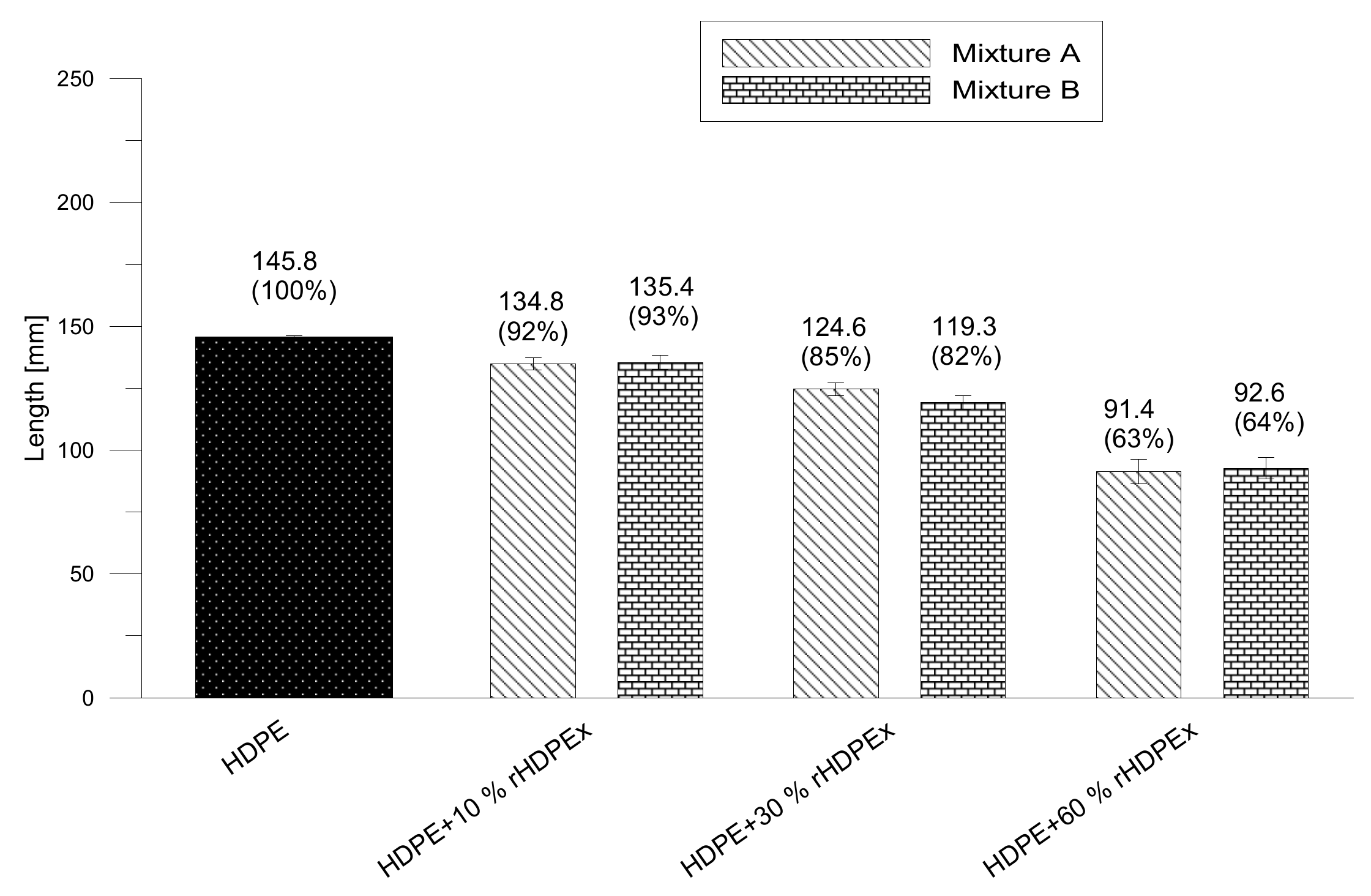

2.4. Polymer Mixture Fluidity

2.5. Tensile Test

2.6. Shore D Hardness (ShD)

2.7. Vicat Softening Temperature

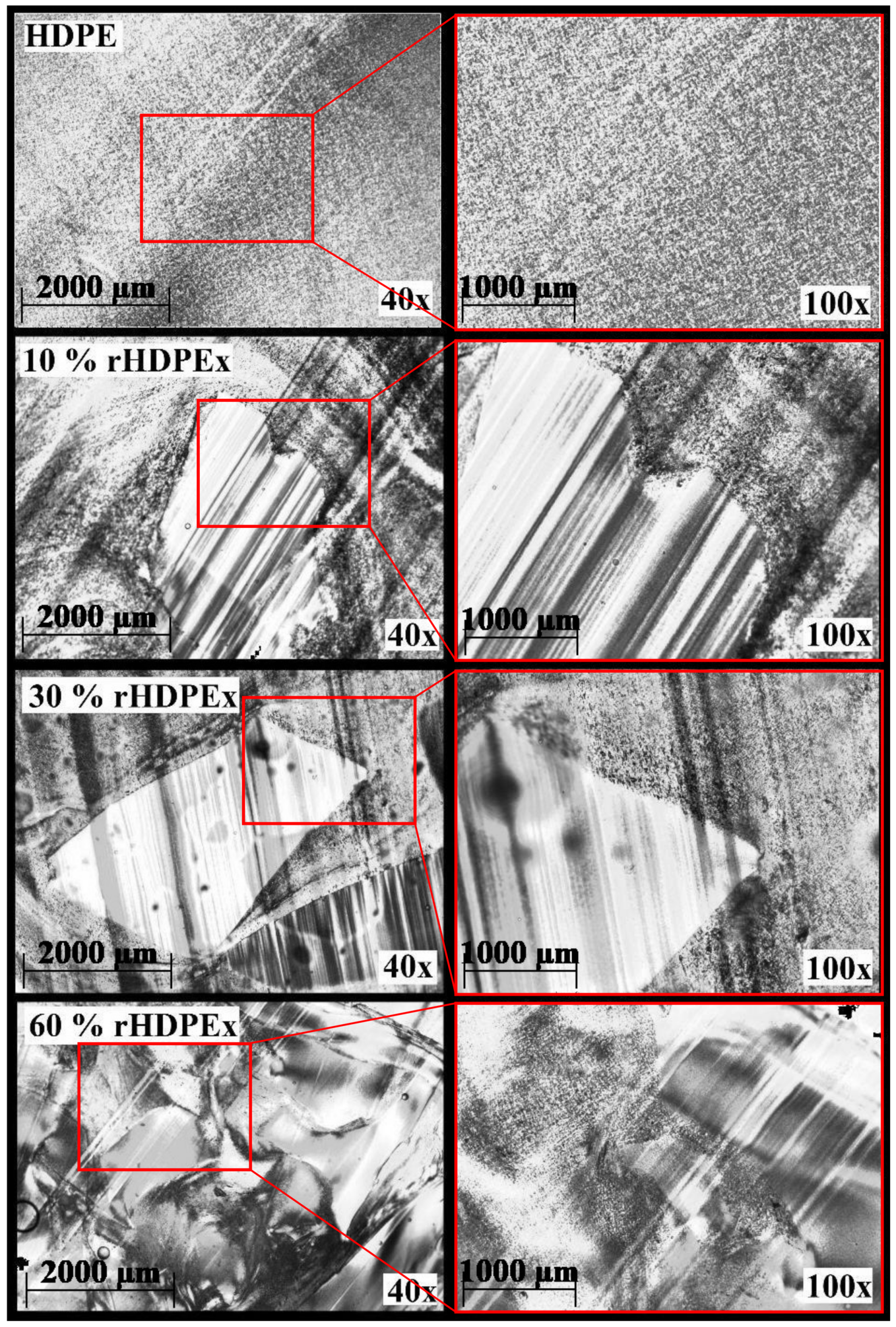

2.8. Structural Analysis

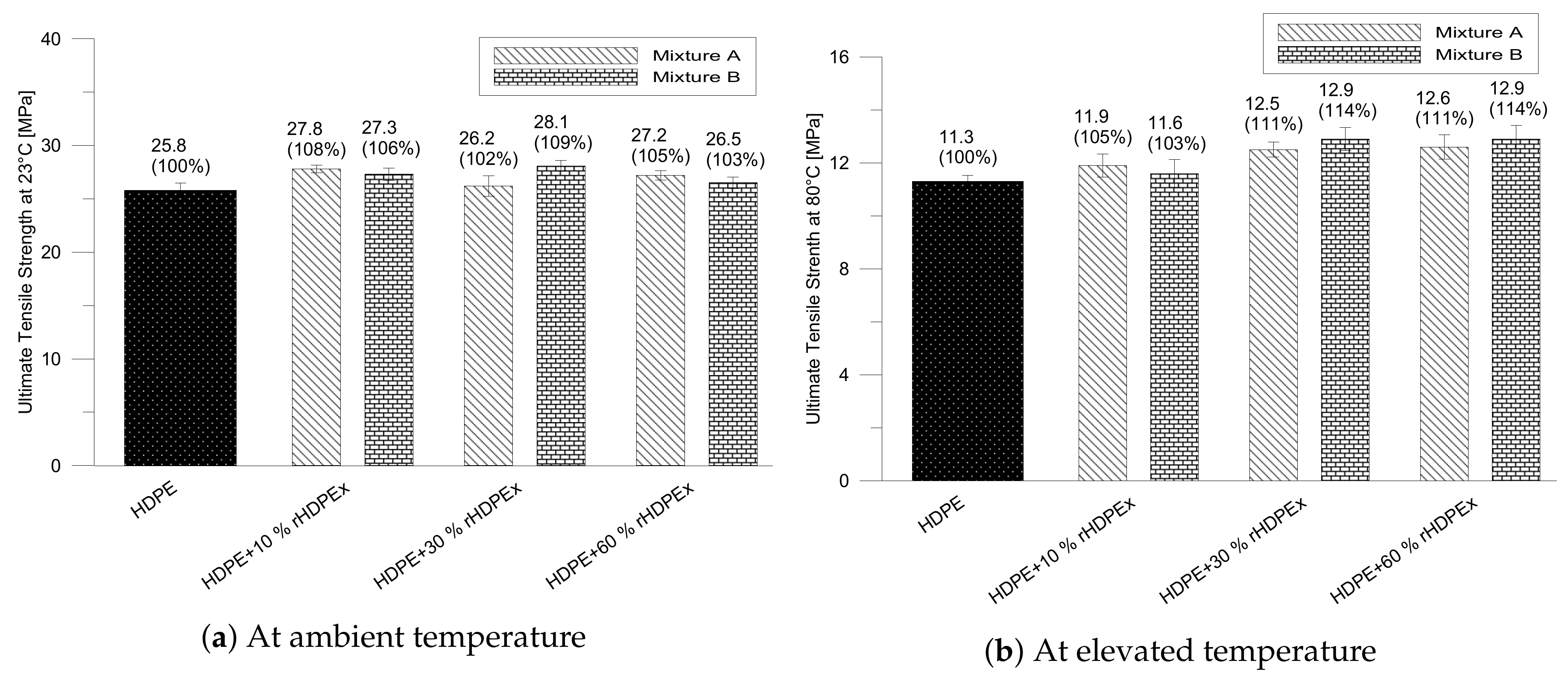

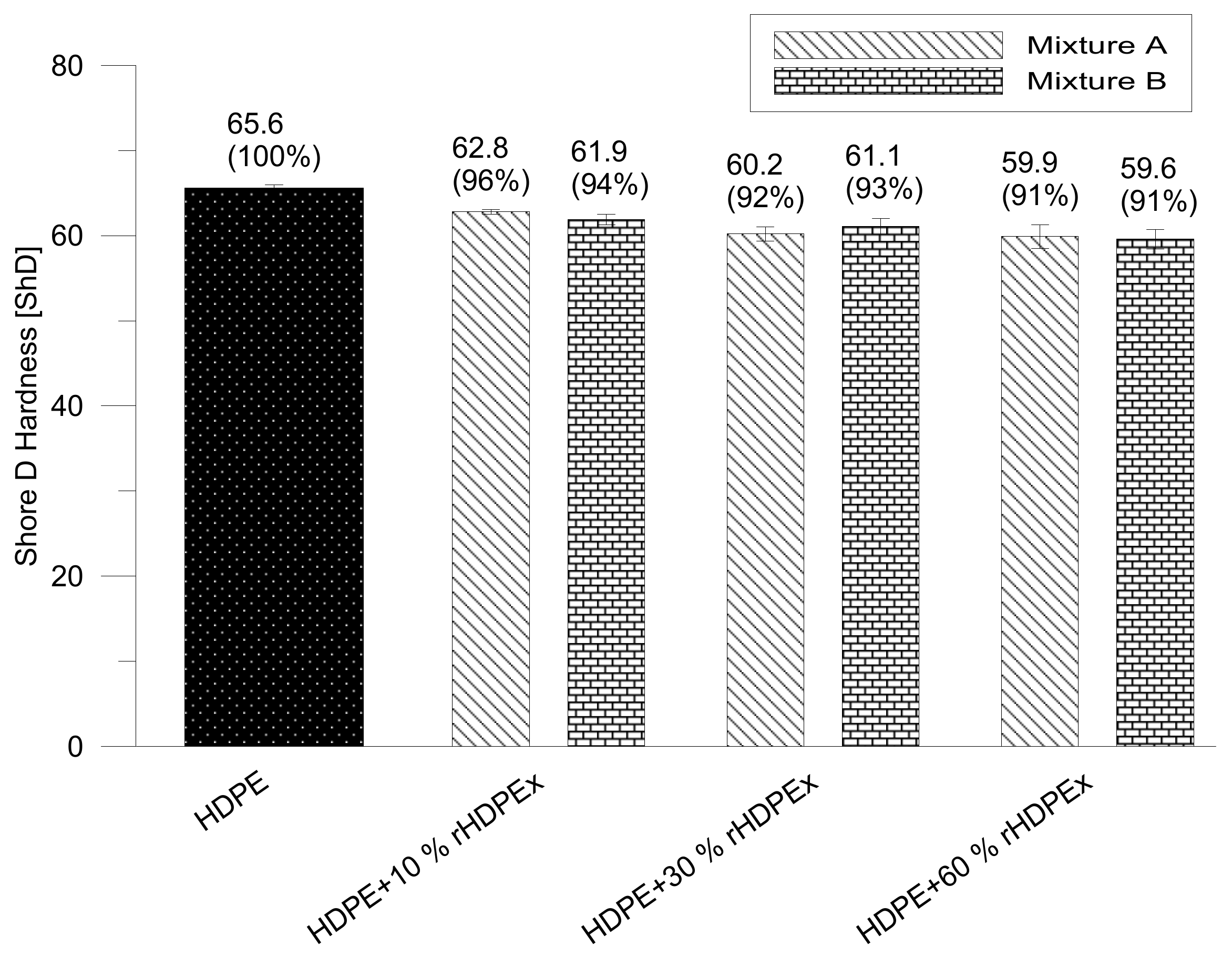

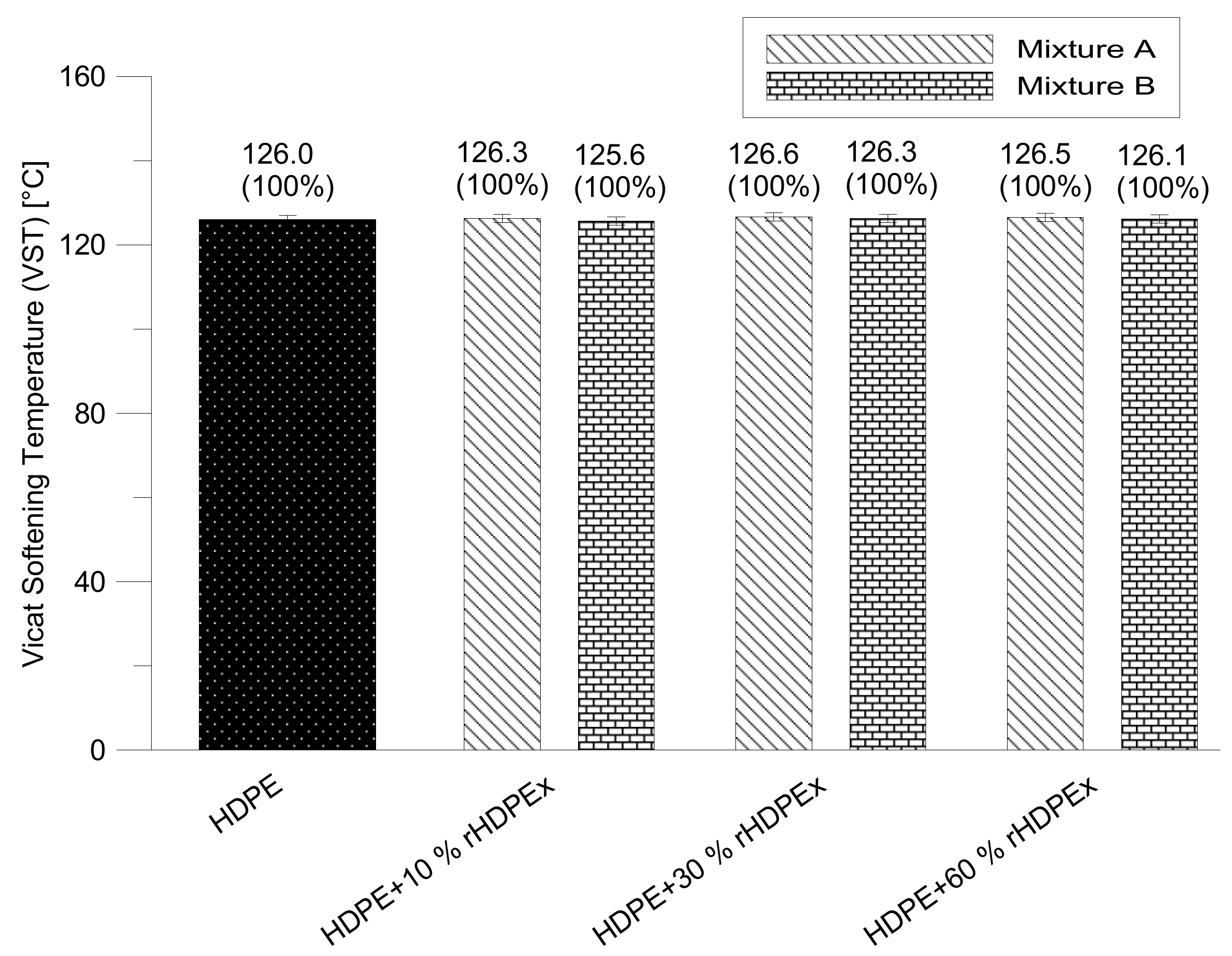

3. Results and Discussion

4. Conclusions

- The measured properties of the new composite change only slightly. The composite properties are superior to those of the virgin HDPE.

- It is possible to use the rHDPEx filler in the form of grit or powder.

- Both mixtures—HDPE with rHDPEx as filler, can be processed by injection-moulding up to a filler content of 60 wt %.

- One can say that a new way of waste-processing from radiation cross-linked polymer (rHDPEx) has been found.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ignatyev, I.A.; Thielemans, W.; Vander Beke, B. Recycling of Polymers: A Review. ChemSusChem 2014, 7, 1579–1593. [Google Scholar] [CrossRef] [PubMed]

- Hubo, S.; Leite, L.; Martins, C.; Ragaert, K. Evaluation of post-industrial and post-consumer polyolefin-based polymer waste streams for injection moulding. In Proceedings of the 6th Polymers & Mould Innovations International Conference, University of Minho, Guimarães, Portugal, 10–12 September 2014; pp. 201–206. [Google Scholar]

- Brandrup, J. Recycling and Recovery of Plastics; Hanser Publishers: Munich, German, 1996. [Google Scholar]

- Ragaert, K.; Delva, L.; Geem, K.V. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Oblak, P.; Gonzalez-Gutierrez, J.; Zupančič, B.; Aulova, A.; Emri, I. Processability and mechanical properties of extensively recycled high density polyethylene. Polym. Degrad. Stab. 2015, 114, 133–145. [Google Scholar] [CrossRef]

- Al-Salem, S.; Lettieri, P.; Baeyens, J. Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef] [PubMed]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. Lond. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [PubMed]

- Bajracharya, R.M.; Manalo, A.C.; Karunasena, W.; Lau, K.T. Characterisation of recycled mixed plastic solid wastes: Coupon and full-scale investigation. Waste Manag. 2016, 48, 72–80. [Google Scholar] [CrossRef] [PubMed]

- Díaz, S.; Ortega, Z.; McCourt, M.; Kearns, M.P.; Benítez, A.N. Recycling of polymeric fraction of cable waste by rotational moulding. Waste Manag. 2018, 76, 199–206. [Google Scholar] [CrossRef]

- Stenvall, E.; Tostar, S.; Boldizar, A.; Foreman, M.R.; Möller, K. An analysis of the composition and metal contamination of plastics from waste electrical and electronic equipment (WEEE). Waste Manag. 2013, 33, 915–922. [Google Scholar] [CrossRef]

- Censori, M.; Marca, F.L.; Carvalho, M.T. Separation of plastics: The importance of kinetics knowledge in the evaluation of froth flotation. Waste Manag. 2016, 54, 39–43. [Google Scholar] [CrossRef]

- Arvanitoyannis, I.S.; Bosnea, L.A. Recycling of polymeric materials used for food packaging: Current status and perspectives. Food Rev. Int. 2001, 17, 291–346. [Google Scholar] [CrossRef]

- Rem, P.; Maio, F.D.; Hu, B.; Houzeaux, G.; Baltes, L.; Tierean, M. Magnetic fluid equipment for sorting secondary polyolefins from waste. Environ. Eng. Manag. J. 2013, 12, 951–958. [Google Scholar]

- Baričević, A.; Rukavina, M.J.; Pezer, M.; Štirmer, N. Influence of recycled tire polymer fibers on concrete properties. Cement Concrete Compos. 2018, 91, 29–41. [Google Scholar] [CrossRef]

- Stenvall, E.; Boldizar, A. Mechanical and Thermal Characterization of Melt-Filtered, Blended and Reprocessed Post-Consumer WEEE Thermoplastics. Recycling 2016, 1, 89–100. [Google Scholar] [CrossRef]

- Puig-Arnavat, M.; Bruno, J.C.; Coronas, A. Review and analysis of biomass gasification models. Renew. Sustain. Energy Rev. 2010, 14, 2841–2851. [Google Scholar] [CrossRef]

- Angyal, A.; Miskolczi, N.; Bartha, L. Petrochemical feedstock by thermal cracking of plastic waste. J. Anal. Appl. Pyrolysis 2007, 79, 409–414. [Google Scholar] [CrossRef]

- Kumar, A.; Jones, D.D.; Hanna, M.A. Thermochemical Biomass Gasification: A Review of the Current Status of the Technology. Energies 2009, 2, 556–581. [Google Scholar] [CrossRef]

- Kögel, G. Synthesegas aus Kunststoffabfällen. K Magazin, 3 July 2018; 40–41. [Google Scholar]

- Lubos, P. Schluss mit der Recyclinglüge. K Magazin, 26 June 2018; 10–14. [Google Scholar]

- Emans, T. Immer größere Kapazitäten für PE. K Magazin, 28 June 2018; 20. [Google Scholar]

- Packaging recycling in US rises by 10%. Film and Sheet Extrusion, March 2018; 11.

- Nikolić, M.A.; Gauthier, E.; Colwell, J.M.; Halley, P.; Bottle, S.E.; Laycock, B.; Truss, R. The challenges in lifetime prediction of oxodegradable polyolefin and biodegradable polymer films. Polym. Degrad. Stab. 2017, 145, 102–119. [Google Scholar] [CrossRef]

- Laycock, B.; Nikolić, M.; Colwell, J.M.; Gauthier, E.; Halley, P.; Bottle, S.; George, G. Lifetime prediction of biodegradable polymers. Prog. Polym. Sci. 2017, 71, 144–189. [Google Scholar] [CrossRef]

- Drobny, J.G. 9—Safety and Hygiene. In Ionizing Radiation and Polymers; Drobny, J.G., Ed.; Plastics Design Library, William Andrew Publishing: Norwich, NY, USA, 2013; pp. 237–243. [Google Scholar]

- Rouif, S. Radiation cross-linked polymers: Recent developments and new applications. Nuclear Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2005, 236, 68–72. [Google Scholar] [CrossRef]

- Gehring, J. With radiation crosslinking of engineering plastics into the next millennium. Radiat. Phys. Chem. 2000, 57, 361–365. [Google Scholar] [CrossRef]

- Navratil, J.; Manas, M.; Mizera, A.; Bednarik, M.; Stanek, M.; Danek, M. Recycling of irradiated high-density polyethylene. Radiat. Phys. Chem. 2015, 106, 68–72. [Google Scholar] [CrossRef]

- Burillo, G.; Clough, R.L.; Czvikovszky, T.; Guven, O.; Moel, A.L.; Liu, W.; Singh, A.; Yang, J.; Zaharescu, T. Polymer recycling: Potential application of radiation technology. Radiat. Phys. Chem. 2002, 64, 41–51. [Google Scholar] [CrossRef]

- Adem, E.; Avalos-Borja, M.; Carrillo, D.; Vazquez, M.; Sanchez, E.; Carreon, M.; Burillo, G. Crosslinking of recycled polyethylene by gamma and electron beam irradiation. Radiat. Phys. Chem. 1998, 52, 171–176. [Google Scholar] [CrossRef]

- Navratil, J.; Manas, M.; Stanek, M.; Manas, D.; Bednarik, M.; Mizera, A. Influence of Recycled Irradiated HDPE on Mechanical Behavior of LDPE/Hdpex Blends. Adv. Mater. Res. 2014, 1025, 265–269. [Google Scholar] [CrossRef]

- Tokuda, S.; Horikawa, S.; Negishi, K.; Uesugi, K.; Hirukawa, H. Thermoplasticizing technology for the recycling of crosslinked polyethylene. Furukawa Rev. 2003, 23, 88–93. [Google Scholar]

- Sam Janajreh, I.; Alshrah, M. Remolding of Cross-Linked Polyethylene Cable Waste: Thermal and Mechanical Property Assessment. Int. J. Therm. Environ. Eng. 2013, 5, 191–198. [Google Scholar]

- Qudaih, R.; Janajreh, I.; Vukusic, S. Recycling of Cross-linked Polyethylene Cable Waste via Particulate Infusion. In Advances in Sustainable Manufacturing; Springer: Berlin/Heidelberg, Germany, 2011; pp. 233–239. [Google Scholar]

- Manas, D.; Manas, M.; Mizera, A.; Navratil, J.; Ovsik, M.; Tomanova, K.; Sehnalek, S. Use of Irradiated Polymers after Their Lifetime Period. Polymers 2018, 10, 641. [Google Scholar] [CrossRef]

- Practice for Calibration of Routine Dosimetry Systems for Radiation Processing; International Organization for Standardization: Geneva, Switzerland, 2013.

- Standard Test Method for Determining Gel Content in Crosslinked Ethylene Plastics Using Pressurized Liquid Extraction (Withdrawn 2015); ASTM International: West Conshohocken, PA, USA, 2009.

- Plastics—Determination of Tensile Properties; International Organization for Standardization: Geneva, Switzerland, 2012.

- Stanek, M.; Manas, D.; Manas, M. Stavebnicova Testovaci Vstrikovaci Forma; Uzitny vzor 23338; Urad Prumysloveho Vlastnictvi: Prague, Czech Republic, 2012. [Google Scholar]

- Plastics and Ebonite—Determination of Indentation Hardness by Means of a Durometer (Shore Hardness); International Organization for Standardization: Geneva, Switzerland, 2003.

- Plastics—Thermoplastic Materials—Determination of Vicat Softening Temperature; International Organization for Standardization: Geneva, Switzerland, 2013.

| ARBURG ALLROUNDER 470H | ||

| Injection Velocity | 60 | mm s |

| Injection Pressure | 80 (100 ) | MPa |

| Cooling Time | 20 | s |

| Mould Temperature | 40 | C |

| Holding Time | 25 | s |

| Holding Pressure | 60 (85 ) | MPa |

| Temperature of Plasticizing Unit Zones | ||

| Temperature under the Hopper | 60 | C |

| Temperature Zone 1 | 200 | C |

| Temperature Zone 2 | 215 | C |

| Temperature Zone 3 | 220 | C |

| Temperature Zone 4 | 235 | C |

| Temperature Zone 5 | 250 | C |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manas, D.; Manas, M.; Mizera, A.; Stoklasek, P.; Navratil, J.; Sehnalek, S.; Drabek, P. The High Density Polyethylene Composite with Recycled Radiation Cross-Linked Filler of rHDPEx. Polymers 2018, 10, 1361. https://doi.org/10.3390/polym10121361

Manas D, Manas M, Mizera A, Stoklasek P, Navratil J, Sehnalek S, Drabek P. The High Density Polyethylene Composite with Recycled Radiation Cross-Linked Filler of rHDPEx. Polymers. 2018; 10(12):1361. https://doi.org/10.3390/polym10121361

Chicago/Turabian StyleManas, David, Miroslav Manas, Ales Mizera, Pavel Stoklasek, Jan Navratil, Stanislav Sehnalek, and Pavel Drabek. 2018. "The High Density Polyethylene Composite with Recycled Radiation Cross-Linked Filler of rHDPEx" Polymers 10, no. 12: 1361. https://doi.org/10.3390/polym10121361

APA StyleManas, D., Manas, M., Mizera, A., Stoklasek, P., Navratil, J., Sehnalek, S., & Drabek, P. (2018). The High Density Polyethylene Composite with Recycled Radiation Cross-Linked Filler of rHDPEx. Polymers, 10(12), 1361. https://doi.org/10.3390/polym10121361