4.1. Investigation of the Properties of PDLCsNBA107

The PDLCs

NBA107 was studied by investigating the transmission versus applied voltage (T-V) curves of the PDLCs

NBA107 with five different ratios of LCs (E7) and polymer (NBA107).

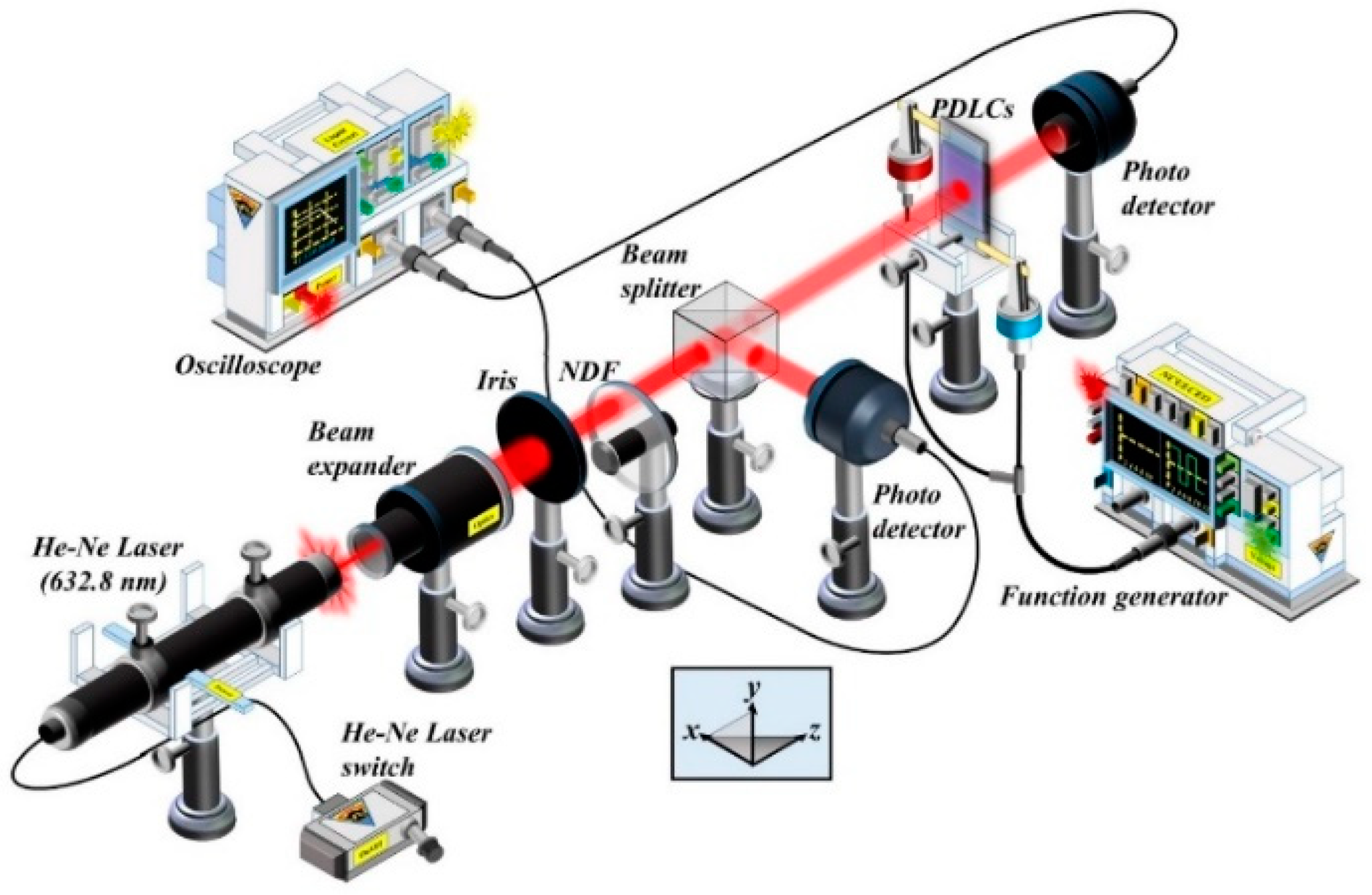

Figure 3 shows the experimental setup for the measurement of the T-V curves. The PDLCs

NBA107 cells (without any surface alignment treatment onto the substrates) with five different ratios of LCs to polymers were fabricated using PIPS through UV illumination with a UV intensity of 1.0 mW/cm

2 for 60 min. The reason for selecting this particular UV intensity and illumination duration for fabrication processes will be discussed later. In

Figure 3, the probe beam from a He–Ne laser was expanded by using a beam expander, and then passed through an iris. The intensity was reduced using a neutral density filter (NDF). The light was split into two beams by using a beam-splitter cube. One beam was used to measure the transmission of the PDLCs

NBA107 cell, whereas the other beam was used to detect the intensity stability of the probed He–Ne laser. The distance between the photo-detector and the PDLC cell for all T-V curve measurements was set at around 30 cm for the baseline, and the collection angle of the scattering was about 0.8°.

The red, green, blue, orange, and black curves shown in

Figure 4 present the T-V curves of the PDLCs

NBA107 with different weight ratios (E7:NBA107) of 9:1, 8:2, 7:3, 6:4, and 5:5, respectively. The experimental results of the transmissions shown in

Figure 4 are based on the experimental setup shown in

Figure 3. The PDLCs

NBA107 cells were fabricated using the UV PIPS processes as described previously.

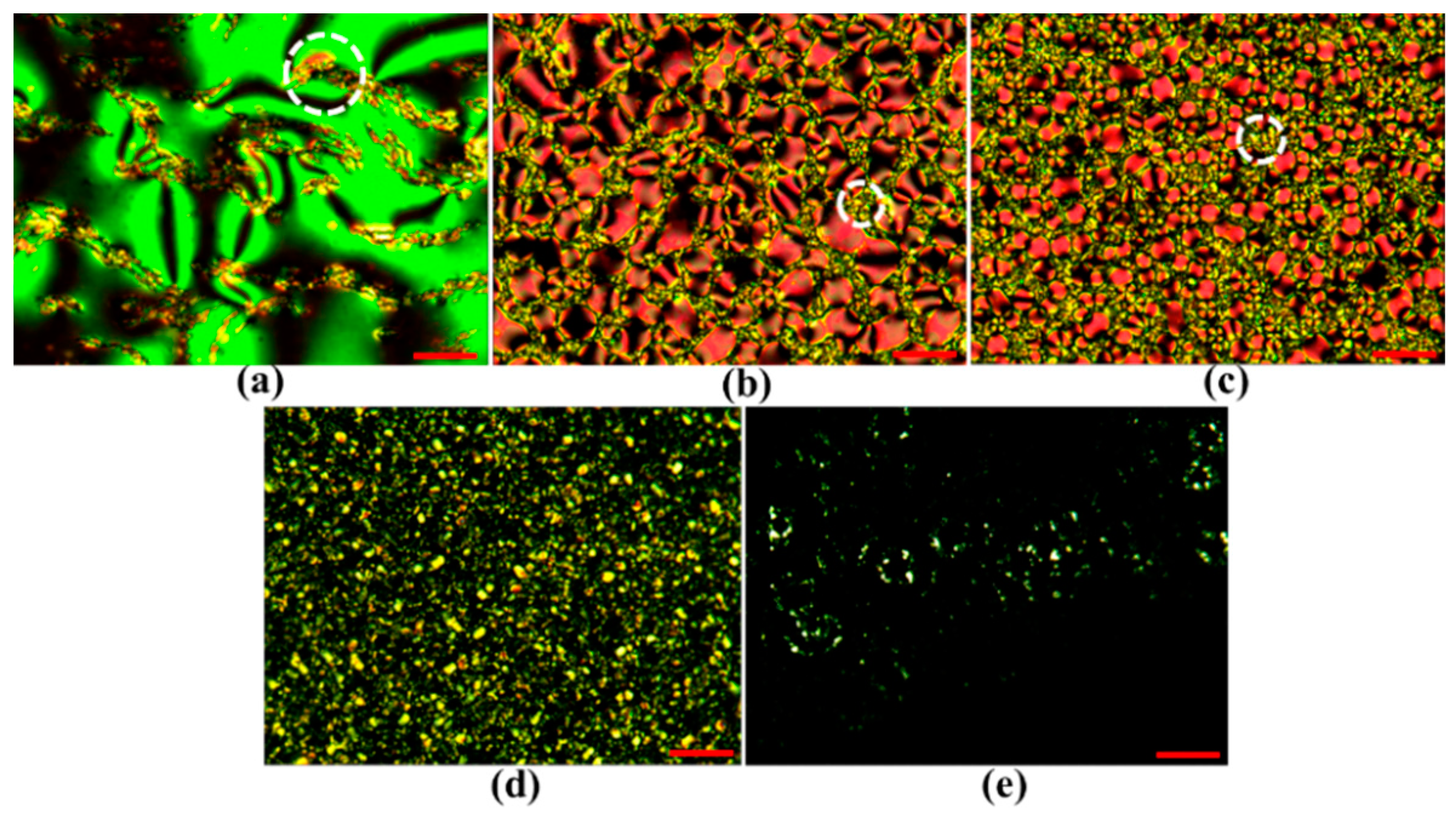

Figure 5a–e present the microscopic images of the PDLCs

NBA107 with different weight ratios (E7:NBA107) of 9:1, 8:2, 7:3, 6:4, and 5:5, respectively, observed under a cross-polarized optical microscope (cross-POM). The cell thickness of the PDLCs

NBA107 shown in

Figure 4 and

Figure 5 was 7 μm.

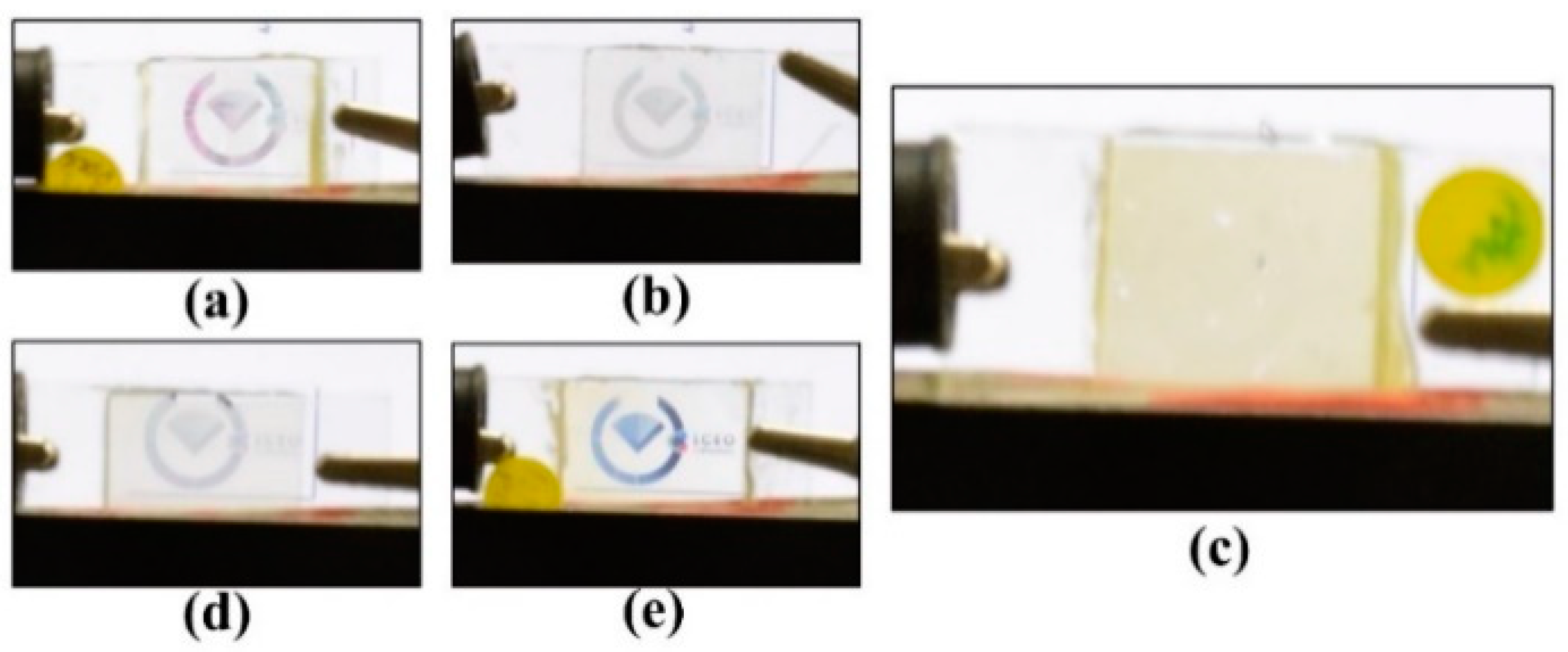

Figure 6a–e show the observations of these PDLCs

NBA107 cells with different ratios (E7:NBA107) of 9:1, 8:2, 7:3, 6:4, and 5:5 without any applied voltage, corresponding to the initial transmissions of the red, green, blue, orange, and black curves shown in

Figure 4, respectively. The detailed discussion will be provided in the next paragraph.

In

Figure 5a, the concentration of the mixed monomer, NBA107, was too low to generate suitable LC droplets and a continuous polymer matrix to achieve good light-scattering for the case of [9:1]-PDLCs

NBA107. The figure indicates that most parts of the LC cell contained LCs with various orientations. The small, polymer-rich areas (white circle in

Figure 5a), which were randomly distributed, were formed through the aggregation of polymers during PIPS to cause light scattering [

1]. The red curve in

Figure 4 shows that the slight light loss/scattering of 13% (82% to 69%) was caused by the small polymer-rich areas and the large LC domains. For further discussion, the relatively small LC droplets in polymer-rich areas are called LC-droplets

PRA. Some of the sizes of the LC-droplets

PRA were believed to be within the regime (~0.2–10 μm) to cause visible light scattering.

With the increase in polymer (NBA107) concentration,

Figure 5b,c clearly show that the LC droplets with different sizes were generated via PIPS for the cases of [8:2]-PDLCs

NBA107 and [7:3]-PDLCs

NBA107, respectively. Generally, the LC droplets in these two cases were relatively much larger than the LC-droplets

PRA (white circles in

Figure 5b,c), and thus, the large LC droplets were called LC-droplets

L to distinguish them from the LC-droplets

PRA.

Figure 7a,b show the scanning electron microscope (SEM) images of the [7:3]-PDLCs

NBA107 with magnifications of 500× and 2000×, respectively. The large, circle-like area and relatively small black area indicate the size/shape of the LC-droplets

L and LC-droplets

PRA, respectively.

Figure 7a,b show that the size of the LC-droplets

PRA is approximately within 0.2–10 μm. Clearly, the size of the LC droplets shown in

Figure 5b is larger than that shown in

Figure 5c because the polymer concentration of the former was lower than that of the latter. However, the sizes of the LC-droplets

L shown in

Figure 5b,c were both larger than the thicknesses of the LC cell (7 μm). This result indicates that the shapes of the LC-droplets

L in [8:2]-PDLCs

NBA107 and [7:3]-PDLCs

NBA107 were not sphere-like, but rather cylindrical. The formation of the LC-droplets

L grew from one substrate to the other during PIPS processes, and thus, the incident light passed through the LC-droplets

L areas with only slight light-scattering. Based on

Figure 5 and

Figure 7, the sizes of most of the LC-droplets

PRA of the [8:2]-PDLCs

NBA107 and [7:3]-PDLCs

NBA107, marked as white circles in

Figure 5b,c, which are approximately in the order of 0.2–10 μm, were capable of causing visible light-scattering. Overall, as the transparent LC-droplets

L areas and scattering polymer-rich area in [8:2]-PDLCs

NBA107 are larger and smaller than those in [7:3]-PDLCs

NBA107, respectively, the initial transmission of the former (green curve in

Figure 4) is higher than that of the latter (blue curve in

Figure 4).

By increasing the polymer (NBA107) concentration further, we deduced that the sizes of some LC-droplets

PRA of the [6:4]-PDLCs

NBA107 [

Figure 5d] were not in the order of ~0.2–10 μm to cause scattering for visible lights. The polarization directions of the incident lights after passing through the non-scattering polymer-rich areas remained almost unchanged because the phase retardation contributed by the LCs in LC-droplets

PRA was limited and were absorbed by the analyzer of the cross-POM. Accordingly, some small black domains, shown in

Figure 5d, can be observed. The sizes of some LC-droplets

L (light-yellow areas in

Figure 5d) are larger than 7 μm, thereby allowing the incident lights to pass through the LC-droplets

L areas with slight light scattering. Some LC-droplets

PRA/LC-droplets

L with sizes in the order of 0.2–10 μm were the main reason to cause the scattering of visible lights. Overall, the initial transmission of the [6:4]-PDLCs

NBA107 (orange curve in

Figure 4) is higher than that of the [7:3]-PDLCs

NBA107 (blue curve in

Figure 4) because some lights can pass through the [6:4]-PDLCs

NBA107 with non-scattering polymer-rich areas and some LC-droplets

L areas, whose sizes are larger than 7 μm.

With an increasingly high polymer (NBA107) concentration, the sizes of most LC-droplets

PRA in [5:5]-PDLCs

NBA107 were considered smaller than 0.2 μm, which did not cause scattering of visible lights. The polarization directions of the incident lights after passing through the non-scattering polymer-rich areas remained almost unchanged. Hence,

Figure 5e shows the observations of an almost black state under cross-POM because most incident lights were absorbed by the analyzer. The LC-droplets

L (light-yellow areas in

Figure 5e) with a few micrometers in size can be observed under cross-POM. However, LC-droplets with their size smaller than several hundreds of nanometers were not clearly observed because their sizes were beyond the microscope resolution limit [

30]. Accordingly, the initial transmission of the [5:5]-PDLCs

NBA107 was ~75%, which is close to the transmission (~82%) of an empty cell. The light loss of 7% was mostly caused by the light scattering resulting from the LC-droplets

L areas, the sizes of which were in the order of 0.2–10 μm.

Figure 4 shows that the vibrations of the transmissions of the red, green, and blue T-V curves (black circles) occurred when the applied voltages were not high enough. Based on the green and blue T-V curves in

Figure 4, we infer that the LCs applied with low external fields in the center of each LC-droplets

L/ LC-droplets

PRA started to rotate slightly, because the anchoring strength of the polymer surface was relatively weak there [

1,

2]. A small LC domain formed in the center of each LC droplet, of which the refractive index was different from the surrounding LCs, causing weak light scattering. The cause of the vibration of the red T-V curve in

Figure 4 can be understood as being because the applied field induced reorientations of LCs in the central parts of large LC areas and LC-droplets

PRA, of which the refractive indices were different from the adjacent LCs anchored by the polymer matrix to cause light scattering. Beyond the vibrations, the transmissions shown in these curves, except for the black one in

Figure 4, increase with an increase of applied voltage because LCs gradually rotate to be perpendicular to the substrates through the application of various applied voltages to reduce refractive index mismatch between LCs and polymers. The increase in the transmission of the [5:5]-PDLCs

NBA107 (black curve in

Figure 4) was limited because the light-scattering source, i.e., the LC-droplets

L areas in

Figure 5e, was extremely small. Among the curves in

Figure 4, the optimized ratio of the PDLCs

NBA107 to approach the lowest V

th (<1 V

rms) and the lowest transmission (~9.4%) is 7:3.

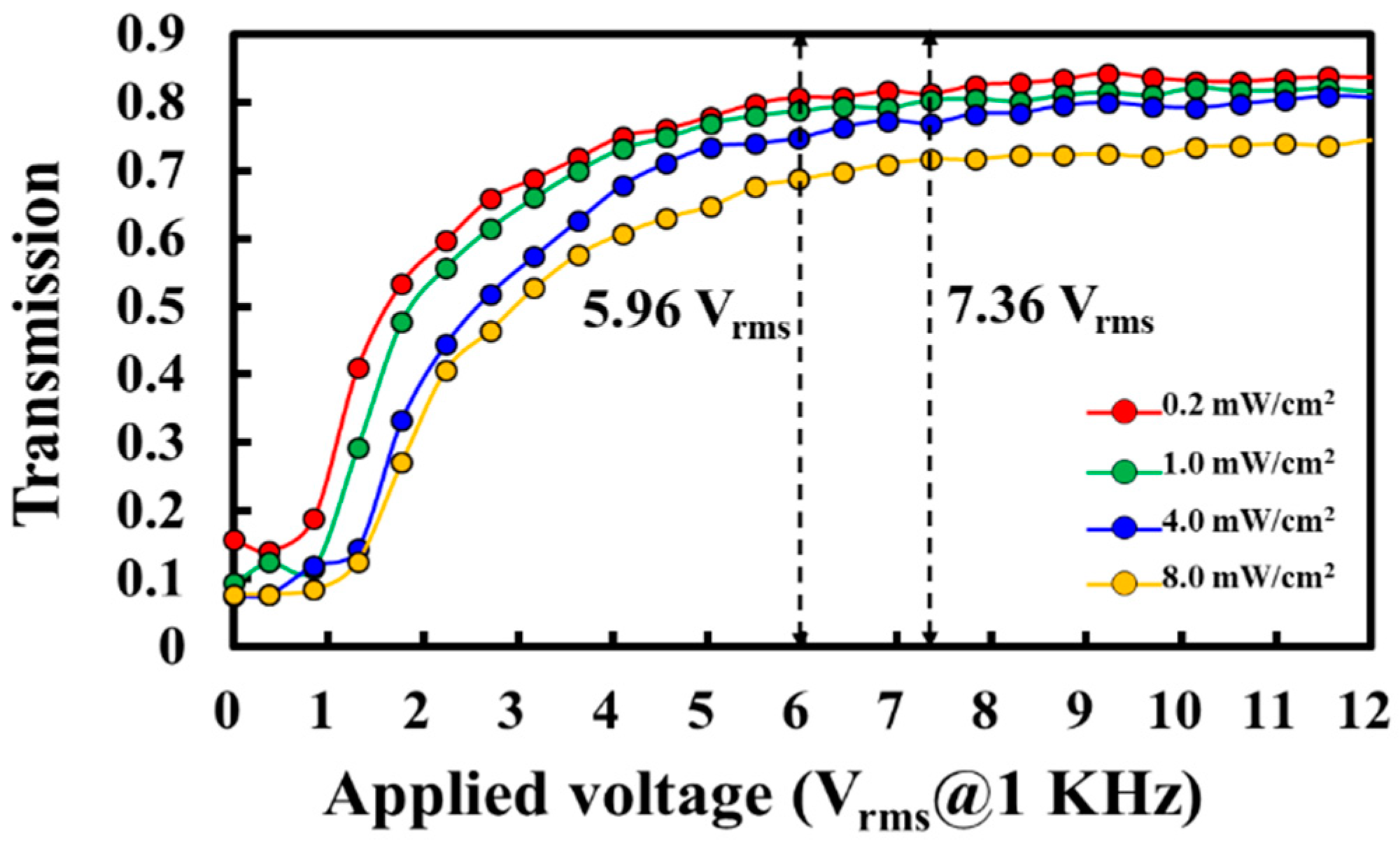

The selected intensity (1.0 mW/cm

2) of UV light for PIPS in the aforementioned experiments was optimized. The red, green, blue, and yellow curves shown in

Figure 8 present the T-V curves of the [7:3]-PDLCs

NBA107 cells fabricated via PIPS through illumination of UV lights with intensities of 0.2, 1.0, 4.0, and 8.0 mW/cm

2, respectively, for 60 min. The cell thickness of the four cells was 7 μm. In accordance with these experimental results,

Table 3 lists the V

th, initial transmission, and saturated transmission of these four [7:3]-PDLCs

NBA107 cells. The values of V

op, defined as the applied voltage to approach the saturated transmission, of the four [7:3]-PDLCs

NBA107 cells shown as the red, green, blue, and orange curves in

Figure 8 are considered to be approximately below 7.36 V

rms. The saturated transmission remains almost invariant when the applied voltage is higher than V

op.

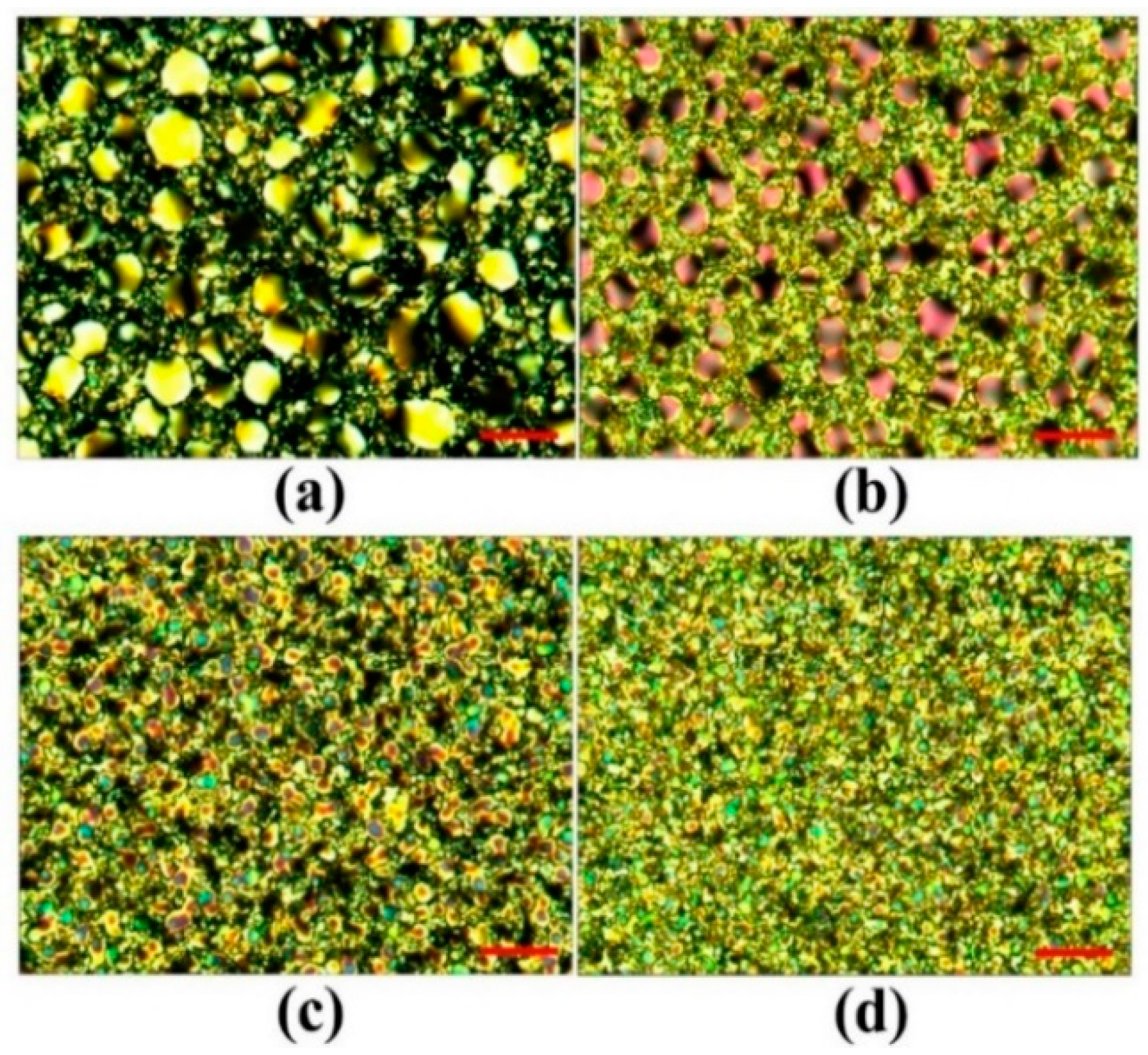

Figure 9a–d show the microscopic images of the abovementioned [7:3]-PDLCs

NBA107 cells fabricated via PIPS with UV intensities of 0.2, 1.0, 4.0, and 8.0 mW/cm

2, respectively, observed under a cross-POM. In

Figure 8, the initial transmission of the [7:3]-PDLCs

NBA107 cells applied with an AC voltage of approximately 7.36 V

rms and the V

th decreased and increased with the increase of UV light intensity, respectively. Based on the images shown in

Figure 9, this result is reasonable because the polymer-rich area (size of LC-droplet

L) increased (decreased) with the increase of UV light intensity [

1,

2]. Moreover, a large (small) LC-droplets

L (polymer-rich area) suggests that less incident lights can be scattered, resulting in an increase in initial transmission.

To approach low V

th, among all curves in

Figure 8, and based on

Table 3, the V

th (<1 V

rms) of the [7:3]-PDLCs

NBA107 of the red and green curves were the lowest. Given that the latter had lower initial transmission than the former, the PIPS of UV illumination with the intensity of 1.0 mW/cm

2 was selected to be the optimized fabrication condition. The V

op (~5.96 V

rms) of the [7:3]-PDLCs

NBA107 of the green curve was relatively low. Moreover, the contrast ratio of [7:3]-PDLCs

NBA107 fabricated following the optimized processes was high enough for real applications, such as electrically switchable windows, light shutters, and e-papers [

1,

2]. Regarding the response time of the optimized [7:3]-PDLCs

NBA107, its rise (decay) time was measured to be about 1.5 (193) ms. Compared with other PDLCs, the cause of such low V

th and relatively long decay time can be understood because the [7:3]-PDLCs

NBA107 possesses relatively weak surface-anchoring [

1,

20,

31,

32,

33]. A method to shorten the decay time in [7:3]-PDLCs

NBA107 will be proposed in

Section 4.2. Generally, PDLCs with weak surface-anchoring possess low V

th, and the relationship between the V

th and LC droplet size of PDLCs with weak surface-anchoring can be described using Equation (1) [

1]:

where

Eth,

Vth,

d,

W,

∆ε, and

D represent the threshold field, threshold voltage, cell thickness (gap), anchoring strength of droplet surface, LC dielectric anisotropy, and droplet size (diameter), respectively.

asurface and

aelectric are constants. Equation (1) represents the fact that the V

th decreases with the increase [decrease] of UV light intensity [LC droplet size,

D] as shown in

Figure 8. To further investigate the surface anchoring conditions of the [7:3]-PDLCs

NBA107 onto the V

th of PDLCs, another famous polymer of Norland Products Inc., NOA65, was selected for comparison with NBA107. We fabricated [7:3]-PDLCs

NBA107, [7:3]-PDLCs

NOA65 and [5:5]-PDLCs

NOA65by using the PIPS of UV illumination (1.0 mW/cm

2) for 60 min. The cell thickness used in the [7:3]-PDLCs

NBA107 and [7:3]-PDLCs

NOA65 cells was 7 μm

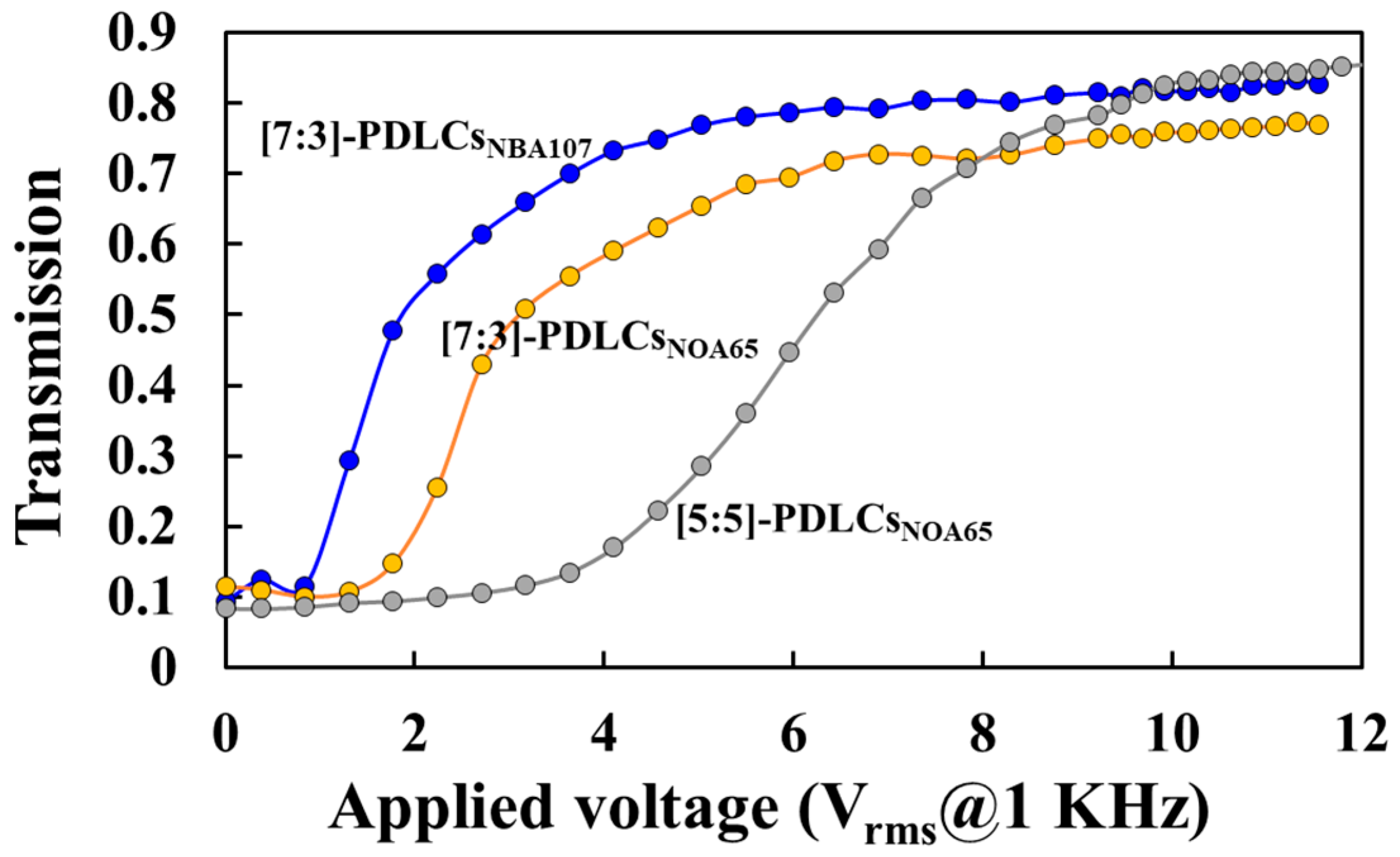

Figure 10 illustrates the measurements of the T-V curves of the [7:3]-PDLCs

NBA107, [7:3]-PDLCs

NOA65 and [5:5]-PDLCs

NOA65. Clearly, the V

th of the [7:3]-PDLCs

NBA107 (blue curve) is the lowest among the three PDLCs. Moreover, the initial transmission of [7:3]-PDLCs

NBA107 (blue curve) is slightly lower than that of the [7:3]-PDLCs

NOA65 (orange curve). Decreasing concentration of NOA65 to increase LC droplet size can further decrease V

th (orange curve), but the initial transmission might increase to decrease the contrast ratio, which can refer to

Figure 4 [

1,

2]. It is well-known that the surface anchoring of NOA65 is weak [

1]. Thus, based on

Figure 10, the surface anchoring of the NBA107 is believed to be weaker than or equal to that of NOA65 [

1,

33]. We deduce that the reason for the weak surface anchoring of the PDLCs

NBA107 could be the low interaction force between LC and polymer molecules [

20].

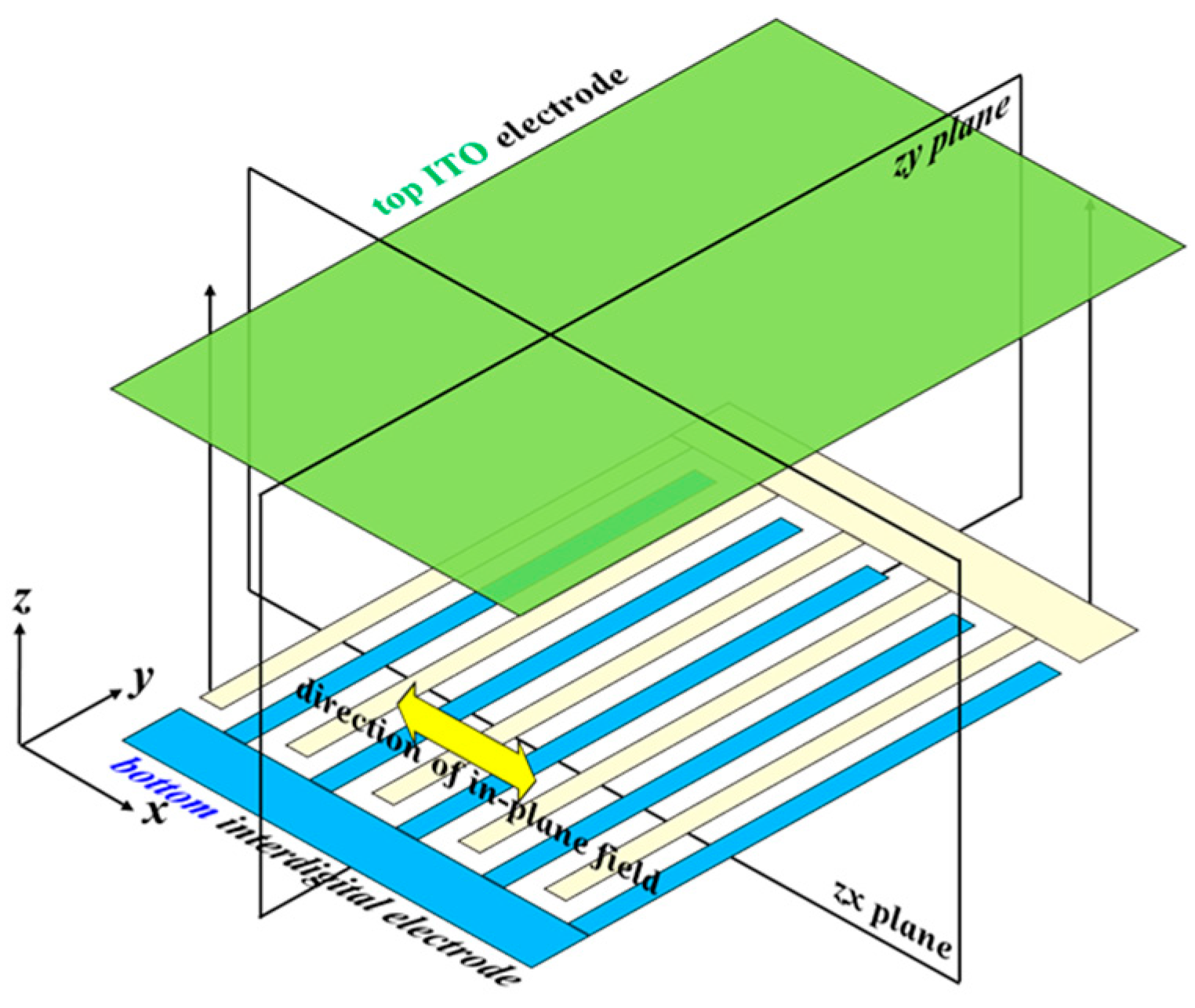

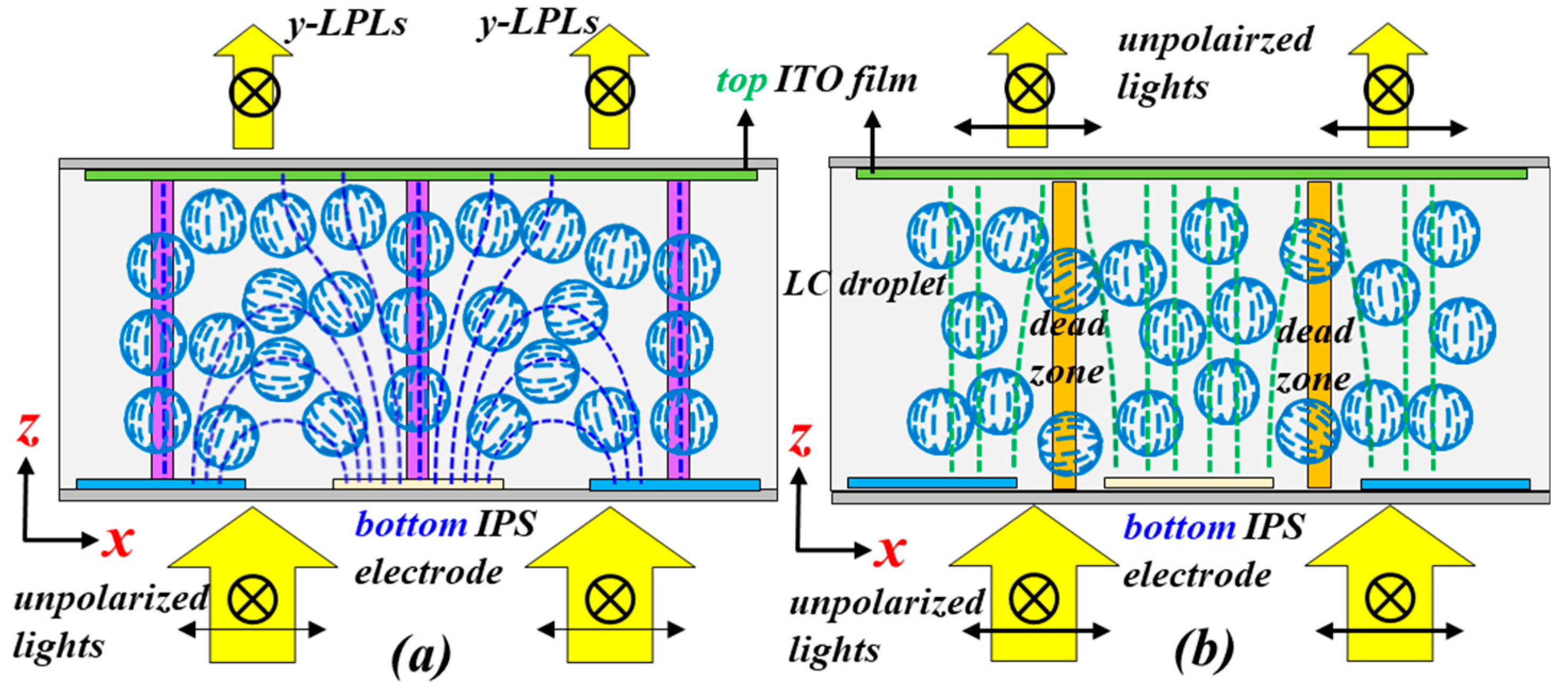

4.2. Electrically Switchable Dual-Polarization Scattering Shutter

The experimental setup for the following experiments was identical with that shown in

Figure 3, except for the addition of the polarizer, which was placed between the NDF and the beam splitter. The measurement of the T-V curve of the PSMLS was achieved by rotating the transmission axis of the polarizer. The PSMLS was fabricated based on [7:3]-PDLCs

NBA107 through PIPS with the optimized fabrication processes (UV light illumination with intensity of 1.0 mW/cm

2 for 60 min). The scattering performances of the PSMLS when various electric potentials were applied onto the blue and light-yellow interdigital electrode stripes (

Figure 2a) are discussed in the following paragraph.

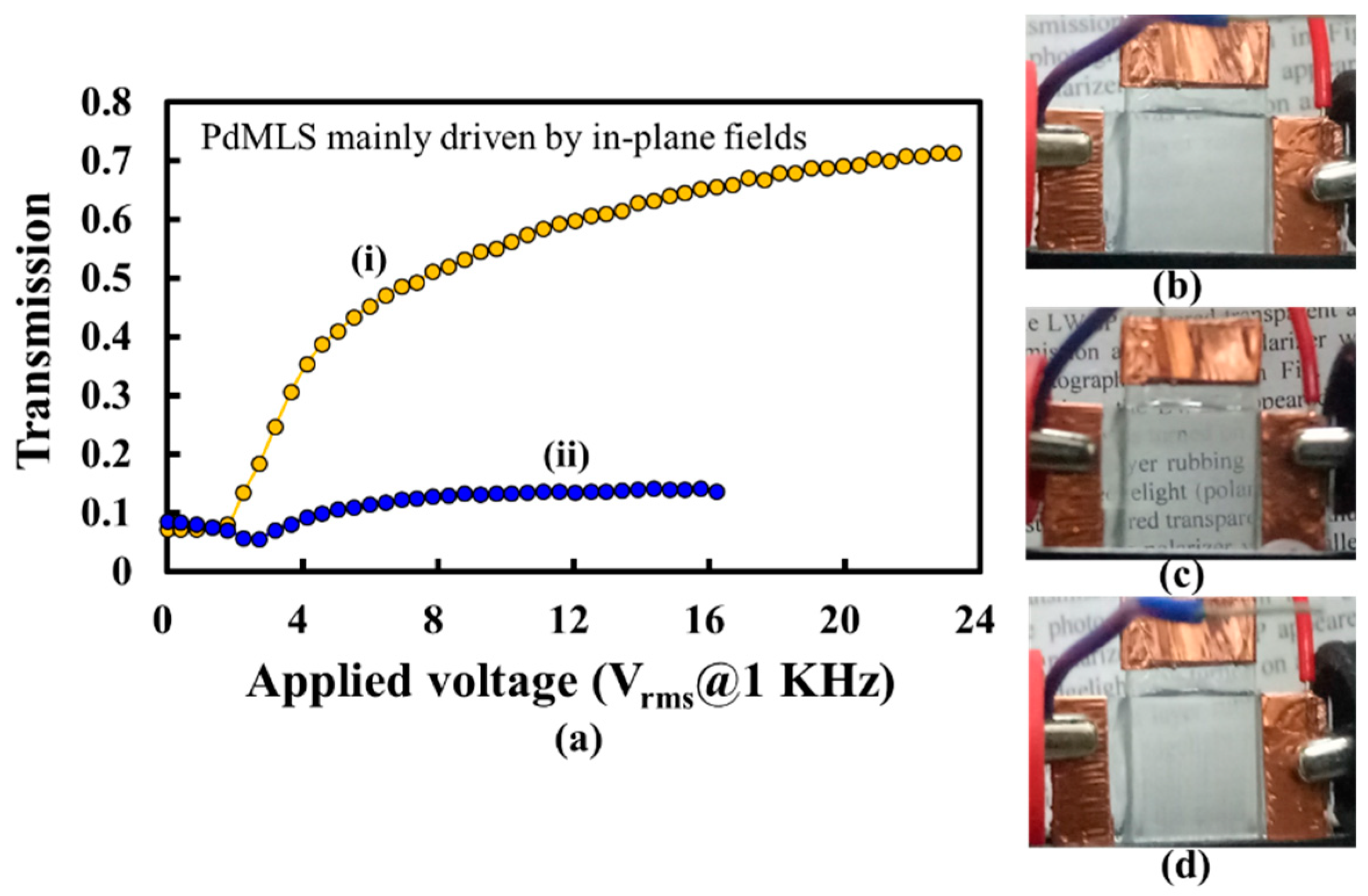

The orange and blue curves in

Figure 11a show the T-V curves of the PSMLS when the polarization directions of the incident lights were parallel and perpendicular to the direction of the interdigital electrode stripes, respectively. The experimental results show that the lights with a polarization direction parallel to the direction of the interdigital electrode stripes can pass through the PSMLS, whereas the lights with a polarization direction perpendicular to the interdigital electrode stripes are scattered. The V

th of the fabricated PSMLS was lower than 2 V

rms because of the use of [7:3]-PDLCs

NBA107, which was fabricated via optimized fabrication processes.

Figure 11b shows the observation of the PSMLS in the initial scattering condition (without any application of an external voltage). A linear polarizer was placed between the PSMLS and camera.

Figure 11c,d shows the experimental results, where the PSMLS was transparent (opaque) when the polarization direction of the incident lights was parallel (perpendicular) to the direction of the interdigital electrode stripes (when applied voltage is 18.5 V

rms). However, based on the orange curve in

Figure 11a, the V

op of the PSMLS was larger than 22 V

rms, which is higher than the original V

op (~5.96 V

rms) shown in

Figure 8. The reason for this low original V

op (

Figure 8) is that the applied field strength onto a common PDLC cell, assembled by using two ITO-coated glass substrates, is uniform across the bulk of the PDLC cell. This result indicates that the LCs in all LC droplets in the bulk of the cell orient at the same time through the application of an external field. By contrast, the applied field strength is reduced gradually from the bottom interdigital electrode to the top substrate in the PSMLS (

Figure 2a). When specific suitable electric potentials are applied onto the blue and light-yellow interdigital electrode stripes (

Figure 2a), the field strength can rotate the LCs with their director projection on the ±

x-axis in LC droplets near the bottom interdigital electrodes (

Figure 2a) to be perpendicular to the direction of the interdigital electrode stripes; however, the field strength near the top substrate is not high enough to rotate the LCs in LC droplets. Hence, the applied voltage must be increased further to rotate the LCs in all LC droplets in the bulk of PSMLS. Moreover, the blue curve (

Figure 11a) shows that the transmission of the PSMLS applied with approximately 16 V

rms for the case of incident lights with the polarization direction perpendicular to the direction of the interdigital electrode stripes was higher than the initial transmission. This result indicates that the scattering strength is stronger when the LCs in LC droplets point to random directions than that when the LCs in LC droplets are rotated to be the configuration of

Figure 2a via the applied voltage (16 V

rms). The cause can be understood because the corresponding refractive index mismatches were different.

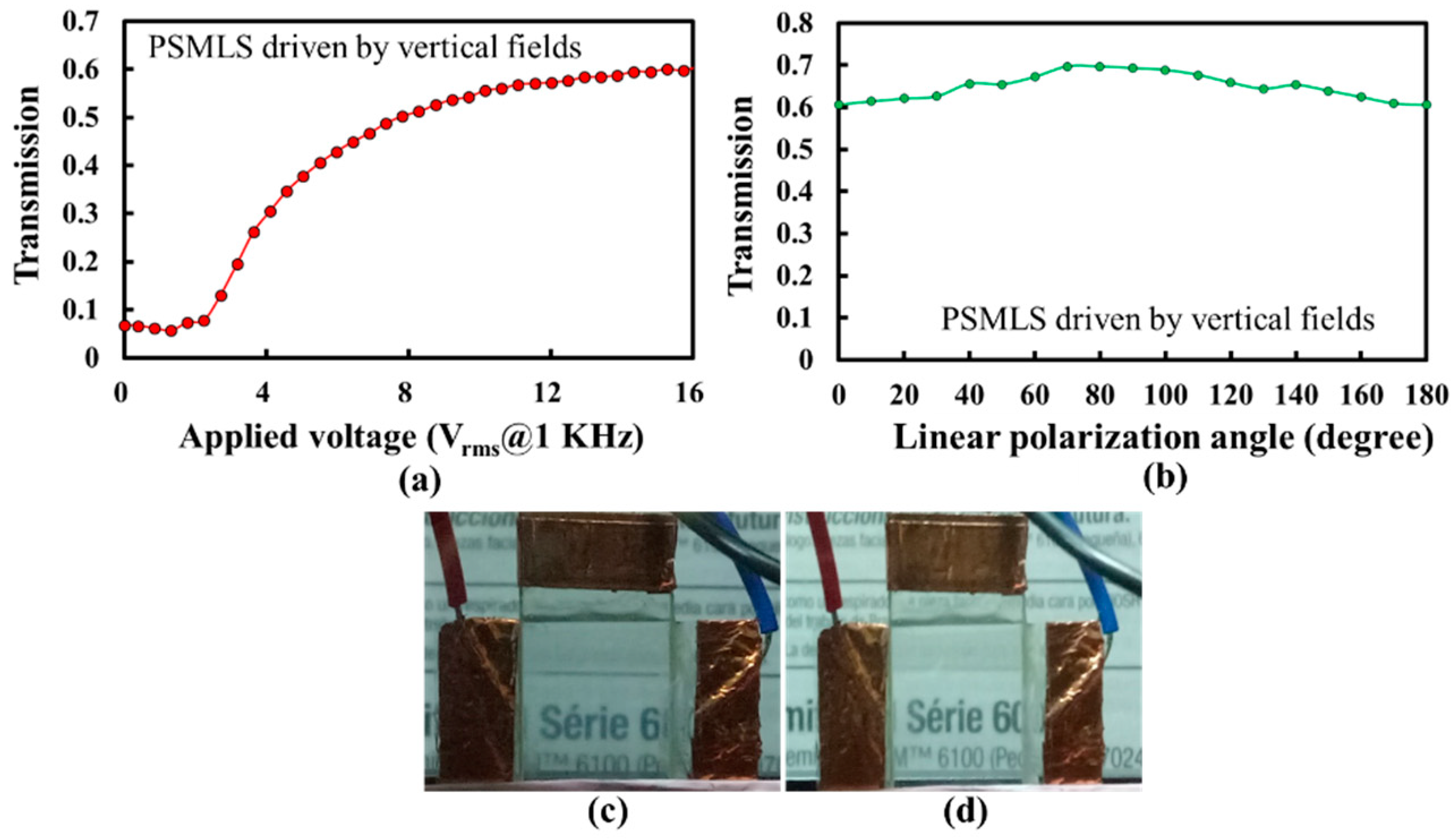

The scattering performances of the PSMLS driven by the applied vertical fields, as shown in

Figure 2b, are discussed in the following paragraph.

Figure 12a shows the T-V curve when the polarization direction of the incident lights is perpendicular to the interdigital electrode stripes. The T-V curve in

Figure 11a should be similar to that in

Figure 8 because both curves were measured from the PDLC cells driven by vertical fields. However, the V

op and V

th shown in

Figure 12a are higher than those shown in

Figure 8 because of the dead zones with slight fringe fields (

Figure 2b) in the PSMLS. The highest transmission in

Figure 12a was also lower than that in

Figure 8, which was elucidated in

Section 2. Briefly, on the basis of

Figure 2b, the fringing electric fields close to the electrode stripe edges were not completely perpendicular to the substrates, so light-scattering occurred there because of a small refractive index mismatch between LCs and polymers to reduce the transmission. A small amount of LCs in LC droplets close to the dead zones (orange region in

Figure 2b), which cannot be electrically oriented, also caused the reduction of transmittance. Moreover, the V

op in

Figure 12a is higher than that in

Figure 8, which is reasonable because a high applied voltage was required to reorient LCs closer to the edges of the electrode stripes. The transmission versus linear polarization angle (LPA) curve of the PSMLS through the application of an applied voltage (~13.9 V

rms) was measured to investigate the polarization sensitivity of the PSMLS driven by vertical fields, as shown in

Figure 12b. The LPA is defined as the angle between the absorption axis of the polarizer and the direction of the interdigital electrode stripes. On the basis of

Figure 2b, when the LPA is 0°/180° (90°), i.e., the incident light with the polarization direction is perpendicular (parallel) to the direction of the interdigital electrode stripe, the incident lights encounter

ne/

neff (

no) of LCs in the LC droplets close to the interdigital electrode stripe edges. As the refractive index of the polymer (NBA107) becomes closer to the

no of nematic LC (E7), the incident lights with the polarization direction perpendicular (parallel) to interdigital electrode stripes encounter a small (~0) refractive index mismatch between polymer and LCs close to the interdigital electrode stripe edges. The incident lights with the polarization direction perpendicular to the interdigital electrode stripes should be slightly scattered. The transmission when the LPA is 0°/180° is slightly lower than that when the LPA is 90°, as shown in

Figure 12b. We infer that the slightly low transmission (LPA of 0°/180°) results from the slight mismatch of refractive indices between the LCs and polymer (NBA107) close to the interdigital electrode stripe edges.

Figure 12c,d show the images of the PSMLS when the LPAs are 0°/180° and 90°, respectively. A linear polarizer for the setup of

Figure 12c,d was placed between the PSMLS and camera. The clarity of the words (background) in

Figure 12c,d is approximately the same.

The [7:3]-PDLCs

NBA107 can realize low V

th and V

op due to its weak surface-anchoring, but the cost is a relatively long decay time (~193 ms). To apply [7:3]-PDLCs

NBA107 for PSMLSs, a method to shorten its decay time is elucidated as follows. Based on the results in

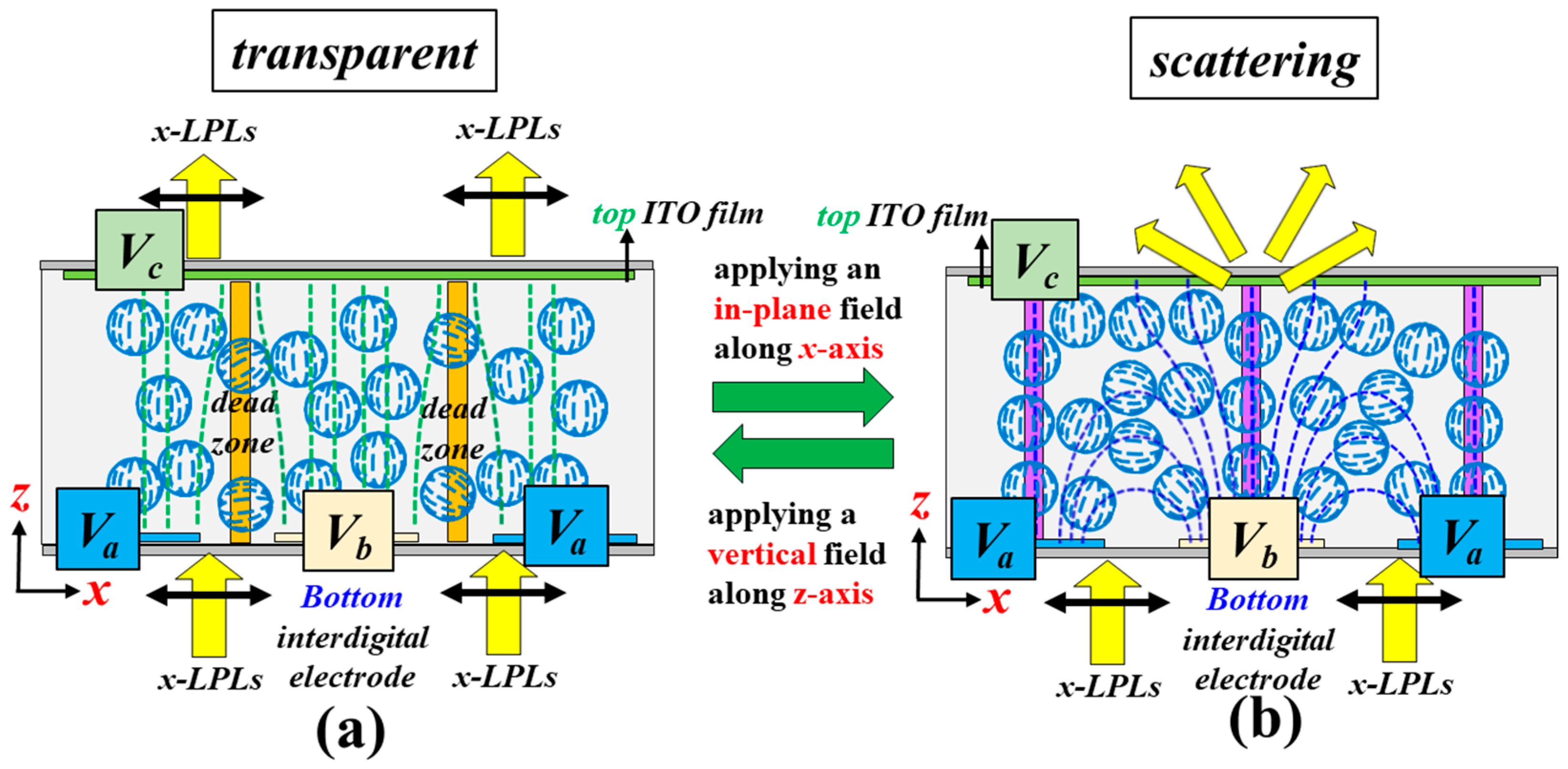

Figure 11c,d, we proposed the method to approach a fast switch between a polarization-selective scattering state and polarization-independent transparent state.

Figure 13a shows that when the PSMLS is applied with a vertical field, the input

x-LPLs can pass through the PSMLS (

Figure 12c). The potentials of V

a, V

b, and V

c to obtain the transparent state, as shown in

Figure 13a, are V

op, V

op, and 0, respectively.

Figure 13b shows that to obtain the light scattering of

x-LPLs (

Figure 11d), the potentials of V

a, V

b, and V

c of the PSMLS are 0, V

op, and open circuit potential (floating), respectively. Because the switch from transparent to scattering states of

x-LPLs in PSMLS is driven by the applied electric fields rather than the weak surface anchoring in each LC droplet, the switch time can be further shortened [

1,

22,

23]. By contrast, the required time of switch from transparent to scattering states in a common PDLC device depends only on surface anchoring in each LC droplet; therefore, its switch time is relatively long [

1,

2]. To simplify the design to approach this method, the interdigital electrode stripes can be replaced by using a configuration consisting of grid electrodes located on top of a common electrode [

22,

23].