Effect of Aging on Chemical and Rheological Properties of Bitumen

Abstract

1. Introduction

2. Experimental Design

2.1. Materials

2.2. Testing Program

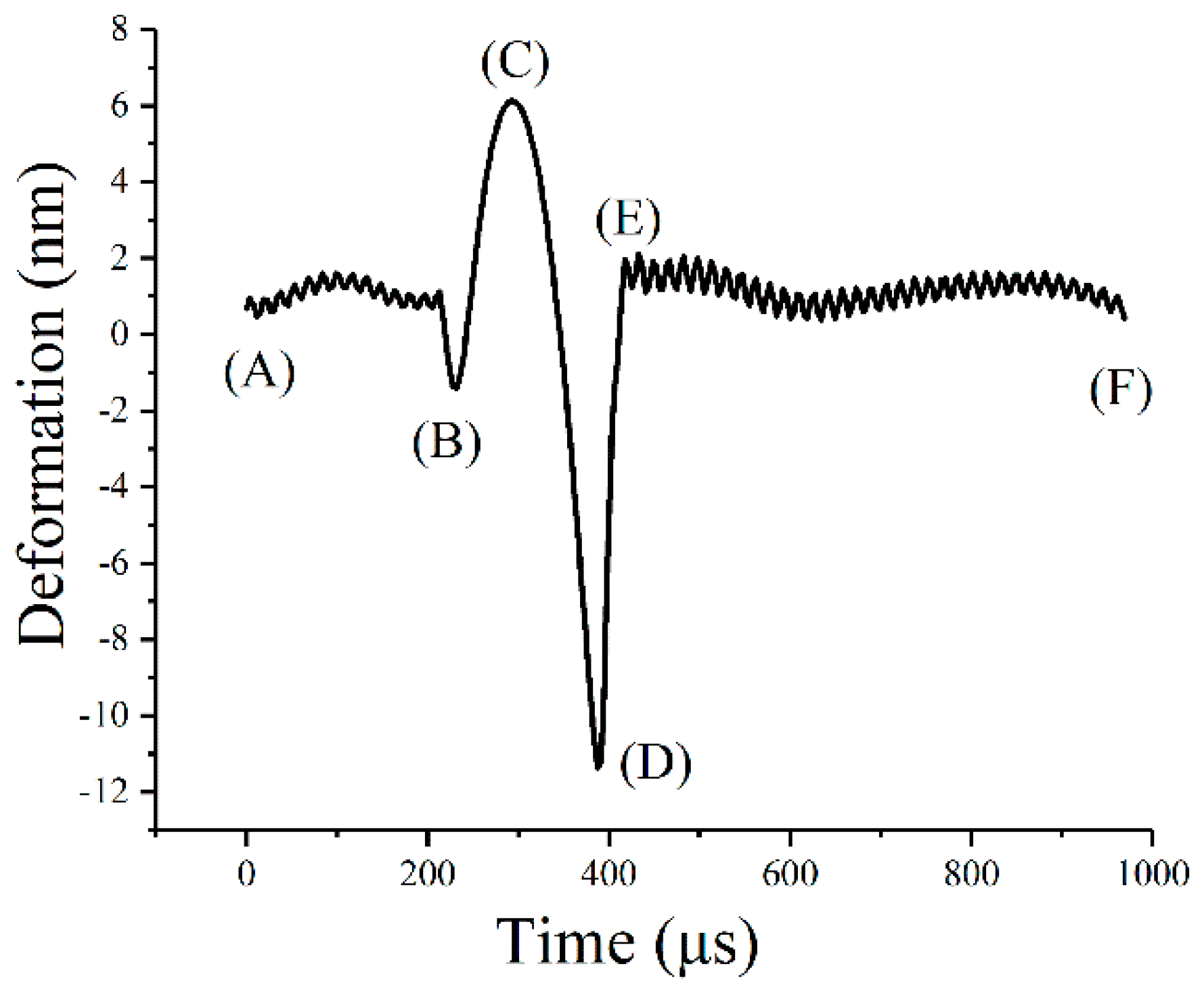

2.2.1. AFM Test

2.2.2. FTIR Test

2.2.3. DSR test

3. Results and Discussion

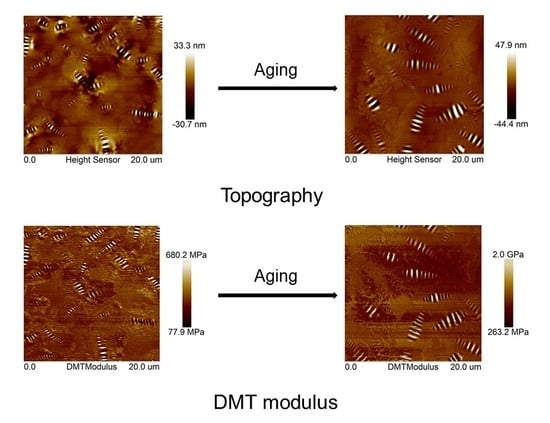

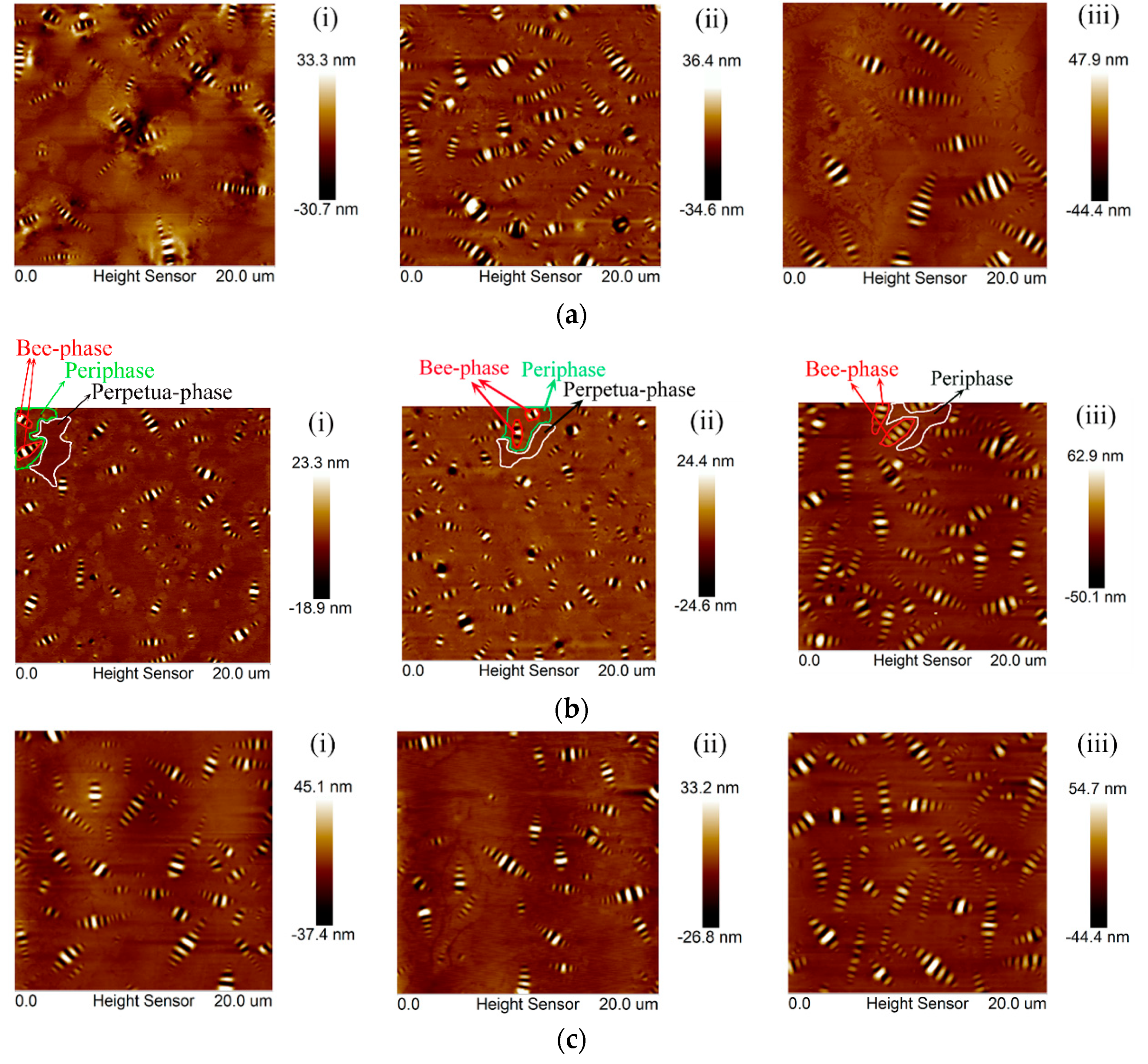

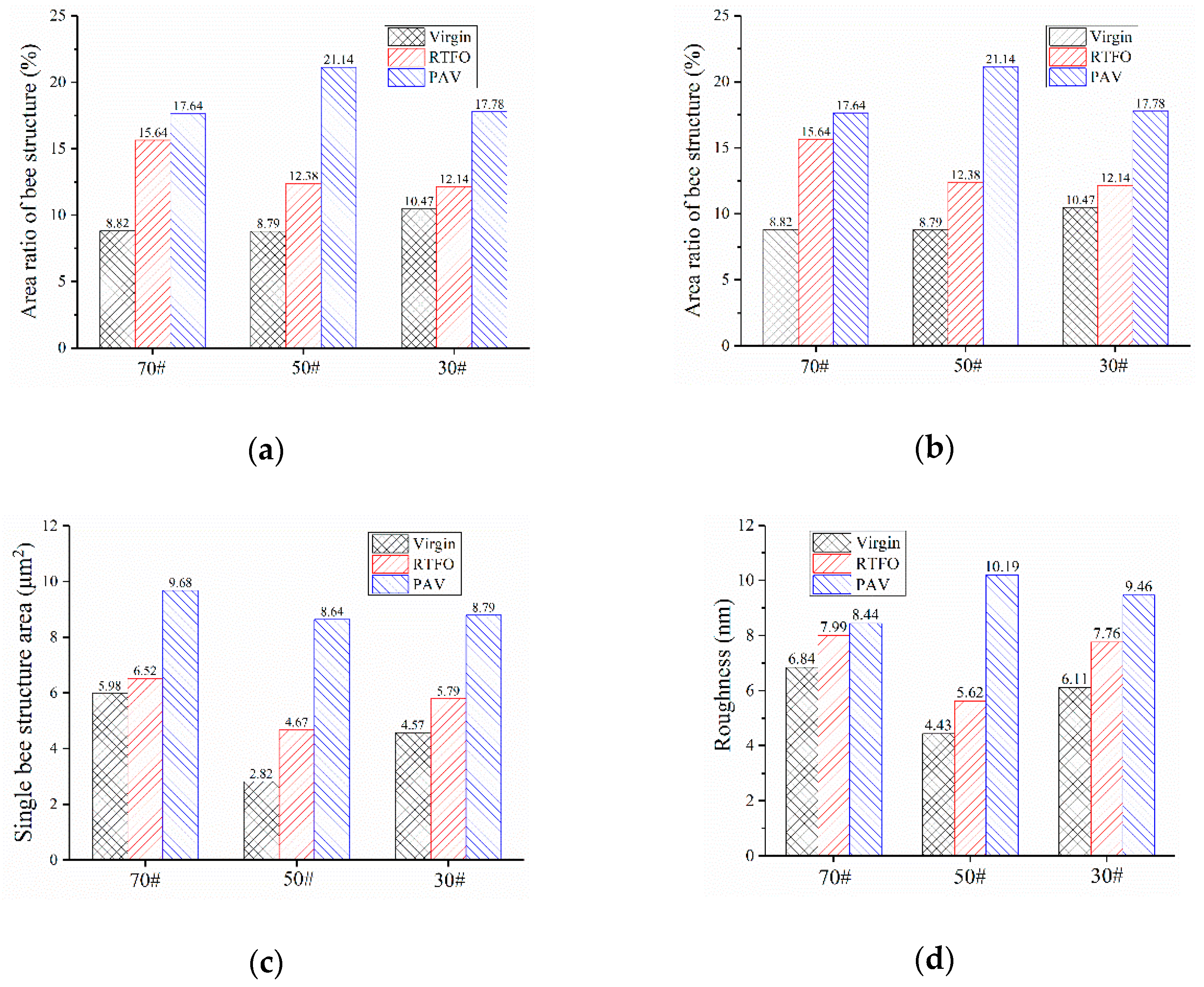

3.1. AFM Morphology Evaluation

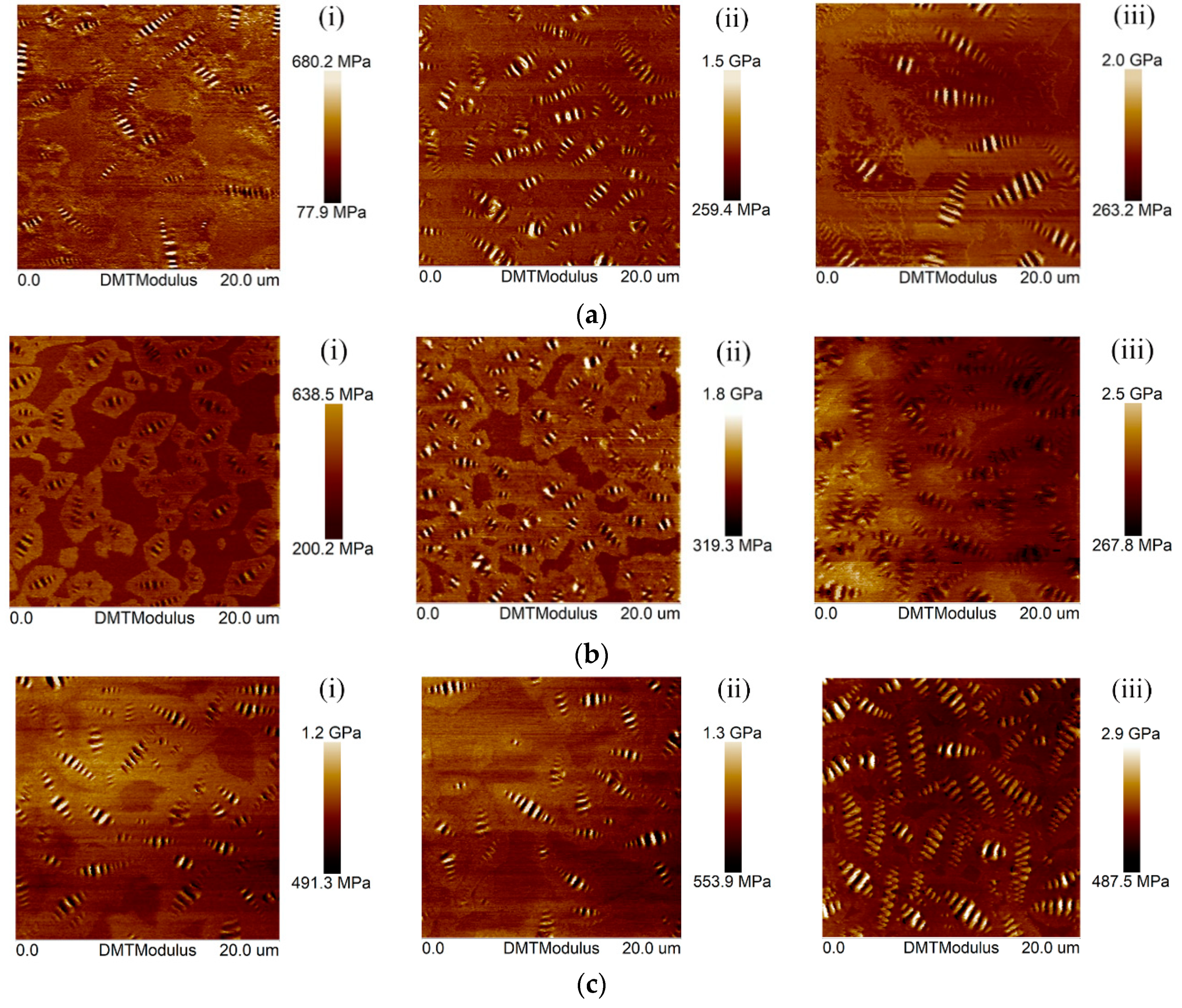

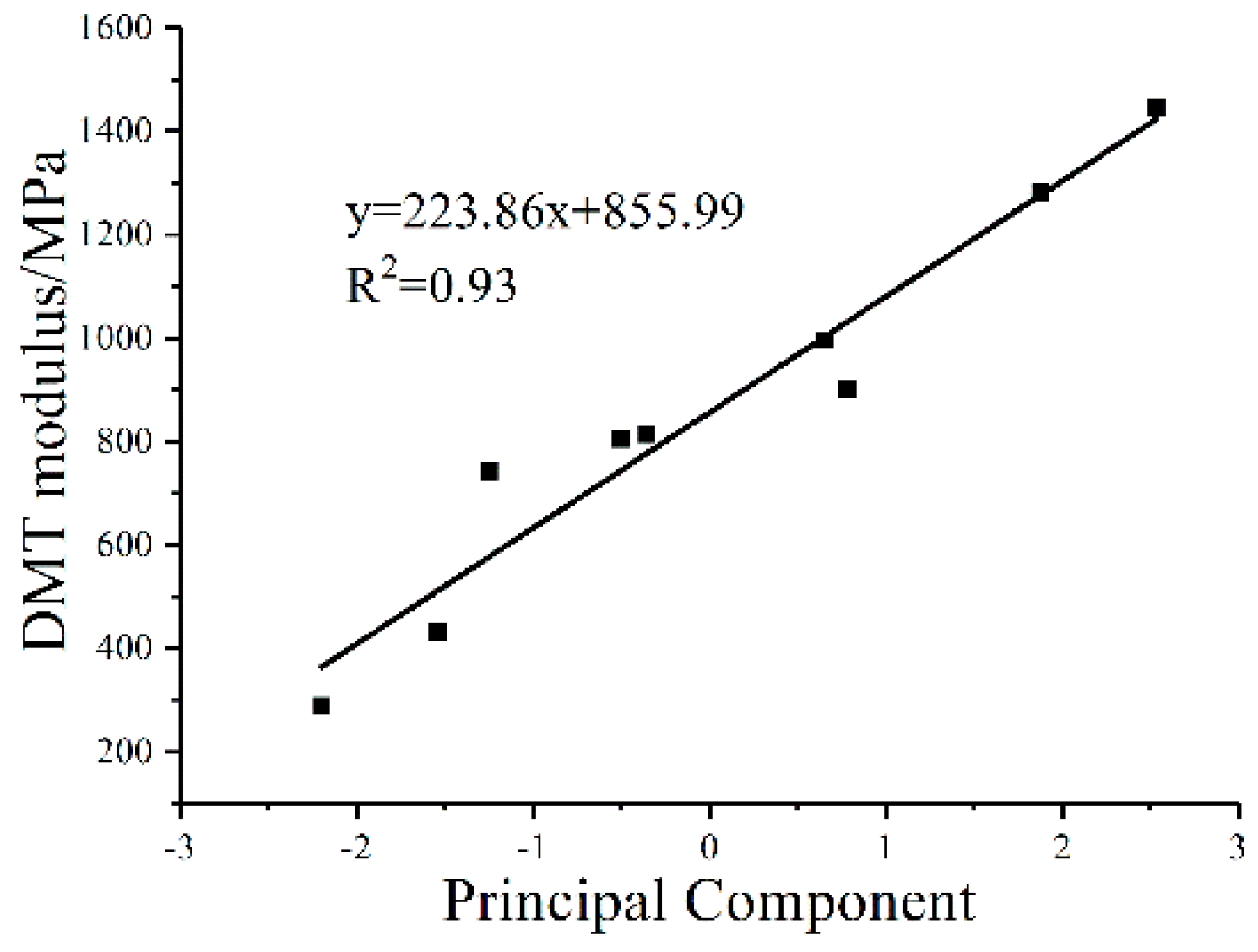

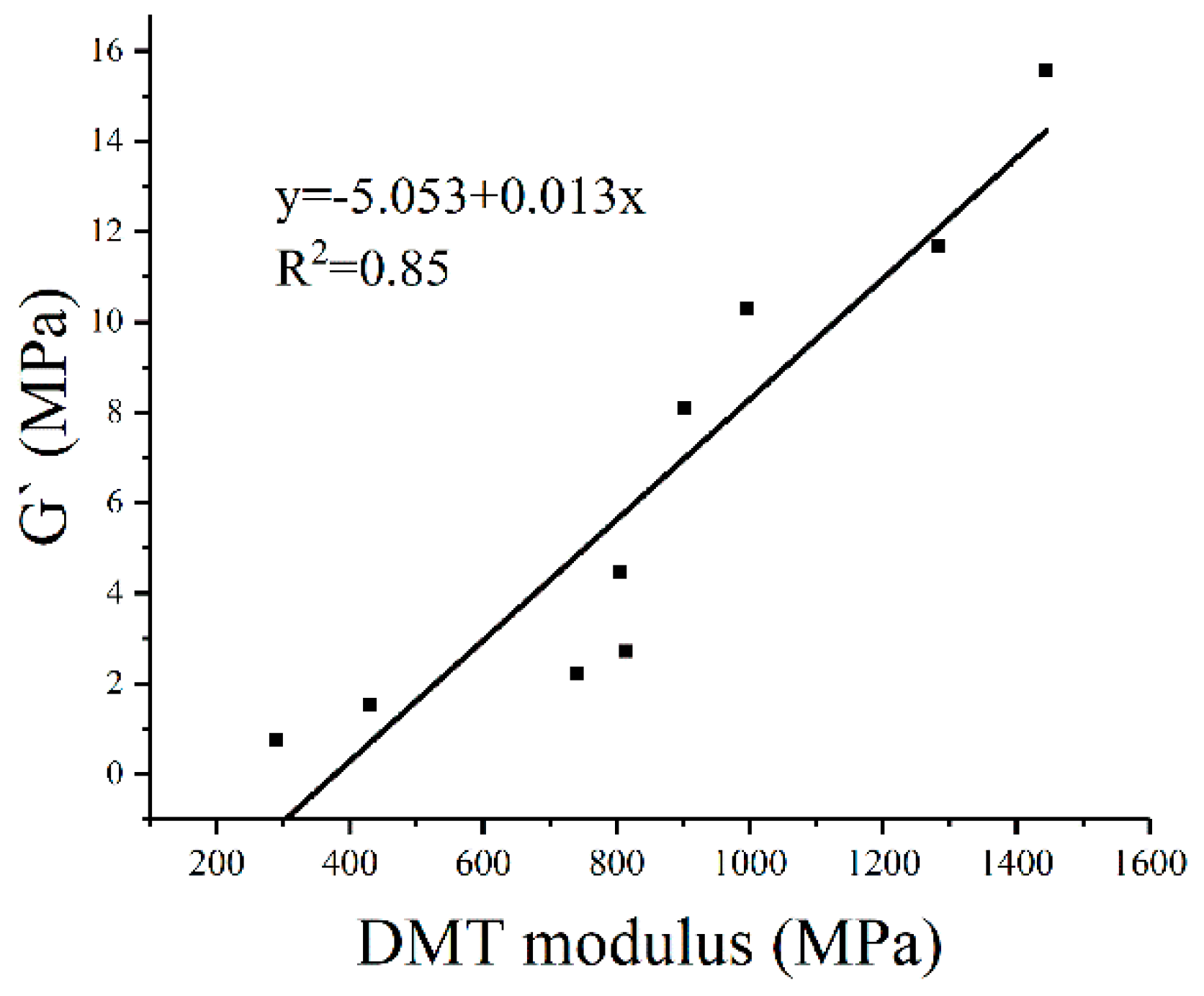

3.2. AFM DMT Analysis

3.3. Fourier Transform Infrared Analysis

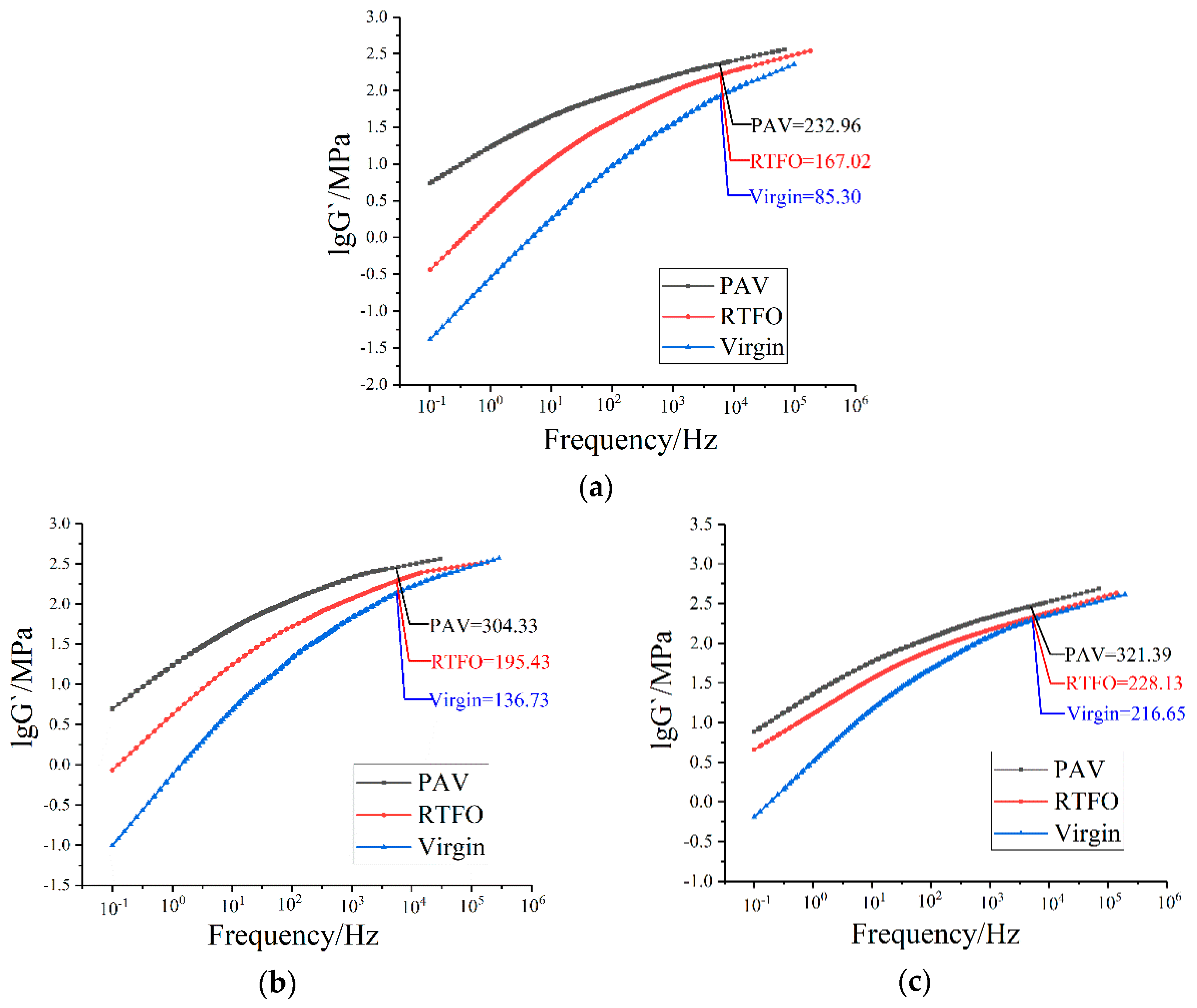

3.4. Dynamic Rheological Characterization

4. Conclusions

- ●

- Consistent to the colloid theory of bitumen, aging results in aggregation of bitumen surface and higher surface roughness.

- ●

- Aging greatly increases the DMT modulus, which results in a hardening of bitumen, making it more prone to stress concentrations when subjected to external forces.

- ●

- Aging leads to increased carbonyl, sulfoxide and aromatic ring indexes. The micro-mechanics of the bitumen surface are influenced by a synergistic effect of the chemical composition.

- ●

- Macro-mechanics is directly influenced by the micro-mechanics, and it is the embodiment of the micro-mechanics at the macro level.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, J.; Yuan, J.; Kim, K.W.; Xiao, F. Chemical, thermal and rheological characteristics of composite polymerized asphalts. Fuel 2018, 227, 289–299. [Google Scholar] [CrossRef]

- Yuan, J.; Wang, J.; Xiao, F.; Amirkhanian, S.; Wang, J.; Xu, Z. Impacts of multiple-polymer components on high temperature performance characteristics of airfield modified binders. Constr. Build. Mater. 2017, 134, 694–702. [Google Scholar] [CrossRef]

- Yu, J.; Yu, X.; Gao, Z.; Guo, F.; Wang, D.; Yu, H. Fatigue Resistance Characterization of Warm Asphalt Rubber by Multiple Approaches. Appl. Sci. 2018, 8, 1495. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, X.; Guo, D.; Wang, F.; Xie, H. The interlaminar shear failure characteristics of asphalt pavement coupled heating cables. Mater. Struct. 2018, 51, 67. [Google Scholar] [CrossRef]

- Zeng, W.; Wu, S.; Wen, J.; Chen, Z. The temperature effects in aging index of asphalt during UV aging process. Constr. Build. Mater. 2015, 93, 1125–1131. [Google Scholar] [CrossRef]

- Banerjee, A.; de Fortier Smit, A.; Prozzi, J.A. The effect of long-term aging on the rheology of warm mix asphalt binders. Fuel 2012, 97, 603–611. [Google Scholar] [CrossRef]

- Huang, B.; Shu, X.; Vukosavljevic, D. Laboratory investigation of cracking resistance of hot-mix asphalt field mixtures containing screened reclaimed asphalt pavement. J. Mater. Civ. Eng. 2010, 23, 1535–1543. [Google Scholar] [CrossRef]

- Yao, H.; You, Z.; Li, L.; Shi, X.; Goh, S.W.; Mills-Beale, J.; Wingard, D. Performance of asphalt binder blended with non-modified and polymer-modified nanoclay. Constr. Build. Mater. 2012, 35, 159–170. [Google Scholar] [CrossRef]

- Shenoy, A. A method to estimate the rheological properties of aged asphalt binders without actually aging them. Road Mater. Pavement Des. 2002, 3, 331–343. [Google Scholar] [CrossRef]

- Edwards, Y.; Tasdemir, Y.; Isacsson, U. Influence of commercial waxes on bitumen aging properties. Energy Fuels 2005, 19, 2519–2525. [Google Scholar] [CrossRef]

- Zhu, C.; Zhang, H.; Xu, G.; Shi, C. Aging rheological characteristics of SBR modified asphalt with multi-dimensional nanomaterials. Constr. Build. Mater. 2017, 151, 388–393. [Google Scholar] [CrossRef]

- Feng, Z.G.; Bian, H.J.; Li, X.J.; Yu, J.Y. FTIR analysis of UV aging on bitumen and its fractions. Mater. Struct. 2016, 49, 1381–1389. [Google Scholar] [CrossRef]

- Yang, X.; You, Z.; Mills-Beale, J. Asphalt binders blended with a high percentage of biobinders: Aging mechanism using FTIR and rheology. J. Mater. Civ. Eng. 2014, 27, 04014157. [Google Scholar] [CrossRef]

- Siddiqui, M.N. NMR finger printing of chemical changes in asphalt fractions on oxidation. Pet. Sci. Technol. 2009, 27, 2033–2045. [Google Scholar] [CrossRef]

- Yu, R.; Zhu, X.; Zhang, M.; Fang, C. Investigation on the Short-Term Aging-Resistance of Thermoplastic Polyurethane-Modified Asphalt Binders. Polymers 2018, 10, 1189. [Google Scholar] [CrossRef]

- Yao, H.; You, Z.; Li, L.; Goh, S.W.; Lee, C.H.; Yap, Y.K.; Shi, X. Rheological properties and chemical analysis of nanoclay and carbon microfiber modified asphalt with Fourier transform infrared spectroscopy. Constr. Build. Mater. 2013, 38, 327–337. [Google Scholar] [CrossRef]

- Xu, S.; Yu, J.; Zhang, C.; Sun, Y. Effect of ultraviolet aging on rheological properties of organic intercalated layered double hydroxides modified asphalt. Constr. Build. Mater. 2015, 75, 421–428. [Google Scholar] [CrossRef]

- Qin, Q.; Schabron, J.F.; Boysen, R.B.; Farrar, M.J. Field aging effect on chemistry and rheology of asphalt binders and rheological predictions for field aging. Fuel 2014, 121, 86–94. [Google Scholar] [CrossRef]

- Fini, E.H.; Hajikarimi, P.; Rahi, M.; Moghadas Nejad, F. Physiochemical, rheological, and oxidative aging characteristics of asphalt binder in the presence of mesoporous silica nanoparticles. J. Mater. Civ. Eng. 2015, 28, 04015133. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, L.; Qin, Y. Aging mechanism of SBS modified asphalt based on chemical reaction kinetics. Constr. Build. Mater. 2015, 91, 47–56. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U. Effect of ageing on bitumen chemistry and rheology. Constr. Build. Mater. 2012, 16, 15–22. [Google Scholar] [CrossRef]

- Shen, J.; Amirkhanian, S. The influence of crumb rubber modifier (CRM) microstructures on the high temperature properties of CRM binders. Int. J. Pavement Eng. 2005, 6, 265–271. [Google Scholar] [CrossRef]

- De Lira, R.R.; Cortes, D.D.; Pasten, C. Reclaimed asphalt binder aging and its implications in the management of RAP stockpiles. Constr. Build. Mater. 2015, 101, 611–616. [Google Scholar] [CrossRef]

- Fang, C.; Yu, R.; Li, Y.; Zhang, M.; Hu, J.; Zhang, M. Preparation and characterization of an asphalt-modifying agent with waste packaging polyethylene and organic montmorillonite. Polym. Test. 2013, 32, 953–960. [Google Scholar] [CrossRef]

- Liu, Z.; Tu, Z.; Li, Y.; Yang, F.; Han, S.; Yang, W.; Zhang, L.; Wang, G.; Xu, C.; Gao, J. Synthesis of three-dimensional graphene from petroleum asphalt by chemical vapor deposition. Mater. Lett. 2014, 122, 285–288. [Google Scholar] [CrossRef]

- Vargas, M.A.; Moreno, L.; Montiel, R.; Manero, O.; Vázquez, H. Effects of montmorillonite (Mt) and two different organo-Mt additives on the performance of asphalt. Appl. Clay Sci. 2017, 139, 20–27. [Google Scholar] [CrossRef]

- Loeber, L.; Muller, G.; Morel, J.; Sutton, O. Bitumen in colloid science: A chemical, structural and rheological approach. Fuel 1998, 77, 1443–1450. [Google Scholar] [CrossRef]

- Pauli, A.T.; Grimes, R.W.; Beemer, A.G.; Turner, T.F.; Branthaver, J.F. Morphology of asphalts, asphalt fractions and model wax-doped asphalts studied by atomic force microscopy. Int. J. Pavement Eng. 2011, 12, 291–309. [Google Scholar] [CrossRef]

- De Moraes, M.B.; Pereira, R.B.; Simão, R.A.; Leite, L.F.M. High temperature AFM study of CAP 30/45 pen grade bitumen. J. Microsc. 2010, 239, 46–53. [Google Scholar] [CrossRef]

- Soenen, H.; Besamusca, J.; Fischer, H.R.; Poulikakos, L.D.; Planche, J.P.; Das, P.K.; Kringos, N.; Grenfell, J.R.A.; Lu, X.; Chailleux, E. Laboratory investigation of bitumen based on round robin DSC and AFM tests. Mater. Struct. 2014, 47, 1205–1220. [Google Scholar] [CrossRef]

- Das, P.K.; Kringos, N.; Wallqvist, V.; Birgisson, B. Micromechanical investigation of phase separation in bitumen by combining atomic force microscopy with differential scanning calorimetry results. Road Mater. Pavement Des. 2013, 14, 25–37. [Google Scholar] [CrossRef]

- Allen, R.G.; Little, D.N.; Bhasin, A. Structural characterization of micromechanical properties in asphalt using atomic force microscopy. J. Mater. Civ. Eng. 2012, 24, 1317–1327. [Google Scholar] [CrossRef]

- Allen, R.G.; Little, D.N.; Bhasin, A.; Glover, C.J. The effects of chemical composition on asphalt microstructure and their association to pavement performance. Int. J. Pavement Eng. 2014, 15, 9–22. [Google Scholar] [CrossRef]

- Lyne, Å.L.; Wallqvist, V.; Birgisson, B. Adhesive surface characteristics of bitumen binders investigated by atomic force microscopy. Fuel 2013, 113, 248–256. [Google Scholar] [CrossRef]

- Yu, X.; Zaumanis, M.; Dos Santos, S.; Poulikakos, L.D. Rheological, microscopic, and chemical characterization of the rejuvenating effect on asphalt binders. Fuel 2014, 135, 162–171. [Google Scholar] [CrossRef]

- Wu, S.P.; Pang, L.; Mo, L.T.; Chen, Y.C.; Zhu, G.J. Influence of aging on the evolution of structure, morphology and rheology of base and SBS modified bitumen. Constr. Build. Mater. 2009, 23, 1005–1010. [Google Scholar] [CrossRef]

- Wang, P.Y.; Zhao, K.; Glover, C.; Chen, L.; Wen, Y.; Chong, D.; Hu, C. Effects of aging on the properties of asphalt at the nanoscale. Constr. Build. Mater. 2015, 80, 244–254. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, X.; Yu, J.; Xu, W. Effects of Aging on the Multiscale Properties of SBS-Modified Asphalt. Arab. J. Sci. Eng. 2018, 1–10. [Google Scholar] [CrossRef]

- Li, Y.; Yang, J.; Tan, T. Study on adhesion between asphalt binders and aggregate minerals under ambient conditions using particle-modified atomic force microscope probes. Constr. Build. Mater. 2015, 101, 159–165. [Google Scholar] [CrossRef]

- Wang, P.; Dong, Z.J.; Tan, Y.Q.; Liu, Z.Y. Investigating the interactions of the saturate, aromatic, resin, and asphaltene four fractions in asphalt binders by molecular simulations. Energy Fuels 2015, 29, 112–121. [Google Scholar] [CrossRef]

- Fischer, H.; Stadler, H.; Erina, N. Quantitative temperature-depending mapping of mechanical properties of bitumen at the nanoscale using the AFM operated with PeakForce TappingTM mode. J. Microsc. 2013, 250, 210–217. [Google Scholar] [CrossRef]

- American Association of State and Highway Transportation Officials. Effect of heat and air on a moving film of asphalt binder (rolling thin-film oven test). In AASHTO Standard T 240; American Association of State and Highway Transportation Officials: Washington, DC, USA, 2013. [Google Scholar]

- American Association of State and Highway Transportation Officials. Accelerated aging of asphalt binder using a pressurized aging vessel. In AASHTO Standard R 28; American Association of State and Highway Transportation Officials: Washington, DC, USA, 2013. [Google Scholar]

- Yu, H.; Leng, Z.; Zhou, Z.; Shih, K.; Xiao, F.; Gao, Z. Optimization of preparation procedure of liquid warm mix additive modified asphalt rubber. J. Clean. Prod. 2017, 141, 336–345. [Google Scholar] [CrossRef]

- Davis, C.; Castorena, C. Implications of physico–chemical interactions in asphalt mastics on asphalt microstructure. Constr. Build. Mater. 2015, 94, 83–89. [Google Scholar] [CrossRef]

- Das, P.K.; Baaj, H.; Tighe, S.; Kringos, N. Atomic force microscopy to investigate asphalt binders: A state-of-the-art review. Road Mater. Pavement Des. 2016, 17, 693–718. [Google Scholar] [CrossRef]

- Xu, G.; Wang, H. Molecular dynamics study of oxidative aging effect on asphalt binder properties. Fuel 2017, 188, 1–10. [Google Scholar] [CrossRef]

- Lesueur, D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv. Colloid Interface Sci. 2009, 145, 42–82. [Google Scholar] [CrossRef] [PubMed]

- Fischer, H.R.; Dillingh, E.C.; Hermse, C.G.M. On the microstructure of bituminous binders. Road Mater. Pavement Des. 2014, 15, 1–15. [Google Scholar] [CrossRef]

- Makowska, M.; Pellinen, T.; Martinez, P.O.; Laukkanen, O.V. Analytical Methodology to Determine the Composition of Filler Used in Hot-Mix Asphalt: Case Study. Transp. Res. Rec. 2014, 2445, 12–20. [Google Scholar] [CrossRef]

- Zhang, F.; Yu, J.; Han, J. Effects of thermal oxidative ageing on dynamic viscosity, TG/DTG, DTA and FTIR of SBS-and SBS/sulfur-modified asphalts. Constr. Build. Mater. 2011, 25, 129–137. [Google Scholar] [CrossRef]

- Bernard, F.L.; Polesso, B.B.; Cobalchini, F.W.; Donato, A.J.; Seferin, M.; Ligabue, R.; Chaban, V.V.; do Nascimento, J.F.; Vecchia, F.D.; Einloft, S. CO2 capture: Tuning cation-anion interaction in urethane based poly (ionic liquids). Polymer 2016, 102, 199–208. [Google Scholar] [CrossRef]

- Ouyang, C.; Wang, S.; Zhang, Y.; Zhang, Y. Preparation and properties of styrene–butadiene–styrene copolymer/kaolinite clay compound and asphalt modified with the compound. Polym. Degrad. Stab. 2005, 87, 309–317. [Google Scholar] [CrossRef]

- Tur Rasool, R.; Wang, S.; Zhang, Y.; Li, Y.; Zhang, G. Improving the aging resistance of SBS modified asphalt with the addition of highly reclaimed rubber. Constr. Build. Mater. 2017, 145, 126–134. [Google Scholar] [CrossRef]

| Sample | Penetration (25 °C, 0.1 mm) | Softening Point (°C) | Ductility (10 °C, cm) | |

|---|---|---|---|---|

| 70# | Virgin | 61 | 50.4 | 20.5 |

| RTFO | 52 | 55.8 | 13.1 | |

| PAV | 27 | 63.5 | 1.2 | |

| 50# | Virgin | 55 | 53.1 | 14.7 |

| RTFO | 34 | 59.7 | 5.9 | |

| PAV | 23 | 67.2 | 1.1 | |

| 30# | Virgin | 36 | 61.3 | 6.2 |

| RTFO | 30 | 66.1 | 4.3 | |

| PAV | 13 | 72.9 | 0.3 | |

| Sample | 70# | 50# | 30# | |

|---|---|---|---|---|

| Virgin | MV | 0.8521 | 0.8946 | 0.8295 |

| SD | 0.0099 | 0.0158 | 0.0294 | |

| RTFO | MV | 0.9000 | 0.9055 | 0.8353 |

| SD | 0.0105 | 0.0057 | 0.0254 | |

| PAV | MV | 0.8954 | 0.8588 | 0.8611 |

| SD | 0.0221 | 0.0427 | 0.0125 | |

| Sample | 70# | 50# | 30# | |||

|---|---|---|---|---|---|---|

| MV/MPa | SD/MPa | MV/MPa | SD/MPa | MV/MPa | SD/MPa | |

| Virgin | 289.47 | 86.15 | 431.21 | 56.37 | 804.67 | 67.03 |

| RTFO | 741.52 | 104.83 | 813.33 | 186.33 | 901.33 | 96.33 |

| PAV | 996.39 | 203.67 | 1281.67 | 218.82 | 1445.67 | 269.76 |

| Samples | IC=O | IS=O | IAromatics | |

|---|---|---|---|---|

| 70# | Virgin | 0.0379 | 0.0051 | 0.0597 |

| RTFO | 0.0502 | 0.0073 | 0.0617 | |

| PAV | 0.0742 | 0.0115 | 0.0665 | |

| 50# | Virgin | 0.0467 | 0.004 | 0.0651 |

| RTFO | 0.0618 | 0.0065 | 0.0682 | |

| PAV | 0.0917 | 0.0111 | 0.0739 | |

| 30# | Virgin | 0.0472 | 0.0064 | 0.0707 |

| RTFO | 0.0725 | 0.0097 | 0.0709 | |

| PAV | 0.1045 | 0.0145 | 0.0714 | |

| Correlation Analysis | DMT Modulus | IC=O | IS=O | IAromaticity | ||||

|---|---|---|---|---|---|---|---|---|

| R2 | Sig | R2 | Sig | R2 | Sig | R2 | Sig | |

| DMT modulus | — | — | 0.95 | 0.00 | 0.92 | 0.00 | 0.79 | 0.01 |

| IC=O | 0.95 | 0.00 | — | — | 0.94 | 0.00 | 0.73 | 0.03 |

| IS=O | 0.92 | 0.00 | 0.94 | 0.00 | — | — | 0.59 | 0.09 |

| IAromatics | 0.79 | 0.01 | 0.73 | 0.03 | 0.59 | 0.09 | — | — |

| Kaiser-Meyer-Olkin Measure of Sampling Adequacy | 0.56 | |

|---|---|---|

| Bartlett’s Test of Sphericity | Approx. Chi-Square | 18.72 |

| df | 3 | |

| Sig | 0.00 | |

| Samples | Component Value | |

|---|---|---|

| 70# | Virgin | −2.200 |

| RTFO | −1.246 | |

| PAV | 0.657 | |

| 50# | Virgin | −1.542 |

| RTFO | −0.358 | |

| PAV | 1.877 | |

| 30# | Virgin | −0.504 |

| RTFO | 0.783 | |

| PAV | 2.532 | |

| Samples | G*/MPa | δ/° | G′/MPa | |

|---|---|---|---|---|

| 70# | Virgin | 1.78 | 64.7 | 0.76 |

| RTFO | 3.90 | 55.3 | 2.22 | |

| PAV | 13.37 | 39.7 | 10.29 | |

| 50# | Virgin | 2.99 | 59.4 | 1.52 |

| RTFO | 4.57 | 53.5 | 2.72 | |

| PAV | 14.60 | 36.8 | 11.69 | |

| 30# | Virgin | 6.69 | 48.1 | 4.47 |

| RTFO | 10.50 | 39.6 | 8.09 | |

| PAV | 17.76 | 28.8 | 15.56 | |

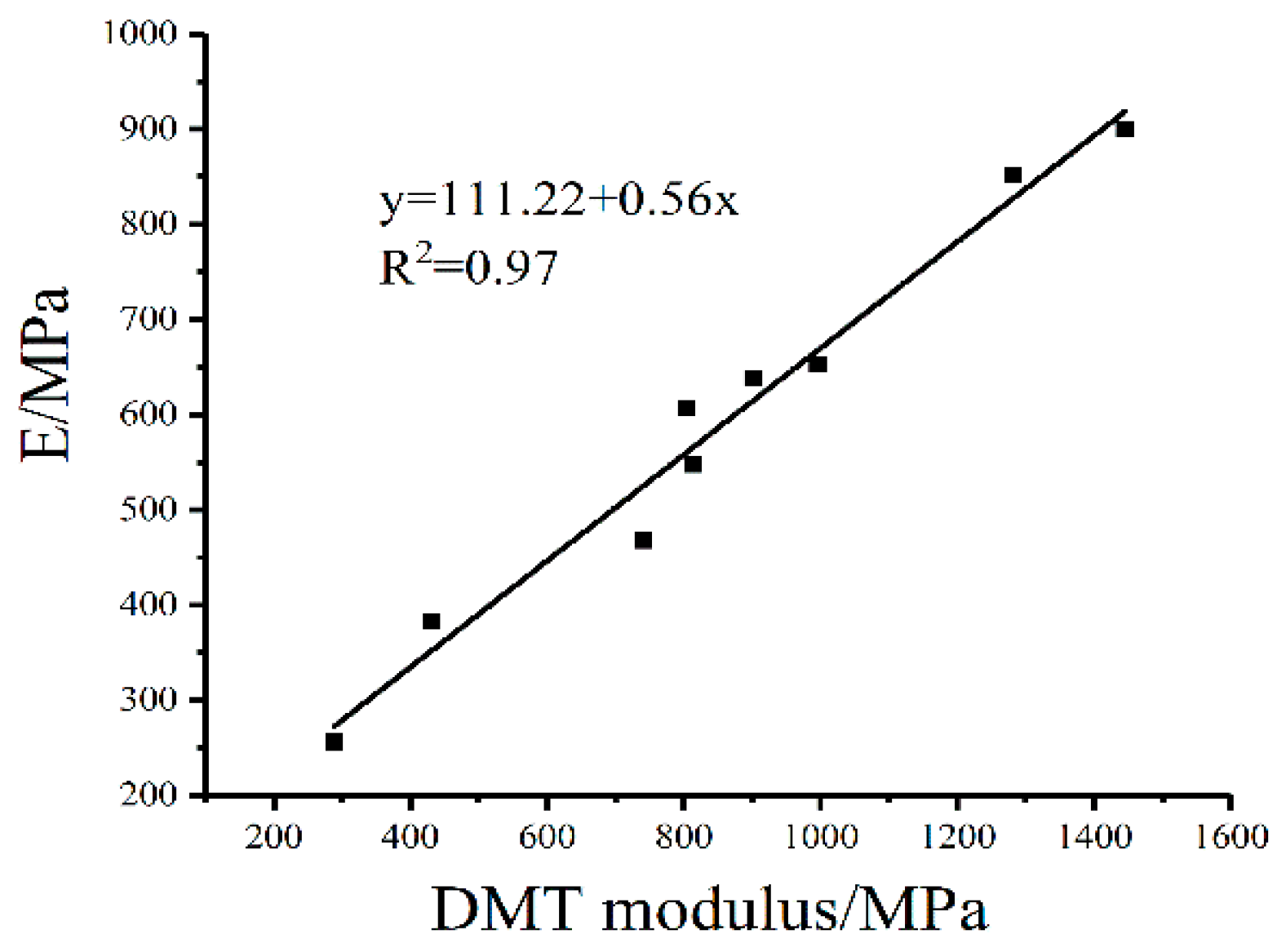

| Samples | E/MPa | DMT Modulus/MPa | |

|---|---|---|---|

| 70# | Virgin | 255.91 | 289.47 |

| RTFO | 467.65 | 741.52 | |

| PAV | 652.29 | 996.39 | |

| 50# | Virgin | 382.84 | 431.21 |

| RTFO | 547.2 | 813.33 | |

| PAV | 852.13 | 1281.67 | |

| 30# | Virgin | 606.61 | 804.67 |

| RTFO | 638.75 | 901.33 | |

| PAV | 899.89 | 1445.67 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Zhang, X.; Zhang, Z.; Zou, B.; Zhu, Z.; Lu, G.; Xu, W.; Yu, J.; Yu, H. Effect of Aging on Chemical and Rheological Properties of Bitumen. Polymers 2018, 10, 1345. https://doi.org/10.3390/polym10121345

Yang Z, Zhang X, Zhang Z, Zou B, Zhu Z, Lu G, Xu W, Yu J, Yu H. Effect of Aging on Chemical and Rheological Properties of Bitumen. Polymers. 2018; 10(12):1345. https://doi.org/10.3390/polym10121345

Chicago/Turabian StyleYang, Zhen, Xiaoning Zhang, Zeyu Zhang, Bingjie Zou, Zihan Zhu, Guoyang Lu, Wei Xu, Jiangmiao Yu, and Huayang Yu. 2018. "Effect of Aging on Chemical and Rheological Properties of Bitumen" Polymers 10, no. 12: 1345. https://doi.org/10.3390/polym10121345

APA StyleYang, Z., Zhang, X., Zhang, Z., Zou, B., Zhu, Z., Lu, G., Xu, W., Yu, J., & Yu, H. (2018). Effect of Aging on Chemical and Rheological Properties of Bitumen. Polymers, 10(12), 1345. https://doi.org/10.3390/polym10121345