Mechanical, Thermal, and Shape Memory Properties of Three-Dimensional Printing Biomass Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composites Preparation

2.3. Tensile Tests

2.4. Scanning Electron Microscopy (SEM)

2.5. Dynamic Mechanical Analysis (DMA)

2.6. Thermogravimetric Analysis (TGA)

2.7. Differential Scanning Calorimetry (DSC)

2.8. Shape Memory Effect Characterization

3. Results and Discussion

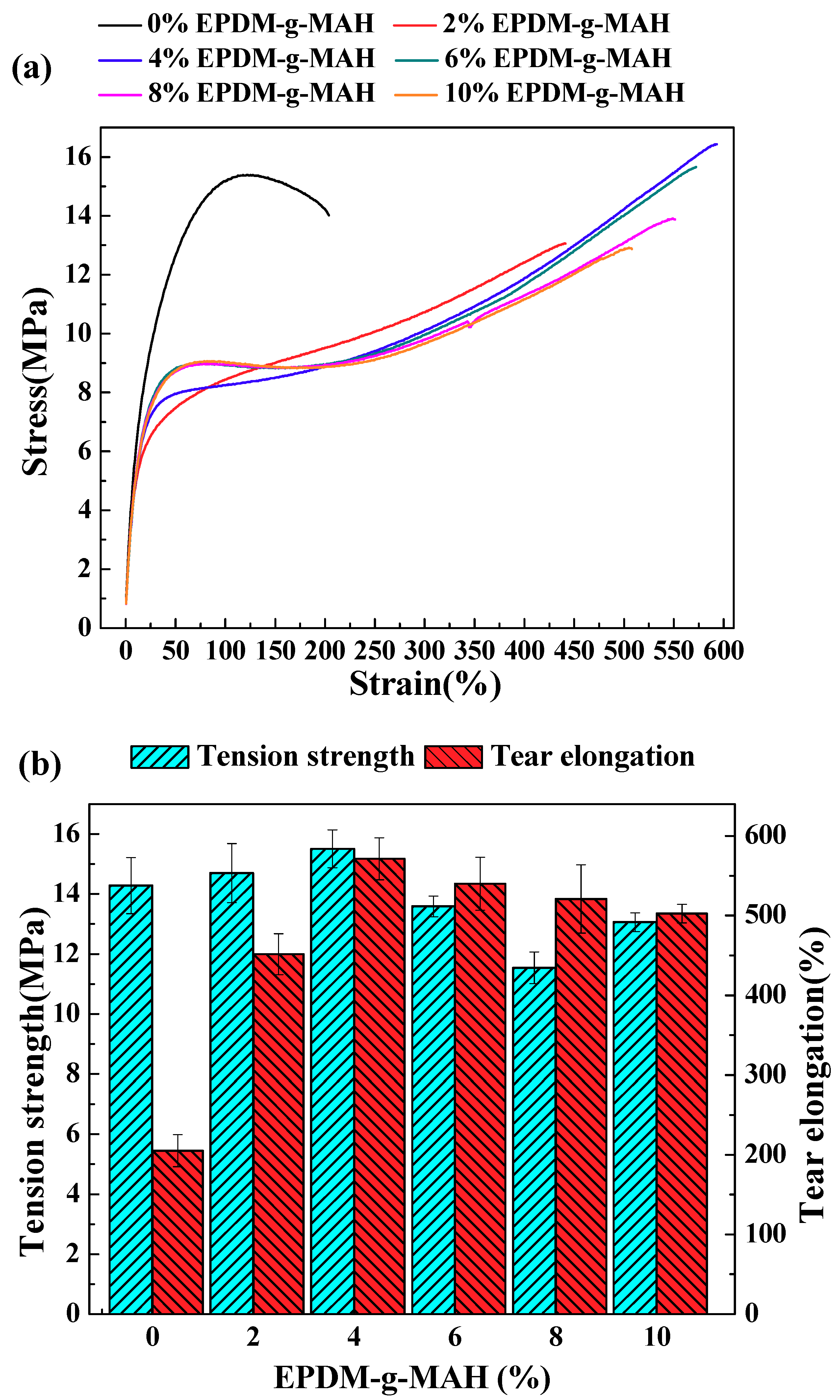

3.1. Mechanical Properties

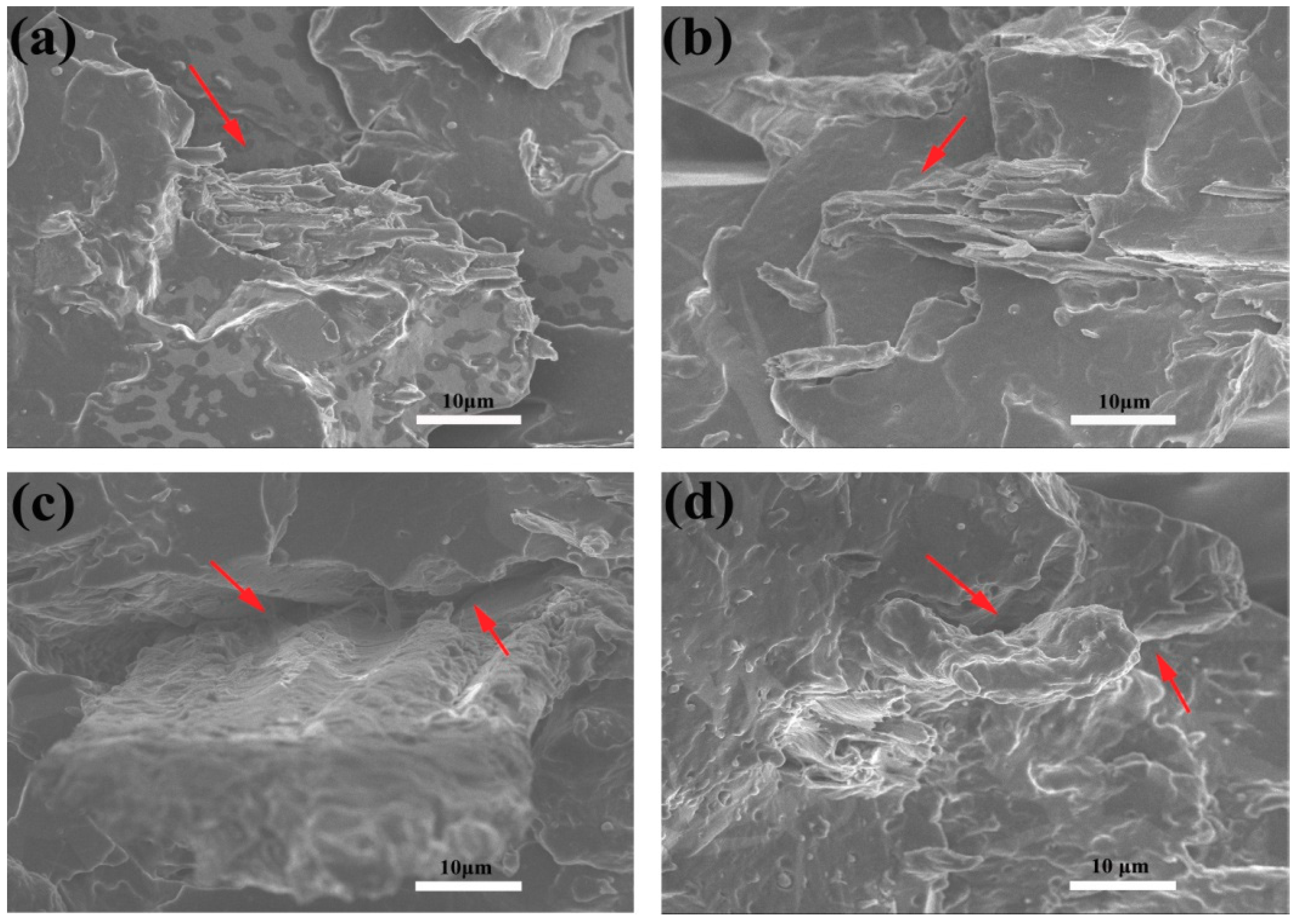

3.2. Morphology of the TPU/WF Composites

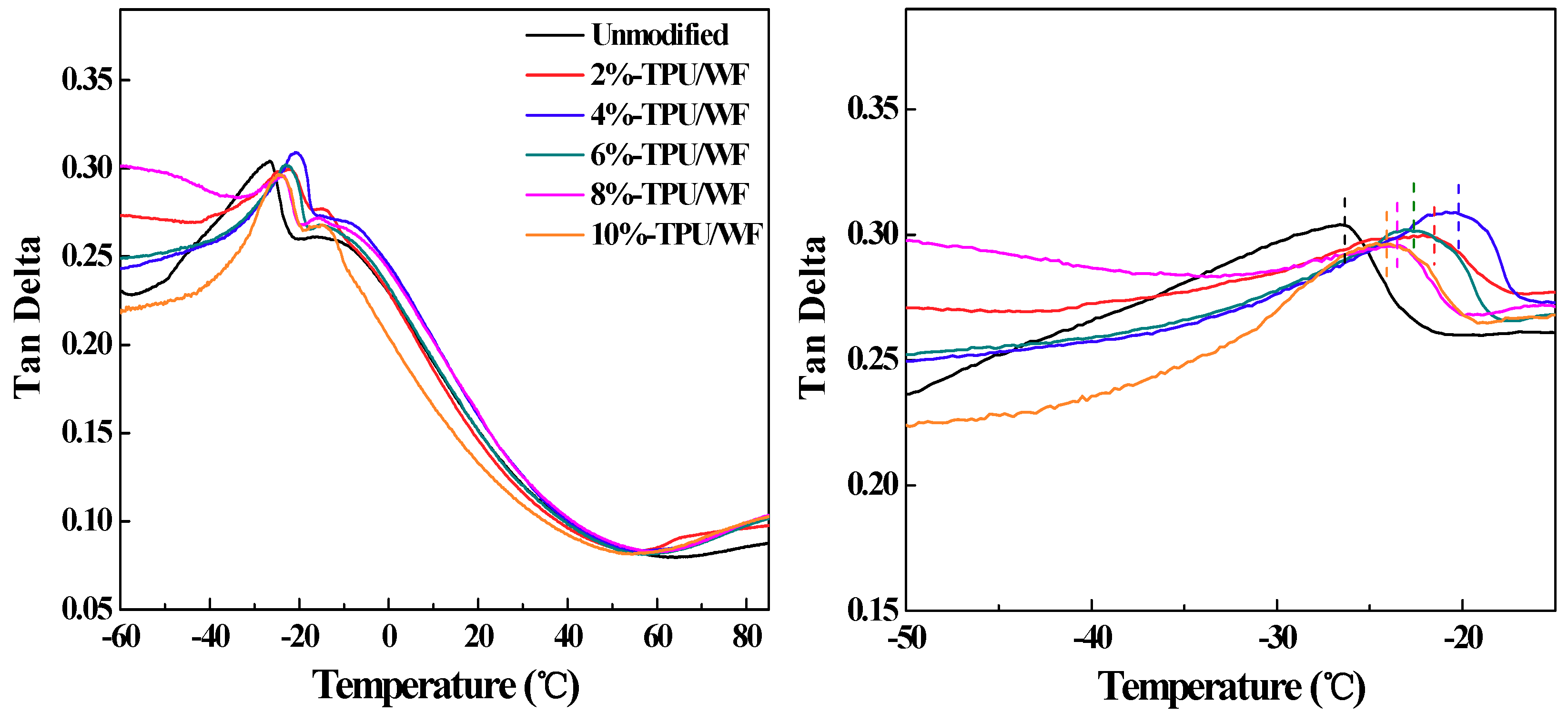

3.3. Dynamic Mechanical Analysis

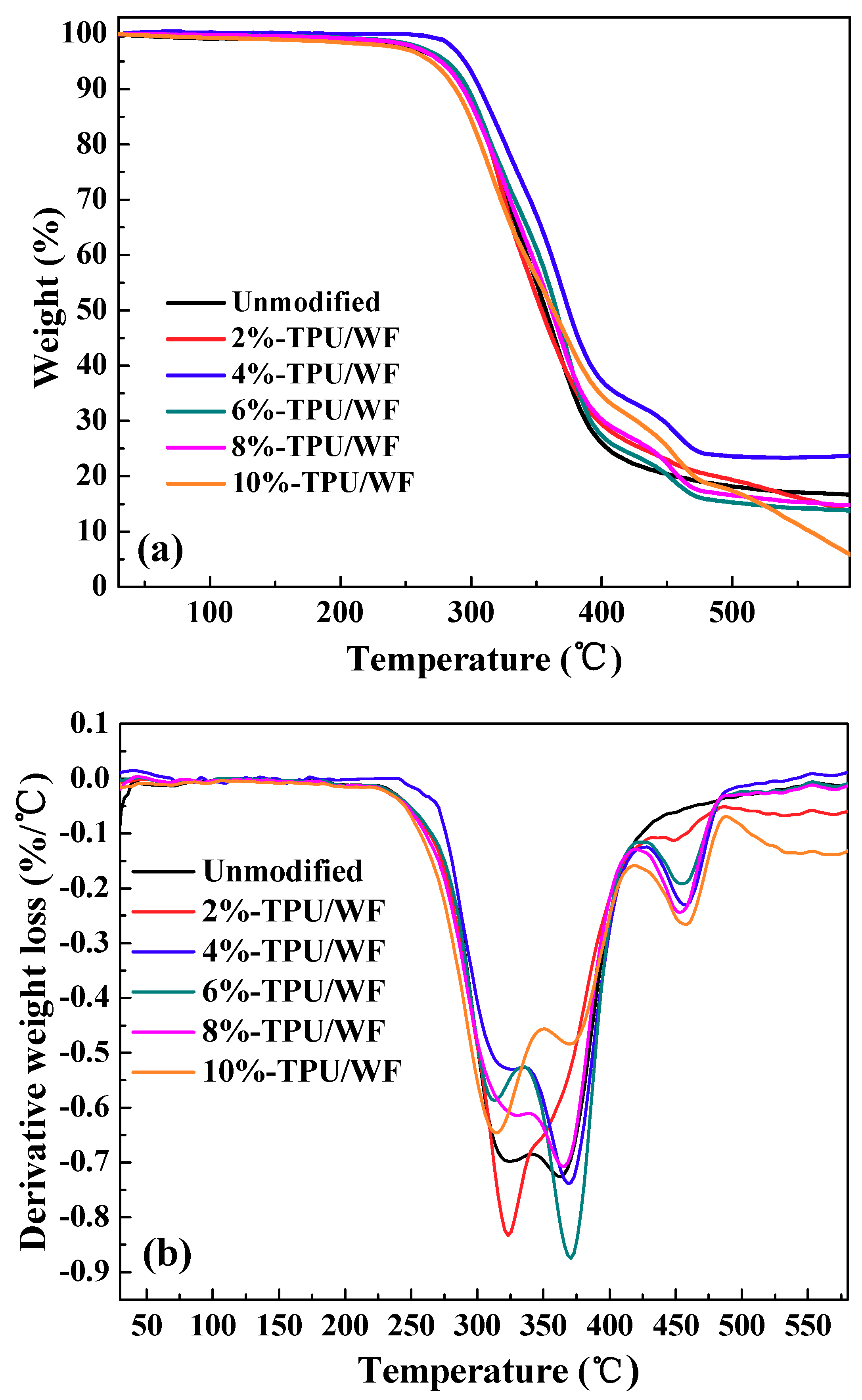

3.4. Thermal Property Analysis

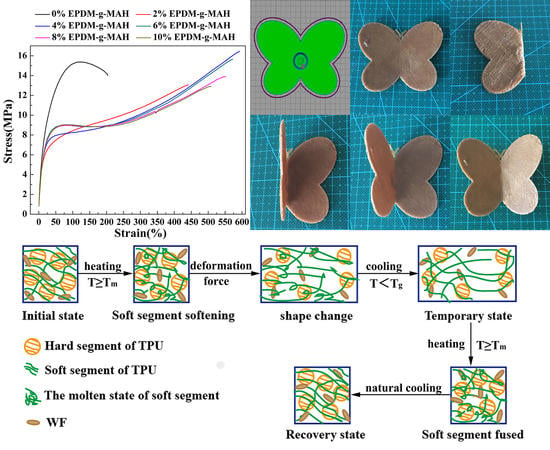

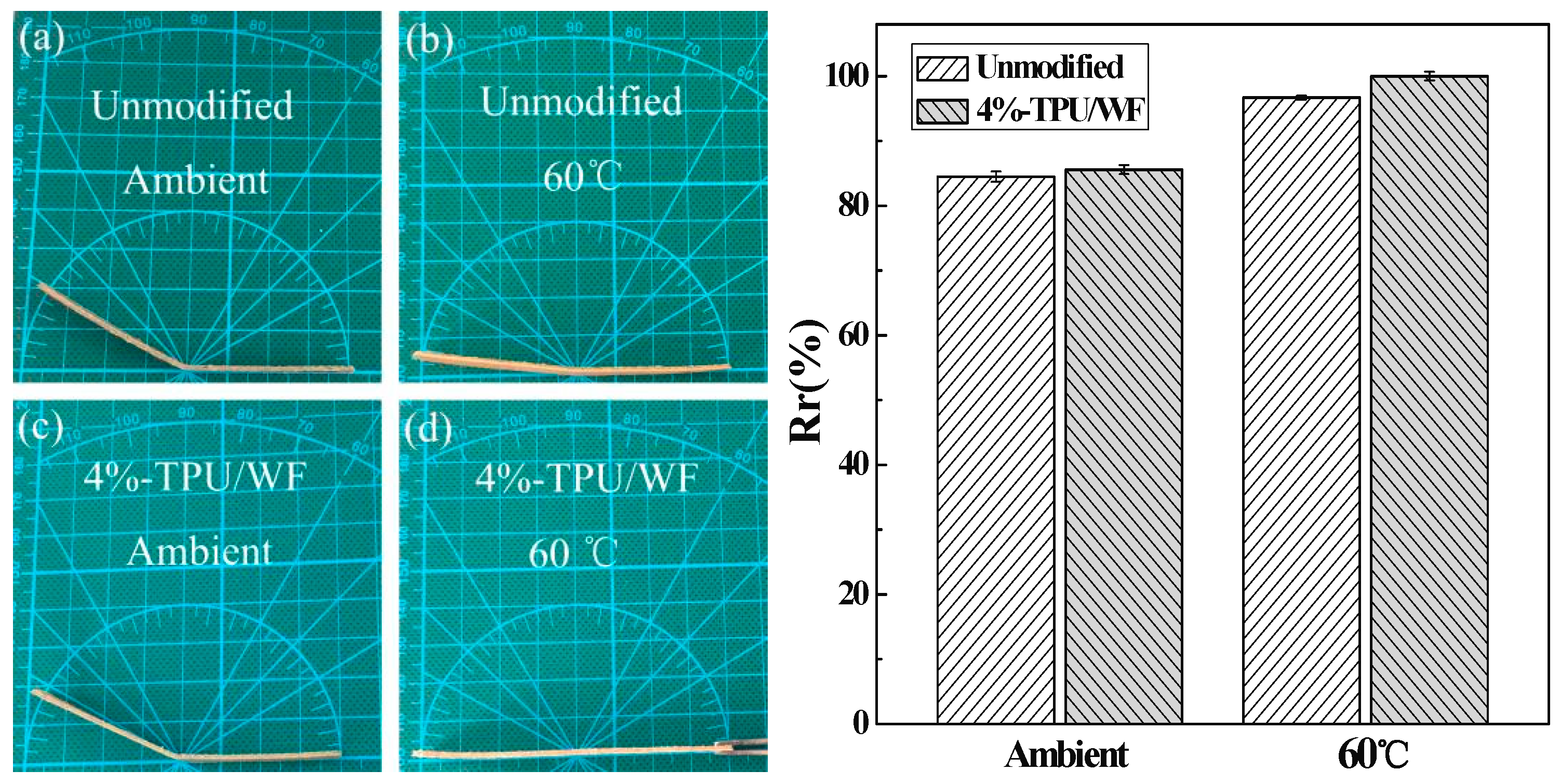

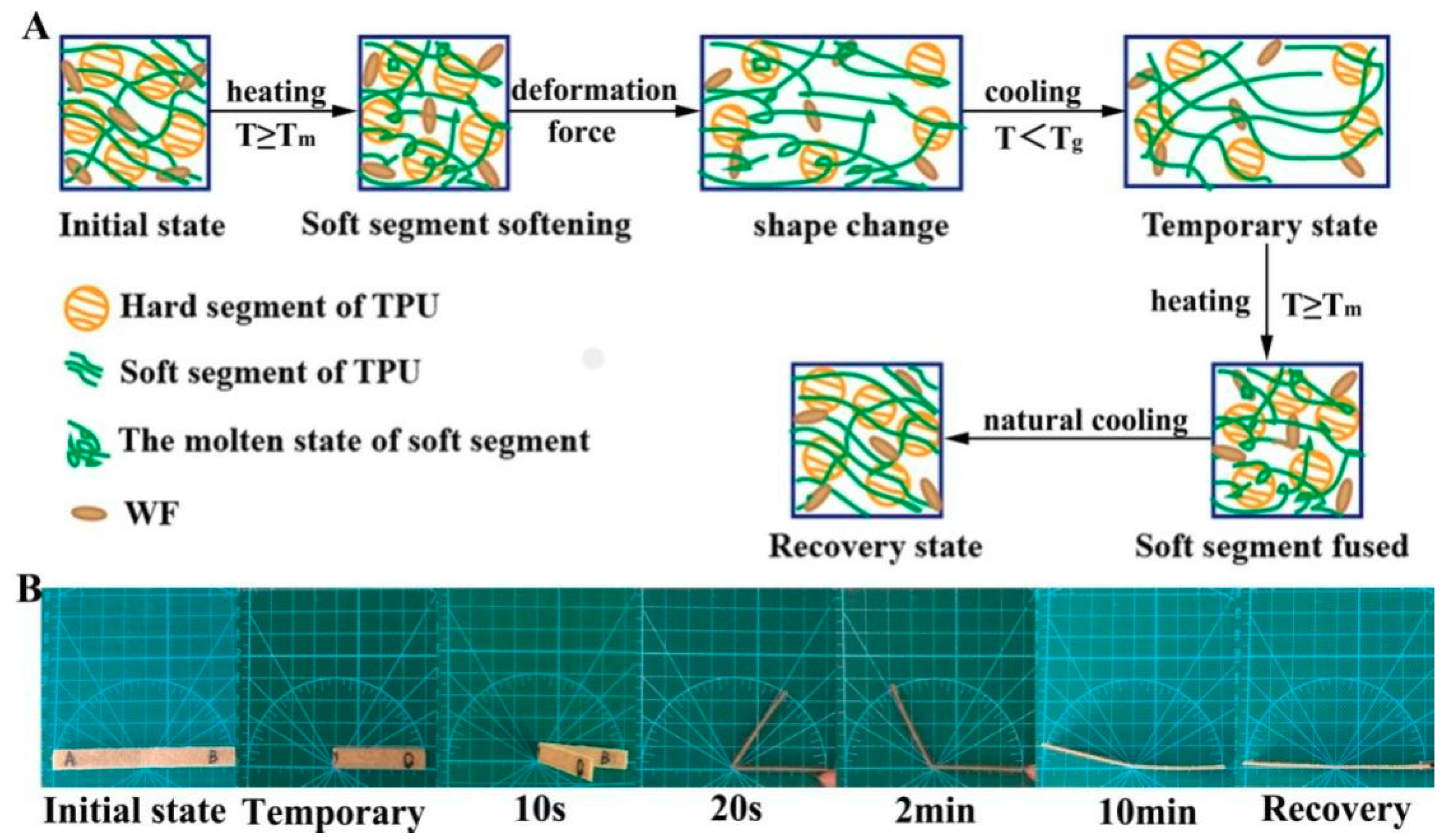

3.5. Shape Memory Properties of TPU/WF Composites

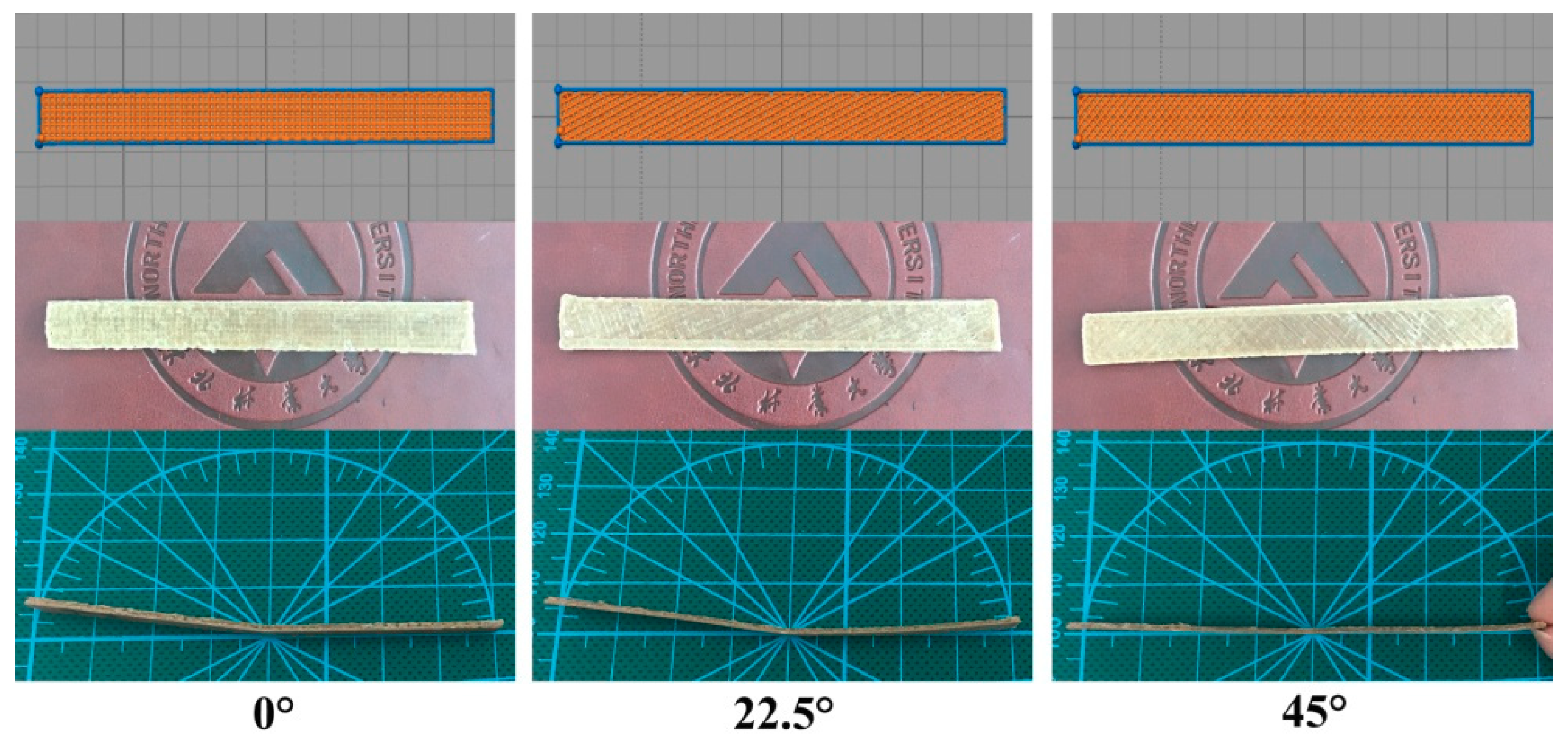

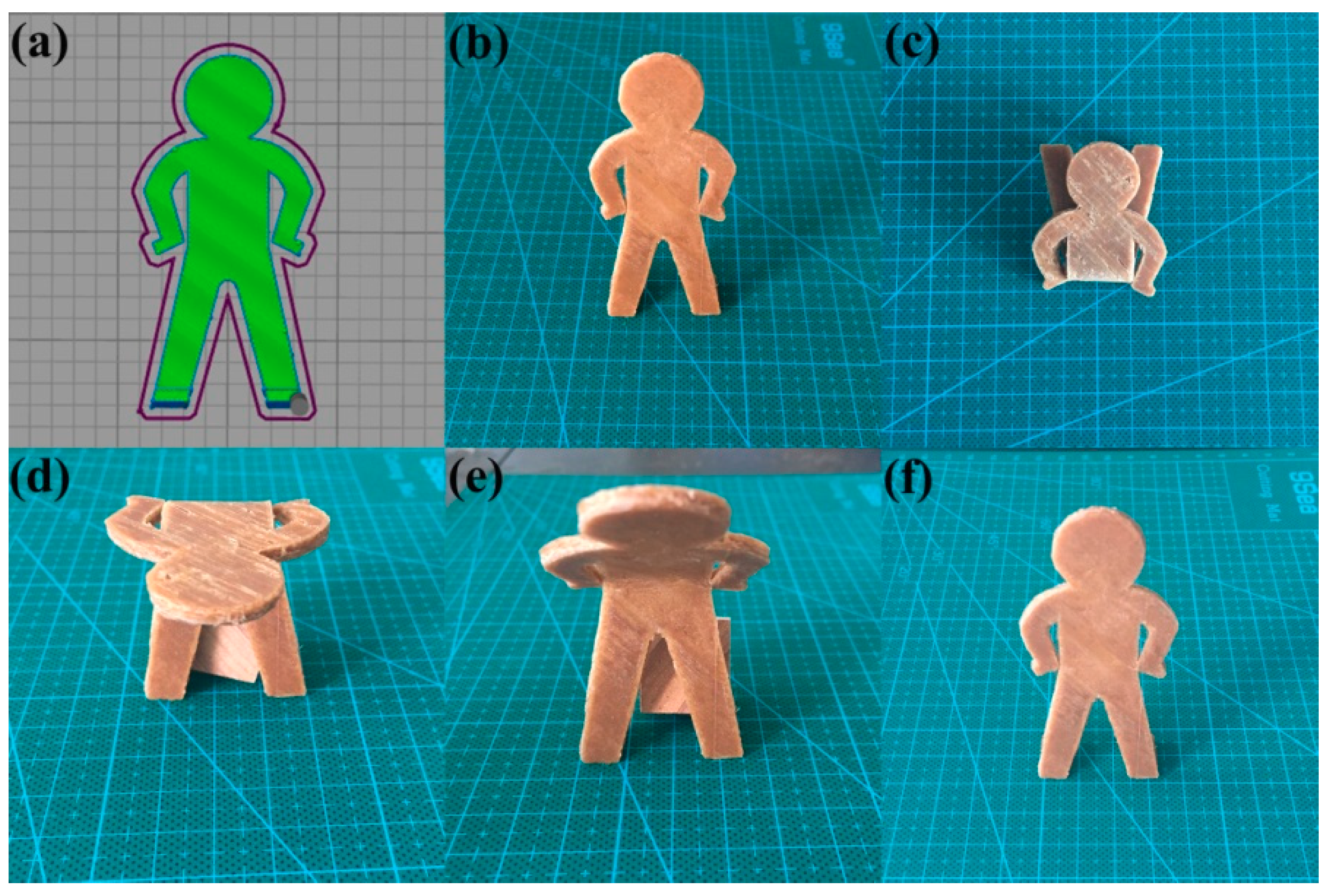

3.6. Demonstrative Object

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, W.X.; Lu, H.B.; Liu, Y.J.; Leng, J.S. Sodium dodecyl sulfate/epoxy composite: Water-induced shape memory effect and its mechanism. J. Mater. Chem. A 2014, 2, 5441–5449. [Google Scholar] [CrossRef]

- Wei, H.; Zhang, Q.; Yao, Y.; Liu, L.; Liu, Y.; Leng, J.S. Direct-write fabrication of 4d active shape-changing structures based on a shape memory polymer and its nanocomposite. ACS Appl. Mater. Interface 2017, 9, 876–883. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Chen, H.; Liu, D.; Wang, W.; Liu, Y.; Zhou, S. pH-responsive shape memory poly(ethylene glycol)-poly(ε-caprolactone)-based polyurethane/cellulose nanocrystals nanocomposite. ACS Appl. Mater. Interface 2015, 7, 12988–12999. [Google Scholar] [CrossRef] [PubMed]

- Shi, S.; Shen, D.; Xu, T. Microstructural and mechanical property evolutions of shape memory polyurethane during a thermodynamic cycle. J. Appl. Polym. Sci. 2017, 135, 45703. [Google Scholar] [CrossRef]

- Wang, W.; Liu, Y.; Leng, J.S. Recent developments in shape memory polymer nanocomposites: Actuation methods and mechanisms. Coord. Chem. Rev. 2016, 320–321, 38–52. [Google Scholar] [CrossRef]

- Mendez, J.; Annamalai, P.K.; Eichhorn, S.J.; Rusli, R.; Rowan, S.J.; Foster, E.J. Bioinspired mechanically adaptive polymer nanocomposites with water-activated shape-memory effect. Macromolecules 2015, 44, 6827–6835. [Google Scholar] [CrossRef]

- Duan, L.; D’Hooge, D.R.; Spoerk, M.; Cornillie, P.; Cardon, L. Facile and low-cost route for sensitive stretchable sensors by controlling kinetic and thermodynamic conductive network regulating strategies. ACS Appl. Mater. Interface 2018, 10, 22678–22691. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.S.; Ni, Q.; Fu, S.Y.; Kurashiki, K. Electromagnetic interference shielding effect of nanocomposites with carbon nanotube and shape memory polymer. Compos. Sci. Technol. 2007, 67, 2973–2980. [Google Scholar] [CrossRef]

- Monzón, M.D.; Paz, R.; Pei, E.; Ortega, F.; Suárez, L.A.; Ortega, Z. 4D printing: Processability and measurement of recovery force in shape memory polymers. Int. J. Adv. Manuf. Technol. 2017, 89, 1827–1836. [Google Scholar] [CrossRef]

- Barmouz, M.; Behravesh, A.H. Shape memory behaviors in cylindrical shell pla/tpu-cellulose nanofiber bio-nanocomposites: Analytical and experimental assessment. Composites Part A 2017, 101, 160–172. [Google Scholar] [CrossRef]

- Jing, X.; Mi, H.Y.; Salick, M.R.; Peng, X.F.; Turng, L.S. Preparation of thermoplastic polyurethane/graphene oxide composite scaffolds by thermally induced phase separation. Polym. Compos. 2013, 35, 1408–1417. [Google Scholar] [CrossRef]

- Chen, Q.; Mangadlao, J.D.; Wallat, J.; Leon, A.D.; Pokorski, J.K.; Advincula, R.C. 3D printing biocompatible polyurethane/poly(lactic acid)/graphene oxide nanocomposites: Anisotropic properties. ACS Appl. Mater. Interface 2017, 9, 4015–4023. [Google Scholar] [CrossRef] [PubMed]

- Mosleh, Y.; Ebrahimi, N.G.; Mahdavian, A.; Ashjari, M. TPU/PCL/nanomagnetite ternary shape memory composites: Studies on their thermal, dynamic-mechanical, rheological and electrical properties. Iran. Polym. J. 2014, 23, 137–145. [Google Scholar] [CrossRef]

- Jing, X.; Mi, H.Y.; Huang, H.X. Shape memory thermoplastic polyurethane (TPU)/poly (ε-caprolactone) (PCL) blends as self-knotting sutures. J. Mech. Behav. Biomed. 2016, 64, 94–103. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.; O’Kelly, K.; Chen, B. Poly (vinyl alcohol) particle-reinforced elastomer composites with water-active shape-memory effects. Eur. Polym. J. 2014, 53, 230–237. [Google Scholar] [CrossRef]

- Wu, T.; Frydrych, M.; O’Kelly, K. Poly (glycerol sebacate urethane)–cellulose nanocomposites with water-active shape-memory effects. Biomacromolecules 2014, 15, 2663–2671. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Li, Y.; Yang, G.; Zheng, X.; Zhou, S. Multi-stimuli responsive shape-memory polymer nanocomposite network cross-linked by cellulose nanocrystals. ACS Appl. Mater. Interface 2015, 7, 4118–4126. [Google Scholar] [CrossRef] [PubMed]

- Miller, A.T.; Safranski, D.L.; Smith, K.E.; Sycks, D.G.; Guldberg, R.E.; Gall, K. Fatigue of injection molded and 3d printed polycarbonate urethane in solution. Polymer 2017, 108, 121–134. [Google Scholar] [CrossRef]

- Christ, J.F.; Aliheidari, N.; Ameli, A.; Pötschke, P. 3D printed highly elastic strain sensors of multiwalled carbon nanotube/thermoplastic polyurethane nanocomposites. Mater. Des. 2017, 131, 394–401. [Google Scholar] [CrossRef]

- Kumar, S.; Wardle, B.L.; Arif, M.F. Strength and performance enhancement of bonded joints by spatial tailoring of adhesive compliance via 3D printing. ACS Appl. Mater. Interface 2017, 9, 884–891. [Google Scholar] [CrossRef] [PubMed]

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K. Highly oriented carbon fiber–polymer composites via additive manufacturing. Compos. Sci. Technol. 2017, 105, 144–150. [Google Scholar] [CrossRef]

- Nadgorny, M.; Xiao, Z.; Chao, C.; Connal, L.A. Three-dimensional printing of pH-responsive and functional polymers on an affordable desktop printer. ACS Appl. Mater. Interface 2016, 8, 28946–28954. [Google Scholar] [CrossRef] [PubMed]

- Wieme, T.; Tang, D.; Delva, L.; D’Hooge, D.R.; Cardon, L. The relevance of material and processing parameters on the thermal conductivity of thermoplastic composites. Polym. Eng. Sci. 2018, 58, 466–474. [Google Scholar] [CrossRef]

- Spoerk, M.; Savandaiah, C.; Arbeiter, F.; Traxler, G.; Cardon, L.; Holzer, C. Anisotropic properties of oriented short carbon fibre filled polypropylene parts fabricated by extrusion-based additive manufacturing. Composites Part A 2018, 113, 95–104. [Google Scholar] [CrossRef]

- Castro, N.J.; Tan, W.N.; Shen, C.; Zhang, L.G. Simulated body fluid nucleation of three-dimensional printed elastomeric scaffolds for enhanced osteogenesis. Tissue Eng. Part A 2016, 22, 940–948. [Google Scholar] [CrossRef] [PubMed]

- Bi, H.; Ren, Z.; Guo, R.; Xu, M.; Song, Y. Fabrication of flexible wood flour/thermoplastic polyurethane elastomer composites using fused deposition molding. Ind. Crops Prod. 2018, 122, 76–84. [Google Scholar] [CrossRef]

- Du, J.; Wang, Y.; Xie, X.; Xu, M.; Song, Y. Styrene-assisted maleic anhydride grafted poly(lactic acid) as an effective compatibilizer for wood flour/poly(lactic acid) bio-composites. Polymers 2017, 9, 623. [Google Scholar] [CrossRef]

- Wu, D.; Zhan, J.; Xu, G.; Jiang, L.; Jin, R. The effect of EPDM-g-MAH on the Structure and Properties of PPO/PA6 Blends. Polym. Mater. Sci. Eng. 2006, 4, 126–129. [Google Scholar]

- Huang, B.; Zhang, G.; Wang, Y. Effect of EPDM-g-MAH on properties of PA6/ABS alloy. Eng. Plast. Appl. 2007, 35, 12–15. [Google Scholar]

- Vajrasthira, C.; Amornsakchai, T.; Bualek-Limcharoen, S. Fiber-matrix interactions in aramid-short-fiber-reinforced thermoplastic polyurethane composites. J. Appl. Polym. Sci. 2003, 87, 1059–1067. [Google Scholar] [CrossRef]

- Wang, J.H.; Zhu, B.K.; Zhu, L.P.; You-Yi, X.U. Fabrication of maco-nano hierarchical structure hybrid surfaces based on ultrahigh molecular poly (styrene-alt-maleic). J. Funct. Mater. 2014, 45, 05041–05044. [Google Scholar]

- El-Shekeil, Y.A.; Sapuan, S.M.; Abdan, K.; Zainudin, E.S. Influence of fiber content on the mechanical and thermal properties of kenaf fiber reinforced thermoplastic polyurethane composites. Mater. Des. 2012, 40, 299–303. [Google Scholar] [CrossRef]

- Yao, X.; Qi, X.; He, Y.; Tan, D.; Chen, F.; Fu, Q. Simultaneous reinforcing and toughening of polyurethane via grafting on the surface of microfibrillated cellulose. ACS Appl. Mater. Interface 2014, 6, 2497–2507. [Google Scholar] [CrossRef] [PubMed]

- Zhu, G. Shape Memory Polymer and Its Application; M. Chem Indus Press: Beijing, China, 2002. [Google Scholar]

- Lei, W.; Yu, W.; Ren, C.; Yang, T.; Wu, H. Melting properties and surface tension of high density polyethylene/wood-flour composites. Shanghai Plast. 2008, 142, 8–11. [Google Scholar]

- Nicharat, A.; Shirole, A.; Foster, E.J.; Weder, C. Thermally activated shape memory behavior of melt-mixed polyurethane/cellulose nanocrystal composites. J. Appl. Polym. Sci. 2017, 134, 45033. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, K.; Wang, Y.; Xu, C. Biobased heat-triggered shape-memory-polymers based on polylactide/epoxidized natural rubber blend system fabricated via peroxide-induced dynamic vulcanization: Co-continuous phase structure, shape memory behavior and interfacial compatibilization. Ind. Eng. Chem. Res. 2015, 54, 8723–8731. [Google Scholar] [CrossRef]

- Feng, W.; Qin, M.; Katsumi, Y.; Guo, H.; Feng, Y. Infrared-actuated recovery of polyurethane filled by reduced grphene oxide-carbon nanotube hibrids with high energy density. ACS Appl. Mater. Interface 2013, 5, 10882–10888. [Google Scholar] [CrossRef] [PubMed]

- Chi, B.; Ma, H.; Liu, X. The Influence of 3D printing process parameters on the mechanical behavior of TPU products. Plastic 2017, 46, 9–12. [Google Scholar]

| Parameter | Value |

|---|---|

| Nozzle size (mm) | 1 |

| Layer thickness (mm) | 0.2 |

| Infill density (%) | 100 |

| Printing speed (mm/s) | 25 |

| Nozzle temperature (°C) | 230 |

| Buildplate temperature (°C) | 30 |

| Filing structure | rectilinear |

| Filling angle (°) | 45 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bi, H.; Xu, M.; Ye, G.; Guo, R.; Cai, L.; Ren, Z. Mechanical, Thermal, and Shape Memory Properties of Three-Dimensional Printing Biomass Composites. Polymers 2018, 10, 1234. https://doi.org/10.3390/polym10111234

Bi H, Xu M, Ye G, Guo R, Cai L, Ren Z. Mechanical, Thermal, and Shape Memory Properties of Three-Dimensional Printing Biomass Composites. Polymers. 2018; 10(11):1234. https://doi.org/10.3390/polym10111234

Chicago/Turabian StyleBi, Hongjie, Min Xu, Gaoyuan Ye, Rui Guo, Liping Cai, and Zechun Ren. 2018. "Mechanical, Thermal, and Shape Memory Properties of Three-Dimensional Printing Biomass Composites" Polymers 10, no. 11: 1234. https://doi.org/10.3390/polym10111234

APA StyleBi, H., Xu, M., Ye, G., Guo, R., Cai, L., & Ren, Z. (2018). Mechanical, Thermal, and Shape Memory Properties of Three-Dimensional Printing Biomass Composites. Polymers, 10(11), 1234. https://doi.org/10.3390/polym10111234