Carrier Transport and Molecular Displacement Modulated dc Electrical Breakdown of Polypropylene Nanocomposites

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication of PP/Al2O3 Nanocomposite Materials

2.2. Characterization of PP/Al2O3 Nanocomposite Materials

3. Experimental Results

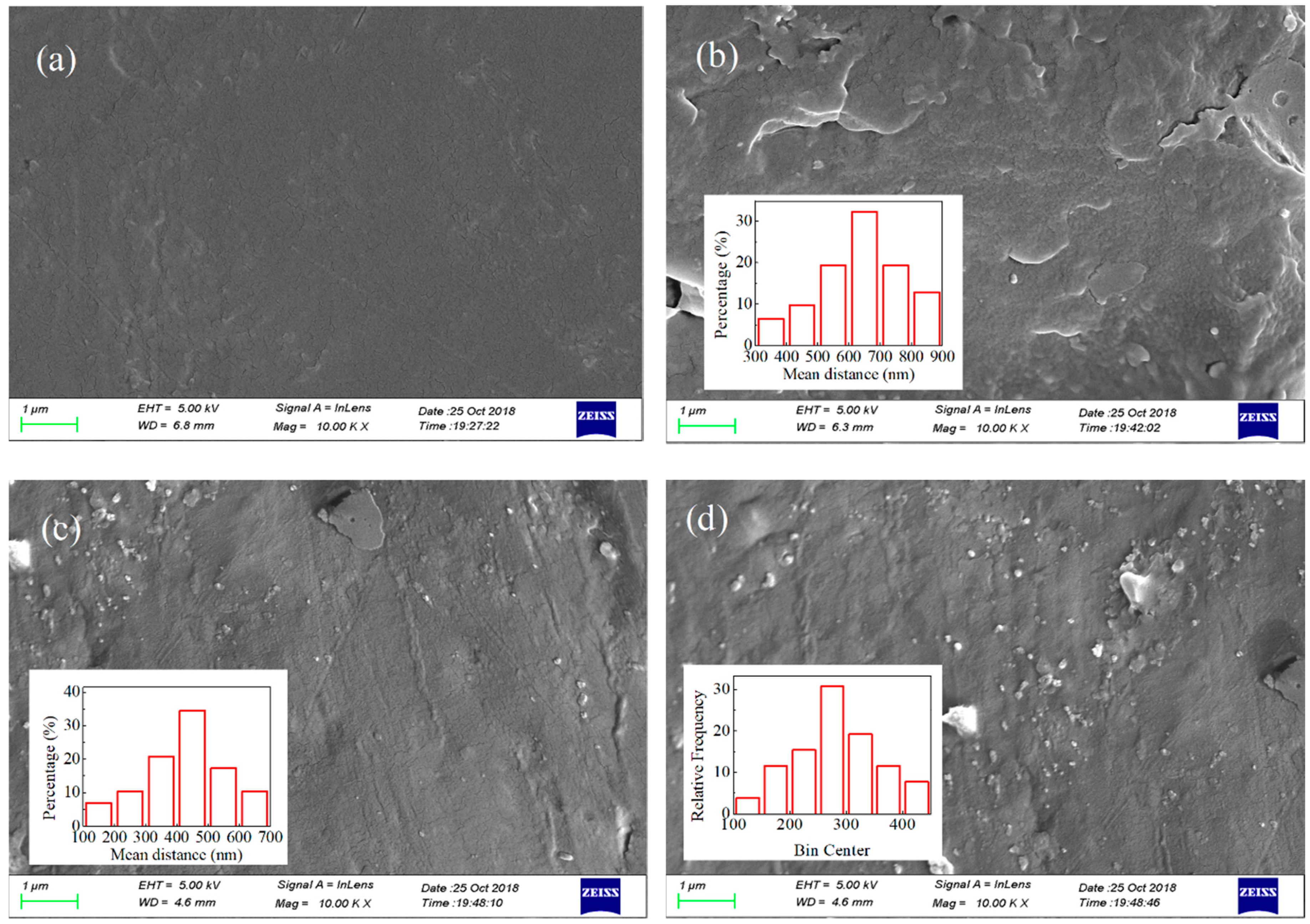

3.1. Morphology of PP/Al2O3 Nanocomposite Materials

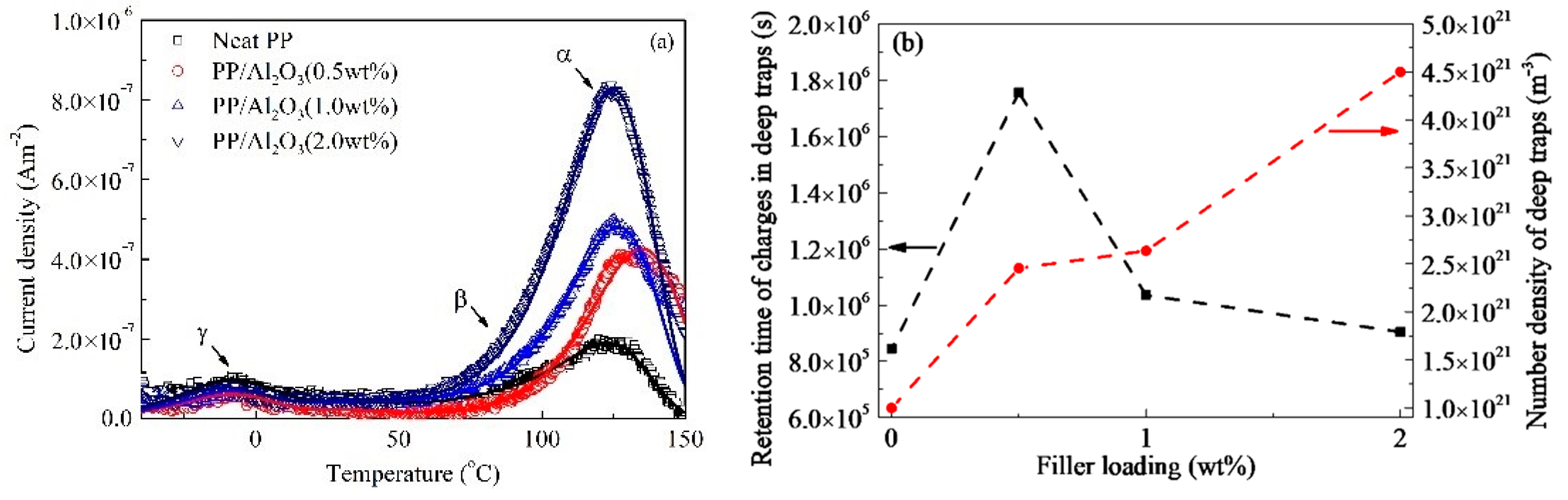

3.2. Trap Properties for Charge Carriers

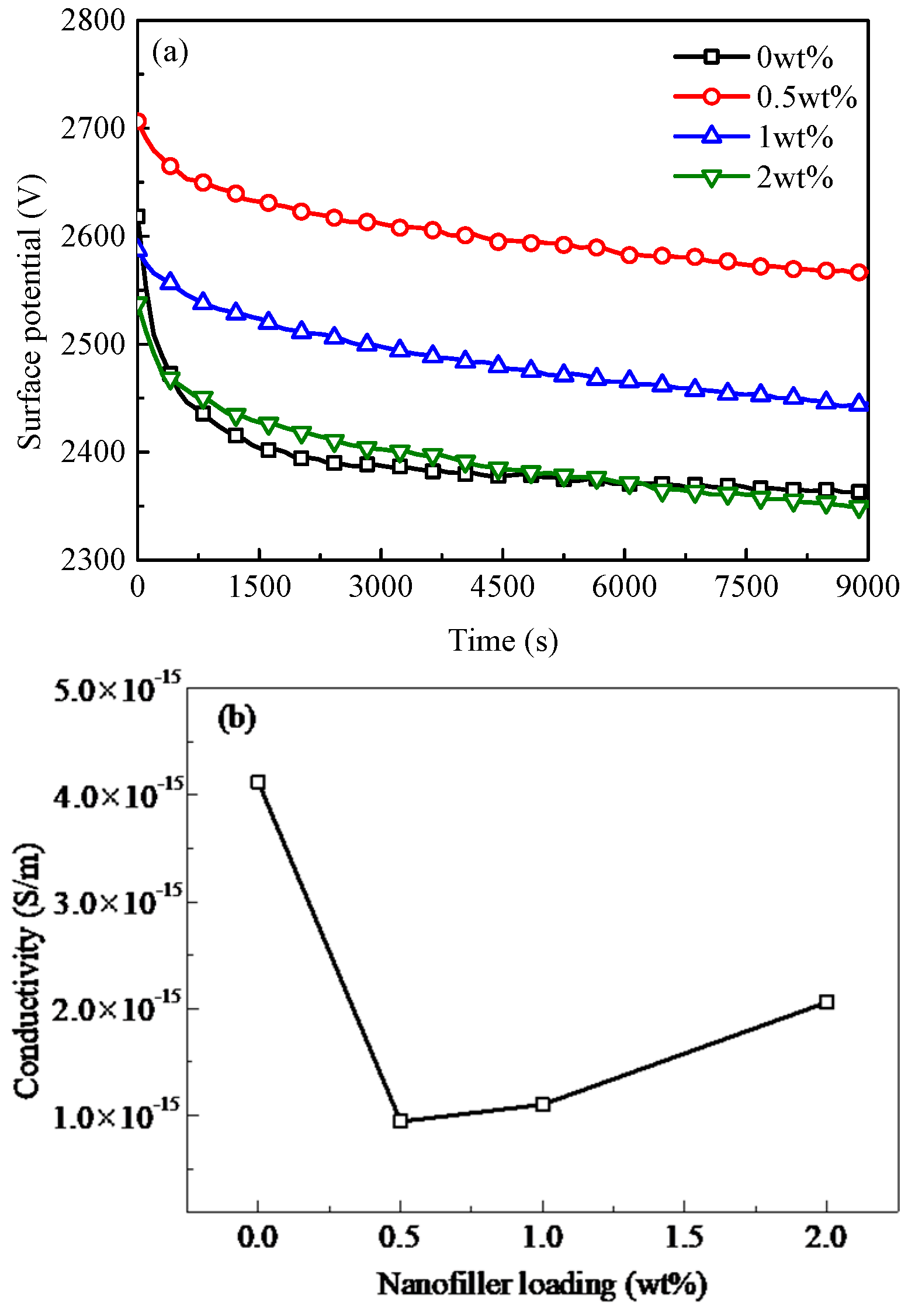

3.3. DC Conductivity

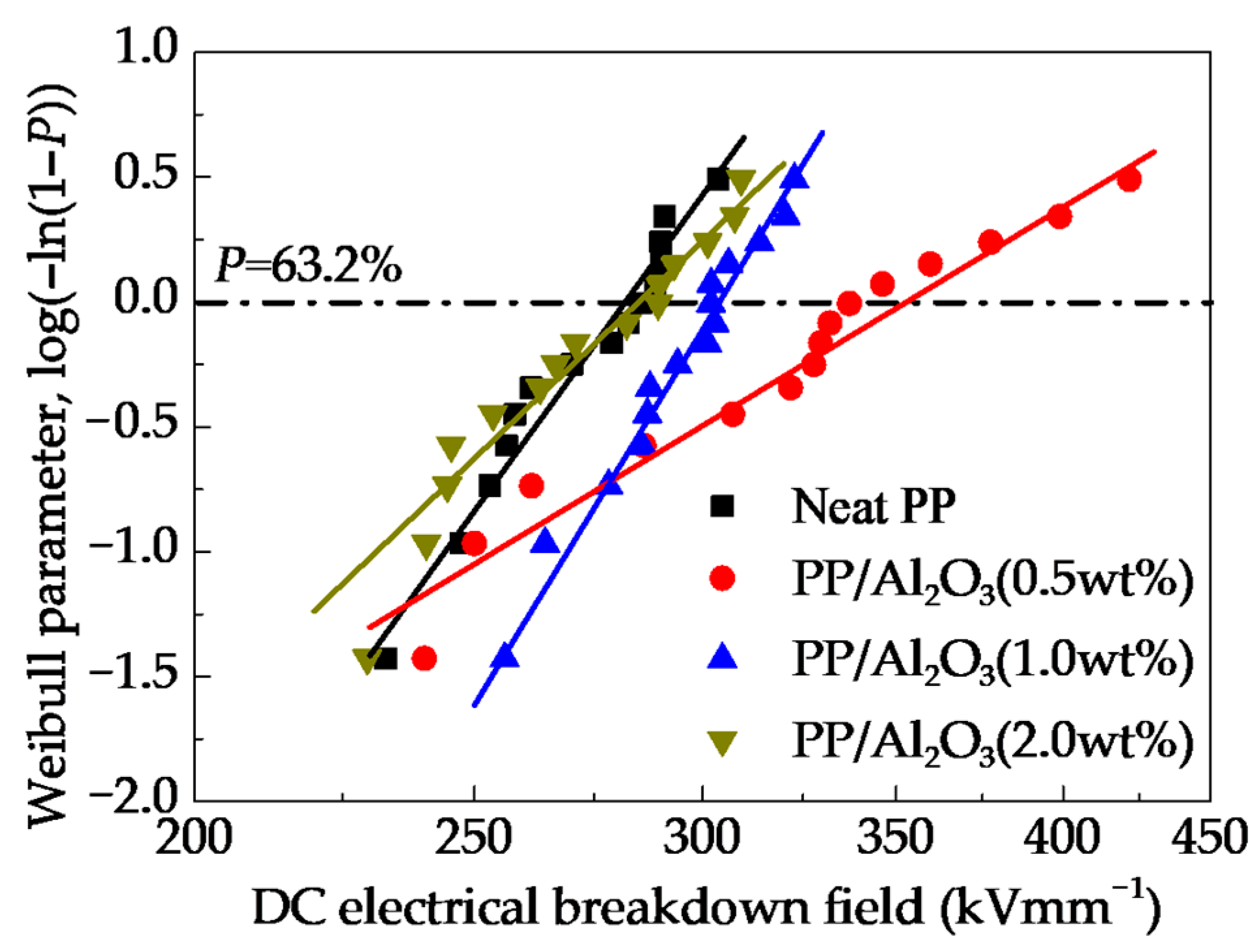

3.4. DC Electrical Breakdown Strength of PP Nanocomposites

3.5. Influence of Trap Properties on dc Conductivity and Electrical Breakdown Strength

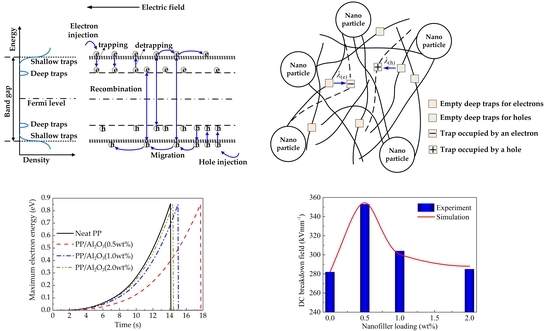

4. Modelling Analysis of dc Electrical Breakdown of PP Nanocomposites

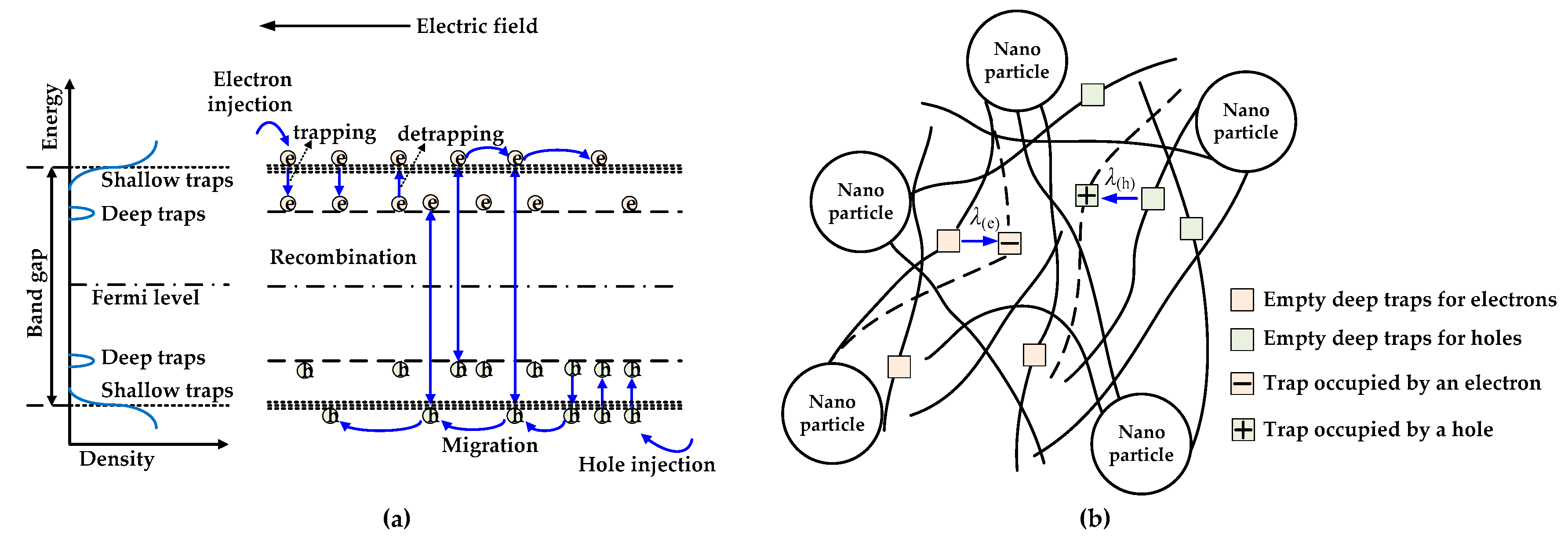

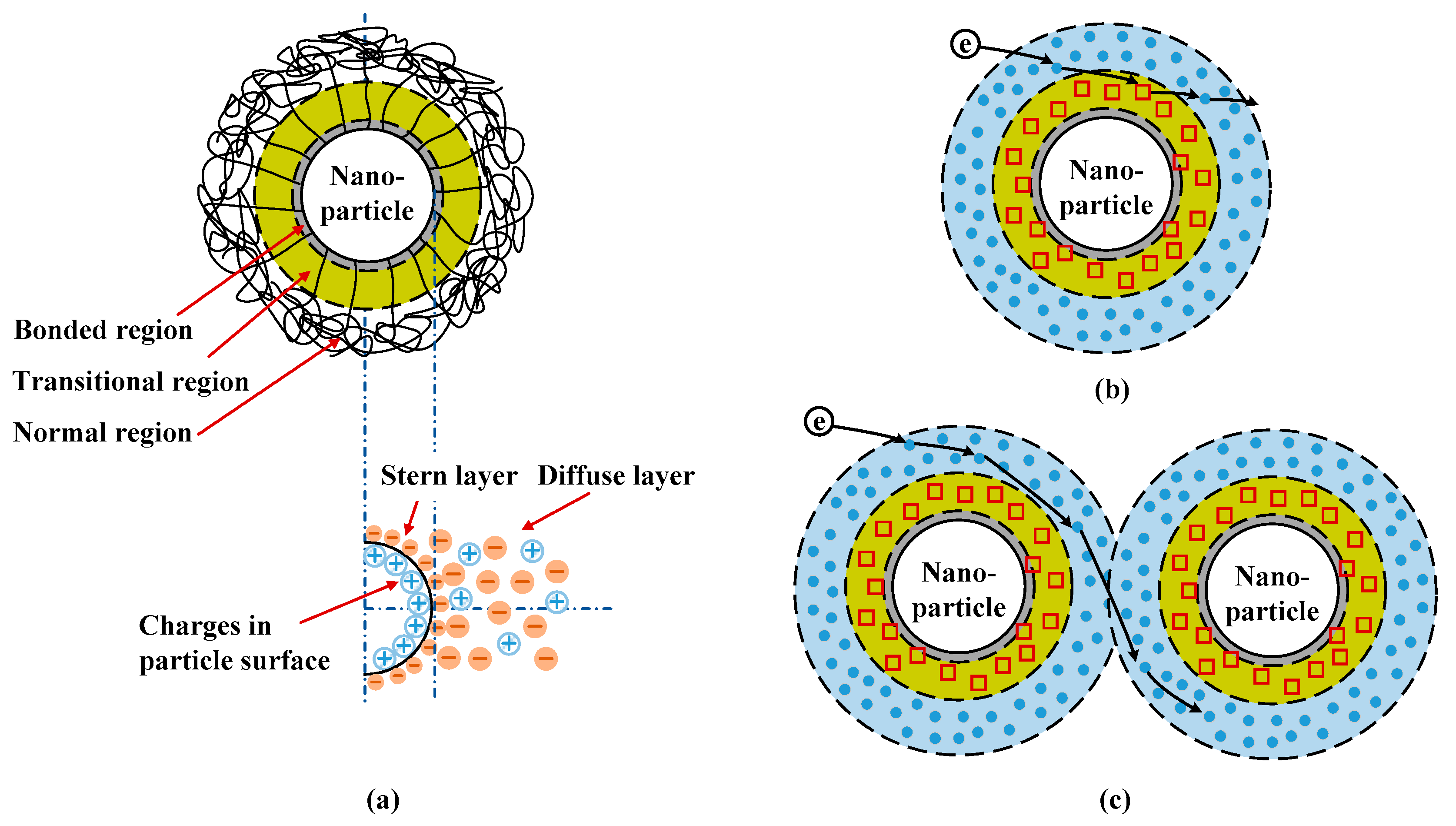

4.1. Carrier Transport and Molecular Displacement Modulated Electrical Breakdown Model

4.2. Parameters and Numerical Computation Methods

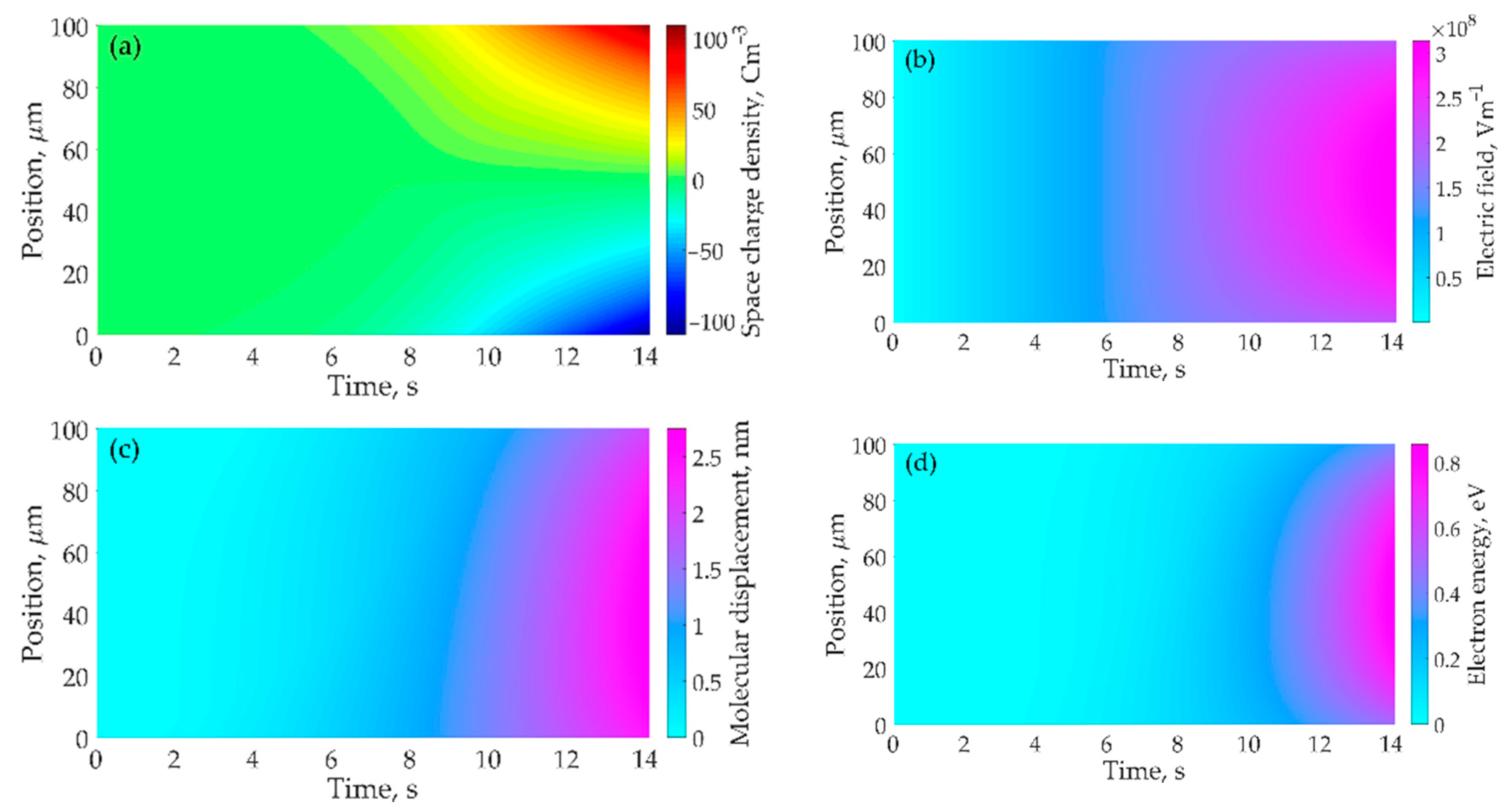

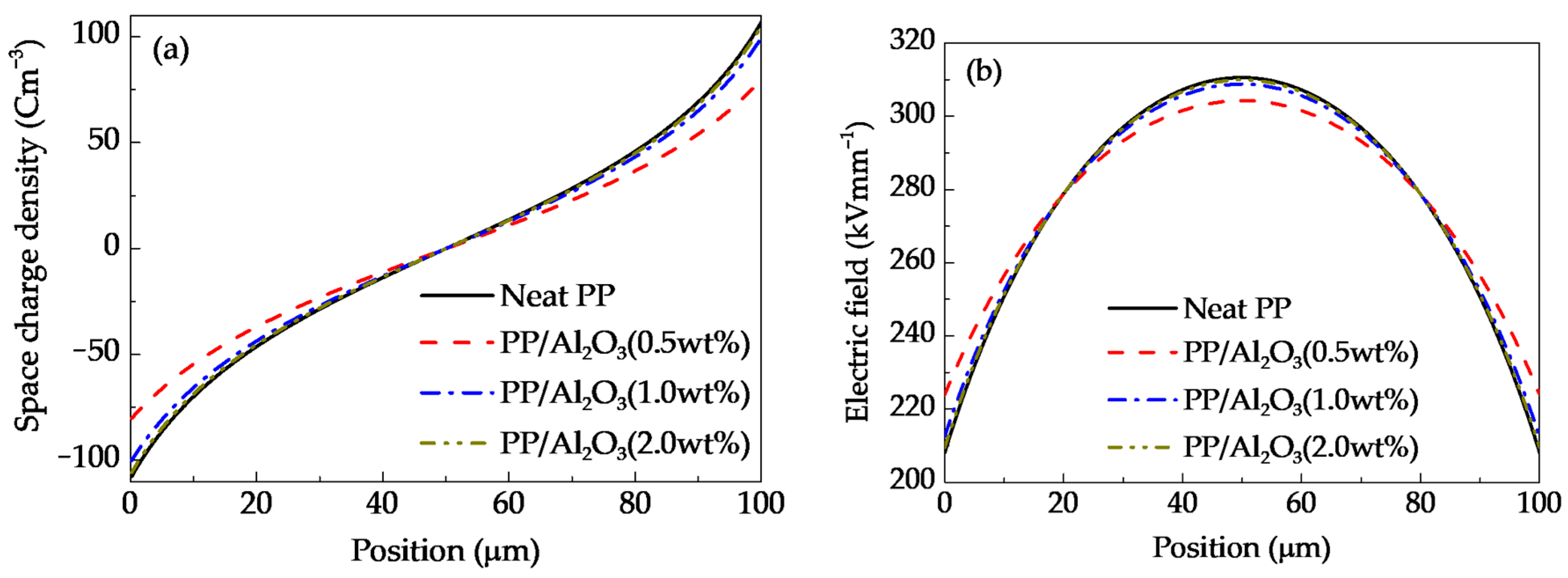

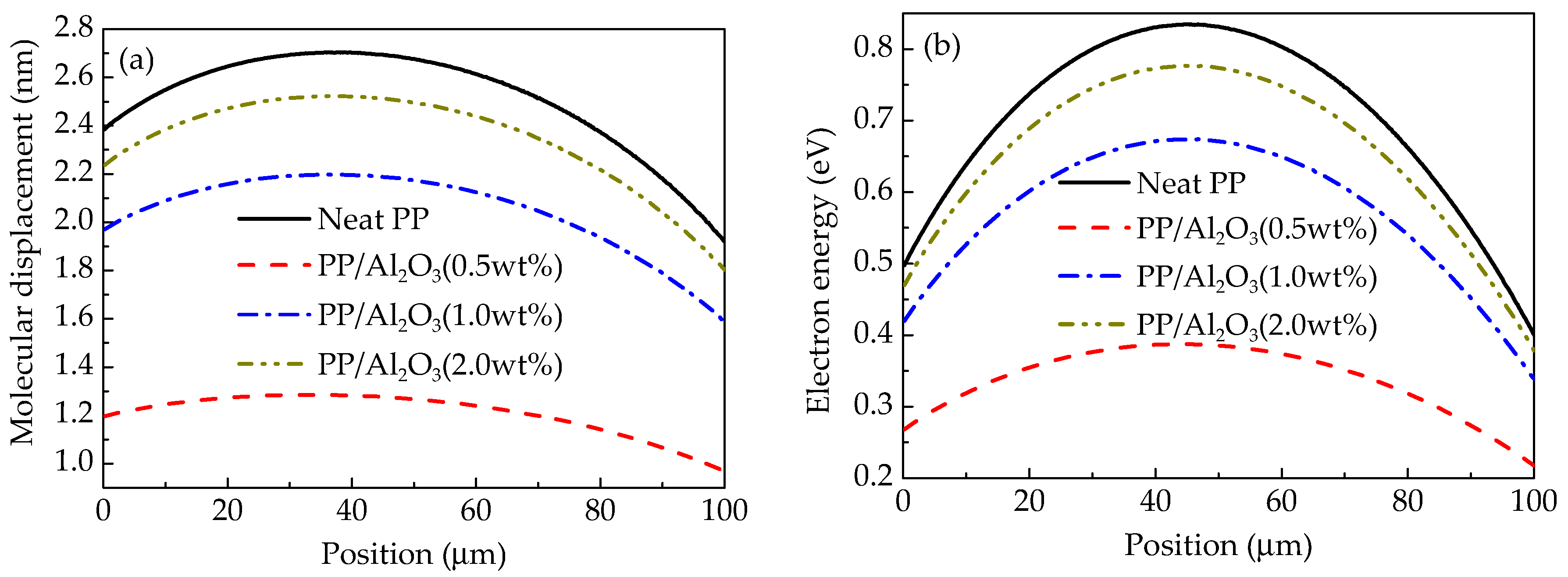

4.3. Simulation Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chu, S.; Cui, Y.; Liu, N. The path towards sustainable energy. Nat. Mater. 2016, 16, 16–22. [Google Scholar] [CrossRef] [PubMed]

- Chu, S.; Majumdar, A. Opportunities and challenges for a sustainable energy future. Nature 2012, 488, 294–303. [Google Scholar] [CrossRef] [PubMed]

- Harsha, P.; Dahleh, M. Optimal management and sizing of energy storage under dynamic pricing for the efficient integration of renewable energy. IEEE Trans. Power Syst. 2015, 30, 1164–1181. [Google Scholar] [CrossRef]

- Chu, B.J.; Zhou, X.; Ren, K.L.; Neese, B.; Lin, M.R.; Wang, Q.; Bauer, F.; Zhang, Q.M. A dielectric polymer with high electric energy density and fast discharge speed. Science 2006, 313, 333–336. [Google Scholar] [CrossRef] [PubMed]

- Huan, T.D.; Boggs, S.; Teyssedre, G.; Laurent, C.; Cakmak, M.; Kumar, S.; Ramprasad, R. Advanced polymeric dielectrics for high energy density applications. Prog. Mater. Sci. 2016, 83, 236–269. [Google Scholar] [CrossRef]

- Huang, X.Y.; Zhi, C.Y. Polymer Nanocomposites: Electrical and Thermal Properties; Springer: Basel, Switzerland, 2016; pp. 1–346. [Google Scholar]

- Dang, Z.M.; Zhou, T.; Yao, S.H.; Yuan, J.K.; Zha, J.W.; Song, H.T.; Li, J.Y.; Chen, Q.; Yang, W.T.; Bai, J.B. Advanced calcium copper titanate/polyimide functional hybrid films with high dielectric permittivity. Adv. Mater. 2009, 21, 2077–2082. [Google Scholar] [CrossRef]

- Nelson, J.K. Dielectric Polymer Nanocomposites; Springer: Spring, NY, USA, 2010; pp. 1–285. [Google Scholar]

- Zhou, Y.; Hu, J.; Dang, B.; He, J.L. Effect of different nanoparticles on tuning electrical properites of polypropylene nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1380–1389. [Google Scholar] [CrossRef]

- Cao, W.K.; Li, Z.; Sheng, G.H.; Jiang, X.C. Insulating property of polypropylene nanocomposites filled with nano-MgO of different concentration. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1430–1437. [Google Scholar] [CrossRef]

- Takala, M.; Ranta, H.; Nevalainen, P.; Pakonen, P.; Pelto, J.; Karttunen, M.; Virtanen, S.; Koivu, V.; Pettersson, M.; Sonerud, B.; et al. Dielectric properties and partial discharge endurance of polypropylene-silica nanocomposite. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1259–1267. [Google Scholar] [CrossRef]

- Lewis, T.J. Interfaces are the dominant feature of dielectrics at the nanometric level. IEEE Trans. Dielectr. Electr. Insul. 2004, 11, 739–753. [Google Scholar] [CrossRef]

- Lewis, T.J. Interfaces: Nanometric dielectrics. J. Phys. D Appl. Phys. 2005, 38, 202–212. [Google Scholar] [CrossRef]

- Li, S.; Yin, G.; Chen, G.; Li, J.; Bai, S.; Zhong, L.; Zhang, Y.; Lei, Q.Q. Short-term Breakdown and Long-term Failure in Nanodielectrics: A Review. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1523–1535. [Google Scholar] [CrossRef]

- Tanaka, T. Dielectric nanocomposites with insulating properties. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 914–928. [Google Scholar] [CrossRef]

- Tanaka, T.; Kozako, M.; Fuse, N.; Ohki, Y. Proposal of a multi-core model for polymer nanocomposite dielectrics. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 669–681. [Google Scholar] [CrossRef]

- Takada, T.; Hayase, Y.; Tanaka, Y.; Okamoto, T. Space Charge Trapping in Electrical Potential Well Caused by Permanent and Induced Dipoles for LDPE/MgO Nanocomposite. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 152–160. [Google Scholar] [CrossRef]

- Min, D.M.; Wang, W.W.; Li, S.T. Numerical Analysis of Space Charge Accumulation and Conduction Properties in LDPE Nanodielectrics. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 1483–1491. [Google Scholar] [CrossRef]

- Dang, B.; He, J.L.; Hu, J.; Zhou, Y. Large improvement in trap level and space charge distribution of polypropylene by enhancing the crystalline-amorphous interface effect in blends. Polym. Int. 2016, 65, 371–379. [Google Scholar] [CrossRef]

- Dang, B.; HU, J.; Zhou, Y.; He, J.L. Remarkably improved electrical insulating performances of lightweight polypropylene nanocomposites with fullerene. J. Phys. D Appl. Phys. 2017, 50, 455303–455308. [Google Scholar] [CrossRef]

- Van Turnhout, J. Electrets; Springer: Berlin, Germany, 1987; pp. 81–215. [Google Scholar]

- Dang, B.; Zhou, Y.; He, J.L.; Hu, J. Relationship between space charge behaviors and trap level distribution in polypropylene/propylene ethylene rubber/ZnO nanocomposites. In Proceedings of the 2016 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Toronto, ON, Canada, 16–19 October 2016; pp. 595–598. [Google Scholar]

- Zhang, C.; Zha, J.W.; Yan, H.D.; Li, W.K.; Dang, Z.M. High improvement in trap level density and direct current breakdown strength of block polypropylene by doping with a β-nucleating agent. Appl. Phys. Lett. 2018, 112, 91902–91905. [Google Scholar] [CrossRef]

- Le Roy, S.; Teyssedre, G.; Laurent, C.; Montanari, G.C.; Palmieri, F. Description of charge transport in polyethylene using a fluid model with a constant mobility: Fitting model and experiments. J. Phys. D Appl. Phys. 2006, 39, 1427–1436. [Google Scholar] [CrossRef]

- Teyssèdre, G.; Laurent, C. Charge transport modeling in insulating polymers: From molecular to macroscopic scale. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 857–875. [Google Scholar] [CrossRef]

- Berlepsch, H.V. Interpretation of surface potential kinetics in HDPE by a trapping model. J. Phys. D Appl. Phys. 1985, 18, 1155–1170. [Google Scholar] [CrossRef]

- Sonnonstine, T.J.; Perlman, M.M. Surface-potential decay in insulators with field-dependent mobility and injection efficiency. J. Appl. Phys. 1975, 46, 3975–3981. [Google Scholar] [CrossRef]

- Wintle, H.J. Surface-Charge Decay in Insulators with Nonconstant Mobility and with Deep Trapping. J. Appl. Phys. 1972, 43, 2927–2930. [Google Scholar] [CrossRef]

- Hoang, A.T.; Pallon, L.; Liu, D.M.; Serdyuk, Y.V.; Gubanski, S.M.; Gedde, U.W. Charge transport in LDPE nanocomposites part I–experimental approach. Polymers 2016, 8, 87. [Google Scholar] [CrossRef]

- Coelho, R.; Aladenize, B.; Cornet, N. On the transient potential in insulators. IEEE Trans. Dielectr. Electr. Insul. 2001, 8, 760–770. [Google Scholar] [CrossRef]

- Dissado, L.A.; Fothergill, J.C. Electrical Degradation and Breakdown in Polymers; The Institution of Engineering and Technology: London, UK, 1992; pp. 24–316. [Google Scholar]

- Kao, K.C. Dielectric Phenomena in Solids; Elsevier: San Diego, CA, USA, 2004; pp. 327–572. [Google Scholar]

- Matsui, K.; Tanaka, Y.; Takada, T.; Fukao, T. Space Charge Behavior in Low-density Polyethylene at Pre-breakdown. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 406–415. [Google Scholar] [CrossRef]

- Min, D.M.; Li, S.T.; Ohki, Y. Numerical Simulation on Molecular Displacement and DC Breakdown of LDPE. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 507–516. [Google Scholar] [CrossRef]

- Le Roy, S.; Segur, P.; Teyssedre, G.; Laurent, C. Description of Bipolar Charge Transport in Polyethylene Using a Fluid Model with a Constant Mobility: Model Prediction. J. Phys. D Appl. Phys. 2004, 37, 298–305. [Google Scholar] [CrossRef]

- Chen, G.; Zhao, J.; Li, S.; Zhong, L. Origin of thickness dependent dc electrical breakdown in dielectrics. Appl. Phys. Lett. 2012, 100, 222904. [Google Scholar] [CrossRef]

- Lowell, J. Absorption and conduction currents in polymers: A unified model. J. Phys. D Appl. Phys. 1990, 23, 205–210. [Google Scholar] [CrossRef]

- Scott, J.C.; Malliaras, G.G. Charge injection and recombination at the metal-organic interface. Chem. Phys. Lett. 1999, 299, 115–119. [Google Scholar] [CrossRef]

- Van der Holst, J.J.M.; van Oost, F.W.A.; Coehoorn, R.; Bobbert, P.A. Electron-hole recombination in disordered organic semiconductors: Validity of the Langevin formula. Phys. Rev. B 2009, 80, 235202–235208. [Google Scholar] [CrossRef]

- Shockley, W.; Read, W.T. Statistics of the Recombinations of Holes and Electrons. Phys. Rev. 1952, 87, 835–842. [Google Scholar] [CrossRef]

- Kuik, M.; Koster, L.J.A.; Wetzelaer, G.A.H.; Blom, P.W.M. Trap-assisted recombination in disordered organic semiconductors. Phys. Rev. Lett. 2011, 107, 256805. [Google Scholar] [CrossRef] [PubMed]

- Collins, G.; Federici, J.; Imura, Y.; Catalani, L.H. Charge generation, charge transport, and residual charge in the electrospinning of polymers: A review of issues and complications. J. Appl. Phys. 2012, 111, 44701. [Google Scholar] [CrossRef]

- Das-Gupta, D.K. Dielectric and related molecular processes in polymers. IEEE Trans. Dielectr. Electr. Insul. 2001, 8, 6–14. [Google Scholar] [CrossRef]

- Artbauer, J. Electric strength of polymers. J. Phys. D Appl. Phys. 1996, 29, 446–456. [Google Scholar] [CrossRef]

- Boufayed, F.; Teyssedre, G.; Laurent, C.; Le Roy, S.; Dissado, L.A.; Segur, P.; Montanari, G.C. Models of bipolar charge transport in polyethylene. J. Appl. Phys. 2006, 100, 104105–104110. [Google Scholar] [CrossRef]

- Neagu, E.R. A method to measure the electric charge injected/extracted at the metal-dielectric interface. Appl. Phys. Lett. 2008, 92, 1829041–1829043. [Google Scholar] [CrossRef]

- Huzayyin, A.; Boggs, S.; Ramprasad, R. Quantum Mechanical Study of Charge Injection at the Interface of Polyethylene and Platinum. In Proceedings of the 2011 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Cancun, Mexico, 16–19 October 2011; pp. 800–803. [Google Scholar]

- Chen, L.H.; Huan, T.D.; Quintero, Y.C.; Ramprasad, R. Charge injection barriers at metal/polyethylene interfaces. J. Mater. Sci. 2016, 51, 506–512. [Google Scholar] [CrossRef]

- Cockburn, B.; Shu, C.W. Runge-Kutta Discontinuous Galerkin Methods for Convection-Dominated Problems. J. Sci. Comput. 2001, 16, 173–261. [Google Scholar] [CrossRef]

- Gottlieb, S.; Shu, C.W. Total Variation Diminishing Runge-Kutta Schemes. Math. Comput. 1998, 67, 73–85. [Google Scholar] [CrossRef]

- Min, D.M.; Li, S.T. A Comparison of Numerical Methods for Charge Transport Simulation in Insulating Materials. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 955–964. [Google Scholar]

- Bansal, A.; Yang, H.; Li, C.; Cho, K.; Benicewicz, B.C.; Kumar, S.K.; Schadler, L.S. Quantitative equivalence between polymer nanocomposites and thin polymer films. Nat. Mater. 2005, 4, 693–698. [Google Scholar] [CrossRef] [PubMed]

- Seiler, J.; Kindersberger, J. Insight into the interphase in polymer nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 537–547. [Google Scholar] [CrossRef]

- Gong, S. Segmental dynamics of polymer melts with spherical nanoparticles. ACS Macro Lett. 2014, 3, 773–777. [Google Scholar] [CrossRef]

- Baeza, G.P.; Dessi, C.; Costanzo, S.; Zhao, D.; Gong, S.; Alegría, A.; Colby, R.H.; Rubinstein, M.; Vlassopoulos, D.; Kumar, S.K. Network dynamics in nanofilled polymers. Nat. Commun. 2016, 7, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Min, D.M.; Li, Y.W.; Yan, C.Y.; Xie, D.R.; Li, S.T.; Wu, Q.Z.; Xing, Z.L. Thickness-Dependent DC Electrical Breakdown of Polyimide Modulated by Charge Transport and Molecular Displacement. Polymers 2018, 10, 12. [Google Scholar] [CrossRef]

- Jones, J.P.; Llewellyn, J.P.; Lewis, T.J. The contribution of field–induced morphological change to the electrical aging and breakdown of polyethylene. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 951–966. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Min, D.; Yan, C.; Mi, R.; Ma, C.; Huang, Y.; Li, S.; Wu, Q.; Xing, Z. Carrier Transport and Molecular Displacement Modulated dc Electrical Breakdown of Polypropylene Nanocomposites. Polymers 2018, 10, 1207. https://doi.org/10.3390/polym10111207

Min D, Yan C, Mi R, Ma C, Huang Y, Li S, Wu Q, Xing Z. Carrier Transport and Molecular Displacement Modulated dc Electrical Breakdown of Polypropylene Nanocomposites. Polymers. 2018; 10(11):1207. https://doi.org/10.3390/polym10111207

Chicago/Turabian StyleMin, Daomin, Chenyu Yan, Rui Mi, Chao Ma, Yin Huang, Shengtao Li, Qingzhou Wu, and Zhaoliang Xing. 2018. "Carrier Transport and Molecular Displacement Modulated dc Electrical Breakdown of Polypropylene Nanocomposites" Polymers 10, no. 11: 1207. https://doi.org/10.3390/polym10111207

APA StyleMin, D., Yan, C., Mi, R., Ma, C., Huang, Y., Li, S., Wu, Q., & Xing, Z. (2018). Carrier Transport and Molecular Displacement Modulated dc Electrical Breakdown of Polypropylene Nanocomposites. Polymers, 10(11), 1207. https://doi.org/10.3390/polym10111207