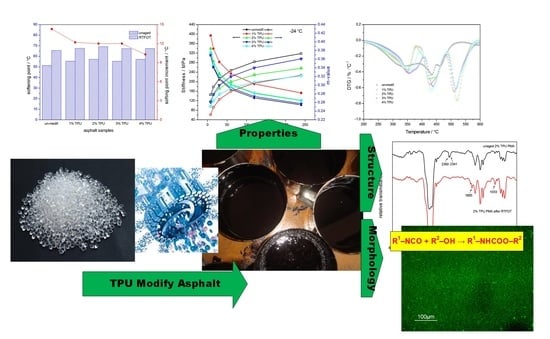

Investigation on the Short-Term Aging-Resistance of Thermoplastic Polyurethane-Modified Asphalt Binders

Abstract

:1. Introduction

2. The Experimental Process

2.1. Materials

2.2. Sample Preparations

2.3. Aging Procedure

2.4. Tests Procedures

2.4.1. Physical Properties Test

2.4.2. Low-Temperature Creep Test

2.4.3. Thermal Gravity Test

2.4.4. Storage Stability Test

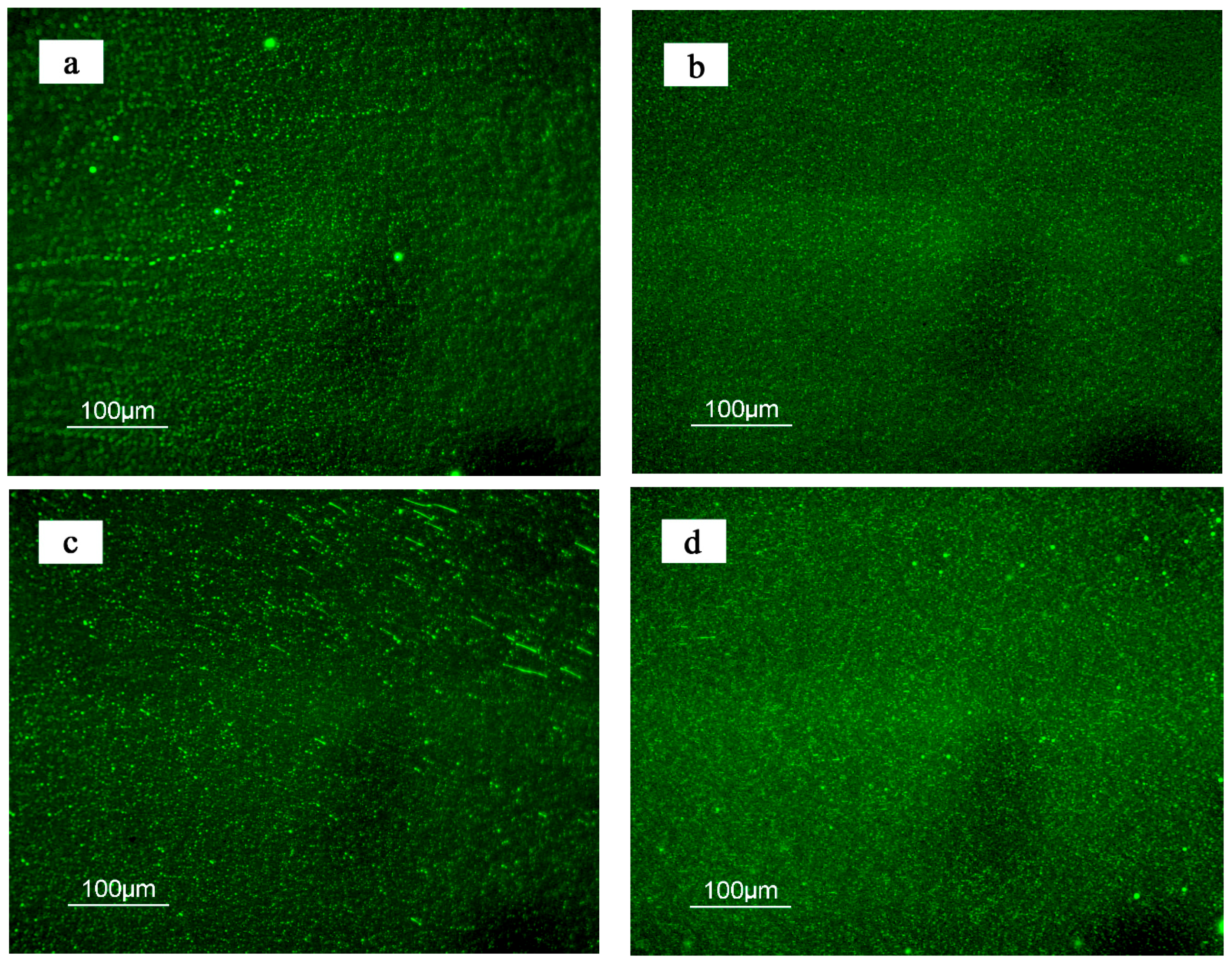

2.4.5. Morphology Observation

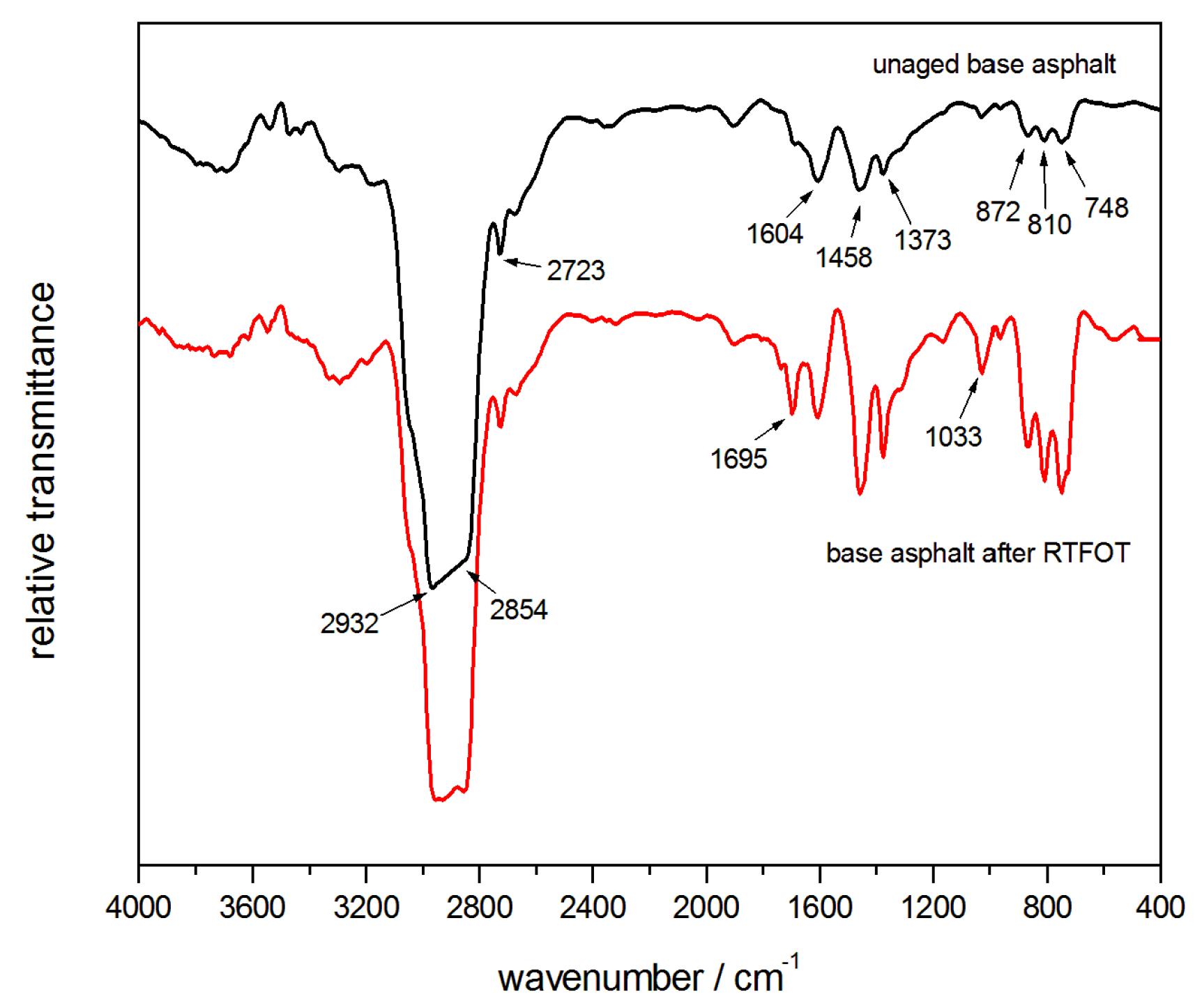

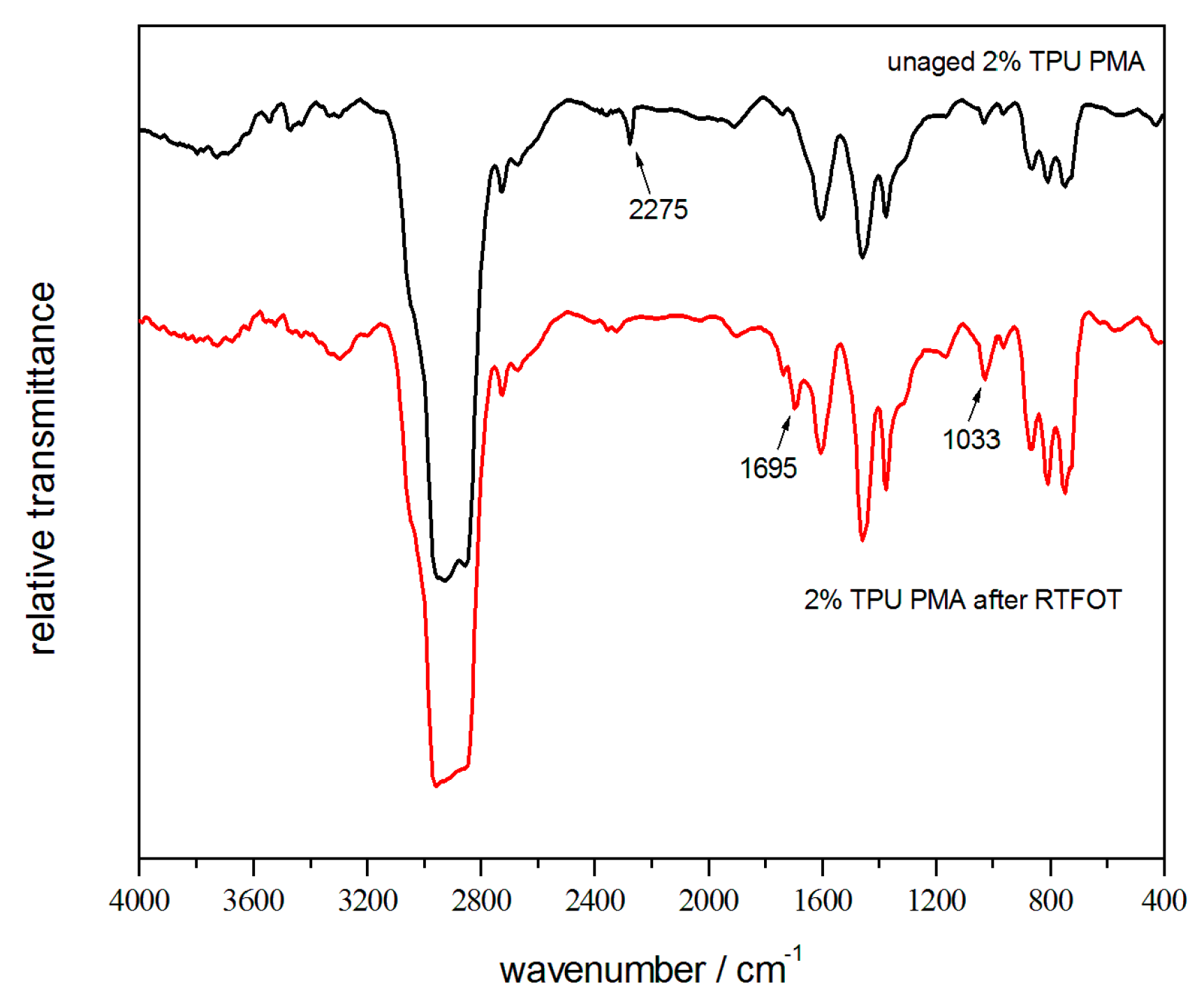

2.4.6. FTIR Test

3. Results and Discussion

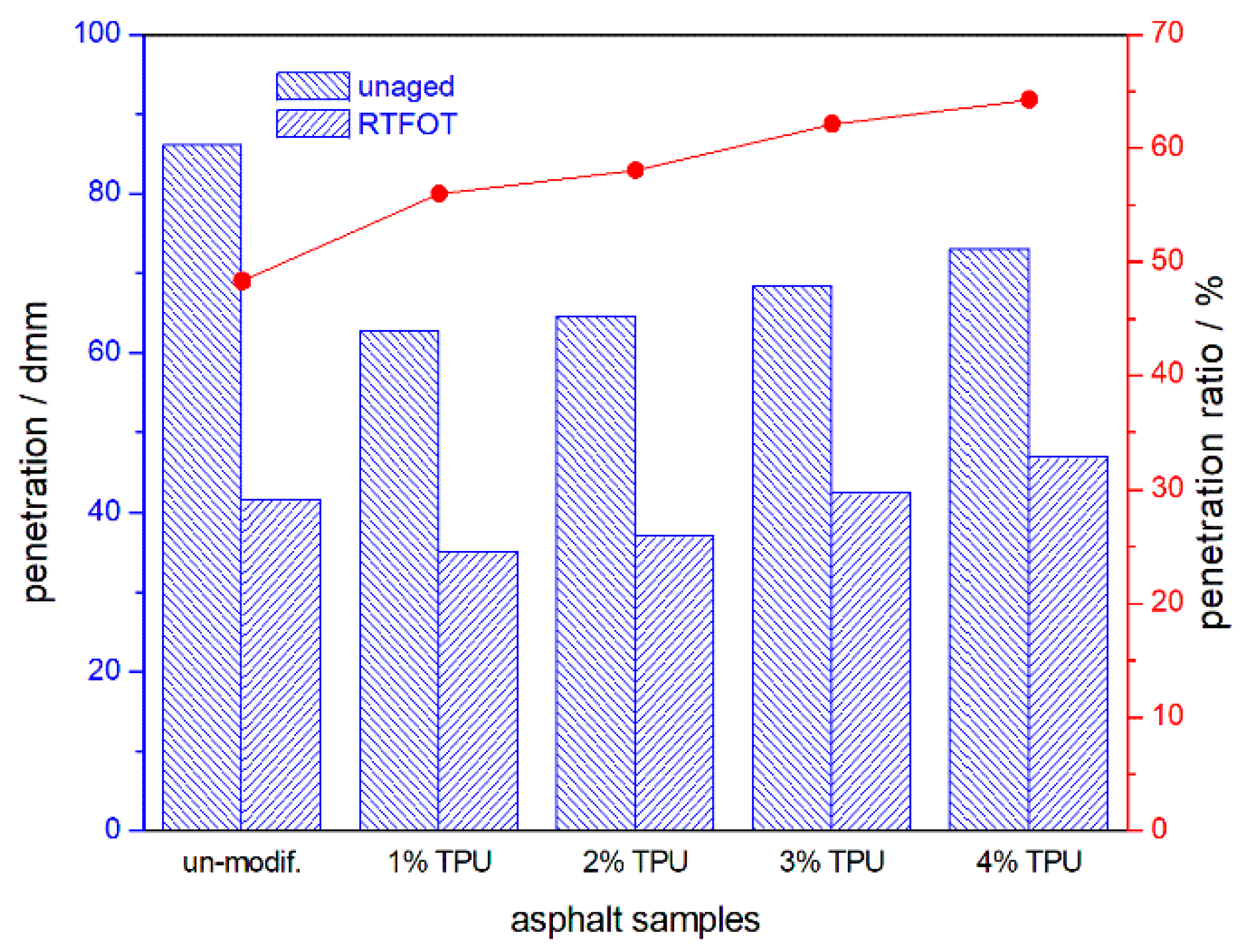

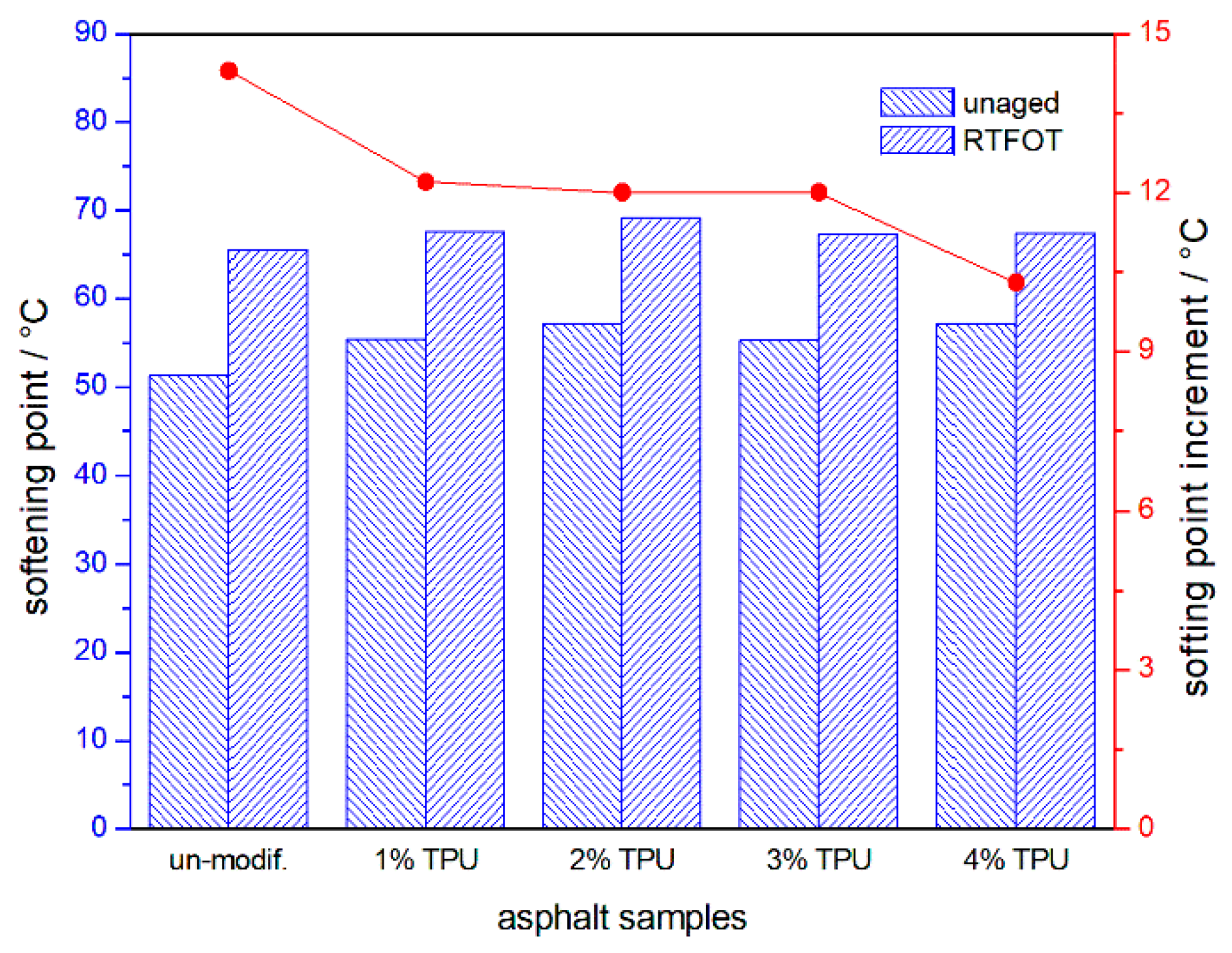

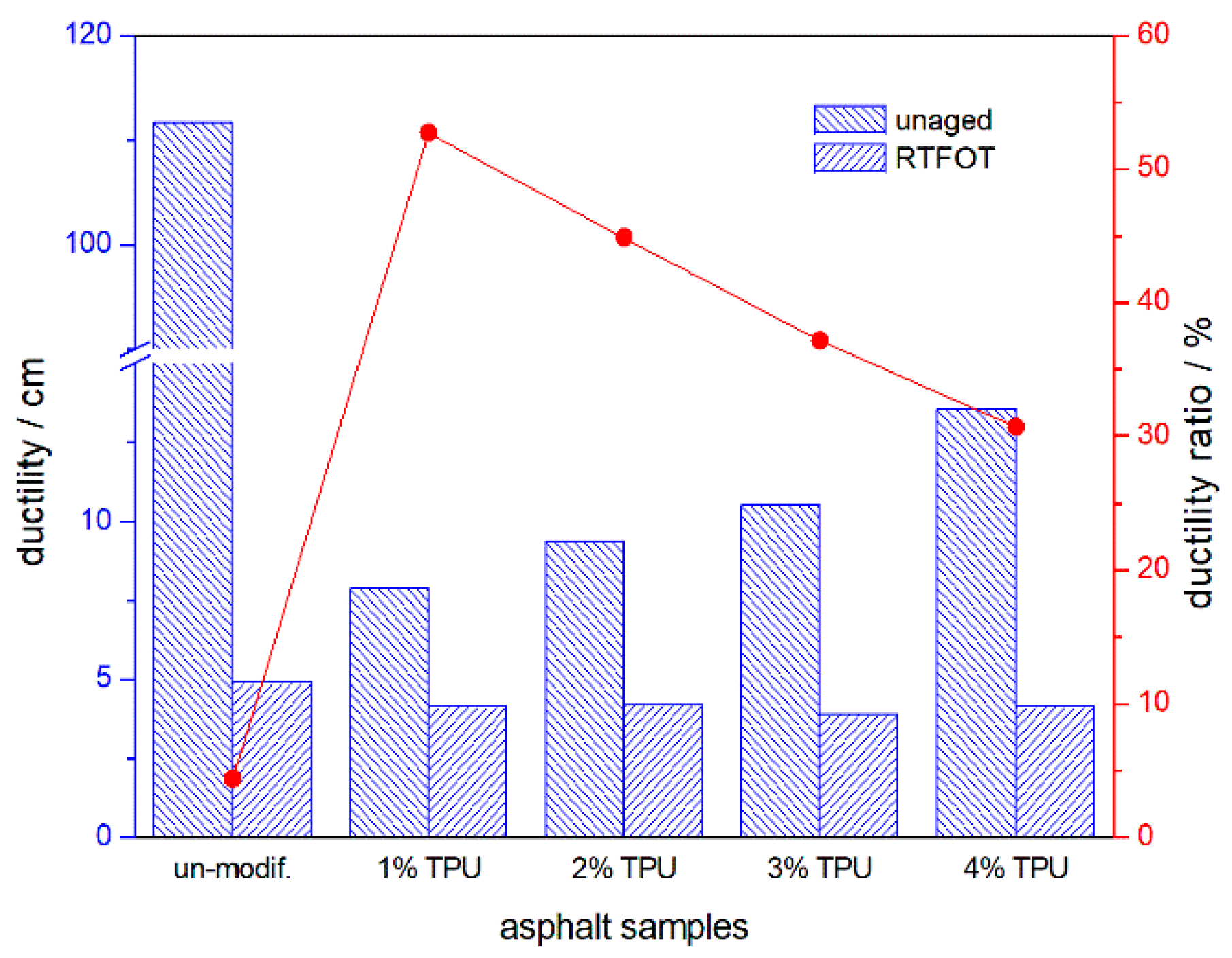

3.1. Physical Properties

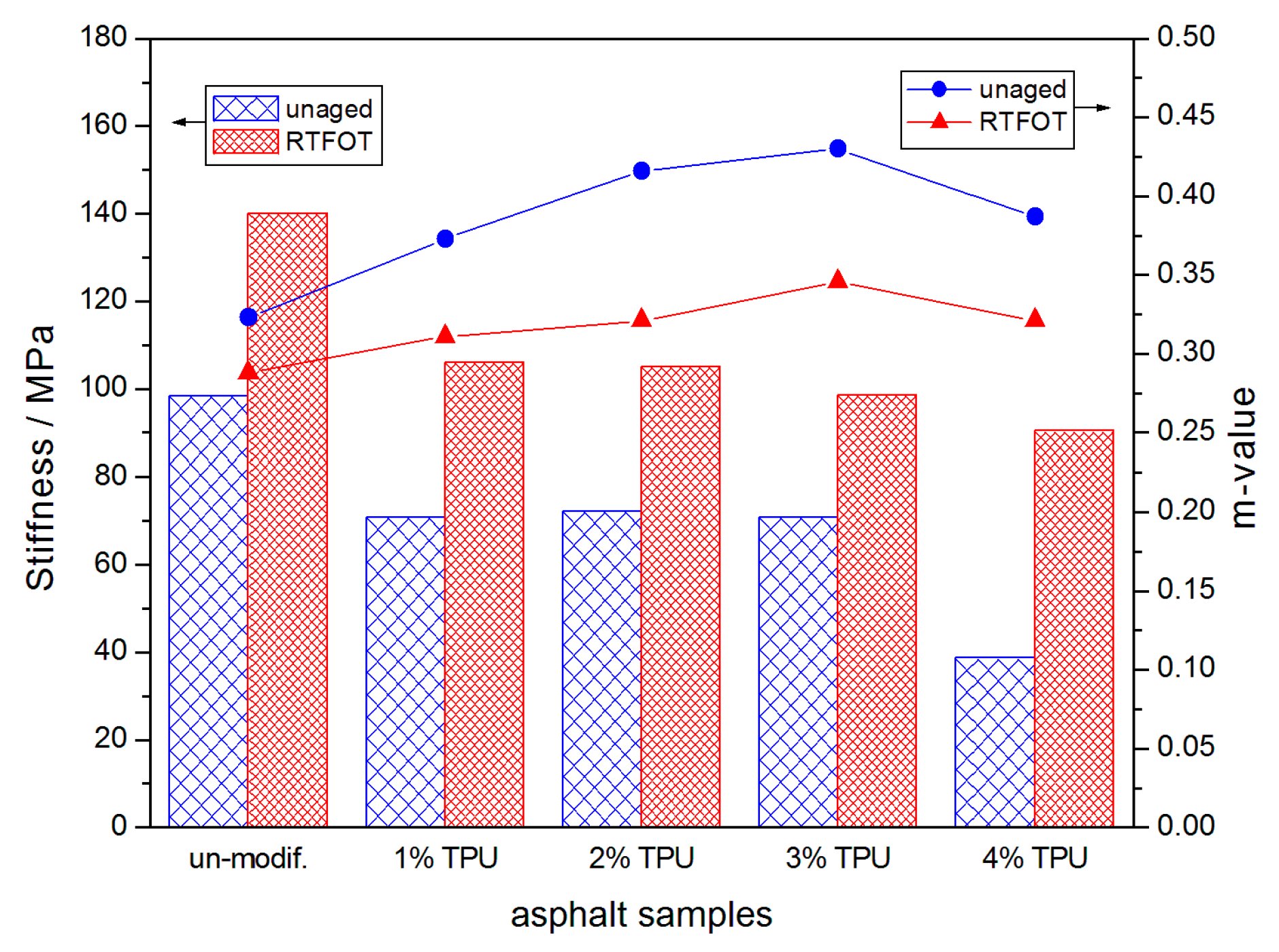

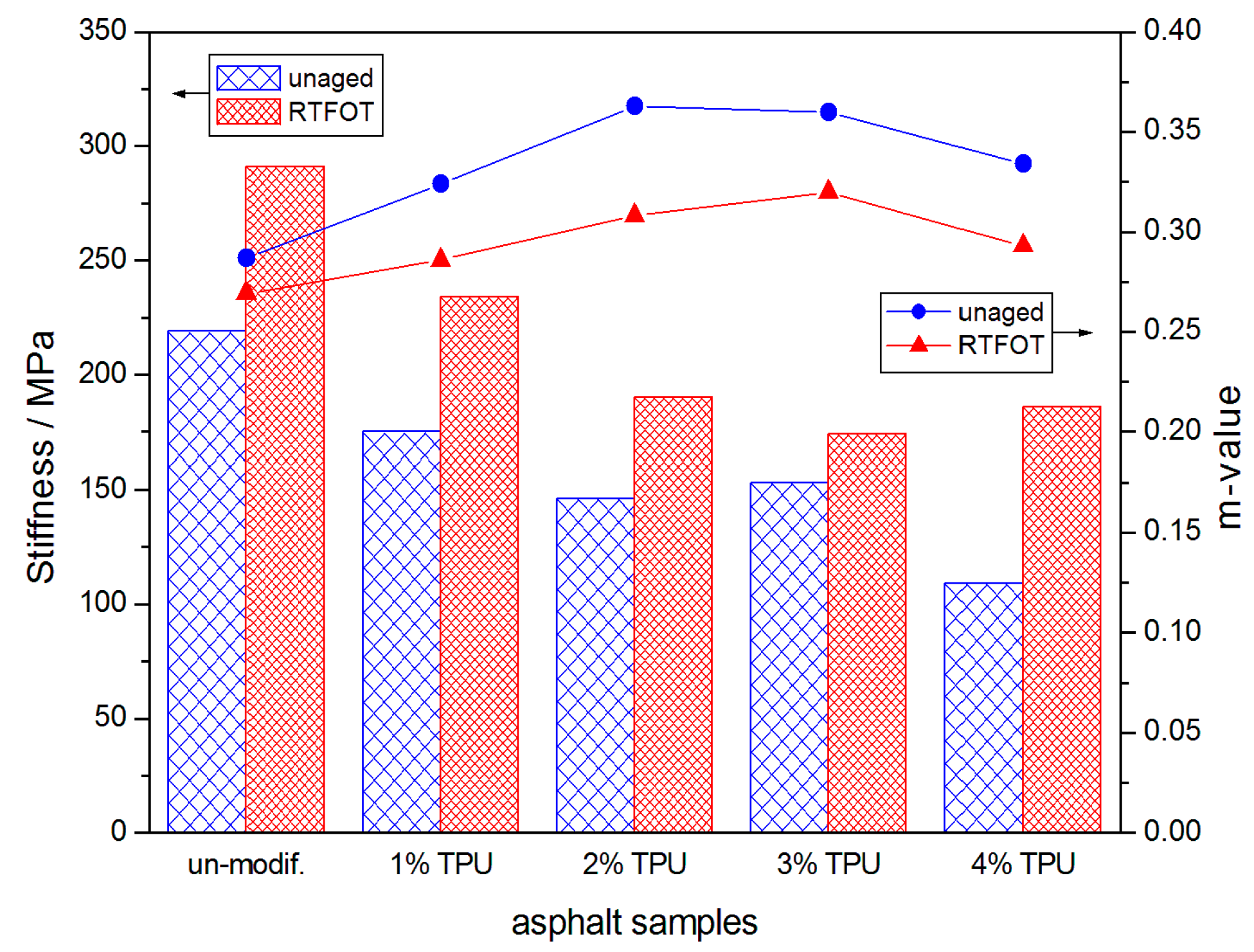

3.2. Low-Temperature Creep Properties

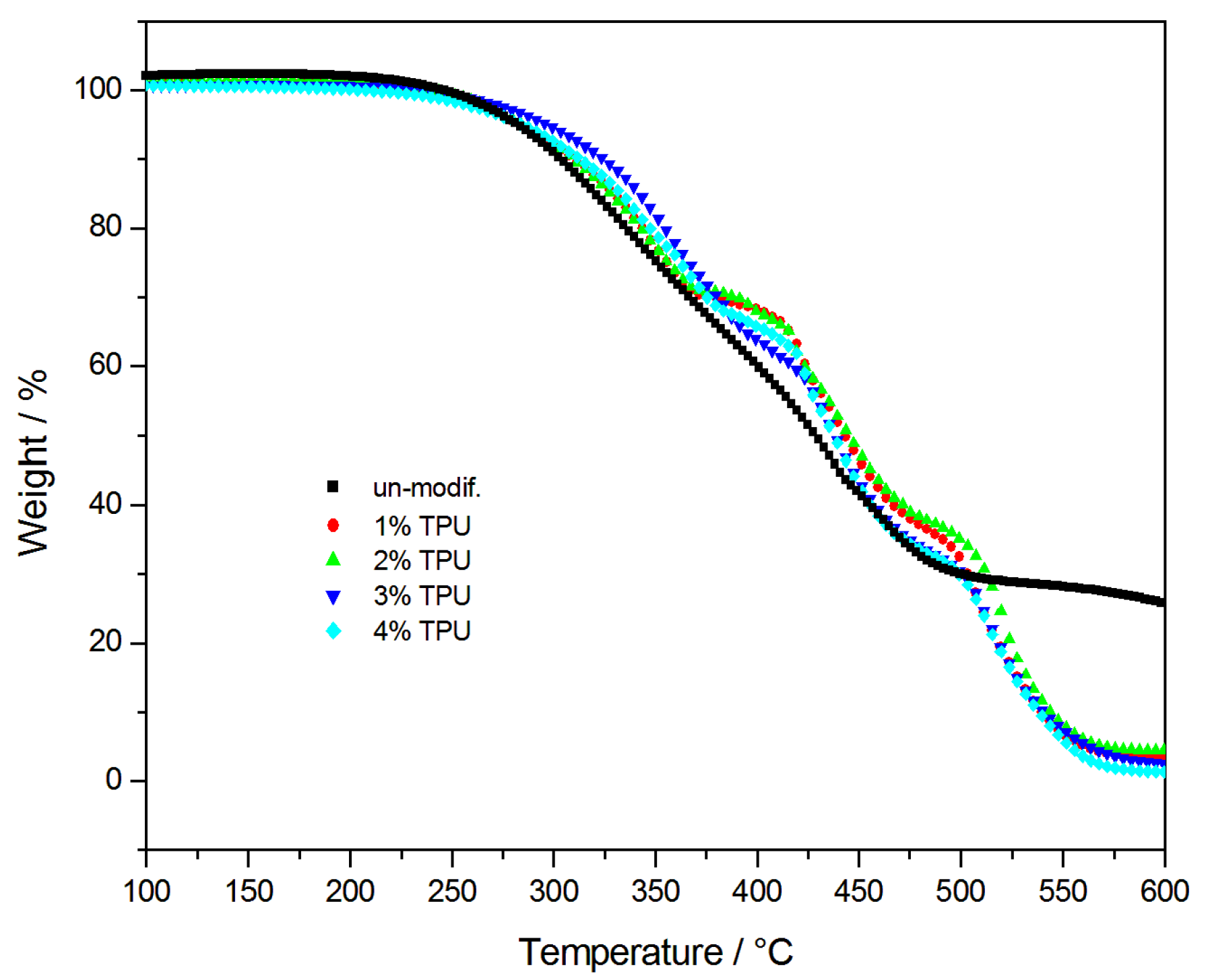

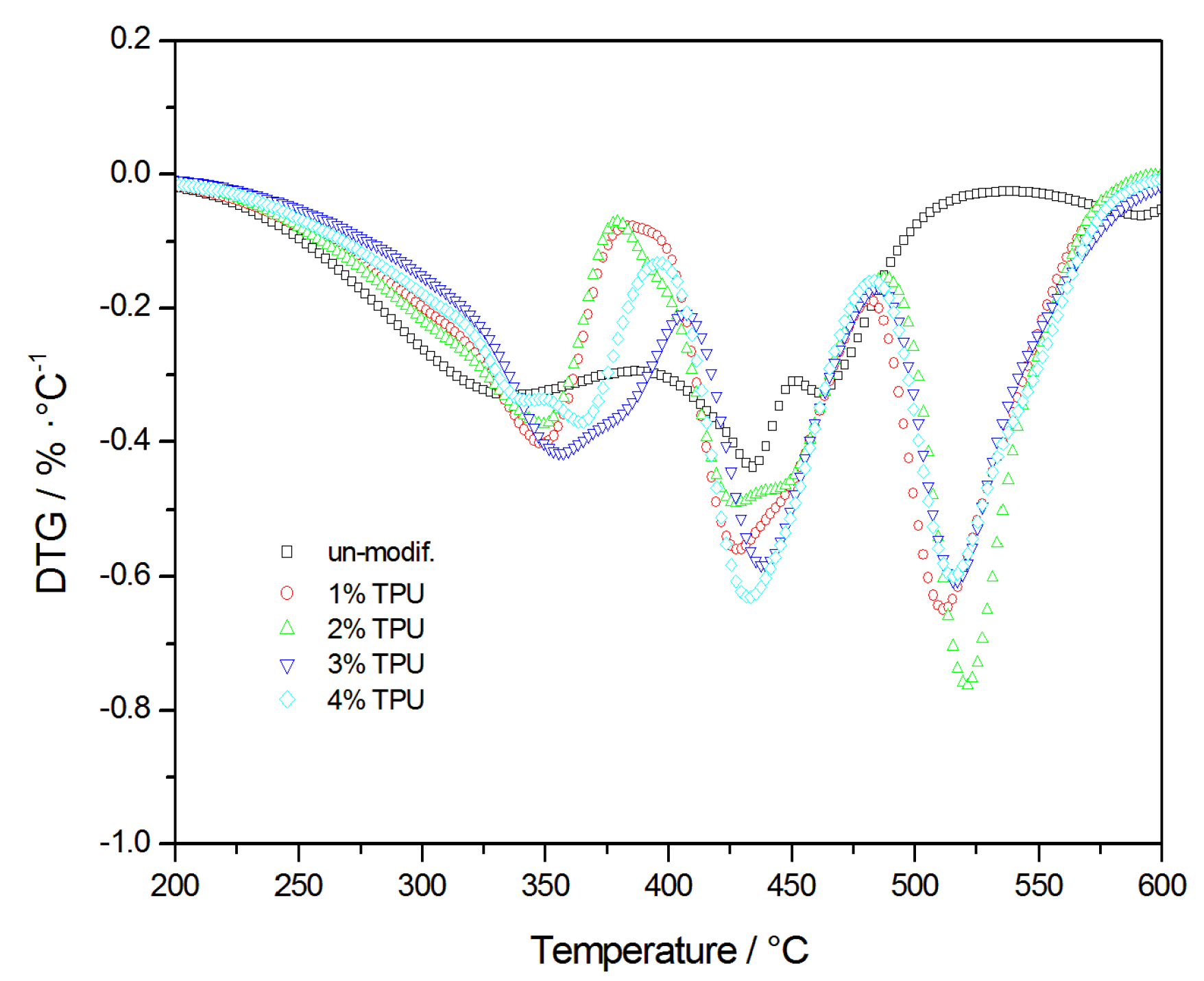

3.3. Thermal Properties

3.4. Storage Stability

3.5. Morphology

3.6. FTIR Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- McNally, T. Introduction to Polymer Modified Bitumen. In Polymer Modified Bitumen: Properties and Characterization; McNally, T., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2011; pp. 1–21. ISBN 978-0-85709-048-5. [Google Scholar]

- Chen, H.X.; Xu, Q.W. Experimental Study of Fibers in Stabilizing and Reinforcing Asphalt Binder. Fuel 2010, 89, 1616–1622. [Google Scholar] [CrossRef]

- Yu, R.E.; Zhu, X.J.; Zhou, X.; Kou, Y.F.; Zhang, M.R.; Fang, C.Q. Rheological properties and storage stability of asphalt modified with nanoscale polyurethane emulsion. Petrol. Sci. Technol. 2018, 36, 85–90. [Google Scholar] [CrossRef]

- Jeong, K.D.; Lee, S.J.; Amirkhanian, S.N.; Kim, K.W. Interaction Effects of Crumb Rubber Modified Asphalt Binders. Constr. Build. Mater. 2010, 24, 824–831. [Google Scholar] [CrossRef]

- Pang, L.; Liu, K.Y.; Wu, S.P.; Lei, M.; Chen, Z.W. Effect of LDHs on the Aging Resistance of Crumb Rubber Modified Asphalt. Constr. Build. Mater. 2014, 67, 239–243. [Google Scholar] [CrossRef]

- Modarres, A. Investigating the Toughness and Fatigue Behavior of Conventional and SBS Modified Asphalt Mixes. Constr. Build. Mater. 2013, 47, 218–222. [Google Scholar] [CrossRef]

- Bai, M. Investigation of Low-temperature Properties of Recycling of Aged SBS Modified Asphalt Binder. Constr. Build. Mater. 2017, 150, 766–773. [Google Scholar] [CrossRef]

- Özen, H. Rutting Evaluation of Hydrated Lime and SBS Modified Asphalt Mixtures for Laboratory and Field Compacted Samples. Constr. Build. Mater. 2011, 25, 756–765. [Google Scholar] [CrossRef]

- Behnood, A.; Olek, J. Rheological Properties of Asphalt Binders Modified with Styrene-butadiene-styrene (SBS), Ground Tire Rubber (GTR), or Polyphosphoric Acid (PPA). Constr. Build. Mater. 2017, 151, 464–478. [Google Scholar] [CrossRef]

- Yu, R.E.; Liu, X.L.; Zhang, M.R.; Zhu, X.J.; Fang, C.Q. Dynamic Stability of Ethylene-vinyl Acetate Copolymer/Crumb Rubber Modified Asphalt. Constr. Build. Mater. 2017, 156, 284–292. [Google Scholar] [CrossRef]

- Liang, M.; Xin, X.; Fan, W.Y.; Ren, S.S.; Shi, J.T.; Luo, H. Thermo-stability and Aging Performance of Modified Asphalt with Crumb Rubber Activated by Microwave and TOR. Mater. Des. 2017, 127, 84–96. [Google Scholar] [CrossRef]

- Rodríguez-Alloza, A.M.; Gallego, J.; Pérez, I.; Bonati, A.; Giuliani, F. High and Low Temperature Properties of Crumb Rubber Modified Binders Containing Warm Mix Asphalt Additives. Constr. Build. Mater. 2014, 53, 460–466. [Google Scholar] [CrossRef]

- Polacco, G.; Filippi, S.; Merusi, F.; Stastna, G. A Review of the Fundamentals of Polymer-modified Asphalts: Asphalt/polymer Interactions and Principles of Compatibility. Adv. Colloid Interface Sci. 2015, 224, 72–112. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.L.; Yu, J.Y.; Wang, H.C.; Xue, L.H. Investigation of Microstructures and Ultraviolet Aging Properties of Organo-Montmorillonite/SBS Modified Bitumen. Mater. Chem. Phys. 2011, 129, 769–776. [Google Scholar] [CrossRef]

- Zhang, H.L.; Yu, J.Y.; Wu, S.P. Effect of Montmorillonite Organic Modification on Ultraviolet Aging Properties of SBS Modified Bitumen. Constr. Build. Mater. 2012, 27, 553–559. [Google Scholar] [CrossRef]

- Drobny, J.G. Handbook of Thermoplastic Elastomers; William Andrew Publishing: New York, NY, USA, 2007; p. 179. ISBN 978-0-323-22136-8. [Google Scholar]

- Cuadri, A.A.; García-Morales, M.; Navarro, F.J.; Partal, P. Processing of Bitumens Modified by a Bio-Oil-Derived Polyurethane. Fuel 2014, 118, 83–90. [Google Scholar] [CrossRef]

- Martín-Alfonso, M.J.; Partal, P.; Navarro, F.J.; García-Morales, M.; Gallegos, C. Use of a MDI-Functionalized Reactive Polymer for the Manufacture of Modified Bitumen with Enhanced Properties for Roofing Applications. Eur. Polym. J. 2008, 44, 1451–1461. [Google Scholar] [CrossRef]

- Carrera, V.; Partal, P.; García-Morales, M.; Gallegos, C.; Páez, A. Influence of Bitumen Colloidal Nature on the Design of Isocyanate-Based Bituminous Products with Enhanced Rheological Properties. Ind. Eng. Chem. Res. 2009, 48, 8464–8470. [Google Scholar] [CrossRef]

- Carrera, V.; Garcia-Morales, M.; Partal, P.; Gallegos, C. Novel Bitumen/Isocyanate-Based Reactive Polymer Formulations for the Paving Industry. Rheol. Acta 2010, 49, 563–572. [Google Scholar] [CrossRef]

- Xia, L.; Cao, D.W.; Zhang, H.Y.; Guo, Y.S. Study on the Classical and Rheological Properties of Castor Oil-Polyurethane Prepolymer (C-PU) Modified Asphalt. Constr. Build. Mater. 2016, 112, 949–955. [Google Scholar] [CrossRef]

- Cong, P.L.; Chen, S.F.; Yu, J.Y.; Wu, S.P. Effects of Aging on the Properties of Modified Asphalt Binder with Flame Retardants. Constr. Build. Mater. 2010, 24, 2554–2558. [Google Scholar] [CrossRef]

- Dai, Z.; Shen, J.N.; Shi, P.C.; Zhu, H.; Li, X.S. Nano-sized Morphology of Asphalt Components Separated from Weathered Asphalt Binders. Constr. Build. Mater. 2018, 182, 588–596. [Google Scholar] [CrossRef]

- Bonati, A.; Merusi, F.; Polacco, G.; Filippi, S.; Giuliani, F. Ignitability and Thermal Stability of Asphalt Binders and Mastics for Flexible Pavements in Highway Tunnels. Constr. Build. Mater. 2012, 37, 660–668. [Google Scholar] [CrossRef]

- Singh, B.; Tarannum, H.; Gupta, M. Use of Isocyanate Production Waste in the Preparation of Improved Waterproofing Bitumen. J. Appl. Polym. Sci. 2003, 90, 1365–1377. [Google Scholar] [CrossRef]

- Navarro, F.J.; Partal, P.; García-Morales, M.; Martínez-Boza, F.J.; Gallegos, C. Bitumen Modification with a Low-Molecular-Weight Reactive Isocyanate-Terminated Polymer. Fuel 2007, 86, 2291–2299. [Google Scholar] [CrossRef]

- Fang, C.Q.; Liu, P.; Yu, R.E.; Liu, X.L. Preparation Process to Affect Stability in Waste Polyethylene-Modified Bitumen. Constr. Build. Mater. 2014, 54, 320–325. [Google Scholar] [CrossRef]

- Sengoz, B.; Isikyakar, G. Analysis of Styrene-Butadiene-Styrene Polymer Modified Bitumen Using Fluorescent Microscopy and Conventional Test Methods. J. Hazard. Mater. 2008, 150, 424–432. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Yu, J.Y.; Han, J. Effects of Thermal Oxidative Ageing on Dynamic Viscosity, TG/DTG, DTA and FTIR of SBS- and SBS/Sulfur-Modified Asphalts. Constr. Build. Mater. 2011, 25, 129–137. [Google Scholar] [CrossRef]

- Fang, C.Q.; Yu, R.E.; Li, Y.; Zhang, M.Y.; Hu, J.B.; Zhang, M. Preparation and Characterization of an Asphalt-Modifying Agent with Waste Packaging Polyethylene and Organic Montmorillonite. Polym. Test. 2013, 32, 953–960. [Google Scholar] [CrossRef]

| Asphalt Samples | Combustion Process | ||

|---|---|---|---|

| Stage 1 (Tpeak)/°C | Stage 2 (Tpeak)/°C | Stage 3 (Tpeak)/°C | |

| un-modif. | 282–387 (337) | 387–452(434) | 452–536 (461) |

| 1% TPU | 283–383 (349) | 383–482 (428) | 482–575 (512) |

| 2% TPU | 286–379 (349) | 379–488 (428) | 488–577 (521) |

| 3% TPU | 297–407 (356) | 407–485 (439) | 485–578 (517) |

| 4% TPU | 284–396 (364) | 396–483 (433) | 483–580 (516) |

| Asphalt Samples | 1% TPU | 2% TPU | 3% TPU | 4% TPU |

|---|---|---|---|---|

| Softening point in top/°C | 55.0 | 55.5 | 56.6 | 57.3 |

| Softening point in bottom/°C | 55.6 | 56.3 | 56.1 | 56.7 |

| ΔSP a | −0.6 | −0.8 | 0.5 | 0.6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, R.; Zhu, X.; Zhang, M.; Fang, C. Investigation on the Short-Term Aging-Resistance of Thermoplastic Polyurethane-Modified Asphalt Binders. Polymers 2018, 10, 1189. https://doi.org/10.3390/polym10111189

Yu R, Zhu X, Zhang M, Fang C. Investigation on the Short-Term Aging-Resistance of Thermoplastic Polyurethane-Modified Asphalt Binders. Polymers. 2018; 10(11):1189. https://doi.org/10.3390/polym10111189

Chicago/Turabian StyleYu, Ruien, Xijing Zhu, Maorong Zhang, and Changqing Fang. 2018. "Investigation on the Short-Term Aging-Resistance of Thermoplastic Polyurethane-Modified Asphalt Binders" Polymers 10, no. 11: 1189. https://doi.org/10.3390/polym10111189

APA StyleYu, R., Zhu, X., Zhang, M., & Fang, C. (2018). Investigation on the Short-Term Aging-Resistance of Thermoplastic Polyurethane-Modified Asphalt Binders. Polymers, 10(11), 1189. https://doi.org/10.3390/polym10111189