Monotype Organic Dual Threshold Voltage Using Different OTFT Geometries

Abstract

1. Introduction

2. Materials and Methods

3. Results

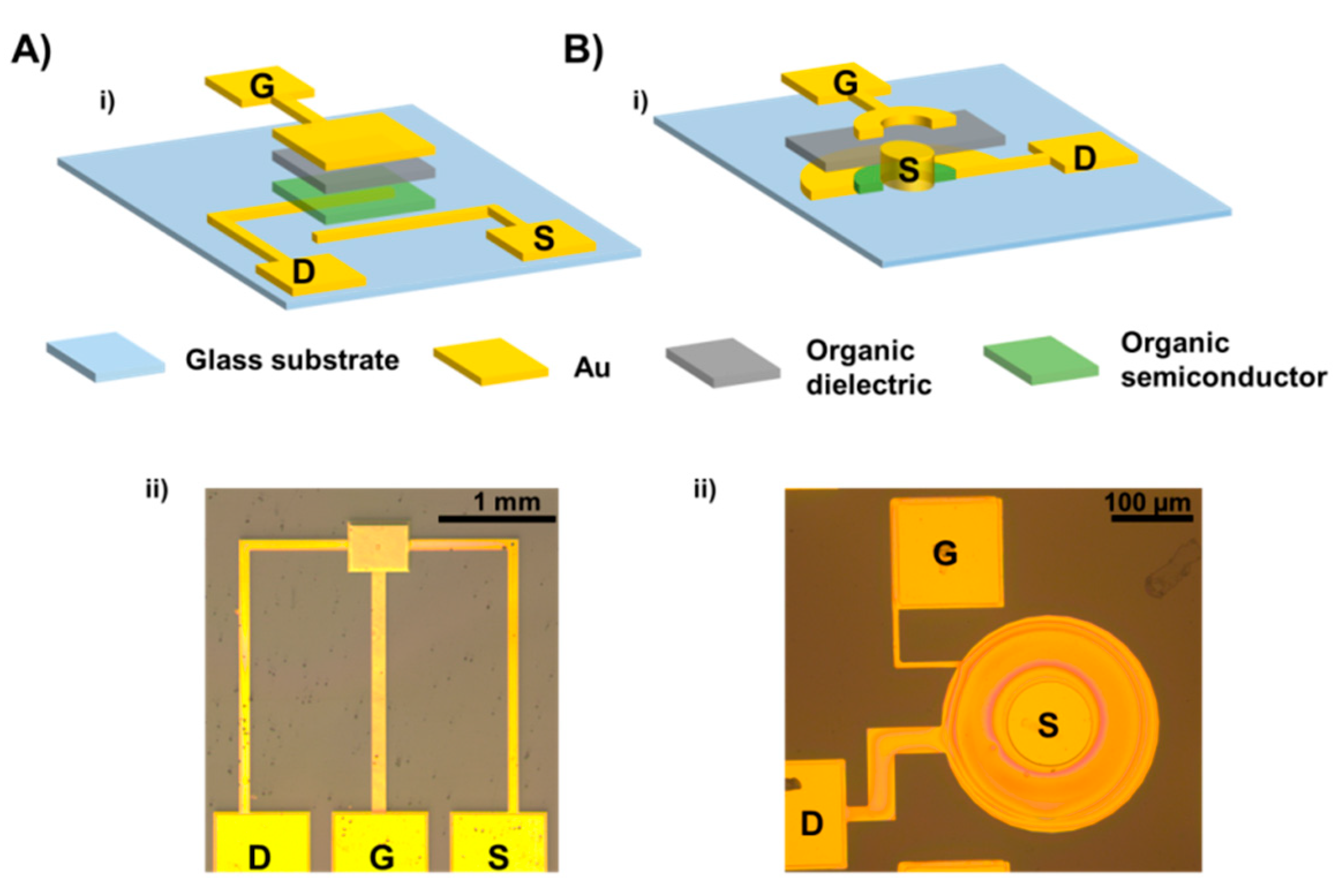

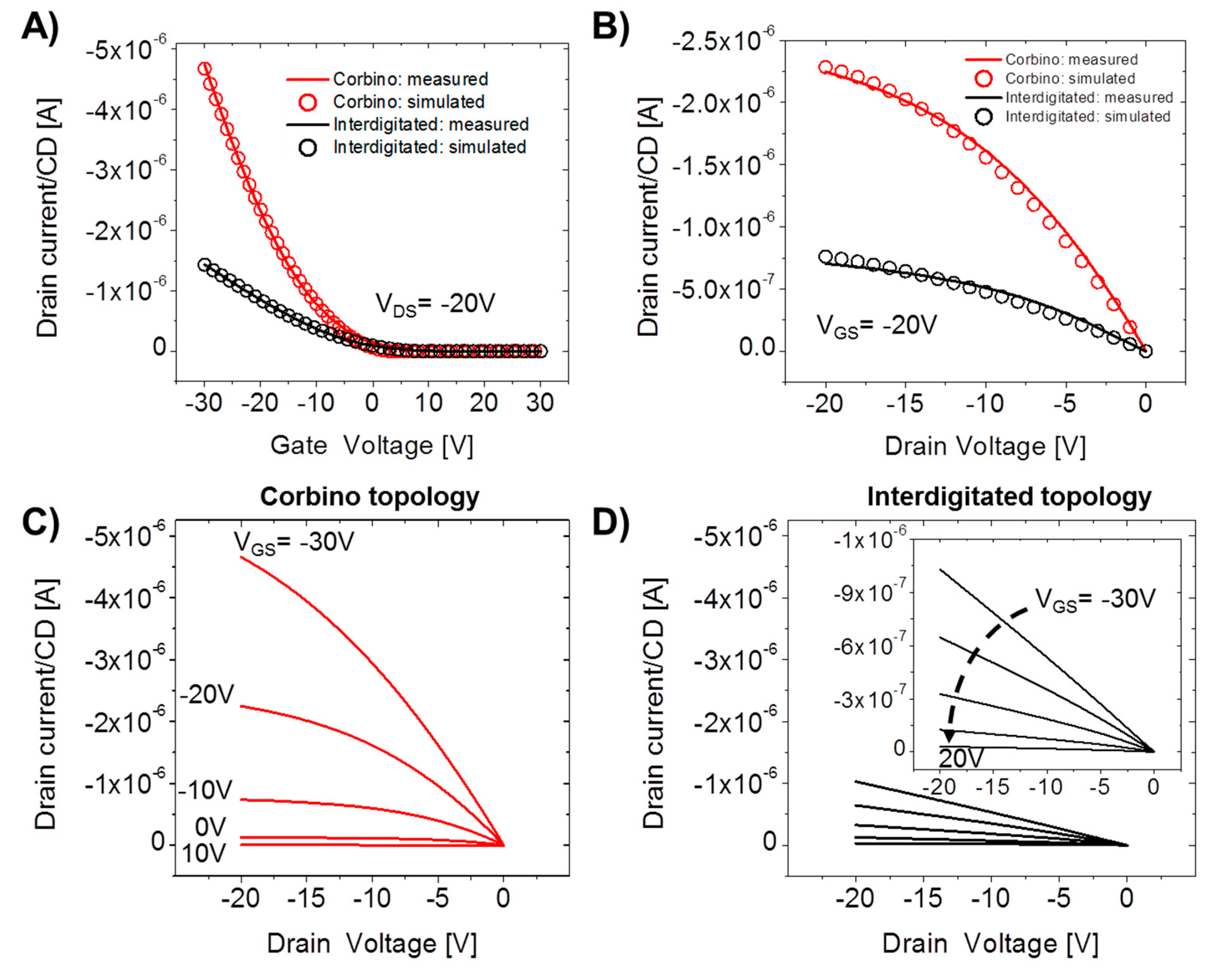

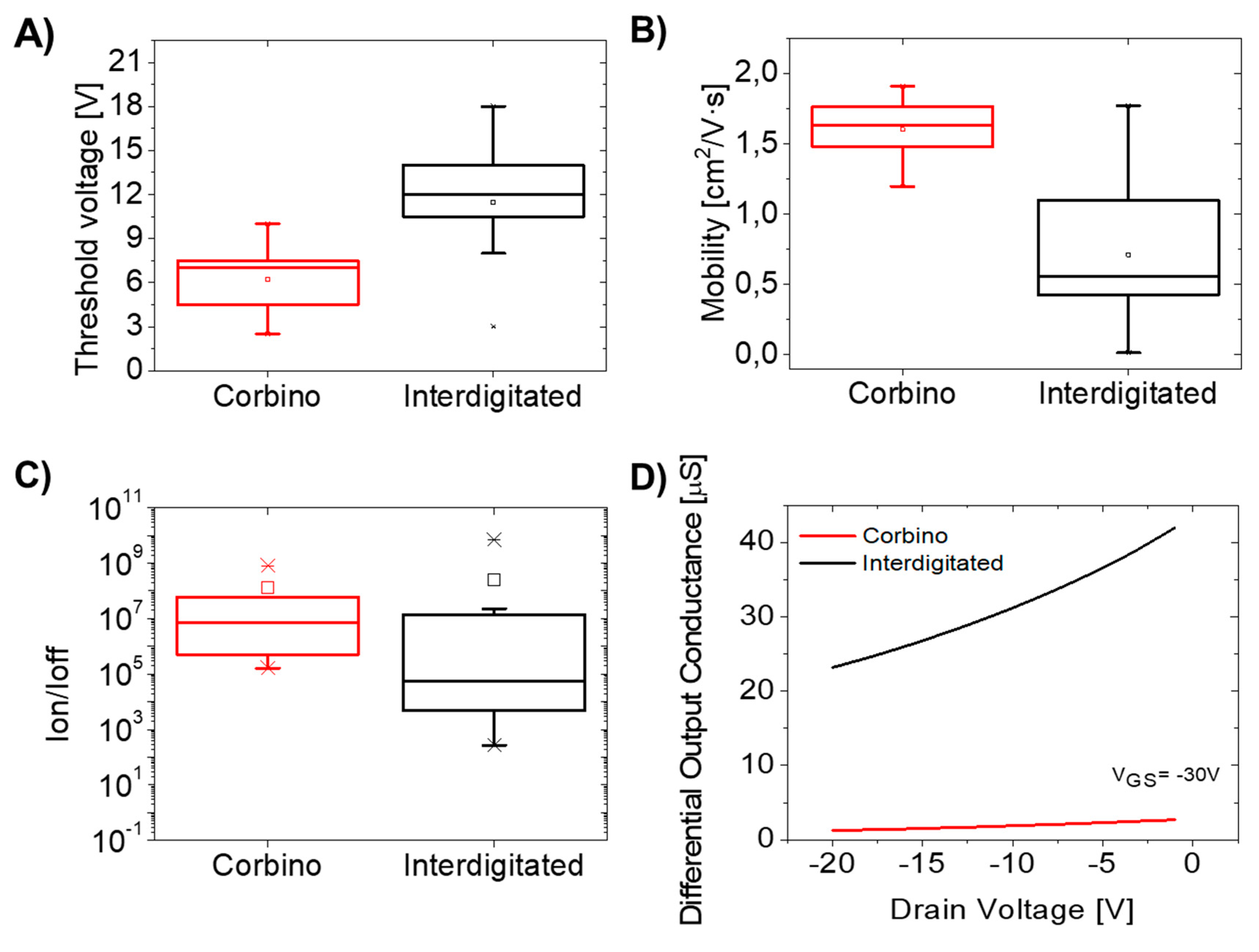

3.1. Interdigitated and Corbino OTFTs

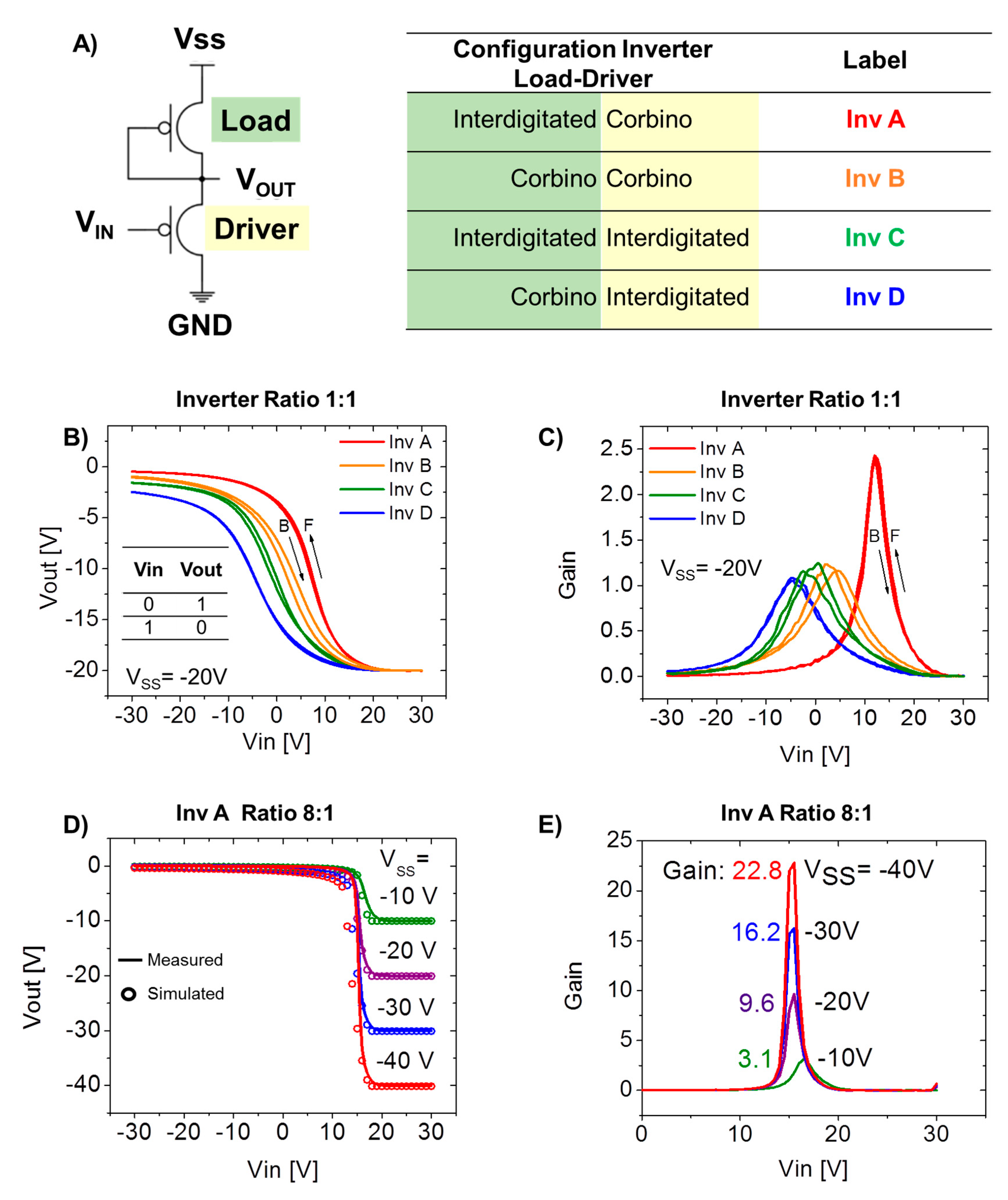

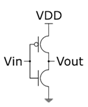

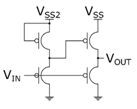

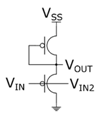

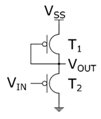

3.2. Unipolar Organic Dual-Geometry Threshold Voltage Inverter

4. Discussion

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tang, W.; Huang, Y.; Han, L.; Liu, R.; Su, Y.; Guo, X.; Yan, F. Recent progress in printable organic field effect transistors. J. Mater. Chem. C 2019, 7, 790–808. [Google Scholar] [CrossRef]

- Sirringhaus, H. 25th anniversary article: Organic field-effect transistors: The path beyond amorphous silicon. Adv. Mater. 2014, 26, 1319–1335. [Google Scholar] [CrossRef] [PubMed]

- Chang, J.S.; Facchetti, A.F.; Reuss, R.; Member, S.; Facchetti, A.F.; Reuss, R. A Circuits and Systems Perspective of Organic/Printed Electronics: Review, Challenges, and Contemporary and Emerging Design Approaches. IEEE J. Emerg. Sel. Top. Circuits Syst. 2017, 7, 7–26. [Google Scholar] [CrossRef]

- Gamota, D.R. Printed organic and molecular electronics. Mater. Today 2004, 7, 53. [Google Scholar]

- Ling, M.M.; Bao, Z. Thin film deposition, patterning, and printing in organic thin film transistors. Chem. Mater. 2004, 16, 4824–4840. [Google Scholar] [CrossRef]

- Chabinyc, M.L.; Salleo, A. Materials requirements and fabrication of active matrix arrays of organic thin-film transistors for displays. Chem. Mater. 2004, 16, 4509–4521. [Google Scholar] [CrossRef]

- Chou, W.Y.; Kuo, C.W.; Cheng, H.L.; Chen, Y.R.; Tang, F.C.; Yang, F.Y.; Shu, D.Y.; Liao, C.C. Effect of surface free energy in gate dielectric in pentacene thin-film transistors. Appl. Phys. Lett. 2006, 89, 2004–2007. [Google Scholar] [CrossRef]

- Forrest, S.R. The path to ubiquitous and low-cost organic electronic appliances on plastic. Nature 2014, 428, 911–918. [Google Scholar] [CrossRef]

- Anthopoulos, T.D.; De Leeuw, D.M.; Cantatore, E.; Setayesh, S.; Meijer, E.J.; Tanase, C.; Hummelen, J.C.; Blom, P.W.M. Organic complementary-like inverters employing methanofullerene-based ambipolar field-effect transistors. Appl. Phys. Lett. 2004, 85, 4205–4207. [Google Scholar] [CrossRef]

- Meijer, E.J.; De Leeuw, D.M.; Setayesh, S.; Van Veenendaal, E.; Huisman, B.H.; Blom, P.W.M.; Hummelen, J.C.; Scherf, U.; Klapwijk, T.M. Solution-processed ambipolar organic field-effect transistors and inverters. Nat. Mater. 2003, 2, 678–682. [Google Scholar] [CrossRef]

- Yoneya, N.; Ono, H.; Ishii, Y.; Himori, K.; Hirai, N.; Abe, H.; Yumoto, A.; Kobayashi, N.; Nomoto, K. Flexible electrophoretic display driven by solution-processed organic thin-film transistors. J. Soc. Inf. Disp. 2012, 20, 143. [Google Scholar] [CrossRef]

- Myny, K.; Steudel, S.; Vicca, P.; Beenhakkers, M.J.; van Aerle, N.A.J.M.; Gelinck, G.H.; Genoe, J.; Dehaene, W.; Heremans, P. Plastic circuits and tags for 13.56 MHz radio-frequency communication. Solid. State. Electron. 2009, 53, 1220–1226. [Google Scholar] [CrossRef]

- Cao, Q.; Kim, H.S.; Pimparkar, N.; Kulkarni, J.P.; Wang, C.; Shim, M.; Roy, K.; Alam, M.A.; Rogers, J.A. Medium-scale carbon nanotube thin-film integrated circuits on flexible plastic substrates. Nature 2008, 454, 495–500. [Google Scholar] [CrossRef]

- Fluxman, S.M. Design and performance of digital polysilicon thin-film-transistor circuits on glass. IEE Proc. Circuits, Devices Syst. 1994, 141, 56. [Google Scholar] [CrossRef]

- Bae, B.S.; Choi, J.W.; Oh, J.H.; Jang, J. Level shifter embedded in drive circuits with amorphous silicon TFTs. IEEE Trans. Electron Devices 2006, 53, 494–498. [Google Scholar]

- Greening, B.; Kuo, C.C.; Sheraw, C.D.; Gundlach, D.J.; Cuomo, F.P.; Klauk, H.; Campi, J.; Nichols, J.A.; Huang, J.R.; Jia, L.; et al. Analog and digital circuits using organic thin-film transistors on polyester substrates. IEEE Electron Device Lett. 2000, 21, 534–536. [Google Scholar]

- Fuketa, H.; Yoshioka, K.; Shinozuka, Y.; Ishida, K.; Yokota, T.; Matsuhisa, N.; Inoue, Y.; Sekino, M.; Sekitani, T.; Takamiya, M.; et al. 1 µm-Thickness Ultra-Flexible and High Electrode-Density Surface Electromyogram Measurement Sheet With 2 V Organic Transistors for Prosthetic Hand Control. IEEE Trans. Biomed. Circuits Syst. 2014, 8, 824–833. [Google Scholar] [CrossRef]

- Ishida, K.; Huang, T.C.; Honda, K.; Sekitani, T.; Nakajima, H.; Maeda, H.; Takamiya, M.; Someya, T.; Sakurai, T. A 100-V AC energy meter integrating 20-V organic CMOS digital and analog circuits with a floating gate for process variation compensation and a 100-V organic pMOS rectifier. IEEE J. Solid-State Circuits 2012, 47, 301–309. [Google Scholar] [CrossRef]

- Feng, L.; Tang, W.; Zhao, J.; Cui, Q.; Jiang, C.; Guo, X. All-solution-processed low-voltage organic thin-film transistor inverter on plastic substrate. IEEE Trans. Electron Devices 2014, 61, 1175–1180. [Google Scholar] [CrossRef]

- Myny, K.; Beenhakkers, M.; van Aerle, N.; Gelinck, G.; Genoe, J.; Dehaene, W.; Heremans, P. Unipolar organic transistor circuits made robust by dual-gate technology. IEEE J. Solid-State Circuits 2011, 46, 1223–1230. [Google Scholar] [CrossRef]

- Kergoat, L.; Herlogsson, L.; Piro, B.; Pham, M.C.; Horowitz, G.; Crispin, X.; Berggren, M. Tuning the threshold voltage in electrolyte-gated organic field-effect transistors. Proc. Natl. Acad. Sci. USA 2012, 109, 8394–8399. [Google Scholar] [CrossRef] [PubMed]

- Hoon Kim, S.; Rim Hwang, H.; Joong Kwon, H.; Jang, J. Unipolar depletion-load organic circuits on flexible substrate by self-organized polymer blending with 6, 13-bis (triisopropylsilylethynyl) pentacene using ink-jet printing. Appl. Phys. Lett. 2012, 100, 053302. [Google Scholar] [CrossRef]

- Pernstich, K.P.; Haas, S.; Oberhoff, D.; Goldmann, C.; Gundlach, D.J.; Batlogg, B.; Rashid, A.N.; Schitter, G. Threshold voltage shift in organic field effect transistors by dipole monolayers on the gate insulator. J. Appl. Phys. 2004, 96, 6431–6438. [Google Scholar] [CrossRef]

- Kobayashi, S.; Nishikawa, T.; Takenobu, T.; Mori, S.; Shimoda, T.; Mitani, T.; Shimotani, H.; Yoshimoto, N.; Ogawa, S.; Iwasa, Y. Control of carrier density by self-assembled monolayers in organic field-effect transistors. Nat. Mater. 2004, 3, 317–322. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.M.; Im, S. Optimum channel thickness of rubrene thin-film transistors. Appl. Phys. Lett. 2008, 93, 2006–2009. [Google Scholar] [CrossRef]

- Wang, A.; Kymissis, I.; Bulović, V.; Akinwande, A.I. Tunable threshold voltage and flatband voltage in pentacene field effect transistors. Appl. Phys. Lett. 2006, 89, 112109. [Google Scholar] [CrossRef]

- Wang, A.; Kymissis, I.; Bulović, V.; Akinwande, A.I. Engineering density of semiconductor-dielectric interface states to modulate threshold voltage in OFETs. IEEE Trans. Electron Devices 2006, 53, 9–13. [Google Scholar] [CrossRef]

- Takamiya, M.; Sekitani, T.; Kato, Y.; Kawaguchi, H.; Someya, T.; Sakurai, T. An Organic FET SRAM for Braille Sheet Display with Back Gate to Increase Static Noise Margin. 2006 IEEE Int. Solid State Circuits Conf.-Dig. Tech. Pap. 2006, 42, 1060–1069. [Google Scholar]

- Koo, J.B.; Ku, C.H.; Lim, J.W.; Kim, S.H. Novel organic inverters with dual-gate pentacene thin-film transistor. Org. Electron. 2007, 8, 552–558. [Google Scholar] [CrossRef]

- Ogier, S.D.; Matsui, H.; Feng, L.; Simms, M.; Mashayekhi, M.; Carrabina, J.; Terés, L.; Tokito, S. Uniform, high performance, solution processed organic thin-film transistors integrated in 1 MHz frequency ring oscillators. Org. Electron. 2018, 54, 40–47. [Google Scholar] [CrossRef]

- Mativenga, M.; Choe, Y.; Um, J.; Jang, J. Corbino Oxide TFTs for Flexible AMOLED Display Stability; Wiley Publishing: San Francisco, CA, USA, 2016; pp. 1147–1150. [Google Scholar]

- Lee, H.; Yoo, J.S.; Kim, C.D.; Chung, I.J.; Kanicki, J. Asymmetric electrical properties of Corbino a-Si:H TFT and concepts of its application to flat panel displays. IEEE Trans. Electron Devices 2007, 54, 654–662. [Google Scholar] [CrossRef]

- Mativenga, M.; Ha, S.H.; Geng, D.; Kang, D.H.; Mruthyunjaya, R.K.; Heiler, G.N.; Tredwell, T.J.; Jang, J. Infinite output resistance of corbino thin-film transistors with an amorphous-InGaZnO active layer for large-area AMOLED displays. IEEE Trans. Electron Devices 2014, 61, 3199–3205. [Google Scholar] [CrossRef]

- Chen, J.; Tee, C.K.; Shtein, M.; Anthony, J.; Martin, D.C. Grain-boundary-limited charge transport in solution-processed 6,13 bis (tri-isopropylsilylethynyl) pentacene thin film transistors. J. Appl. Phys. 2008, 103, 114513. [Google Scholar] [CrossRef]

- Steiner, F.; Poelking, C.; Niedzialek, D.; Andrienko, D.; Nelson, J. Influence of orientation mismatch on charge transport across grain boundaries in tri-isopropylsilylethynyl (TIPS) pentacene thin films. Phys. Chem. Chem. Phys. 2017, 19, 10854–10862. [Google Scholar] [CrossRef] [PubMed]

- Fayez, M.; Morsy, K.; Sabry, M. Simulation of Organic Thin Film Transistor at both Device and Circuit Levels. Int. Conf. Aerosp. Sci. Aviat. Technol. 2019, 16, 1–6. [Google Scholar] [CrossRef]

- Dobrescu, L.; Petrov, M.; Dobrescu, D.; Ravariu, C. Threshold voltage extraction methods for MOS transistors. In Proceedings of the 2000 International Semiconductor Conference, Sinaia, Romania, 10–14 October 2000; pp. 371–374. [Google Scholar]

- Munteanu, D.; Cristoloveanu, S.; Hovel, H. Circular Pseudo-Metal Oxide Semiconductor Field Effect Transistor in Silicon-on-Insulator Analytical Model, Simulation, and Measurements. Electrochem. Solid-State Lett. 1999, 2, 242–243. [Google Scholar] [CrossRef]

- Guo, X.; Xu, Y.; Ogier, S.; Ng, T.N.; Caironi, M.; Perinot, A.; Li, L.; Zhao, J.; Tang, W.; Sporea, R.A.; et al. Current Status and Opportunities of Organic Thin-Film Transistor Technologies. IEEE Trans. Electron Devices 2017, 64, 1906–1921. [Google Scholar] [CrossRef]

- Mashayekhi, M. Inkjet-Configurable Gate Arrays. Towards Application Specific Printed Electronic Circuits. Available online: https://www.tesisenred.net/bitstream/handle/10803/402272/moma1de1.pdf?sequence=1&isAllowed=y (accessed on 27 June 2019).

- Fujisaki, Y.; Takahashi, D.; Nakajima, Y.; Nakata, M.; Tsuji, H.; Yamamoto, T. Alignment Control of Patterned Organic Semiconductor Crystals in Short-Channel Transistor Using Unidirectional Solvent Evaporation Process. IEEE Trans. Electron Devices 2015, 62, 2306–2312. [Google Scholar] [CrossRef]

- Bi, S.; He, Z.; Chen, J.; Li, D. Solution-grown small-molecule organic semiconductor with enhanced crystal alignment and areal coverage for organic thin film transistors. AIP Adv. 2015, 5, 077170. [Google Scholar] [CrossRef]

- Tisserant, J.N.; Wicht, G.; Göbel, O.F.; Bocek, E.; Bona, G.L.; Geiger, T.; Hany, R.; Mezzenga, R.; Partel, S.; Schmid, P.; et al. Growth and alignment of thin film organic single crystals from dewetting patterns. ACS Nano 2013, 7, 5506–5513. [Google Scholar] [CrossRef]

- Goto, O.; Tomiya, S.; Murakami, Y.; Shinozaki, A.; Toda, A.; Kasahara, J.; Hobara, D. Organic single-crystal arrays from solution-phase growth using micropattern with nucleation control region. Adv. Mater. 2012, 24, 1117–1122. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhao, X.; Cai, B.; Pei, T.; Tong, Y.; Tang, Q.; Liu, Y. Controllable fabrication of oriented micro/nanowire arrays of dibenzo-tetrathiafulvalene by a multiple drop-casting method. Nanoscale 2014, 6, 1323–1328. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Ji, D.; Liu, J.; Yao, Y.; Fu, X.; Zhu, W.; Xu, C.; Dong, H.; Li, J.; Hu, W. Quick Fabrication of Large-area Organic Semiconductor Single Crystal Arrays with a Rapid Annealing Self-Solution-Shearing Method. Sci. Rep. 2015, 5, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Sou, A.; Jung, S.; Gili, E.; Pecunia, V.; Joimel, J.; Fichet, G.; Sirringhaus, H. Programmable logic circuits for functional integrated smart plastic systems. Org. Electron. 2014, 15, 3111–3119. [Google Scholar] [CrossRef]

- Xu, W.; Liu, Z.; Zhao, J.; Xu, W.; Gu, W.; Zhang, X.; Qian, L.; Cui, Z. Flexible logic circuits based on top-gate thin film transistors with printed semiconductor carbon nanotubes and top electrodes. Nanoscale 2014, 6, 14891–14897. [Google Scholar] [CrossRef] [PubMed]

- Sirringhaus, H.; Friend, R.H.; Li, X.C.; Moratti, S.C.; Holmes, A.B.; Feeder, N. Bis(dithienothiophene) organic field-effect transistors with a high ON/OFF ratio. Appl. Phys. Lett. 1997, 71, 3871–3873. [Google Scholar] [CrossRef]

- Chandar Shekar, B.; Lee, J.; Rhee, S.W. Organic thin film transistors: Materials, processes and devices. Korean J. Chem. Eng. 2007, 21, 267–285. [Google Scholar] [CrossRef]

- Briseno, A.L.; Tseng, R.J.; Li, S.H.; Chu, C.W.; Yang, Y.; Falcao, E.H.L.; Wudl, F.; Ling, M.M.; Chen, H.Z.; Bao, Z.; et al. Organic single-crystal complementary inverter. Appl. Phys. Lett. 2006, 89, 1–4. [Google Scholar] [CrossRef]

- Wu, Q.; Zhang, J.Y.; Qin, R.Q. Design Considerations for Digital Circuits Using Organic Thin Film Transistors on a Flexible Substrate. In Proceedings of the 2006 IEEE International Symposium on Circuits and Systems, Island of Kos, Greece, 21–24 May 2006; Volume 1, pp. 1267–1270. [Google Scholar]

- Lugli, P.; Csaba, G.; Erlen, C. Modeling of circuits and architectures for molecular electronics. J. Comput. Electron. 2009, 8, 410–426. [Google Scholar] [CrossRef]

- Krumm, J. CIRCUIT ANALYSIS METHODOLOGY FOR ORGANIC TRANSISTORS. Available online: https://opus4.kobv.de/opus4-fau/files/627/diss.pdf (accessed on 27 June 2019).

- Lee, C.A.; Jin, S.H.; Jung, K.D.; Lee, J.D.; Park, B.G. Full-swing pentacene organic inverter with enhancement-mode driver and depletion-mode load. Solid. State. Electron. 2006, 50, 1216–1218. [Google Scholar] [CrossRef]

- Brown, A.R.; De Leeuw, D.M.; Havinga, E.E.; Pomp, A. Field-effect transistors made from solution-processed organic semiconductors. Synth. Met. 1994, 68, 65–70. [Google Scholar] [CrossRef]

- Huang, T.C.; Fukuda, K.; Lo, C.M.; Yeh, Y.H.; Sekitani, T.; Someya, T.; Cheng, K.T. Pseudo-CMOS: A design style for low-cost and robust flexible electronics. IEEE Trans. Electron Devices 2011, 58, 141–150. [Google Scholar] [CrossRef]

- Zeng, W.J.; Zhou, X.Y.; Pan, X.J.; Song, C.L.; Zhang, H.L. High performance CMOS-like inverter based on an ambipolar organic semiconductor and low cost metals. AIP Adv. 2013, 3, 012101. [Google Scholar] [CrossRef]

- Fukuda, K.; Sekitani, T.; Yokota, T.; Kuribara, K.; Huang, T.C.; Sakurai, T.; Zschieschang, U.; Klauk, H.; Ikeda, M.; Kuwabara, H.; et al. Organic pseudo-CMOS circuits for low-voltage large-gain high-speed operation. IEEE Electron Device Lett. 2011, 32, 1448–1450. [Google Scholar] [CrossRef]

- Kim, S.H.; Jang, J.; Jeon, H.; Yun, W.M.; Nam, S.; Park, C.E. Hysteresis-free pentacene field-effect transistors and inverters containing poly (4-vinyl phenol-co-methyl methacrylate) gate dielectrics. Appl. Phys. Lett. 2008, 92, 1–4. [Google Scholar] [CrossRef]

- Kim, S.H.; Choi, D.; Chung, D.S.; Yang, C.; Jang, J.; Park, C.E.; Park, S.H.K. High-performance solution-processed triisopropylsilylethynyl pentacene transistors and inverters fabricated by using the selective self-organization technique. Appl. Phys. Lett. 2008, 93, 1–4. [Google Scholar] [CrossRef]

- Koo, J.B.; Ku, C.H.; Lim, S.C.; Kim, S.H.; Lee, J.H. Hysteresis and threshold voltage shift of pentacene thin-film transistors and inverters with Al2O3 gate dielectric. Appl. Phys. Lett. 2007, 90, 1–4. [Google Scholar] [CrossRef]

- Park, S.K.; Member, S.; Anthony, J.E.; Jackson, T.N. Solution-Processed TIPS-Pentacene Organic Thin-Film-Transistor Circuits. IEEE Electron Device Lett. 2007, 28, 2007–2009. [Google Scholar] [CrossRef]

- Myny, K.; Beenhakkers, M.; van Aerle, N.; Gelinck, G.; Genoe, J.; Dehaene, W.; Heremans, P. Robust digital design in organic electronics by dual-gate technology. IEEE Int. Solid-State Circuits Conf. Dig. Tech. Pap. 2010, 8, 140–141. [Google Scholar]

- Spijkman, M.J.; Myny, K.; Smits, E.C.P.; Heremans, P.; Blom, P.W.M.; De Leeuw, D.M. Dual-gate thin-film transistors, integrated circuits and sensors. Adv. Mater. 2011, 23, 3231–3242. [Google Scholar] [CrossRef]

- Nausieda, I.; Ryu, K.K.; He, D.D.; Akinwande, A.I.; Bulovic, V.; Sodini, C.G. Mixed-signal organic integrated circuits in a fully photolithographic dual threshold voltage technology. IEEE Trans. Electron Devices 2011, 58, 865–873. [Google Scholar] [CrossRef]

- Nausieda, I.; Ryu, K.K.; He, D.D.; Akinwande, A.I.; Bulović, V.; Sodini, C.G. Dual threshold voltage organic thin-film transistor technology. IEEE Trans. Electron Devices 2010, 57, 3027–3032. [Google Scholar] [CrossRef]

- Wei, L.; Chen, Z.; Johnson, M.; Roy, K.; De, V. Design and optimization of low voltage high performance dual threshold CMOS circuits. In Proceedings of the 35th annual Design Automation Conference, San Francisco, CA, USA, 15–19 June 1998; pp. 489–494. [Google Scholar]

- Sundararajan, V.; Parhi, K.K. Low power synthesis of dual threshold voltage CMOS VLSI circuits. In Proceedings of the 1999 International Symposium on Low Power Electronics and Design, San Diego, CA, USA, 17 August 1999; pp. 139–144. [Google Scholar]

- Ghosh, A.; Ghosh, D. Optimization of static power, leakage power and delay of full adder circuit using dual threshold MOSFET based design and T-spice simulation. In Proceedings of the 2009 International Conference on Advances in Recent Technologies in Communication and Computing, Kerala, India, 27–28 October 2009; pp. 903–905. [Google Scholar]

- Islam, A.; Akram, M.W.; Pable, S.D.; Hasan, M. Design and analysis of robust dual threshold CMOS full adder circuit in 32nm technology. In Proceedings of the 2010 International Conference on Advances in Recent Technologies in Communication and Computing, Kottayam, India, 16–17 October 2010; pp. 418–420. [Google Scholar]

- Ghavami, B.; Pedram, H. Design of dual threshold voltages asynchronous circuits. In Proceedings of the 2008 international symposium on Low Power Electronics & Design, Bangalore, India, 11–13 August 2008; p. 185. [Google Scholar]

- Wang, C.; Huang, C.; Lee, C. A Low Power High-Speed 8-Bit Pipelining CLA Design Using Dual-Threshold Voltage Domino Logic. IEEE Trans. Very Large Scale Integr. VLSI Syst. 2008, 16, 594–598. [Google Scholar] [CrossRef][Green Version]

- Slimani, M.; Matherat, P.; Mathieu, Y. A dual threshold voltage technique for glitch minimization. In Proceedings of the 2012 19th IEEE International Conference on Electronics, Circuits, and Systems (ICECS 2012), Seville, Spain, 9–12 December 2012; pp. 444–447. [Google Scholar]

| Inverter Topologies | CMOS | Pseudo-CMOS | Dual-Gate | Diode-Load | Dual-Threshold |

|---|---|---|---|---|---|

| Transistors | 2 | 4 | 2 | 2 | 2 |

| Power rails | 2 | 3 | 3 | 2 | 2 |

| Noise Margin | Most Robust | High Robust | Robust | Poor Robust | Medium Robust |

| Voltage swing | Full Swing | Full Swing | Non-Full Swing | Non-Full Swing | Almost-Full Swing |

| Power | Dynamic | Static and Dynamic | Static and Dynamic | Static and Dynamic | Static and Dynamic |

| Device Type | Complementary type | Mono-type | Mono-type | Mono-type | Mono-type |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arnal, A.; Martínez-Domingo, C.; Ogier, S.; Terés, L.; Ramon, E. Monotype Organic Dual Threshold Voltage Using Different OTFT Geometries. Crystals 2019, 9, 333. https://doi.org/10.3390/cryst9070333

Arnal A, Martínez-Domingo C, Ogier S, Terés L, Ramon E. Monotype Organic Dual Threshold Voltage Using Different OTFT Geometries. Crystals. 2019; 9(7):333. https://doi.org/10.3390/cryst9070333

Chicago/Turabian StyleArnal, August, Carme Martínez-Domingo, Simon Ogier, Lluís Terés, and Eloi Ramon. 2019. "Monotype Organic Dual Threshold Voltage Using Different OTFT Geometries" Crystals 9, no. 7: 333. https://doi.org/10.3390/cryst9070333

APA StyleArnal, A., Martínez-Domingo, C., Ogier, S., Terés, L., & Ramon, E. (2019). Monotype Organic Dual Threshold Voltage Using Different OTFT Geometries. Crystals, 9(7), 333. https://doi.org/10.3390/cryst9070333