A Novel Liquid Packaging Structure of Deep-Ultraviolet Light-Emitting Diodes to Enhance the Light-Extraction Efficiency

Abstract

:1. Introduction

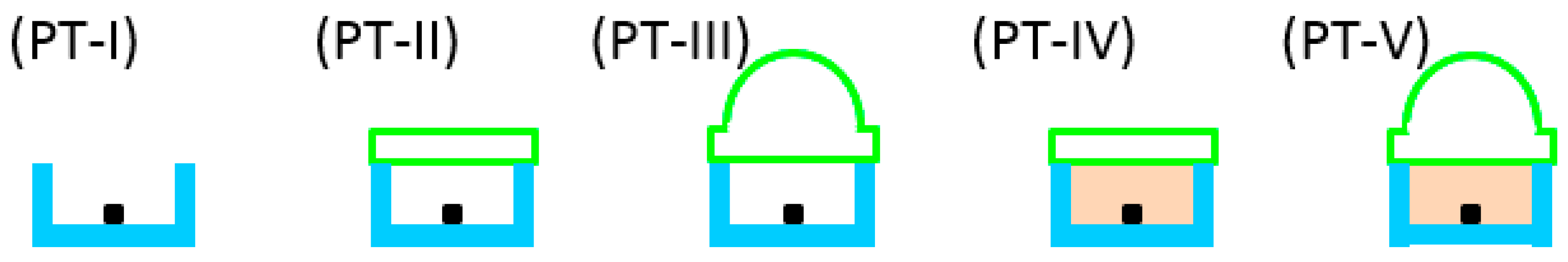

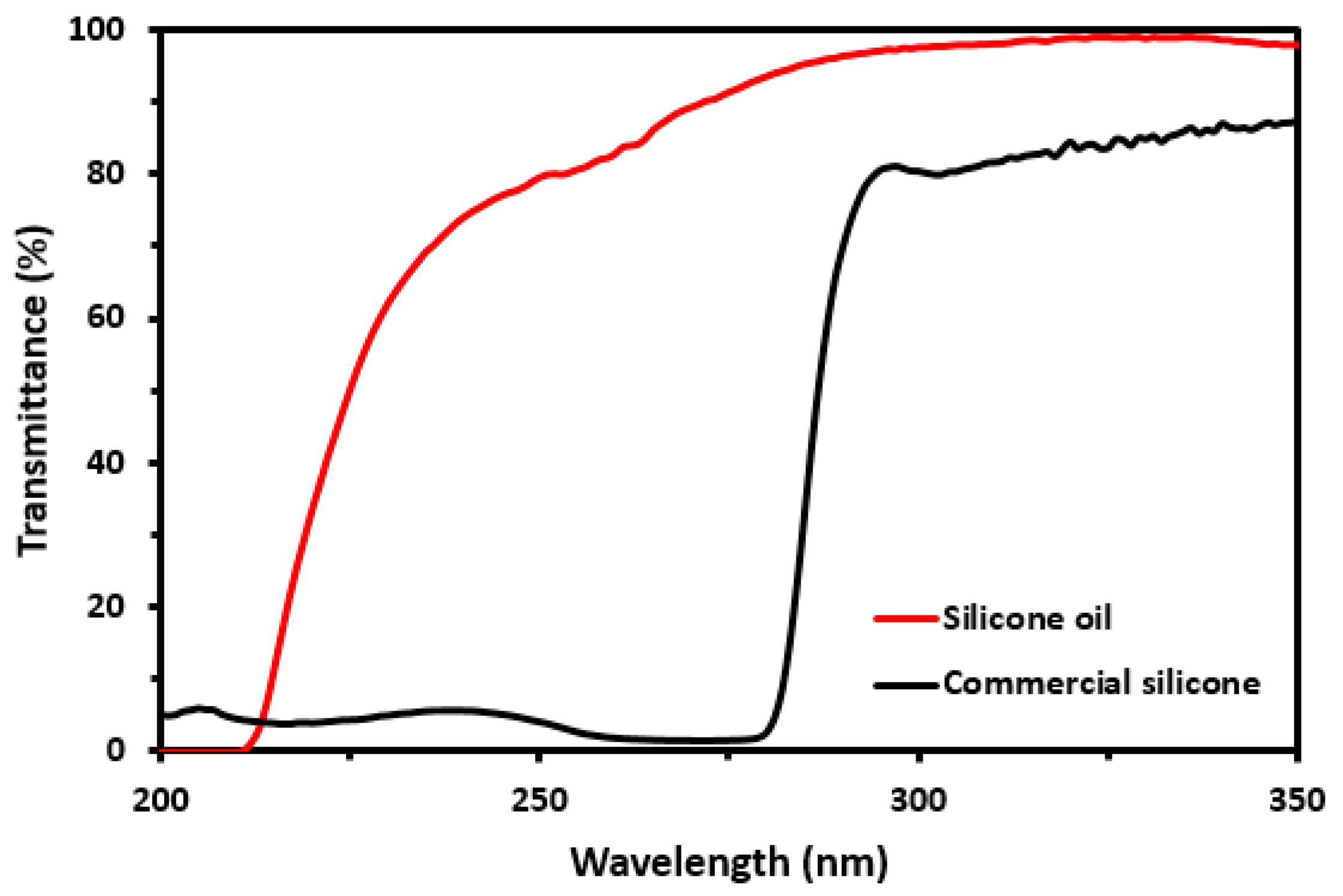

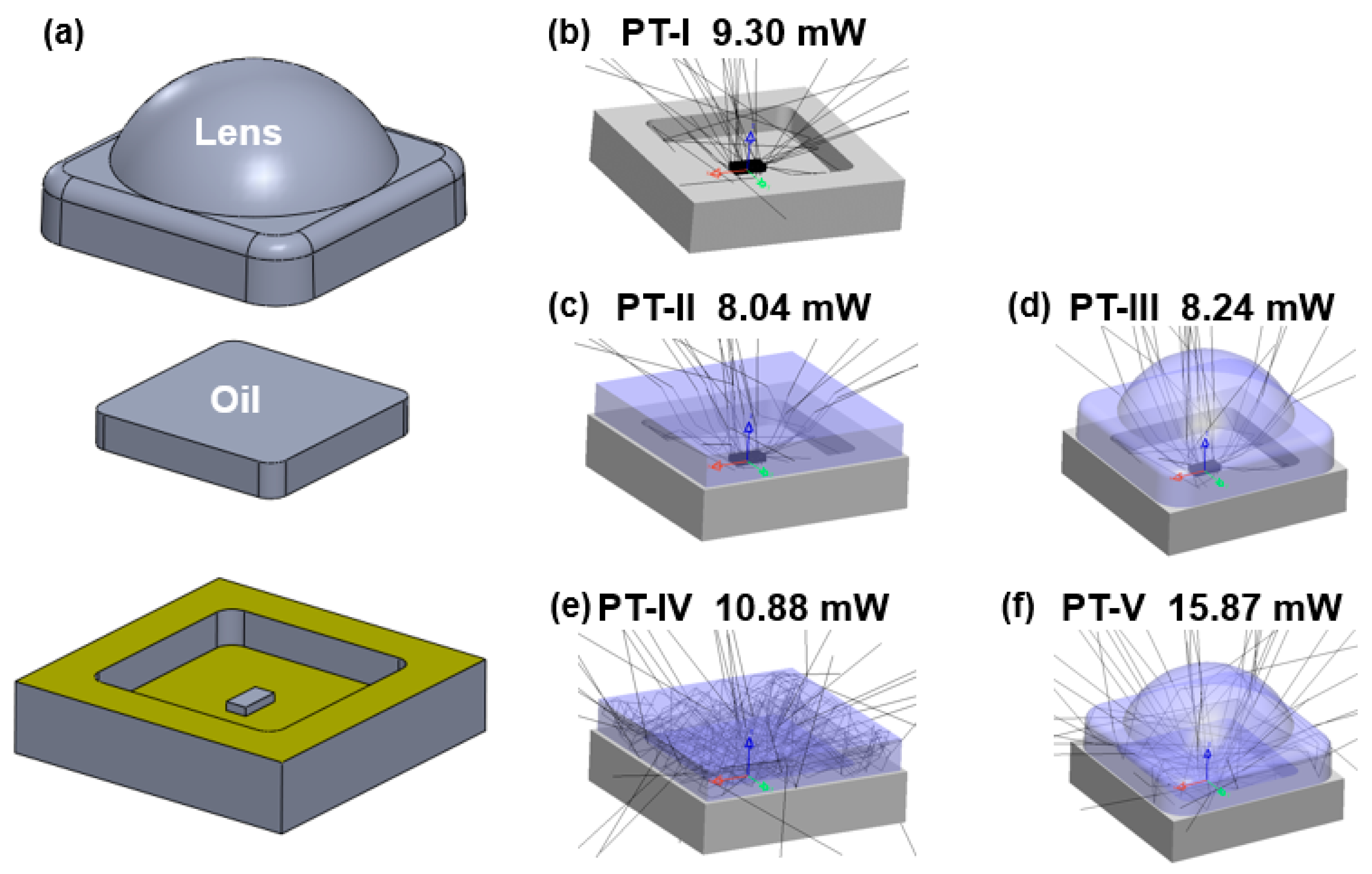

2. Materials and Methods

3. Experiment and Results

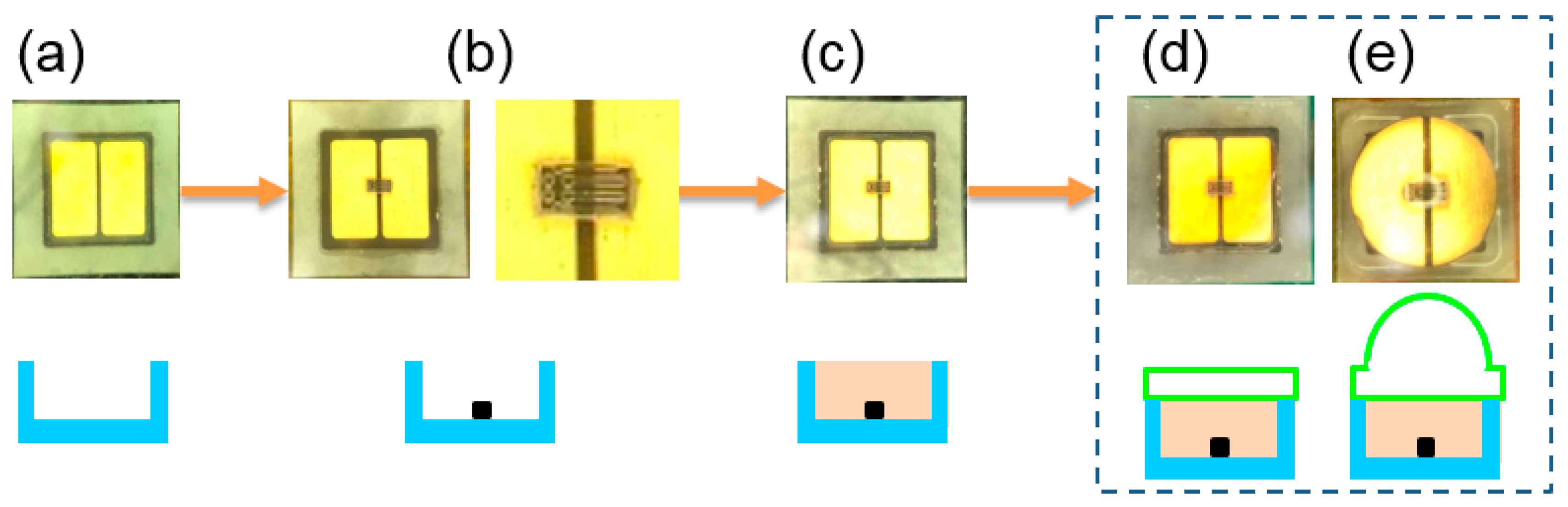

3.1. Fabrication

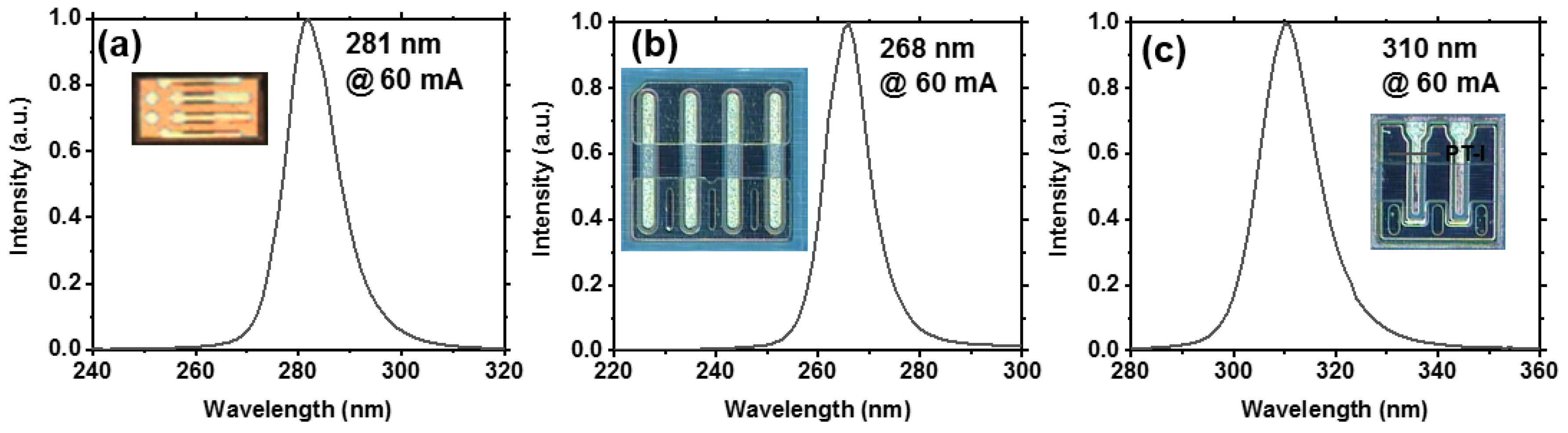

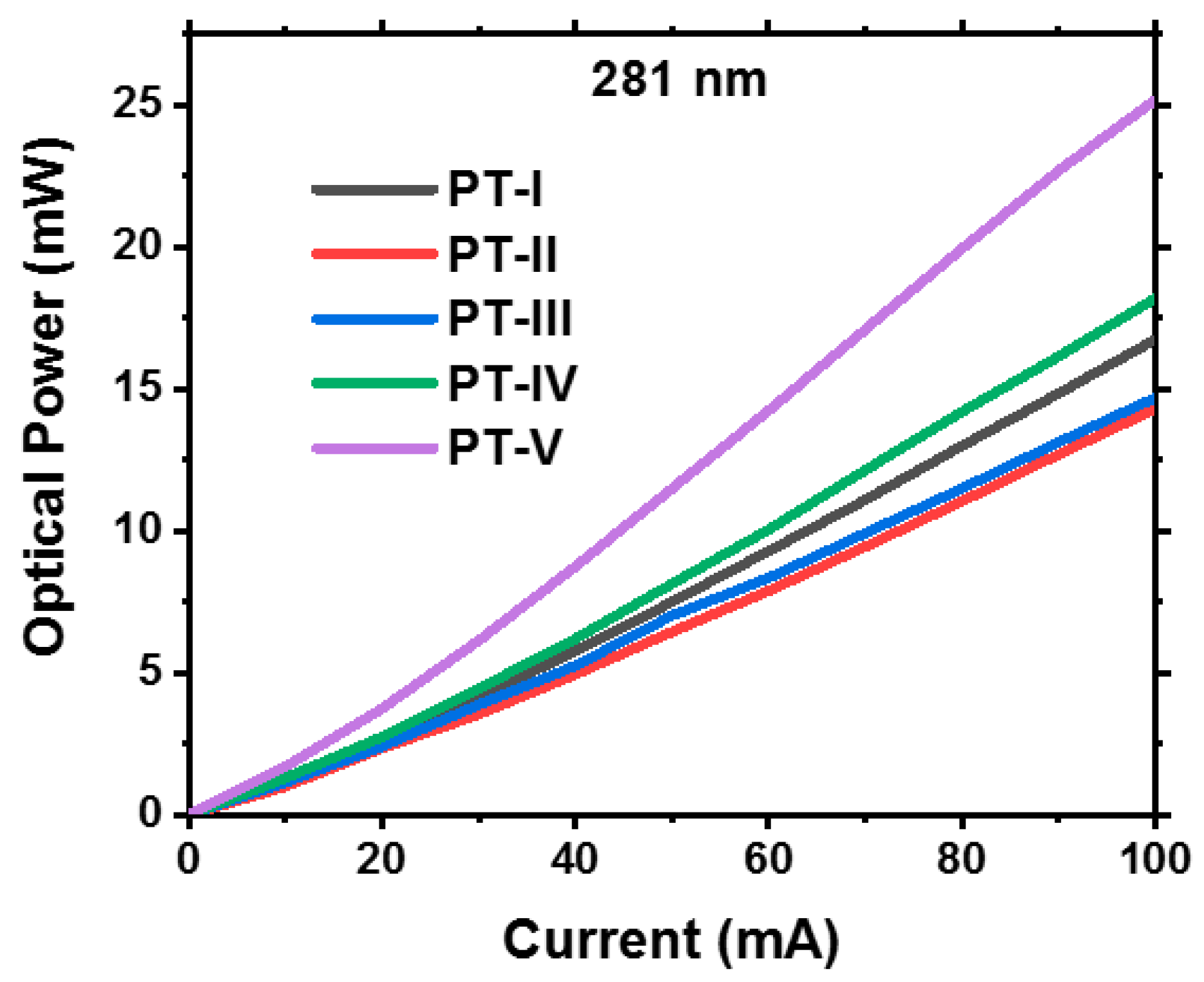

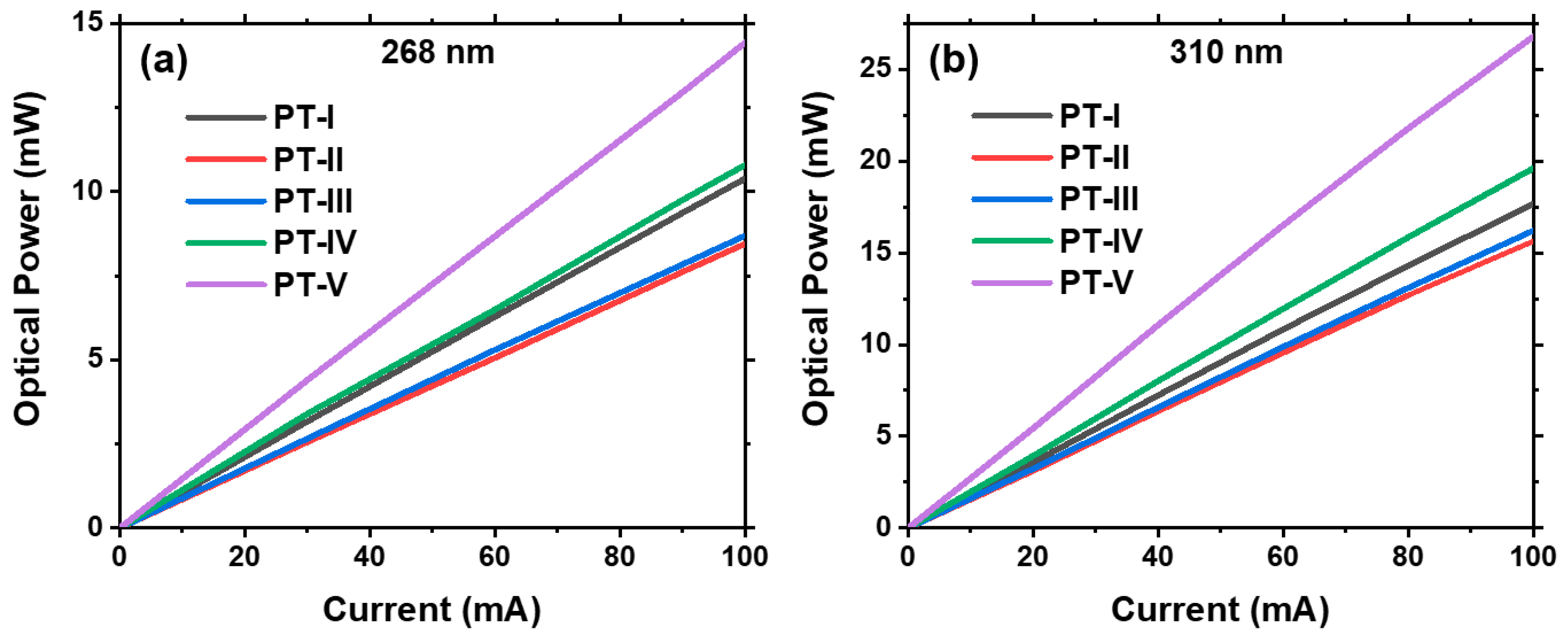

3.2. Optical Measurement Results

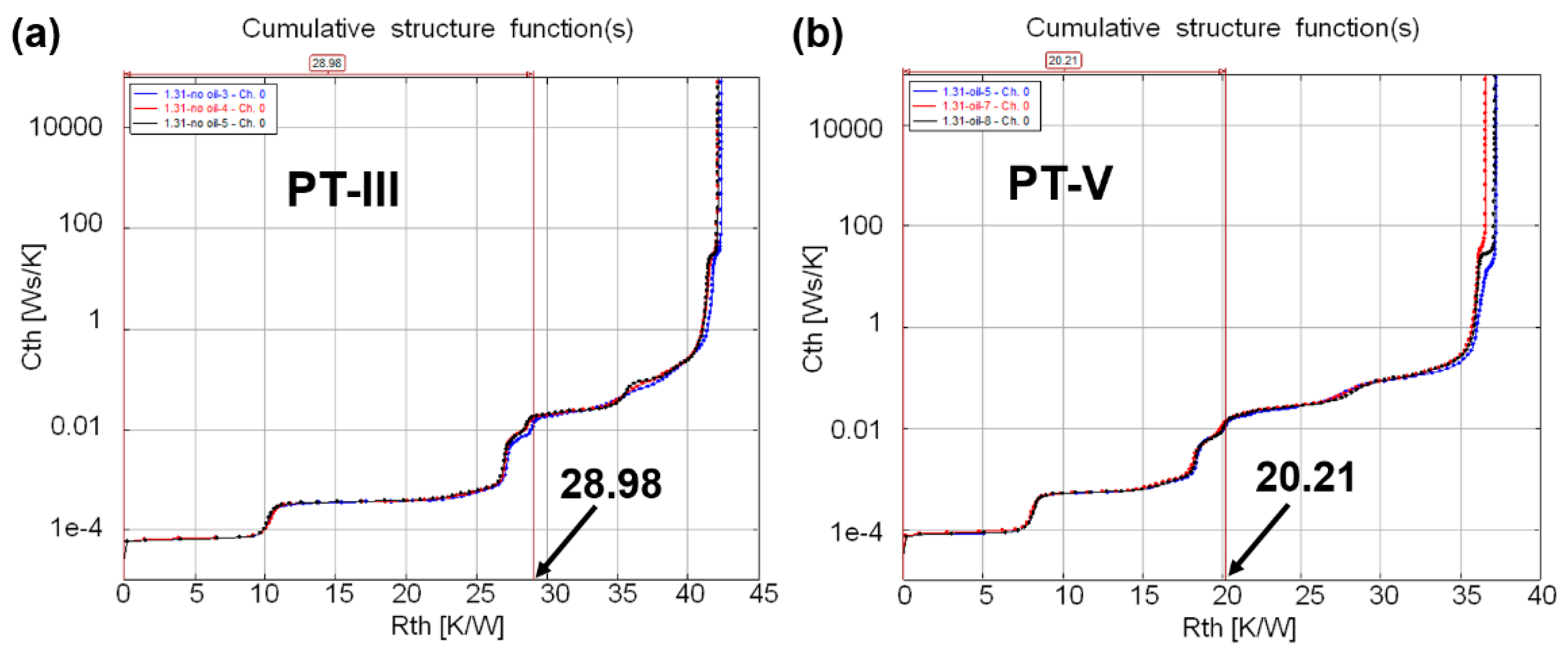

3.3. Thermal Resistance Measurement Result

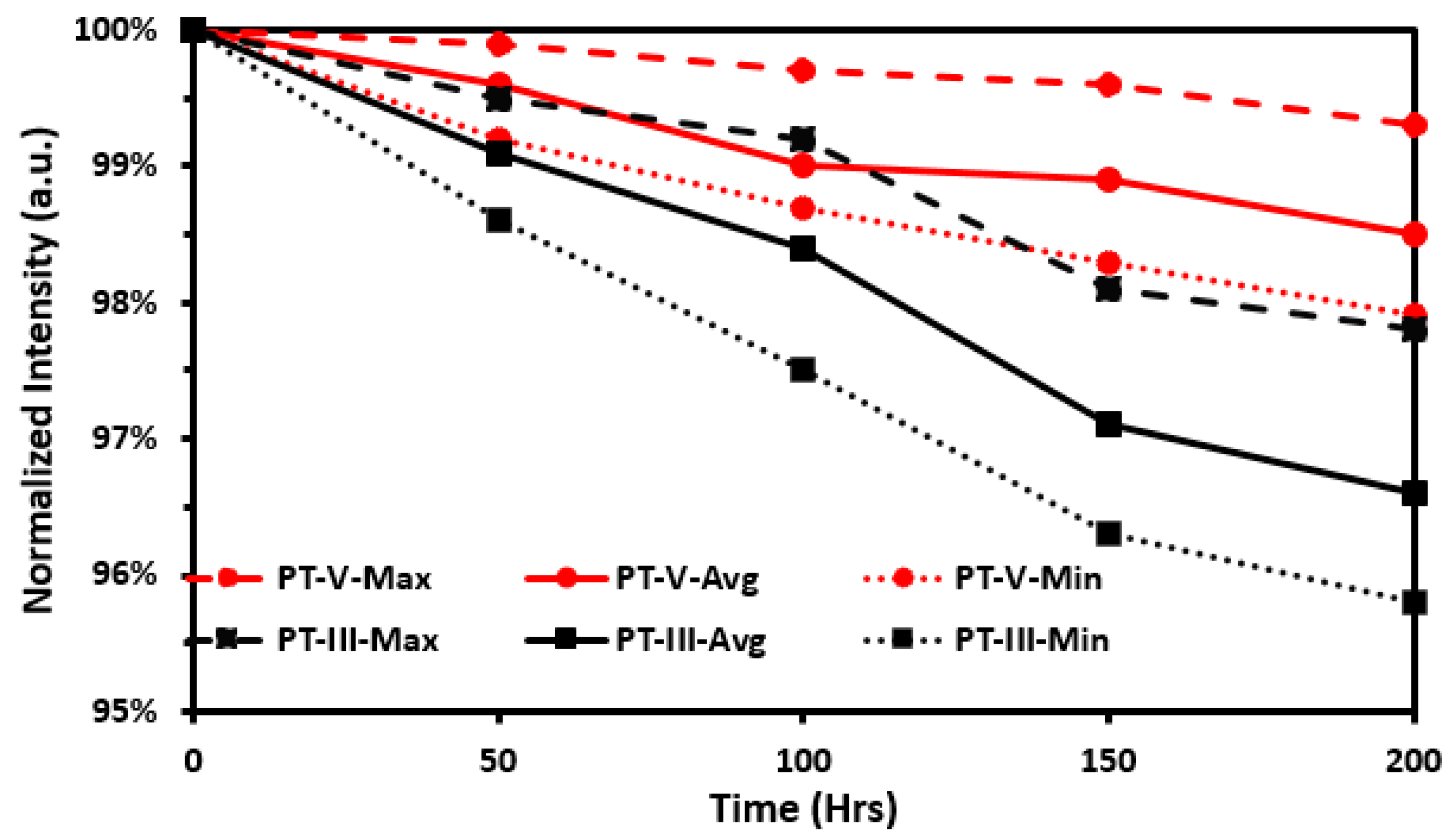

3.4. Reliability Test Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Muramoto, Y.; Kimura, M.; Nouda, S. Development and future of ultraviolet light-emitting diodes: UV-LED will replace the UV lamp. Semicond. Sci. Technol. 2014, 29, 084004. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Loeb, S.; Kim, J.-H. LED revolution: fundamentals and prospects for UV disinfection applications. Environ. Sci.-Wat. Res. 2017, 3, 188–202. [Google Scholar] [CrossRef]

- Shin, J.Y.; Kim, S.J.; Kim, D.K.; Kang, D.H. Fundamental Characteristics of Deep-UV Light-Emitting Diodes and Their Application to Control Foodborne Pathogens. Appl. Environ. Microbiol. 2016, 82, 2–10. [Google Scholar] [CrossRef]

- Hirayama, H.; Maeda, N.; Fujikawa, S.; Toyoda, S.; Kamata, N. Recent progress and future prospects of AlGaN-based high-efficiency deep-ultraviolet light-emitting diodes. Jpn. J. Appl. Phys. 2014, 53, 100209. [Google Scholar] [CrossRef] [Green Version]

- Inoue, S.I.; Tamari, N.; Taniguchi, M. 150 mW deep-ultraviolet light-emitting diodes with large-area AlN nanophotonic light-extraction structure emitting at 265nm. Appl. Phys. Lett. 2017, 110, 141106. [Google Scholar] [CrossRef]

- De Santi, C.; Meneghini, M.; Monti, D.; Glaab, J.; Guttmann, M.; Rass, J.; Einfeldt, S.; Mehnke, F.; Enslin, J.; Wernicke, T.; et al. Recombination mechanisms and thermal droop in AlGaN-based UV-B LEDs. Photonics Res. 2017, 5, A44–A51. [Google Scholar] [CrossRef]

- Fujioka, A.; Asada, K.; Yamada, H.; Ohtsuka, T.; Ogawa, T.; Kosugi, T.; Kishikawa, D.; Mukai, T. High-output-power 255/280/310 nm deep ultraviolet light-emitting diodes and their lifetime characteristics. Semicond. Sci. Technol. 2014, 29, 084005. [Google Scholar] [CrossRef]

- Inoue, S.; Naoki, T.; Kinoshita, T.; Obata, T.; Yanagi, H. Light extraction enhancement of 265 nm deep-ultraviolet light-emitting diodes with over 90 mW output power via an AlN hybrid nanostructure. Appl. Phys. Lett. 2015, 106, 131104. [Google Scholar] [CrossRef]

- Lu, C.-C.; Wang, C.-P.; Liu, C.-Y.; Hsu, C.-P. The Efficiency and Reliability Improvement by Utilizing Quartz Airtight Packaging of UVC LEDs. IEEE T. Electron Dev. 2016, 63, 3143–3146. [Google Scholar] [CrossRef]

- Bae, J.-Y.; Kim, Y.; Kim, H.; Kim, Y.; Jin, J.; Bae, B.-S. Ultraviolet Light Stable and Transparent Sol-Gel Methyl Siloxane Hybrid Material for UV Light-Emitting Diode (UV LED) Encapsulant. ACS Appl. Mater. Interfaces 2015, 7, 1035–1039. [Google Scholar] [CrossRef]

- Peng, Y.; Wang, S.; Cheng, H.; Chen, M. Whole Inorganic Hermetic Packaging Technology Using Localized Induction Heating for Deep Ultraviolet Light-Emitting Diodes. IEEE T. Comp. Pack. Man. 2016, 6, 1456–1461. [Google Scholar] [CrossRef]

- Yamada, K.; Furusawan, Y.; Nagai, S.; Hirano, A.; Ippommatsu, M.; Aosaki, K.; Morishima, N.; Amano, H.; Akasaki, I. Development of underfilling and encapsulation for deep-ultraviolet LEDs. Appl. Phys. Express 2015, 8, 012101. [Google Scholar] [CrossRef]

- Nagai, S.; Yamada, K.; Hirano, A.; Ippommatsu, M.; Ito, M.; Morishima, N.; Aosaki, K.; Honda, Y.; Amano, H.; Akasaki, I. Development of highly durable deep-ultraviolet AlGaN-based LED multichip array with hemispherical encapsulated structures using a selected resin through a detailed feasibility study. Jpn. J. Appl. Phys. 2016, 55, 082101. [Google Scholar] [CrossRef]

- Peng, Y.; Guo, X.; Liang, R.; Cheng, H.; Chen, M. Enhanced Light Extraction From DUV-LEDs by AlN-Doped Fluoropolymer Encapsulation. IEEE Photonic. Tech. L. 2017, 29, 1151–1154. [Google Scholar] [CrossRef]

- Malitson, I.H. Refraction and dispersion of synthetic sapphire. J. Opt. Soc. Am. 1962, 52, 1377–1379. [Google Scholar] [CrossRef]

- Schneider, F.; Draheirn, J.; Kamberger, R.; Wallrabe, U. Process and material properties of polydimethylsiloxane (PDMS) for Optical MEMS. Sensor. Actuat. A-Phys. 2009, 151, 95–99. [Google Scholar] [CrossRef]

- Khan, M.A. AlGaN multiple quantum well based deep UV LEDs and their applications. Phys. Status Solidi A 2006, 203, 1764–1770. [Google Scholar] [CrossRef]

- Kneissl, M.; Kolbe, T.; Chua, C.; Kueller, V.; Lobo, N.; Stellmach, J.; Knauer, A.; Rodriguez, H.; Einfeldt, S.; Yang, Z.; et al. Advances in group III-nitride-based deep UV light-emitting diode technology. Semicond. Sci. Technol. 2011, 26, 014036. [Google Scholar] [CrossRef]

- Malitson, I.H. Interspecimen comparison of the refractive index of fused silica. J. Opt. Soc. Am. 1965, 55, 1205–1209. [Google Scholar] [CrossRef]

- Xin, G.C.; Wang, Y.P.; Sun, Y.; Huang, Q.W.; Zhu, L. Experimental study of liquid-immersion III-V multi-junction solar cells with dimethyl silicon oil under high concentrations. Energ. Convers. Manage. 2015, 94, 169–177. [Google Scholar] [CrossRef]

- Han, X.Y.; Wang, Y.P.; Zhu, L. The performance and long-term stability of silicon concentrator solar cells immersed in dielectric liquids. Energ. Convers. Manage. 2013, 66, 189–198. [Google Scholar] [CrossRef]

- Zhang, W.H.; Lin, W.K.; Yeh, C.T.; Chiang, S.B.; Jao, C.S. A novel liquid-packaging technology for highly reliable UV-LED encapsulation. Heat Transf. Res. 2019, 50, 349–360. [Google Scholar] [CrossRef]

- Yang, K.S.; Chung, C.H.; Tu, C.W.; Wong, C.C.; Yang, T.Y.; Lee, M.T. Thermal spreading resistance characteristics of a high power light emitting diode module. Appl. Therm. Eng. 2014, 70, 361–368. [Google Scholar] [CrossRef]

| Component | Optical Parameters |

|---|---|

| Chip | Refractive index: 1.82 for sapphire [15] |

| Surface: Fresnel loss | |

| Substrate | Reflectance: 16% for AlN surface |

| Reflectance: 38% for Au surface | |

| Quartz | Refractive index: 1.492 [19]; |

| Transmittance: 95% @ 10 mm | |

| Surface: Fresnel loss | |

| Silicone oil | Refractive index: 1.487 |

| Transmittance: 94% @ 10 mm | |

| Surface: Fresnel loss |

| Packagetype | 281 nm | 268 nm | 310 nm | |||

|---|---|---|---|---|---|---|

| Power (mW) | EQE (%) | Power (mW) | EQE (%) | Power (mW) | EQE (%) | |

| PT-I | 9.30 | 3.52 | 6.28 | 2.26 | 10.84 | 4.52 |

| PT-II | 7.90 | 2.99 | 5.06 | 1.82 | 9.56 | 3.98 |

| PT-III | 8.35 | 3.17 | 5.30 | 1.90 | 9.88 | 4.12 |

| PT-IV | 10.05 | 3.81 | 6.50 | 2.34 | 11.96 | 4.98 |

| PT-V | 14.25 | 5.39 | 8.68 | 3.12 | 16.52 | 6.89 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, C.-Y.; Lin, C.-H.; Wu, T.; Lee, P.-T.; Chen, Z.; Kuo, H.-C. A Novel Liquid Packaging Structure of Deep-Ultraviolet Light-Emitting Diodes to Enhance the Light-Extraction Efficiency. Crystals 2019, 9, 203. https://doi.org/10.3390/cryst9040203

Kang C-Y, Lin C-H, Wu T, Lee P-T, Chen Z, Kuo H-C. A Novel Liquid Packaging Structure of Deep-Ultraviolet Light-Emitting Diodes to Enhance the Light-Extraction Efficiency. Crystals. 2019; 9(4):203. https://doi.org/10.3390/cryst9040203

Chicago/Turabian StyleKang, Chieh-Yu, Chih-Hao Lin, Tingzhu Wu, Po-Tsung Lee, Zhong Chen, and Hao-Chung Kuo. 2019. "A Novel Liquid Packaging Structure of Deep-Ultraviolet Light-Emitting Diodes to Enhance the Light-Extraction Efficiency" Crystals 9, no. 4: 203. https://doi.org/10.3390/cryst9040203

APA StyleKang, C.-Y., Lin, C.-H., Wu, T., Lee, P.-T., Chen, Z., & Kuo, H.-C. (2019). A Novel Liquid Packaging Structure of Deep-Ultraviolet Light-Emitting Diodes to Enhance the Light-Extraction Efficiency. Crystals, 9(4), 203. https://doi.org/10.3390/cryst9040203