Cohesive Element Model for Fracture Behavior Analysis of Al2O3/Graphene Composite Ceramic Tool Material

Abstract

1. Introduction

2. Simulation Method

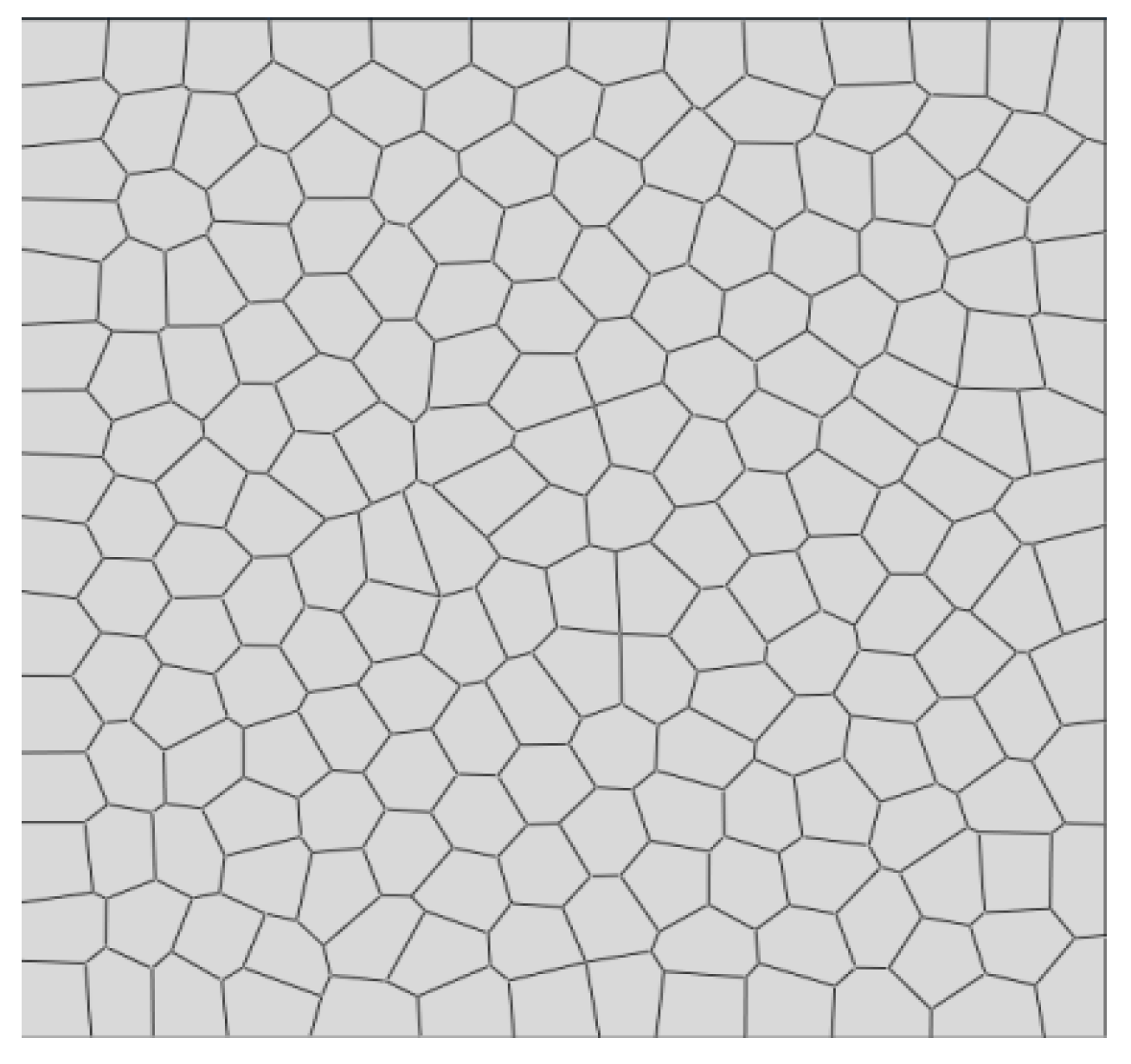

2.1. Voronoi Tessellation

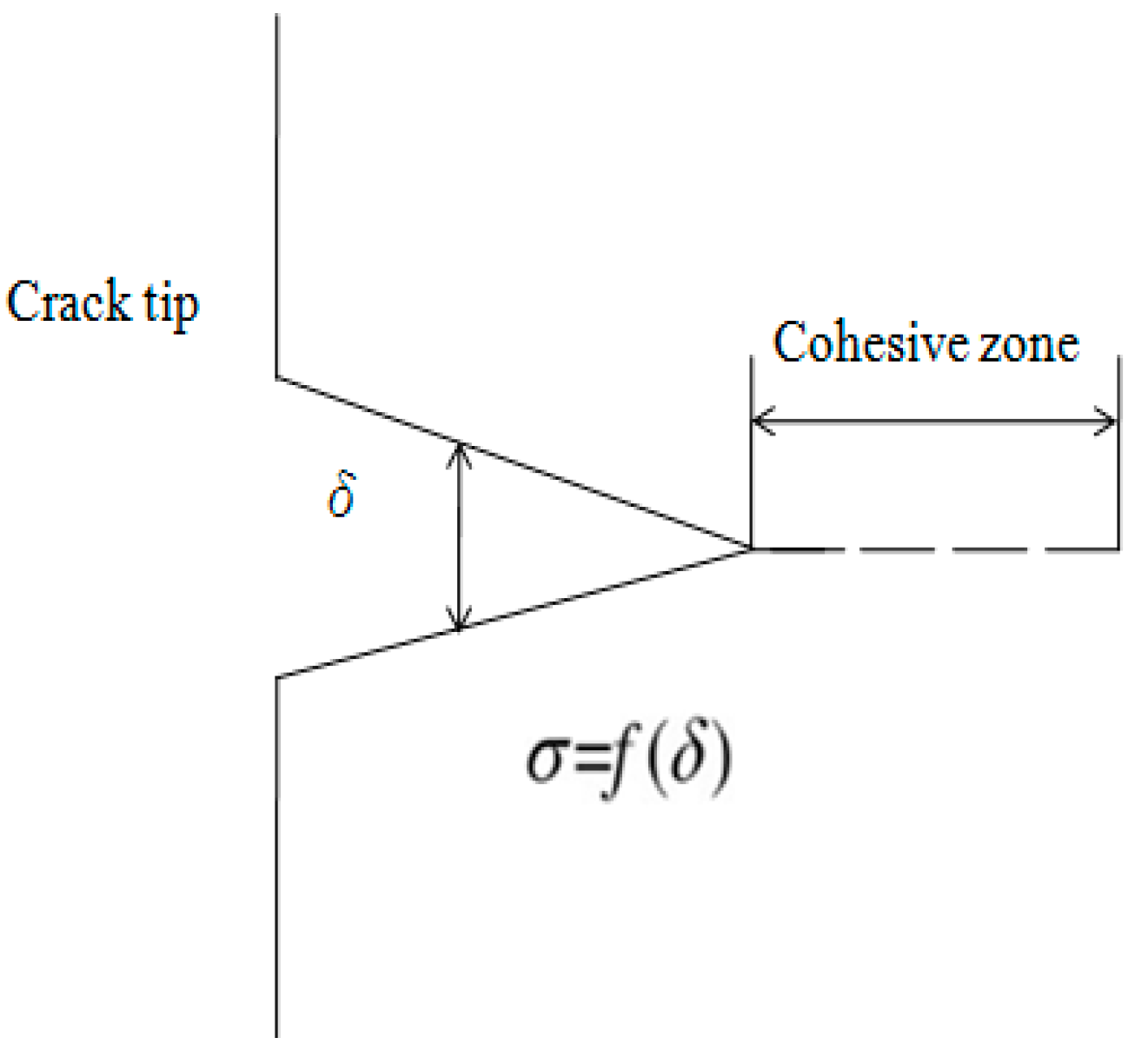

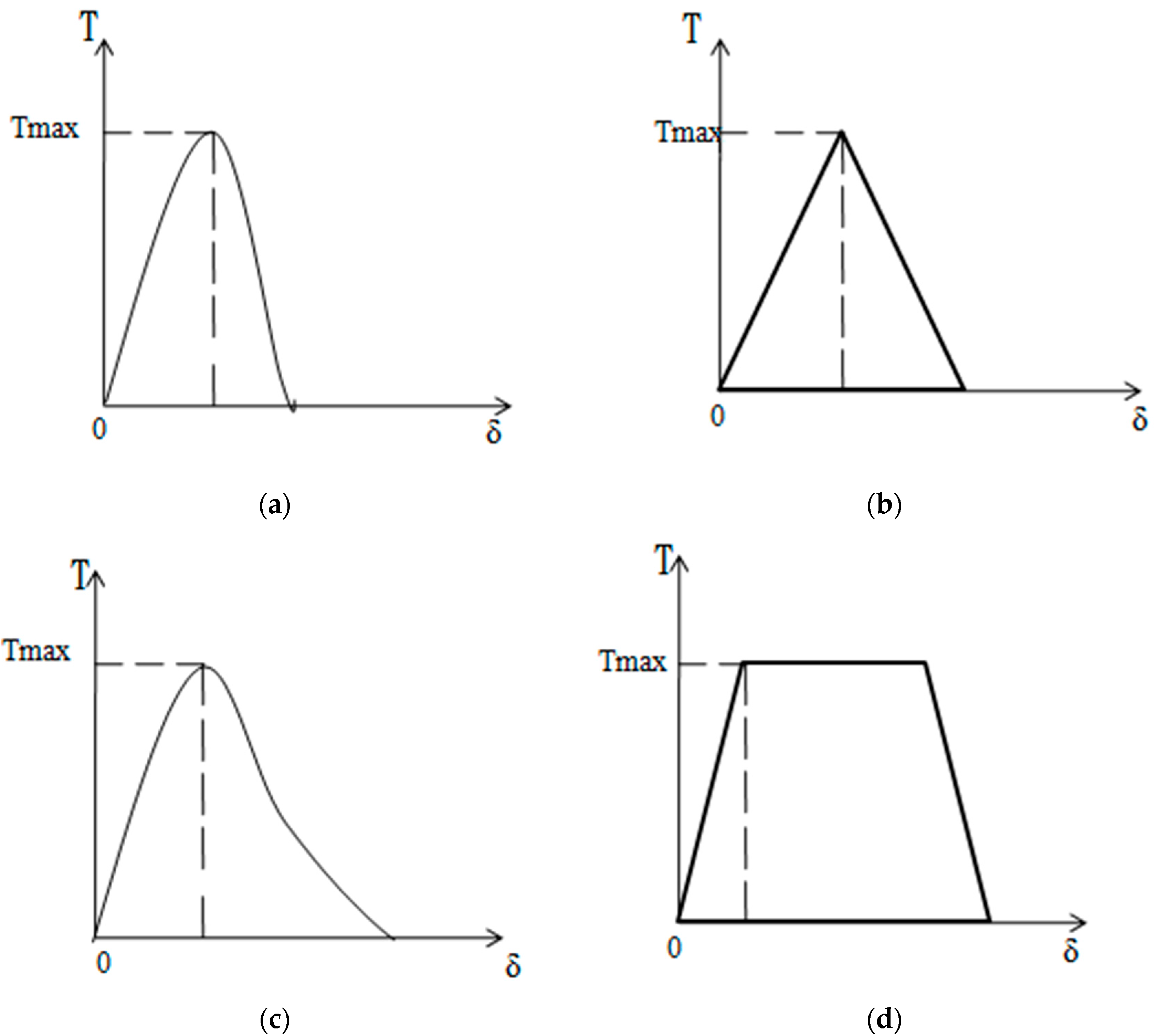

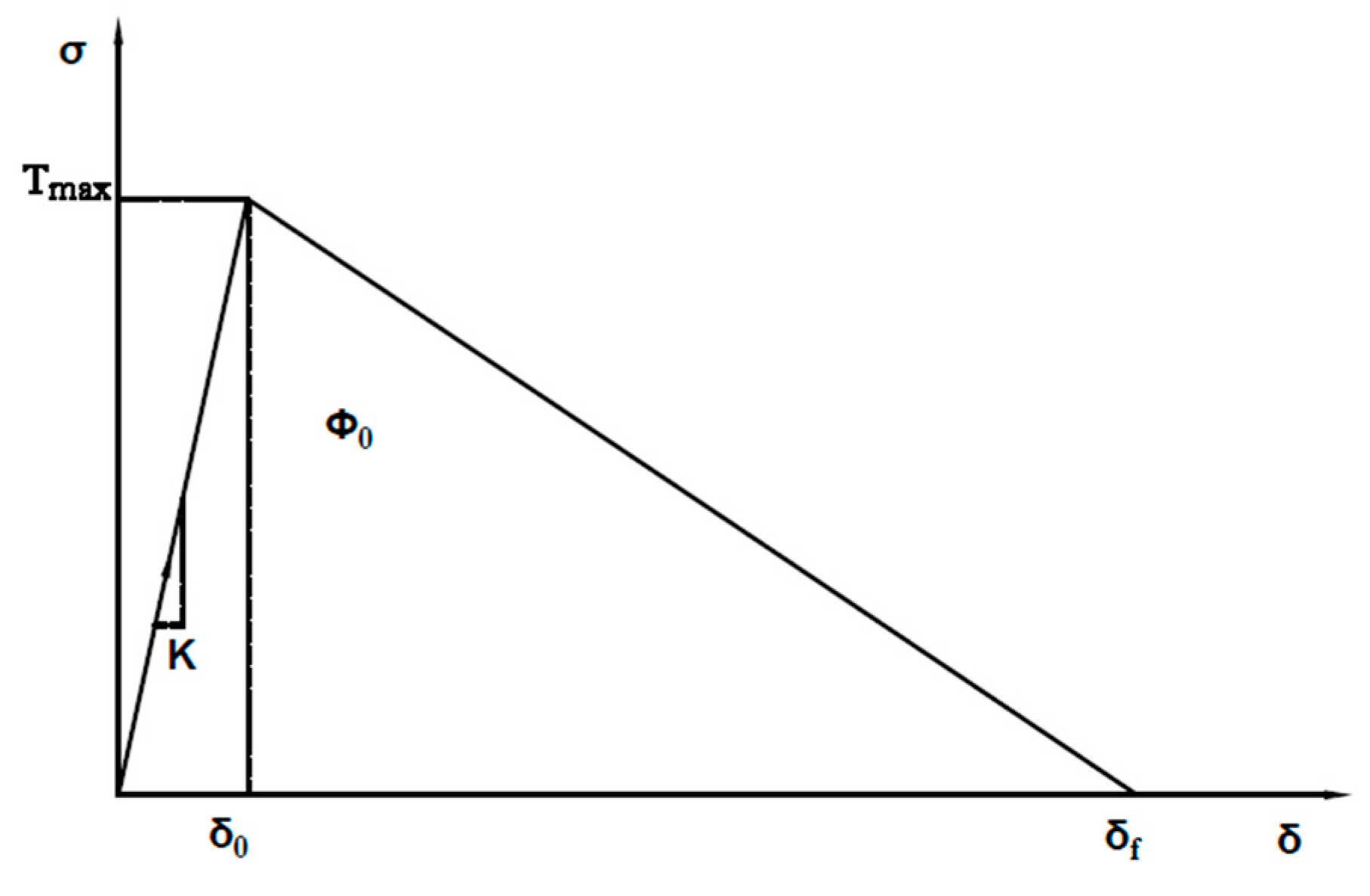

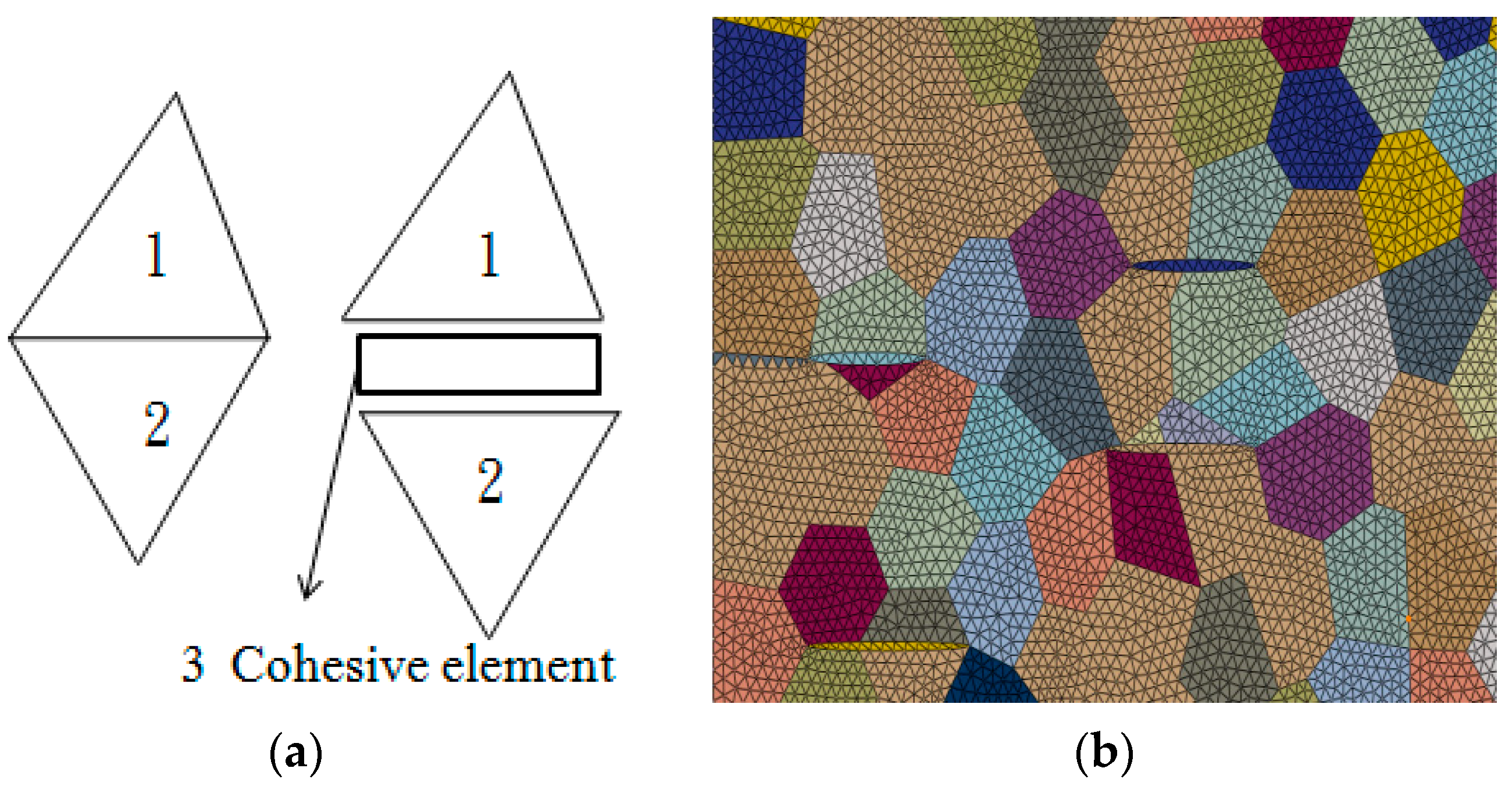

2.2. Cohesive Element Model

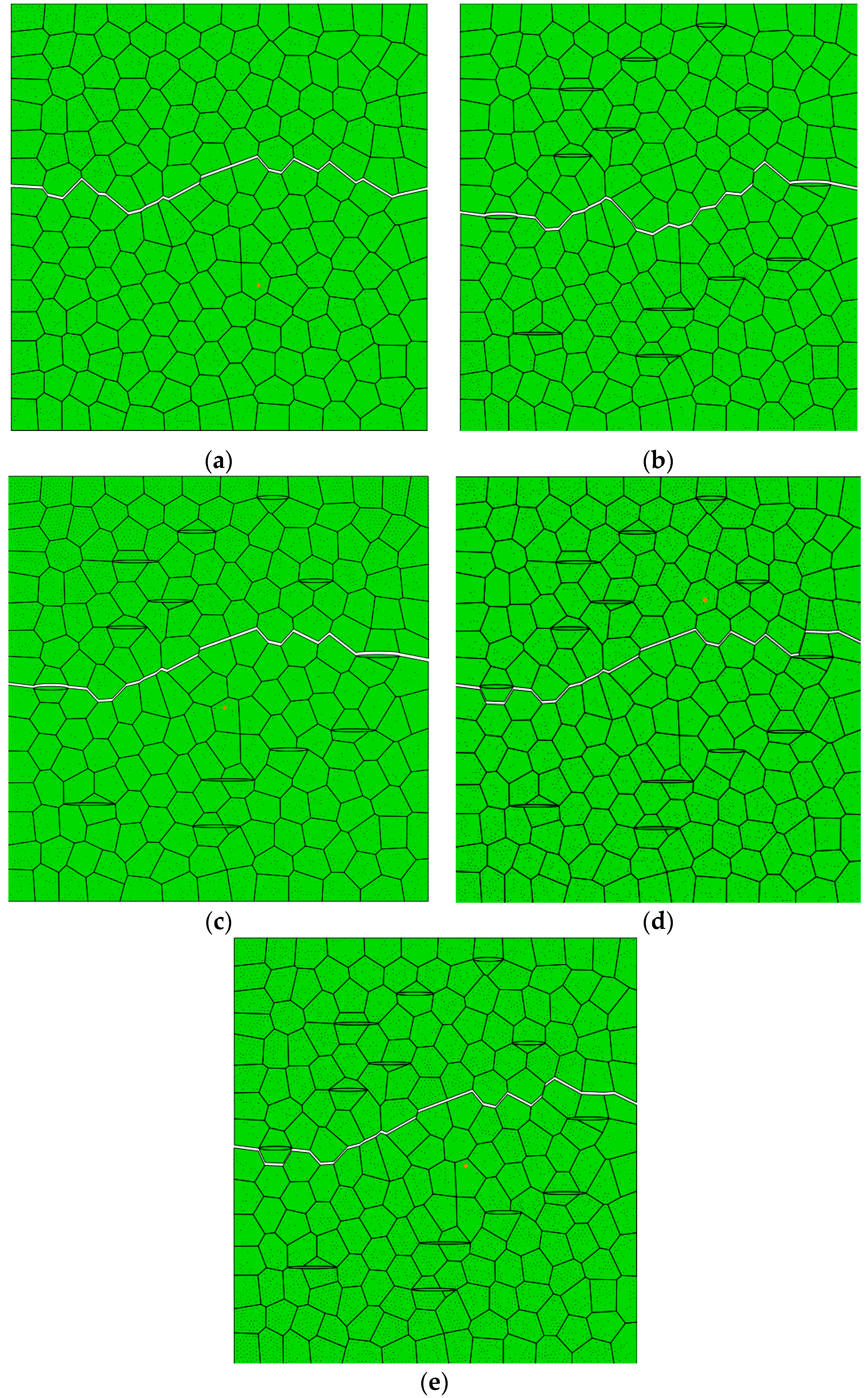

3. Microstructure Model and Simulation Procedure

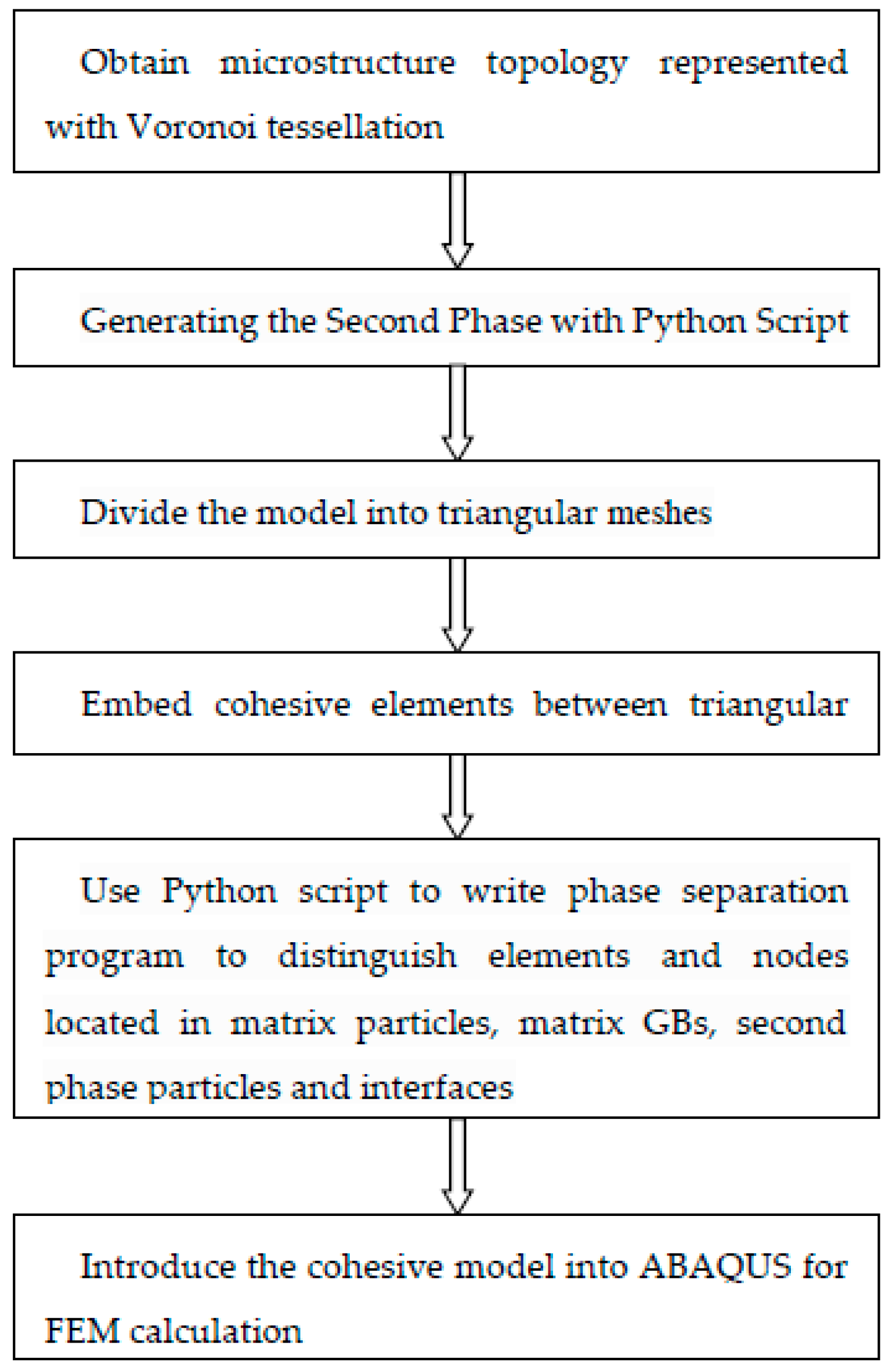

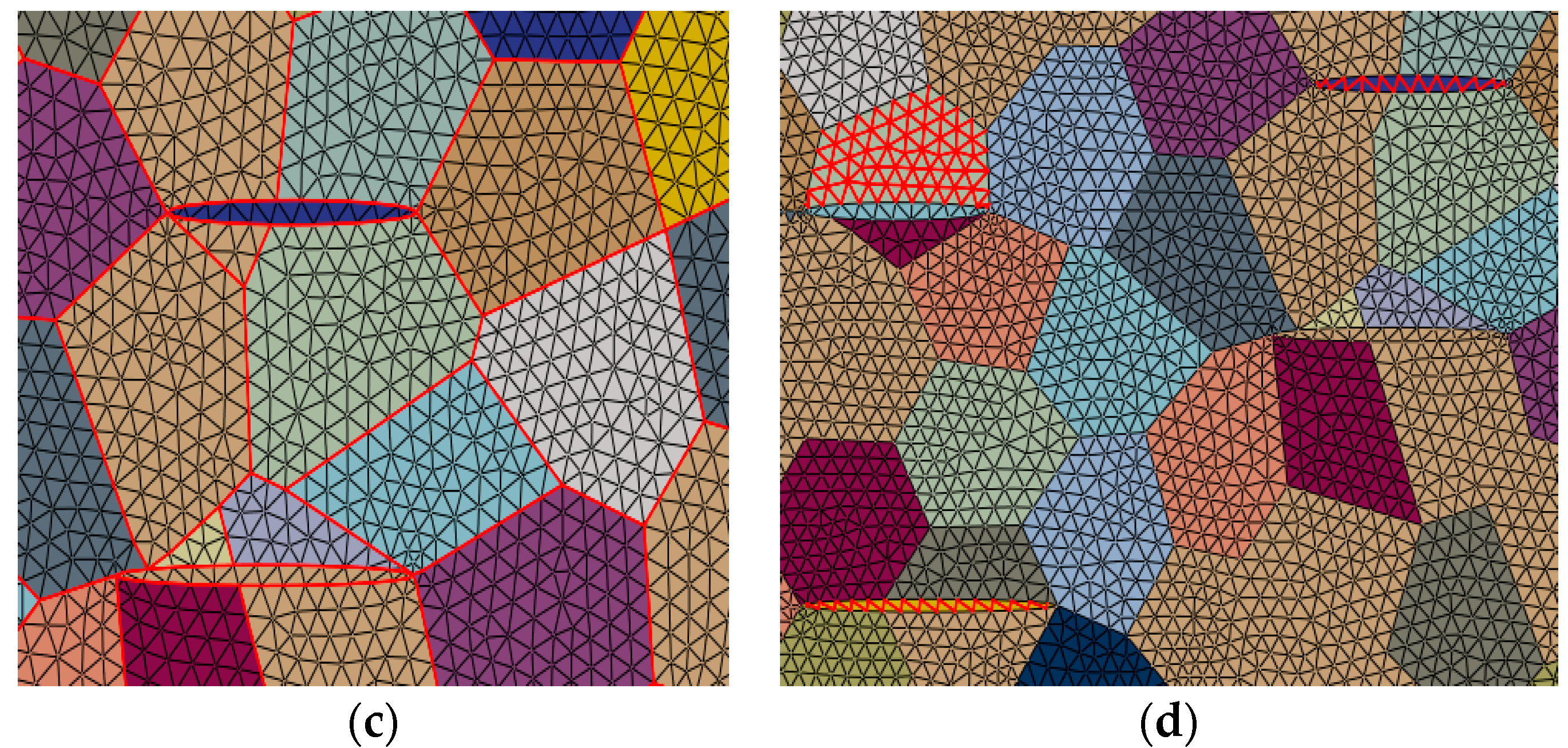

3.1. Simulation Process

3.2. Boundary Conditions of FEM Calculation

4. Results and Discussion

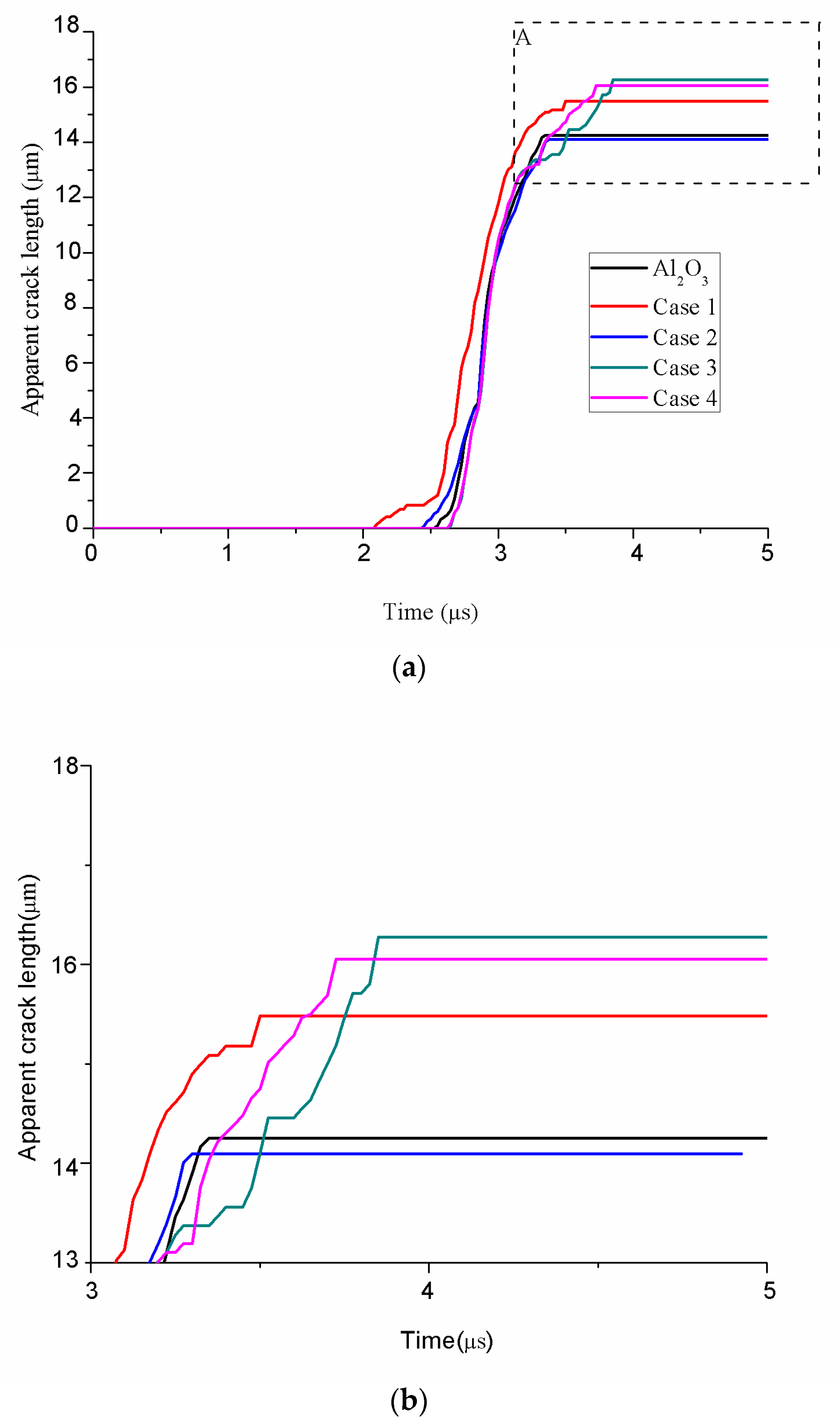

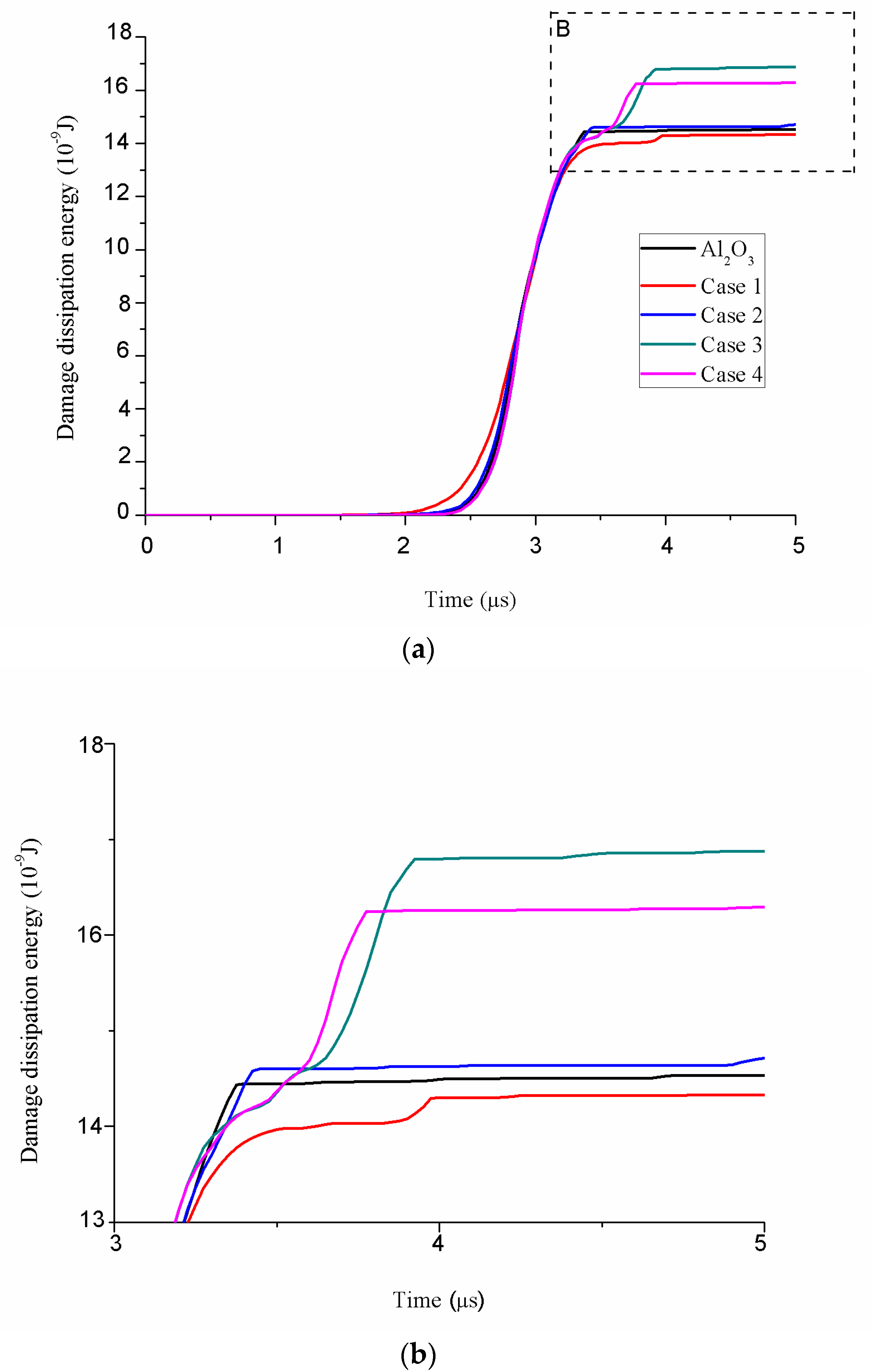

4.1. Results

4.2. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Firsov, A.A. Electric Field Effect in Atomically Thin Carbon Films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Bolotin, K.I.; Sikes, K.J.; Jiang, Z.; Klima, M.; Fudenberg, G.; Hone, J.; Kim, P.; Stormer, H.L. Ultrahigh Electron Mobility in Suspended Graphene. Solid State Commun. 2008, 146, 351–355. [Google Scholar] [CrossRef]

- Yin, Z.; Yuan, J.; Xu, W.; Liu, K.; Yan, S. Graphene nanosheets toughened TiB2-based ceramic tool material by spark plasma sintering. Ceram. Int. 2018, 44, 8977–8982. [Google Scholar] [CrossRef]

- Cui, E.; Zhao, J.; Wang, X.; Sun, J.; Huang, X.; Wang, C. Microstructure and toughening mechanisms of Al2O3/(W, Ti)C/Graphene composite ceramic tool material. Ceram. Int. 2018, 44, 13538–13543. [Google Scholar] [CrossRef]

- Zhou, T.; Huang, C.; Liu, H.; Wang, J.; Zou, B.; Zhu, H. Crack propagation simulation in microstructure of ceramic tool materials. Comput. Mater. Sci. 2012, 54, 150–156. [Google Scholar] [CrossRef]

- Guazzato, M.; Albakry, M.; Ringer, S.P.; Swain, M.V. Strength, fracture toughness and microstructure of a selection of all-ceramic materials. Part I. Pressable and alumina glass-infiltrated ceramics. Dent. Mater. 2004, 20, 441–448. [Google Scholar] [CrossRef]

- Guazzato, M.; Albakry, M.; Ringer, S.P.; Swain, M.V. Strength, fracture toughness and microstructure of a selection of all-ceramic materials. Part II. Zirconia-based dental ceramics. Dent. Mater. 2004, 20, 449–456. [Google Scholar] [CrossRef] [PubMed]

- Šajgalik, P.; Dusza, J.; Hoffmann, M.J. Relationship between Microstructure, Toughening Mechanisms, and Fracture Toughness of Reinforced Silicon Nitride Ceramics. J. Am. Ceram. Soc. 1995, 78, 2619–2624. [Google Scholar] [CrossRef]

- Zhai, J.; Tomar, V.; Zhou, M. Micromechanical Simulation of Dynamic Fracture Using the Cohesive Finite Element Method. J. Eng. Mater. Technol. 2004, 126, 179–191. [Google Scholar] [CrossRef]

- Bolander, J.; Saito, S. Fracture analyses using spring networks with random geometry. Eng. Fract. Mech. 1998, 61, 569–591. [Google Scholar] [CrossRef]

- Wang, D.; Zhao, J.; Zhou, Y.; Chen, X.; Li, A.; Gong, Z. Extended finite element modeling of crack propagation in ceramic tool materials by considering the microstructural features. Comput. Mater. Sci. 2013, 77, 236–244. [Google Scholar] [CrossRef]

- Barenblatt, G.I. The Mathematical Theory of Equilibrium Cracks in Brittle Fracture. Adv. Appl. Mech. Vol. 1962, 7, 55–129. [Google Scholar]

- Xu, X.P.; Needleman, A. Numerical simulations of fast crack growth in brittle solids. J. Mech. Phys. Solids 1994, 42, 1397–1434. [Google Scholar] [CrossRef]

- Hillerborg, A.; Modéer, M.; Petersson, P.E. Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem. Concr. Res. 1976, 6, 773–781. [Google Scholar] [CrossRef]

- Ghosh, S.; Liu, Y. Voronoi cell finite element model based on micropolar theory of thermoelasticity for heterogeneous materials. Int. J. Numer. Methods Eng. 1995, 38, 1361–1398. [Google Scholar] [CrossRef]

- Quey, R.; Dawson, P.R.; Barbe, F. Large-scale 3D random polycrystals for the finite element method: Generation, meshing and remeshing. Comput. Methods Appl. Mech. Eng. 2011, 200, 1729–1745. [Google Scholar] [CrossRef]

- Cornec, A.; Scheider, I.; Schwalbe, K.H. On the practical application of the cohesive model. Eng. Fract. Mech. 2003, 70, 1963–1987. [Google Scholar] [CrossRef]

- Tvergaard, V.; Hutchinson, J.W. The relation between crack growth resistance and fracture process parameters in elastic-plastic solids. Mech. Phys. Solids 1992, 40, 1377–1397. [Google Scholar] [CrossRef]

- Tvergaard, V.; Hutchinson, J.W. Effect of T-stress on mode I crack growth resistance in a ductile solid. Int. J. Solids Struct. 1994, 31, 823–833. [Google Scholar] [CrossRef]

- Yu, H.B.; Huang, C.Z.; Liu, H.L.; Zou, B.; Zhu, H.T.; Wang, J. A 3D Cohesive Element Model for Fracture Behavior Analysis of Ceramic Tool Materials Microstructure. Mater. Sci. Forum 2012, 723, 119–123. [Google Scholar] [CrossRef]

- Zhang, P.; Ma, L.; Fan, F.; Zeng, Z.; Peng, C.; Loya, P.E.; Liu, Z.; Gong, Y.J.; Zhang, J.N.; Zhang, X.X. Fracture toughness of graphene. Nat. Commun. 2014, 5, 3782. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.L.; Zhao, J.; Sun, J.L.; Gong, F.; Ni, X.Y. Reinforcing effect of graphene on the mechanical properties of Al2O3/TiC ceramics. Int. J. Miner. Metall. Mater. 2017, 24, 1403–1411. [Google Scholar] [CrossRef]

- Tomar, V.; Zhai, J.; Zhou, M. Bounds for Element Size in a Variable Stiffness Cohesive Finite Element Model. Int. J. Numer. Methodsin Eng. 2004, 61, 1840–1920. [Google Scholar] [CrossRef]

- Tomar, V. Analyses of the Role of the Second Phase SiC Particles in Microstructure Dependent Fracture Resistance Variation of SiC-Si3N4Nanocomposites. Model. Simul. Mat. Sci. Eng. 2008, 16, 035001. [Google Scholar] [CrossRef]

- Olson, G.B. Computational Design of Hierarchically Structured Materials. Science 1997, 277, 1237–1242. [Google Scholar] [CrossRef]

| Element Type | Tmax (MPa) | Γ (J/m2) | K (Mpa/mm) |

|---|---|---|---|

| Cohesive elements in Al2O3 | 644 | 2.3 | 9 × 109 |

| Cohesive elements in Al2O3 grain boundaries | 186 | 1 | 1.73 × 109 |

| Cohesive elements in graphene | 2090 | 15.9 | 1.37 × 1010 |

| Case 1 phase interface | 129 | 0.46 | 1.78 × 109 |

| Case 2 phase interface | 186 | 1 | 1.73 × 109 |

| Case 3 phase interface | 644 | 2.3 | 9 × 109 |

| Case 4 phase interface | 2090 | 15.9 | 1.37 × 1010 |

| Microstructure | Apparent Crack Length (μm) | Energy Dissipated (10−9 J) | GC (10−3 J/m2) |

|---|---|---|---|

| Al2O3 | 14.25 | 14.5 | 1.018 |

| Case 1 | 15.48 | 14.3 | 0.924 |

| Case 2 | 14.09 | 14.7 | 1.042 |

| Case 3 | 16.27 | 16.9 | 1.039 |

| Case 4 | 16.05 | 16.3 | 1.016 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Xiao, G.; Xu, C.; Zhou, T.; Yi, M.; Chen, Z. Cohesive Element Model for Fracture Behavior Analysis of Al2O3/Graphene Composite Ceramic Tool Material. Crystals 2019, 9, 669. https://doi.org/10.3390/cryst9120669

Zhang Y, Xiao G, Xu C, Zhou T, Yi M, Chen Z. Cohesive Element Model for Fracture Behavior Analysis of Al2O3/Graphene Composite Ceramic Tool Material. Crystals. 2019; 9(12):669. https://doi.org/10.3390/cryst9120669

Chicago/Turabian StyleZhang, Yongpeng, Guangchun Xiao, Chonghai Xu, Tingting Zhou, Mingdong Yi, and Zhaoqiang Chen. 2019. "Cohesive Element Model for Fracture Behavior Analysis of Al2O3/Graphene Composite Ceramic Tool Material" Crystals 9, no. 12: 669. https://doi.org/10.3390/cryst9120669

APA StyleZhang, Y., Xiao, G., Xu, C., Zhou, T., Yi, M., & Chen, Z. (2019). Cohesive Element Model for Fracture Behavior Analysis of Al2O3/Graphene Composite Ceramic Tool Material. Crystals, 9(12), 669. https://doi.org/10.3390/cryst9120669