Single Crystal Growth of URu2Si2 by the Modified Bridgman Technique

Abstract

:1. Introduction

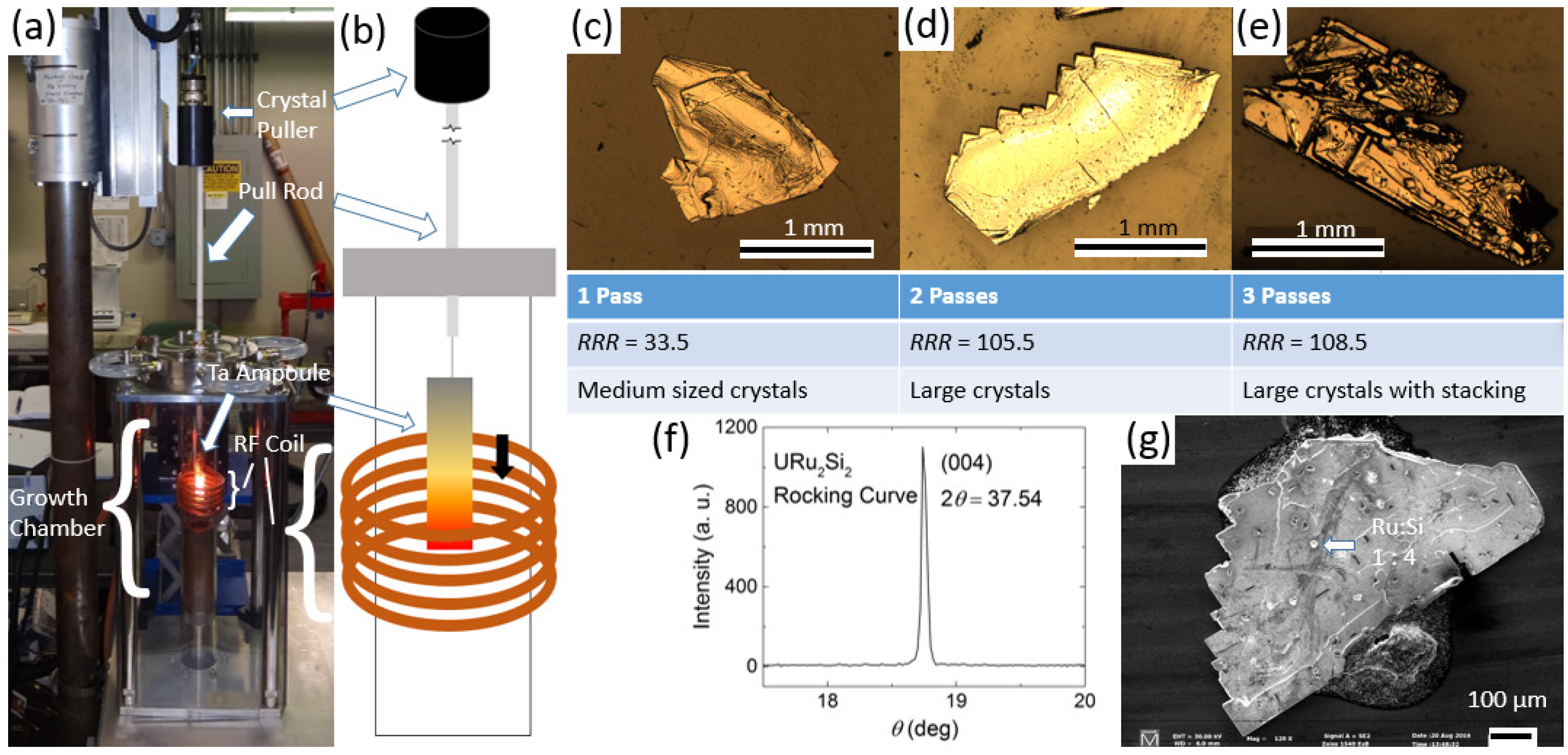

2. Experimental Methods

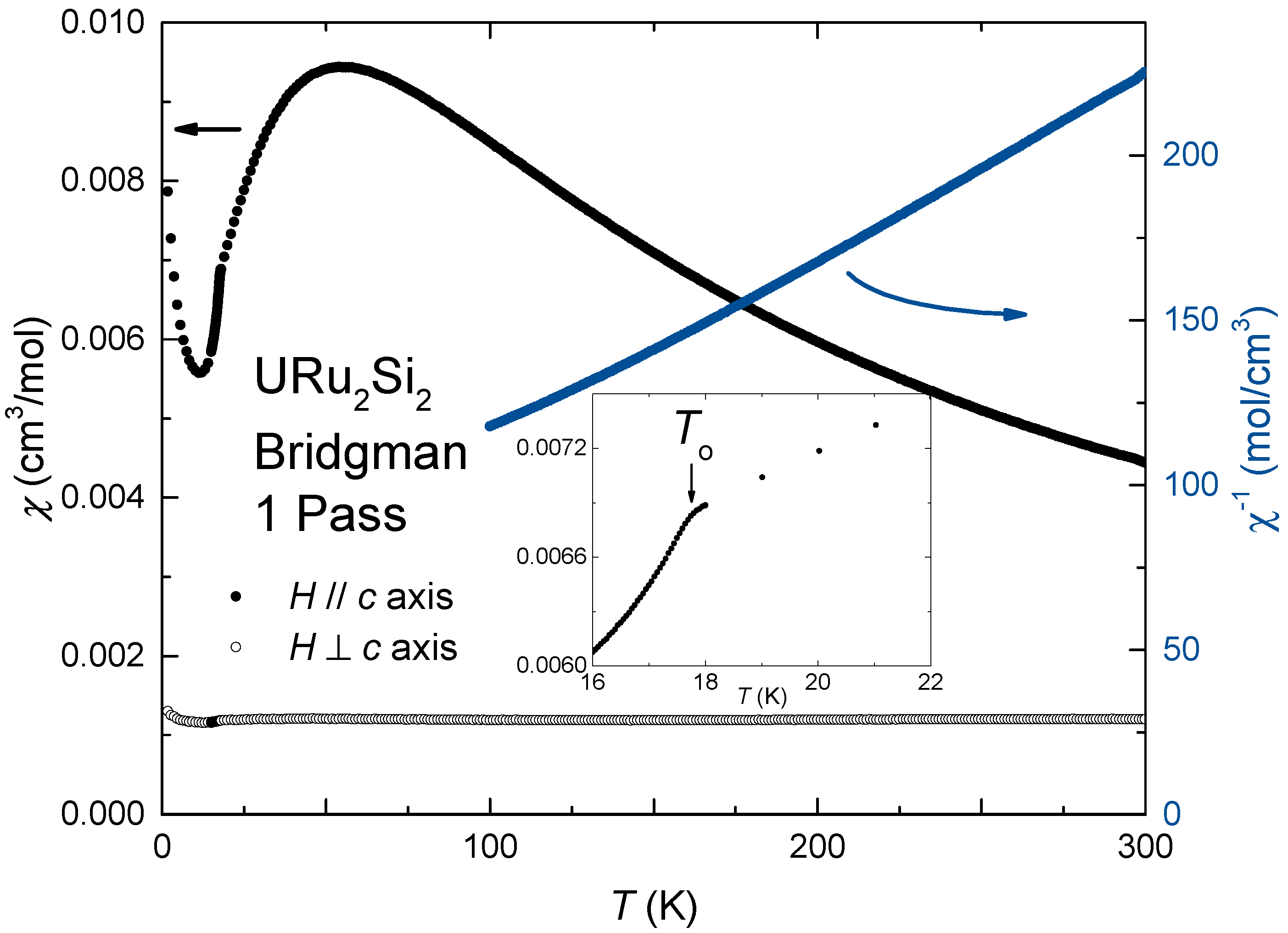

3. Results

4. Summary

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Palstra, T.T.M.; Menovsky, A.A.; van den Berg, J.; Dirkmaat, A.J.; Kes, P.H.; Nieuwenhuys, G.J.; Mydosh, J.A. Superconducting and Magnetic Transitions in the Heavy-Fermion System URu2Si2. Phys. Rev. Lett. 1985, 55, 2727. [Google Scholar] [CrossRef] [PubMed]

- Schlabitz, W.; Baumann, J.; Pollit, B.; Rauchschwalbe, U.; Mayer, H.M.; Ahlheim, U.; Bredl, C.D. Superconductivity and magnetic order in a strongly interacting Fermi-system: URu2Si2. Z. Phys. B 1986, 62, 171–177. [Google Scholar] [CrossRef]

- Maple, M.B.; Chen, J.W.; Dalichaouch, Y.; Kohara, T.; Rossel, C.; Torikachvili, M.S.; McElfresh, M.W.; Thompson, J.D. Partially gapped Fermi surface in the heavy-electron superconductor URu2Si2. Phys. Rev. Lett. 1986, 56, 185. [Google Scholar] [CrossRef] [PubMed]

- Mydosh, J.A.; Oppeneer, P.M. Colloquium: Hidden order, superconductivity, and magnetism: The unsolved case of URu2Si2. Rev. Mod. Phys. 2011, 83, 1301. [Google Scholar] [CrossRef]

- Baumbach, R.E.; Fisk, Z.; Ronning, F.; Movshovich, R.; Thompson, J.D.; Bauer, E.D. High purity specimens of URu2Si2 produced by a molten metal flux technique. Philos. Mag. 2014, 94, 3663–3671. [Google Scholar] [CrossRef]

- Matsuda, T.D.; Aoki, D.; Ikeda, S.; Yamamoto, E.; Haga, Y.; Ohkuni, H.; Settai, R.; Onuki, Y. Super Clean Sample of URu2Si2. J. Phys. Soc. Jpn. 2008, 77, 362–364. [Google Scholar] [CrossRef]

- Matsuda, T.D.; Hassinger, E.; Aoki, D.; Taufour, V.; Knebel, G.; Tateiwa, N.; Yamamoto, E.; Haga, Y.; Onuki, Y.; Fisk, Z.; et al. Details of Sample Dependence and Transport Properties of URu2Si2. J. Phys. Soc. Jpn. 2011, 80, 114710. [Google Scholar] [CrossRef]

- Kung, H.-H.; Baumbach, R.E.; Bauer, E.D.; Thorsmolle, V.K.; Zhang, W.-L.; Haule, K.; Mydosh, J.A.; Blumberg, G. Chirality density wave of the “hidden order” phase in URu2Si2. Science 2015, 347, 1339–1342. [Google Scholar] [CrossRef] [PubMed]

- Riggs, S.C.; Shapiro, M.C.; Maharaj, A.V.; Raghu, S.; Bauer, E.D.; Baumbach, R.E.; Giraldo-Gallo, P.; Wartenbe, M.; Fisher, I.R. Evidence for a nematic component to the hidden-order parameter in URu2Si2 from differential elastoresistance measurements. Nat. Commun. 2015, 6, 6425. [Google Scholar] [CrossRef] [PubMed]

- Yanagisawa, T.; Mombetsu, S.; Hidaka, H.; Amitsuka, H.; Akatsu, M.; Yasin, S.; Zherlitsyn, S.; Wosnitza, J.; Huang, K.; Janoschek, M.; et al. Hybridization-driven orthorhombic lattice instability in URu2Si2. Phys. Rev. B 2013, 88, 195150. [Google Scholar] [CrossRef]

- Schemm, E.R.; Baumbach, R.E.; Tobash, P.H.; Ronning, F.; Bauer, E.D.; Kapitulnik, A. Evidence for broken time-reversal symmetry in the superconducting phase of URu2Si2. Phys. Rev. B 2015, 91, 140506. [Google Scholar] [CrossRef]

- Tonegawa, S.; Kasahara, S.; Fukuda, T.; Sugimoto, K.; Yasuda, N.; Tsuruhara, Y.; Watanabe, D.; Mizukami, Y.; Haga, Y.; Matsuda, T.D.; et al. Direct observation of lattice symmetry breaking at the hidden-order transition in URu2Si2. Nat. Commun. 2014, 5, 4188. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nakashima, M.; Ohkuni, H.; Inada, Y.; Settai, R.; Haga, Y.; Yamamoto, E.; Onuki, Y. The de Haas-van Alphen effect in URu2Si2 under pressure. J. Phys. Condens. Matter 2003, 15, s2011–s2014. [Google Scholar] [CrossRef]

- Hassinger, E.; Knebel, G.; Matsuda, T.D.; Aoki, V.; Taufour, V.; Flouquet, J. Similarity of the Fermi Surface in the Hidden Order State and in the Antiferromagnetic State of URu2Si2. Phys. Rev. Lett. 2010, 105, 216409. [Google Scholar] [CrossRef] [PubMed]

- Altarawneh, M.M.; Harrison, N.; Sebastian, S.E.; Balicas, L.; Tobash, P.H.; Thompson, J.D.; Ronning, F.; Bauer, E.D. Sequential Spin Polarization of the Fermi Surface Pockets in URu2Si2 and Its Implications for the Hidden Order. Phys. Rev. Lett. 2011, 106, 146403. [Google Scholar] [CrossRef] [PubMed]

- Gallagher, A.; Chen, K.-W.; Moir, C.M.; Cary, S.; Kametani, F.; Kikugawa, N.; Albrect-Schmitt, T.; Riggs, S.C.; Shekhter, A.; Baumbach, R.E. Unfolding the physics of URu2Si2 through Si → P substitution. Nat. Commun. 2016, 7, 10712. [Google Scholar] [CrossRef] [PubMed]

- Matsumoto, Y.; Haga, Y.; Tateiwa, N.; Aoki, H.; Kimura, N.; Yamamura, T.; Yamamoto, E.; Matsuda, T.D.; Fisk, Z.; Yamagami, H. Fermi Surface of ThRu2Si2 as a Reference to the Strongly Correlated Isostructural Metals Investigated by Quantum Oscillations. J. Phys. Soc. Jpn. 2016, 85, 104709. [Google Scholar] [CrossRef]

- Kanchanavatee, N.; Janoschek, M.; Baumbach, R.E.; Hamlin, J.J.; Zocco, D.A.; Huang, K.; Maple, M.B. Twofold enhancement of the hidden-order/large-moment antiferromagnetic phase boundary in the URu2−xFexSi2 system. Phys. Rev. B. 2011, 84, 245122. [Google Scholar] [CrossRef]

- Das, P.; Kanchanavatee, N.; Helton, J.S.; Huang, K.; Baumbach, R.E.; Bauer, E.D.; White, B.D.; Burnett, V.W.; Maple, M.B.; Lynn, J.W.; et al. Chemical pressure tuning of URu2Si2 via isoelectronic substitution of Ru with Fe. Phys. Rev. B. 2015, 91, 085122. [Google Scholar] [CrossRef]

- Yokoyama, M.; Amitsuka, H.; Itoh, S.; Kawasaki, I.; Tenya, K.; Yoshizawa, H. Neutron Scattering Study in competition between hidden order and antiferromagnetism in U(Ru1−xRhx)2Si2 (x < 0.05). J. Phys. Soc. Jpn. 2004, 73, 545–548. [Google Scholar]

- Kanchanavatee, N.; White, B.D.; Burnett, V.W.; Maple, M.B. Enhancement of the hidden order/large moment antiferromagnetic transition temperature in the URu2−xOsxSi2 system. Philos. Mag. 2014, 94, 3681–3690. [Google Scholar] [CrossRef]

- Butch, N.P.; Maple, M.B. The suppression of hidden order and the onset of ferromagnetism in URu2Si2 via Re substitution. J. Phys. Condens. Matter 2010, 22, 164204. [Google Scholar] [CrossRef] [PubMed]

- Dalichaouch, Y.; Maple, M.B.; Chen, J.W.; Kohara, T.; Rossel, C.; Torikachvili, M.S.; Giorgi, A.L. Effect of transition-metal substitutions on competing electronic transitions in the heavy-electron compound URu2Si2. Phys. Rev. B 1990, 41, 1829. [Google Scholar] [CrossRef]

- Endstra, T.; Nieuwenhuys, G.J.; Mydosh, J.A. Hybridization model for the magnetic-ordering behavior of uranium and cerium based 1:2:2 intermetallic compounds. Phys. Rev. B 1993, 48, 9595. [Google Scholar] [CrossRef]

- Haga, Y.; Honma, T.; Yamamoto, E.; Ohkuni, H.; Onuki, Y.; Ito, M.; Kimura, N. Purification of Uranium Metal using the Solid State Electrotransport Method under Ultrahigh Vacuum. Jpn. Soc. Appl. Phys. 1998, 37, 6A. [Google Scholar] [CrossRef]

- Emi, N.; Hamabata, R.; Nakayama, D.; Miki, T.; Koyama, T.; Ueda, K.; Mito, T.; Kohori, Y.; Matsumoto, Y.; Haga, Y.; et al. Magnetic and Electronic Properties of URu2Si2 Revealed by Comparison with Nonmagnetic References ThRu2Si2 and LaRu2Si2. J. Phys. Soc. Jpn. 2015, 84, 063702. [Google Scholar] [CrossRef]

- Mydosh, J.A.; Oppeneer, P.M. Hidden order Behaviour in URu2Si2. Philos. Mag. 2014, 94, 3642. [Google Scholar] [CrossRef]

- Palstra, T.T.M.; Menovsky, A.A.; Mydosh, J.A. Anisotropic electrical resistivity of the magnetic heavy fermion superconductor URu2Si2. Phys. Rev. B 1986, 33, 6527. [Google Scholar] [CrossRef]

- Menovsky, A.A.; Gortenmulder, T.J.; Tan, H.J.; Palstra, T.T.M. Crystal growth and characterization of MT2Si2 ternary intermetallics (M = U, RE and T = 3d, 4d, 5d transition metals). J. Cryst. Growth 1986, 79, 316–321. [Google Scholar] [CrossRef]

| Compound | Passes | Sample | (K) | (K) | |

|---|---|---|---|---|---|

| URuSi | 1 | S1 | 31 | 17.40 | 1.21 |

| URuSi | 1 | S2 | 36 | 17.39 | 1.19 |

| URuSi | 2 | S1 | 95 | 17.55 | 1.3 |

| URuSi | 2 | S2 | 116 | 17.63 | 1.32 |

| URuSi | 3 | S1 | 111 | 17.48 | |

| URuSi | 3 | S2 | 106 | 17.48 | |

| ThRuSi | 2 | S1 | 127 | ||

| ThRuSi | 2 | S2 | 187 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gallagher, A.; Nelson, W.L.; Chen, K.W.; Besara, T.; Siegrist, T.; Baumbach, R.E. Single Crystal Growth of URu2Si2 by the Modified Bridgman Technique. Crystals 2016, 6, 128. https://doi.org/10.3390/cryst6100128

Gallagher A, Nelson WL, Chen KW, Besara T, Siegrist T, Baumbach RE. Single Crystal Growth of URu2Si2 by the Modified Bridgman Technique. Crystals. 2016; 6(10):128. https://doi.org/10.3390/cryst6100128

Chicago/Turabian StyleGallagher, Andrew, William L. Nelson, Kuan Wen Chen, Tiglet Besara, Theo Siegrist, and Ryan E. Baumbach. 2016. "Single Crystal Growth of URu2Si2 by the Modified Bridgman Technique" Crystals 6, no. 10: 128. https://doi.org/10.3390/cryst6100128

APA StyleGallagher, A., Nelson, W. L., Chen, K. W., Besara, T., Siegrist, T., & Baumbach, R. E. (2016). Single Crystal Growth of URu2Si2 by the Modified Bridgman Technique. Crystals, 6(10), 128. https://doi.org/10.3390/cryst6100128