1. Introduction

The modern development of nuclear energy requires stricter standards for the radiation safety of both research and industrial installations. Traditional protective materials—such as concrete, lead, and borated polymers—offer only a partial combination of the desired properties. They usually provide either strong neutron shielding or mechanical resistance, but rarely both, and they often lack low density or chemical stability [

1,

2,

3,

4,

5,

6].

In recent years, researchers have actively developed composites based on ultra-high molecular weight polyethylene (UHMWPE) with functional fillers. Such systems can simultaneously provide effective neutron absorption and improved mechanical strength [

7]. For example, Zhang et al. [

8,

9] showed that adding boron nitride (BN) to UHMWPE achieves high neutron-shielding efficiency (neutron transmission decreased to 0.28% at 3.2 mm thickness with 20 wt% BN) and significantly enhances tensile strength (550–750 MPa).

This has increased interest in polymer composites that combine neutron and gamma radiation absorption with long-term mechanical and chemical resistance. UHMWPE is a promising matrix because its high hydrogen content effectively slows down fast neutrons [

2,

3]. However, functional fillers are required to absorb thermal neutrons and mitigate gamma-dose loads. The most widely used are boron-containing compounds (B

4C, H

3BO

3, BN), which have large thermal neutron capture cross-sections [

3].

The effectiveness of boron-based fillers is confirmed in the work of Toyen et al. [

10], who reported that adding 50 wt% B

2O

3 to UHMWPE significantly improved neutron shielding. A two-step fabrication method (extrusion followed by compression molding) ensured uniform filler distribution, enhancing both mechanical strength and radiation resistance.

Other fillers, such as Sm

2O

3, provide simultaneous attenuation of neutrons and gamma radiation due to their high neutron absorption cross-section (5922 barns) and high density. Toyen et al. [

11] showed that adding 11–13 wt% Sm

2O

3 achieved shielding comparable to commercial borated polyethylene, but at reduced thickness.

Boron compounds (B

4C, H

3BO

3) remain among the most effective fillers for thermal neutron protection. It has been shown [

7] that introducing BN into polymer matrices not only increases neutron absorption but also improves mechanical characteristics. For example, the elastic modulus of polyethylene increased from 588 to 735 MPa at 15 vol% BN. Heavy oxides (PbO, Sm

2O

3) and tungsten carbide (WC) are also under study, as they can enhance radiation resistance while providing heat stability and mechanical rigidity [

1,

2,

3,

4,

5,

6,

8].

Sayyed et al. [

12] investigated UHMWPE/WO

3 composites and demonstrated that adding 5 mol% WO

3 significantly increased the neutron removal cross-section (ΣR) and reduced the mean free path, as confirmed experimentally and through Monte Carlo simulations (GEANT4).

Due to the large number of irradiation experiments and the diversity of compositions of the samples studied, the following labeling system was developed (

Table 1):

The first digit in the sample name indicates the run number. The second digit indicates the sample composition.

The corresponding compositions were as follows:

B10W10Pb10—10% H3BO3, 10% WC, 10% PbO.

B20W20Pb10—20% H3BO3, 20% WC, 10% PbO.

B30W5Pb20—30% H3BO3, 5% WC, 20% PbO.

Hybrid systems are also promising. Mehelli et al. [

13] reported that composites of UHMWPE fibers, epoxy resin, and B

4C exhibited high shielding efficiency against fast neutrons while remaining lightweight and flexible, making them attractive for personal protective equipment and aerospace applications.

However, most existing studies remain limited to laboratory conditions (γ-sources, simulation stands). They often overlook the behavior of materials under real reactor irradiation, where thermal and fast neutrons, γ-quanta, and thermal loads act simultaneously [

13,

14,

15,

16,

17,

18]. Even materials with high laboratory efficiency may degrade in reactors due to polymer destruction, leaching, or filler phase transformations. To date, there are few systematic studies of UHMWPE-based composites irradiated in research reactors, which limits their practical application [

15,

16].

The novelty of this work lies in conducting full-scale tests of UHMWPE composites with fillers (H3BO3, WC, PbO) produced by flame formation. For the first time, these composites were studied under the neutron spectrum of the IVG-1M research reactor. This made it possible to experimentally determine neutron absorption coefficients at different fluences simulating real conditions; to monitor changes in flexural strength and the balance between radiation crosslinking and degradation; and to evaluate chemical resistance before and after irradiation—an aspect rarely addressed in previous studies.

Thus, this work goes beyond evaluating absorption properties alone. It examines the overall radiation resistance of UHMWPE composites under real reactor irradiation. The findings provide a basis for designing a new generation of multifunctional protective materials for nuclear power and other fields that require long-term performance under intense radiation exposure.

2. Materials and Methods

The material chosen for the study was a composite material based on ultra-high molecular weight polyethylene with fillers, produced by Nantong Yangba Polyethylene Co., Ltd., Haimen, China. UHMWPE is a white powder with an average particle size of 150 μm, Tm = 135 °C, density of 930 kg/m

3, with a molecular weight of 2.0 × 10

6 mol

−1, bulk density > 0.4 g/cm

3 [

19]. The fillers of the composite material were H

3BO

3 powders with a molar mass of 61.83 g/mol in accordance with National Standard (GOST) 18704-78 [

20], WC with a bulk density of 15.77 g/cm

3 in accordance with Standard (TU) 6-09-03-360-78 [

21] with an average particle size of 60 μm, PbO with a molar mass of 239.1988 g/mol, density of 9.38 g/cm

3.

The composite material based on UHMWPE was obtained by the developed flame method [

19,

22]. The polymer-based material was obtained in the following way: filler powders were pre-dried at a temperature of 50–100 °C, then all the powders were mixed in a roller mill; tungsten carbide, boric acid, and lead oxide were used as fillers. Before spraying, the substrate was preheated to a temperature of 95–100 °C, after which spraying was carried out using the flame method of applying a protective coating. After that, three cylindrical samples with a diameter of 20 mm and a height of 25 mm were cut out of each type. The mass of one sample is 10 g.

Irradiation of UHMWPE-based composite samples with different fillers was performed at various neutron fluences in the IVG.1M research reactor of the National Nuclear Center of the Republic of Kazakhstan.

After irradiation at the reactor, the samples were transferred to a special room in the reactor building to measure the activity of the radioactive isotopes and the activity of the samples themselves in accordance with the well-known activation analysis technique [

23].

Mechanical tests for three-point bending were carried out using an Instron 5966 [

24,

25,

26] universal testing machine using a special device that allows for the installation and fixation of supports at the required distance between them (

Figure 1). The distance between the supports for the samples was set at 14 mm. The test was carried out until the failure of the test sample at a crosshead travel speed of 1 mm/min. The strength characteristics were calculated according to the recommendations of National Standard (GOST) R 56810-2015, “Bending Test Method for Flat Samples.” The load on the sample was measured using a high-precision dynamometer with a load limit of 5 kN (class 0.5, ISO 7500-1), and the deflection was measured using a crosshead travel sensor on the testing machine [

19,

20,

21,

22].

From each type of sample with different fillers, 2 test samples with nominal dimensions of 18 × 7 × 3 mm were selected. The scheme for selecting test samples is shown in

Figure 2. The cutting of test samples was carried out on a JET 351 V band saw. The finishing of the sample sizes was carried out manually using abrasive paper with a grain size of P240.

Bending strength

σi, MPa, was calculated using the formula

σi

where

Fmax—maximum load preceding the destruction of the sample, N;

L—span between supports, mm;

b—sample width, mm;

h—sample thickness, mm.

The chemical resistance of the composite material was determined on non-irradiated and irradiated samples according to the method described in the National Standard (GOST) 12020-72 [

27,

28]. The samples for chemical resistance testing were taken in the form of a disk with nominal dimensions Ø20 × 3 mm cut from the original cylindrical sample. The essence of the method lies in determining the change in the mass of the test material samples in a non-stressed state after holding for a certain period of time in a mixture of 10% sulfuric and 10% hydrochloric acids. Before testing, the samples were dried and kept in a desiccator at room temperature. The mass of the samples was measured on a Mettler Toledo MS205DU analytical balance. Before performing intermediate mass measurements, the sample was rinsed with water and wiped with a paper napkin. The tests were carried out at room temperature (20 ± 2 °C) for 120 h. Each test sample was placed in a separate glass vessel with a loosely closed lid and with a reagent amount of about 150 mL, taken at the rate of 20 mL of liquid for each square centimeter of the total surface of the test sample.

The structure of irradiated and non-irradiated composite material samples was studied using an Xpert PRO PANalytical X-ray diffractometer. The exposure time (time per step) during shooting was 61.2 s, the scanning step size for diffraction patterns was 0.026º2θ, and the studied angular range was 5–20º2θ. The operating mode of the PIXcel1D detector is a scanning line detector. Radiation: Cu Kα; voltage and current: 45 kV, 40 mA. A fixed divergence slit with an angular divergence of 1°, an antiscatter slit of 2°, and an incident beam mask marked 10, providing an incident beam width of 9.9 mm, was used.

The fractography of the structure and elemental analysis of irradiated and non-irradiated samples were studied on a Tescan Vega 3 electron microscope using a secondary electron detector. The samples were sputtered with carbon to reduce the effect of charge accumulation on the surfaces of the fragments using a JEOL JEC-560 automatic sputtering device.

3. Reactor Irradiation

The IVG.1M is a water-cooled, heterogeneous thermal neutron research reactor with a beryllium reflector. Its design enables the irradiation of samples under a wide range of conditions. The central physical experimental channel (PEC) allows the placement of devices and samples directly in the reactor core, while alternative positions outside the PEC cavity are also available depending on the experimental requirements.

The reactor has a nominal design power of 72 MW, with current experiments typically conducted at 10 MW.

Figure 3a,b show the general layout of the IVG.1M reactor. The core consists of water-cooled process channels (WCPCs) containing fuel assemblies (FAs). Each fuel assembly includes a thin-walled cylindrical shell, end-permeable grids, and a package of fuel elements in the form of spiral rods with a two-bladed profile. Beryllium is used as the material for the central, interchannel, and lateral displacers. The main technical parameters of the IVG.1M reactor are summarized in

Table 2.

To ensure the safety of the experiments and optimize the irradiation regime, neutron-physical and thermophysical calculations were performed. The neutron-physical calculations determined the energy release in the samples, while the thermophysical calculations established the temperature distribution within the irradiation package.

Neutron-physical modeling was carried out using the MCNP5 code with ENDF/B-V and ENDF/B-VI cross-section libraries, which enable radiation transport simulations in arbitrary three-dimensional geometries. The temperature field of the sample package was evaluated using the ANSYS Fluent software package.

Figure 4a shows the calculation model of the specially developed experimental device (ED). The ED is a polyethylene film package designed in the form of a cartridge belt, allowing up to nine UHMWPE samples to be placed on the outer surface of the PEC under identical irradiation conditions.

The temperature distribution in the model was determined by energy release in the samples and convective heat transfer to the environment. Natural convection was assumed on the outer boundary with a heat transfer coefficient of 5 W/(m

2·°C) and an ambient water temperature of 40 °C. Material properties were taken from reference data and defined as functions of temperature. The sample properties were calculated based on mass fractions of their compositions. Since the energy values were low, a double-precision solver was used for higher accuracy. Iterative calculations were performed with an energy convergence criterion of 10

−8 W. The resulting temperature field is presented in

Figure 4b, while

Figure 4c shows the temperature distribution in the cartridge belt cross-section at mid-height of the samples.

Irradiation of composite samples was carried out during three reactor runs on the IVG.1M reactor. The samples, containing different fillers, were installed in the ED above the reactor lid on the side surface of the PEC extension (

Figure 5a). The upper end of the samples was located 30 cm below the upper end of the PEC extension. To assess neutron flux attenuation, the samples were equipped with activation indicators (AIs) made of copper and nickel wires (1 mm diameter, 20 mm length). Each sample contained an axial hole (1.4 mm diameter) for “internal” AI1s, while “external” AI2s were placed in the lower part of the pockets.

Figure 5b shows a photograph of the package with installed samples fixed at the PEC upper section.

Polyethylene samples 2.1, 2.2, 2.3, 1.0, 3.1, 3.2, and 3.3 were placed in seven cartridge-belt pockets. Copper AI1s and AI2s were inserted into samples 2.1, 2.2, 2.3, and 1.0, while nickel AIs were installed in samples 3.1, 3.2, and 3.3 (both internally and externally). An additional nickel AI was placed in the empty pocket 1.3.

During the first run, the reactor operated at three power levels: 1 MW (71 min), 3 MW (71 min), and 6 MW (71 min), with a total integrated power of 11.83 MW·h.

In the second run, samples 3.1, 3.2, 3.3, and 1.0 were reinstalled at the same position, 35 mm below the PEC extension top. The reactor operated at two power levels: 1 MW (71 min) and 3 MW (71 min), with an integrated power of 4.73 MW·h.

In the third run, irradiation was performed at four power levels: 1 MW (41 min), 3 MW (41 min), 6 MW (71 min), and 10 MW (31 min), with a total integrated power of 15 MW·h.

4. Determination of Activity and Neutron Flux Density on Activation Indicators

Measurements of gamma spectra of irradiated nuclear reactors were carried out after their exposure for more than 22 h. The activity of the activation products

64Cu and

58Co, formed in the reactions

58Ni (n,p)

58Co and

63Cu(n,γ)

64Cu, was calculated at the moment of completion of the start-up according to the formula [

19,

21]:

where

S—area of the full-energy peak at E = 511 and 810 keV;

tl—live measurement time (s);

η—gamma-ray emission probability (yield);

K—correction factor for geometry and self-absorption of gamma radiation in the source material (K = 1.03 for E = 511 and 810 keV);

ε—detection efficiency;

λ—decay constant of the nuclide formed in the activation indicator (AI), λ(64Cu) = 1.52 × 10−5 s−1, λ(58Co) = 1.13 × 10−7 s−1;

th—decay (cooling) time of the activation indicator.

The gamma-ray detection efficiency was determined using calibration sources Eu-152, Cs-137, Na-22, and Co-60 from the OSGI-RT (Standard Gamma Radiation Sources) set (Closed Joint-Stock Company “RITVERTS”).

Gamma spectra of the OSGI sources were measured to determine the detection efficiency and the activity of the activation indicators (AIs) under identical geometry conditions.

The detection efficiency was calculated using the following formula:

where

S(E)—area of the full-energy peak at energy E;

tl—“live” measurement time, s;

A0—activity of the standard gamma source (OSGI) at the time of certification, Bq;

η—gamma-ray emission probability (yield);

λ—decay constant of the radionuclide;

th—time elapsed since the certification of the standard gamma source (OSGI).

The radiation characteristics of the radioisotopes used were presented in [

13]. The reaction rate RRR, normalized per single target isotope nucleus for irradiation at multiple power levels, was calculated based on the activity (At) of the irradiated sample at the end of the irradiation period and subsequently normalized to a reactor power of 3 MW:

N = m·ν·Na/M—number of target isotope nuclei in the activation indicator (AI);

m—mass of the AI;

ν—natural abundance of the target isotope;

M—molar mass of the target isotope;

F—saturation factor, determined by the formula:

where

Pi—reactor power at the i-th power level, MW;

λ—decay constant of the nuclide formed in the activation indicator (AI), s−1;

—effective irradiation time at the i-th reactor power level, s;

—time elapsed from the end of the i-th reactor power level until the end of the startup, s.

The reaction rate is the initial value for subsequent calculations of neutron field characteristics.

The fast neutron flux density with energy above 2.3 MeV is determined by the following formula:

where

R—reaction rate of 58Ni(n,p)58Co on nickel;

σeff—effective microscopic cross-section for the threshold reaction 58Ni(n,p)58Co with a threshold of 2.3 MeV, σeff = 335 mbarn.

5. Results and Discussion

Paired activation measurements with indicator placement “before the sample” (ext) and “after the sample” (int) were processed strictly according to Formulas (2)–(6): activities were obtained from calibrated full-energy peak areas using OSGI standards (taking into account geometry and self-absorption via the coefficient K, as well as corrections for live time and cooling time); reaction rates were normalized to 3 MW; and fast-flux reconstruction was performed using Formula (6) with the effective cross-section adopted therein. The synthesized results are presented in

Table 3, which compiles the neutron absorption coefficients Rext/Rint for UHMWPE composites in all reactor runs. The coefficients exhibit a stable hierarchy—UHMWPE ≈ 1.21 ≤ B10W10Pb10 ≈ 3.31 ≤ B20W20Pb10 ≈ 7.57 ≤ B30W5Pb20 ≈ 9.17 (averaged over runs)—and vary by approximately ±10% across the integral dose range of ~7.2 × 10

15–1.36 × 10

17 n·cm

−2, indicating no statistically significant radiation-induced degradation of shielding performance. Such dose invariance is consistent with the preservation of UHMWPE matrix crystallinity and the observed bending strength behavior of composites with moderate filler contents (in line with the effect of radiation-induced crosslinking). In practice, the composition can be tuned to application requirements: B30W5Pb20 maximizes thermal-neutron capture with additional γ-attenuation; B20W20Pb10 provides a strong yet balanced response at high doses; and B10W10Pb10 ensures enhanced chemical resistance while nearly tripling the absorption coefficient compared with neat UHMWPE.

During the tests to determine the strength characteristics of unirradiated UHMWPE samples with fillers, load–deflection (stress–deflection) bending curves were recorded before and after irradiation, as shown in

Figure 6.

Table 4 presents the strength characteristics of UHMWPE samples with fillers, both non-irradiated and irradiated.

After neutron irradiation, the strength of the studied samples changed differently depending on their composition.

Type 1 samples (pure UHMWPE) showed a decrease in strength. This effect is attributed to the predominance of radiation-induced degradation over macromolecular crosslinking. As a result, the molecular weight decreased, leading to deterioration of the mechanical properties.

Type 2 samples (UHMWPE with B, W, and Pb additives) exhibited an increase in strength. Boron effectively absorbs thermal neutrons, while tungsten and lead reduce γ-radiation intensity, thereby limiting the radiation load on the matrix. Under these conditions, crosslinking processes prevailed over degradation, causing structural densification and improved mechanical performance.

In contrast, type 3 samples with a high content of B, W, and Pb again demonstrated strength reduction. The most probable reasons are local stress development, excessive neutron absorption, and weakening of the interphase interaction between matrix and filler, which increases brittleness. Overall, the greatest strengthening effect was observed at an optimal additive content (type 2). Both insufficient and excessive filler concentrations led to property degradation. As can be seen from the results of determining the strength characteristics of the composite material based on UHMWPE with fillers, the tensile strength for the first type of samples of the composition UHMWPE plus H3BO3 10%, WC 10%, PbO10% changes depending on the irradiation dose. As can be seen, the tensile strength of the unirradiated material based on UHMWPE with fillers is within 16.1 MPa, and for the irradiated sample at a dose of 7.2 × 1015 N/cm2, the tensile strength is in the range from 18.2 to 20.4 MPa. It is also seen that with an increase in the irradiation dose to values of 13.6 × 1016 N/cm2, the tensile strength for this sample decreases and is in the range from 4.71 to 6.04 MPa. For the second type of samples of the composition UHMWPE plus H3BO3 20% WC 20%, PbO10%, the tensile strength of the unirradiated is in the range from 11.9 to 14.2 MPa, for those irradiated at a dose of 7.2 × 1015 N/cm2 it is in the range from 10.9 to 11.8 MPa, and for those irradiated at a dose of 13.6 × 1016 N/cm2 it is in the range from 15.1 to 18.9 MPa. The tensile strength values for the third type of samples of the composition UHMWPE plus H3BO3 30%, WC 5%, PbO 20% do not undergo major changes. Thus, the ultimate strength for non-irradiated material is in the range from 3.2 to 3.9 MPa, for irradiated material at a dose of 7.2 × 1015 N/cm2 it is in the range from 2.7 to 3.5 MPa, and for irradiated material at a dose of 13.6 × 1016 N/cm2 it is in the range from 2.21 to 3.52 MPa.

Samples of the UHMWPE plus H3BO3 10%, WC 10%, PbO10% composition demonstrate a mass gain from the first hours before testing up to 48 h and practically retain it until the end of the test. Although in comparison with the non-irradiated sample, the mass gain for the irradiated ones is greater, which indicates the effect of reactor irradiation on the properties of the material. We did not detect any mass loss during testing, thus the chemical resistance of this type of samples is good. Samples of the UHMWPE plus H3BO3 20%, WC 20%, PbO10% composition gain mass only during the first hours, and then their sharp decrease below the initial mass is observed. Hence, it is clear that the chemical resistance of this type of samples is poor. Samples of the UHMWPE composition with 30% H3BO3, 5% WC, and 20% PbO exhibit a behavior similar to that of composition 2; however, the magnitude of the mass gain reaches up to 15%.

After drying, significant mass changes were recorded in type 3 samples, exceeding 20% of the initial mass. Type 1 and type 2 samples exhibited mass losses of 7.0–7.5% and 15.6–18.0% of the initial mass, respectively. It is noteworthy that samples without fillers (type 0) showed almost no change in mass. Upon completion of the tests, the chemical reagent was visually examined, and no visible extractable particles or color changes were observed.

Based on the obtained data, we constructed diagrams that show the nature of the mass change during testing of composite material samples, which are presented in

Figure 7.

After determining the chemical resistance of the composite material based on UHMWPE with fillers, we carried out work on studying the structure and phase state of irradiated samples exposed to chemical environments.

Figure 8 shows the structure of the composite material of type 1 before and after exposure to a chemical environment. As can be seen from the figure, the structure of the polymer has not undergone changes, but the fillers that were on the surface of the sample have undergone changes. The structure of the scaly form related to boric acid has been crushed and changed shape.

Figure 9 shows the structure of the type 2 and 3 composite material before and after exposure to a chemical environment. Here, too, we see a change in the shape of the filler.

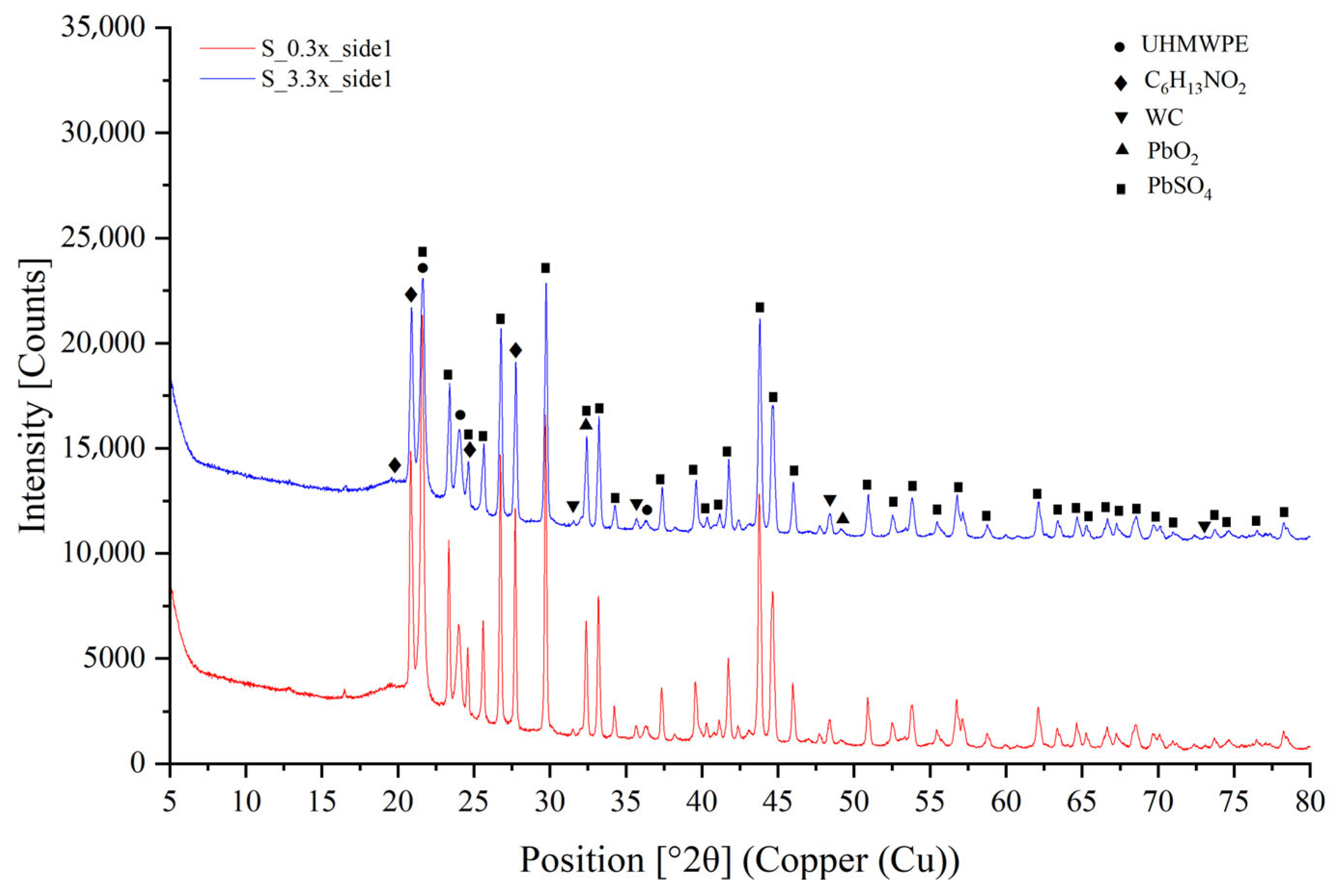

X-ray phase analysis of the samples after exposure to aggressive chemical environments showed that the main changes were associated with the fillers rather than the UHMWPE matrix. Under acidic conditions, the fillers underwent partial dissolution, while the UHMWPE structure remained chemically stable and essentially unchanged. This explains the observed mass loss of the composites: it resulted from the leaching of filler particles, whereas the overall phase composition was preserved.

These results confirm the high chemical resistance of UHMWPE. The variations observed in the diffraction patterns were primarily due to shifts in phase ratios and changes in peak intensities.

For type 1 composites (

Figure 10), an increase in the intensity of UHMWPE diffraction peaks was recorded after chemical treatment. This effect can be explained by the higher relative content of UHMWPE following partial filler dissolution, as well as by the redistribution of its crystallites. Importantly, the phase composition remained stable: no new phases were formed, and the crystalline structure of the polymer was not degraded.

A similar trend was observed for type 2 composites (

Figure 11). After chemical exposure, the intensity of the UHMWPE diffraction peaks increased, indicating that the polymer matrix did not degrade and preserved its crystalline structure. In contrast, the fillers underwent partial dissolution and leaching from the matrix. As a result, the diffraction patterns showed an apparent enhancement of the UHMWPE contribution without the appearance of new phases.

A more complex pattern was observed for composite type 3 (

Figure 12). Unlike the previous samples, the intensity of UHMWPE peaks decreased after exposure to the chemical environment. This behavior is most likely associated with the specifics of prior treatment: these samples were subjected to reactor irradiation, which may have led to disruptions in the macromolecular structure of UHMWPE. The subsequent chemical exposure further intensified these processes, resulting in partial polymer degradation. Nevertheless, despite the reduction in peak intensity, the phase composition of the composite remained unchanged—no new phases were formed in the material.

It is important to note that, in addition to the described effects, an additional PbSO4 phase was detected in the diffraction patterns of some samples after chemical exposure. This phase formed due to the reaction of PbO in the composite with sulfuric acid, leading to the precipitation of poorly soluble lead sulfate on the sample surface. The presence of this new crystalline product explains the additional diffraction peaks observed after treatment. Thus, the formation of PbSO4 reflects secondary chemical reactions between the inorganic filler and the aggressive environment.

6. Conclusions

This study investigated how composites based on UHMWPE with various fillers absorb reactor-spectrum neutrons.

The set of conducted tests demonstrated that UHMWPE-based composites with functional fillers integrate into a single material the combined protective functionality that is traditionally achieved only by multilayer systems (“boronated polymer + lead/steel”) or heavy monolithic shields. The hydrogen-rich UHMWPE matrix effectively moderates fast neutrons, while the additions of H3BO3, WC, and PbO provide, respectively, thermal neutron capture and γ-ray attenuation. The neutron absorption coefficient increases with the H3BO3 content, reaching approximately ~3–4 at 10%, ~7–8 at 20%, and ~9–10 at 30%, thereby demonstrating the tunability of the shielding performance to the required spectrum. Owing to the low density of the matrix, the target attenuation levels can be achieved at a reduced structural mass compared to metallic or lead-based shields. Furthermore, the favorable processing characteristics of UHMWPE enable the fabrication of panels and components of complex geometry without toxic liquid binders—simplifying system integration and reducing fastening and transportation requirements.

Microstructural and phase analyses confirm the preservation of UHMWPE crystallinity after irradiation and chemical testing; the observed changes primarily affect the inorganic fillers (e.g., in acidic media, PbSO4 forms on the surface in the presence of PbO) without leading to degradation of the polymer phase. A typical polymer trend of decreasing tensile strength with increasing dose was recorded; however, for compositions with moderate filler fractions, flexural strengthening was observed at high doses, indicating the predominance of radiation-induced cross-linking. This behavior represents an advantage over brittle binders and ceramics. In terms of chemical stability, the B10W10Pb10 composition demonstrated superior resistance to aggressive environments both before and after irradiation, outperforming the “heavier” B20W20Pb10 and B30W5Pb20 systems, which, in turn, provide higher neutron absorption and γ-attenuation efficiency. Thus, a controllable compromise is achieved between neutron shielding, γ-screening, chemical resistance, and mechanical performance: B10W10Pb10 is optimal where corrosion resistance and operational versatility are prioritized; B20W20Pb10 offers a balanced level of neutron–γ protection with satisfactory mechanical integrity; and B30W5Pb20 is rational for applications where maximum thermal neutron capture is required under relaxed mechanical constraints.

Overall, the results indicate that UHMWPE-based composites provide a superior balance of properties compared to common alternatives (concrete, lead, corrosion-prone metals, and purely boronated polymers), particularly where mass efficiency, complex geometry, and combined neutron–γ shielding are critical. Further improvements are anticipated through the design of multilayer/gradient architectures (e.g., an outer chemically resistant B10W10Pb10 layer with inner γ-attenuating layers) and through long-term durability testing under combined neutron–γ irradiation and thermal cycling.