All MOVPE Grown Quadruple Junction InGaP/InGaAs/Ge/Ge Solar Cell

Abstract

1. Introduction

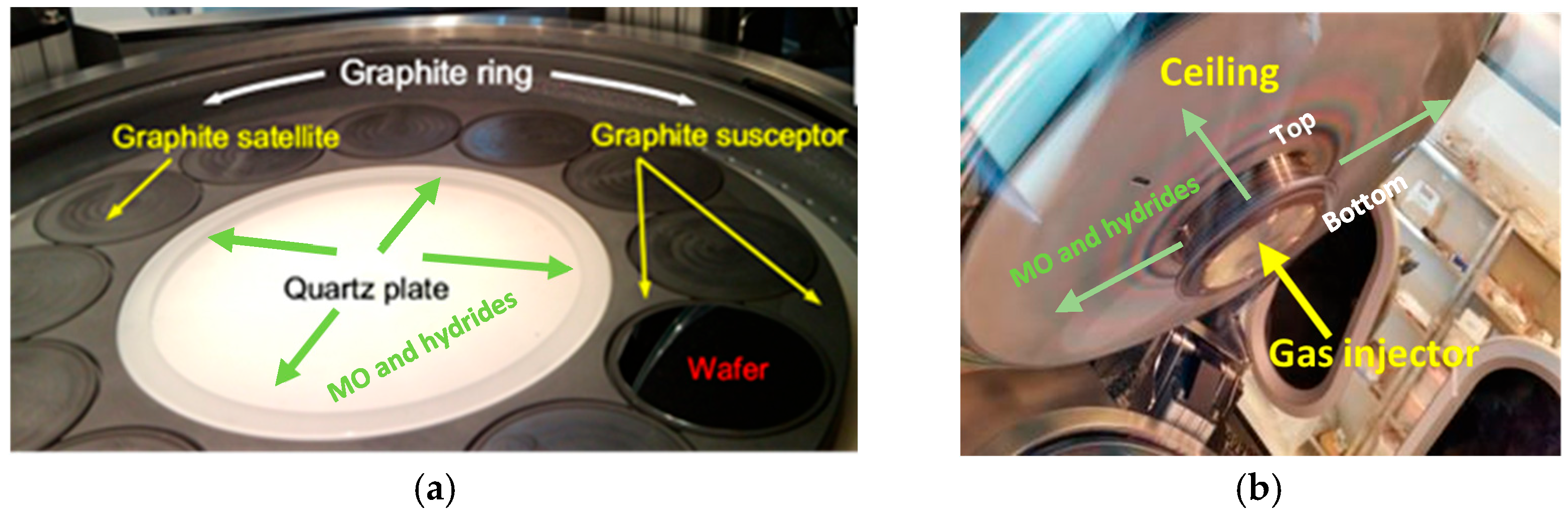

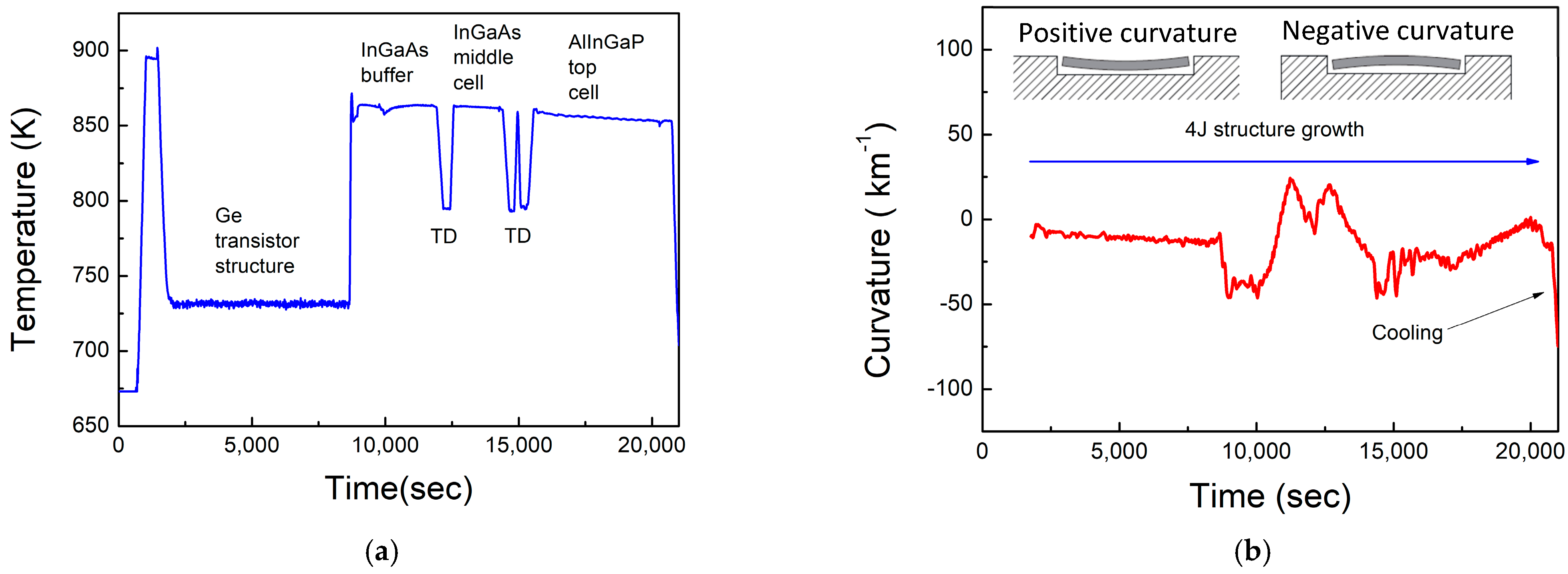

2. Materials and Methods

2.1. MOVPE Growth Strategy

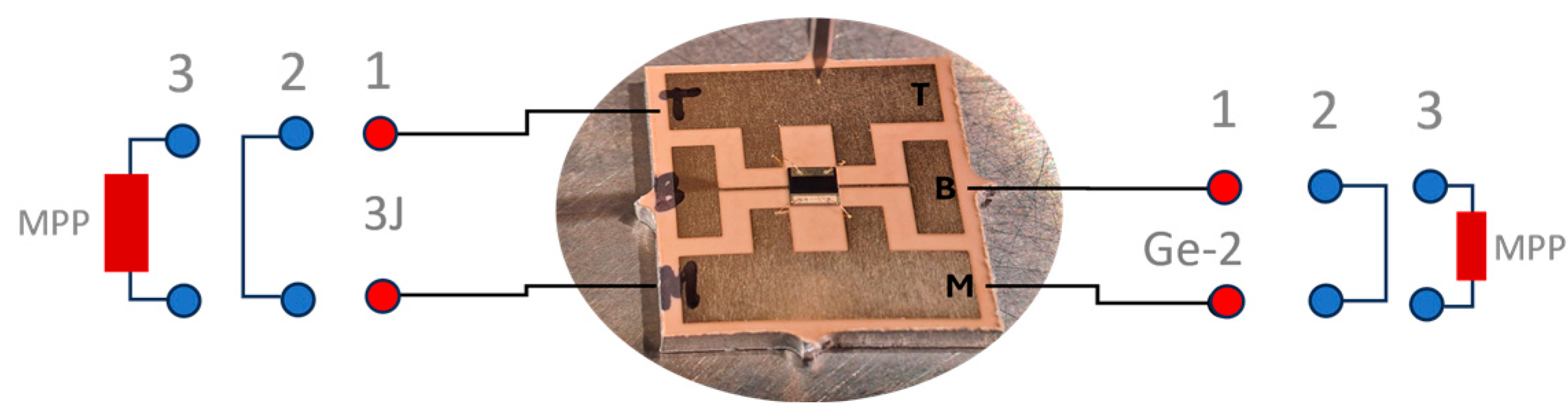

2.2. MJ Device Strategy Realization

3. Results and Discussion

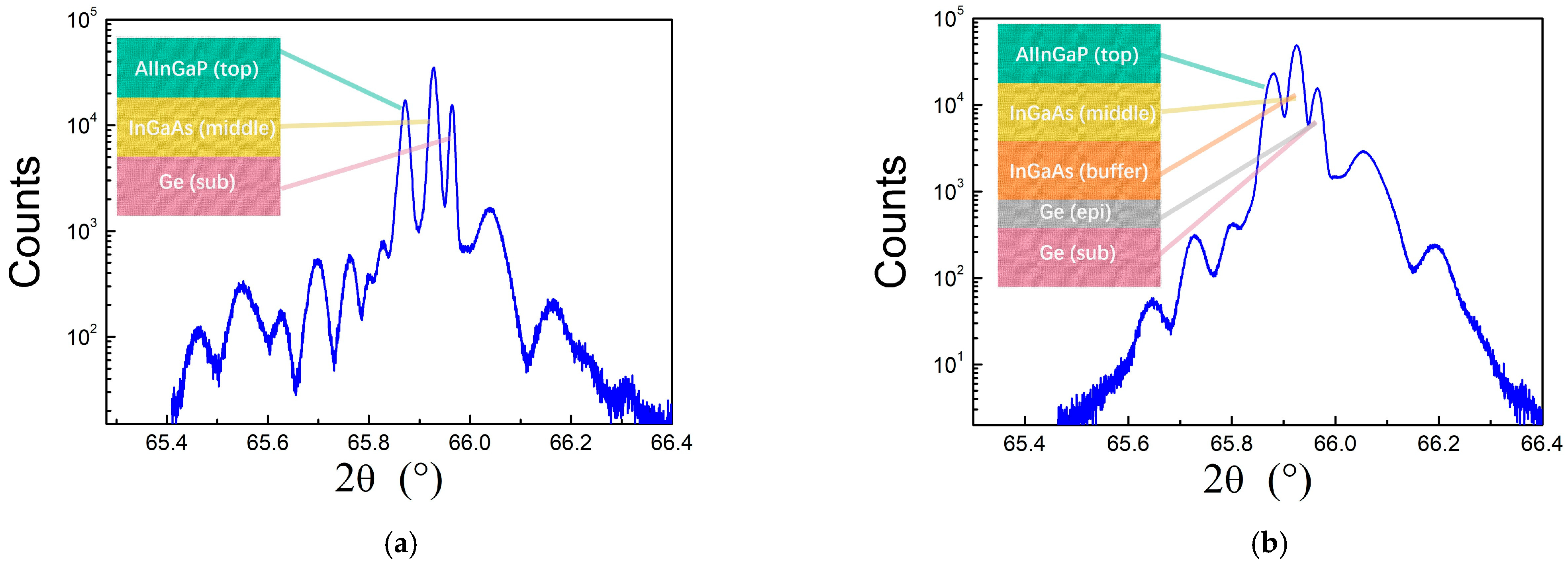

3.1. MOVPE Growth Results and Discussion

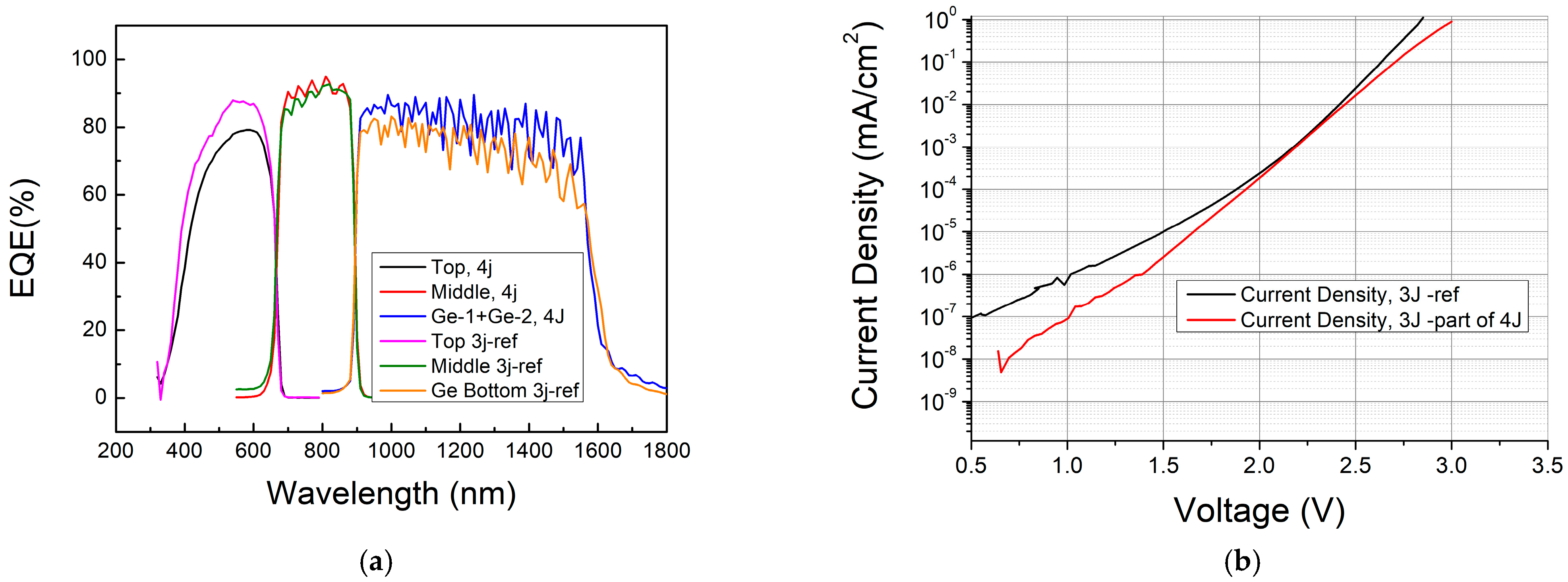

3.2. 4J InGaP/GaAs/Ge/Ge Device Optoelectronic Characterization Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| EQE | External quantum efficiency |

| MOVPE | Metalorganic vapor phase epitaxy |

| FF | Fill factor |

| I–V | Current-voltage |

| Jsc | Short circuit current density |

| MJ | Multijunction |

| MPP | Maximum power point |

| Voc | Open circuit voltage |

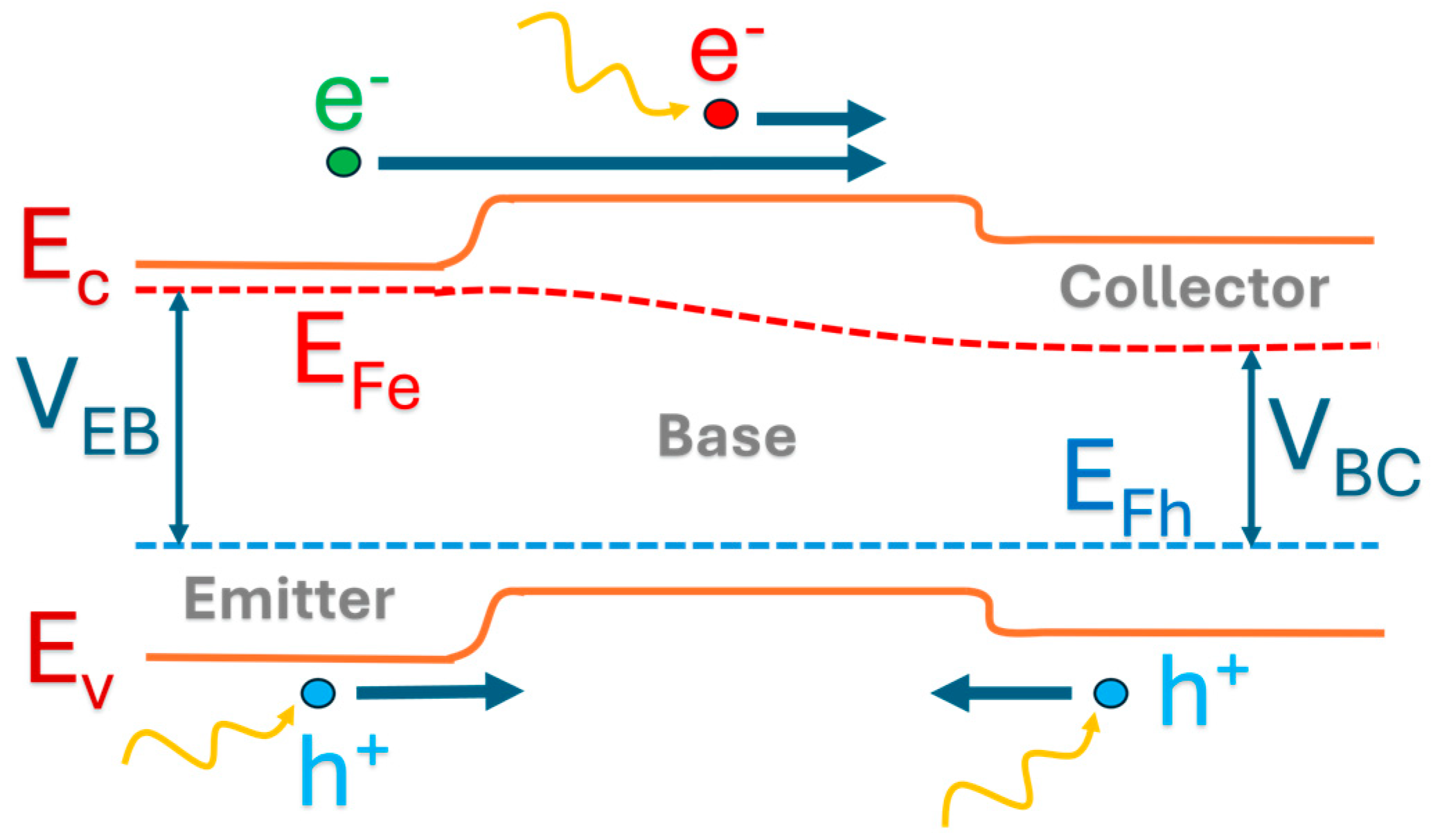

| Ec | Energy of the conduction band |

| Ev | Energy of the valence band |

| EFe | Quasi Fermi level of electrons |

| EFh | Quasi Fermi level of halls |

| VEB | Voltage of the emitter/base junction |

| VBC | Voltage of the base/collector junction |

References

- Shockley, W.; Queisser, H.J. Detailed balance limit of efficiency of p-n junction solar cells. J. Appl. Phys. 1961, 32, 510–519. [Google Scholar] [CrossRef]

- Kurtz, S.R.; Myers, D.; Olson, J.M.; Kurtz, S.R. Projected Performance of Three-and Four-Junction Devices Using GaAs and GaInP. In Proceedings of the Conference Record of the Twenty Sixth IEEE Photovoltaic Specialists Conference—1997, Anaheim, CA, USA, 29 September–3 October 1997. [Google Scholar]

- Kujofsa, T.; Ayers, J.E. Equilibrium Lattice Relaxation and Misfit Dislocations in Step-Graded InxGa1−xAs/GaAs (001) and InxAl1−xAs/GaAs (001) Metamorphic Buffer Layers. J. Electron. Mater. 2016, 45, 2831–2836. [Google Scholar] [CrossRef]

- Geisz, J.F.; France, R.M.; Schulte, K.L.; Steiner, M.A.; Norman, A.G.; Guthrey, H.L.; Young, M.R.; Song, T. Six-junction III–V solar cells with 47.1% conversion efficiency under 143 Suns concentration. Nat. Energy 2020, 5, 326–335. [Google Scholar] [CrossRef]

- Tanabe, K. Semiconductor Wafer Bonding for Solar Cell Applications: A Review. Adv. Energy Sustain. Res. 2023, 4, 2300073. [Google Scholar] [CrossRef]

- Green, M.A.; Dunlop, E.D.; Yoshita, M.; Kopidakis, N.; Bothe, K.; Siefer, G.; Hao, X.; Jiang, J.Y. Solar Cell Efficiency Tables (Version 66). Prog. Photovolt. Res. Appl. 2025, 33, 795–810. [Google Scholar] [CrossRef]

- Aiken, D.J. InGaP/GaAs/Ge multi-junction solar cell efficiency improvements using epitaxial germanium. In Proceedings of the Conference Record of the IEEE Photovoltaic Specialists Conference, Anchorage, AK, USA, 15–22 September 2000; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2000; pp. 994–997. [Google Scholar] [CrossRef]

- King, R.R.; Bhusari, D.; Larrabee, D.; Liu, X.-Q.; Rehder, E.; Edmondson, K.; Cotal, H.; Jones, R.K.; Ermer, J.H.; Fetzer, C.M.; et al. Solar cell generations over 40% efficiency. Prog. Photovolt. Res. Appl. 2012, 20, 801–815. [Google Scholar] [CrossRef]

- Roucka, R.; Clark, A.; Landini, B. Si-Ge-Sn alloys with 1.0 eV gap for CPV multijunction solar cells. In Proceedings of the 11th International Conference on Concentrator Photovoltaic Systems: CPV-11, Aix-les-Bains, France, 13–15 April 2015; American Institute of Physics Inc.: College Park, MD, USA, 2015. [Google Scholar] [CrossRef]

- Wilson, T.; Thomas, T.; Führer, M.; Ekins-Daukes, N.J.; Roucka, R.; Clark, A.; Johnson, A.; Hoffman, R.J.; Begarney, D. Single and multi-junction solar cells utilizing a 1.0 eV SiGeSn junction. In Proceedings of the 12th International Conference on Concentrator Photovoltaic Systems (CPV-12), Freiburg, Germany, 25–27 April 2016; American Institute of Physics Inc.: College Park, MD, USA, 2016. [Google Scholar] [CrossRef]

- Caño, P.; Hinojosa, M.; Nguyen, H.; Morgan, A.; Marrón, D.F.; García, I.; Johnson, A.; Rey-Stolle, I. Hybrid III-V/SiGe solar cells grown on Si substrates through reverse graded buffers. Sol. Energy Mater. Sol. Cells 2020, 205, 110246. [Google Scholar] [CrossRef]

- Timò, G.; Calicchio, M.; Abagnale, G.; Armani, N.; Achilli, E.; Cornelli, M.; Annoni, F.; Schineller, B.; Andreani, L.C. Study of the cross-influence between iii-v and iv elements deposited in the same movpe growth chamber. Materials 2021, 14, 1066. [Google Scholar] [CrossRef] [PubMed]

- Martin, C.; Dauelsberg, M.; Protzmann, H.; Boyd, A.R.; Thrush, E.J.; Heuken, M.; Talalaev, R.A.; Yakovlev, E.V.; Kondratyev, A.V. Modelling of group-III nitride MOVPE in the closed coupled showerhead reactor and Planetary Reactor®. J. Cryst. Growth 2007, 303, 318–322. [Google Scholar] [CrossRef]

- Welser, E.; Guter, W.; Wekkeli, A.; Dimroth, F. Memory effect of Ge in III–V semiconductors. J. Cryst. Growth 2008, 310, 4799–4802. [Google Scholar] [CrossRef]

- Timò, G. A New Path to Combine III–V and IV Elements for High-Efficiency and Low-Cost Multi-Junction Solar Cells. Ph.D. Thesis, University of Pavia, Pavia, Italy, 2022. Available online: https://iris.unipv.it/retrieve/e1f104fd-1e9b-8c6e-e053-1005fe0aa0dd/Tesi%20Timo_def.pdf (accessed on 28 August 2025).

- Timò, G.; Calicchio, M.; Armani, N.; Achilli, E.; Cornelli, M.; Annoni, F.; Trespidi, F.; Imperatore, M.; Malvisi, E. First demonstration of a three terminals-quadruple junction InGaP/InGaAs/Ge/T/Ge solar cell—All MOVPE grown-exploiting the transistor effect. In Proceedings of the 53rd IEEE Photovoltaic Specialist Conference, Montreal, QC, USA, 8–13 June 2025. [Google Scholar] [CrossRef]

- Breiland, W.G.; Killeen, K.P. A virtual interface method for extracting growth rates and high temperature optical constants from thin semiconductor films using in situ normal incidence reflectance. J. Appl. Phys. 1995, 78, 6726–6736. [Google Scholar] [CrossRef]

- Takamoto, T.; Ikeda, E.; Kurita, H.; Ohmori, M. Structural optimization for single junction InGaP solar cells. Sol. Energy Mater. Sol. Cells 1994, 35, 25–31. [Google Scholar] [CrossRef]

- Takamoto, T.; Kaneiwa, M.; Imaizumi, M.; Yamaguchi, M. InGaP/GaAs-based multijunction solar cells. Prog. Photovolt. Res. Appl. 2005, 13, 495–511. [Google Scholar] [CrossRef]

- Kurtz, S.R.; Olson, J.M.; Friedman, D.J.; Geisz, J.F.; Kibbler, A.E.; Bertness, K.A. Passivation of Interfaces in High-Efficiency Photovoltaic Devices. 1999. Available online: https://docs.nrel.gov/docs/fy99osti/26494.pdf (accessed on 29 August 2025).

- Niemeyer, M.; Ohlmann, J.; Walker, A.W.; Kleinschmidt, P.; Lang, R.; Hannappel, T.; Dimroth, F.; Lackner, D. Minority carrier diffusion length, lifetime and mobility in p-type GaAs and GaInAs. J. Appl. Phys. 2017, 122, 115702. [Google Scholar] [CrossRef]

- Gilberti, G. Multiterminal Solar Cells with Heterojunction-Bipolar Transistor Structure: Analysis and Design. Master’s Thesis, Politecnico Di Torino, Torin, Italy, 2019. Available online: http://webthesis.biblio.polito.it/id/eprint/11003 (accessed on 24 August 2025).

- Martí, A.; Luque, A. Three-terminal heterojunction bipolar transistor solar cell for high-efficiency photovoltaic conversion. Nat. Commun. 2015, 6, 6902. [Google Scholar] [CrossRef] [PubMed]

- Linares, P.G.; Antolín, E.; Martí, A. Novel heterojunction bipolar transistor architectures for the practical implementation of high-efficiency three-terminal solar cells. Sol. Energy Mater. Sol. Cells 2019, 194, 54–61. [Google Scholar] [CrossRef]

- Zhang, X.; Ang, Y.S.; Ye, Z.; Su, S.; Chen, J.; Ang, L.K. Three-terminal heterojunction bipolar transistor solar cells with non-ideal effects: Efficiency limit and parametric optimum selection. Energy Convers. Manag. 2019, 188, 112–119. [Google Scholar] [CrossRef]

- King, R.R.; Fetzer, C.; Chiu, P.; Rehder, E.; Edmondson, K.; Karam, N. (Invited) Group-IV Subcells in Multijunction Concentrator Solar Cells. ECS Trans. 2013, 50, 287–295. [Google Scholar] [CrossRef]

| Jsc (mA/cm2) | Voc (V) | FF (%) | Efficiency (%) 1 |

|---|---|---|---|

| 12.7 | 2.41 | 80 | 24.5 |

| Jsc (mA/cm2) | Voc (V) | FF (%) | Efficiency (%) 1 | 3J Electrical Connection |

|---|---|---|---|---|

| 20.5 | 0.181 | 56.3 | 2.1 | Open circuit |

| 13.9 | 0.171 | 58.7 | 1.4 | MPP |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Timò, G.; Calicchio, M.; Achilli, E.; Armani, N.; Annoni, F.; Trespidi, F.; Imperatore, M.V.; Celi, E.; Minuto, A. All MOVPE Grown Quadruple Junction InGaP/InGaAs/Ge/Ge Solar Cell. Crystals 2025, 15, 816. https://doi.org/10.3390/cryst15090816

Timò G, Calicchio M, Achilli E, Armani N, Annoni F, Trespidi F, Imperatore MV, Celi E, Minuto A. All MOVPE Grown Quadruple Junction InGaP/InGaAs/Ge/Ge Solar Cell. Crystals. 2025; 15(9):816. https://doi.org/10.3390/cryst15090816

Chicago/Turabian StyleTimò, Gianluca, Marco Calicchio, Elisabetta Achilli, Nicola Armani, Filippo Annoni, Franco Trespidi, Mario V. Imperatore, Edoardo Celi, and Alessandro Minuto. 2025. "All MOVPE Grown Quadruple Junction InGaP/InGaAs/Ge/Ge Solar Cell" Crystals 15, no. 9: 816. https://doi.org/10.3390/cryst15090816

APA StyleTimò, G., Calicchio, M., Achilli, E., Armani, N., Annoni, F., Trespidi, F., Imperatore, M. V., Celi, E., & Minuto, A. (2025). All MOVPE Grown Quadruple Junction InGaP/InGaAs/Ge/Ge Solar Cell. Crystals, 15(9), 816. https://doi.org/10.3390/cryst15090816