In Situ TEM Investigation of Dislocation-Mediated Deformation in Eutectic Fe36Ni18Mn33Al13 Alloy

Abstract

1. Introduction

2. Experiments

3. Results and Discussion

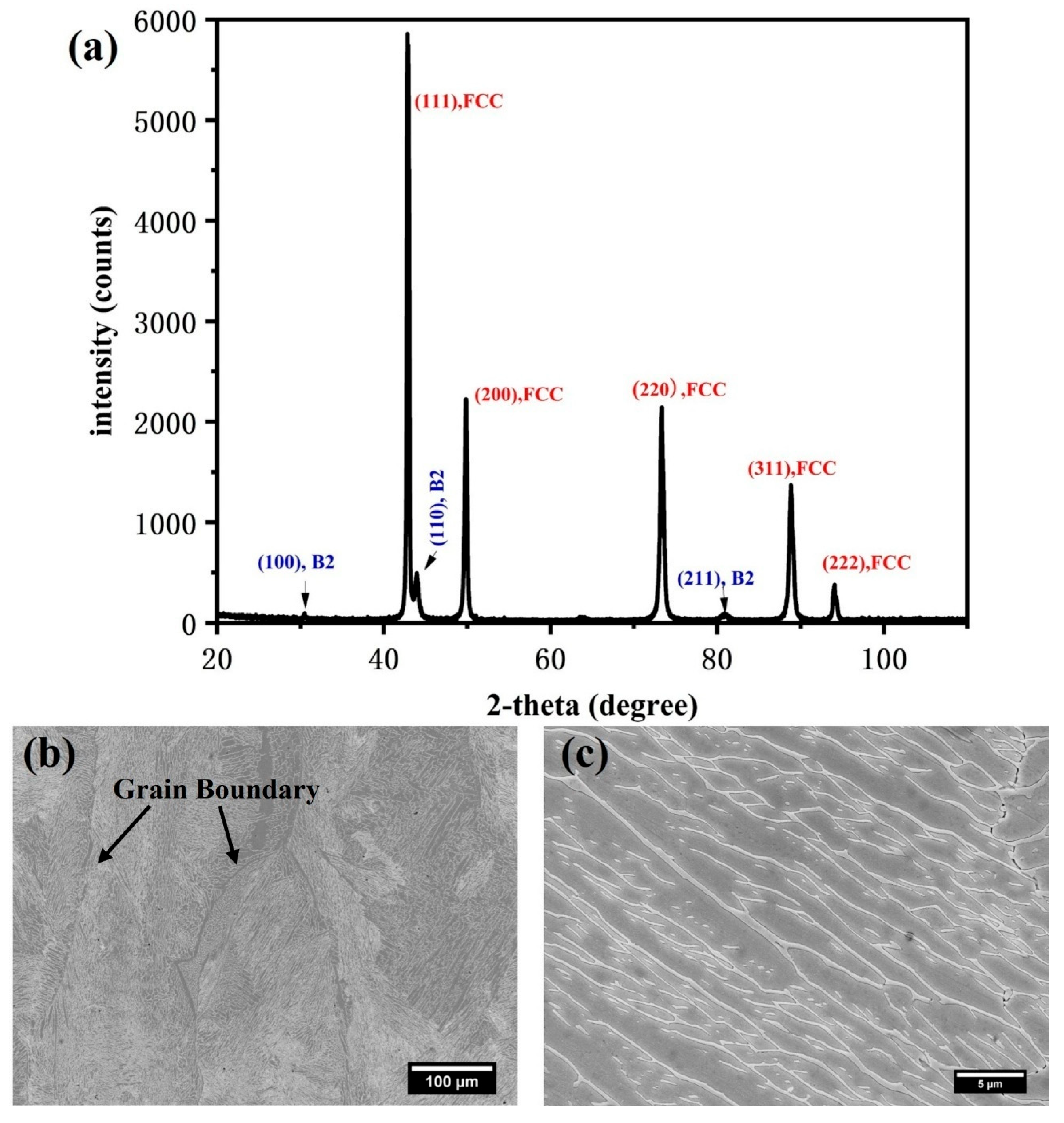

3.1. Phase Identification and Lamellar Microstructure

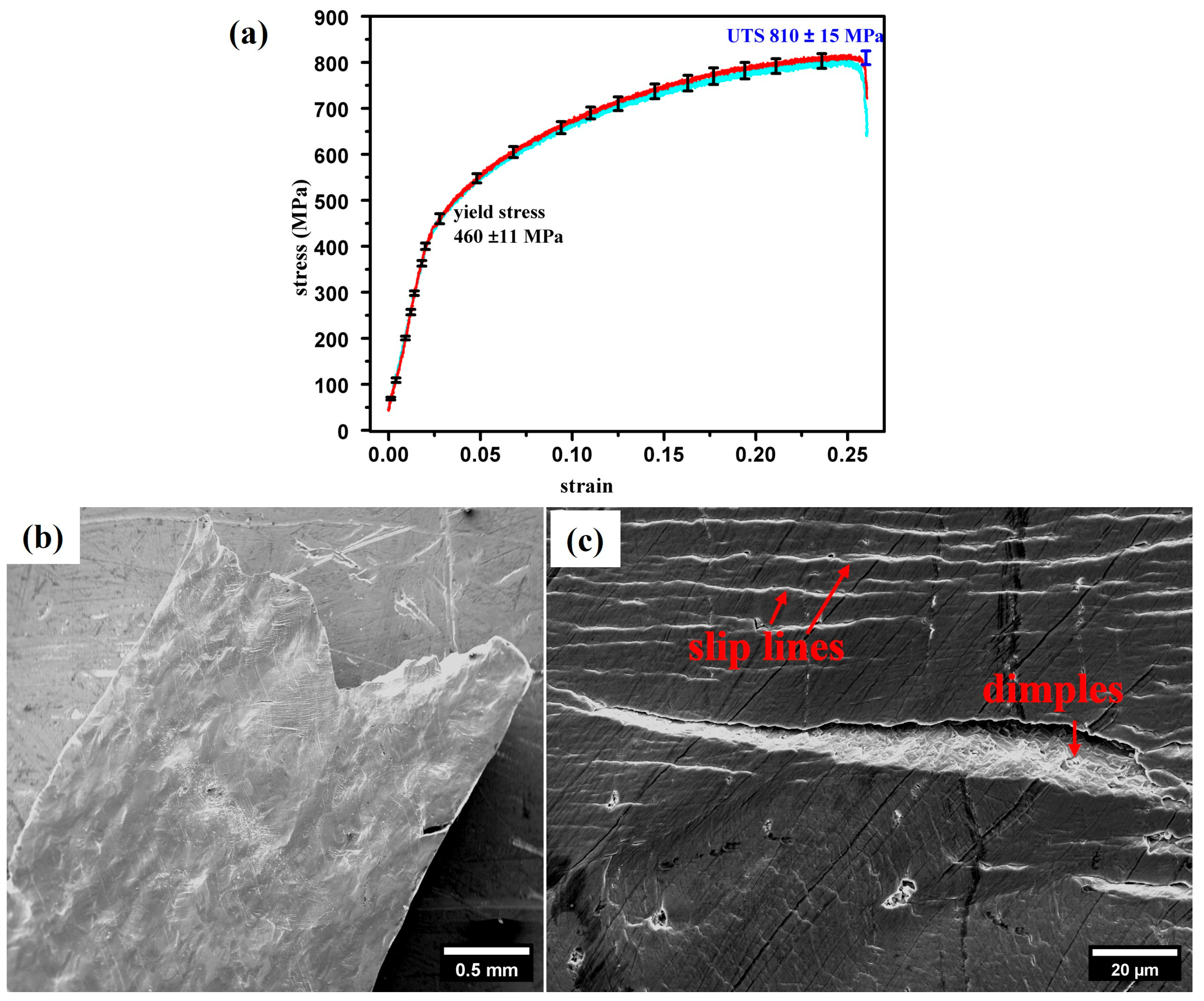

3.2. Mechanical Properties

3.3. Deformation Mechanisms

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yeh, J.-W. Recent progress in high-entropy alloys. Eur. J. Control. 2006, 31, 633–648. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Liao, Y.; Meng, F.; Baker, I. Environmental embrittlement of two-phase Fe30Ni20Mn35Al15. Intermetallics 2011, 19, 1533–1537. [Google Scholar] [CrossRef]

- Liao, Y.; Baker, I. Microstructure and room-temperature mechanical properties of Fe30Ni20Mn35Al15. Mater. Charact. 2008, 59, 1546–1549. [Google Scholar] [CrossRef]

- Wu, X.; Baker, I.; Miller, M.K.; More, K.L.; Bei, H.; Wu, H. Microstructure and mechanical behavior of directionally solidified Fe35Ni15Mn25Al25. Intermetallics 2013, 32, 413–422. [Google Scholar] [CrossRef]

- Baker, I.; Wu, X.L.; Meng, F.L.; Munroe, P.R. Microstructures and Mechanical Properties of Two-Phase FeNiMnAl Alloys. Mater. Sci. Forum 2014, 783–786, 2549–2554. [Google Scholar] [CrossRef]

- Liao, Y.; Baker, I. On the room-temperature deformation mechanisms of lamellar-structured Fe30Ni20Mn35Al15. Mater. Sci. Eng. A 2011, 528, 3998–4008. [Google Scholar] [CrossRef]

- Hanna, J.A.; Baker, I.; Wittmann, M.W.; Munroe, P.R. A new high-strength spinodal alloy. J. Mater. Res. 2005, 20, 791–795. [Google Scholar] [CrossRef]

- Meng, F.; Qiu, J.; Baker, I. Effect of Al content on the microstructure and mechanical behavior of two-phase FeNiMnAl alloys. J. Mater. Sci. 2014, 49, 1973–1983. [Google Scholar] [CrossRef]

- Liao, Y.; Baker, I. Evolution of the microstructure and mechanical properties of eutectic Fe30Ni20Mn35Al15. J. Mater. Sci. 2011, 46, 2009–2017. [Google Scholar] [CrossRef]

- Guha, S.; Munroe, P.R.; Baker, I. Room temperature deformation behavior of multiphase Ni-20at.%Al-30at.%Fe and its constituent phases. Mater. Sci. Eng. A 1991, 131, 27–37. [Google Scholar] [CrossRef]

- Ritchie, R.O. The conflicts between strength and toughness. Nat. Mater. 2011, 10, 817–822. [Google Scholar] [CrossRef]

- Jiang, K.; Xiong, Z.; Chen, X. High-Strain-Rate Deformation Behavior of Co0.96Cr0.76Fe0.85Ni1.01Hf0.40 Eutectic High-Entropy Alloy at Room and Cryogenic Temperatures. Materials 2024, 17, 2995. [Google Scholar] [CrossRef]

- Lee, S.; Duarte, M.J.; Feuerbacher, M.; Soler, R.; Kirchlechner, C.; Liebscher, C.H.; Oh, S.H.; Dehm, G. Dislocation plasticity in FeCoCrMnNi high-entropy alloy: Quantitative insights from in situ transmission electron microscopy deformation. Mater. Res. Lett. 2020, 8, 216–224. [Google Scholar] [CrossRef]

- Zhang, Z.; Sheng, H.; Wang, Z.; Gludovatz, B.; Zhang, Z.; George, E.P.; Yu, Q.; Mao, S.X.; Ritchie, R.O. Dislocation mechanisms and 3D twin architectures generate exceptional strength-ductility-toughness combination in CrCoNi medium-entropy alloy. Nat. Commun. 2017, 8, 14390. [Google Scholar] [CrossRef] [PubMed]

- Oh, S.H.; Legros, M.; Kiener, D.; Dehm, G. In situ observation of dislocation nucleation and escape in a submicrometre aluminium single crystal. Nat. Mater. 2009, 8, 95–100. [Google Scholar] [CrossRef]

- Loudis, J.A.; Baker, I. Dislocation identification and in situ straining in the spinodal Fe30Ni20Mn25Al25 alloy. Microsc. Res. Tech. 2008, 71, 489–496. [Google Scholar] [CrossRef] [PubMed]

- Baker, I.; Wu, H.; Wu, X.; Miller, M.K.; Munroe, P.R. The microstructure of near-equiatomic B2/f.c.c. FeNiMnAl alloys. Mater. Charact. 2011, 62, 952–958. [Google Scholar] [CrossRef]

- Umeda, H.; Kishida, K.; Inui, H.; Yamaguchi, M. Effects of Al-concentration and lamellar spacing on the room-temperature strength and ductility of PST crystals of TiAl. Mater. Sci. Eng. A 1997, 239–240, 336–343. [Google Scholar] [CrossRef]

- Gogia, A.K.; Nandy, T.K.; Banerjee, D.; Carisey, T.; Strudel, J.L.; Franchet, J.M. Microstructure and mechanical properties of orthorhombic alloys in the Ti-Al-Nb system. Intermetallics 1998, 6, 741–748. [Google Scholar] [CrossRef]

- Guha, S.; Baker, I.; Munroe, P.R. Elevated temperature deformation behaviour of multi-phase Ni-20 at % Al-30 at % Fe and its constituent phases. J. Mater. Sci. 1996, 31, 4055–4065. [Google Scholar] [CrossRef]

- Misra, A.; Gibala, R. Plasticity in multiphase intermetallics. Intermetallics 2000, 8, 1025–1034. [Google Scholar] [CrossRef]

- Nam, W.J.; Bae, C.M.; Lee, C.S. Effect of carbon content on the Hall-Petch parameter in cold drawn pearlitic steel wires. J. Mater. Sci. 2002, 37, 2243–2249. [Google Scholar] [CrossRef]

- Kim, Y.-W.; Dimiduk, D.M. Progress in the understanding of gamma titanium aluminides. JOM 1991, 43, 40–47. [Google Scholar] [CrossRef]

- Embury, J.D.; Fisher, R.M. The structure and properties of drawn pearlite. Acta Metall. 1966, 14, 147–159. [Google Scholar] [CrossRef]

- Maruyama, K.; Yamada, N.; Sato, H. Effects of lamellar spacing on mechanical properties of fully lamellar Ti–39.4mol%Al alloy. Mater. Sci. Eng. A 2001, 319–321, 360–363. [Google Scholar] [CrossRef]

- Hyzak, J.M.; Bernstein, I.M. The role of microstructure on the strength and toughness of fully pearlitic steels. Metall. Trans. A 1976, 7, 1217–1224. [Google Scholar] [CrossRef]

- Kim, S.-H.; Kim, H.; Kim, N.J. Brittle intermetallic compound makes ultrastrong low-density steel with large ductility. Nature 2015, 518, 77–79. [Google Scholar] [CrossRef]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Zhang, Y.; Zeng, Z.; Zhou, H.; He, J.; Liu, P.; Chen, M.; Han, J.; Srolovitz, D.J.; Teng, J.; et al. Tracking the sliding of grain boundaries at the atomic scale. Science 2022, 375, 1261–1265. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Umakoshi, Y. The deformation behaviour of intermetallic superlattice compounds. Prog. Mater. Sci. 1990, 34, 1–148. [Google Scholar] [CrossRef]

- Shen, S.; Xie, P.; Wu, C.; Luo, J.; Chen, J. Cross-slip of extended dislocations and secondary deformation twinning in a high-Mn TWIP steel. Int. J. Plast. 2024, 175, 103922. [Google Scholar] [CrossRef]

- Xie, B.; Chen, H.; Wang, P.; Zhang, C.; Xing, B.; Xu, M.; Wang, X.; Valdevit, L.; Rimoli, J.; Pan, X.; et al. Divergent evolution of slip banding in CrCoNi alloys. Nat. Commun. 2025, 16, 3631. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.-D.; Park, J.Y.; Park, S.J.; Jang, J.H.; Moon, J.; Ha, H.Y.; Lee, C.H.; Kang, J.Y.; Shin, J.H.; Lee, T.H. Direct observation of dislocation plasticity in high-Mn lightweight steel by in-situ TEM. Sci. Rep. 2019, 9, 15171. [Google Scholar] [CrossRef]

- Hirth, J.P.; Lothe, J. Theory of Dislocations, 2nd ed.; Krieger Pub. Co.: Malabar, FL, USA, 1992. [Google Scholar]

- Mughrabi, H. Dislocation wall and cell structures and long-range internal stresses in deformed metal crystals. Acta Metall. 1983, 31, 1367–1379. [Google Scholar] [CrossRef]

- Dehm, G.; Howe, J.M.; Zweck, J. In-Situ Electron Microscopy: Applications in Physics, Chemistry and Materials Science; Wiley-VCH: Weinheim, Germany, 2012. [Google Scholar]

- Yang, J.; Wang, W.; Zhang, M.; Liu, J.; Qin, S. Improving Mechanical Properties of Mg-Al-RE Alloys with the Formed Dimples of Al10Mn2RE Particles and Activated Pyramidal <a> Slip with Mn Additions. Materials 2023, 16, 6747. [Google Scholar] [CrossRef]

- Lv, X.; Wang, X.; Lan, A.; Qiao, J. Synergistic Effect of Al and Ni on Microstructure Evolutions and Mechanical Properties of Fe-Mn-Al-C Low-Density Steels. Metals 2024, 14, 495. [Google Scholar] [CrossRef]

- Eshelby, J.D.; Frank, F.C.; Nabarro, F.R.N. XLI. The equilibrium of linear arrays of dislocations. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1951, 42, 351–364. [Google Scholar] [CrossRef]

- Alhamdi, I.; Algamal, A.; Almotari, A.; Ali, M.; Gandhi, U.; Qattawi, A. Fe-Mn-Al-Ni Shape Memory Alloy Additively Manufactured via Laser Powder Bed Fusion. Crystals 2023, 13, 1505. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, F.; Zhu, J.; Wang, H.; Li, J.; Lu, Y. In Situ TEM Investigation of Dislocation-Mediated Deformation in Eutectic Fe36Ni18Mn33Al13 Alloy. Crystals 2025, 15, 792. https://doi.org/10.3390/cryst15090792

Meng F, Zhu J, Wang H, Li J, Lu Y. In Situ TEM Investigation of Dislocation-Mediated Deformation in Eutectic Fe36Ni18Mn33Al13 Alloy. Crystals. 2025; 15(9):792. https://doi.org/10.3390/cryst15090792

Chicago/Turabian StyleMeng, Fanling, Jiaqi Zhu, Heyi Wang, Jiayi Li, and Yang Lu. 2025. "In Situ TEM Investigation of Dislocation-Mediated Deformation in Eutectic Fe36Ni18Mn33Al13 Alloy" Crystals 15, no. 9: 792. https://doi.org/10.3390/cryst15090792

APA StyleMeng, F., Zhu, J., Wang, H., Li, J., & Lu, Y. (2025). In Situ TEM Investigation of Dislocation-Mediated Deformation in Eutectic Fe36Ni18Mn33Al13 Alloy. Crystals, 15(9), 792. https://doi.org/10.3390/cryst15090792