Decomposition of Elasticity Tensor on Material Constants and Mesostructures of Metal Plates

Abstract

1. Introduction

2. Irreducible Decomposition of Elasticity Tensors

3. Stress Tensor, Strain Tensor, Elasticity Tensor, and Rotation Tensor Under Kelvin Notation

3.1. Representation of Stress Tensor and Strain Tensor Under Kelvin Notation

3.2. Representation of Elasticity Tensor Under Kelvin Notation

3.3. Representation of 4th-Order Rotation Tensor Under Kelvin Notation

4. Representation of Elasticity Tensor and Its Irreducible Basis Tensors

5. Elastic Constants and Mesostructure Tensors on Elasticity Tensor of Cubic Crystals

5.1. Decomposition of Elasticity Tensor on Elastic Constants and Mesostructure Tensors of Crystals

5.2. Elastic Constants and Mesostructure Tensors on Elasticity Tensor of Cubic Crystals

6. Elastic Constants and Mesostructures on an Orthorhombic Set of Four Cubic Crystallites’ Orientations

7. Upper Bound and Lower Bound of Elasticity Tensor on Metal Plate of Cubic Crystallites

8. Example and Discussion of Decomposition on Elasticity Tensor

8.1. Elastic Constants and Crystallite Orientation Distribution of Cubic Crystallites on Representation Element of Metal Plate

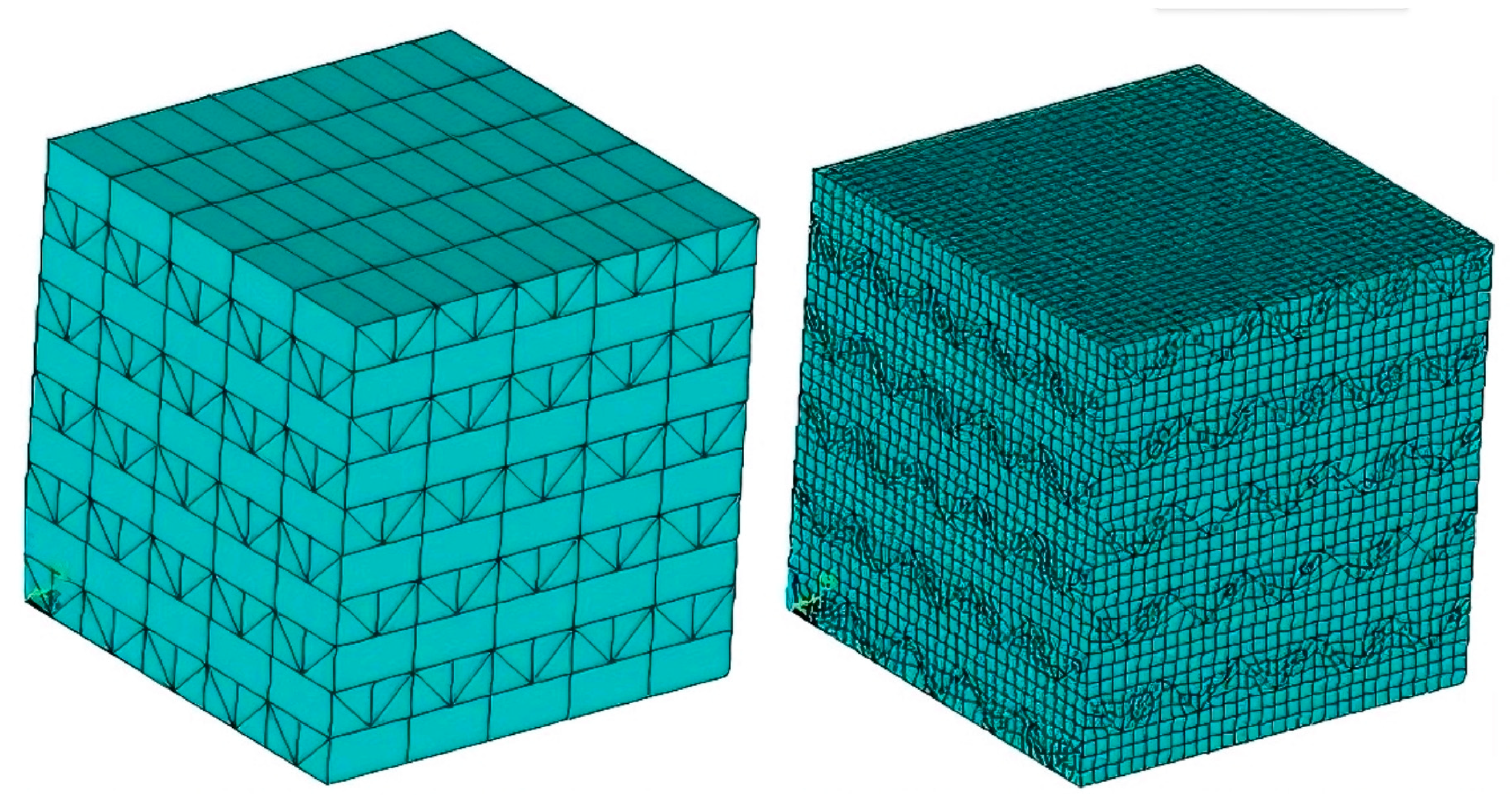

8.2. Effective Elasticity Tensor Simulated by FEM on Representation Element in (106)

8.3. Upper Bound and Lower Bound of Effective Elasticity Tensor Under Voigt Model and Under the Reuss Model, Respectively

8.3.1. Mesostructure Coefficients and Mesostructure Tensor of Ω in (106)

8.3.2. Elastic Constants of Elasticity Tensor on

8.3.3. Upper Bound and Lower Bound of Effective Elasticity Tensor Under Voigt Model and Under the Reuss Model

8.4. Discussion of Decomposition on Elasticity Tensor

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, M. The n-point orientation correlation function and its application. Int. J. Solids Struct. 2004, 42, 1425–1441. [Google Scholar] [CrossRef]

- Huang, M.; Man, C.S. Constitutive relation of elastic polycrystal with quadratic texture dependence. J. Elast. 2003, 72, 183–212. [Google Scholar] [CrossRef]

- Huang, M. Elastic constants of a polycrystal with an orthorhombic texture. Mech. Mater. 2004, 36, 623–632. [Google Scholar] [CrossRef]

- Huang, M.; Xiao, F.Y.; Lan, Z.W. A New Drucker Yield Function for Orthorhombic Aggregates of Cubic Crystallites. J. Elast. 2023, 155, 573–599. [Google Scholar] [CrossRef]

- Hill, R. The elastic behaviour of a crystalline aggregate. Proc. Phys. Soc. Sect. A 1952, 65, 349–354. [Google Scholar] [CrossRef]

- Bunge, H.J. Texture Analysis in Materials Science: Mathematical Methods; Butterworths: London, UK, 1969. [Google Scholar]

- Roe, R.J. Description of crystallite orientation in polycrystalline materials. iii. general solution to pole figure inversion. J. Appl. Phys. 1965, 36, 2024–2031. [Google Scholar] [CrossRef]

- Morris, P.R. Averaging fourth-rank tensors with weight functions. J. Appl. Phys. 1969, 40, 447–448. [Google Scholar] [CrossRef]

- Sayers, C.M. Ultrasonic velocities in anisotropic polycrystalline aggregates. J. Phys. D Appl. Phys. 1982, 15, 2157–2167. [Google Scholar] [CrossRef]

- Morris, P.R. Elastic constants of polycrystals. Int. J. Eng. Sci. 1970, 8, 49–61. [Google Scholar] [CrossRef]

- Man, C.S. On the constitutive equations of some weakly-textured materials. Arch. Ration. Mech. Anal. 1998, 143, 77–103. [Google Scholar] [CrossRef]

- Man, C.S.; Huang, M. Identification of material parameters in yield functions and flow rules for weakly textured sheets of cubic metals. Int. J. Non-Linear Mech. 2001, 36, 501–514. [Google Scholar] [CrossRef]

- Man, C.S.; Huang, M. Strict convexity of yield surfaces of some weakly-textured materials. Mech. Mater. 2024, 196, 1–10. [Google Scholar] [CrossRef]

- Zhao, T.; Wang, X.; Yin, S. Comprehensive average model for determining the effective thermal conductivity of graphite composite insulation boards: Experimental validation and numerical simulation verification. J. Build. Eng. 2024, 95, 110217. [Google Scholar] [CrossRef]

- Liu, Q.; Jiang, Q.; Zhao, H.; Yu, Y.; Zhao, T. Porous diatomite promotes lightweight and low-carbon concrete 3D printing: An exploratory study. J. Build. Eng. 2025, 103, 112071. [Google Scholar] [CrossRef]

- Zhao, T.; Bayat, M.J.; Asemi, K. Free vibration analysis of functionally graded multilayer hybrid composite cylindrical shell panel reinforced by GPLs and CNTs surrounded by Winkler elastic foundation. Eng. Struct. 2024, 308, 117975. [Google Scholar] [CrossRef]

- Rossin, J.; Leser, P.; Pusch, K.; Frey, C.; Murray, S.P.; Torbet, C.J.; Smith, S.; Daly, S.; Pollock, T.M. Bayesian inference of elastic constants and texture coefficients in additively manufactured cobalt-nickel superalloys using resonant ultrasound spectroscopy. Acta Mater. 2021, 220, 117287. [Google Scholar] [CrossRef]

- Biswas, A.; Vajragupta, N.; Hielscherb, R.; Hartmaier, A. Optimized reconstruction of the crystallographic orientation density function based on a reduced set of orientations. J. Appl. Crystallogr. 2020, 53, 178–187. [Google Scholar] [CrossRef] [PubMed]

- Glüge, R.; Bucci, S. Does convexity of yield surfaces in plasticity have a physical significance. Math. Mech. Solids 2018, 23, 1364–1373. [Google Scholar] [CrossRef]

- Oberman, A.; Salvador, T. A Partial Differential Equation Obstacle Problem for the Level Set Approach to Visibility. J. Sci. Comput. 2020, 82, 508–519. [Google Scholar] [CrossRef]

- Lou, Y.; Yoon, W.J. J2-J3 based anisotropic yield function under spatial loading. Procedia Eng. 2017, 207, 233–238. [Google Scholar] [CrossRef]

- Cazacu, O. New yield criteria for isotropic and textured metallic materials. Int. J. Solids Struct. 2018, 139–140, 200–210. [Google Scholar] [CrossRef]

- Man, C.S. Material tensors of weakly-textured polycrystals. In Proceedings of the Third International Conference on Nonlinear Mechanics, Shanghai, China, 17–20 August 1998; Chien, W., Chang, C., Dai, S., Eds.; Shanghai University Press: Shanghai, China, 1998; pp. 87–94. [Google Scholar]

- Han, Q.; Sun, H. Group Theory; Peking University Press: Beijing, China, 1987. (In Chinese) [Google Scholar]

- Sirotin, Y. Decomposition of material tensors into irreducible parts. Sov. Phys. Crystallogr. 1975, 19, 565–568. [Google Scholar]

- Biedenharn, L.C.; Louck, J.D.; Carruthers, P.A. Angular Momentum in Quantum Physics: Theory and Application; Cambridge University Press: Cambridge, UK, 1984. [Google Scholar]

- Varshalovich, D.A.; Moskalev, A.N.; Khersonskii, V.K.M. Quantum Theory of Angular Momentum; Word Scientific: Singapore, 1988. [Google Scholar]

- Man, C.S.; Huang, M. A simple explicit formula for the voigt-reuss-hill average of elastic polycrystals with arbitrary crystal and texture symmetries. J. Elast. 2011, 105, 29–48. [Google Scholar] [CrossRef]

- Man, C.S.; Huang, M. A representation theorem for material tensors of weakly-textured polycrystals and its applications in elasticity. J. Elast. 2012, 106, 1–42. [Google Scholar] [CrossRef]

- Man, C.S. Crystallographic Texture and Group Representations. J. Elast. 2022, 149, 3–445. [Google Scholar] [CrossRef]

- Huang, M.; Man, C.S. A finite-element study on constitutive relation HM-V for elastic polycrystals. Comput. Mater. Sci. 2005, 32, 378–386. [Google Scholar] [CrossRef]

| Model | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 276.17 | 244.12 | 270.24 | 230.81 | 166.70 | 218.96 | 134.48 | 108.35 | 140.41 | |

| 275.29 | 243.87 | 269.31 | 230.82 | 164.56 | 218.58 | 134.57 | 109.14 | 140.55 | |

| 259.92 | 240.14 | 256.26 | 229.17 | 138.08 | 204.25 | 137.60 | 121.48 | 141.26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Wang, C.; Zhu, R.; Zhao, T.; Lan, Z.; Huang, M. Decomposition of Elasticity Tensor on Material Constants and Mesostructures of Metal Plates. Crystals 2025, 15, 788. https://doi.org/10.3390/cryst15090788

Liu G, Wang C, Zhu R, Zhao T, Lan Z, Huang M. Decomposition of Elasticity Tensor on Material Constants and Mesostructures of Metal Plates. Crystals. 2025; 15(9):788. https://doi.org/10.3390/cryst15090788

Chicago/Turabian StyleLiu, Genbao, Chukun Wang, Risheng Zhu, Tengfei Zhao, Zhiwen Lan, and Mojia Huang. 2025. "Decomposition of Elasticity Tensor on Material Constants and Mesostructures of Metal Plates" Crystals 15, no. 9: 788. https://doi.org/10.3390/cryst15090788

APA StyleLiu, G., Wang, C., Zhu, R., Zhao, T., Lan, Z., & Huang, M. (2025). Decomposition of Elasticity Tensor on Material Constants and Mesostructures of Metal Plates. Crystals, 15(9), 788. https://doi.org/10.3390/cryst15090788