Deformation Behavior of Ti48Zr18V12Cu5Be17 Semi-Solid Amorphous Composites

Abstract

1. Introduction

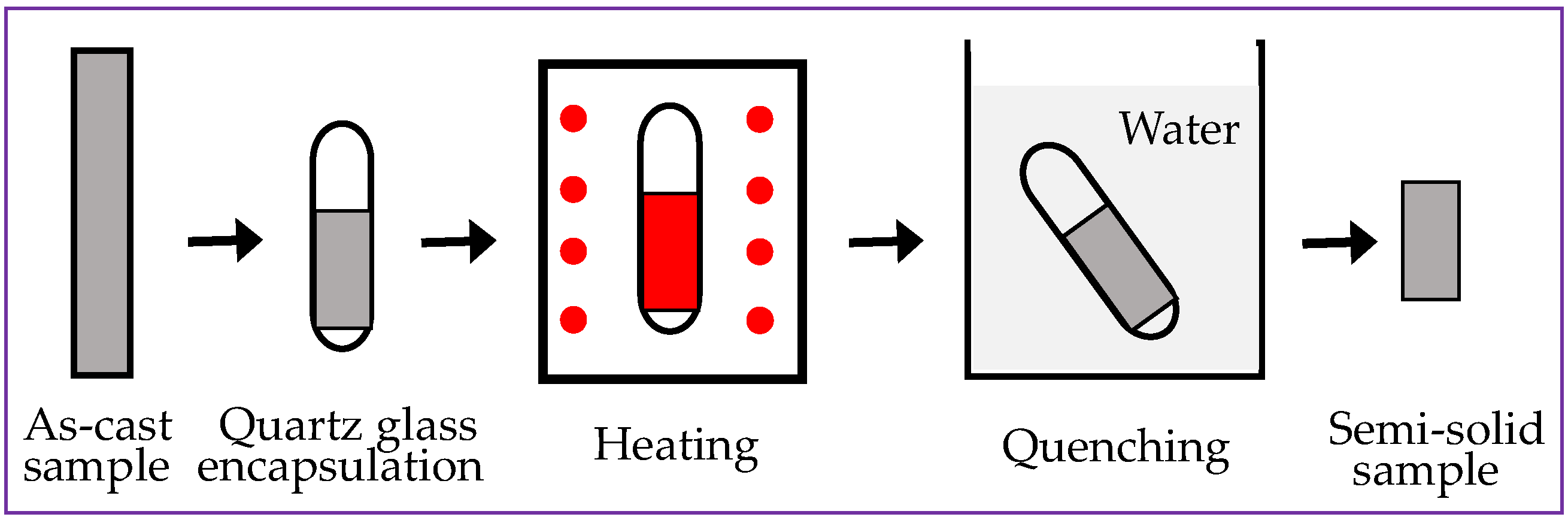

2. Experimental

3. Results

3.1. Phases Composition Analysis

3.2. Microstructure Observation

3.3. Mechanical Performance Testing and Analysis

3.4. Observation of Side-Surface Morphology of Compressed Specimens

4. Discussion

5. Conclusions

6. Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, W.; Zhao, W.Y.; Mu, W.Z.; Li, Z.; Weng, Z.K.; Zhang, W.D.; Wang, N.; Bai, P.K. Effect of hot-rolling process on the microstructure, mechanical and corrosion behaviors of dual-phase Co-based entropic alloys. Mater. Sci. Eng. A 2024, 918, 147433. [Google Scholar] [CrossRef]

- Yao, W.F.; Chen, Z.; Lyu, B.H.; Jiang, L.; Zhang, L.H. Corona discharge assisted shear thickening polishing: Non-Newtonian elastohydrodynamics and electrostatics. Int. J. Mech. Sci. 2025, 289, 110048. [Google Scholar] [CrossRef]

- Gao, X.F.; Ge, N.; Dong, F.Y. Deformation and fracture of a Zr-Al-Cu metallic glass ribbon under tension near glass transition temperature. China Foundry 2018, 15, 216–221. [Google Scholar] [CrossRef]

- Shan, S.F.; Wang, H.; Zhang, B. Influence of niobium and yttrium on plastic deformation energy and plasticity of Ti-based amorphous alloys. China Foundry 2021, 18, 60–67. [Google Scholar] [CrossRef]

- Lu, Y.Z.; Su, S.; Zhang, S.B. Controllable additive manufacturing of gradient bulk metallic glass composite with high strength and tensile ductility. Acta Mater. 2021, 206, 116632. [Google Scholar] [CrossRef]

- Liu, J.H.; Xu, J.H.; Paik, K.W.; He, P.; Zhang, S.Y. In-situ isothermal aging TEM analysis of a micro Cu/ENIG/Sn solder joint for flexible interconnects. J. Mater. Sci. Technol. 2024, 169, 42–52. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, C.; Zhao, H.; Xu, Q.; Tong, X.; Ma, S.; Li, D.; Yu, P. The synergistic enhancement of strength-plasticity of Zr53Cu30Ni9Al8 bulk metallic glass by adding carbon nanoparticles. J. Mater. Res. Technol. 2025, 35, 3547–3555. [Google Scholar] [CrossRef]

- Chi, J.; Hu, H.; Lin, Y.; Ma, Y.; Du, Y. Effect of tungsten-particle size on the room temperature compressive deformation behaviour of Zr55Cu30Al10Ni5 amorphous alloy. J. Alloys Compd. 2024, 1008, 176730. [Google Scholar] [CrossRef]

- Liu, C.; Kong, F.; Wang, H.; Zhu, S.; Liu, G.; Inoue, A. High mechanical strength and good plasticity of ZrAlNiCu bulk glassy alloys containing icosahedral or bcc β-Zr plus hexagonal ω-Zr phases prepared by annealing. Mat. Sci. Eng. A-Struct. 2025, 931, 148217. [Google Scholar] [CrossRef]

- Zhang, P.C.; Ouyang, D.; Liu, L. Enhanced mechanical properties of 3D printed Zr-based BMG composite reinforced with Ta precipitates. J. Alloys Compd. 2019, 803, 476–483. [Google Scholar] [CrossRef]

- Wang, P.; Lei, Y.; Ma, J.; Song, K.; Deng, L.; Liu, Z.Y.; Chen, Z.W.; Liu, X.F.; Ramasamy, P.; Eckert, J. Influence of Mo micro-particles on crack formation, microstructure, and mechanical behaviour of laser powder bed fusion fabricated CuZrAl bulk metallic glass composites. Virtual Phys. Prototyp. 2023, 18, 108199. [Google Scholar] [CrossRef]

- Zou, Y.M.; Qiu, Z.G.; Tan, C.L.; Wu, Y.S.; Li, K.F.; Zeng, D.C. Microstructure and mechanical properties of Fe-based bulk metallic glass composites fabricated by selective laser melting. J. Non-Cryst. Solids 2020, 538, 120046. [Google Scholar] [CrossRef]

- Karuppusamy, P.; Lingadurai, K.; Sivananth, V. Effects of T4 and T6 heat treatments on the wear behaviour of WC-reinforced Mg alloy matrix composite. T. Indian I. Met. 2020, 73, 521–530. [Google Scholar] [CrossRef]

- Kang, L.M.; Pang, X.; Tan, H.G.; Qiu, Y.F.; Liu, H.L.; Luo, X.C.; Li, Z.J.; Yang, C. Microstructure and mechanical properties of TiNbFeCoAl alloys prepared by semi-solid sintering assisted by thermo-mechanical field. Vacuum 2021, 190, 110316. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Z.; Yang, H.J. A flow model in bulk metallic glasses. Scr. Mater. 2023, 222, 115047. [Google Scholar] [CrossRef]

- Hofmann, D.C.; Roberts, S.N.; Kozachkov, H. Infrared thermal processing history of a Ti-based bulk metallic glass matrix composite manufactured via semi-solid forging. Acta Mater. 2015, 95, 192–200. [Google Scholar] [CrossRef]

- Inoue, A.; Kong, F.L.; Zhu, S.L. Production methods of engineering glassy alloys and composites. Intermetallics 2015, 58, 20–30. [Google Scholar] [CrossRef]

- Hofmann, D.C.; Suh, J.Y.; Wiest, A. Designing metallic glass matrix composites with high toughness and tensile ductility. Nature 2008, 451, 1085–1089. [Google Scholar] [CrossRef]

- Hofmann, D.C.; Suh, J.Y.; Wiest, A. Development of tough, low-density titanium-based bulk metallic glass matrix composites with tensile ductility. Proc. Natl. Acad. Sci. USA 2008, 105, 20136–20140. [Google Scholar] [CrossRef] [PubMed]

- Hofmann, D.C.; Suh, J.Y.; Wiest, A. New processing possibilities for highly toughened metallic glass matrix composites with tensile ductility. Scr. Mater. 2008, 59, 684–687. [Google Scholar] [CrossRef]

- Sun, X.H.; Qiao, J.W.; Jiao, Z.M.; Wang, Z.H.; Yang, H.J.; Xu, B.S. An improved tensile deformation model for in-situ dendrite/metallic glass matrix composites. Sci. Rep. 2015, 5, 13964. [Google Scholar] [CrossRef] [PubMed]

- Qiu, J.; Li, Y.; Zhou, H.; Bi, G. Exploring the interfacial microstructure evolution and bonding properties of Al/steel composite plates fabricated through semi-solid cast-rolling. Metals 2025, 15, 162. [Google Scholar] [CrossRef]

- Sun, G.Y.; Chen, G.; Chen, G.L. Comparison of microstructures and properties of Zr-based bulk metallic glass composites with dendritic and spherical BCC phase precipitates. Intermetallics 2007, 15, 632–634. [Google Scholar] [CrossRef]

- Xiang, Q.C.; Feng, Z.B.; Zhang, W. Effect of infiltrating time on interfacial reaction and properties of tungsten particles reinforced Zr-based bulk metallic glass composites. China Foundry 2020, 17, 253–259. [Google Scholar] [CrossRef]

- Huang, X.H.; Zhu, L.H.; Guo, H.M.; Jin, H.L.; Yang, X.J. Shear bands of as-cast and semi-solid Ti48Zr27Cu6Nb5Be14 bulk metallic glass matrix composites. China Foundry 2021, 18, 75–82. [Google Scholar] [CrossRef]

- Huang, X.H.; Pu, J.W.; Luo, Y.X.; Ouyang, Y.J. Microstructure evolution of Ti48Zr27Cu6Nb5Be14 amorphous alloy after semi-solid isothermal treatment. China Foundry 2024, 21, 287–294. [Google Scholar] [CrossRef]

- Mu, J.; Zhu, Z.; Su, R.; Wang, Y.; Zhang, H.; Ren, Y. In situ high-energy X-ray diffraction studies of deformation-induced phase transformation in Ti-based amorphous alloy composites containing ductile dendrites. Acta Mater. 2013, 61, 5008–5017. [Google Scholar] [CrossRef]

- Yesudhas, S.; Levitas, V.I.; Lin, F.; Pandey, K.K.; Smith, J.S. Unusual plastic strain-induced phase transformation phenomena in silicon. Nat. Commun. 2024, 15, 7054. [Google Scholar] [CrossRef]

- Mazilkin, A.; Straumal, B.; Kilmametov, A.; Straumal, P.; Baretzky, B. Phase transformations induced by severe plastic deformation. Mater. Trans. 2019, 60, 1489–1499. [Google Scholar] [CrossRef]

- Lan, T.; Zhu, J.; Jiang, Y.; Wu, P.; Wei, Y. Shear bands in amorphous polymers under four-point bending. Int. J. Mech. Sci. 2024, 269, 109062. [Google Scholar] [CrossRef]

- Hu, W.; Yu, Z.; Lu, Y.; Huo, J.; Qin, Z.; Lu, X.; Narayan, R.L. Enhanced plasticity in laser additive manufactured Nb-reinforced bulk metallic glass composite. J. Alloys Compd. 2022, 918, 165539. [Google Scholar] [CrossRef]

- Zhong, X.; Zhang, Q.; Ma, M.; Ye, J.; Wu, M.; Ren, J. Dynamic mechanical response and constitutive model of (Ti37.31Zr22.75Be26.39Al4.55Cu9)94Co6 high-entropy bulk metallic glass. Int. J. Plast. 2024, 179, 104047. [Google Scholar] [CrossRef]

- Chang, Z.; Bi, W.; Ge, Y.; Xu, H.; Song, Y. The micro-zones characteristics and mechanical properties of Nb-reinforced Zr-based bulk metallic glass composites prepared by selective laser melting. J. Alloys Compd. 2025, 1033, 181336. [Google Scholar] [CrossRef]

- Zhang, Z.S.; Jin, C.J.; Cao, G.Y.; Su, S.; Zhang, L.Y.; Shen, H.X.; Sun, J.F. Controlling mechanical performance and structural homogeneity of large-sized Zr-based bulk metallic glasses via mold temperature regulation. J. Mater. Res. Technol. 2025, 37, 938–947. [Google Scholar]

- Zhang, C.Y.; Zhu, Z.W.; Li, S.T.; Wang, Y.Y.; Li, Z.K.; Li, H.; Zhang, H.F. Shear band evolution and mechanical behavior of cold-rolled Zr-based amorphous alloy sheets: An in-situ study. J. Mater. Sci. Technol. 2024, 181, 115–127. [Google Scholar] [CrossRef]

- Tao, J.; Zou, K.; Zhou, J.; Wu, H.; Xu, L.; Wang, J.; Tao, X.; Huang, H.; Yao, Z. Phenolic multiple kinetics-dynamics and discrete crystallization thermodynamics in amorphous carbon nanostructures for electromagnetic wave absorption. Nat. Commun. 2024, 15, 10337. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhu, Q.; Yang, X.; Chen, J.; Qu, Y. Deformation mechanism of metastable oriented grains in high-purity tantalum under different strain paths. J. Mater. Res. Technol. 2024, 30, 5465–5473. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, X.; Li, J.; Wang, G.; Chen, B.; Wei, C.; Ouyang, Y. Deformation Behavior of Ti48Zr18V12Cu5Be17 Semi-Solid Amorphous Composites. Crystals 2025, 15, 749. https://doi.org/10.3390/cryst15090749

Huang X, Li J, Wang G, Chen B, Wei C, Ouyang Y. Deformation Behavior of Ti48Zr18V12Cu5Be17 Semi-Solid Amorphous Composites. Crystals. 2025; 15(9):749. https://doi.org/10.3390/cryst15090749

Chicago/Turabian StyleHuang, Xinhua, Junnan Li, Guang Wang, Bin Chen, Chenhao Wei, and Yuejun Ouyang. 2025. "Deformation Behavior of Ti48Zr18V12Cu5Be17 Semi-Solid Amorphous Composites" Crystals 15, no. 9: 749. https://doi.org/10.3390/cryst15090749

APA StyleHuang, X., Li, J., Wang, G., Chen, B., Wei, C., & Ouyang, Y. (2025). Deformation Behavior of Ti48Zr18V12Cu5Be17 Semi-Solid Amorphous Composites. Crystals, 15(9), 749. https://doi.org/10.3390/cryst15090749