Abstract

This study systematically examines the influence of Zn addition (≤0.6 wt.%) on the microstructure and mechanical properties of Mg-2Al-0.8Sn-0.5Ca (wt.%) alloys. Minor Zn alloying marginally increases secondary phase fraction in as-cast alloys, with complete Zn dissolution achieved after solution treatment and asymmetric severe shear extrusion. Extruded alloys exhibit non-monotonic strength evolution with Zn content, peaking at 0.2 wt.% Zn (yield strength ≈ 235.1 MPa, ultimate tensile strength ≈ 289.2 MPa), while elongation reaches 16.1%. This strength enhancement originates from synergistic grain boundary, solid-solution, and dislocation strengthening mechanisms. These results demonstrate Zn’s critical role in optimizing the strength-ductility balance of rare-earth-free magnesium alloys.

1. Introduction

Magnesium (Mg) alloys, as lightweight and high-strength materials, are well-suited to address energy conservation and emission reduction needs due to their unique physical and chemical properties [1,2,3]. This affords Mg alloys broad application potential in fields such as aerospace, automobile manufacturing, electronic communications, and biomedicine [4,5,6].

Recent years have witnessed significantly expanded research on Mg-Al-Sn-Ca alloys [7,8,9,10]. Wang et al. [11] established that Al and Sn co-addition reduces non-basal stacking fault energy (SFE) in magnesium alloys, specifically enhancing room-temperature (RT) deformation capability. Li et al. [12] successfully fabricated an alloy exhibiting both high yield strength (YS, ~290 MPa) and high elongation (EL, ~18.2%) using differential temperature asymmetric extrusion on a Mg-3.8Al-1.1Sn-0.4Ca (wt.%) alloy, employing mold and billet temperatures of 200 °C and 400 °C, respectively. Additionally, Miao et al. [13] examined the influence of Ca content on tensile properties and associated mechanisms in Mg-2.0Al-0.8Sn (wt.%) alloy. Their analysis revealed that Ca addition simultaneously enhances YS (~226.0 MPa) and EL (~20.2%) while concurrently weakening crystallographic texture. This YS improvement predominantly originates from Ca-induced grain refinement and precipitation strengthening, with a particular emphasis on CaMgSn phase precipitation.

Furthermore, Zn exhibits high solubility in pure Mg at RT [14] and is frequently added in trace amounts alongside other elements to enhance the mechanical properties of Mg alloys [15,16,17]. For example, the addition of Zn with Ca during thermo-mechanical treatment results in the formation of Ca2Mg6Zn3 and Mg2Ca second phases smaller than 1 μm [18]. These secondary phases effectively anchor grain boundaries and inhibit basal texture formation. Zhang et al. [19] demonstrated that the cold drawing of Mg-2.46Zn-0.69Ca (wt.%) alloy produces uniformly distributed nanoparticles (semi-coherent Ca2Mg6Zn3 + coherent MgZn2), yielding wire with ~285 MPa YS and ~11.8% EL. Zeng et al. [20] found that Mg-0.3Zn-0.1Ca (wt.%) exhibits superior EL (~24%) compared to binary Mg-Zn, Mg-Ca, or pure Mg with equivalent recrystallized grain sizes. Moreover, non-basal slip was exclusively activated in Mg-0.3Zn-0.1Ca (wt.%) during tensile deformation. Shi et al. [21] performed tensile tests on hot-rolled and annealed Mg-2.0Zn (wt.%), revealing that at higher strains (~15%), the Zn solute hardening of basal slip significantly enhanced pyramidal ⟨c + a⟩ slip activity. This activation induced higher local stresses, activating secondary deformation mechanisms and conferring excellent RT elongation. Son et al. [22] conducted high-strain hot torsion tests (~400 °C) on AZ31 and AM30 alloys, observing that Zn solute slightly accelerated strain accumulation during initial deformation stages and promoted recrystallization at high strains.

Asymmetric extrusion introduces asymmetric deformation conditions through specially designed dies or adjusted process parameters, achieving grain refinement and texture modification in materials [23,24,25]. Building upon prior work [12,26], we applied asymmetric extrusion to synthesize Mg-2.0Al-0.8Sn-0.5Ca-xZn (x = 0, 0.2, 0.4, and 0.6 wt.%) alloys exhibiting balanced high strength and ductility. This work systematically assesses Zn content effects on extruded sheet microstructures, analyzes dynamic recrystallization (DRX) processes, and tracks microstructural evolution during asymmetric extrusion. These analyses elucidate how Zn content modulates alloy microstructure and mechanical properties, providing a scientific basis for Mg alloy design and optimization.

2. Experimental Procedures

Mg-2.0Al-0.8Sn-0.5Ca-xZn (x = 0, 0.2, 0.4, and 0.6 wt.%) alloys were prepared from pure magnesium (99.90 wt.%), aluminum (99.90 wt.%), tin (99.90 wt.%), and Mg-20Ca master alloy. Raw materials underwent melting at 710 °C under protective atmosphere (99.5% CO2 + 0.5% SF6) within a resistance furnace, followed by casting via sub-rapid cooling copper mold. Resultant alloys were designated ATX2105, ATX2105-0.2Zn, ATX2105-0.4Zn, and ATX2105-0.6Zn based on zinc content. SRS ingots were wire-cut to 70 mm × 50 mm × 10 mm extrusion billets and subjected to stepwise solution treatment (320 °C/2 h → 430 °C/2 h → 490 °C/2 h) to minimize elemental segregation [27].

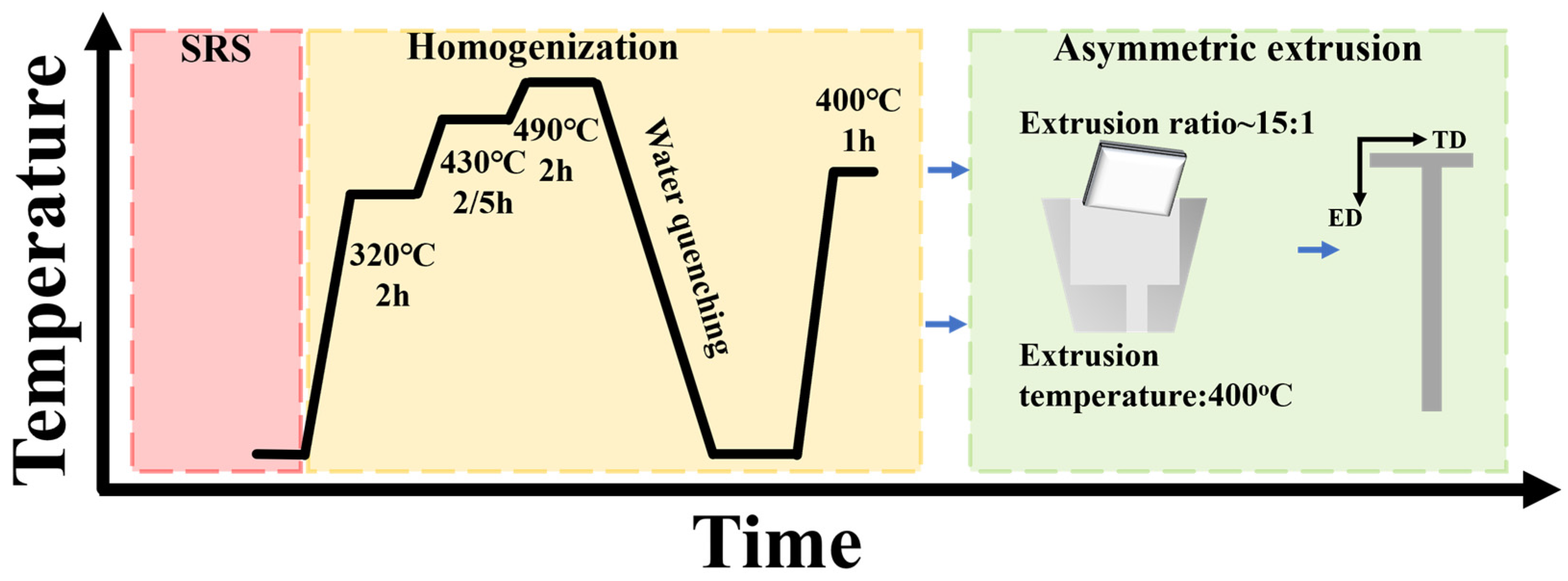

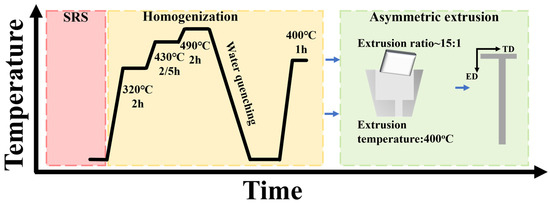

Asymmetric extrusion utilized a die with asymmetry coefficient 1.5 (extrusion channel length ratio). Following 400 °C/1 h preheating of alloys and die, extrusion proceeded at a ratio of 15 and a speed of ~16 mm/s. Water quenching produced 22 mm × 3 mm cross-section sheets. The experimental sequence is detailed in Figure 1.

Figure 1.

The schematic diagram for the preparation process of extruded ATX2105-xZn sheets.

Microstructural characterization employed a field emission scanning electron microscope (FESEM, Zeiss Sigma 500, Oberkochen, Germany) equipped with electron backscatter diffraction (EBSD, Oxford Symmetry, Oxford, UK) and energy dispersive spectroscopy (EDS, Oxford Ultim Max, Oxford, UK) systems. Specimens for SEM/EBSD analysis were subjected to sequential grinding with SiC papers (#600-#7000 grit), followed by mechanical polishing using 0.25 μm diamond suspension until obtaining scratch-free surfaces. EBSD samples underwent electrochemical polishing at −30 °C for ~90 s (20 V; ~0.2 A) prior to analysis. EBSD data (step size: 0.4 μm) processing utilized Oxford Instruments Channel 5 software (Version: 5.12.74.0).

Nanoscale phase characterization utilized transmission electron microscopy (TEM, FEI Talos F200X, Waltham, MA, USA). Specimen preparation involved mechanical thinning to ~80 μm thickness, punching into 3 mm disks, and electrolytic polishing via the RL-2 twin-jet system (−45 °C, 30 V; electrolyte: 860 mL ethanol + 40 mL HClO4). Polishing terminated immediately upon perforation, with subsequent liquid nitrogen-cooled ion milling minimizing thermal artifacts.

Tensile testing employed ED-oriented dog-bone specimens (30 × 10 × 2 mm gauge section) at a 10−3 s−1 strain rate using an AGS-X 100KN (Shimadzu, Kyoto, Japan) universal testing machine equipped with a video extensometer.

3. Results

3.1. Microstructures

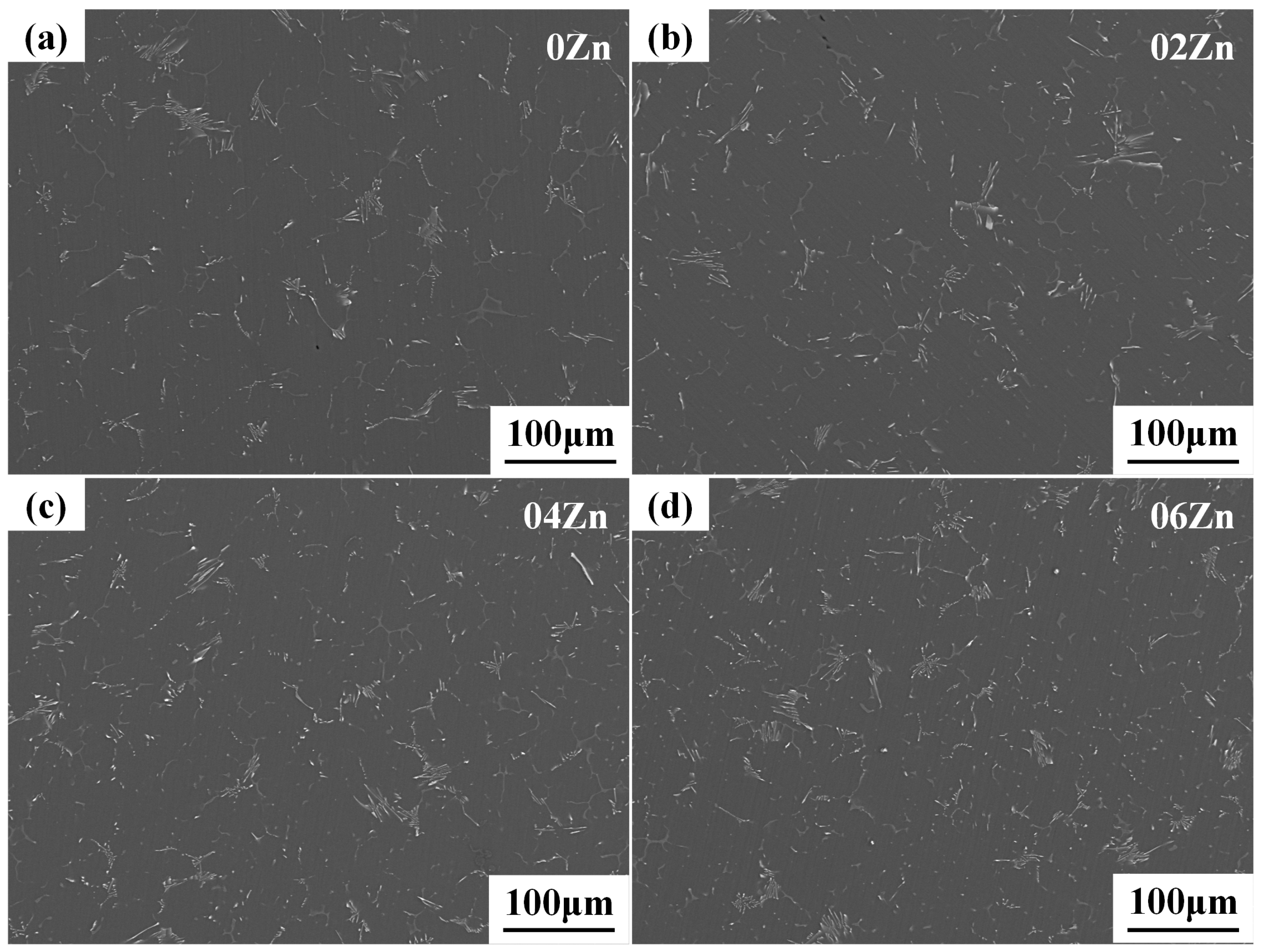

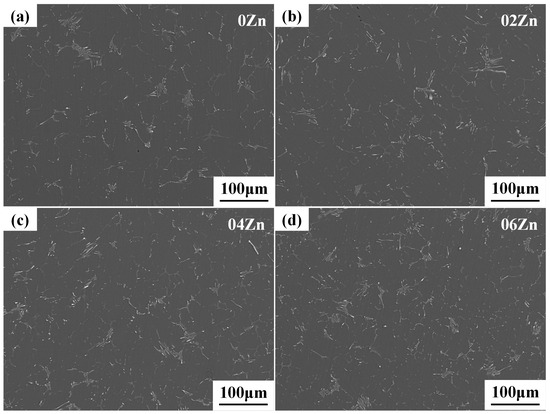

Figure 2 presents scanning electron microscopy (SEM) micrographs of sub-rapidly solidified (SRS) as-cast alloys. Quantitative analysis reveals that the Zn-free alloy contains substantial lamellar and block-shaped secondary phases, accompanied by minor spherical constituents, yielding a total secondary phase area fraction of ~4.77%. Upon incorporation of 0.2 wt.% Zn, the phase fraction remains essentially unchanged at ~4.81% with comparable morphological characteristics. When Zn content increases to 0.4 wt.%, a marginal elevation in secondary phase coverage to ~5.01% is observed, while phase morphology maintains predominantly similar features. At the maximum Zn addition of 0.6 wt.%, the alloys exhibit peak secondary phase density, reaching a ~5.16% areal fraction. Throughout the compositional series, the spatial distribution of secondary phases remains uniformly dispersed without notable clustering tendencies.

Figure 2.

SEM images of as-cast ATX2105-xZn (wt.%) alloys: (a) 0Zn, (b) 0.2Zn, (c) 0.4Zn, and (d) 0.6Zn.

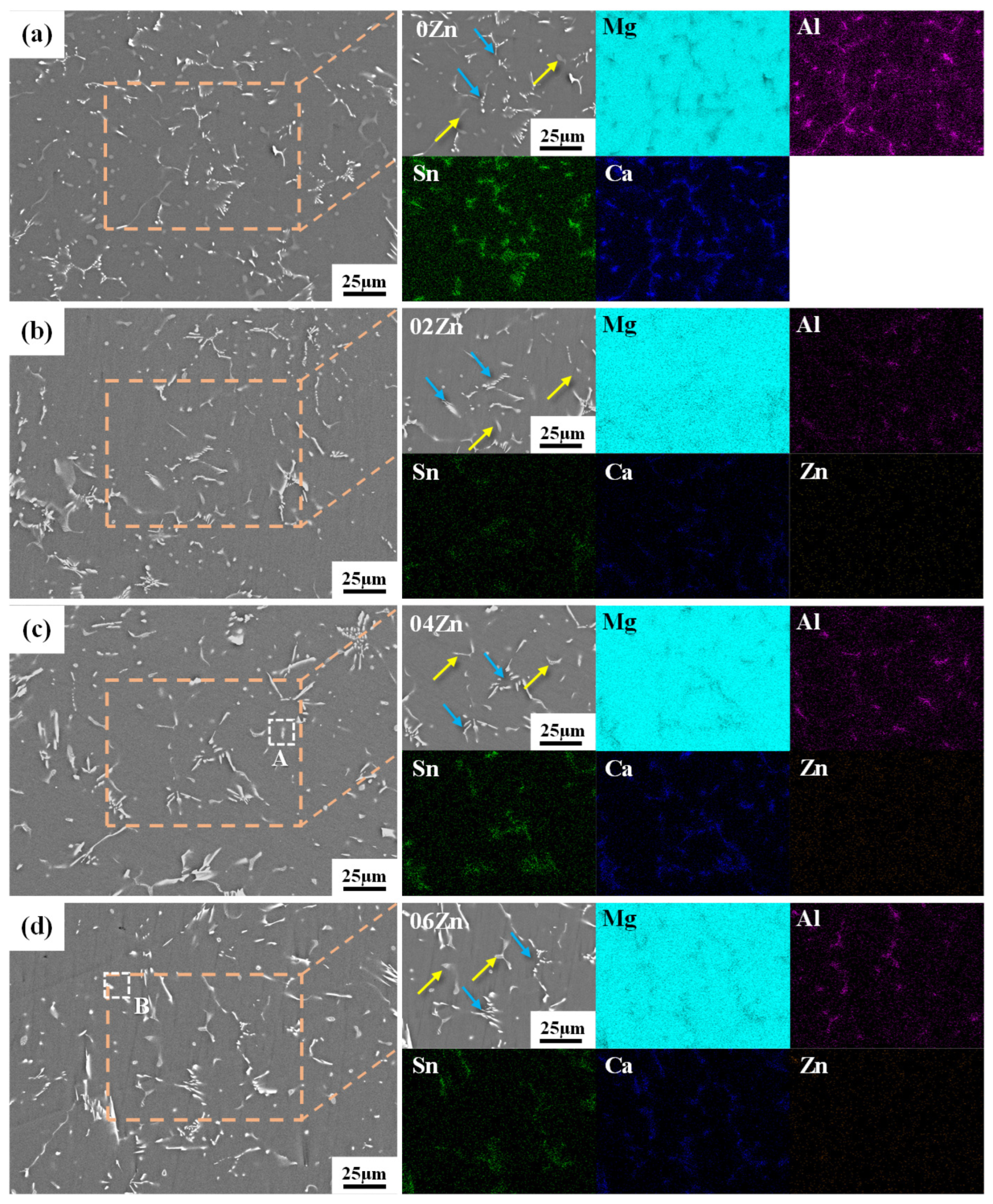

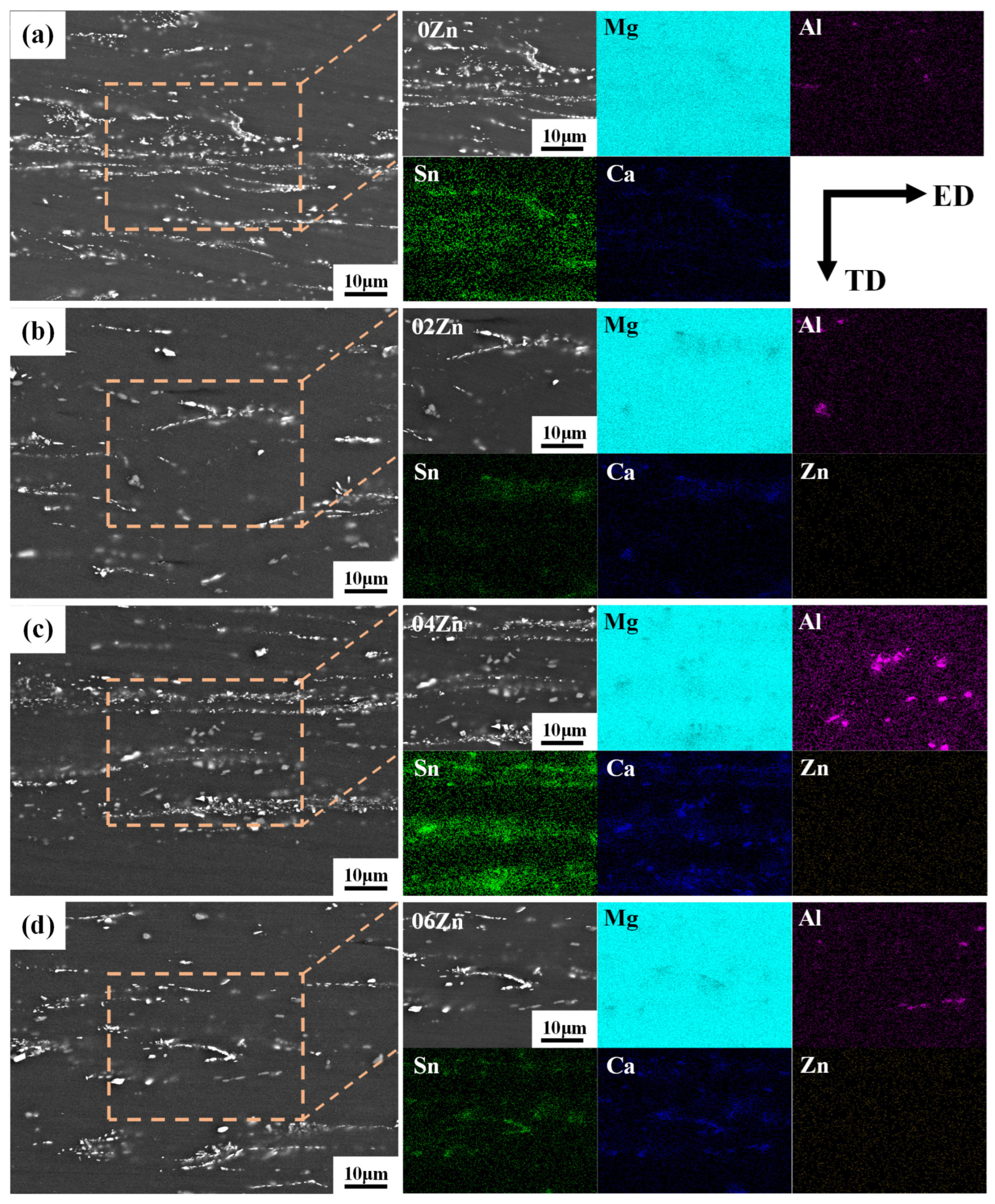

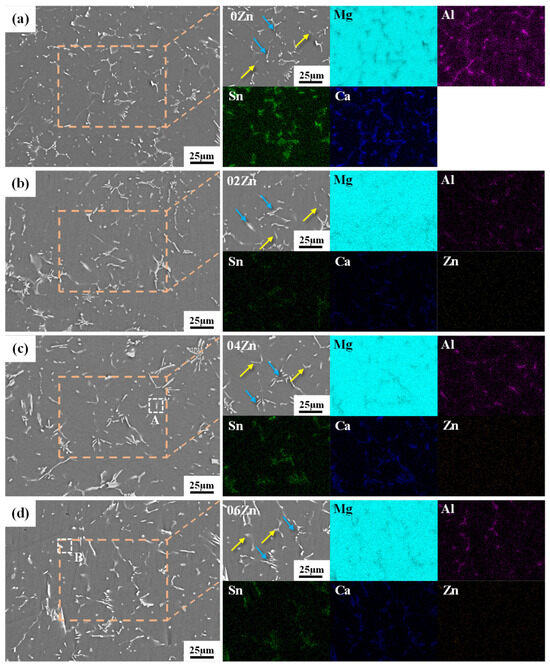

To further determine the composition of secondary phases in as-cast alloys, energy dispersive spectroscopy (EDS) analysis was systematically conducted across alloys with varying Zn contents, as presented in Figure 3 and Figure 4. Note that Figure 4 provides a high-magnification view corresponding to the white dashed box region in Figure 3. Two primary secondary phase types were consistently identified in all four alloys: one phase enriched predominantly in Mg, Sn, and Ca elements, and another phase enriched mainly in Mg, Al, and Ca elements. Via cross-referencing with established literature [27] and our EDS results, these secondary phases are identified as CaMgSn (blue arrow) and (Mg,Al)2Ca (yellow arrow) intermetallic compounds. Both phases exhibit preferential distribution along grain boundaries, a phenomenon driven by the higher free energy at grain boundary regions compared to grain interiors, which thermodynamically favors secondary phase formation to reduce the system’s total energy.

Figure 3.

SEM images and corresponding EDS analysis of as-cast ATX2105-xZn (wt.%) alloys: (a) 0Zn, (b) 0.2Zn, (c) 0.4Zn, and (d) 0.6Zn. Colored arrows denote secondary precipitates: blue arrow (CaMgSn), yellow arrow ((Mg,Al)2Ca).

Figure 4.

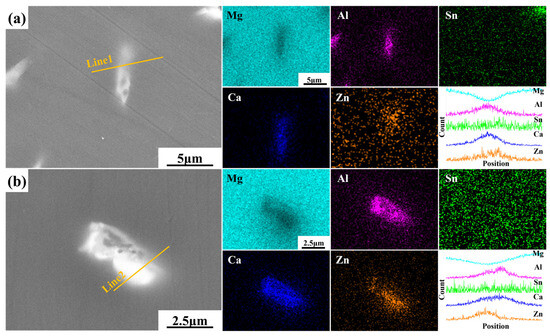

SEM micrographs and corresponding EDS analyses: (a) ATXZ210504, (b) ATXZ210506.

Furthermore, Zn-containing secondary phases were only detected when Zn content reached 0.4 wt.% and 0.6 wt.% (Figure 4). These Zn-bearing phases appeared in limited quantities and were consistently associated with the (Mg,Al)2Ca phase. Based on combined EDS analysis and literature reports [28], this Zn-containing phase is confirmed as Ca2Mg6Zn3. Thermodynamic calculations reveal mixing enthalpies of −45 kJ/mol for Sn-Ca, −20 kJ/mol for Al-Ca, and −22 kJ/mol for Zn-Ca pairs [29,30]. The significantly lower (more negative) enthalpy for Sn-Ca indicates stronger chemical affinity between these elements, facilitating stable compound formation. In the Mg-2.0Al-0.8Sn-0.5Ca-0.2Zn (wt.%) alloy, the higher concentration of Al relative to Zn, combined with Zn’s high solid solubility in the Mg matrix, results in secondary phases dominated by CaMgSn and (Mg,Al)2Ca. However, with sufficient Zn addition, increased Zn chemical potential enables its reaction with Ca to form the stable Ca2Mg6Zn3 intermetallic compound.

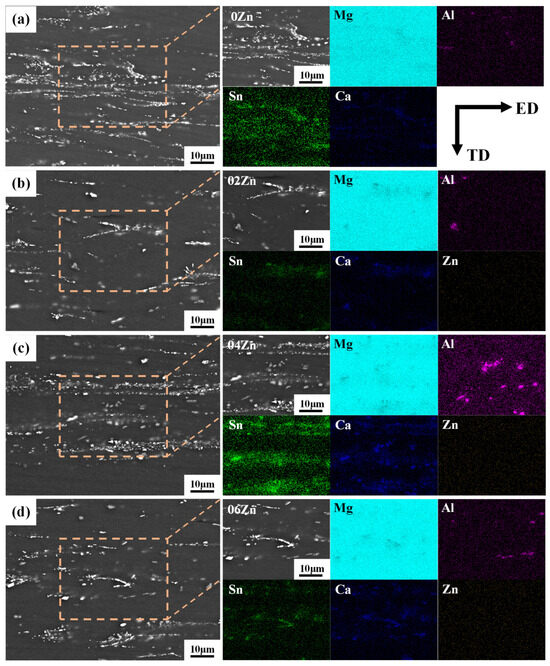

Figure 5 presents scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS) results for extruded ATX2105-xZn sheets (ED-TD plane). The coarse secondary phase particles present in the initial as-cast microstructure underwent fragmentation into fine particles during solid solution treatment and asymmetric extrusion processing. These refined particles exhibit discontinuous alignment along the extrusion direction (ED), forming characteristic extrusion-induced banding structures. Despite systematic Zn content increases, no substantial morphological alterations occurred in the secondary phases. EDS elemental mapping analysis confirms that the secondary phases consist primarily of (Mg,Al)2Ca and CaMgSn intermetallic compounds, with no detectable Zn-containing phases.

Figure 5.

SEM micrographs and corresponding EDS mapping results of extruded ATX2105-xZn (wt.%) sheets: (a) 0Zn, (b) 0.2Zn, (c) 0.4Zn, and (d) 0.6Zn.

This absence of Zn-bearing phases is attributed to the complete dissolution of Zn solute into the Mg matrix during high-temperature solid solution treatment and subsequent hot extrusion processing in ATX2105-xZn sheets. Consequently, Zn failed to precipitate as discrete secondary phase constituents under these processing conditions.

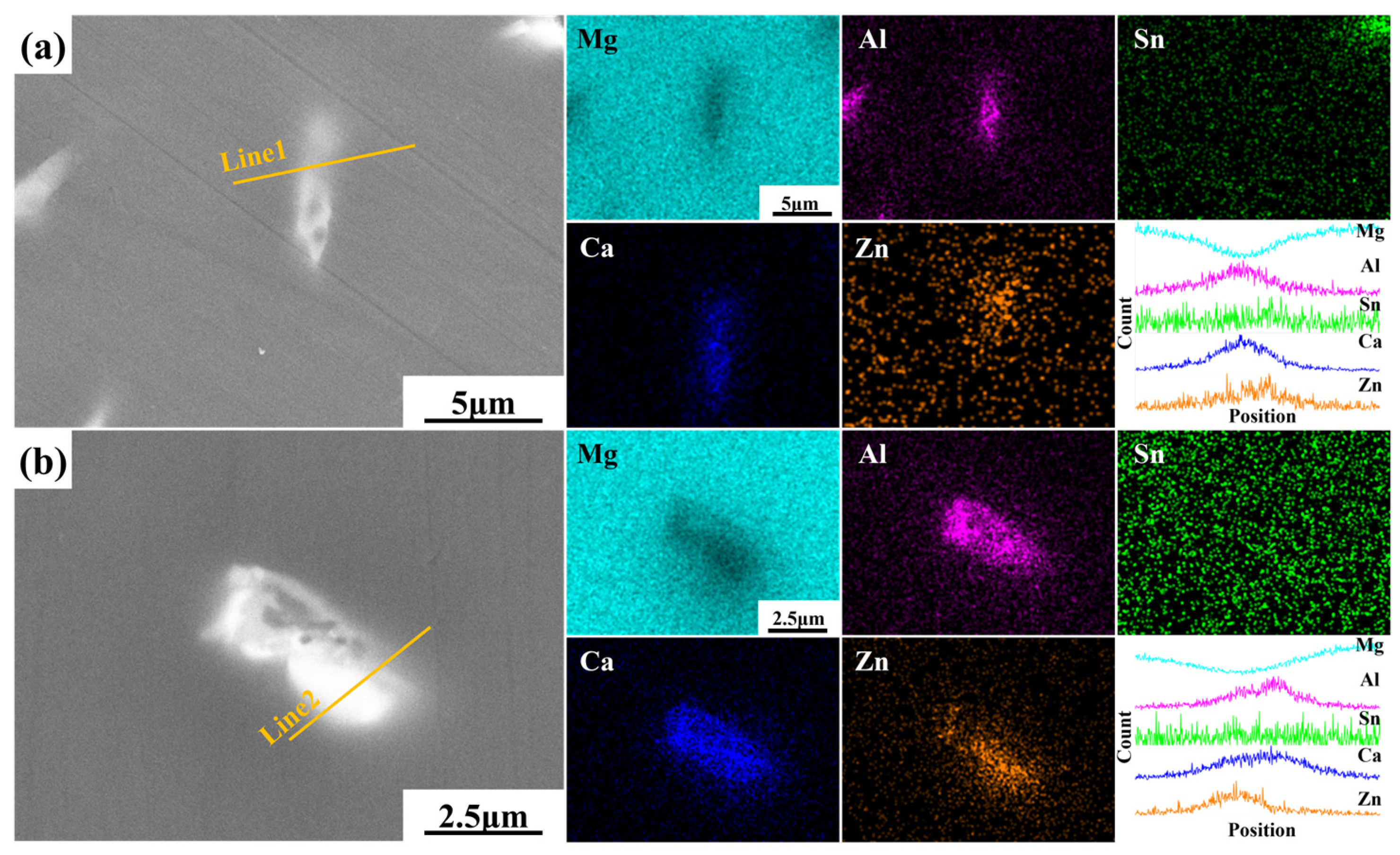

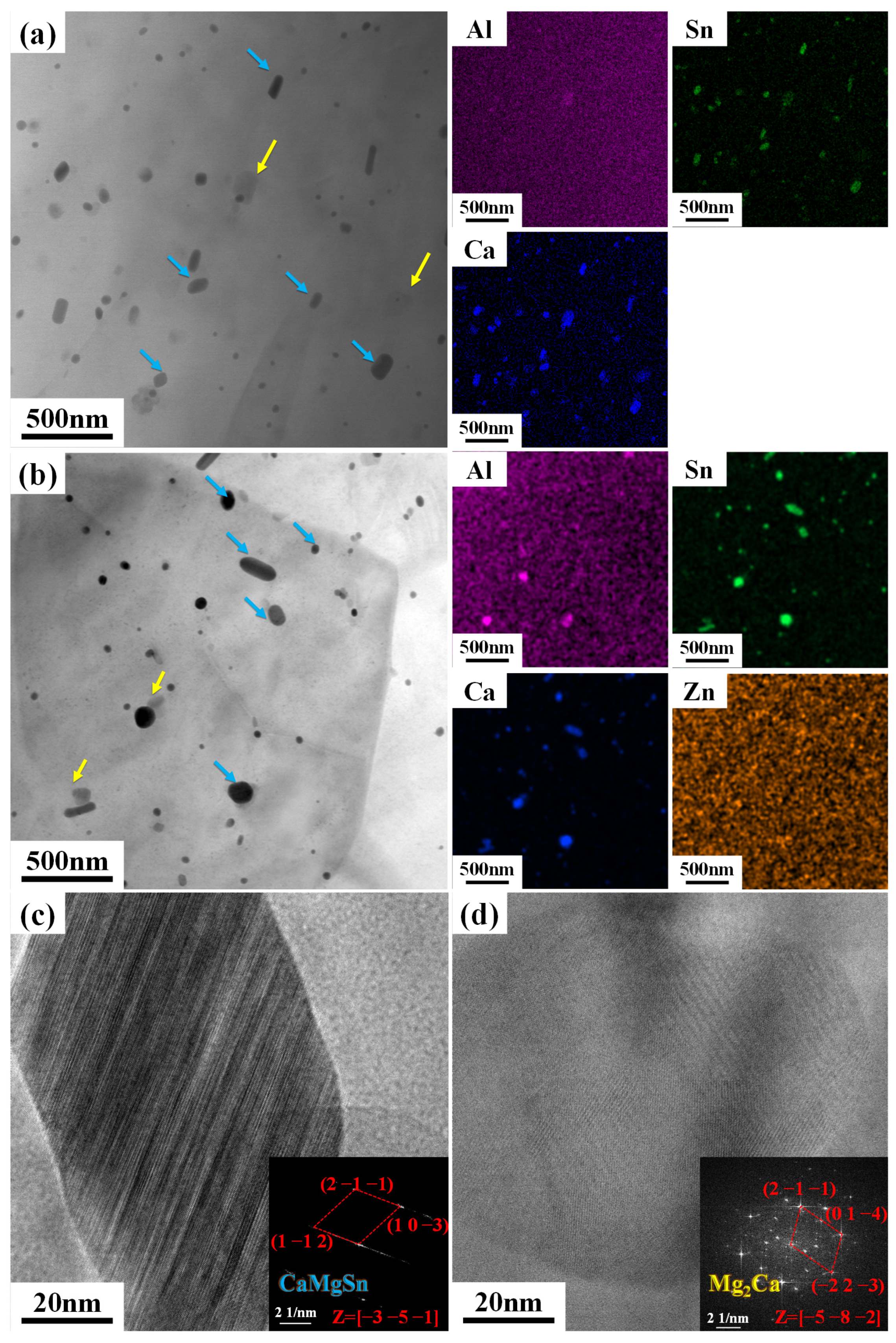

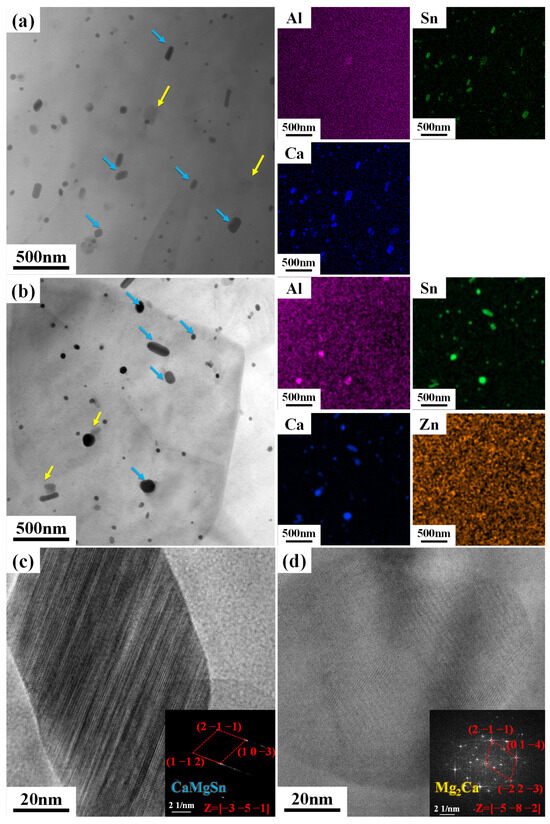

To further identify nanoscale secondary phases in extruded alloys, transmission electron microscopy (TEM) characterization with corresponding energy dispersive spectroscopy (EDS) analysis was performed on extruded ATX2105 and ATX2105-0.6Zn plates (Figure 6). The results reveal nanoscale secondary phases uniformly distributed along grain boundaries and within grain interiors in both alloys. The phase density shows no significant increase, maintaining a consistent volume fraction of ~1.71% across both compositions. Combined EDS and high-resolution TEM (HRTEM) analyses confirm these nanoscale precipitates consist predominantly of CaMgSn (blue arrow), supplemented by minor (Mg,Al)2Ca and Mg2Ca phases (yellow arrow). Crucially, no Zn-containing nanoscale secondary phases were detected in the ATX2105-0.6Zn alloy. Correlating with Figure 5 observations, this confirms Zn exists in solid solution rather than forming discrete intermetallic compounds.

Figure 6.

TEM micrographs and corresponding energy spectrum diagrams of extruded alloys: (a) ATX2105, (b) ATXZ210506; and (c,d) HRTEM micrographs of the second phase in the extruded ATXZ210506 alloy. Colored arrows denote secondary precipitates: blue arrow (CaMgSn), yellow arrow (Mg2Ca or (Mg,Al)2Ca).

The CaMgSn phase functions as a hard reinforcement that effectively suppresses grain growth during asymmetric extrusion and refines grain structure through grain boundary segregation. Intragranular nanoscale CaMgSn phases provide dislocation pinning, thereby slowing dislocation accumulation at grain boundaries during plastic deformation while significantly enhancing strength through dislocation motion inhibition. This dual mechanism concurrently improves the material’s overall deformation capability.

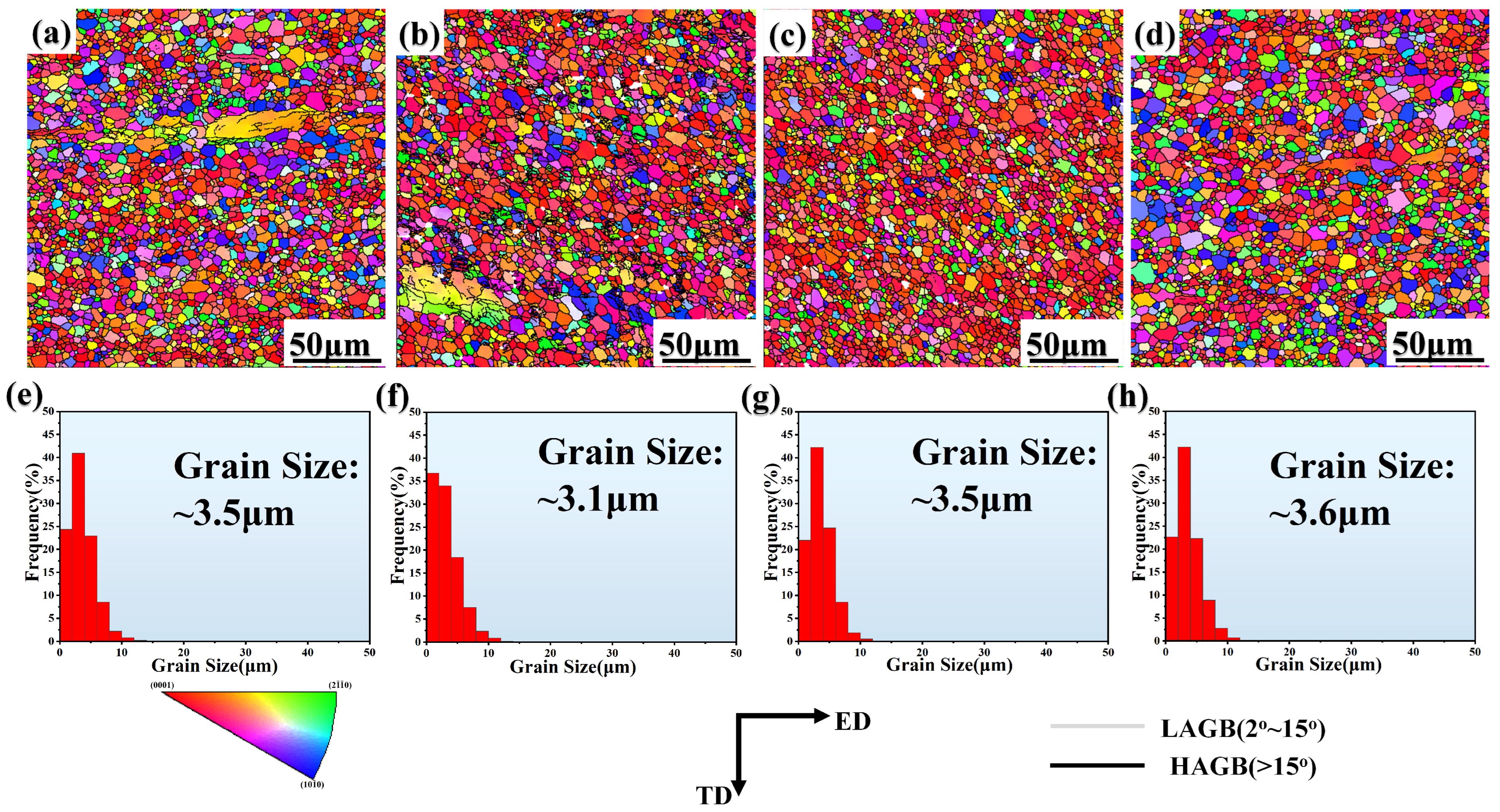

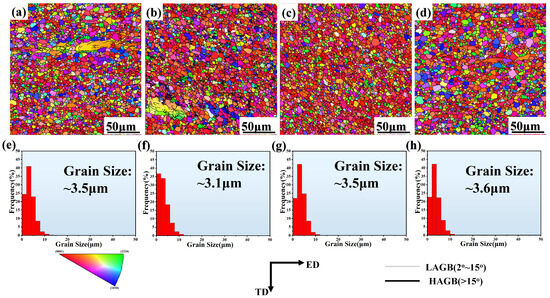

Presented in Figure 7 are inverse pole figure (IPF) maps and corresponding grain size distributions for extruded ATX2105-xZn plates. Microstructural analysis demonstrates significant refinement upon 0.2 wt.% Zn addition compared to Zn-free ATX2105, reducing the average grain size from ~3.5 μm to ~3.1 μm. Progressive grain coarsening occurs with further Zn additions, reaching ~3.6 μm at 0.6 wt.% Zn. This non-monotonic behavior reveals that while trace Zn additions (≤0.2 wt.%) enhance grain refinement during extrusion, surpassing this threshold reverses the effect via altered grain growth mechanisms.

Figure 7.

EBSD IPF maps (a–d) and corresponding grain size distribution (e–h) of the extruded alloys: (a,e) ATX2105, (b,f) ATXZ210502, (c,g) ATXZ210504, and (d,h) ATXZ210506.

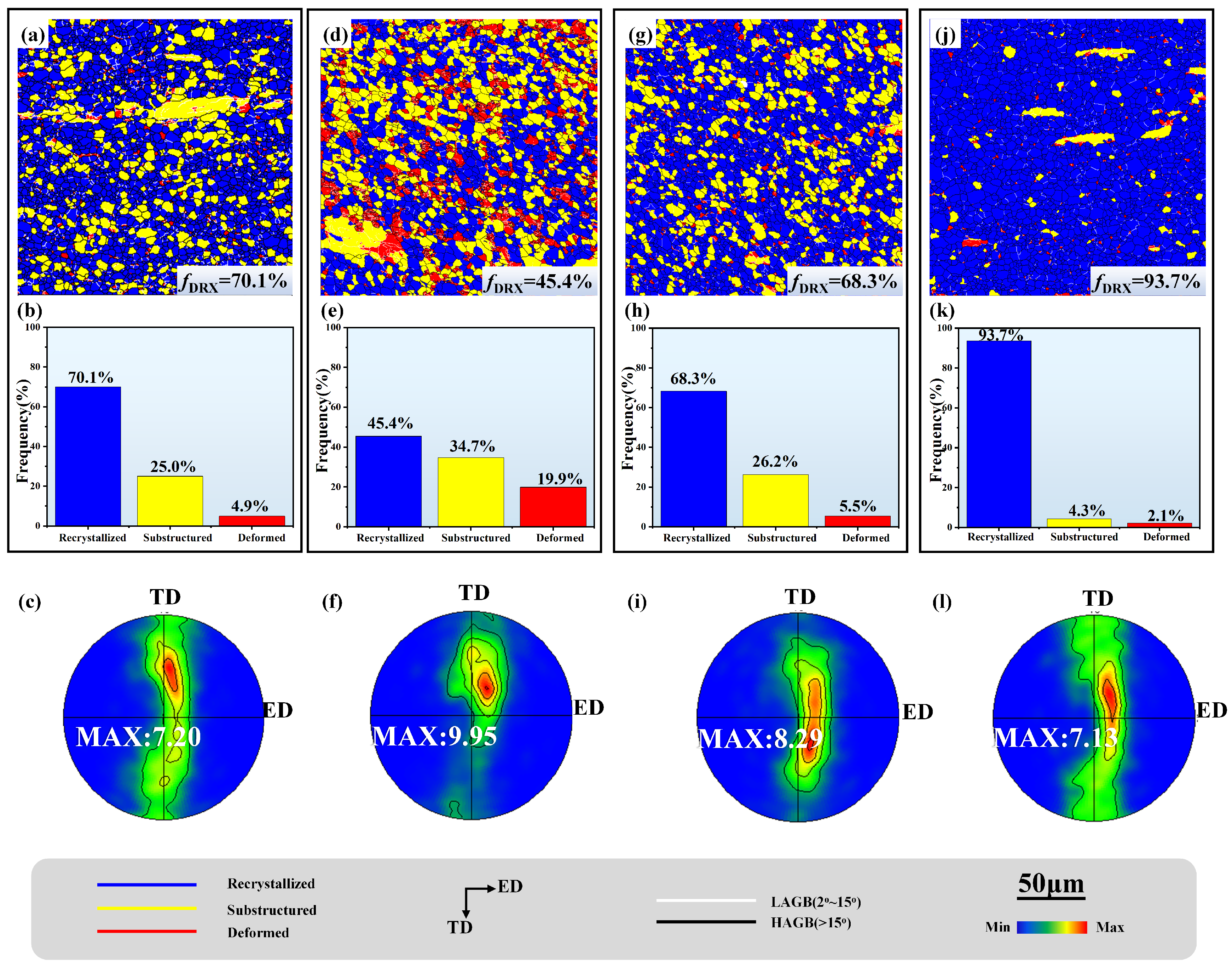

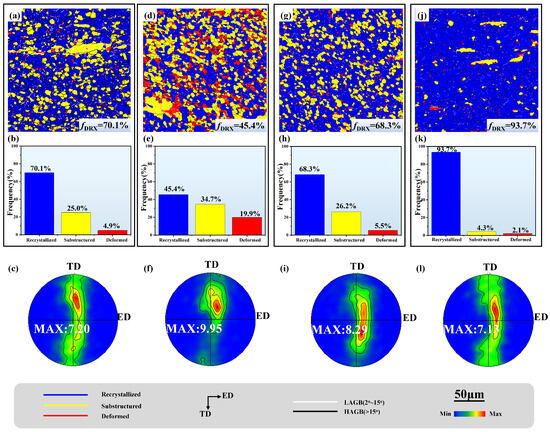

Figure 8 presents the distribution of grain types, their statistical proportions, and (0001) pole figures for extruded ATX2105-xZn plates. The addition of 0.2 wt.% Zn to the ATX2105 alloy substantially reduces the recrystallized grain fraction from ~70.1% to ~45.4% while increasing deformed grains from ~4.9% to ~19.9%, indicating recrystallization inhibition at low Zn concentrations. However, higher Zn additions (0.4–0.6 wt.%) significantly enhance recrystallization, raising the recrystallized fraction to ~93.7%.

Figure 8.

Distribution maps of different types of grains, corresponding statistical charts of their proportions, and {0001} pole figures in extruded alloys: (a–c) ATX2105, (d–f) ATXZ210502, (g–i) ATXZ210504, and (j–l) ATXZ210506.

The (0001) pole figures demonstrate that after asymmetric extrusion of solution-treated ATX2105, ATXZ210502, ATXZ210504, and ATXZ210506 sheets, the basal texture diverges along the transverse direction (TD). Most grains exhibit c-axis orientations tilted ~10–40° from the normal direction (ND) toward TD. Notably, the ATX2105-0.2Zn plate shows maximum texture intensity (9.95 MRD), exceeding the Zn-free alloy by 2.75 MRD. Increasing Zn content reduces texture intensity to 8.29 MRD (0.4 wt.% Zn) and 7.13 MRD (0.6 wt.% Zn). This progressive weakening correlates directly with the recrystallization degree, as randomly oriented recrystallized grains diminish overall texture strength. Significantly, the intensified basal texture intensity and more concentrated texture distribution in the ATXZ210502 sheet may contribute to its reduced elongation, a correlation subsequently validated by mechanical property assessments.

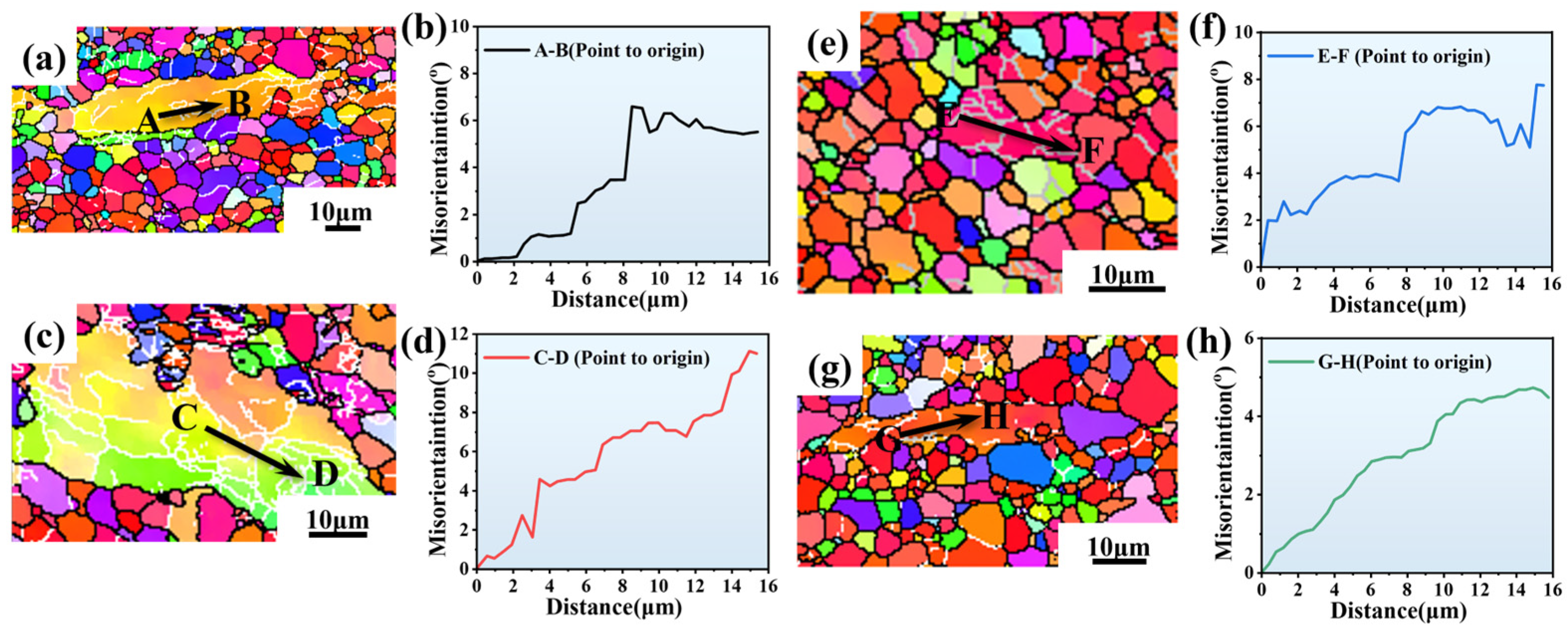

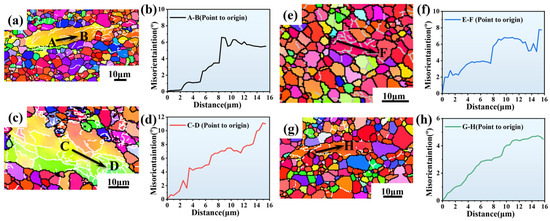

From Figure 7, the four extruded alloys comprise fine dynamically recrystallized (DRX) grains and deformed coarse grains. The deformed coarse grains contained a high density of low-angle grain boundaries (LAGBs), indicative of accumulated residual dislocations. To investigate the recrystallization mechanisms across alloys with varying Zn contents, four regions were selected from Figure 7, as presented in Figure 9. Along the directions marked by black arrows (A to B, C to D, E to F, and G to H in Figure 9), the cumulative misorientation angles increase with increasing distance between measurement points. This indicates that LAGBs within deformed coarse grains can evolve into high-angle grain boundaries (HAGBs) through the continuous absorption of surrounding dislocations. Consequently, significant continuous dynamic recrystallization (CDRX) occurred in the extruded ATX2105, ATXZ210502, ATXZ210504, and ATXZ210506 sheets. These results confirm that continuous dynamic recrystallization dominates the recrystallization process in these sheets.

Figure 9.

IPF of the selected areas and orientation distribution maps along the drawn lines: (a,b) ATX2105, (c,d) ATXZ210502, (e,f) ATXZ210504, and (g,h) ATXZ210506.

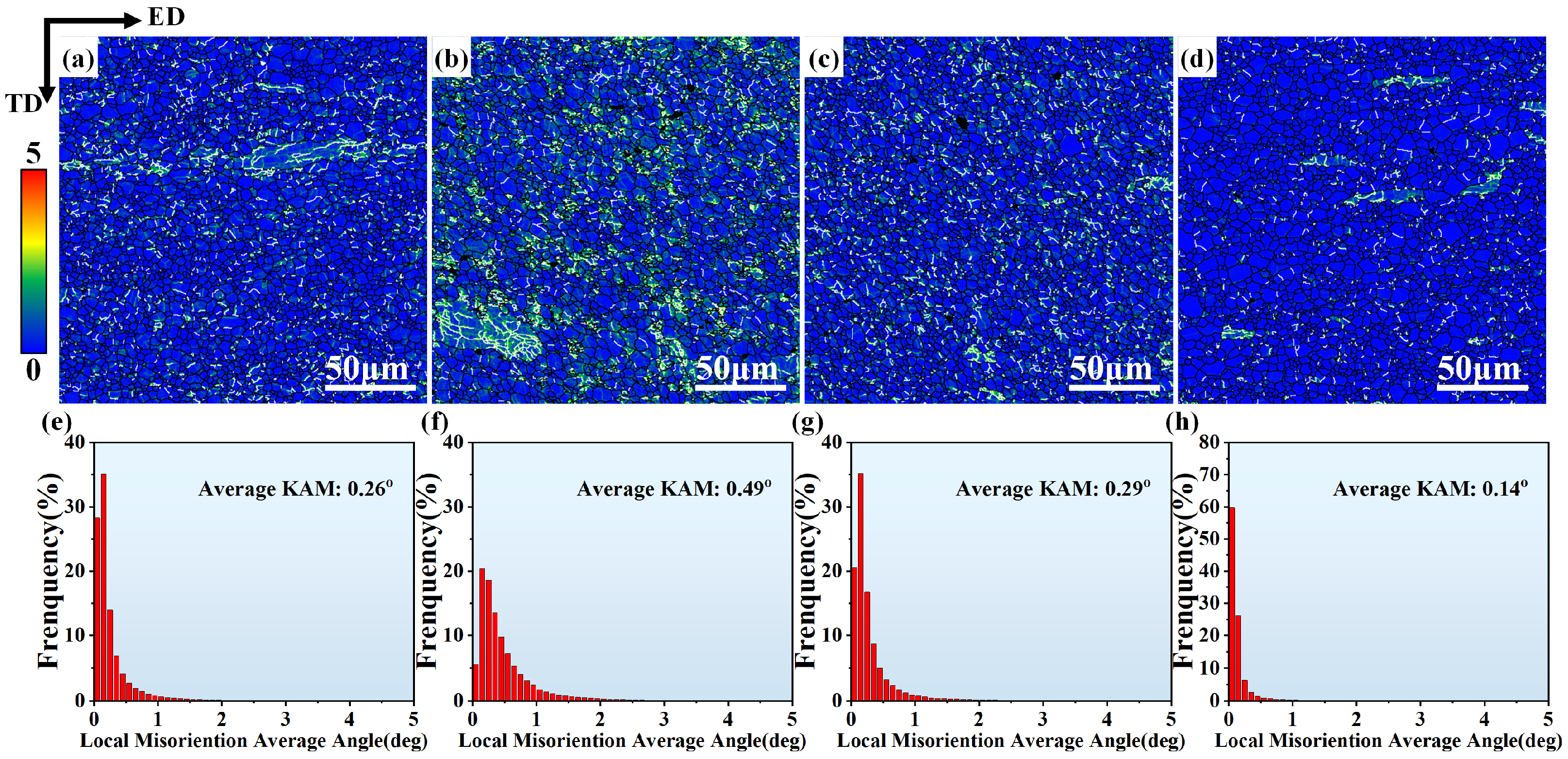

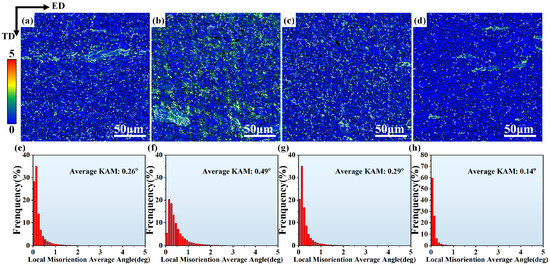

The Kernel Average Misorientation (KAM) maps of the extruded alloys are presented in Figure 10. Measured KAM values for extruded ATXZ2105, ATXZ210502, ATXZ210504, and ATXZ210506 sheets are ~0.26°, ~0.49°, ~0.29°, and ~0.14°, respectively. This non-monotonic variation indicates that dislocation density initially rises then declines with increasing Zn content. Specifically, the elevated KAM value (~0.49°) in the 0.2 wt.% Zn-containing ATXZ210502 alloy implies that Zn addition inhibits dislocation recovery. This inhibition likely originates from Zn atoms residing entirely in solid solution within the matrix, increasing lattice distortion and enhancing the energy barrier for dislocation motion. Consequently, the dislocation slip and its absorption (via conversion to high-angle grain boundaries, HAGBs) become restricted, yielding high residual dislocation density in deformed grains and a lower fraction of recrystallized grains. In contrast, at elevated Zn levels (exemplified by ATXZ210506), the notably lower KAM value (~0.14°) reflects reduced residual dislocation density. Such a reduction may stem from the activation of the <c + a> dislocation slip during severe hot deformation in high-Zn conditions, which promotes recrystallization in Mg-Al-based alloys [22] and may lead to grain coarsening.

Figure 10.

KAM maps (a–d) and corresponding statistical histograms (e–h) of (a,e) ATX2105, (b,f) ATXZ210502, (c,g) ATXZ210504, and (d,h) ATXZ210506.

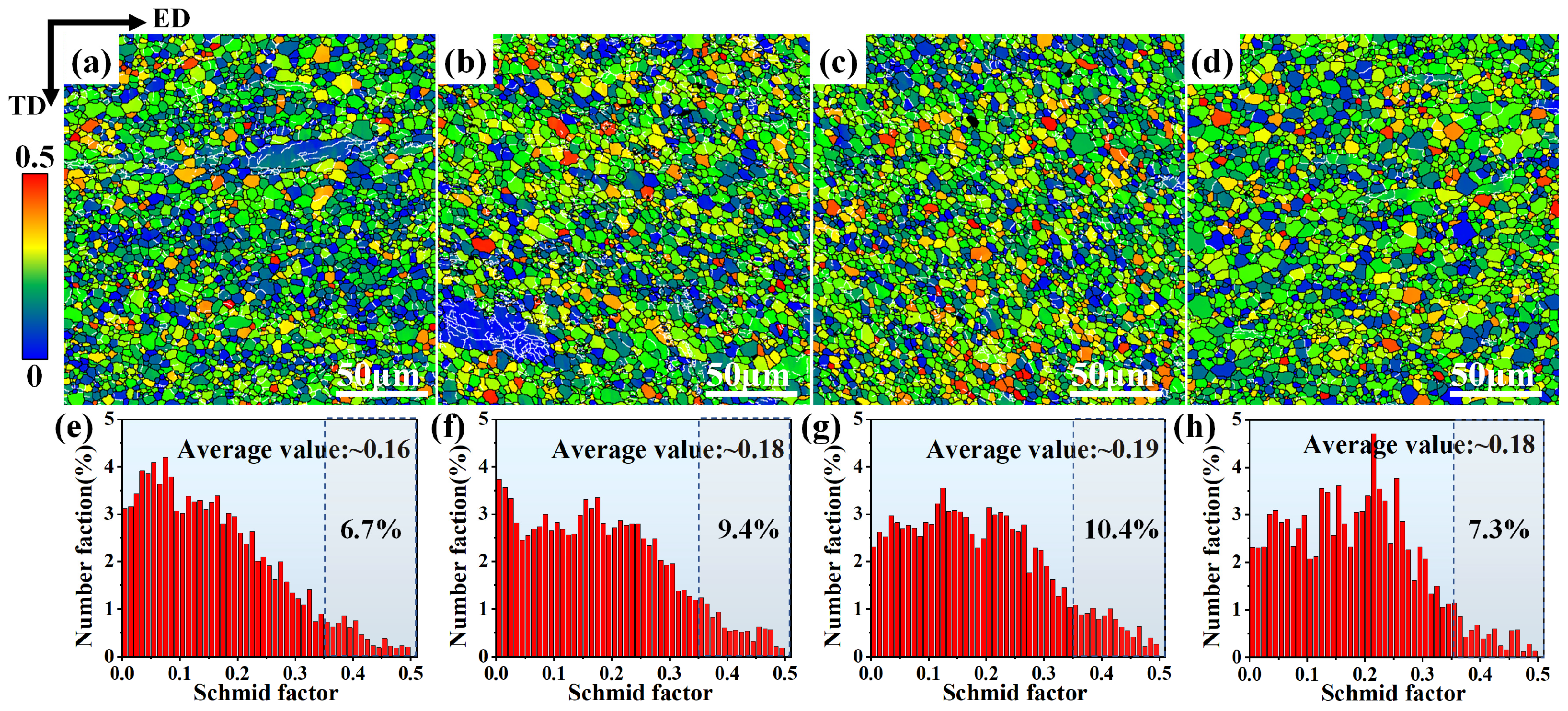

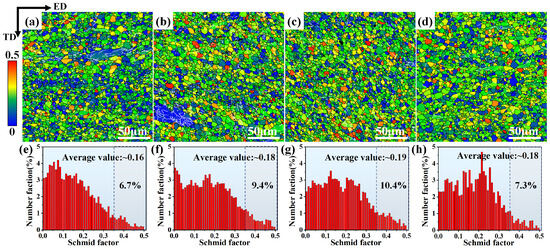

The Schmid factor (SF) serves as a critical quantitative indicator for slip system activation propensity, offering fundamental insights into plastic deformation behavior and mechanical performance under applied stress. Figure 11 presents SF distribution maps for basal <a> slip in extruded sheets during tensile loading along the extrusion direction (ED). Per Schmid’s law, elevated SF values correspond to higher slip system activation probabilities. The measured average basal SF values for ATX2105, ATXZ210502, ATXZ210504, and ATXZ210506 sheets are ~0.16, 0.18, 0.19, and 0.18, respectively. Concurrently, high-SF region fractions increase to ~6.7%, ~9.4%, 10.4%, and ~7.3%. Crucially, Zn addition systematically shifts the SF distribution toward higher values, reflecting enhanced basal slip activation that promotes elongation in ATXZ210504 and ATXZ210506 alloys by mitigating strain localization.

Figure 11.

Schmid factor distribution maps (a–d) and corresponding statistical histograms (e–h) for basal slip in the extruded alloys under tensile loading along the ED direction: (a,e) ATX2105, (b,f) ATXZ210502, (c,g) ATXZ210504, and (d,h) ATXZ210506. Dashed boxes highlight high-SF regions.

3.2. Tensile Properties

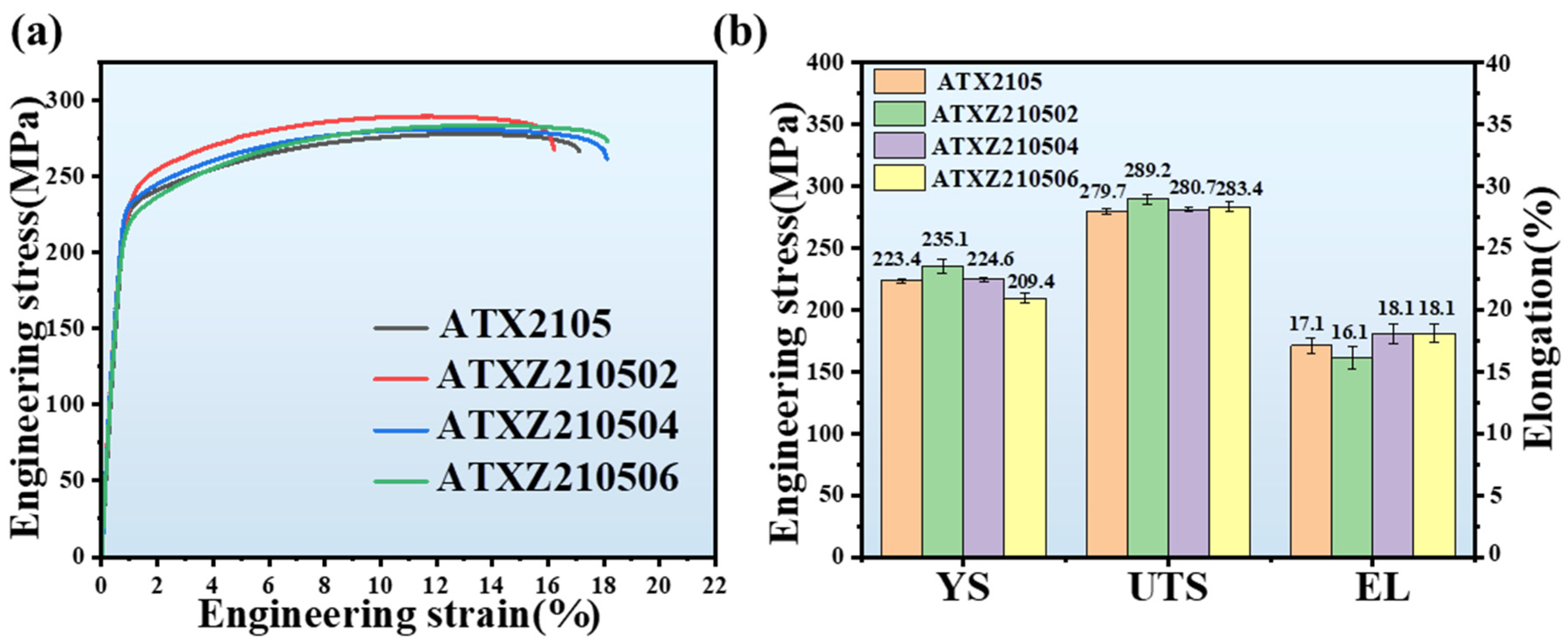

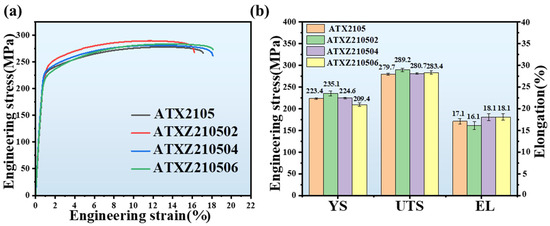

Figure 12 presents room-temperature tensile engineering stress-strain curves and summarizes mechanical properties of as-extruded ATX2105-xZn plates. Compared to the Zn-free alloy, the Zn-containing extruded sheets exhibit various enhancements in YS, ultimate tensile strength (UTS), and EL. This improvement primarily originates from extrusion-induced grain refinement, elevated dislocation density, and fragmentation/redistribution of secondary phases. Notably, extruded alloy strength displays non-monotonic dependence on Zn content, initially increasing then decreasing. Specifically, the as-extruded ATX2105-0.2Zn sheet achieves peak strength (YS: ~235.1 MPa, UTS: ~289.2 MPa). Further Zn addition reduces strength concomitantly, with ATX2105-0.6Zn sheet showing decreased YS (~209.4 MPa) and UTS (~283.4 MPa).

Figure 12.

(a) Engineering stress-strain responses of extruded ATX2105-xZn alloys at room temperature; (b) comparative analysis of tensile properties across varying Zn contents.

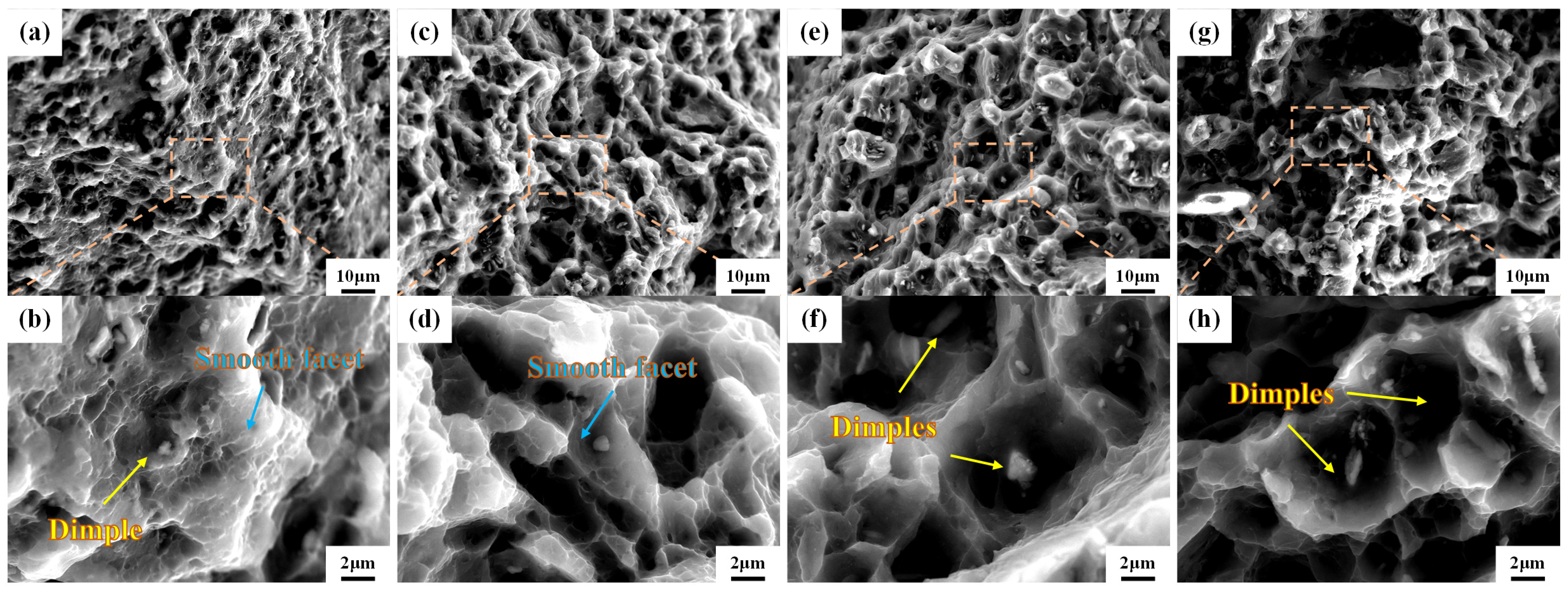

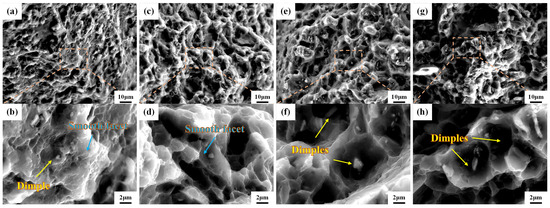

3.3. Fracture Behavior

Analysis of tensile fracture morphologies in extruded ATX2105-xZn alloys reveals distinct fracture mechanisms. As evidenced in Figure 13e,f, ATXZ210504 displays abundant dimples containing centrally located secondary phase particles. During tensile loading, deformation incompatibility between the magnesium matrix and hard secondary phases triggers microcrack nucleation at interfaces. Subsequent crack propagation under stress develops the characteristic dimple morphology. Consequently, ATXZ210504 exhibits pronounced ductile fracture behavior, correlating with its enhanced elongation. Comparable fracture features are observed in ATXZ210506 (Figure 13g,h). Conversely, ATX2105 (Figure 13a,b) develops finer dimples alongside smooth facets, suggesting diminished plasticity. ATXZ210502 (Figure 13c,d) demonstrates extensively distributed smooth facets, in agreement with its minimal elongation.

Figure 13.

Tensile fracture morphology of: (a,b) ATX2105, (c,d) ATXZ210502, (e,f) ATXZ210504, and (g,h) ATXZ210506.

4. Discussion

Mechanical Property Analysis

The yield strength (YS) of magnesium alloys is governed by multiple strengthening mechanisms, including grain boundary strengthening, solid-solution strengthening, dislocation strengthening, and second-phase strengthening. This section undertakes a quantitative assessment of the individual contributions of these four mechanisms to the YS of extruded ATX2105, ATXZ210502, ATXZ210504, and ATXZ210506 sheets, with particular emphasis on elucidating the dominant role of Zn addition in strength enhancement.

Figure 7 presents average grain sizes of extruded ATX2105-xZn sheets, with corresponding yield strength (YS) values displayed in Figure 12. The grain refinement contribution to YS () was calculated using the Hall–Petch equation [31]:

Here σ0 represents the intrinsic material strength, while k and d denote the Hall–Petch coefficient and average grain size, respectively. As presented in Figure 7, the extruded ATX2105, ATXZ210502, ATXZ210504, and ATXZ210506 sheets exhibit average grain sizes of ~3.5 μm, ~3.1 μm, ~3.5 μm, and ~3.6 μm. Based on the Hall–Petch relationship, the calculated grain boundary strengthening contributions to yield strength are ~155.0 MPa, ~164.7 MPa, ~155.0 MPa, and ~152.8 MPa for these alloys, respectively.

Concerning solid-solution strengthening in the ATX2105-xZn alloys, Al, Sn, Ca, and Zn theoretically contribute. However, the negligible atomic radius difference between Sn and Mg (Δr ≈ 1.5%) induces minimal lattice distortion, rendering Sn’s solid-solution strengthening effect insignificant. Furthermore, studies confirm that in Sn-containing magnesium alloys, the substantial electronegativity difference between Ca and Sn (Δχ ≈ 0.6) preferentially drives CaMgSn phase formation over matrix dissolution. Consequently, only Al and Zn provide effective solid-solution strengthening in the extruded ATX2105, ATXZ210502, ATXZ210504, and ATXZ210506 sheets:

Within the formula, n represents a constant (2/3) [32], while KAl and KZn denote solute constants for Al (196 MPa (at.%)−2/3) [32] and Zn (905 MPa (at.%)−2/3) [33], respectively. CAl and CZn correspond to atomic fractions of Al and Zn. For all four alloys, the Al atomic fraction remains ~1.82 at.%, whereas Zn atomic fractions in extruded ATXZ210502, ATXZ210504, and ATXZ210506 sheets measure 0.075 at.%, 0.15 at.%, and 0.23 at.%. Computational substitution yields solid-solution strengthening contributions to yield strength: ATX2105: ~13.6 MPa, ATX2105-0.2Zn: ~21.0 MPa, ATX2105-0.4Zn: ~25.5 MPa, and ATX2105-0.6Zn: ~29.3 MPa.

Dislocation strengthening is primarily governed by the accumulated dislocation density, quantified via the following equation [34,35]:

where θ denotes the average misorientation angle, and μ can be understood as the scanning step of EBSD (400 nm in this work). For these calculations, α = 0.3 and M represents the Taylor factor (defined as the reciprocal of the Schmid factor). Consequently, the dislocation strengthening contributions to YS are ~14.5 MPa, ~17.7 MPa, ~13.0 MPa, and ~9.0 MPa, respectively.

The second-phase strengthening contribution to yield strength () is quantified via the Orowan equation:

Here, M represents the Taylor factor, G the shear modulus (~1.66 × 104 MPa), b the Burgers vector (3.2 × 10−10 m), ν Poisson’s ratio (0.3), dt the average diameter of precipitated second phases, and f their volume fraction. Figure 5 and Figure 6 demonstrate that Zn addition introduces no new secondary phases in extruded alloys. Consequently, second-phase parameters dt ≈ 109.2 nm and f ≈ 1.71% remain consistent across all compositions. Substituting these values into the Orowan equation gives the second-phase strengthening contribution to yield strength: ≈ 27.3 MPa.

In summary, theoretical yield strength calculations demonstrate fundamental agreement with experimental measurements (Table 1). Mechanical property variations across zinc-modified extruded alloys primarily stem from the synergistic grain boundary, solid-solution, and dislocation strengthening mechanisms. Mechanistically, the strength enhancement in the ATX2105-0.2Zn alloy is primarily attributable to grain boundary strengthening coupled with dislocation strengthening and solid-solution strengthening contributions.

Table 1.

Contributions of different strengthening mechanisms to the YS of extruded ATX2105, ATXZ210502, ATXZ210504, and ATXZ210506 Sheets.

5. Conclusions

This study systematically investigates the microstructural evolution and mechanical properties of Zn-modified Mg-2.0Al-0.8Sn-0.5Ca alloys. The principal conclusions are organized as follows.

- Minor Ca2Mg6Zn3 phases formed exclusively in as-cast alloys with Zn contents at or above 0.4 wt.%. Following solution treatment and hot extrusion processing, all Zn-containing phases dissolved completely into the magnesium matrix. The extruded alloys consistently contained CaMgSn as the dominant secondary phase accompanied by minor (Mg,Al)2Ca constituents.

- The Zn content significantly influenced the dynamic recrystallization during thermomechanical processing. At 0.2 wt.% Zn addition, recrystallization was substantially suppressed, resulting in a recrystallized fraction of approximately 45.4%. Conversely, 0.6 wt.% Zn addition strongly promoted recrystallization, achieving approximately 93.7% recrystallized fraction. This demonstrates Zn’s capacity to induce divergent recrystallization responses.

- Extruded alloy strength displayed non-monotonic dependence on Zn content, peaking at 0.2 wt.% Zn, while elongation followed an inverse trend. The ATX2105-0.2Zn alloy achieved optimal strength-ductility balance with yield strength of approximately 235.1 MPa, ultimate tensile strength of approximately 289.2 MPa, and elongation of approximately 16.1%. These enhancements originated from synergistic contributions of grain boundary strengthening, solid-solution strengthening, and dislocation strengthening mechanisms.

Author Contributions

Writing—original draft, C.W. and W.-Q.L.; methodology, C.W. and H.D.; investigation, C.W. and Z.-G.L.; formal analysis, C.W. and H.D.; data curation, C.W. and H.-Q.Z.; writing—review and editing, W.-Q.L., J.-L.C. and Z.-G.L.; conceptualization, H.D., H.-Q.Z. and Z.-G.L.; supervision, Z.-G.L.; and funding acquisition, Z.-G.L. All authors have read and agreed to the published version of the manuscript.

Funding

This study is supported by the Jilin Province Science and Technology Development Program (20240301033GX), the National Natural Science Foundation of China (52271031), the National Key Research and Development Program of China (2022YFB4301201), and the Research and Development Program of China State Railway Group Co., Ltd. (N2024J024).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Authors Chao Wang, Hai Deng, and Huai-Qiang Zhang were employed by the company CRRC Changchun Railway Vehicles Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as potential conflicts of interest.

References

- Pollock, T.M. Weight Loss with Magnesium Alloys. Science 2010, 328, 986–987. [Google Scholar] [CrossRef]

- Liu, B.-Y.; Liu, F.; Yang, N.; Zhai, X.-B.; Zhang, L.; Yang, Y.; Li, B.; Li, J.; Ma, E.; Nie, J.-F.; et al. Large plasticity in magnesium mediated by pyramidal dislocations. Science 2019, 365, 73–75. [Google Scholar] [CrossRef]

- Liu, S.; Wang, C.; Ning, H.; Meng, Z.-Y.; Guan, K.; Wang, H.-Y. Achieving high ductility and low in-plane anisotropy in magnesium alloy through a novel texture design strategy. J. Magnes. Alloy. 2024, 12, 2863–2873. [Google Scholar] [CrossRef]

- Joost, W.J.; Krajewski, P.E. Towards magnesium alloys for high-volume automotive applications. Scr. Mater. 2017, 128, 107–112. [Google Scholar] [CrossRef]

- Hirsch, J.; Al-Samman, T. Superior light metals by texture engineering: Optimized aluminum and magnesium alloys for automotive applications. Acta Mater. 2013, 61, 818–843. [Google Scholar] [CrossRef]

- Luo, A.A. Magnesium: Current and potential automotive applications. JOM 2002, 54, 42–48. [Google Scholar] [CrossRef]

- Zha, M.; Liang, J.-W.; Xing, H.; Xu, H.; Jiang, B.; Wang, C.; Jia, H.-L.; Wang, H.-Y. Spheroiding and refining of coarse CaMgSn phase in Mg–Al–Sn–Ca alloys for simultaneously improved strength and ductility via sub-rapid solidification and controlled rolling. Mater. Sci. Eng. A 2022, 834, 142598. [Google Scholar] [CrossRef]

- Wang, F.; Sun, S.-J.; Yu, B.; Zhang, F.; Mao, P.-L.; Liu, Z. First principles investigation of binary intermetallics in Mg–Al–Ca–Sn alloy: Stability, electronic structures, elastic properties and thermodynamic properties. Trans. Nonferrous Met. Soc. China 2016, 26, 203–212. [Google Scholar] [CrossRef]

- Wang, D.; Dong, K.; Jin, Z.; Guan, K.; Cao, F.; Zhao, H.; Zha, M.; Wang, H.-Y. Novel Mg-Al-Sn-Ca with enhanced mechanical properties and high corrosion rate via sub-rapid solidification for degradable magnesium alloy. J. Alloys Compd. 2022, 914, 165325. [Google Scholar] [CrossRef]

- Li, Y.; Wang, M.; Cai, J.; Wang, C.; Deng, H.; Li, Z. Effect of Ca addition on microstructure and mechanical properties of Mg–3.8Al–1.1Sn alloys. Mater. Today Commun. 2024, 38, 108204. [Google Scholar] [CrossRef]

- Wang, H.-Y.; Zhang, N.; Wang, C.; Jiang, Q.-C. First-principles study of the generalized stacking fault energy in Mg–3Al–3Sn alloy. Scr. Mater. 2011, 65, 723–726. [Google Scholar] [CrossRef]

- Li, Y.; Wang, M.; Cai, J.; Ma, P.; Zhao, X.; Li, Z. Fabrication of high strength-ductility Mg-3.8Al-1.1Sn-0.4Ca alloy via differential-thermal asymmetric extrusion. J. Alloys Compd. 2024, 1002, 175182. [Google Scholar] [CrossRef]

- Miao, Y.; Wang, C.; Wang, M.; Deng, H.; Ma, P.; Li, Z. Enhanced Mechanical Properties and Isotropy of Mg-2Al-0.8Sn Alloy through Ca Addition. Materials 2021, 14, 7557. [Google Scholar] [CrossRef]

- Singh, A.; Tsai, A. Structural characteristics of β1′ precipitates in Mg–Zn-based alloys. Scr. Mater. 2007, 57, 941–944. [Google Scholar] [CrossRef]

- Bian, M.; Huang, X.; Chino, Y. Substantial improvement in cold formability of concentrated Mg–Al–Zn–Ca alloy sheets by high temperature final rolling. Acta Mater. 2021, 220, 117328. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Xu, T.; Yan, H.; Mao, Y.; Chen, R. Regulating the grain refinement and rolling properties of coarse-crystalline Mg-Zn-Gd-Ca-Mn alloy through multi-pass cold rolling and annealing. Mater. Sci. Eng. A 2024, 911, 146940. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, W.; Chen, W.; Li, Z.; Hou, H.; Zhao, Y. Simultaneously improving thermal conductivity, mechanical properties and metal fluidity through Cu alloying in Mg-Zn-based alloys. J. Magnes. Alloys 2024, 12, 3823–3839. [Google Scholar] [CrossRef]

- Zhang, H.; Ding, Y.; Li, R.; Gao, Y. Enhanced strength-ductility synergy and activation of non-basal slip in as-extruded Mg–Zn–Ca alloy via heterostructure. J. Mater. Res. Technol. 2023, 28, 1841–1851. [Google Scholar] [CrossRef]

- Zhang, H.; Ding, Y.; Li, R.; Shen, Y.; Lei, J. Achieving exceptional improvement of yield strength in Mg–Zn–Ca alloy wire by nanoparticles induced by extreme plastic deformation. Mater. Sci. Eng. A 2022, 853, 143733. [Google Scholar] [CrossRef]

- Zeng, Z.R.; Bian, M.Z.; Xu, S.; Davies, C.H.J.; Birbilis, N.; Nie, J.F. Effects of dilute additions of Zn and Ca on ductility of magnesium alloy sheet. Mater. Sci. Eng. A 2016, 674, 459–471. [Google Scholar] [CrossRef]

- Shi, D.; Ma, A.; Pérez-Prado, M.; Cepeda-Jiménez, C. Activation of second-order pyramidal slip and other secondary mechanisms in solid solution Mg-Zn alloys and their effect on tensile ductility. Acta Mater. 2022, 244, 118555. [Google Scholar] [CrossRef]

- Son, H.-W.; Hyun, S.-K. Dislocation characteristics and dynamic recrystallization in hot deformed AM30 and AZ31 alloys. J. Magnes. Alloys 2022, 10, 3495–3505. [Google Scholar] [CrossRef]

- Wang, Q.; Song, J.; Jiang, B.; Tang, A.; Chai, Y.; Yang, T.; Huang, G.; Pan, F. An investigation on microstructure, texture and formability of AZ31 sheet processed by asymmetric porthole die extrusion. Mater. Sci. Eng. A 2018, 720, 85–97. [Google Scholar] [CrossRef]

- Yang, Q.; Jiang, B.; Pan, H.; Song, B.; Jiang, Z.; Dai, J.; Wang, L.; Pan, F. Influence of different extrusion processes on mechanical properties of magnesium alloy. J. Magnes. Alloys 2014, 2, 220–224. [Google Scholar] [CrossRef]

- Yang, Q.; Jiang, B.; He, J.; Song, B.; Liu, W.; Dong, H.; Pan, F. Tailoring texture and refining grain of magnesium alloy by differential speed extrusion process. Mater. Sci. Eng. A 2014, 612, 187–191. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhang, Z.; Wang, M.; Li, Y.; Cai, J.; Li, Z. Microstructure and mechanical properties of Mg-Al-Sn-Ca alloy extruded by asymmetric severe shear extrusion with different asymmetric coefficients. J. Alloys Compd. 2023, 960, 170884. [Google Scholar] [CrossRef]

- Li, Z.-G.; Miao, Y.; Jia, H.-L.; Zheng, R.; Wang, M.-H.; Wang, H.-Y. Designing a low-alloyed Mg–Al–Sn–Ca alloy with high strength and extraordinary formability by regulating fine grains and unique texture. Mater. Sci. Eng. A 2022, 852, 143687. [Google Scholar] [CrossRef]

- Liu, K.; Fu, J.; Liang, H.; Li, S.; Du, X.; Zhang, Y.; Du, W. Elucidating the dominant role of second phase morphology in corrosion behavior of biodegradable Mg-Zn-Mn-Ca alloys. J. Alloys Compd. 2025, 1020, 179540. [Google Scholar] [CrossRef]

- Fan, Y.; Zhu, G.; Park, J.-S.; Zhang, X.; Song, Z.; Wang, H.; Zeng, X.; Wang, L. The role of Ca on the microstructure and tensile properties of Mg-Al-Zn-Ca alloys. Materialia 2023, 29, 101787. [Google Scholar] [CrossRef]

- Takeuchi, A.; Inoue, A. Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element. Mater. Trans. 2005, 46, 2817–2829. [Google Scholar] [CrossRef]

- Zhang, S.-Y.; Wang, C.; Zhao, L.-Q.; Ma, P.-K.; Song, J.-W.; Xu, J.; Cheng, X.-M.; Wang, H.-Y. Superplastic Deformation Behavior of Rolled Mg-8Al-2Sn and Mg-8Al-1Sn-1Zn Alloys at High Temperatures. Materials 2020, 13, 1074. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Guo, Z.-P.; Zhang, P.-Y.; Zhou, Y.; Ma, P.-K. Influence of Texture on the Mechanical Properties of a Mg-6Al-1Zn-0.9Sn Alloy Processed by ECAP. Materials 2021, 14, 2664. [Google Scholar] [CrossRef]

- Ma, C.-Y.; Xia, N.; Wang, C.; Li, M.-X.; Hua, Z.-M.; Ren, M.-W.; Wang, H.-Y. A novel Mg-5Al-2Zn-2Sn alloy with high strength-ductility synergy fabricated via simple hot rolling and annealing treatment. J. Alloys Compd. 2021, 869, 159308. [Google Scholar] [CrossRef]

- Ma, X.; Huang, C.; Moering, J.; Ruppert, M.; Höppel, H.W.; Göken, M.; Narayan, J.; Zhu, Y. Mechanical properties of copper/bronze laminates: Role of interfaces. Acta Mater. 2016, 116, 43–52. [Google Scholar] [CrossRef]

- Pan, H.; Kang, R.; Li, J.; Xie, H.; Zeng, Z.; Huang, Q.; Yang, C.; Ren, Y.; Qin, G. Mechanistic investigation of a low-alloy Mg–Ca-based extrusion alloy with high strength–ductility synergy. Acta Mater. 2020, 186, 278–290. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).