Combined Approach to the Synthesis of WC-(Fe, Ni) Hard Alloys: Mechanical Activation and Spark Plasma Sintering

Abstract

1. Introduction

- -

- synthesis of cobalt-free hard alloys WC/Ni, WC/Fe, and WC/Fe-Ni using the SPS method;

- -

- comprehensive study of the influence of binder composition and WC grain size on the densification, microstructure, and hardness of the obtained composites.

2. Materials and Methods

3. Results and Discussion

- -

- stability of WC as the main solid phase;

- -

- formation of γ-phase plastic (Fe, Ni) as an effective binder;

- -

- elimination of η-phase in optimally ground and sintered systems;

- -

- absence of secondary carbides with the correct choice of Fe/Ni ratio and sintering mode.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shichalin, O.; Buravlev, I.; Papynov, E.; Buravleva, A.; Sakhnevich, V.; Dvornik, M.; Vlasova, N.; Gerasimenko, A.; Reva, V.; Yudakov, A. Comparative study of WC-based hard alloys fabrication via spark plasma sintering using Co, Fe, Ni, Cr, and Ti binders. Int. J. Refract. Met. Hard Mater. 2022, 102, 105725. [Google Scholar] [CrossRef]

- Schubert, W.D.; Lassner, E. Cemented Carbides—A Success Story. ITIA Newsletter. 2010. Available online: https://www.itia.info/assets/files/Newsletter_2010_06.pdf (accessed on 13 September 2019).

- García, J.; Ciprés, V.C.; Blomqvist, A.; Kaplan, B. Cemented carbide microstructures: A review. Int. J. Refract. Met. Hard Mater. 2019, 80, 40–68. [Google Scholar] [CrossRef]

- Zeiler, B. Tungsten and cobalt, the two key elements of the hardmetal industry. In Proceedings of the 11th International Conference on the Science of Hard Materials, Khao Lak, Thailand, 25–29 March 2019. [Google Scholar]

- Vilhena, L.; Domingues, B.; Fernandes, C.; Senos, A.; Ramalho, A. Mechanical and Tribological Characterization of WC-Co and WC-AISI 304 Composites by a Newly Developed Equipment. Materials 2022, 15, 1187. [Google Scholar] [CrossRef]

- Fang, Z.Z.; Koopman, M.C.; Wang, H.T. Cemented tungsten carbide hardmetal—An introduction. In Comprehensive Hard Materials; Mari, D., Llanes, L., Sarin, V.K., Eds.; Elsevier: Oxford, UK, 2014; pp. 123–138. [Google Scholar] [CrossRef]

- Prakash, L. Introduction to hardmetals—Fundamentals and general applications of hardmetals. In Comprehensive Hard Materials; Mari, D., Llanes, L., Sarin, V.K., Eds.; Elsevier: Oxford, UK, 2014; pp. 29–90. [Google Scholar] [CrossRef]

- Krawitz, A.; Drake, E. Residual stresses in cemented carbides—An overview. Int. J. Refract. Met. Hard Mater. 2015, 49, 27–35. [Google Scholar] [CrossRef]

- Krawitz, A.D.; Drake, E.F. Residual stresses. In Comprehensive Hard Materials; Mari, D., Llanes, L., Sarin, V.K., Eds.; Elsevier: Oxford, UK, 2014; pp. 385–404. [Google Scholar] [CrossRef]

- Straumal, B.B.; Shchur, L.N.; Kagramanyan, D.G.; Konstantinova, E.P.; Druzhinin, A.V.; Nekrasov, A.N. Topology of WC/Co Interfaces in Cemented Carbides. Materials 2023, 16, 5560. [Google Scholar] [CrossRef]

- Sverdrup, H.U.; Ragnarsdottir, K.V.; Koca, D. Integrated modelling of the global cobalt extraction, supply, price and depletion of extractable resources using the World6 model. BioPhys. Econ. Resour. Qual. 2017, 2, 4. [Google Scholar] [CrossRef]

- Baklanov, V.; Zhanbolatova, G.; Skakov, M.; Miniyazov, A.; Sokolov, I.; Tulenbergenov, T.; Kozhakhmetov, Y.; Bukina, O.; Orazgaliev, N. Study of the Temperature Dependence of a Carbidized Layer Formation on the Tungsten Surface under Plasma Irradiation. Mater. Res. Express 2022, 9, 016403. [Google Scholar] [CrossRef]

- Skakov, M.; Kozhakhmetov, Y.; Mukhamedova, N.; Miniyazov, A.; Sokolov, I.; Urkunbay, A.; Zhanbolatova, G.; Tulenbergenov, T. Effect of a High-Temperature Treatment on Structural-Phase State and Mechanical Properties of IMC of the Ti-25Al-25Nb at.% System. Materials 2022, 15, 5560. [Google Scholar] [CrossRef] [PubMed]

- Skakov, M.; Miniyazov, A.; Batyrbekov, E.; Baklanov, V.; Koyanbayev, Y.; Gradoboev, A.; Kozhakhmetov, Y.; Sokolov, I.; Tulenbergenov, T.; Zhanbolatova, G. Influence of the Carbidized Tungsten Surface on the Processes of Interaction with Helium Plasma. Materials 2022, 15, 7821. [Google Scholar] [CrossRef]

- Zhanbolatova, G.K.; Baklanov, V.V.; Skakov, M.K.; Sokolov, I.A.; Bukina, O.S.; Kozhakhmetov, Y.A.; Orazgaliev, N.A. Influence of Temperature on Tungsten Carbide Formation in a Beam Plasma Discharge. J. Phys. Conf. Ser. 2021, 2064, 012055. [Google Scholar] [CrossRef]

- Arato, P.; Bartha, L.; Porat, R.; Berger, S.; Rosen, A. Solid or liquid phase sintering of nanocrystalline WC/Co hardmetals. Nanostruct. Mater. 1998, 10, 245–255. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Wang, D.; Nie, L.; Wellmann, D.; Tian, Y. Additive manufacturing of WC-Co hardmetals: A review. Int. J. Refract. Met. Hard Mater. 2020, 108, 1653–1673. [Google Scholar] [CrossRef]

- Wei, C.; Song, X.; Zhao, S.; Zhang, L.; Liu, W. In-situ synthesis of WC–Co composite powder and densification by sinter-HIP. Int. J. Refract. Met. Hard Mater. 2010, 28, 567–571. [Google Scholar] [CrossRef]

- Spalden, M.V.; Pötschke, J.; Michaelis, A. Novel Alternative Ni-Based Binder Systems for Hardmetals. Crystals 2024, 14, 1013. [Google Scholar] [CrossRef]

- Shichalin, O.O.; Buravlev, I.Y.; Portnyagin, A.S.; Dvornik, M.I.; Mikhailenko, E.A.; Golub, A.V.; Zakharenko, A.M.; Sukhorada, A.E.; Talskikh, K.Y.; Buravleva, A.A.; et al. SPS hard metal alloy WC-8Ni-8Fe fabrication based on mechanochemical synthetic tungsten carbide powder. J. Alloys Compd. 2020, 816, 152547. [Google Scholar] [CrossRef]

- Li, H.; Zhang, H.; Jiang, Z. Investigation of the Effect of Partial Co Substitution by Ni and Fe on the Interface Bond Strength of WC Cemented Carbide Based on First-Principles Calculations. Mater. Today Commun. 2024, 40, 109470. [Google Scholar] [CrossRef]

- Sten, S.; Odqvist, J.; Norgren, S.M.; Hedström, P. Functional-Gradient WC-TiC Cemented Carbides with Alternative Binders (Ni and Fe). Int. J. Refract. Met. Hard Mater. 2025, 131, 107214. [Google Scholar] [CrossRef]

- Degeneve, L.; Mari, D.; Machado, P.V.S.; Jimenez-Piqué, E. Cyclic Loading of WC-Ni by FEM with a Realistic 3D Morphology. Int. J. Refract. Met. Hard Mater. 2025, 128, 107085. [Google Scholar] [CrossRef]

- Kurbanbekov, S.; Kozhakhmetov, Y.; Skakov, M.; Seitov, B.; Aidarova, M.; Tabiyeva, Y. Properties, Advantages, and Prospects of Using Cobalt-Free Composites Based on Tungsten Carbide in Industry. Materials 2025, 18, 129. [Google Scholar] [CrossRef]

- Chang, S.H.; Chen, S.L. Characterization and properties of sintered WC–Co and WC–Ni–Fe hard metal alloys. J. Alloys Compd. 2014, 585, 407–413. [Google Scholar] [CrossRef]

- Schubert, W.D.; Fugger, M.; Wittmann, B.; Useldinger, R. Aspects of sintering of cemented carbides with Fe-based binders. Int. J. Refract. Met. Hard Mater. 2015, 49, 110–123. [Google Scholar] [CrossRef]

- Konyashin, I.; Lachmann, F.; Ries, B.; Mazilkin, A.A.; Straumal, B.; Kübel, C.; Llanes, L.; Baretzky, B. Strengthening zones in the Co matrix of WC–Co cemented carbides. Scr. Mater. 2014, 83, 17–20. [Google Scholar] [CrossRef]

- Sun, J.; Huang, Z.; Zhao, J. High-hard and high-tough WC-TiC-Co cemented carbide reinforced with graphene. Mater. Today Commun. 2021, 29, 102841. [Google Scholar] [CrossRef]

- Xie, Z.P.; Li, S.; An, L.N. A novel oscillatory pressure-assisted hot pressing for preparation of high-performance ceramics. J. Am. Ceram. Soc. 2014, 97, 1012–1015. [Google Scholar] [CrossRef]

- Raihanuzzaman, R.M.; Rosinski, M.; Xie, Z.; Ghomashchi, R. Microstructure and Mechanical Properties of Pulse Plasma Compacted WC–Co. Int. J. Refract. Met. Hard Mater. 2016, 60, 58–67. [Google Scholar] [CrossRef]

- Siwak, P.; Garbiec, D. Microstructure and Mechanical Properties of WC–Co, WC–Co–Cr3C2 and WC–Co–TaC Cermets Fabricated by Spark Plasma Sintering. Trans. Nonferrous Met. Soc. China 2016, 26, 2641–2646. [Google Scholar] [CrossRef]

- Liu, K.; Wang, Z.; Yin, Z.; Cao, L.; Yuan, J. Effect of Co Content on Microstructure and Mechanical Properties of Ultrafine-Grained WC–Co Cemented Carbide Sintered by Spark Plasma Sintering. Ceram. Int. 2018, 44, 18711–18718. [Google Scholar] [CrossRef]

- Munir, Z.A.; Ohyanagi, M. Perspectives on the Spark Plasma Sintering Process. J. Mater. Sci. 2021, 56, 1–15. [Google Scholar] [CrossRef]

- Papynov, E.K.; Shichalin, O.O.; Medkov, M.A.; Grishchenko, D.N.; Tkachenko, I.A.; Fedorets, A.N.; Pechnikov, V.S.; Golub, A.V.; Buravlev, I.Y.; Tananaev, I.G.; et al. Spark Plasma Sintering of Special-Purpose Functional Ceramics Based on UO2, ZrO2, Fe3O4/α-Fe2O3. Glas. Phys. Chem. 2018, 44, 632–640. [Google Scholar] [CrossRef]

- Samokhin, A.; Alekseev, N.; Astashov, A.; Dorofeev, A.; Fadeev, A.; Sinayskiy, M.; Kalashnikov, Y. Preparation of W–C–Co Composite Micropowder with Spherical-Shaped Particles Using Plasma Technologies. Materials 2021, 14, 4258. [Google Scholar] [CrossRef] [PubMed]

- Morsi, K. Combustion Synthesis and the Electric Field: A Review. Int. J. Self-Propagating High-Temp. Synth. 2017, 26, 199–209. [Google Scholar] [CrossRef]

- Ritchie, S.M.; Kovacevic, S.; Deshmukh, P.; Christodoulides, A.D.; Malen, J.A.; Mesarovic, S.D.; Panat, R.P. Shape Distortion in Sintering Results from Nonhomogeneous Temperature Activating a Long-Range Mass Transport. Nat. Commun. 2023, 14, 2667. [Google Scholar] [CrossRef] [PubMed]

- Dvornik, M.I.; Zaitsev, A.V. Variation in Strength, Hardness, and Fracture Toughness in Transition from Medium-Grained to Ultrafine Hard Alloy. Russ. J. Non-Ferrous Met. 2018, 27, 3610–3618. [Google Scholar] [CrossRef]

- Pan, Y.; Liu, A.; Huang, L.; Du, Y.; Jin, Y.; Yang, X.; Zhang, J. Effects of Metal Binder Content and Carbide Grain Size on the Microstructure and Properties of SPS Manufactured WC–Fe Composites. J. Alloys Compd. 2019, 784, 519–526. [Google Scholar] [CrossRef]

- Li, C.W.; Chang, K.C.; Yeh, A.C. On the Microstructure and Properties of an Advanced Cemented Carbide System Processed by Selective Laser Melting. J. Alloys Compd. 2019, 782, 440–450. [Google Scholar] [CrossRef]

- Zhang, R.; Chen, B.; Liu, F.; Sun, M.; Zhang, H.; Wu, C. Microstructure and Mechanical Properties of Composites Obtained by Spark Plasma Sintering of Ti3SiC2-15 vol.%Cu Mixtures. Materials 2022, 15, 2515. [Google Scholar] [CrossRef]

- Coëffe-Desvaux, M.; Pradeilles, N.; Marchet, P.; Vandenhende, M.; Joinet, M.; Maître, A. Comparative Study on Electrical Conductivity of CeO2-Doped AlN Ceramics Sintered by Hot-Pressing and Spark Plasma Sintering. Materials 2022, 15, 2399. [Google Scholar] [CrossRef] [PubMed]

- Grigoriev, S.; Smirnov, A.; Pinargote, N.W.S.; Yanushevich, O.; Kriheli, N.; Kramar, O.; Pristinskiy, Y.; Peretyagin, P. Evaluation of Mechanical and Electrical Performance of Aging Resistance ZTA Composites Reinforced with Graphene Oxide Consolidated by SPS. Materials 2022, 15, 2419. [Google Scholar] [CrossRef]

- Medved’, D.; Andrejovská, J.; Puchý, V. Mechanical and Tribological Properties of SPS-Sintered Y-TZP: The Effect of Sintering Temperature. Crystals 2025, 15, 593. [Google Scholar] [CrossRef]

- Rahmani, R.; Lopes, S.I.; Prashanth, K.G. Selective Laser Melting and Spark Plasma Sintering: A Perspective on Functional Biomaterials. J. Funct. Biomater. 2023, 14, 521. [Google Scholar] [CrossRef]

- Zhu, Y.; Liu, Y.; Meng, Z.; Tian, J. Microstructure, Mechanical Properties, and Electrochemical Corrosion Behavior of CoCrFeNiNb and CoCrFeNiV High-Entropy Alloys Prepared via Mechanical Alloying and Spark Plasma Sintering. Metals 2025, 15, 814. [Google Scholar] [CrossRef]

- Zeng, X.; Wang, R.; Tian, X.; Liu, Y. Corrosion Resistance Mechanism in WC/FeCrNi Composites: Decoupling the Role of Spherical Versus Angular WC Morphologies. Metals 2025, 15, 777. [Google Scholar] [CrossRef]

- Bochenek, D. A Combination of Calcination and the Spark Plasma Sintering Method in Multiferroic Ceramic Composite Technology: Effects of Process Temperature and Dwell Time. Materials 2022, 15, 2524. [Google Scholar] [CrossRef] [PubMed]

- Uhrenius, B.; Sundman, B.; Agren, J. Equilibrium Phase Diagrams for WC–Co–Fe–Ni Alloys. Int. J. Refract. Met. Hard Mater. 1997, 15, 17–23. [Google Scholar]

- Kozhakhmetov, E.A.; Mukhamedova, N.M.; Miniyazov, A.Z.; Urkunbay, A.S. Optimization of a Method for High-Energy Grinding of Powder Mixtures of the Ti-Al-Nb System in the Presence of Stearic Acid and Toluene. NNC RK Bull. 2023, 3, 81–90. (In Russian) [Google Scholar] [CrossRef]

- Straumal, B.; Konyashin, I. WC-Based Cemented Carbides with High Entropy Alloyed Binders: A Review. Metals 2023, 13, 171. [Google Scholar] [CrossRef]

- Da Silva, R.M.; Mucino, M.A.; Freitas, I.M.; Lima, S.F.; Mariano, N.A. Spark Plasma Sintering and Characterization of WC–Fe–Ni Cemented Carbides. Int. J. Refract. Met. Hard Mater. 2021, 99, 105535. [Google Scholar]

- Fernandes, C.; Silva, R.M.; Vieira, M.T.; Silva, F.S. Structure and Mechanical Properties of WC–Ni and WC–Ni–Cr Cemented Carbides. Int. J. Refract. Met. Hard Mater. 2009, 27, 717–721. [Google Scholar]

- ISO 3369:2006; Impermeable Sintered Metal Materials and Hardmetals—Determination of Density. ISO: Geneva, Switzerland, 2006.

| Chemical Composition of Powders, at.% | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fe | Cr | Bi | Al | Zn | Mn | Cu | Co | Ca | Ni | C | S | O |

| 0.002 | 0.001 | 0.001 | 0.002 | 0.002 | 0.001 | 0.003 | 0.001 | 0.002 | 0.002 | 0.001 | 0.0005 | |

| Ni | Si | Fe | Zr | |||||||||

| 0.003 | 0.001 | 0.001 | 0.002 | 0.001 | 0.025 | 0.002 | ||||||

| WC | B | F | ||||||||||

| 0.001 | 0.003 | 0.002 | 0.001 | 0.001 | 0.003 | 0.004 | 0.002 | 0.002 | 0.003 | 0.001 | ≤0.040 | |

| Sample Name | Time, min | Rotation Speed, rpm | Environment |

|---|---|---|---|

| Mixing powder mixtures | 20 | 200 | Argon |

| Mechanosynthesis | |||

| Sample 1 88WC-6Fe-6Ni at.% | 60 | 500 | Argon |

| 120 | |||

| 240 | |||

| Sample 2 85WC-7.5Fe-7.5Ni at.% | 60 | ||

| 120 | |||

| 240 | |||

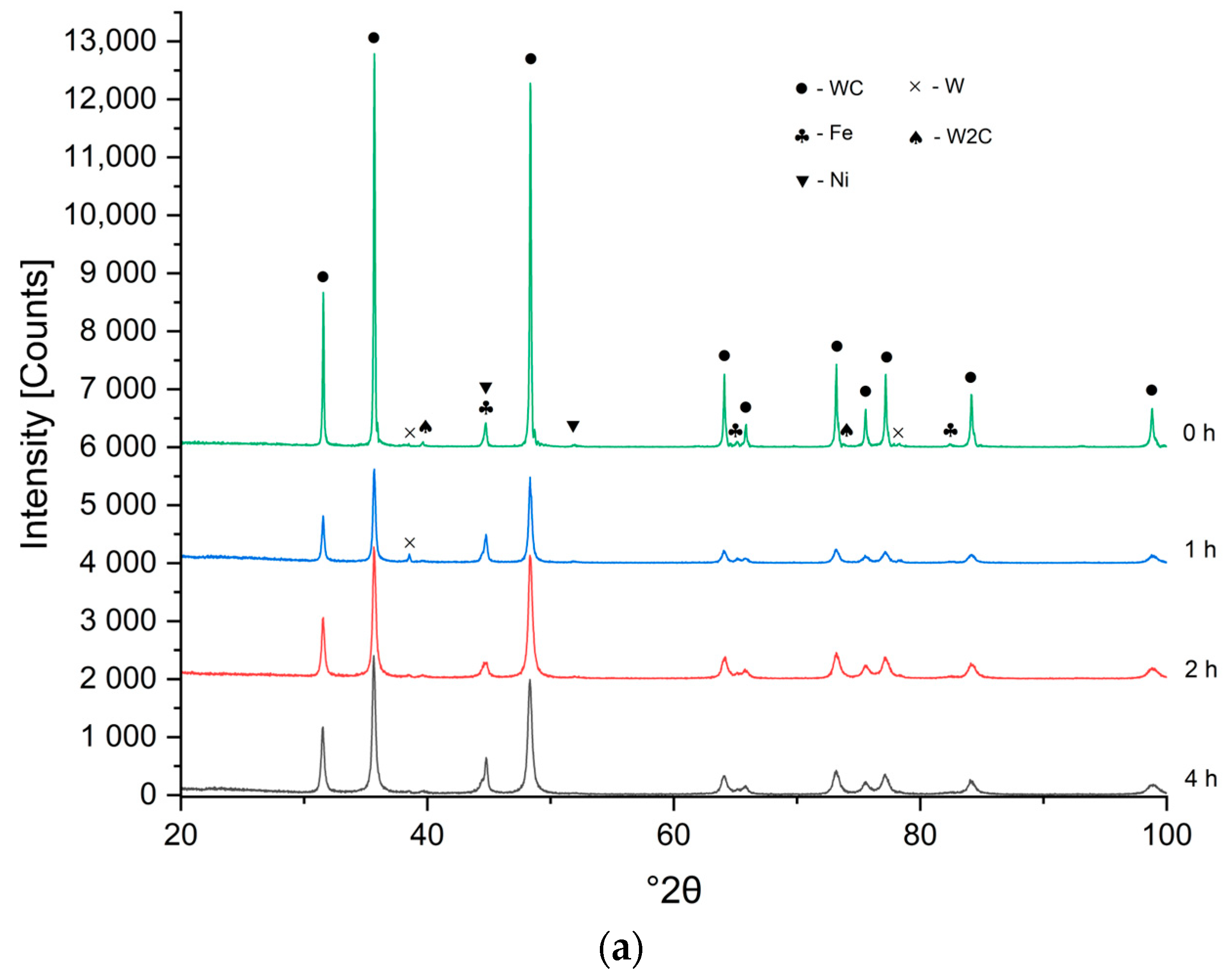

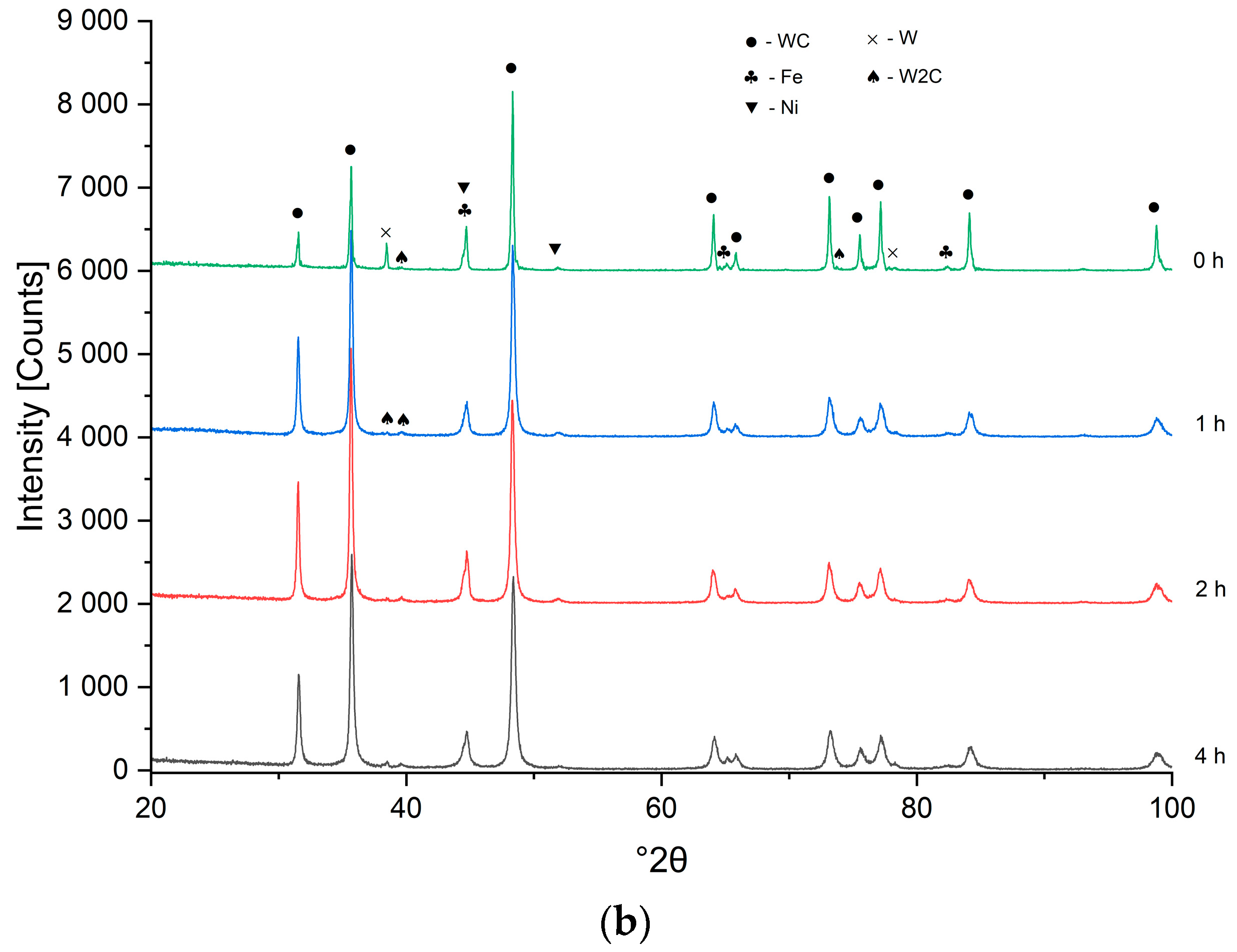

| WC88Ni6Fe6 | WC85Ni7.5Fe7.5 | ||||

|---|---|---|---|---|---|

| Milling time | Lattice strain [%] | Crystallite size [Å] | Milling time | Lattice strain [%] | Crystallite size [Å] |

| 0 h | 0.185 | 517 | 0 h | 0.196 | 489 |

| 1 h | 0.28 | 295 | 1 h | 0.277 | 282 |

| 2 h | 0.325 | 280 | 2 h | 0.318 | 253 |

| 4 h | 0.35 | 265 | 4 h | 0.358 | 222 |

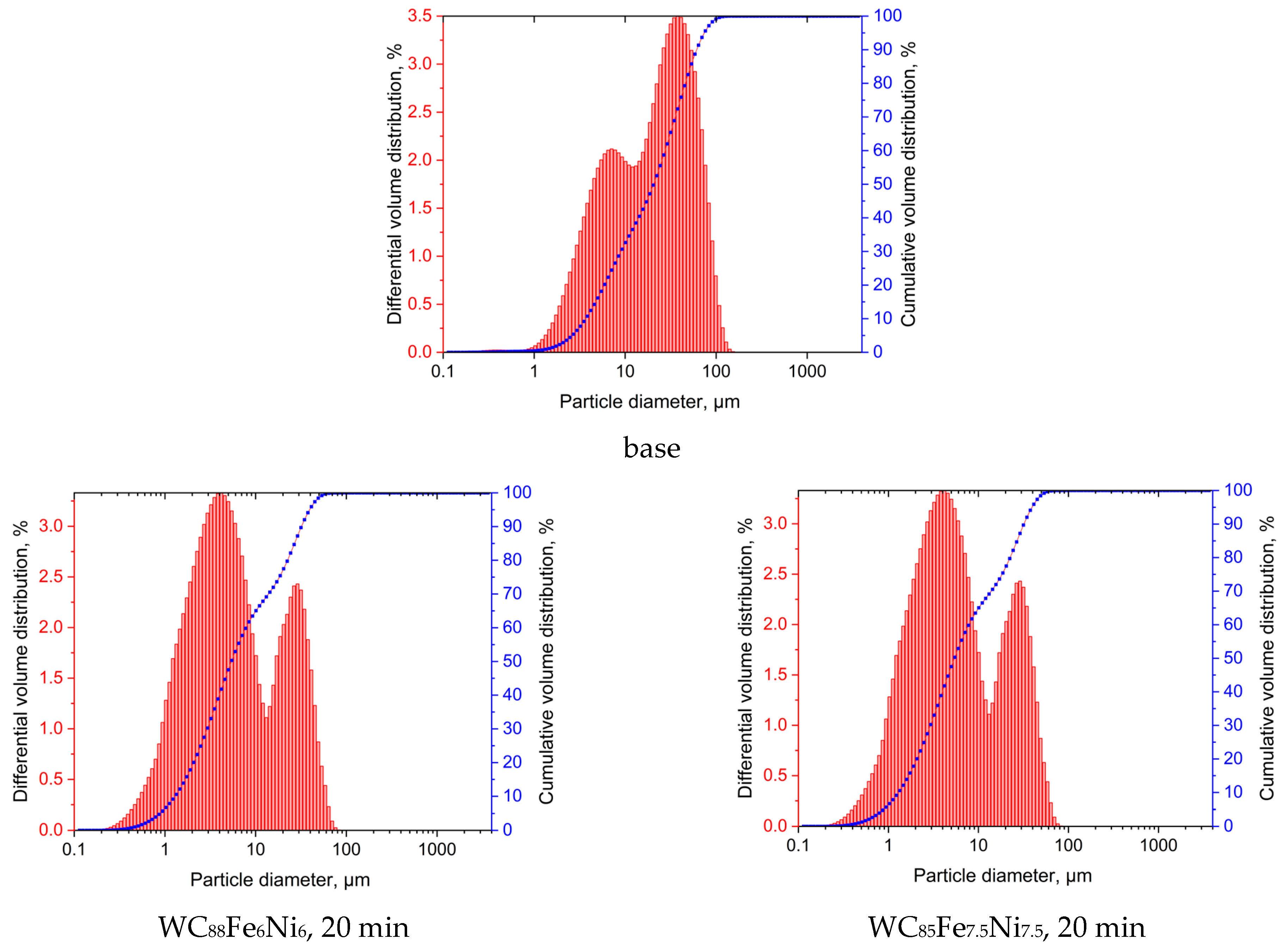

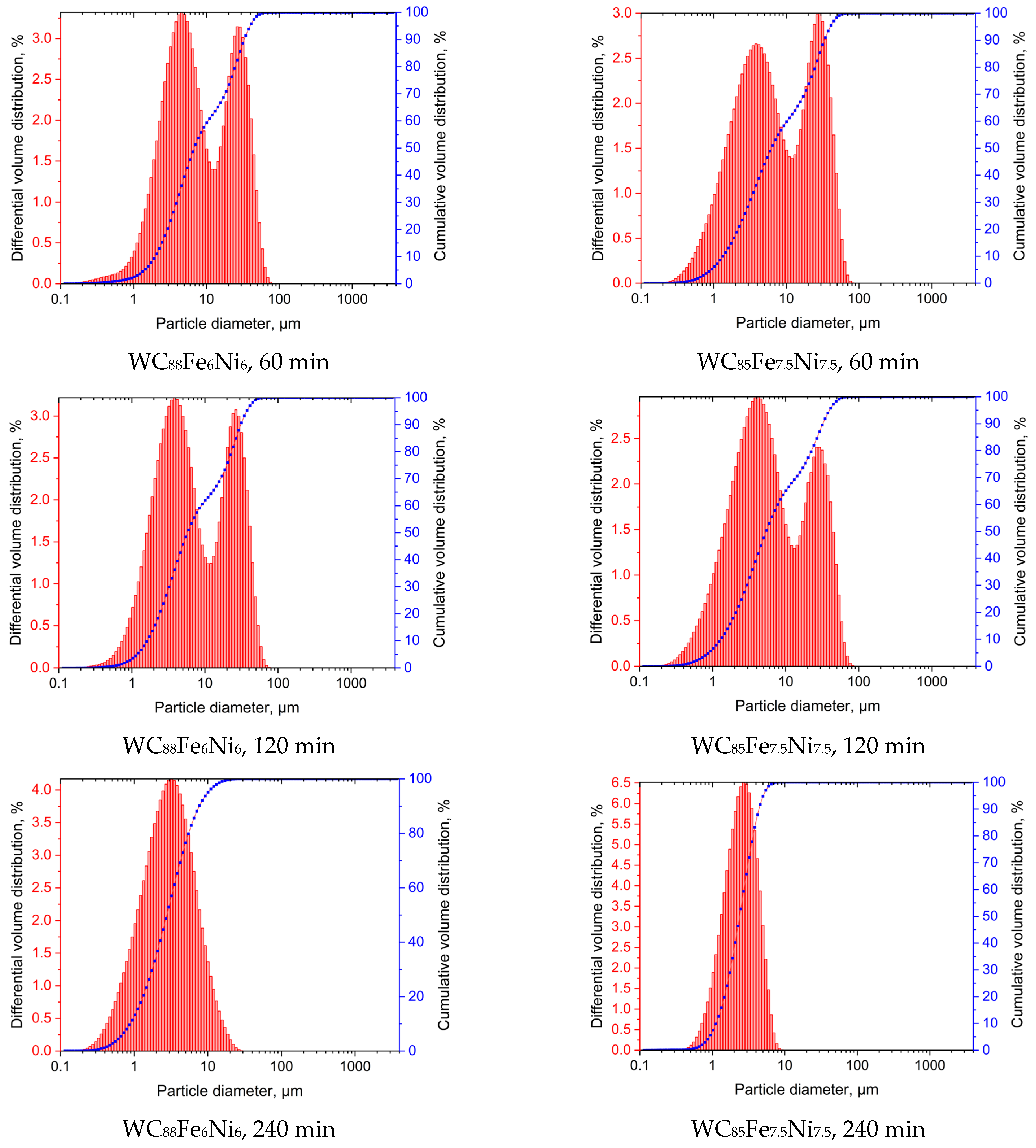

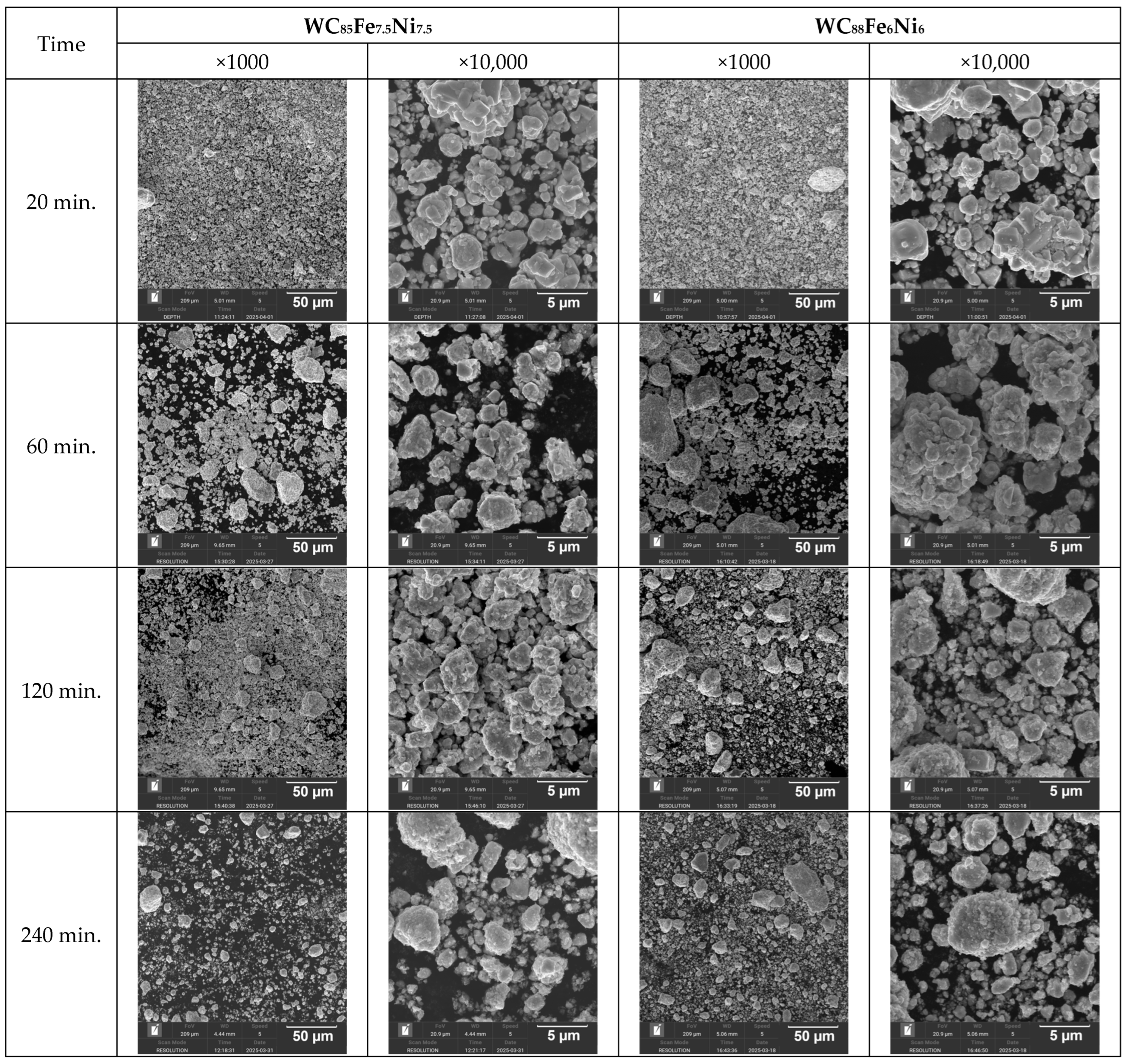

| Duration of the Process | WC88Ni6Fe6 | WC85Ni7.5Fe7.5 |

|---|---|---|

| initial | 27.25 ± 5.66 microns | |

| 20 min | 9.5 +/− 0.45 microns | 9.82 +/− 0.11 microns |

| 60 min | 13.7 +/− 0.53 microns | 13.42 +/− 0.18 microns |

| 120 min | 12.57 +/− 0.39 microns | 12.02 +/− 0.22 microns |

| 240 min | 3.96 +/− 0.25 microns | 2.71 +/− 0.03 microns |

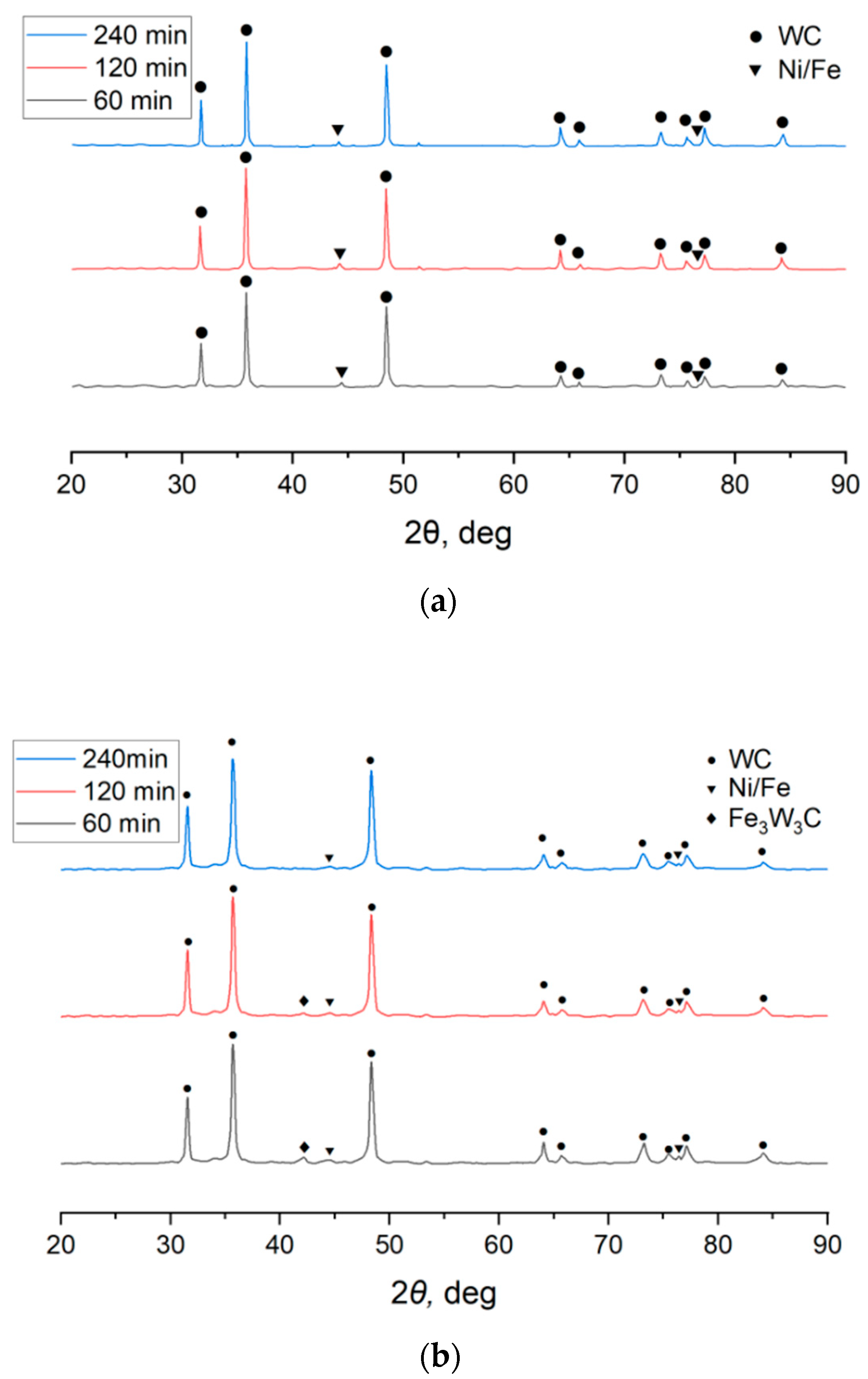

| Sample | Grinding Time (min) | Main Phase | Metal Matrix | Presence of η-Phase (Fe3W3C) | Homogeneity of Phases |

|---|---|---|---|---|---|

| WC85Fe7.5Ni7.5 | 60 | WC | γ-(Fe,Ni) | Presence | low |

| WC85Fe7.5Ni7.5 | 120 | WC | γ-(Fe,Ni) | Traces of the presence | average |

| WC85Fe7.5Ni7.5 | 240 | WC | γ-(Fe,Ni) | No η-phase | high |

| WC88Fe6Ni6 | 60 | WC | γ-(Fe,Ni) | No η-phase | average |

| WC88Fe6Ni6 | 120 | WC | γ-(Fe,Ni) | No η-phase | high |

| WC88Fe6Ni6 | 240 | WC | γ-(Fe,Ni) | No η-phase | high |

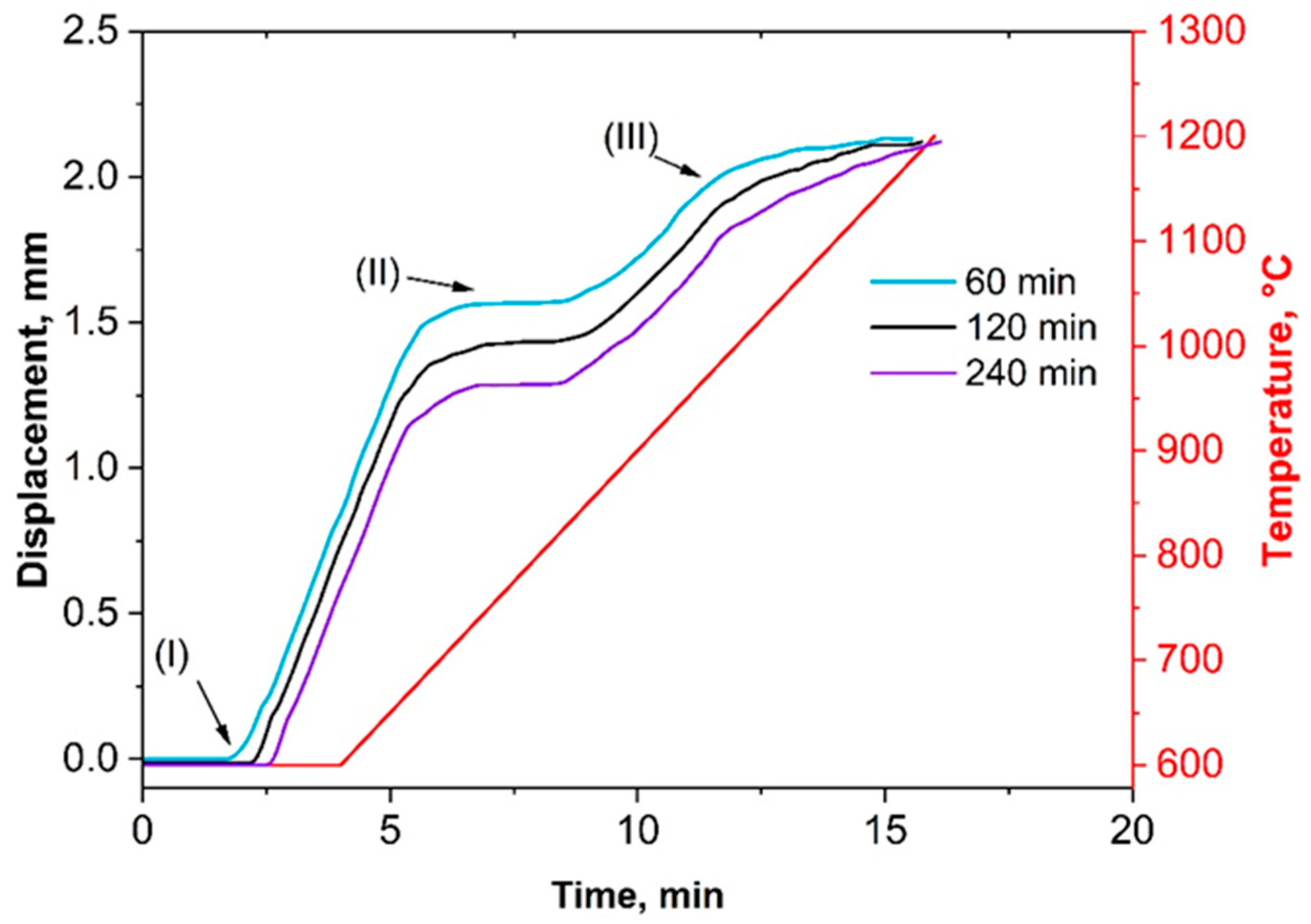

| Sample | Grinding Time (min) | Theoretical Density, g/cm3 | Measured Density, g/cm3 | Relative Density, % |

|---|---|---|---|---|

| WC85Fe7.5Ni7.5 | 60 | 14.5 | 13.8 | 95.2 |

| WC85Fe7.5Ni7.5 | 120 | 14.5 | 14.0 | 96.6 |

| WC85Fe7.5Ni7.5 | 240 | 14.5 | 14.2 | 97.9 |

| WC88Fe6Ni6 | 60 | 14.7 | 14.1 | 95.9 |

| WC88Fe6Ni6 | 120 | 14.7 | 14.3 | 97.3 |

| WC88Fe6Ni6 | 240 | 14.7 | 14.5 | 98.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uazyrkhanova, G.; Kozhakhmetov, Y.; Aidarova, M.; Rutkowska-Gorczyca, M.; Tabiyeva, Y. Combined Approach to the Synthesis of WC-(Fe, Ni) Hard Alloys: Mechanical Activation and Spark Plasma Sintering. Crystals 2025, 15, 724. https://doi.org/10.3390/cryst15080724

Uazyrkhanova G, Kozhakhmetov Y, Aidarova M, Rutkowska-Gorczyca M, Tabiyeva Y. Combined Approach to the Synthesis of WC-(Fe, Ni) Hard Alloys: Mechanical Activation and Spark Plasma Sintering. Crystals. 2025; 15(8):724. https://doi.org/10.3390/cryst15080724

Chicago/Turabian StyleUazyrkhanova, Gulzhaz, Yernat Kozhakhmetov, Madina Aidarova, Małgorzata Rutkowska-Gorczyca, and Yerkezhan Tabiyeva. 2025. "Combined Approach to the Synthesis of WC-(Fe, Ni) Hard Alloys: Mechanical Activation and Spark Plasma Sintering" Crystals 15, no. 8: 724. https://doi.org/10.3390/cryst15080724

APA StyleUazyrkhanova, G., Kozhakhmetov, Y., Aidarova, M., Rutkowska-Gorczyca, M., & Tabiyeva, Y. (2025). Combined Approach to the Synthesis of WC-(Fe, Ni) Hard Alloys: Mechanical Activation and Spark Plasma Sintering. Crystals, 15(8), 724. https://doi.org/10.3390/cryst15080724