Abstract

Microwave dielectric ceramics are indispensable in modern communication technologies, playing a pivotal role in components such as filters, oscillators, and antennas. Among these materials, ZnAl2O4 ceramics have garnered attention for their excellent quality factor (Q × f) and low dielectric constant (εr). However, their high sintering temperature (~1650 °C) limits practical applications. This study investigates ZnAl2-x(Zn0.5Si0.5)xO4 (ZAZS) (x = 0.1–0.9) ceramics, where [Zn0.5Si0.5]3+ substitutes Al3+, to reduce sintering temperature while maintaining high-performance microwave dielectric properties. ZAZS ceramics were synthesized via the solid-state reaction method and characterized for their structural, morphological, and dielectric properties. X-ray diffraction analysis confirmed the formation of a single-phase solid solution up to x = 0.8, with minor secondary phases appearing at x = 0.9. The substitution increased lattice parameters and enhanced material densification, as observed through SEM and relative density calculations. Microwave dielectric measurements showed that ZAZS ceramics achieved a maximum Q × f of 20,200 GHz and a τf value reduced to −62 ppm/°C at x = 0.8, while εr decreased from 7.90 to 6.98. Bond-valence calculations reveal that the reduction of the average Al/Zn/Si–O bond valence weakens octahedral rigidity, systematically tuning τf toward zero. These results demonstrate that ZAZS ceramics, with a reduced sintering temperature of 1400 °C, exhibit excellent potential for application in low-loss microwave devices.

1. Introduction

With the rapid progress of smart homes, smart cars, and various intelligent devices, microwave dielectric materials—integral to ensuring effective communication—have attracted substantial interest. Among these, microwave dielectric ceramics serve as the foundation for microwave frequency communication technologies [1]. These ceramics are essential in the production of high-performance microwave components, such as filters, oscillators, and antennas, which are critical for modern communication systems [2]. Due to their reliable and consistent microwave dielectric properties, these ceramics are widely employed in contemporary communication applications, especially within microwave technology [3]. Their distinctive features make them indispensable for facilitating high-efficiency and precise communication systems. The primary performance metrics of microwave dielectric ceramics include the relative permittivity (εr), the quality factor (Q × f) in relation to the resonant frequency, and the temperature coefficient of resonant frequency (τf) [4]. These parameters offer a comprehensive assessment of the material’s performance and are vital in determining the appropriateness of microwave dielectric ceramics for various applications. A thorough understanding and optimization of these properties are crucial for advancing communication technologies and addressing the growing demands of modern smart systems [5].

ZnAl2O4 ceramic, characterized by its spinel structure and Fd-3m space group, was initially introduced in earlier studies and continues to attract scientific attention due to its high quality factor and the use of relatively inexpensive raw materials [6,7,8]. This ceramic exhibits a low dielectric constant (εr ≈ 8.5), a high Q × f (approximately 57,000 GHz), and a significantly negative temperature coefficient of resonant frequency (τf ≈ –79 ppm/°C), which far exceeds the ±10 ppm/°C range required for practical microwave device applications [9]. Such properties indicate that ZnAl2O4 is a strong candidate for low-loss microwave dielectric applications. Nevertheless, the high sintering temperature of 1650 °C poses a challenge for its practical implementation. Hence, the primary objective of this study is to lower the sintering temperature of the ZnAl2O4 ceramic without substantially compromising its quality factor.

Song et al. [10] demonstrated that the Al3+ site in BaAl2Si2O8 ceramics could be successfully doped with [Zn0.5Si0.5]3+ ions, which also enabled a reduction in the sintering temperature from 1475 °C to 1000 °C. In the present study, [Zn0.5Si0.5]3+ ions were used to substitute for the Al3⁺ site in ZnAl2O4 ceramics, forming ZnAl2-x(Zn0.5Si0.5)xO4 (abbreviated as ZAZS), with the sintering temperature lowered to 1400 °C. Compared with conventional materials, ZAZS ceramics offer a tunable τf value, relatively high Q × f, and chemical/environmental stability. Moreover, the spinel structure allows for easier cation substitution at octahedral sites, facilitating tailored dielectric properties without introducing secondary phases. The surface morphologies, microwave dielectric properties, and lattice structure of ZAZS were thoroughly investigated.

2. Materials and Methods

The ZAZS ceramics (with x ranging from 0.1 to 0.9) were prepared via a solid-state reaction. Initially, stoichiometric amounts of ZnO (99.0%, Shanghai Test Chemical Reagent Co., Ltd., Shanghai, China), Al2O3 (98.5%, Anmai Chemical Reagent Co., Ltd., Qingdao China), and SiO2 (99.0%, China National Pharmaceutical Group Corporation, Beijing, China) were mixed using ball milling with deionized water for 5 hours. After drying, the powder was calcined at 1100 °C for 3 h. The resulting calcined powder was then blended with 10% polyvinyl alcohol (PVA, Aladdin Reagent Co., Ltd., Shanghai, China) and passed through a 40-mesh sieve. The granulated mixture was pressed into disks (10 mm in diameter and approximately 5 mm thick), and subsequently the samples were sintered at temperatures ranging from 1350 °C to 1550 °C. The sintering process was conducted in an electric box-type furnace for 6 hours. After reaching the target temperature, the samples were cooled at a rate of 1 °C/min down to 1000 °C, followed by 2 °C/min down to 800 °C, and finally furnace-cooled to room temperature. Among all samples with compositions ranging from x = 0.1 to 0.8, the sample with x = 0.8 exhibited the lowest dielectric loss. For this composition, the Q × f increased from 14,700 GHz at 1350 °C to a maximum of 20,200 GHz at 1400 °C, but it significantly decreased to 4299 GHz at 1550 °C. Therefore, 1400 °C was selected as the optimal sintering temperature for all compositions to ensure the best overall microwave dielectric performance.

The crystalline structures of the ZAZS ceramics were examined using a Shimadzu XRD-7000 X-ray diffractometer (Shimadzu, Kyoto, Japan), and the lattice parameters were determined via the GSAS software [11]. Raman spectroscopy is a high-precision technique for probing the local structure of materials [12,13]. In this study, Raman analysis was employed to assess how varying concentrations of [Zn0.5Si0.5]3+ in the ZAZS ceramics influence their intrinsic dielectric properties. According to group theory, the spinel structure has 42 vibrational degrees of freedom, which can be decomposed into the following irreducible representations [14,15,16]:

where the symbols R and IR denote Raman-active and infrared-active vibrational modes, respectively, while the remaining modes are silent. Notably, the ideal spinel structure exhibits only five Raman-active modes with the following wavenumber order: T2g(1) < Eg < T2g(2) < T2g(3) < A1g. However, structural disorder and vacancies can relax the Raman selection rules, giving rise to additional phonon modes that are not predicted by group theory. Raman spectra were acquired with a Raman microscope operating at a 532 nm wavelength. Data were collected from 100 to 1000 cm−1 with 1 cm−1 resolution. The ceramic microstructures were analyzed by scanning electron microscopy (SEM, Sirion 200, Thermo Fisher Scientific, Eindhoven, The Netherlands) following polishing and thermal etching. Additionally, the εr and Q × f values of the ZAZS ceramics were measured using the Hakki–Coleman method [17], in which cylindrical dielectric samples were placed between two parallel conducting plates in a TE01δ resonant mode configuration. The resonant frequency and quality factor were recorded using a vector network analyzer (Agilent E8362B, Radnor, PA, USA). To determine τf, the sample’s resonant frequency was measured over a temperature range of 20 °C to 80 °C (in 10 °C increments) using a temperature-controlled chamber. The τf was then calculated from the slope of the linear fit of frequency versus temperature according to the following equation:

where f(T1) and f(T0) denote the resonant frequencies at T1 (80 °C) and T0 (30 °C), respectively.

Γ = A1g(R) + Eg(R) + T1g + 3T2g(R) + 2A2u + 2Eu + 5T1u(IR) + 2T2u

3. Results and Discussion

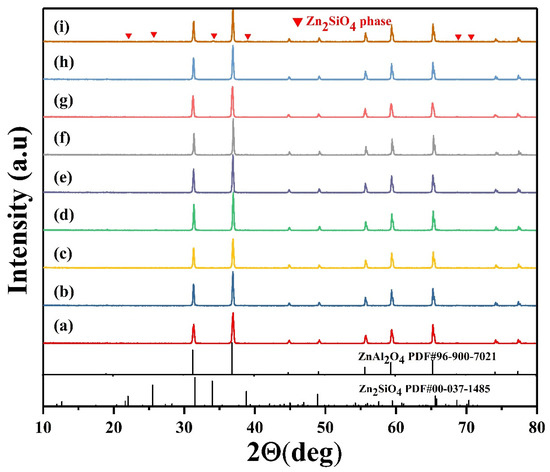

The XRD patterns of the ZAZS ceramics, presented in Figure 1, show that for compositions with x = 0.1 to 0.8, the diffraction profiles correspond to a single-phase Fd-3m structure. This confirms that the [Zn0.5Si0.5]3+ ion successfully substitutes for the Al3+ site, forming a uniform ZnAl2O4 solid solution. However, when x reaches 0.9, a minor phase of Zn2SiO4 is detected, indicating that the substitution limit for [Zn0.5Si0.5]3+ in ZnAl2O4 is approximately x = 0.8.

Figure 1.

XRD patterns of the ZAZS ceramics sintered at 1400 °C for 6 h: (a) x = 0.1; (b) x = 0.2; (c) x = 0.3; (d) x = 0.4; (e) x = 0.5; (f) x = 0.6; (g) x = 0.7; (h) x = 0.8; (i) x = 0.9.

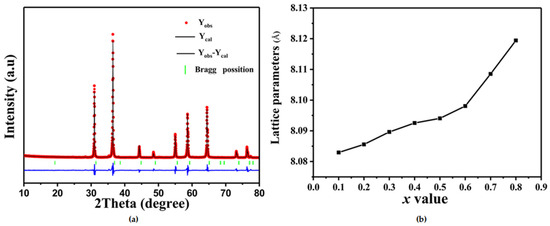

To elucidate the effect of [Zn0.5Si0.5]3+ substitution for Al3+ on the crystal structure of ZnAl2O4, the lattice parameters of all samples were refined using the Rietveld method. Figure 2a presents the Rietveld refinement pattern and the corresponding schematic crystal structure of the ZAZS sample with x = 0.8. In the refinement plot, the red dots (Yobs) represent the observed XRD intensities, the black line (Ycal) indicates the calculated profile, and the blue line at the bottom shows the difference (Yobs–Ycal). The vertical tick marks denote the Bragg reflection positions. The refined lattice parameters for each sample were subsequently determined using this method, and Figure 2b illustrates the relationship between the lattice parameter and the substitution level x. Within the x range of 0.1–0.8, the lattice parameter a of the cubic structure increased modestly from 8.083 Å to 8.119 Å. Based on Shannon’s tabulated ionic radii [18], the average radius of the substituted [Zn0.5Si0.5]3⁺ complex is calculated as Rav = 1/2R(Zn2+) + 1/2R(Si4+) = 0.57 Å, where R(Zn2+) = 0.74 Å and R(Si4+) = 0.40 Å. This averaged radius (0.57 Å) is slightly larger than that of Al3⁺ (0.535 Å). Therefore, the increased incorporation of [Zn0.5Si0.5]3+ ions are likely responsible for the observed expansion in the lattice parameter a.

Figure 2.

(a) Rietveld refinement of ZAZS (x = 0.8) sample; (b) lattice parameters of ZAZS solid solutions as a function of the x value.

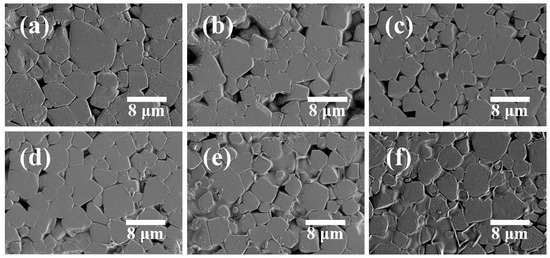

Figure 3 presents the SEM images of the thermally etched ZAZS ceramics, revealing that changes in the ceramic composition significantly influence both the grain size and porosity. As the substitution level of [Zn0.5Si0.5]3+ increases, the grain size gradually decreases, as evidenced in Figure 3. Additionally, the porosity is reduced when the [Zn0.5Si0.5]3+ content is increased from 0.1 to 0.8. At x = 0.8, a small amount of glass phase and indistinct grain boundaries are observed, suggesting that the presence of the glass phase contributes to a more compact ceramic structure. Table 1 summarizes the lattice parameters and calculated relative densities of the ZnAl2-x(Zn0.5Si0.5)xO4 microwave dielectric ceramics. The relative density increases from 93.8% to 96.1% as the substitution level x rises from 0.1 to 0.8, reflecting a progressive densification of the ceramic matrix with increasing [Zn0.5Si0.5]3⁺ content.

Figure 3.

SEM micrograph of the ZAZS ceramics sintered at 1400 °C for 6 h in air atmosphere: (a) x = 0.1; (b) x = 0.2; (c) x = 0.4; (d) x = 0.6; (e) x = 0.7; (f) x = 0.8.

Table 1.

The lattice parameters and densities of the ZnAl2-x(Zn0.5Si0.5)xO4 microwave dielectric ceramics.

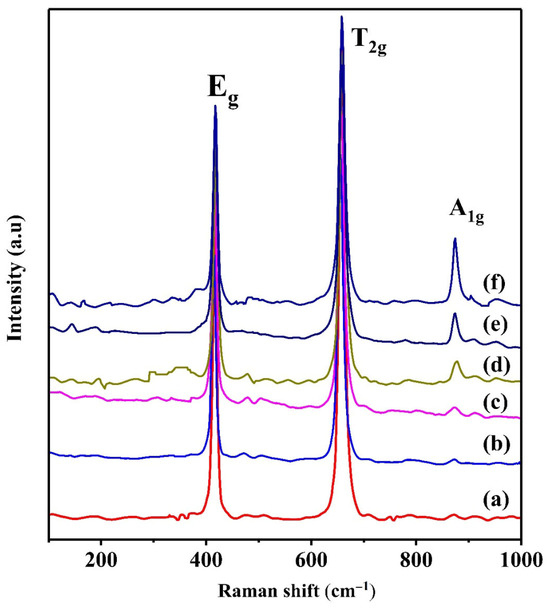

Figure 4 shows three principal Raman-active modes in the ZAZS spinel framework. The Eg band at approximately 420 cm−1 arises from the asymmetric bending of ZnO4 tetrahedra, while the T2g band near 660 cm−1 corresponds to symmetric stretching of the same units. In addition, the high-frequency A1g mode at around 860 cm−1, attributed to AlO4 tetrahedral vibrations [15], exhibits pronounced compositional dependence. As the [Zn0.5Si0.5]3+ content increases (x = 0.1–0.8), this A1g peak not only gains intensity but also narrows markedly—its full width at half maximum (FWHM) decreases—indicating enhanced crystallinity and reduced phonon damping. Such FWHM reduction is well known to reflect lower defect concentration and diminished cation disorder, both of which contribute to a superior microwave Q × f [19,20]. By contrast, the positions of the Eg and T2g bands remain essentially invariant, confirming that the local tetrahedral geometry is preserved across all substitution levels. This sharpening of the A1g band therefore provides spectroscopic evidence that increased [Zn0.5Si0.5]3+ substitution fosters a more ordered lattice, directly correlating with the observed improvements in dielectric quality factor.

Figure 4.

The Raman spectra of the ZAZS ceramics at room temperature: (a) x = 0.1; (b) x = 0.2; (c) x = 0.4; (d) x = 0.6; (e) x = 0.7; (f) x = 0.8.

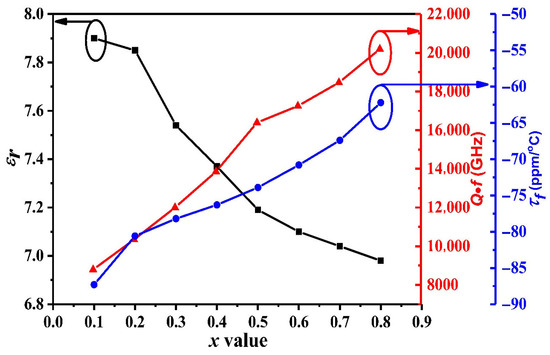

The microwave dielectric properties of the ZAZS ceramics were subsequently examined, revealing a strong dependence on the [Zn0.5Si0.5]3+ content. As depicted in Figure 5 (black line), the εr value steadily decreased from 7.90 to 6.98 when the x value increased from 0.1 to 0.8. This reduction can be attributed to the Si-O bond, which is composed of 45% ionic and 55% covalent character, as previously reported [10,21]. In this series of ceramics, the higher Si content likely contributes to the lower εr value. Concurrently, the Q × f value of the ZAZS ceramics improved significantly, rising from 8800 GHz to 20,200 GHz as x increased from 0.1 to 0.8, as shown by the red line in Figure 5. The Q × f of microwave ceramics is determined by both extrinsic microstructural factors—such as relative density, grain size, and the presence of secondary phases—and intrinsic lattice-level loss mechanisms. Tamura [22] has shown that microwave dielectric loss is dominated by anharmonic terms in the crystal’s potential energy and is exacerbated by lattice defects, particularly disordered charge distributions. In the current ZAZS system, SEM micrographs (Figure 3) and relative density data (Table 1) demonstrate that the x = 0.8 composition achieves the highest densification and most uniform grain morphology. This improved microstructure minimizes extrinsic losses. Simultaneously, the narrowing of the A1g Raman mode FWHM with increasing x (Figure 4) indicates reduced phonon damping and lower defect concentration, thereby suppressing intrinsic anharmonic losses. The combined reduction of extrinsic scattering and intrinsic lattice-defect loss leads to the maximal Q × f observed at x = 0.8.

Figure 5.

The εr, Q × f, and τf values of the ZAZS ceramics as a function of the x value.

Figure 5 (blue line) shows that the τf of the ZAZS ceramics becomes progressively less negative, shifting from −87 to −62 ppm/°C as the [Zn0.5Si0.5]3+ substitution level x increases from 0.1 to 0.8. It is widely recognized that the τf values are strongly influenced by the bond valence [23,24]. According to bond-valence theory of the octahedral network, a larger bond valence corresponds to a more rigid octahedral network [25,26,27], which drives the absolute value of τf to increase (i.e., become more negative). In our study, the bond valences at the octahedral Al/Zn/Si positions were calculated via [28]:

where Rij is the bond-valence parameter, dij is the bond length, and b = 0.37 Å [29]. As shown in Table 2, increasing x leads to a decrease in the average B–O (octahedral Al/Zn/Si positions) bond valence, indicating a weakening of the octahedral framework. This reduced bond valence—and hence diminished network rigidity—explains the observed reduction in |τf|: a less rigid lattice vibrates with lower anharmonicity, producing a smaller change in τf value. Thus, our results confirm that controlled B-site doping in the ZnAl2O4 spinel systematically tunes τf toward zero by reducing bond valence and octahedral rigidity.

Table 2.

Bond valence of the ZAZS (x = 0.1–0.8) ceramics.

4. Conclusions

In this study, spinel ZnAl2-x(Zn0.5Si0.5)xO4 (ZAZS) ceramics with x = 0.1–0.9 were synthesized via a conventional solid-state route, and we demonstrated that aliovalent substitution of [Zn0.5Si0.5]3⁺ for Al3⁺ enabled densification at just 1400 °C—more than 250 °C lower than required for undoped ZnAl2O4—while maintaining single-phase purity up to x = 0.8. Rietveld refinement confirmed an Fd-3m spinel structure for x ≤ 0.8, with the lattice constant expanding from 8.083 Å to 8.119 Å as x increased. SEM imaging and density measurements revealed a steady increase in relative density (from 93.8% to 96.1%) and a more uniform, tightly packed grain morphology, peaking at x = 0.8. Dielectric testing showed that the x = 0.8 composition achieved a high quality factor (Q × f = 20,200 GHz), low permittivity (εr = 6.98), and a τf of −62 ppm/°C. Bond-valence calculations indicated that increasing [Zn0.5Si0.5]3⁺ content reduced the average B–O bond valence, weakening octahedral rigidity and lowering lattice anharmonicity—thereby systematically tuning |τf| toward zero. By significantly lowering the sintering temperature using only readily available, cost-effective oxides, these ZAZS spinel ceramics offer a practical, low-loss microwave dielectric platform with strong potential for scalable device applications.

Author Contributions

Writing—original draft preparation, X.L.; investigation, X.L.; data curation X.L. and H.T.; methodology, W.L. and B.T.; writing—review and editing, B.C. and C.Y.; supervision, W.L. and B.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bao, J.; Zhang, K.-H.; Wang, W.; Liu, Z.-Y.; Fang, Z.; Wang, X.; Wang, C.-H.; Li, Y.-C.; He, G.-Q.; Zhou, T.; et al. A series of ultra-low permittivity ALaP4O12 (A = Li, Na, K) metaphosphate microwave dielectric ceramics for ultra-wideband dielectric resonant antenna application. ACS Appl. Mater. Interfaces 2024, 16, 58898–58911. [Google Scholar] [CrossRef]

- Wan, Q.; Li, Z.; Wang, H.; Xiong, G.; Wang, G. Crystal Structure and Microwave Dielectric Characteristics of Novel Ba(Eu1/5Sm1/5Nd1/5Pr1/5La1/5)2Ti4O12 High-Entropy Ceramic. Crystals 2024, 14, 754. [Google Scholar] [CrossRef]

- Lu, X.; Wu, P.; Yang, H.; Yang, M.; Zheng, Y. Phase Compositions and Microwave Dielectric Properties of Na1+xSrB5O9+0.5x Ceramics. Crystals 2023, 13, 1042. [Google Scholar] [CrossRef]

- Huang, H.; Li, B.; Wang, F.; Lai, Y.; Jiang, G. The Structure and Microwave Dielectric Properties of MgTi1−x(Mn1/3Nb2/3)xO3 Ceramics. Crystals 2023, 13, 1050. [Google Scholar] [CrossRef]

- Li, C.; Xiang, H.; Yin, C.; Tang, Y.; Li, Y.; Fang, L. Ultra-low loss microwave dielectric ceramic Li2Mg2TiO5 and low-temperature firing via B2O3 addition. J Electron Mater. 2018, 47, 6383–6389. [Google Scholar] [CrossRef]

- Liu, C.-L.; Lu, L.; Wu, J.-M.; Wang, C.-A.; Shi, Y.-S. Preparation and properties of 0.79 ZnAl2O4-0.21 TiO2 microwave dielectric ceramics via digital light processing. J. Alloys Compd. 2022, 911, 165095. [Google Scholar] [CrossRef]

- Siragam, S.; Dubey, R.-S.; Pappula, L.; Babu, G.-S. Zinc aluminate-based composite nanoparticles for microwave applications. ACS Omega 2022, 7, 23393–23400. [Google Scholar] [CrossRef]

- Wu, Y.-C.; Tseng, H.-T.; His, C.-S.; Juuti, J.; Hsiang, H.-I. Low dielectric loss ceramics in the Mg4Nb2O9-ZnAl2O4-TiO2 ternary system. J. Eur. Ceram. Soc. 2022, 42, 448–452. [Google Scholar] [CrossRef]

- Lei, W.; Lu, W.-Z.; Zhu, J.-H.; Wang, X.-H. Microwave dielectric properties of ZnAl2O4–TiO2 spinel-based composites. Mater. Lett. 2007, 61, 4066–4069. [Google Scholar] [CrossRef]

- Song, X.Q.; Lu, W.Z.; Wang, X.C.; Wang, X.H.; Fan, G.F.; Muhammad, R.; Lei, W. Sintering behaviour and microwave dielectric properties of BaAl2−2x(ZnSi)xSi2O8 ceramics. J. Eur. Ceram. Soc. 2018, 38, 1529–1534. [Google Scholar] [CrossRef]

- Toby, B.H. EXPGUI, a graphical user interface for GSAS. J. Appl. Crystallogr. 2001, 34, 210–213. [Google Scholar] [CrossRef]

- Pirvaram, A.; Taheri-Nassaj, E.; Taghipour-Armaki, H.; Lu, W.-Z.; Lei, W.; Bafrooei, H. Study on structure, microstructure and microwave dielectric characteristics of CaV2O6 and (Ca0.95M0.05)V2O6 (M = Zn, Ba) Ceramics. J. Am. Ceram. Soc. 2019, 102, 5213–5222. [Google Scholar] [CrossRef]

- Lee, C.-J.; Pezzotti, G.; Kang, S.-H.; Kim, D.-J.; Hong, K.-S. Quantitative analysis of lattice distortion in Ba(Zn1/3Ta2/3)O3 microwave dielectric ceramics with added B2O3 using Raman spectroscopy. J. Eur. Ceram. Soc. 2006, 26, 1385–1391. [Google Scholar] [CrossRef]

- Mohacek-Grosey, V.; Vrankic, M.; Maksimovic, A.; Mandic, V. Influence of titanium doping on the Raman spectra of nanocrystalline ZnAl2O4. J. Alloys Compd. 2017, 697, 90–95. [Google Scholar] [CrossRef]

- Dwibedi, D.; Murugesan, C.; Leskes, M.; Barpanda, P. Role of annealing temperature on cation ordering in hydrothermally prepared zinc aluminate (ZnAl2O4) spinel. Mater. Res. Bull. 2018, 98, 219–224. [Google Scholar] [CrossRef]

- Fang, C.-M.; Loong, C.-K.; With, G. Phonon spectrum of ZnAl2O4 spinel from inelastic neutron scattering and first-principles calculations. Phys. Rev. B 2002, 66, 144301. [Google Scholar] [CrossRef]

- Hakki, B.-W.; Coleman, P.-A. Dielectric resonator method of measuring inductive capacities in the millimeter range. IEEE Trans. Microw. Theory 1960, 8, 402–410. [Google Scholar] [CrossRef]

- Shannon, R.-D. Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Crystallogr. A 1976, 32, 751–767. [Google Scholar] [CrossRef]

- Zhou, D.; Pang, L.-X.; Wang, H.; Guo, J.; Yao, X.; Randall, C. Phase transition, Raman spectra, infrared spectra, band gap and microwave dielectric properties of low temperature firing (Na0.5xBi1−0.5x)(MoxV1−x)O4 solid solution ceramics with scheelite structures. J. Mater. Chem. 2011, 21, 18412–18420. [Google Scholar] [CrossRef]

- Liao, Q.; Li, L. Structural dependence of microwave dielectric properties of ixiolite structured ZnTiNb2O8 materials: Crystal structure refinement and Raman spectra study. Dalton Trans. 2012, 41, 6963–6969. [Google Scholar] [CrossRef]

- Wu, S.; Jiang, C.; Mei, Y.; Tu, W. Synthesis and microwave dielectric properties of Sm2SiO5 ceramics. J. Am. Ceram. Soc. 2012, 95, 37–40. [Google Scholar] [CrossRef]

- Tamura, H. Microwave dielectric losses caused by lattice defects. J. Eur. Ceram. Soc. 2006, 26, 1775–1780. [Google Scholar] [CrossRef]

- Liu, S.; Tang, B.; Zhou, M.; Zhao, P.; Xiang, Q.; Zhang, X.; Fang, Z.; Zhang, S. Microwave dielectric characteristics of high permittivity Ca0.35Li0.25Nd0.35Ti1-x(Zn1/3Ta2/3)xO3 ceramics (x = 0.00–0.12). Ceram. Int. 2019, 45, 8600–8606. [Google Scholar] [CrossRef]

- Xiao, M.; He, S.; Lou, J.; Zhang, P. Influence of Ge4+ substitution for Zr4+ on the microwave dielectric properties of Mg(Zr1-xGex)Nb2O8 (0 ≤ x ≤ 0.4) ceramics. Ceram. Int. 2018, 44, 21585–21590. [Google Scholar] [CrossRef]

- Park, H.-S.; Yoon, K.-H.; Kim, E.-S. Relationship between the bond valence and the temperature coefficient of the resonant frequency in the complex perovskite (Pb1−xCax)[Fe0.5(Nb1−yTay)0.5]O3. J. Am. Ceram. Soc. 2001, 84, 99–103. [Google Scholar] [CrossRef]

- Park, H.-S.; Yoon, K.-H.; Kim, E.-S. Effect of bond valence on microwave dielectric properties of complex perovskite ceramics. Mater. Chem. Phys. 2003, 79, 181–183. [Google Scholar] [CrossRef]

- Zuo, R.; Xu, Y.; Shi, M.; Li, W.; He, L. A new series of low-temperature cofirable Li3Ba2La3(1−x)Y3x(MoO4)8 microwave dielectric ceramics. J. Eur. Ceram. Soc. 2018, 38, 4677–4681. [Google Scholar] [CrossRef]

- Li, J.; Fang, L.; Luo, H.; Tang, Y.; Li, C. Structure and microwave dielectric properties of a novel temperature stable low-firing Ba2LaV3O11 ceramic. J. Eur. Ceram. Soc. 2016, 36, 2143–2148. [Google Scholar] [CrossRef]

- Brese, N.-E.; Okeeffe, M. Bond-valence parameters for solids. Acta Crystallogr. B 1991, 47, 192–197. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).