Influence of Post-Heat Treatment on the Tensile Strength and Microstructure of Metal Inert Gas Dissimilar Welded Joints

Abstract

1. Introduction

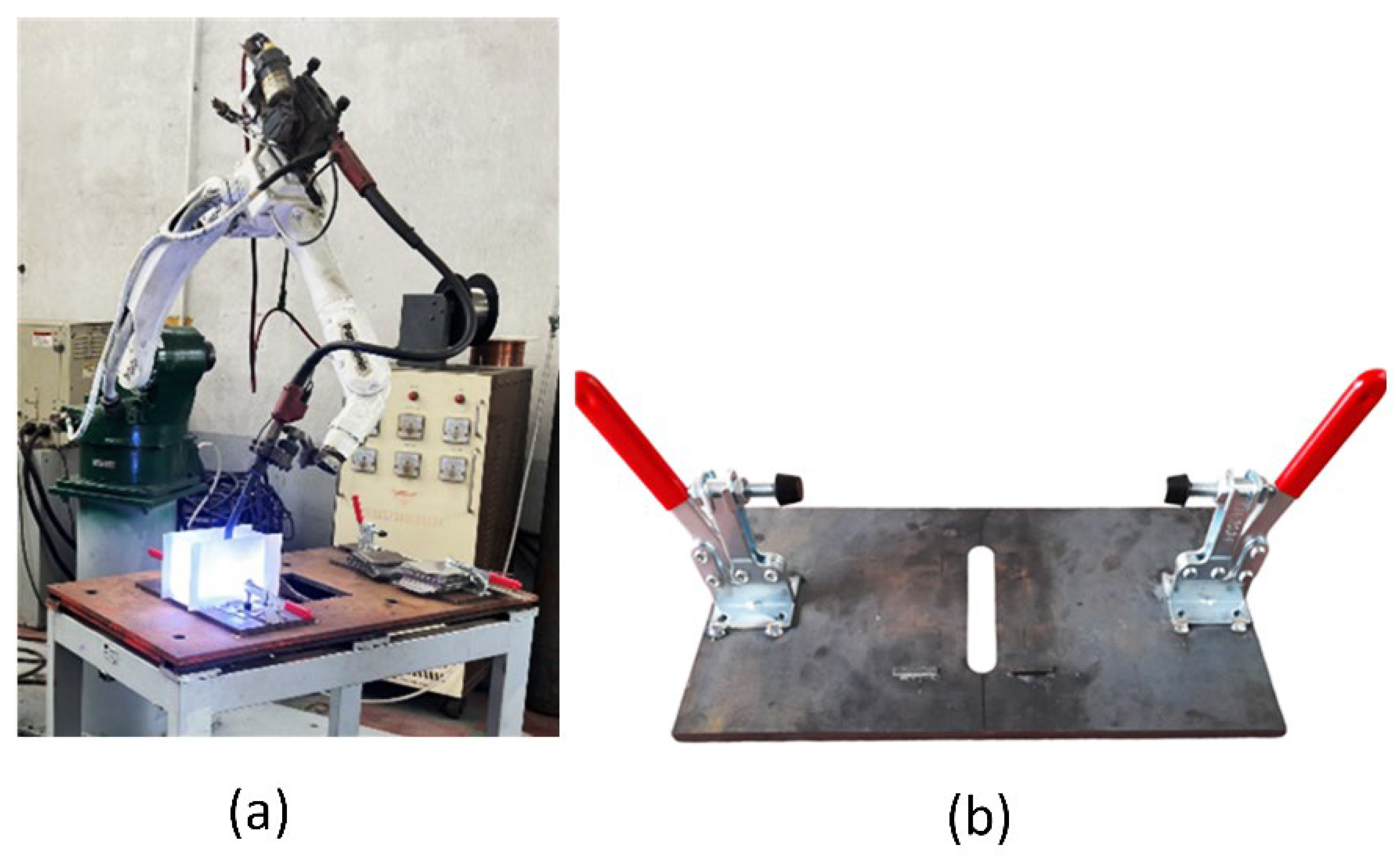

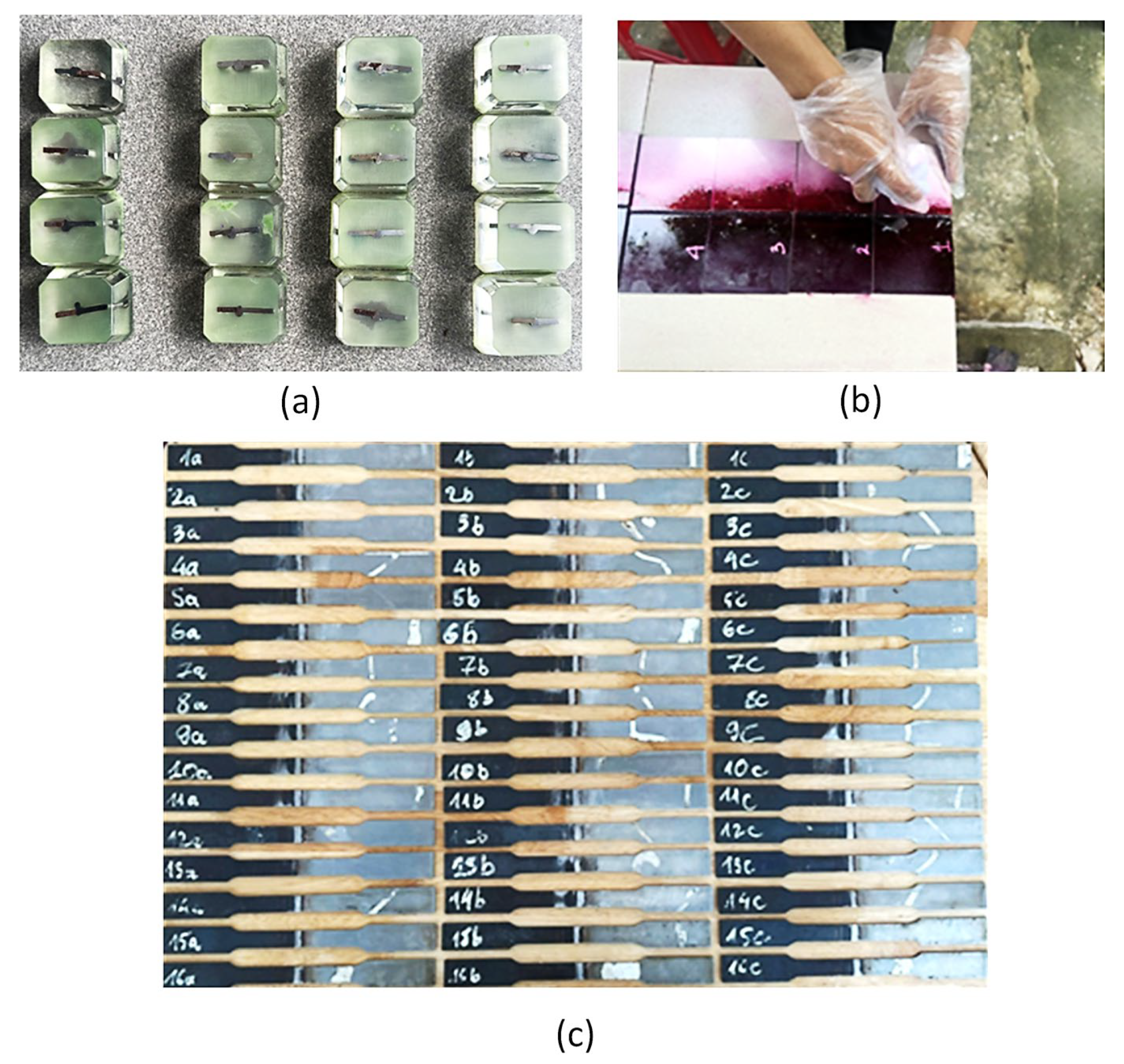

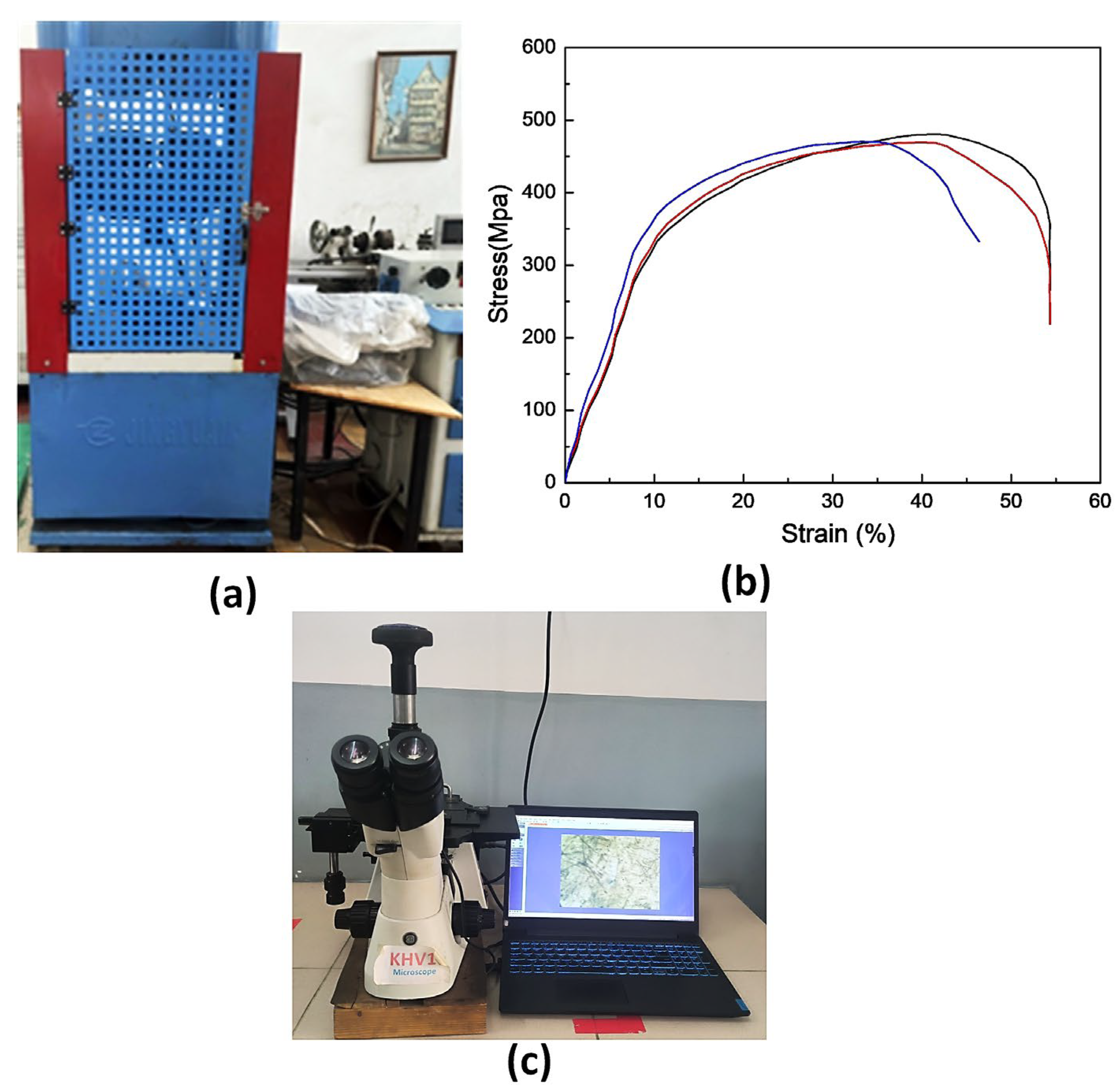

2. Materials and Methods

3. Results and Discussion

3.1. Penetration and Microstructure Examinations

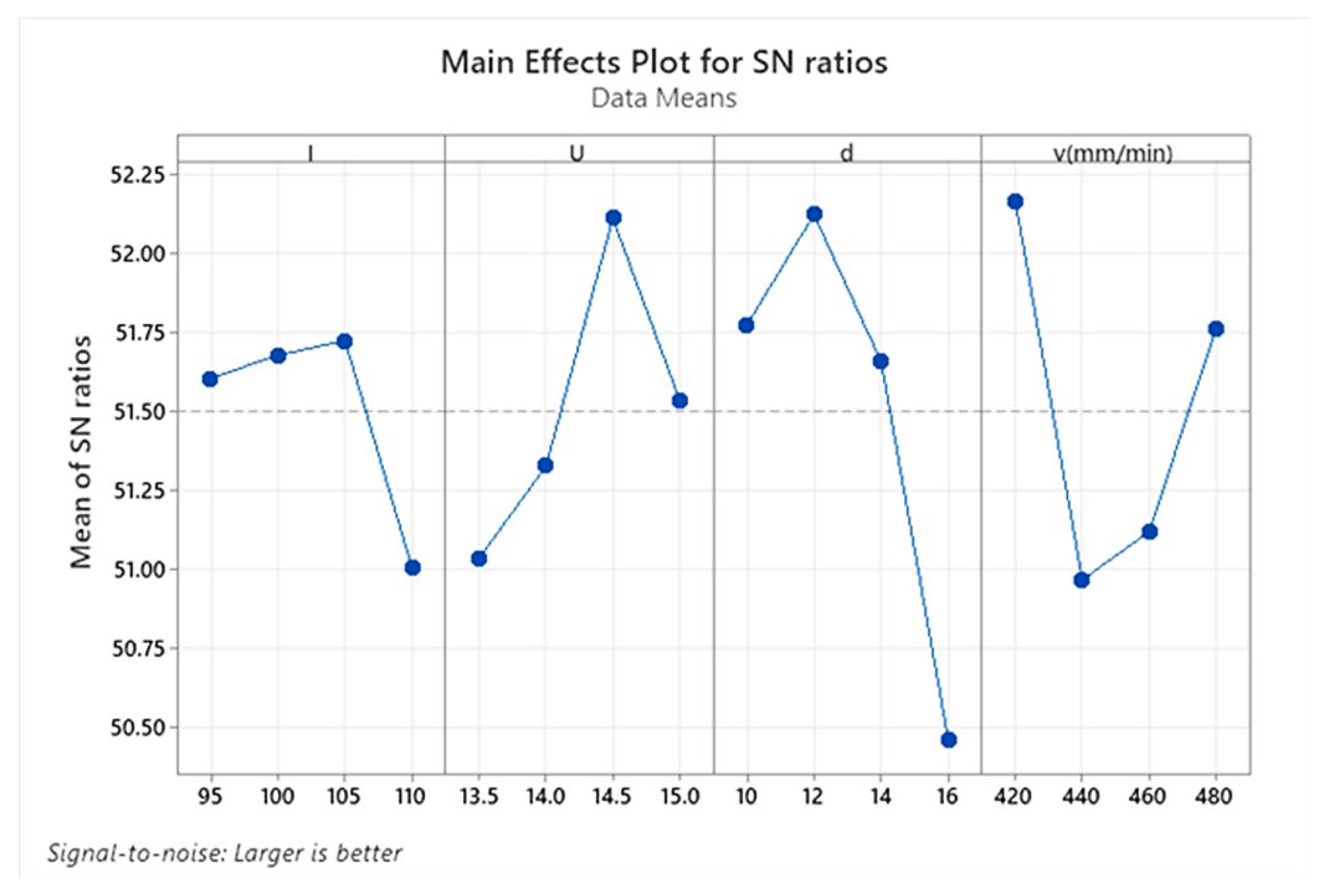

3.2. Taguchi Analysis of Tensile Strength and Confirmation Test

3.3. Post-Heat Treatment Effects

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Maurya, A.K.; Pandey, C.; Chhibber, R. Dissimilar welding of duplex stainless steel with Ni alloys: A review. Int. J. Press. Vessel. Pip. 2021, 192, 104439. [Google Scholar] [CrossRef]

- Mvola, B.; Kah, P.; Martikainen, J.; Suoranta, R. Dissimilar welded joints operating in sub-zero temperature environment. Int. J. Adv. Manuf. Technol. 2016, 87, 3619–3635. [Google Scholar] [CrossRef]

- Liu, L.; Ren, D.; Liu, F. A review of dissimilar welding techniques for magnesium alloys to aluminum alloys. Materials 2014, 7, 3735–3757. [Google Scholar] [CrossRef] [PubMed]

- Morishige, T.; Kawaguchi, A.; Tsujikawa, M.; Hino, M.; Hirata, T.; Higashi, K. Dissimilar welding of Al and Mg alloys by FSW. Mater. Trans. 2008, 49, 1129–1131. [Google Scholar] [CrossRef]

- Fang, X.; Zhang, F. Hybrid joining of a modular multi-material body-in-white structure. J. Mater. Process. Technol. 2020, 275, 116351. [Google Scholar] [CrossRef]

- Kah, P.; Shrestha, M.; Martikainen, J. Trends in joining dissimilar metals by welding. Appl. Mech. Mater. 2014, 440, 269–276. [Google Scholar] [CrossRef]

- Sadeghian, A.; Iqbal, N. A review on dissimilar laser welding of steel-copper, steel-aluminum, aluminum-copper, and steel-nickel for electric vehicle battery manufacturing. Opt. Laser Technol. 2022, 146, 107595. [Google Scholar] [CrossRef]

- Beygi, R.; Carbas, R.; Queiros, A.; Marques, E.A.S.; Shi, R.; Da Silva, L.F.M. Comparative study between stainless steel and carbon steel during dissimilar friction stir welding with aluminum: Kinetics of Al–Fe intermetallic growth. Met. Mater. Int. 2022, 28, 1948–1959. [Google Scholar] [CrossRef]

- Yang, Y.; Luo, Z.; Zhang, Y.; Su, J. Dissimilar welding of aluminium to steel: A review. J. Manuf. Process. 2024, 110, 376–397. [Google Scholar] [CrossRef]

- Mehta, K.P. A review on friction-based joining of dissimilar aluminum–steel joints. J. Mater. Res. 2019, 34, 78–96. [Google Scholar] [CrossRef]

- Kaisheva, D.; Anchev, A.; Dunchev, V.; Kotlarski, G.; Stoyanov, B.; Ormanova, M.; Valkov, S. Electron-Beam Welding Cu and Al6082T6 Aluminum Alloys with Circular Beam Oscillations. Crystals 2022, 12, 1757. [Google Scholar] [CrossRef]

- Martinsen, K.; Hu, S.J.; Carlson, B.E. Joining of dissimilar materials. Cirp Ann. 2015, 64, 679–699. [Google Scholar] [CrossRef]

- Patel, D.; Jani, S. Techniques to weld similar and dissimilar materials by ATIG welding-an overview. Mater. Manuf. Process. 2021, 36, 1–16. [Google Scholar] [CrossRef]

- Neeru, S.S.; Satsangi, P.S. A review on friction stir spot welding of similar and dissimilar materials. In Advances in Engineering Design: Select Proceedings of ICOIED 2020; Springer: Singapore, 2021; pp. 531–541. [Google Scholar]

- Singh, D.K.; Sahoo, G.; Basu, R.; Sharma, V.; Mohtadi-Bonab, M.A. Investigation on the microstructure—Mechanical property correlation in dissimilar steel welds of stainless steel SS 304 and medium carbon steel EN 8. J. Manuf. Process. 2018, 36, 281–292. [Google Scholar] [CrossRef]

- Kim, J.K.; Hong, S.G.; Kang, K.B.; Kang, C.Y. Microstructure and high temperature properties of the dissimilar weld between ferritic stainless steel and carbon steel. Met. Mater. Int. 2009, 15, 843–849. [Google Scholar] [CrossRef]

- Torkamany, M.J.; Tahamtan, S.; Sabbaghzadeh, J. Dissimilar welding of carbon steel to 5754 aluminum alloy by Nd: YAG pulsed laser. Mater. Des. 2010, 31, 458–465. [Google Scholar] [CrossRef]

- Naffakh, H.; Shamanian, M.; Ashrafizadeh, F. Dissimilar welding of AISI 310 austenitic stainless steel to nickel-based alloy Inconel 657. J. Mater. Process. Technol. 2009, 209, 3628–3639. [Google Scholar] [CrossRef]

- Yao, L.; Ramesh, A.; Xiao, Z.; Chen, Y.; Zhuang, Q. Multimetal research in powder bed fusion: A review. Materials 2023, 16, 4287. [Google Scholar] [CrossRef]

- Khan, M.; Dewan, M.W.; Sarkar, M.Z. Effects of welding technique, filler metal and post-weld heat treatment on stainless steel and mild steel dissimilar welding joint. J. Manuf. Process. 2021, 64, 1307–1321. [Google Scholar] [CrossRef]

- Jamaludin, S.B.; Mazlee, M.N.; Kadir, S.K.A.; Ahmad, K.R. Mechanical properties of dissimilar welds between stainless steel and mild steel. Adv. Mater. Res. 2013, 795, 74–77. [Google Scholar] [CrossRef]

- Ma, H.; Qin, G.; Geng, P.; Li, F.; Fu, B.; Meng, X. Microstructure characterization and properties of carbon steel to stainless steel dissimilar metal joint made by friction welding. Mater. Des. 2015, 86, 587–597. [Google Scholar] [CrossRef]

- Liu, Y.; Ge, M.; Zeng, G.; Wang, Z.; Chen, K.; Yin, X.; Wang, W. Process analysis and multi-parameter optimization of 5052 aluminum alloy FSW based on thermo-mechanical coupling and Taguchi method. Sci. Rep. 2025, 15, 335. [Google Scholar] [CrossRef] [PubMed]

- Van Huong, H.; Nguyen, T.T.; Nguyen, V.T.; Nguyen, V.T.T. Material Strength Optimization of Dissimilar MIG Welding between Carbon and Stainless Steels. Metals 2024, 14, 1011. [Google Scholar] [CrossRef]

- Roy, A.; Ghosh, N.; Mondal, S. Analysis of the multi-criteria optimization strategies for determining the weld quality of dissimilar TIG welding between ferritic and austenitic stainless steel. Int. J. Interact. Des. Manuf. 2024, 18, 1443–1457. [Google Scholar] [CrossRef]

- ASTM E290-09; Standard Test Methods for Bend Testing of Material for Ductility. ASTM: West Conshohocken, PA, USA, 2013.

- Chuaiphan, W.; Somrerk, C.A.; Niltawach, S.; Sornil, B. Dissimilar welding between AISI 304 stainless steel and AISI 1020 carbon steel plates. Appl. Mech. Mater. 2013, 268, 283–290. [Google Scholar] [CrossRef]

- Roy, R.; St, C. Design of Experiments Using the Taguchi Approach 16 Steps to Product and Process Improvement; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Ogbonna, O.S.; Akinlabi, S.A.; Madushele, N.; Fatoba, O.S.; Akinlabi, E.T. Grey-based taguchi method for multi-weld quality optimization of gas metal arc dissimilar joining of mild steel and 316 stainless steel. Results Eng. 2023, 17, 100963. [Google Scholar] [CrossRef]

- Ogedengbe, T.I.; Abioye, T.E.; Ekpemogu, A.I. Investigation of mechanical properties and parametric optimization of the dissimilar GTAW of AISI 304 stainless steel and low carbon steel. World J. Eng. 2018, 15, 584–591. [Google Scholar] [CrossRef]

- e Silva, R.H.G.; dos Santos Paes, L.E.; Barbosa, R.C.; Sartori, F.; Schwedersky, M.B. Assessing the effects of solid wire electrode extension (stick out) increase in MIG/MAG welding. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 31. [Google Scholar] [CrossRef]

- Huang, C.H.; Hou, C.H.; Hsieh, T.S.; Tsai, L.; Chiang, C.C. Investigation of distinct welding parameters on mechanical and corrosion properties of dissimilar welded joints between stainless steel and low carbon steel. Sci. Prog. 2022, 105, 00368504221126795. [Google Scholar] [CrossRef]

- Thamprajamjit, J.; Surin, P. Dissimilar metal joining between stainless steel SUS304 and carbon steel SS400 using plasma arc welding process. In Proceedings of the 2018 2nd International Conference on Engineering Innovation (ICEI), Bangkok, Thailand, 5–6 July 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 42–45. [Google Scholar]

- An, J.H.; Lee, J.; Kim, Y.S.; Kim, W.C.; Kim, J.G. Effects of post weld heat treatment on mechanical and electrochemical properties of welded carbon steel pipe. Met. Mater. Int. 2019, 25, 304–312. [Google Scholar] [CrossRef]

- ASTM E112-10; Standard Test Methods for Determining Average Grain Size. ASTM: West Conshohocken, PA, USA, 2013.

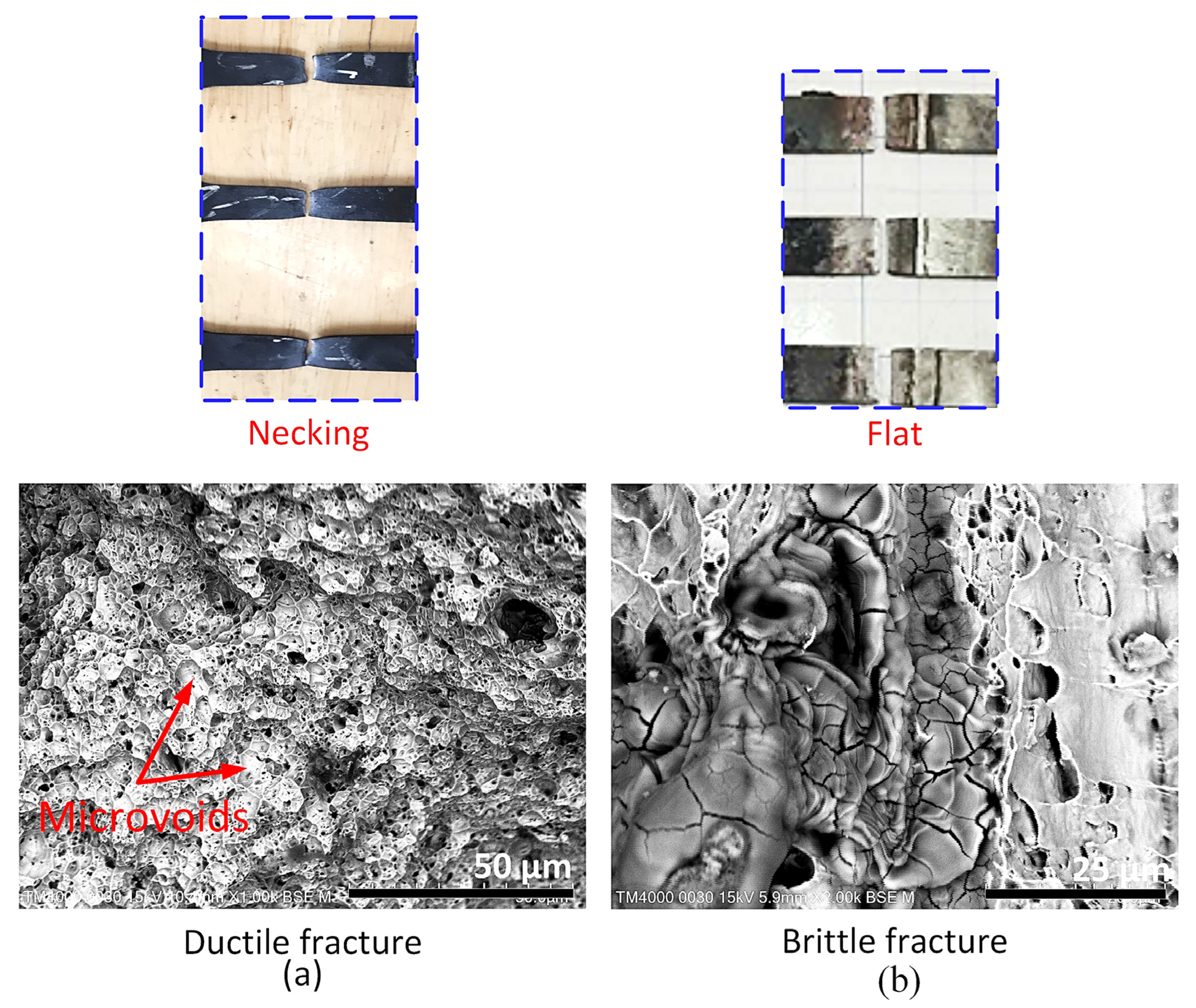

- Wciślik, W.; Lipiec, S. Void-induced ductile fracture of metals: Experimental observations. Materials 2022, 15, 6473. [Google Scholar] [CrossRef]

- Schroeder, C.J.; Parrington, R.J.; Maciejewski, J.O.; Lane, J.F. (Eds.) Fractography; ASM International: Novelty, OH, USA, 2024. [Google Scholar]

- Broek, D. Elementary Engineering Fracture Mechanics; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1982. [Google Scholar]

- Anderson, T.L.; Anderson, T.L. Fracture Mechanics: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

| Standards | C | Si | Mn | P | S | Cr | Ni | Cu | Mo |

|---|---|---|---|---|---|---|---|---|---|

| SUS304 | 0.044 | 0.381 | 1.095 | 0.036 | 0.0007 | 17.694 | 7.669 | 0.037 | 0.049 |

| SS400 | 0.106 | 0.073 | 0.552 | 0.0125 | 0.0085 | 0.0244 | 0.0384 | 0.009 | 0.0005 |

| AWS ER 308L | 0.03 | 0.3–0.65 | 1.0–2.5 | 0.03 max | 0.03 max | 19.5–22 | 9–11 | 0.75 max | 0.75 max |

| Welding Parameters | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|

| Welding Current, I (Ampere) | 95 | 100 | 105 | 110 |

| Welding Voltage, U (Voltage) | 13.5 | 14 | 14.5 | 15 |

| Welding Speed, v (mm/min) | 420 | 440 | 460 | 480 |

| Electrical Stickout, d (mm) | 10 | 12 | 14 | 16 |

| No. | I (A) | U (V) | Stickout (mm) | Speed (mm/min) | UTS (MPa) | Penetration Evaluation |

|---|---|---|---|---|---|---|

| 1 | 95 | 13.5 | 10 | 420 | 429.6 | Fair |

| 2 | 95 | 14 | 12 | 440 | 373.4 | Fair |

| 3 | 95 | 14.5 | 14 | 460 | 394.9 | Fair |

| 4 | 95 | 15 | 16 | 480 | 331.2 | Fair |

| 5 | 100 | 13.5 | 12 | 460 | 354.8 | Fair |

| 6 | 100 | 14 | 10 | 480 | 396.9 | Fair |

| 7 | 100 | 14.5 | 16 | 420 | 392.9 | Fair |

| 8 | 100 | 15 | 14 | 440 | 388.1 | Good |

| 9 | 105 | 13.5 | 14 | 480 | 382.1 | Good |

| 10 | 105 | 14 | 16 | 460 | 340.1 | Good |

| 11 | 105 | 14.5 | 10 | 440 | 373.7 | Good |

| 12 | 105 | 15 | 12 | 420 | 444.4 | Good |

| 13 | 110 | 13.5 | 16 | 440 | 283.9 | Good |

| 14 | 110 | 14 | 14 | 420 | 351.0 | Good |

| 15 | 110 | 14.5 | 12 | 480 | 449.9 | Good |

| 16 | 110 | 15 | 10 | 460 | 359.5 | Good |

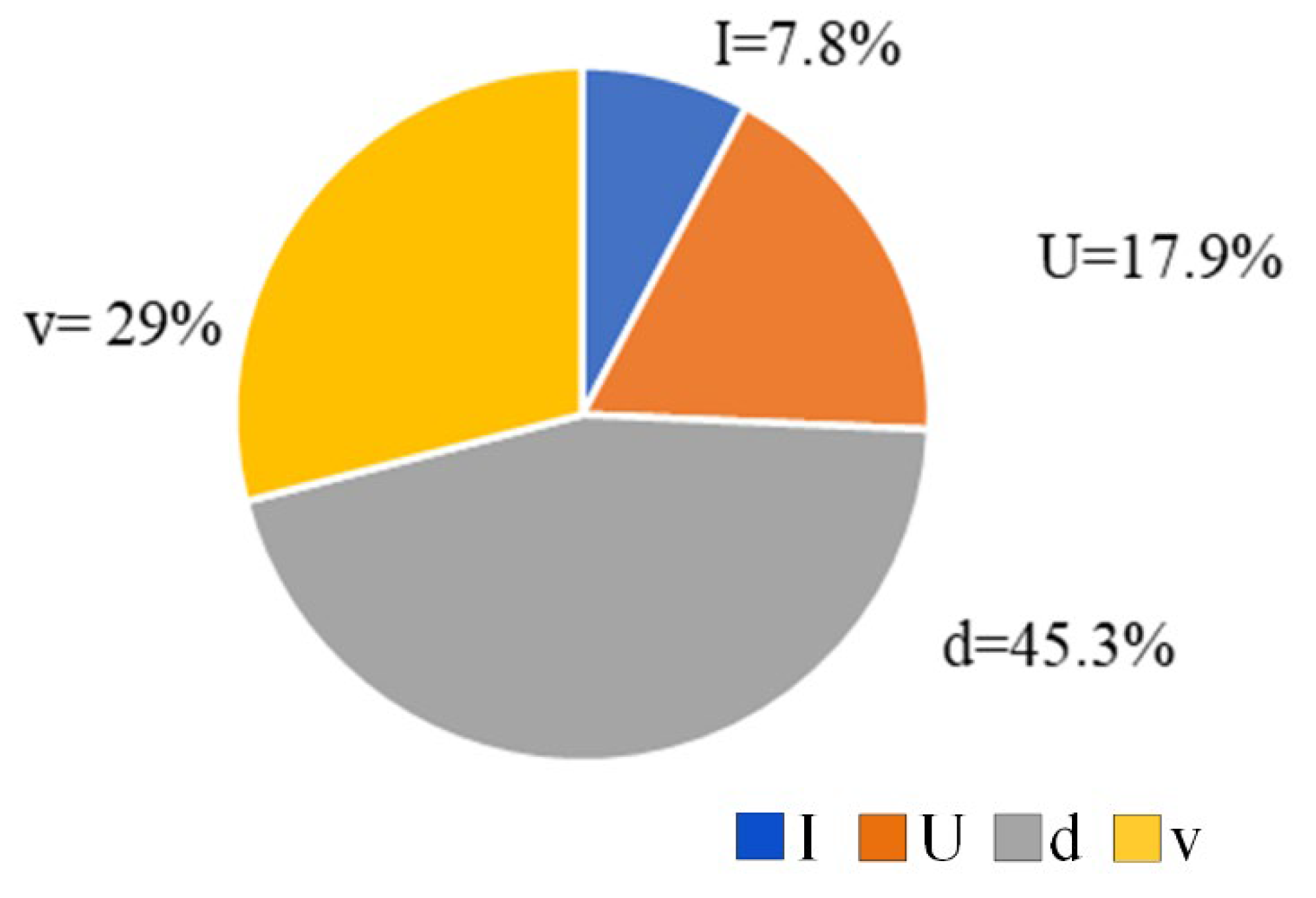

| Level | S/N Value for the Respective Parameter | |||

|---|---|---|---|---|

| I | U | d | v | |

| 1 | 51.61 | 51.09 | 51.80 | 52.10 |

| 2 | 51.66 | 51.24 | 52.11 | 50.93 |

| 3 | 51.67 | 52.08 | 51.56 | 51.17 |

| 4 | 51.04 | 51.56 | 50.50 | 51.77 |

| Delta | 0.63 | 0.99 | 1.62 | 1.17 |

| Rank | 4 | 3 | 1 | 2 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Current (A) | 3 | 1841 | 613.7 | 0.42 | 0.755 |

| Voltage (V) | 3 | 4270 | 1423.3 | 0.97 | 0.511 |

| Stickout (mm) | 3 | 10,841 | 3613.6 | 2.45 | 0.240 |

| V (mm/min) | 3 | 6954 | 2317.9 | 1.57 | 0.359 |

| Error | 3 | 4419 | 1472.8 | ||

| Total | 15 | 28,324 | |||

| S = 38.3776 | R-sq = 84.40% | R-sq (adj) = 22% |

| No. | Temperature (°C) | Average UTS (MPa) |

|---|---|---|

| 1 | 500 | 468.9 |

| 2 | 550 | 467.3 |

| 3 | 600 | 453.9 |

| 4 | 650 | 447.3 |

| 5 | 700 | 312.1 |

| 6 | RT. | 445.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, V.-T.; Nguyen, T.T.; Hoang, V.H.; Thien, T.N.; Yen, D.T.K.; Minh, T.H.; Tuan, L.M.; Nguyen, A.T.; Nghia, H.T.; Anh, P.Q.; et al. Influence of Post-Heat Treatment on the Tensile Strength and Microstructure of Metal Inert Gas Dissimilar Welded Joints. Crystals 2025, 15, 586. https://doi.org/10.3390/cryst15070586

Nguyen V-T, Nguyen TT, Hoang VH, Thien TN, Yen DTK, Minh TH, Tuan LM, Nguyen AT, Nghia HT, Anh PQ, et al. Influence of Post-Heat Treatment on the Tensile Strength and Microstructure of Metal Inert Gas Dissimilar Welded Joints. Crystals. 2025; 15(7):586. https://doi.org/10.3390/cryst15070586

Chicago/Turabian StyleNguyen, Van-Thuc, Thanh Tan Nguyen, Van Huong Hoang, Tran Ngoc Thien, Duong Thi Kim Yen, Tri Ho Minh, Le Minh Tuan, Anh Tu Nguyen, Hoang Trong Nghia, Pham Quan Anh, and et al. 2025. "Influence of Post-Heat Treatment on the Tensile Strength and Microstructure of Metal Inert Gas Dissimilar Welded Joints" Crystals 15, no. 7: 586. https://doi.org/10.3390/cryst15070586

APA StyleNguyen, V.-T., Nguyen, T. T., Hoang, V. H., Thien, T. N., Yen, D. T. K., Minh, T. H., Tuan, L. M., Nguyen, A. T., Nghia, H. T., Anh, P. Q., Bao, P. Q., & Nguyen, V. T. T. (2025). Influence of Post-Heat Treatment on the Tensile Strength and Microstructure of Metal Inert Gas Dissimilar Welded Joints. Crystals, 15(7), 586. https://doi.org/10.3390/cryst15070586