Microstructural Investigation of Stress-Induced Degradation of Gamma and Gamma Prime Phases on the Surface of the Aerofoil of Nickel-Based Single Crystal Superalloy Turbine Blades

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Microstructural Characterisation

3. Results

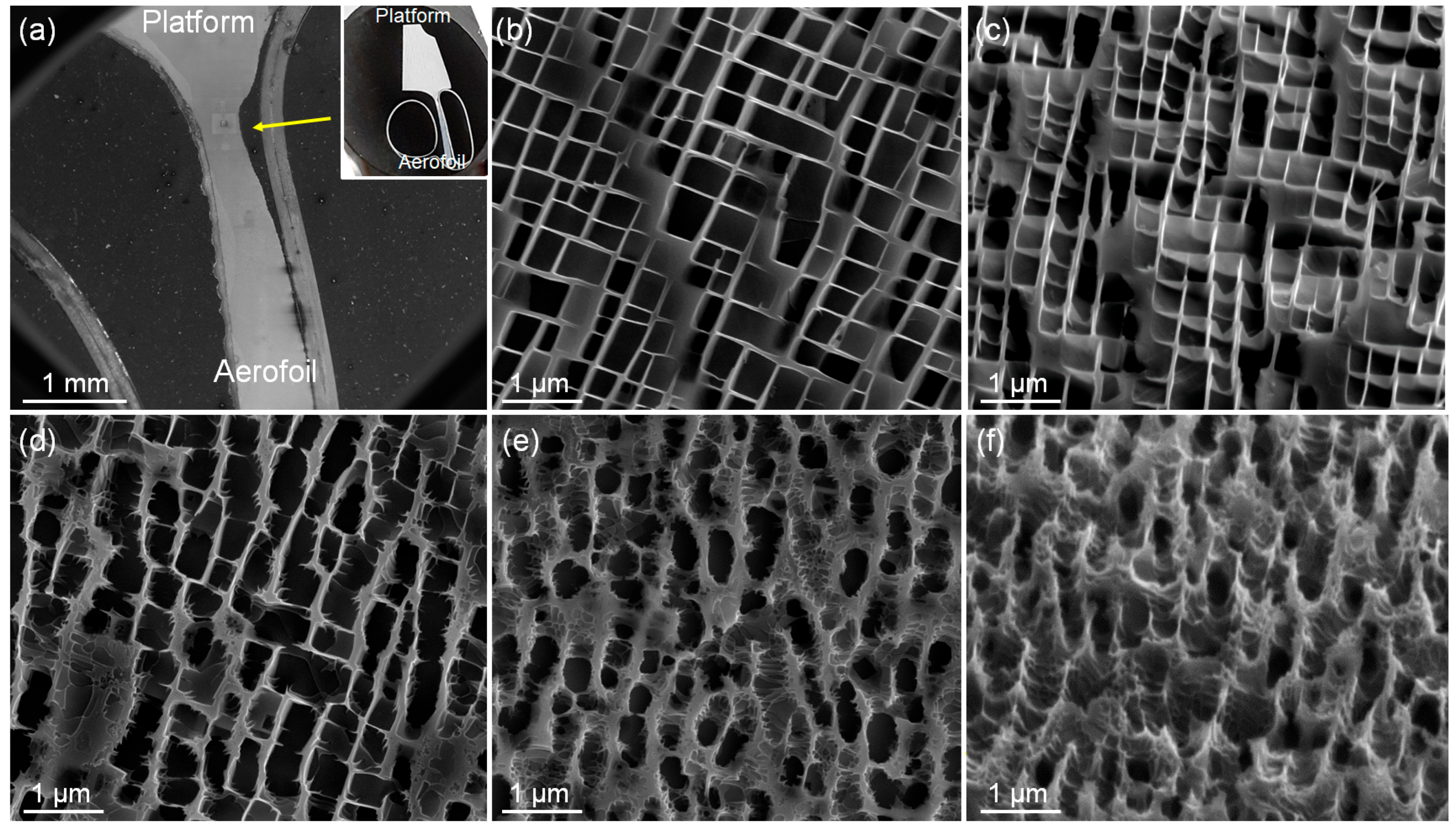

3.1. Observation of the Surface with a Different Contrast

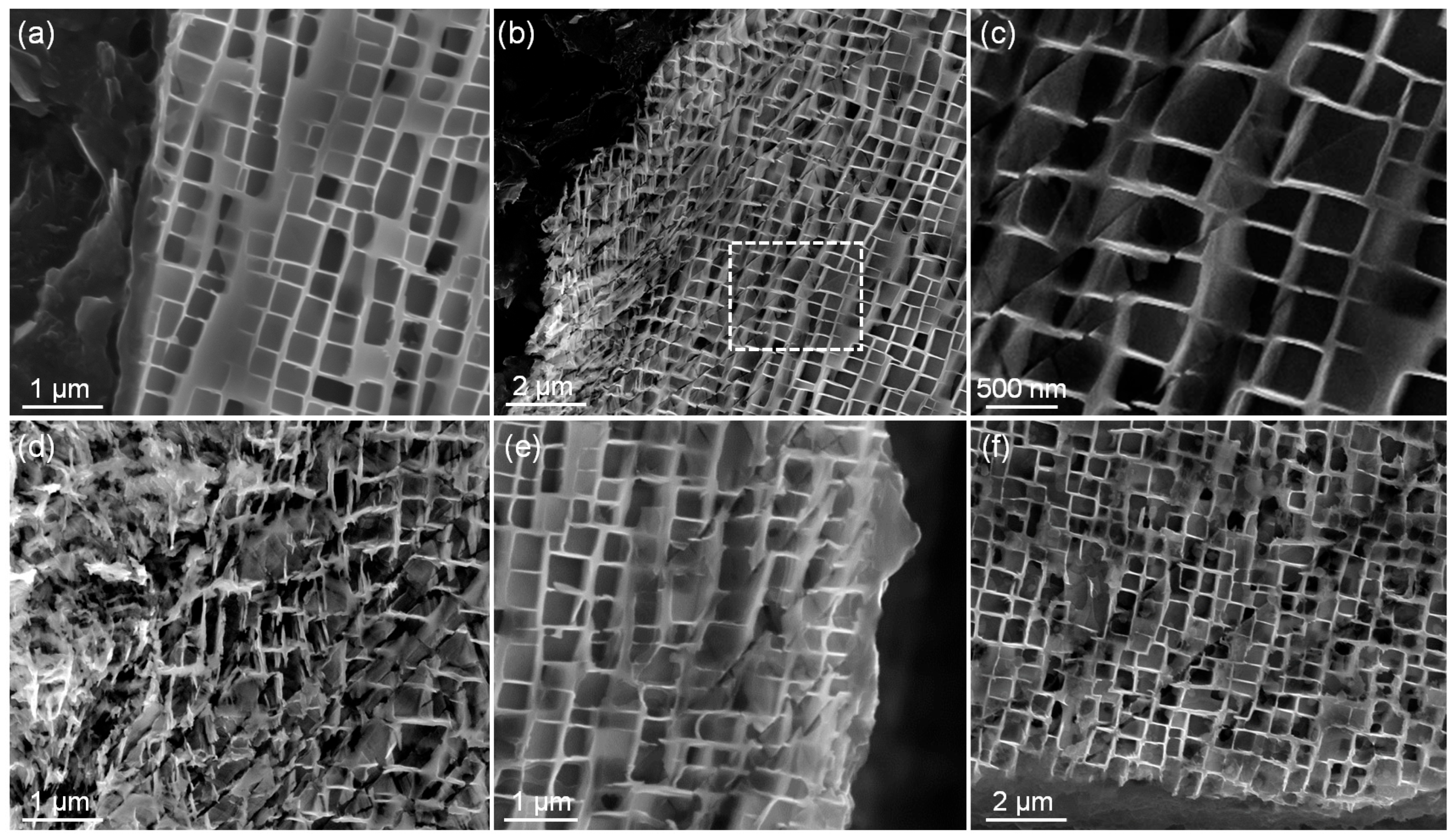

3.2. High Resolution Observation of the Abnormal Microstructure

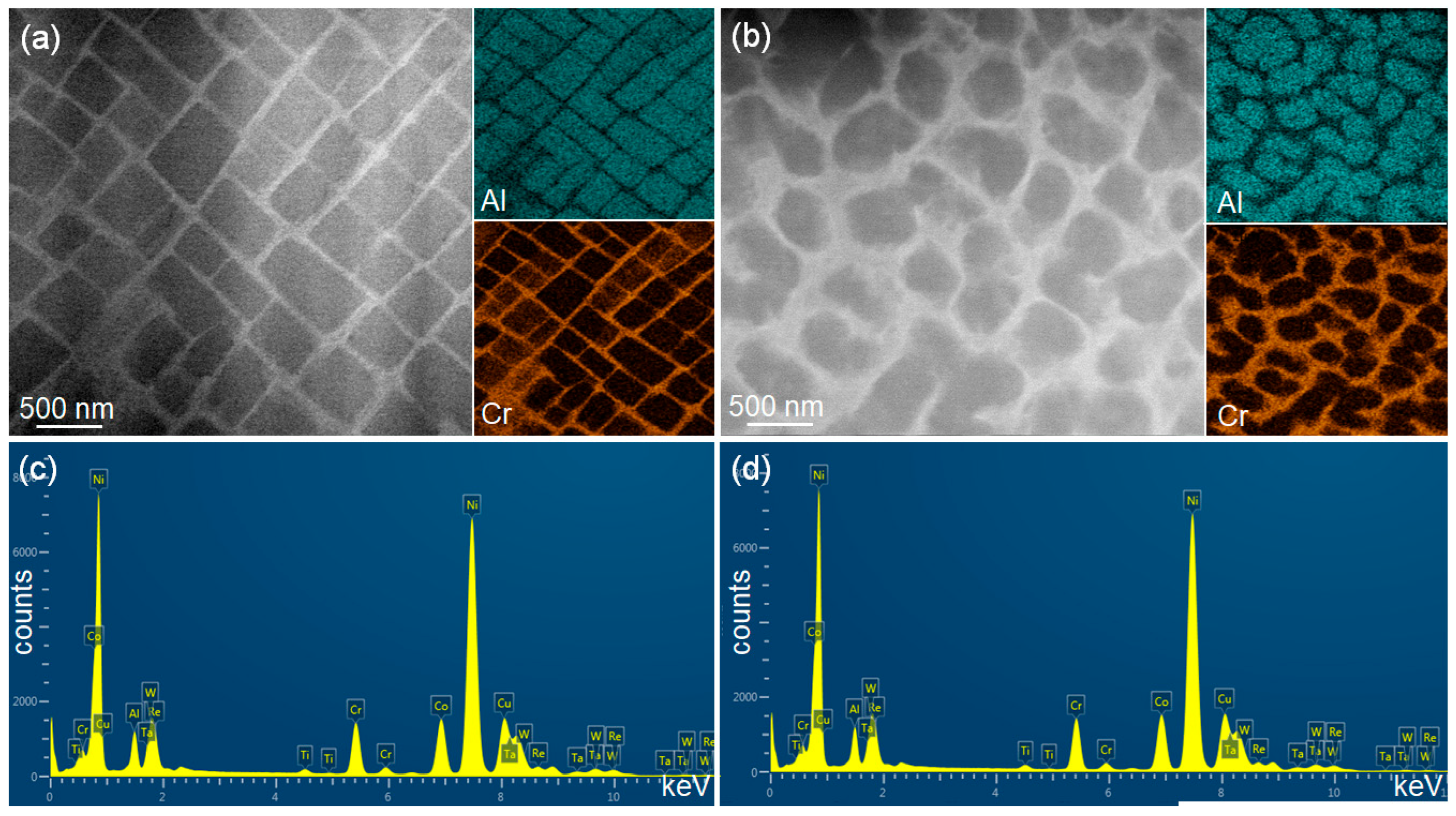

3.3. Comparison of TEM Images Acquired in Normal and Abnormal Regions

4. Discussion

5. Summary

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Hachet, G.; Caillard, D.; Ventelon, L.; Clouet, E. Mobility of screw dislocation in BCC tungsten at high temperature in presence of carbon. Acta Mater. 2022, 222, 117440. [Google Scholar] [CrossRef]

- Gurrutxaga-Lerma, B. How strong is the temperature increase due to a moving dislocation? Int. J. Solids Struct. 2017, 108, 263–274. [Google Scholar] [CrossRef]

- Le, K.C.; Tran, T.M.; Langer, J.S. Thermodynamic dislocation theory of high-temperature deformation in aluminum and steel. Phys. Rev. E 2017, 96, 013004. [Google Scholar] [CrossRef]

- Brewster, G.; D’Souza, N.; Ryder, K.S.; Simmonds, S.; Dong, H.B. Mechanism for Formation of Surface Scale during Directional Solidification of Ni-Base Superalloys. Metall. Mater. Trans. A 2012, 43, 1288–1302. [Google Scholar] [CrossRef]

- Park, K.; Withey, P. Compositions of Gamma and Gamma Prime Phases in an As-Cast Nickel-Based Single Crystal Superalloy Turbine Blade. Crystals 2022, 12, 299. [Google Scholar] [CrossRef]

- Kim, K.; Withey, P. Detection of Rhenium-Rich Particles at Grain Boundaries in Nickel-Base Superalloy Turbine Blades. Mater. Trans. 2016, 57, 1698–1706. [Google Scholar] [CrossRef]

- Yu, Z.H.; Qiang, J.F.; Zhang, J.; Liu, L. Microstructure evolution during heat treatment of superalloys loaded with different amounts of carbon. J. Mater. Res. 2015, 30, 2064–2072. [Google Scholar] [CrossRef]

- Grosdidier, T.; Hazotte, A.; Simon, A. Precipitation and dissolution processes in Υ/Υ′ single crystal nickel-based superalloys. Mater. Sci. Eng. A 1998, 256, 183–196. [Google Scholar] [CrossRef]

- KeeHyun, P.; Paul, W. Observation of the Dissolution of Topologically Close Packed Phases by an Additional Heat Treatment in Third Generation Nickel-Based Single Crystal Superalloy Turbine Blades. Adv. Eng. Mater. 2018, 20, 1700987. [Google Scholar] [CrossRef]

- Rakoczy, Ł.; Milkovič, O.; Rutkowski, B.; Cygan, R.; Grudzień-Rakoczy, M.; Kromka, F.; Zielińska-Lipiec, A. Characterization of γ′ Precipitates in Cast Ni-Based Superalloy and Their Behaviour at High-Homologous Temperatures Studied by TEM and in Situ XRD. Materials 2020, 13, 2397. [Google Scholar] [CrossRef]

- Wang, T.Y.; Wang, X.M.; Zhao, Z.H.; Zhang, Z. Dissolution behaviour of the Υ′ precipitates in two kinds of Ni-based superalloys. Mater. High Temp. 2016, 33, 51–57. [Google Scholar] [CrossRef]

- Ye, L.; Liu, F.; Dong, H.; Ouyang, X.; Xiao, X.; Tan, L.; Huang, L. Investigation on the Microstructure and Mechanical Properties of Ni-Based Superalloy with Scandium. Metals 2023, 13, 611. [Google Scholar] [CrossRef]

- Saenarjhan, N.; Kiatwisarnkij, N.; Korthamniwet, W.; Lothongkum, G.; Rojhirunsakool, T.; Nisaratanaporn, E.; Horňak, P.; Wangyao, P. Development of morphology and lattice misfit in modified Ni-base superalloy with Al, Co and Ni additions. Mater. Test. 2023, 65, 1179–1189. [Google Scholar] [CrossRef]

- Yoo, Y.S.; Yoon, D.Y.; Henry, M.F. The effect of elastic misfit strain on the morphological evolution of γ’-precipitates in a model Ni-base superalloy. Met. Mater. 1995, 1, 47–61. [Google Scholar] [CrossRef]

- Chang, J.C.; Allen, S.M. Elstic energy changes accompanying gamma-prime rafting in nickel-base superalloys. J. Mater. Res. 1991, 6, 1843–1855. [Google Scholar] [CrossRef]

- Saito, T.; Harada, H.; Osawa, M.; Yokokawa, T.; Kawagishi, K.; Suzuki, S. Elastic modulus of tie-lined gamma and gamma prime phases of 6th generation Ni-base single crystal superalloy. Mater. Sci. Eng. A 2025, 941, 148410. [Google Scholar] [CrossRef]

- Parsa, A.B.; Wollgramm, P.; Buck, H.; Somsen, C.; Kostka, A.; Povstugar, I.; Choi, P.-P.; Raabe, D.; Dlouhy, A.; Müller, J.; et al. Advanced Scale Bridging Microstructure Analysis of Single Crystal Ni-Base Superalloys. Adv. Eng. Mater. 2015, 17, 216–230. [Google Scholar] [CrossRef]

- Saito, T.; Chen, Y.-T.; Takata, Y.; Kawagishi, K.; Hsu, W.-C.; Yeh, A.-C.; Murakami, H. Effect of Heat Treatments on the Microstructural Evolution of a Single Crystal High-Entropy Superalloy. Metals 2020, 10, 1600. [Google Scholar] [CrossRef]

- Awais, M.; Hixson, W.R.; Victor, Q.; O’Neal, C.; Ilavsky, J.; Coakley, J. Microstructure Evolution of a Multimodal Gamma-Prime Ni-Based Superalloy Characterized by In Situ Diffraction. Metall. Mater. Trans. A 2023, 54, 2311–2319. [Google Scholar] [CrossRef]

- Feng, Z.; Wen, Z.; Lu, G.; Zhao, Y. Influence of Cooling Scenarios on the Evolution of Microstructures in Nickel-Based Single Crystal Superalloys. Crystals 2022, 12, 74. [Google Scholar] [CrossRef]

- Wang, H.; Liu, D.; Wang, J.; Yang, Y.; Rao, H.; Wang, H.; Nan, J.; Wang, L. Study on the Evolution of the γ′ Phase and Grain Boundaries in Nickel-Based Superalloy during Interrupted Continuous Cooling. Crystals 2021, 11, 1464. [Google Scholar] [CrossRef]

- Nathal, M.V.; Ebert, L.J. Gamma prime shape changes during creep of a nickel-base superalloy. Scr. Metall. 1983, 17, 1151–1154. [Google Scholar] [CrossRef]

- Xu, R.; Li, Y.; Yu, H. Microstructure Evolution and Dislocation Mechanism of a Third-Generation Single-Crystal Ni-Based Superalloy during Creep at 1170 °C. Materials 2023, 16, 5166. [Google Scholar] [CrossRef]

- Parsa, A.B.; Wollgramm, P.; Buck, H.; Kostka, A.; Somsen, C.; Dlouhy, A.; Eggeler, G. Ledges and grooves at γ/γ′ interfaces of single crystal superalloys. Acta Mater. 2015, 90, 105–117. [Google Scholar] [CrossRef]

- Giraud, R.; Hervier, Z.; Cormier, J.; Saint-Martin, G.; Hamon, F.; Milhet, X.; Mendez, J. Strain Effect on the γ′ Dissolution at High Temperatures of a Nickel-Based Single Crystal Superalloy. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 2013, 44A, 131–146. [Google Scholar] [CrossRef]

- Ren, W.L.; Niu, C.L.; Ding, B.; Zhong, Y.B.; Yu, J.B.; Ren, Z.M.; Liu, W.Q.; Ren, L.P.; Liaw, P.K. Improvement in creep life of a nickel-based single-crystal superalloy via composition homogeneity on the multiscales by magnetic-field-assisted directional solidification. Sci. Rep. 2018, 8, 17. [Google Scholar] [CrossRef]

- Tang, Y.T.; D’Souza, N.; Roebuck, B.; Karamched, P.; Panwisawas, C.; Collins, D.M. Ultra-high temperature deformation in a single crystal superalloy: Mesoscale process simulation and micromechanisms. Acta Mater. 2021, 203, 116468. [Google Scholar] [CrossRef]

- Kamaraj, M. Rafting in single crystal nickel-base superalloys—An overview. Sadhana 2003, 28, 115–128. [Google Scholar] [CrossRef]

- Cao, L.; Wollgramm, P.; Bürger, D.; Kostka, A.; Cailletaud, G.; Eggeler, G. How evolving multiaxial stress states affect the kinetics of rafting during creep of single crystal Ni-base superalloys. Acta Mater. 2018, 158, 381–392. [Google Scholar] [CrossRef]

- Gamanov, S.; Dlouhy, A.; Bürger, D.; Eggeler, G.; Thome, P. Evolution of local misorientations in the γ/γ’-microstructure of single crystal superalloys during creep studied with the rotation vector baseline (RVB) EBSD method. Microsc. Res. Tech. 2024, 87, 516–533. [Google Scholar] [CrossRef]

- Wu, X.; Makineni, S.K.; Liebscher, C.H.; Dehm, G.; Rezaei Mianroodi, J.; Shanthraj, P.; Svendsen, B.; Bürger, D.; Eggeler, G.; Raabe, D.; et al. Unveiling the Re effect in Ni-based single crystal superalloys. Nat. Commun. 2020, 11, 389. [Google Scholar] [CrossRef] [PubMed]

- Pollock, T.M.; Argon, A.S. Creep resistance of CMSX-3 nickel base superalloy single crystals. Acta Metall. Mater. 1992, 40, 1–30. [Google Scholar] [CrossRef]

- Epishin, A.; Link, T.; Brückner, U.; Fedelich, B.; Portella, P. Effects of segregation in nickel-base superalloys: Dendritic stresses. In Proceedings of the Superalloys 2004, Champion, PA, USA, 19–23 September 2004; pp. 537–543. [Google Scholar]

- Sengupta, J.; Thomas, B.G.; Wells, M.A. The use of water cooling during the continuous casting of steel and aluminum alloys. Metall. Mater. Trans. A 2005, 36, 187–204. [Google Scholar] [CrossRef]

- Nekahi, S.; Vaferi, K.; Vajdi, M.; Sadegh Moghanlou, F.; Shahedi Asl, M.; Shokouhimehr, M. A numerical approach to the heat transfer and thermal stress in a gas turbine stator blade made of HfB2. Ceram. Int. 2019, 45, 24060–24069. [Google Scholar] [CrossRef]

- Xu, W.; Wang, F.; Ma, D.; Zhu, X.; Li, D.; Bührig-Polaczek, A. Sliver defect formation in single crystal Ni-based superalloy castings. Mater. Des. 2020, 196, 109138. [Google Scholar] [CrossRef]

- Aveson, J.W.; Tennant, P.A.; Foss, B.J.; Shollock, B.A.; Stone, H.J.; D’Souza, N. On the origin of sliver defects in single crystal investment castings. Acta Mater. 2013, 61, 5162–5171. [Google Scholar] [CrossRef]

- Kang, S.K.; Benn, R.C. Microstructural development in high volume fraction gamma prime Ni-base oxide-dispersion-strengthened superalloys. MTA 1985, 16, 1285–1294. [Google Scholar] [CrossRef]

| Al | Ti | Cr | Co | Mo | Hf | Ta | W | Re | Ni | |

|---|---|---|---|---|---|---|---|---|---|---|

| Raw | 5.6 | 1.0 | 6.5 | 9.6 | 0.6 | 0.1 | 6.5 | 6.4 | 3.0 | Bal. |

| Normal | 6.0 | 1.5 | 2.7 | 7.5 | 0.4 | 0.0 | 7.7 | 6.1 | 0.5 | Bal. |

| Abnormal | 5.6 | 1.3 | 2.5 | 7.2 | 0.3 | 0.0 | 7.3 | 6.8 | 0.6 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, K.; Davies, J.; Withey, P. Microstructural Investigation of Stress-Induced Degradation of Gamma and Gamma Prime Phases on the Surface of the Aerofoil of Nickel-Based Single Crystal Superalloy Turbine Blades. Crystals 2025, 15, 553. https://doi.org/10.3390/cryst15060553

Park K, Davies J, Withey P. Microstructural Investigation of Stress-Induced Degradation of Gamma and Gamma Prime Phases on the Surface of the Aerofoil of Nickel-Based Single Crystal Superalloy Turbine Blades. Crystals. 2025; 15(6):553. https://doi.org/10.3390/cryst15060553

Chicago/Turabian StylePark, KeeHyun, Jonathan Davies, and Paul Withey. 2025. "Microstructural Investigation of Stress-Induced Degradation of Gamma and Gamma Prime Phases on the Surface of the Aerofoil of Nickel-Based Single Crystal Superalloy Turbine Blades" Crystals 15, no. 6: 553. https://doi.org/10.3390/cryst15060553

APA StylePark, K., Davies, J., & Withey, P. (2025). Microstructural Investigation of Stress-Induced Degradation of Gamma and Gamma Prime Phases on the Surface of the Aerofoil of Nickel-Based Single Crystal Superalloy Turbine Blades. Crystals, 15(6), 553. https://doi.org/10.3390/cryst15060553